Sustainability Meets Efficiency: Unveiling the Dual Impact on Supply

Chain Performance in the Retail Sector. A Case Study of JB Hi-Fi

Mu Li

Melbourne Business School, University of Melbourne, 200 Leicester St, Carlton, VIC 3053, Australia

Keywords: Corporate Sustainability, Supply Chain Management, Strategic Management, JB Hifi.

Abstract: In recent years, the interplay between environmental sustainability and commercial expansion has emerged

as a critical area of study. This investigation focuses on JB Hi-Fi, a key player in the Australian retail market,

to dissect how sustainable practices influence fundamental supply chain performance indicators, including

Cost of Goods Sold (COGS), inventory turnover, and the operating cycle. By leveraging advanced Lasso

regression techniques to navigate the limitations of sparse data, this analysis uncovers nuanced effects: while

employee engagement significantly elevates supply chain efficiency, initiatives aimed at environmental

conservation, such as the recycling of soft plastics, introduce cost-related and operational complexities. This

study not only deepens the current discourse on balancing sustainability with supply chain optimization but

also offers unique perspectives for retailers striving to merge long-term environmental goals with business

efficiency. Furthermore, it lays a robust foundation for future research to further explore the dynamic

interconnections between sustainability measures and supply chain metrics, advocating for the integration of

broader datasets and a more diverse array of sustainability indicators to enrich the comprehension of these

critical relationships.

1 INTRODUCTION

In the contemporary business environment,

established firms have increasingly integrated

sustainability concepts into their supply chain

management strategies, driven by a dual imperative:

to mitigate risks and to forge a strategic pathway

towards long-term value creation. An illustrative

investigation by Ruiz-Real et al. delineates the

widespread adoption of sustainable supply chain

management (SSCM) policies across a diverse array

of over 30 nations and regions, encompassing a wide

spectrum of criteria such as supply chain ratings,

operating cycles, and environmental ratings, among

others (Ruiz-Real et al., 2018). Similarly, the scrutiny

of Walmart's sustainability report by Jones and

Comfort reveals a significant milestone wherein up to

20 essential goods were procured in compliance with

distinct sustainability standards, with the retail

behemoth achieving an 80% sustainability

compliance rate across its supply chain by 2018

(Jones & Comfort, 2020). This empirical evidence

underscores the profound influence of sustainability

on retail supply chain dynamics, precipitating a

recalibration of company strategies to accommodate

this new paradigm.

Moreover, the comparative analysis of CSR

reports from publicly traded retailers conducted by

Chkanikova and Mont, which focuses on strategic

adjustments in supply chain management, supplier

selection, and inventory lifecycle to enhance the PMI

index(Chkanikova & Mont, 2012), complements

Longo's examination of strategic modifications

within the environmental domain of retailers' supply

chains(Longo, 2012). These analyses collectively

highlight efforts to optimize logistics to curtail carbon

emissions, attain sustainability goals, and reduce

transportation costs by 15%. Despite these significant

insights, a lacuna persists in the literature, with these

studies failing to establish a direct correlation

between supply chain metrics and sustainability

goals, delineate specific sustainability goals

impacting different supply chain facets, or engage in

direct quantitative analysis of these dynamics.

Therefore, this article explores the relationship

between supply chain metrics and sustainability

goals, focusing on quantifying sustainability's impact

on supply networks. It is divided into methodology,

results, and discussion sections. The methodology

72

Li, M.

Sustainability Meets Efficiency: Unveiling the Dual Impact on Supply Chain Performance in the Retail Sector. A Case Study of JB Hi-Fi.

DOI: 10.5220/0012909000004508

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 1st International Conference on Engineering Management, Information Technology and Intelligence (EMITI 2024), pages 72-79

ISBN: 978-989-758-713-9

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

outlines selecting key performance indicators (KPIs)

for both supply chain and sustainability, data

gathering, and regression analysis to examine metric

relationships. Results detail this analysis, using

visuals for clarity. The discussion offers solutions and

insights for incorporating sustainability into supply

chains, aiming to aid retail managers in making

strategic decisions aligned with sustainability. This

analysis seeks to fill literature gaps, providing a

framework to understand sustainability's role in

enhancing supply chain resilience and sustainability.

2 LITERATURE REVIEW

2.1 Supply Chain Management,

Sustainability and Retail Business

Cycles Research

Berning and Venter provide additional insights into

retail supply chain management in the review

literature (Berning & Venter, 2015). They describe it

as a continuous process that influences the

sustainability expectations of suppliers. The authors

conducted semi-structured interviews with a major

retailer in South Africa to gather information on

suppliers' sustainability. An in-depth interview with a

major retailer in South Africa uncovered the

suppliers' eagerness to enhance their supply chain

hierarchy, emphasizing the significance of

sustainability. In their comprehensive study of the

retail market in China, Han and Guo found that

sustainable supply chain management necessitates a

holistic approach to achieve the integration of

economic, social, and environmental advantages

(Han & Guo, 2014). By examining the current state

of the retail industry and discussing sustainable

supply chain management, the researchers concluded

that companies must consider the entire supply chain

to attain long-term economic benefits and gain a

competitive edge. Sustained economic benefits and

advantages in competition over a lengthy period. The

literature emphasizes the significance of enhancing

collaboration to achieve supply chain sustainability,

underscores the crucial role of individuals and

communities in supply chain management, and offers

valuable recommendations for the report to choose

suitable sustainability indicators. Furthermore,

Negrutiu et al. employ a white paper from Roland

Berger, a well-known management consulting firm,

to offer an external viewpoint on the connection

between suppliers, logistics, and transportation

providers (Negrutiu et al., 2020). This perspective

highlights the trend towards reduced consumption

and increased efficiency in logistics and

transportation. It demonstrates the significant

enthusiasm of organizations and transporters to

minimize logistics and transportation expenses and

align them with sustainability objectives.

In the research-based literature, Rao et al.

conducted a mathematical modeling study on green e-

commerce. By establishing the relationship between

perceived ease of use (PEOU) and green consumption

(GC), the regression results in a correlation

coefficient of 0.12 and a strong correlation between

them, confirming the importance of a green supply

chain for the development of the retail industry (Rao

et al., 2021), while the study by Chauhan et al. also

utilizes data modeling. It measures the impact of

sustainable supply chain changes on a company's

product sales by dividing them into single and dual-

channel sales. In this study, the total cost of dual-

channel retailing was reduced by about 14.0625%,

product quality was improved by 80%, and consumer

satisfaction was improved (Chauhan et al., 2023). It

confirms the importance of optimizing the

operational cycle. In addition, de Vass et al.

emphasized the importance of IoT for sustainable

supply chain management at the big data level. They

conducted a large number of questionnaires

collection and collation in the data collection section

and analyzed the employee engagement by VIF as

3.3, i.e., it confirms the importance of the employees

for the supply chain management, which further helps

the report for the confirmation of the sustainable

variables (Vass et al., 2020).

2.2 Enterprise Sustainable Strategy

Adjustment

Ekinci et al. suggest that the study used a mixed

decision-making approach to assess the resilience and

overall score of the retail sector (Ekinci et al., 2024).

It enables resilience to be adjusted to the supply

chain's condition in different environments to meet

managerial needs. Vadakkepatt et al., on the other

hand, are keen on the dynamic assessment of social

dimensions involving the entire business process,

from raw material sourcing to product disposal, reuse,

or recycling, as well as the safety and well-being of

the employees to reflect the need for sustainable

development of the company.

(Vadakkepatt et al.,

2020) Besides, Carter and Rogers see SCM as a

holistic process that requires the development of

standards-compliant sustainable optimization for

each level of the supply chain.

(Carter & Rogers,

2008)

Sustainability Meets Efficiency: Unveiling the Dual Impact on Supply Chain Performance in the Retail Sector. A Case Study of JB Hi-Fi

73

In summary, the report gives a clear idea about

supply chain management and the choice of

sustainable variables by referring to different kinds of

literature. Based on a full understanding of supply

chain sustainability, the design of data modeling in

the literature is referenced for the construction of the

methodology. At the same time, the strategic

alignment of the firms covered in the literature will

provide more insights for the discussion part of the

report.

3 METHODOLOGY

3.1 The Introduction of JB HiFi

This paper investigates the correlation between

supply chain metrics and sustainability in retail,

focusing on JB Hi-Fi, an Australian consumer

electronics retailer. JB Hi-Fi emphasizes effective

inventory management and strategic partnerships to

streamline goods movement from production to

consumer. Its supply chain strategy incorporates

technological advancements to improve partner

coordination and adaptability. Key to its operations is

a commitment to sustainability, targeting packaging

waste reduction and logistic optimization to lower

carbon emissions. The company's 2023 Sustainability

Report highlights its digital transformation goals,

exploring blockchain for transparency and AI

analytics for demand forecasting, to enhance supply

chain efficiency and sustainability.

3.2 Data Selection and Source

In selecting the data, the report fully integrates the

important components of supply chain management

and corporate sustainability mentioned in the

previous literature. It incorporates the JB HiFi 2020-

2023 Sustainability Report. It aims to continuously

narrow down the number of variables selected, reduce

the data sample's instability and ensure the data's

accuracy.

3.2.1 Quantitative Data on Supply Chain

Management

This report will explore three of the supply chain's

most highly visible and relevant data to a company's

bottom line as the dependent variables to be analyzed.

First, supply chain cost signifies the value invested in

the supply chain, influencing how much value a

company expects to place on building a sustainable

supply chain. The variable chosen for the report is the

Cost of Goods Sold (COGS), which includes the

direct costs of making a product, such as raw

materials, direct labor, and other direct costs of the

production process. It visualizes the initial cost at the

top of the supply chain and is easily obtained from

annual reports. Second, inventory turnover is the

variable of choice in defense of supply chain

efficiency. It reflects how often a company sells and

replaces inventory over a given period. It can be used

to assess a company's ability to manage its inventory

efficiently, and a high inventory turnover ratio may

indicate that a company can manage its inventory

efficiently and quickly convert it into sales. It is also

one of the key indicators that reflect supply chain

management. In addition to the above two metrics,

the operating cycle is also one of the chosen metrics,

which signifies the average number of days the

complete supply chain is in operation and the number

of days within which the company can make dynamic

adjustments to its supply chain. These three variables

interpret the study of supply chain management from

a three-dimensional perspective and are considered

Supply Chain Performance Indicators for data

modeling.

3.2.2 Quantitative Data on Supply Chain

Sustainability

This study will gather three quantitative metrics about

the JB HiFi Sustainability study's "most aligned with

the sustainability." The Sustainability Report includes

the number of individuals chosen by JB HiFi in

partnership with TGG who have an employee

engagement rating of over 70% and have been in the

job market for at least 5 years in the "People" section.

These diligent employees are involved in several

aspects of the supply chain, such as transportation,

loading, translating, inventory counting, and order

administration. Their inclusion is vital to the

company's sustainability and was selected as a

quantitative sustainability metric. Furthermore,

regarding the "Community" aspect discussed in the

Sustainability Report, it has selected the aggregate

sum of funds that JB HiFi AU contributes to the

community annually. This financial contribution is

deemed a "sustainable investment" by the company

and is utilized to enhance and streamline various

operations throughout the supply chain. Operations.

The Sustainability Report states that significant

financial backing for carbon optimization, employee

welfare, and community delivery services makes it a

key quantitative measure of sustainability.

Additionally, the Sustainability Report places

significant importance on the "Environment." JB

EMITI 2024 - International Conference on Engineering Management, Information Technology and Intelligence

74

HiFi, the top electronics retailer in Australia,

produces a significant quantity of soft plastic garbage

annually. To assess the company's overall

environmental impact, recycling this waste was

selected as the third sustainability indicator.

In summary, the report selects COGS, Inventory

Turnover, and Operating Cycle as the dependent

factors, while "People," "Community," and

"Environment" are picked as the independent

variables. The objective is to optimize the alignment

between the company's supply chain management

and sustainability requirements and ensure that the

final model is standardized and precise.

3.3 Establishment of Data Model and

Selection of Regression Tools

3.3.1 Establishment of Data Model

As this report focuses on exploring the quantitative

relationship between supply chain management and

sustainability indicators, the report mainly used to

conduct multiple linear regressions. The benefit of

multiple linear regressions is that they are able to be

illustrated by multiple models of the same level, for

COGS, inventory turnover, and whether or not the

operating cycle is affected by the sustainability

variables can be presented specifically and illustrated

by regression tests. At the same time, this also greatly

preserves the direct influence between the dependent

and independent variables, reducing omitted

variables and measurement error.

Supply Chain Performance Indicator

= 𝛽0+𝛽1×People

+ 𝛽2

× Community + 𝛽3

×Environmen

t

+ 𝜀

(1)

In the model developed, 𝛽0 is the intercept term,

𝛽1, 𝛽2, 𝛽3 correspond to employee engagement,

community donations, and soft plastic recycling

respectively, and 𝜀 is the error term. This is the initial

mathematical regression model that have constructed

and will be brought in for regression analysis after

proper instrument selection.

3.3.2 Lasso Regressions

This study on JB Hi-Fi's sustainability efforts faced

challenges due to a small dataset with only four data

points. To overcome the limitations of Ordinary Least

Squares (OLS) regression, which is prone to

overfitting with such datasets, it employed Lasso

regression. Lasso, or the Least Absolute Shrinkage

and Selection Operator, incorporates a regularization

parameter to mitigate overfitting and selectively

identify the most significant predictors by penalizing

the absolute size of the regression coefficients. This

approach is effective in datasets with predictors

nearly equal to the number of observations, as it

simplifies the model, enhances prediction accuracy,

and improves interpretability.

By applying Lasso regression, it focused on

identifying the critical factors influencing JB Hi-Fi's

sustainability key performance indicators (KPIs),

including Cost of Goods Sold (COGS), Inventory

Turnover, and Operating Cycle. Despite Lasso

regression introducing some bias, it compensates by

lowering variance and improving the model's

predictive reliability, which is crucial for drawing

dependable conclusions from limited data. This

methodology allowed us to derive more accurate

insights into how JB Hi-Fi's sustainability initiatives

impact its operational metrics, providing valuable

guidance for strategic decision-making. The

effectiveness of Lasso regression in this context

underscores its utility in extracting meaningful

insights from constrained datasets.

3.3.3 Python Analysis Tool

Python serves as the primary tool for analyzing JB Hi-

Fi's sustainability data due to its powerful ecosystem

and ease of use. Its libraries, including pandas,

NumPy, and sci-kit-learn, facilitate complex data

analyses like Lasso regression, streamlining data

handling, and statistical modeling. Python's

supportive community fosters innovation, making it

ideal for sustainability studies. Moreover, its

scalability and automation enhance the accuracy and

applicability of analytical insights, supporting JB Hi-

Fi's data-driven decision-making.

4 RESULTS

4.1 Data Summary

The report imports the organized and summarized

data into Python and describes the data to get the

organized summary tables. The table presents the

three variables involved in supply chain management.

The mean value of COGS is AUD 3936.75 million,

and the data ranges from AUD 3797.4 to AUD 4076.7

million. Inventory turnover has a mean value of 7.41

times, a minimum value of 6.84 times, and a

maximum value of 8.27 times. The mean value of the

Sustainability Meets Efficiency: Unveiling the Dual Impact on Supply Chain Performance in the Retail Sector. A Case Study of JB Hi-Fi

75

operating cycle is 49.59 days, ranging from 44.41

days to 53.35 days. In addition, regarding

sustainability quantification, the mean value of the

number of loyal employees is 1034 (rounded) with a

standard deviation of 155. with a minimum value of

904 and a maximum value of 1233. at the same time,

the mean value of the community investment is about

AUD 316 million, with a range of data from about

296 million to about 332 million. As for recycled soft

plastics, the mean value is 57,166kg, and the data

ranges from 49,580kg to 65,934kg. It shows that JB

HiFi has good supply chain management, and all the

supply chain and sustainability metrics are in the

middle of the road.

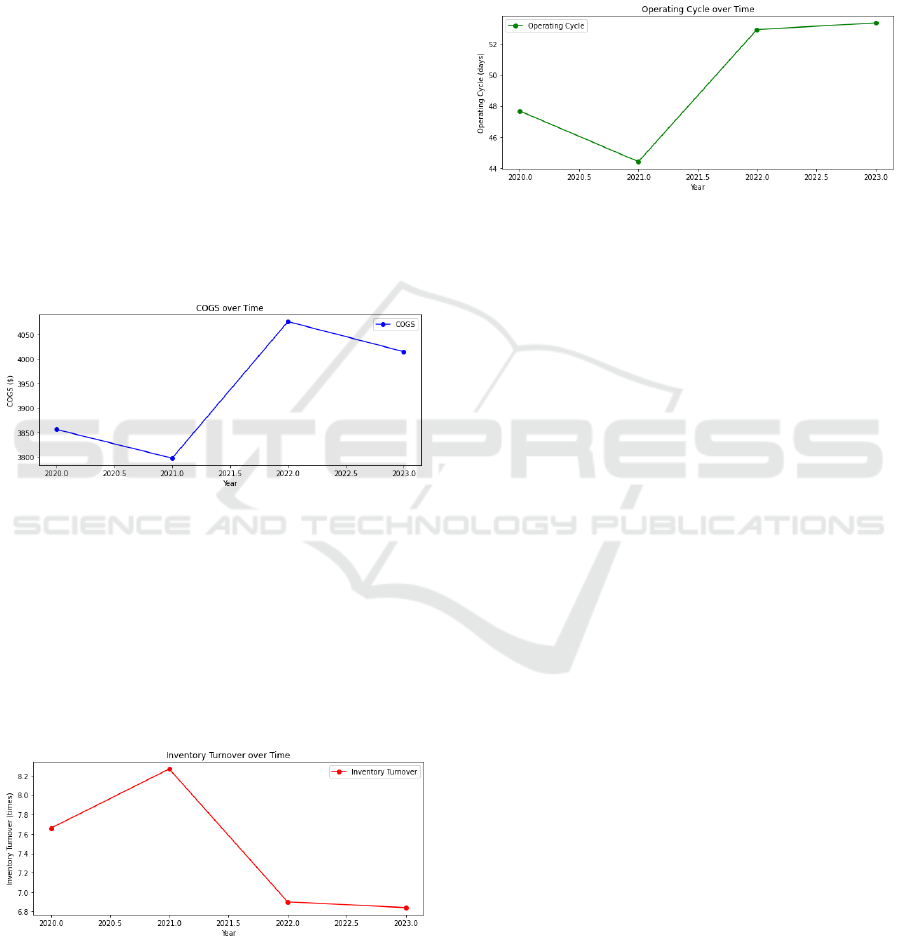

4.2 Time Series Plots of SCM Variables

After completing the overview of the report's data, the

report produces time-series images of the temporal

changes in the three variables of the SCM.

Figure 1: COGs time series plot.

Figure 1 shows the cost of goods sold (COGS)

from 2020 to 2023. COGS increases significantly

from 2020 to 2021, thanks to the spike in online sales

volume brought about by Covid-19, then rises sharply

in 2022 before flattening slightly in 2023. The general

trend shows an overall increase in the cost of goods

sold during this period. However, the overall situation

is under SCM control.

Figure 2: Inventory turnover time series plot.

As shown in Figure 2, inventory turnover

measures how often inventory is sold and replaced

over time. From 2020 to 2021, the inventory turnover

ratio increased, indicating that inventory is being

turned over at a faster rate. However, from 2021 to

2022, a spike in online purchases led to a sharp drop

in inventory, and JB HiFi stocks up on merchandise

in large quantities. By 2023, inventory turns will

remain low, which could indicate excess inventory or

slowing sales.

Figure 3: Operating cycle time series plot.

Figure 3 displays the duration, in days, that a

company requires to convert its purchases into cash

inflows from sales. The data suggests a rising trend

from 2020 to 2023. It indicates that the duration for

the company to sell its product and get payments is

growing, which may indicate possible inefficiencies

in the sales and collections procedures.

4.3 The Lasso Regressions

Since the report only uses data within the period of

the sustainability report (i.e., only four years of data),

the amount of data is too small for stable OLS

regression and is prone to multicollinearity. Lasso

regression allows for a more refined analysis without

adding more variables, reducing the model's

instability. It will complete the regularization analysis

by adding penalty terms. In the model, it starts with

data clarity and use the python runtime environment

to create the relevant 𝛼 variables suitable for lasso

regression.

The report got the best 𝛼-variable of 39.4421 for

COGs, 0.1485 for Inventory turnover, and 0.9545 for

the operating cycle through the data. After that, it

needs to perform Lasso regression for each of the

three variables according to the mathematical model

that have established to get three different sets of data:

Firstly, for COGs. With the optimal 𝛼 variable,

the intercept term is 3936.3499 million AUD.

However, the people and community part of it is

almost all zero, i.e., the effect of these two sustainable

quantitative variables on COGs is insignificant.

Meanwhile, the environment component is shown as

58.5465, which means that when the plastic collection

is increased, the supply chain cost also increases.

EMITI 2024 - International Conference on Engineering Management, Information Technology and Intelligence

76

There is a conflict between the company's efforts to

reduce supply chain costs and maintain sustainability

and the measures to protect the environment, which

have increased supply chain costs.

Secondly, the intercept term for the inventory

turnover ratio is 7.4175, which means that the

community does not affect the inventory turnover

ratio. Among the other two sustainability variables,

the growth of people increases the inventory turnover

rate, which shows the positive effect of having

enough dedicated employees on the sustainability of

supply management. On the contrary, the

environment decreases the inventory turnover, i.e., -

0.3322, which indicates a negative correlation

between the two. The initiative to recycle soft plastics

has caused inventory turnover to become more

difficult.

Finally, in the direction of the operating cycle, the

intercept term is 49.5899 (approximately equal to 50

days). In this case, the Community still does not play

any role, and the People component is negative with

an impact value of -0.4608, which again implies that

a sufficient number of dedicated employees can help

reduce the operating cycle, thus facilitating the SCM

to change strategy. On the other hand, the

environment had a positive impact with a value of

2.2503, which means that the increased task of

collecting soft plastics made the reform of the supply

chain, which was already poorly turned around,

difficult.

To summarize, after identifying the optimal 𝛼

variable through Lasso analysis, it can get the

following conclusions: the People variable has a good

impact on all SCM variables (except COGs), the

Community has no impact, and the environment (the

initiative to recycle soft plastics) may have increased

the burden on SCM. Specific reasons for this, as well

as measures for improvement, will be explored

below.

4.4 Bootstrap Stability Analysis and

Risk Management

To assess the risk associated with the three

sustainability variables (people, community, and

environment), the report performs a risk analysis by

looking at the variability of the predictions made by

the model. A bootstrap approach was used to generate

predictive distributions for each variable, and metrics

such as variance or confidence intervals were then

looked at for those predictions. It will provide an

estimate of risk based on the variability of the model's

predictions. A high standard deviation of the

bootstrap predictions indicates a high risk or

uncertainty in the model predictions.

By comparing the mean and standard deviation of

the predictions, this model remains essentially stable

after doing the Lasso regression. Taking COGs as an

example, the predicted mean of COGs is 3893.0600,

which is the same as the predicted means of the other

sustainability variables (3902.1845, 3968.0725, and

4005.6815), which means that the model tends to

fundamentally remain linear into the future (i.e.,

future studies can utilize linear regression as well).

Similarly, in the standard deviation, the variance of

COGs is 57.6611, which is the same as the standard

deviation of the other sustainable variables, again

indicating the stability of the model. After utilizing

Bootstrap for prediction, the stability of the model

was ensured, avoiding widespread measurement error

and multicollinearity.

5 DISCUSSION

5.1 Result Analysis and Reason

Explanation

By combining the regression results, the modeling

study shows a significant association between JB Hi-

Fi's sustainability indicators and supply chain

management indicators. In particular, employee

engagement (the "People" variable) positively affects

the supply chain management variables (except the

cost of goods), indicating that active employee

participation is essential for improving supply chain

efficiency and reducing operational cycle time.

Employees with good engagement can speed up the

supply chain process to a certain extent, improve

supply chain management efficiency, and avoid delay

problems. Meanwhile, the Community component

does not significantly impair, confirming that

community investment does not create any enablers

or impediments to the supply chain. However,

environmental protection measures (especially the

soft plastic recycling program) seem to hurt supply

chain costs and inventory turnover, suggesting that

promoting sustainable practices may have a negative

impact on supply chain efficiency and cost-

effectiveness.

There are multiple reasons for this phenomenon.

First, environmental protection measures usually

require initial capital investment and operating costs,

which may temporarily increase the overall cost of

the supply chain; as mentioned by Morcillo-Bellido

and Duran-Heras in their study, environmental

protection is a "difficult and complex" process

Sustainability Meets Efficiency: Unveiling the Dual Impact on Supply Chain Performance in the Retail Sector. A Case Study of JB Hi-Fi

77

(Morcillo-Bellido & Duran-Heras, 2020). It is a

"difficult and complex" process that requires

significant upfront investment. It shows that too much

investment in the supply chain can lead to rigidity in

supply chain management. Secondly, implementing

new sustainable practices may take time to adjust and

optimize, which may initially hinder the fluidity and

efficiency of the supply chain. Finally, the positive

impact of employee engagement emphasizes the

importance of human resources in supply chain

management, and a report by Gencer suggests that

supply chain performance can be effectively

enhanced by increasing employee responsibility and

engagement. It also coincides with the findings of the

report (Gencer, 2017).

5.2 Suggestions on Future

Sustainability of Supply Chain

In response to this analysis, the report provides some

recommendations for the future sustainability of JB

HiFi's supply chain. Firstly, it is essential to continue

to enhance employee training. In particular, enhance

employee training in sustainable supply chain

management, such as low-carbon transportation,

smart warehousing, and AI supply order review. It

will increase employee engagement and efficiency

while accomplishing the company's sustainability

goals. Secondly, it is important to make the right

sustainable investments for community investment.

JB HiFi mentioned refining the sustainable

investment program in its 2023 sustainability report.

Therefore, the company can invest in more

sustainable projects to meet the development needs in

the future, such as packaging recycling, delivery

protection for senior citizens, and pickup accessibility

service stations., which will contribute to supply

chain efficiency to a certain extent. Finally, in terms

of the environment, it is important to balance

environmental protection with cost-effectiveness.

Companies should look for ways to reduce the cost of

environmental measures, such as investing in more

efficient recycling technologies or exploring the

possibility of partnering with other businesses to

share resources. It can avoid negative impacts on the

cost and flexibility of the supply chain itself.

5.3 Study Design Limitations and

Model Defects

Although this study provides valuable insights into JB

Hi-Fi, there are still some issues with model design

and reporting. First, reporting is limited by the

amount of data. As the report only uses sustainability

indicators from the time period of the JB Hi-Fi

Sustainability Report's release, which is only four

years, the dataset used is relatively small. This may

limit the ability to generalize the model and the

robustness of the conclusions. Second, for the

selection of variables, the report selected only three

representative quantitative sustainability variables,

but there may be other important factors that were not

taken into account. The omitted variables may also

have implications for certain aspects of supply chain

management. Finally, for model construction,

although Lasso regression was used to minimize the

risk of overfitting, the small sample data may still

lead to an overly complex model, affecting its

predictive ability. Moreover, the Lasso model cannot

completely solve the problem of model instability,

and the discussion of supply chain management and

sustainability should be more in-depth and use a more

stable and logical research-oriented model.

6 CONCLUSION

This research delves into the complex interplay

between sustainability initiatives and their impact on

supply chain metrics within JB Hi-Fi, a leading

Australian retail company. It critically examines the

sustainability practices in supply chain management,

uncovering both benefits and challenges. The study

finds that employee engagement is key to enhancing

supply chain performance, highlighting the critical

role of human elements in achieving sustainability.

Conversely, environmental strategies, particularly

soft plastic recycling efforts, present a dilemma by

increasing operational costs and potentially slowing

inventory turnover. This dichotomy underscores the

intricate challenges retailers face in aligning

sustainability goals with operational efficiency. The

study calls for a nuanced approach to sustainable

supply chain management and advocates for more

comprehensive sustainability metrics and extended

research to understand the long-term effects. It

emphasizes the strategic importance of integrating

sustainability into supply chain management beyond

compliance, essential for maintaining

competitiveness in the retail industry. This

investigation opens new avenues for academic and

practical advancements in the nexus of sustainability

and supply chain management, offering significant

implications for both scholars and practitioners.

EMITI 2024 - International Conference on Engineering Management, Information Technology and Intelligence

78

REFERENCES

Berning, A., & Venter, C, 2015. Sustainable Supply Chain

Engagement in a Retail. Environment. Sustainability,

7(5), 6246–6263.

Carter, C.R., & Rogers, D. S, 2008. Aspects of sustainable

supply chain management(SSCM): conceptual

framework and empirical example. Supply Chain

Management: An International Journal, 13(5), 362-

371.

Chauhan, R., Majumder, A., & Kumar, V, 2023. The impact

of adopting customization policy and sustainability for

improving consumer service in a dual-channel retailing.

Journal of Retailing and Consumer Services, 75(12),

103504.

Chkanikova, O., & Mont, O. ,2012. Corporate Supply

Chain Responsibility: Drivers and Barriers for

Sustainable Food Retailing. Corporate Social

Responsibility and Environmental Management, 22(2),

65–82.

Ekinci, E., Sezer, M. D., Mangla, S. K., & Kazancoglu, Y.

2024. Building sustainable resilient supply chain in

retail sector under disruption. Journal of Cleaner

Production, 434(5), 139980.

Gencer, Y. G., 2017. Supply Chain Management in

Retailing Business, IGI Global.

Han, J., & Guo, Y., 2014. Sustainable Supply Chain

Management in Retail Industry. Proceedings of the

2014 International Conference on Information,

Business and Education Technology, 3(2).

Jones, P., & Comfort, D., 2020. Sustainability in Retail

Supply Chains. International Journal of Sales, Retailing

and Marketing, 9(2), 51–60.

Longo, F., 2012. Sustainable supply chain design: an

application example in local business retail. Simulation,

88(12), 1484–1498.

Morcillo-Bellido, J., & Duran-Heras, A., 2020.

Sustainability Governance Mechanisms in Supply

Chains. An Application in the Retail Sector.

Sustainability, 12(17), 6911.

Negrutiu, C., Vasiliu, C., & Enache, C., 2020. Sustainable

Entrepreneurship in the Transport and Retail Supply

Chain Sector. Journal of Risk and Financial

Management, 13(11), 267.

Rao, P., Balasubramanian, S., Vihari, N., Jabeen, S.,

Shukla, V., & Chanchaichujit, J., 2021. The e-

commerce supply chain and environmental

sustainability: An empirical investigation on the online

retail sector. Cogent Business & Management, 8(1).

Ruiz-Real, J., Uribe-Toril, J., Gázquez-Abad, J., & de Pablo

Valenciano, J., 2018. Sustainability and Retail:

Analysis of Global Research. Sustainability, 11(1), 14.

Vadakkepatt, G. G., Winterich, K. P., Mittal, V., Zinn, W.,

Beitelspacher, L., Aloysius, J., Ginger, J., & Reilman,

J., 2020. Sustainable Retailing. Journal of Retailing,

97(1).

Vass, T., Shee, H., & Miah, S. J., 2020. Iot in supply chain

management: a narrative on retail sector sustainability.

International Journal of Logistics Research and

Applications, 24(6), 1–20.

Sustainability Meets Efficiency: Unveiling the Dual Impact on Supply Chain Performance in the Retail Sector. A Case Study of JB Hi-Fi

79