Nanosensors for Soft Robotics Exoskeletons

Fredy A. Cuellar

1 a

, Juan C. Salcedo-Reyes

3 b

, Diana Montoya

3

, Catalina Alvarado-Rojas

1 c

and

Julian D. Colorado

1,2 d

1

School of Engineering, Pontificia Universidad Javeriana, Bogota, 110231, Colombia

2

Omics Science Research Institute, iOMICAS, Pontificia Universidad Javeriana, Cali 760031, Colombia

3

Laboratorio de Pel

´

ıculas Delgadas y Nanofot

´

onica, Departamento de F

´

ısica, Facultad de Ciencias,

Pontificia Universidad Javeriana, Bogota, 110231, Colombia

Keywords:

Piezoelectric Sensor, Robotic Exoskeletons, Neuromuscular Rehabilitation, Carbon-Based Nano-Inks,

Reduced Graphene Oxide, Biocompatibility, Wearable Healthcare Technologies, Mechanical Stress

Characterization, Therapeutic Applications.

Abstract:

This paper presents a multi-layered piezoelectric nanosensor designed for robotic exoskeletons, aimed at en-

hancing neuro-muscular rehabilitation. Green-driven methods were used to achieve biocompatibility throught

the incorporation of carbon-based nano-inks, reduced graphene oxide, and an optimized piezoelectric layer to

enhance electrical conductivity under mechanical stress. These components are integrated with a triboelectric

layer composed of a teflon-copper core. Electrical characterization tests demonstrate that the proposed sensor

exhibits robust performance and high reliability, both critical issues for hand grasping sensing under rehabili-

tation scenarios.

1 INTRODUCTION

The advent of robotic-driven neurological physiother-

apy has been significantly reducing recovery times

in rehabilitation scenarios. In particular, the pre-

cise actuation and sensing capabilities integrated in

robotic-based exoskeletons facilitate the mobility of

affected limbs through highly intense and repetitive

therapies. This enhances the precision of the treat-

ment and provides a straightforward method for gen-

erating quantitative data necessary for assessing pa-

tient progress. An important body of work in the

literature has demonstrated significant clinical-based

improvements in upper-limb mobility in post-stroke

patients, while using such robotic devices (Abdullah

et al., 2011).

Several devices have been specifically designed

for patients with hand motion impairments. These

devices include orthoses, exoskeletons, and terminal

effector devices (Mayer et al., 2022). Orthoses pro-

vide static support, whereas motorized exoskeletons

enable both passive and active therapeutic exercises

a

https://orcid.org/0009-0003-2261-1654

b

https://orcid.org/0000-0002-6209-0502

c

https://orcid.org/0000-0002-2315-5692

d

https://orcid.org/0000-0002-6925-0126

under the supervision of a physiotherapist (Jackson

and Abdullah, 2023). In general, exoskeleton con-

trol systems are organized into three hierarchical lev-

els: perception, control, and execution. This structure

facilitates precise responses based on data collected

from the environment, the device, and the user’s in-

teractions (Ne

ˇ

tukov

´

a et al., 2022).

The integration of precise sensing capabilities is

key to provide active assistance able to adapt to

the patient (Pan et al., 2023). In this arena, bio-

compatible nanosensors have opened new alternatives

for precise sensing with ease and flexible integration.

In this regard, nanosensors integrated into wearable

devices, such as gloves or exoskeletons, can provide

real-time feedback on hand grasping strength, pres-

sure distribution, and finger movement (Luo et al.,

2024). This level of detailed monitoring is crucial for

tailoring rehabilitation exercises to the specific needs

of the user, ensuring optimal recovery and function-

ality. Additionally, the incorporation of nanosensors

into these devices allows for the development of more

sophisticated control algorithms, which can improve

the accuracy and responsiveness of assistive technolo-

gies (Yang et al., 2024).

This paper reports the development of a bio-

nanosensor fabricated using green-based methods for

synthesizing nanomaterials, aimed at decreasing tox-

640

Cuellar, F. A., Salcedo-Reyes, J. C., Montoya, D., Alvarado-Rojas, C. and Colorado, J. D.

Nanosensors for Soft Robotics Exoskeletons.

DOI: 10.5220/0012906500003822

In Proceedings of the 21st International Conference on Informatics in Control, Automation and Robotics (ICINCO 2024) - Volume 1, pages 640-644

ISBN: 978-989-758-717-7; ISSN: 2184-2809

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

Soft exoskeleton

(compliant joints)

Bio-nanosensor

Caracterización

Sustrato de nanocelulosa

Fabricación de (Nanoparticulas de cobre)

Se sintetizan nanopartículas de cobre de 30

nm mediante el uso de ácido ascórbico.

Estas nanopartículas se utilizan para crear la

siguiente capa, que se aplicará sobre el

sustrato y entrará en contacto con la capa

de óxido de grafeno reducido. De esta

manera, se logra la construcción de un

sensor piezorresistivo que emula los

mecanorreceptores de adaptación lenta.

Fabricación de Nanomateriales (óxido de grafeno reducido)

• El objetivo es la fabricación de un sensor diseñado para imitar mecanorreceptores en

aplicaciones de electromiografía. Este sensor consta de múltiples capas y utiliza

nanomateriales, y está destinado a aplicarse en la piel para detectar dichas señales.

• Los nanomateriales son desarrollados utilizando métodos verdes o de bio-fabricación

con el objetivo de disminuir la toxicidad y aumentar la biocompatibilidad para

aplicaciones en medicina, en las Figuras A, B, C se realiza la primera fase de óxido de

grafeno y en la figura C y E se realiza la fabricación de óxido de grafeno reducido.

Fabricación de Sensores Basados en

Nanomateriales para Aplicaciones en

Electromiografía y Detección de

Esfuerzo

La creciente demanda de tecnologías avanzadas en el campo de la medicina y la

ingeniería ha impulsado la búsqueda de sensores altamente sensibles y versátiles. En

este contexto, la incorporación de nanomateriales en la fabricación de sensores ha

emergido como una solución prometedora. Presentamos una investigación centrada en

el desarrollo de sensores basados en nanomateriales diseñados específicamente para

medir señales electromiográficas (EMG) y esfuerzo para su aplicación en la creciente

área de la robótica blanda (soft robotics). Estos sensores ofrecen una combinación única

de sensibilidad, flexibilidad y adaptabilidad, lo que los convierte en herramientas ideales

para la detección precisa de señales biológicas y su integración en sistemas de control en

la robótica blanda.

!

Facultad de Ingeniería, Pontificia Universidad Javeriana, Bogotá, Colombia

"

Departamento de Física, Pontificia Universidad Javeriana Bogotá, Colombia.

Fredy A. Cuellar

1

, Julián D. Colorado

1

,

Catalina Alvarado-Rojas

1

, Juan Carlos Salcedo Reyes

2

, Hernán

Rodríguez Hernández

2

Introducción

Métodos

Resultados

Conclusiones

Rector

Vicerrector Académico

Vicerrector del Medio Universitario

Secretario General

FACULTA D DE MED IC INA

Decana Académica

Decano del Medio Universitario

Directora de Carrera

Director de Posgrados

Secretaria de Facultad

Director General

Directores de Departamento

Directores de Instituto

Editor

Comité Editorial

Corrección de Estilo

Diseño, preprensa e impresión

La Revista Universitas Médica -

San Ignacio. Todo el material remitido es revisado por el Comité Editorial

sus autores.

Commons Reconocimiento 4.0 Internacional.

Rector

Vicerrector Académico

Vicerrector del Medio Universitario

Secretario General

FACU LTAD D E ME DICI NA

Decana Académica

Decano del Medio Universitario

Directora de Carrera

Director de Posgrados

Secretaria de Facultad

Director General

Directores de Departamento

Directores de Instituto

Editor

Comité Editorial

Corrección de Estilo

Diseño, preprensa e impresión

La Revista Universitas Médica -

San Ignacio. Todo el material remitido es revisado por el Comité Editorial

sus autores.

Commons Reconocimiento 4.0 Internacional.

Somos una sede que pertenece al Hospital

Universitario San Ignacio, vinculado con el Instituto

de Envejecimiento de la Facultad de Medicina de la

Pontificia Universidad Javeriana y otras unidades

académicas como el Departamento de Psiquiatría y

Salud Mental. Ofrecemos atención integral,

humana, segura y eficiente a personas con

problemas cognoscitivos del comportamiento y

deterioro funcional.

Evaluamos, entrenamos,

asesoramos a familiares y cuidadores para el

manejo del paciente en casa, así como para su

permanencia activa en la sociedad.

Robotic Exoskeleton for smart

rehabilitation

cognoscitiva.

Musicoterapia.

SEGUIMIENTO

CUIDADOS A LARGO PLAZO

Con la apertura de la nueva sede, tendremos

una Unidad con cobertura para pacientes que

requieran una larga estancia, ofreciendo

condiciones de vivienda dignas de alta calidad.

Tendremos servicios dirigidos al cuidado de

adultos y personas mayores, principalmente

con trastornos cognitivos, así como

alteraciones del comportamiento y la conducta,

con condiciones que les impidan continuar

viviendo en su hogar, para la asistencia y

seguimiento de sus comorbilidades.

Se indica la fabricación un sensor multifuncional utilizando nanomateriales para replicar

mecanorreceptores. Los nanomateriales se obtienen mediante métodos sostenibles y

biocompatibles, lo que los hace adecuados para aplicaciones médicas y de robótica

blanda. Ofrecen sensibilidad, flexibilidad y adaptabilidad, lo que los hace ideales para

detectar señales biológicas y controlar dispositivos de robótica blanda.

Sensores Señal EMG

Aplicación Soft para

rehabilitación

Microscopio

de Fuerza Atómica

Interdigitated electrode layout

Flexible fabric

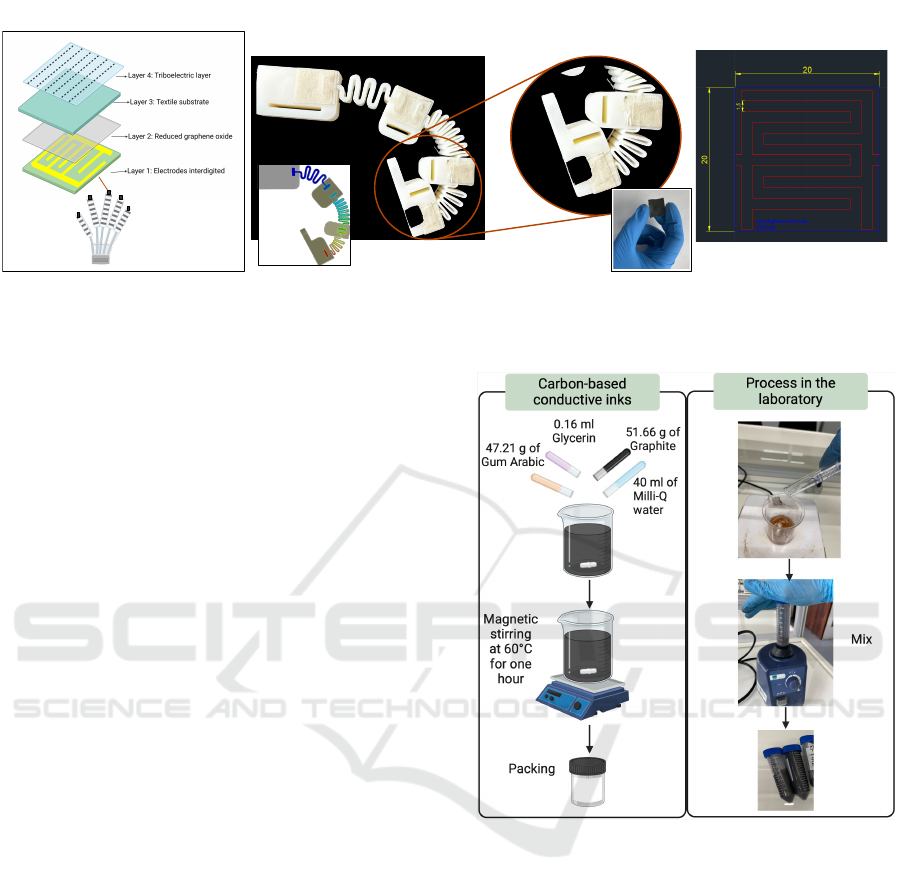

Figure 1: Bio-nanosensor design layers and integration with a hand-based soft robotic exoskeleton to support tactile pressure

sensing in grasping-driven rehabilitation.

icity and maximize its bio-compatibility with the hu-

man skin. The sensor has multiple layers to mimic cu-

taneous mechanoreceptors with piezoelectric and tri-

boelectric layers. Electrical characterization is pre-

sented, demonstrating the potential of these flexi-

ble sensing devices synthesized in a small footprint,

while providing accurate sensitivity and precision.

2 METHODS

Figure 1 depicts the multilayered architecture of the

sensor composed by 4 stacked layers. A flexible

fabric was used to allow proper integration with the

exoskeleton prototype developed in previous work

reported in (Bonilla et al., 2023). As shown, the

first two layers constitute the main piezoelectric sen-

sor. The interdigitated electrode structure, fabricated

through screen printing with carbon-based inks, im-

parts conductivity to the sensor.

A flexible textile substrate is employed, highlight-

ing the applicability of sustainable and flexible mate-

rials for wearable technology. This electrode is paired

with a layer of reduced graphene oxide, synthesized

using an environmentally friendly method, to improve

the sensor’s performance. The subsequent layer is a

triboelectric layer, integrated to enhance the sensor

with surface texturing capabilities, which are crucial

for exoskeletons designed for hand rehabilitation.

2.1 Piezoelectric Layer Fabrication

The fabrication process is described as follows:

• Substrate preparation: A flexible and durable tex-

tile substrate is selected for its suitability in wear-

able technologies.

Figure 2: Conductive ink manufacturing process.

• Electrode patterning: Interdigitated electrodes are

directly printed onto the textile substrate using

conductive carbon-based inks through the screen-

printing technique. This method allows precise

control over the electrode patterns and thick-

nesses. Figure 2 details the fabrication process of

these conductive inks, highlighting the formula-

tion and application steps involved.

• Graphene-oxide application: Reduced graphene

oxide, produced via an environmentally friendly

reduction process, is subsequently applied to the

interdigitated electrodes. This coating is crucial

for enhancing the piezoelectric properties of the

sensor. Figures 3 and 4, provide a detailed expla-

nation of the synthesis process for this nanomate-

rial.

Nanosensors for Soft Robotics Exoskeletons

641

Figure 3: Graphene oxide manufacturing process.

Figure 4: Reduced graphene oxide manufacturing process.

2.2 Triboelectric Layer Fabrication

The triboelectric layer comprises fine teflon fibers

with an embedded copper core. This specific structure

is selected to generate the triboelectric effect, with

Teflon providing the requisite triboelectric properties

and the copper core enhancing electrical conductivity

and overall layer effectiveness.

2.3 Assembly

All layers are carefully aligned in the correct order

and bonded using environmentally friendly biocom-

patible adhesives. This ensures both the biocompat-

ibility and functionality of the sensor. Proper align-

ment is critical to ensure cohesive performance when

integrated into the exoskeleton.

3 RESULTS

3.1 Conductive Inks Characterization

The electrical properties of inks applied to paper and

plastic substrates are crucial, significantly influencing

their suitability for flexible devices. To simulate re-

alistic usage conditions, the inks were bent and fixed

at angles of 180°, 120°, 90°, 45°, and 30°. Electrical

resistivity was measured using the four-point probe

method, and conductivity was subsequently calcu-

lated.

The four-point probe method is a widely accepted

technique for determining the electrical resistivity of

materials. It utilizes four aligned electrodes: the two

outer electrodes supply a constant current to the mate-

rial, while the two inner electrodes measure the volt-

age across them. This arrangement minimizes typical

errors due to contact resistance and the resistance of

the electrodes, ensuring accurate resistivity measure-

ments of the material under test (Ossila, 2024).

Figures 5 and 6 present the electrical properties of

the inks under bending for both substrates. The inks

exhibited no significant change in electrical properties

under bending, indicating their excellent adaptability

to mechanical deformations. This adaptability is vi-

tal for applications requiring high flexibility without

compromising electrical functionality. The robust-

ness and reliability of these conductive inks demon-

strate their potential for use in sensors and other flex-

ible electronic devices, where maintaining electrical

integrity is critical for overall functionality and per-

formance. These findings suggest that the design of

flexible electronic components can leverage the dura-

bility and reliability of these inks under various me-

chanical conditions.

The results demonstrate reliable stability of the

electrical conductivity of conductive inks deposited

on both paper and plastic substrates under various

bending conditions. In both cases, a slight increase

in conductivity is observed as the bending angle de-

creases from 180° to 30°. This trend indicates that

the ink maintains proper conductivity even under sig-

nificant mechanical deformation, which is crucial for

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

642

Figure 5: Conductivity on paper substrate.

Figure 6: Conductivity on plastic substrate.

applications involving flexible or foldable devices.

3.2 Electrical Characterization

Piezoelectric Layer

Figure 7 presents the sensing mechanism of the pro-

posed piezoresistive sensor layer. Unlike flat, hard,

and planar bulk metal layers, the coated textile lay-

ers exhibit pores and roughness. The contact area be-

tween the reduced graphene oxide-coated textile and

the bottom electrodes changes with variations in ex-

ternal pressure. When a compressive force is applied

to the sensor surface, the porous structures deform,

bringing the reduced graphene oxide-coated textile

into closer contact with the interdigital electrodes.

This deformation increases the number of con-

ducting pathways between the graphene oxide and the

carbon nano-ink electrodes, resulting in larger contact

areas and an enhanced current under applied voltage.

Upon unloading, the materials return to their orig-

inal states, reducing the available conduction path-

ways and consequently decreasing the current.

Electrical signal testing was conducted to evaluate

Figure 7: Current measurement configuration.

Figure 8: Measurement of voltage and current relationship

of the piezoelectric layer.

the sensing performance of the textile sensor devices.

As shown in Figure 8, the current-voltage (I-V) curves

of the piezoresistive sensor exhibit highly linear rela-

tionships under static pressure loading. This linearity

indicates that the rGO-coated textile and the carbon

nano-ink electrode textile form ohmic contacts. Ad-

ditionally, the piezoresistive sensor demonstrates high

sensitivity and reliability across a wide range of ap-

plied pressures.

Figure 8 shows the I-V characteristics of the

piezoresistive layer under various applied loads, with

pressures ranging from 1 to 23 kPa. The data were

obtained by measuring the current at different applied

pressures while varying the voltage from 0 to 0.5 V.

The I-V curves clearly show that an increase in volt-

age results in a corresponding increase in current for

all tested pressure levels.

The sensor’s sensitivity is evident from the in-

creasing slope of the I-V curves with higher applied

pressures. For instance, the curve for 1 kPa pres-

sure is relatively low compared to that for 23 kPa,

indicating a more significant response at higher pres-

sures. This feature highlights the sensor’s capability

to distinguish between varying magnitudes of pres-

sure, making it suitable for applications requiring pre-

cise pressure sensing. The linearity of the I-V curves

under each applied pressure confirms the formation

of ohmic contacts by the piezoresistive layer, which is

crucial for the reliability and repeatability of measure-

ments. This linearity also simplifies the calibration of

Nanosensors for Soft Robotics Exoskeletons

643

the sensor in real-world environments, facilitating the

integration of devices utilizing this technology. These

results validate the construction of the piezoresistive

sensor and its application in highly accurate and sen-

sitive pressure monitoring, which is essential for med-

ical devices and advanced robotic systems.

4 CONCLUSIONS

Multilayered piezoelectric sensors offer significant

potential for enhancing robotic exoskeletons used in

neuromuscular rehabilitation. The incorporation of

carbon-based nano-inks and reduced graphene ox-

ide makes these sensors environmentally friendly and

biocompatible, suitable for direct skin contact.

The piezoelectric and triboelectric layers of the

sensor are highly sensitive and capable of distinguish-

ing between different levels of applied pressure. Such

sensitivity is crucial for replicating the sophisticated

mechanoreceptive capabilities of human skin, thereby

enhancing the rehabilitative effectiveness of the ex-

oskeleton. Also, the electrical characterization of the

sensor demonstrates its viability under mechanical

deformation and stability in functional performance.

These are critical considerations for wearable tech-

nologies that must withstand various dynamic phys-

ical stresses. Additionally, the linear I-V characteris-

tics under applied pressures facilitate easier integra-

tion and calibration within exoskeleton frameworks,

broadening its utility in physio-therapeutic applica-

tions.Future research should focus on real-world test-

ing to assess the long-term durability of the sensor

and its integration with other biomedical monitoring

technologies.

ACKNOWLEDGEMENTS

This work was funded by the project “iREHAB: Sis-

tema inteligente de Rehabilitaci

´

on usando un Ex-

oesqueleto para recuperar Habilidad motora en dis-

capacidades post-ACV, usando se

˜

nales Biol

´

ogicas

del paciente” sponsored by The Ministry of Science

Technology and Innovation (MinCiencias), program

918-2022 under GRANT CTO: 622-2022, Award ID:

91805.

REFERENCES

Abdullah, H. A., Tarry, C., Lambert, C., Barreca, S., and

Allen, B. O. (2011). Results of clinicians using a ther-

apeutic robotic system in an inpatient stroke rehabil-

itation unit. Journal of NeuroEngineering and Reha-

bilitation, 8:50.

Bonilla, D., Bravo, M., Bonilla, S. P., Iragorri, A. M.,

Mendez, D., Mondragon, I. F., Alvarado-Rojas, C.,

and Colorado, J. D. (2023). Progressive rehabilitation

based on emg gesture classification and an mpc-driven

exoskeleton. Bioengineering, 10(7).

Jackson, G. and Abdullah, H. A. (2023). Development and

testing of a soft exoskeleton robotic hand training de-

vice. Sensors, 23:8395.

Luo, X., Tan, H., and Wen, W. (2024). Recent advances in

wearable healthcare devices: From material to appli-

cation. Bioengineering, 11:358.

Mayer, T. A., Harsch, A.-K., Koska, D., Hensel-Unger, R.,

and Maiwald, C. (2022). Effects of an active hand

exoskeleton on forearm muscle activity in industrial

assembly grips. Work, 72:1577–1591.

Ne

ˇ

tukov

´

a, S., Bejtic, M., Mal

´

a, C., Hor

´

akov

´

a, L., Kut

´

ılek,

P., Kauler, J., and Krupi

ˇ

cka, R. (2022). Lower

limb exoskeleton sensors: State-of-the-art. Sensors,

22:9091.

Ossila (2024). Calculate sheet resistance using the

four-probe method. https://www.ossila.com/pages/

sheet-resistance-theory. Accessed: 2 May 2024.

Pan, D., Hu, J., Wang, B., Xia, X., Cheng, Y., Wang, C.-

H., and Lu, Y. (2023). Biomimetic wearable sensors:

Emerging combination of intelligence and electronics.

Advanced Science, 10.

Yang, K., Zhang, S., Hu, X., Li, J., Zhang, Y., Tong, Y.,

Yang, H., and Guo, K. (2024). Stretchable, flexible,

breathable, self-adhesive epidermal hand semg sensor

system. Bioengineering, 11:146.

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

644