Asset Administration Shell Digital Twin of 5G Communication

System

Salvatore Cavalieri

a

, Raffaele Di Natale

b

and Salvatore Gambadoro

c

Department of Electrical Electronics and Computer Engineering, University of Catania, Catania, Italy

Keywords: Asset Administration Shell, 5G, Digital Twin, Industry 4.0.

Abstract: A fundamental element within Industry 4.0 is the digital twin, which allows the development of a virtual

model of a facility, with the aim of monitoring, managing, and simulating its operation, thereby enhancing

control in testing, analysis, prediction, and risk prevention for sensitive processes. The communication system

is an important part of highly interconnected Industry 4.0 systems; in particular, that based on wireless

transmission plays a very strategic role mainly due to the reduced complexity in installation and maintenance.

If changes are necessary in the production system, the communication system should be adapted accordingly.

Modelling a communication system by a digital twin has the advantage to quickly allow updating the

communication parameters according to the changed needs of the production system. Among the available

wireless communication systems, the use of 5G inside industrial production seems very promising. This paper

proposes to represent 5G-based communication system elements using the Asset Administration Shell model,

which is one of the existing standards for the digital representation of assets inside Industry 4.0.

1 INTRODUCTION

Among the main features of the Industry 4.0, there is

the definition of increasingly flexible, interoperable,

and innovative systems, focusing on a continuous

evolution of technologies capable of shifting the

management of an asset from the physical domain to

the virtual domain (Xu et al., 2018; Cotrino et al.,

2020). A fundamental architectural element within

Industry 4.0 is the digital twin, which is a digital

representation of a real asset. A digital twin allows

replicating a facility, with the aim of monitoring,

managing, and simulating its operation, thereby

enhancing control in testing, analysis, prediction, and

risk prevention for sensitive processes (Mihai et al.,

2022; Javaid et al., 2023).

A digital twin includes all the information

representative of the real system to be modeled;

furthermore, functions/applications using the digital

information collected from the real system may be

defined inside a digital twin. The digital twin and the

physical part can exchange data for real-time

a

https://orcid.org/0000-0001-9077-3688

b

https://orcid.org/0009-0004-9363-5036

c

https://orcid.org/0000-0001-9840-1379

awareness, process control and decision making

(Schroeder et al., 2016;Wei et al., 2019).

The Asset Administration Shell (AAS) was

introduced by Plattform I4.0 (www.plattform-i40.de)

in 2016 as a core element of the Reference

Architectural Model for Industry 4.0 (RAMI 4.0)

(DIN, 2016). The Industry 4.0 component has been

described within RAMI 4.0 as the combination of the

asset and its digital representation (DIN, 2016;

Wagner et al., 2017; Ye and Hong, 2019). The AAS

is considered the official standard for the digital

representation of components within the Industry 4.0

system.

The communication system is an important part of

highly interconnected Industry 4.0 systems; in

particular, that based on wireless transmission plays a

very strategic role mainly due to the reduced

complexity in installation and maintenance. If

changes are necessary in the production system, the

communication system should be adapted

accordingly. Modelling a communication system by

a digital twin has the advantage to quickly allow

update of the communication parameters according to

Cavalieri, S., Di Natale, R. and Gambadoro, S.

Asset Administration Shell Digital Twin of 5G Communication System.

DOI: 10.5220/0012914200003822

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 21st International Conference on Informatics in Control, Automation and Robotics (ICINCO 2024) - Volume 2, pages 395-402

ISBN: 978-989-758-717-7; ISSN: 2184-2809

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

395

the changed needs of the production system. For this

reason, the communication system and in particular a

WCS, must be considered when realizing the digital

twin of the production system.

Among the available wireless communication

systems, the use of 5G network inside industrial

production seems very interesting. Literature presents

several papers pointing out the advantages of its use

in Industry 4.0 contest (Ordonez-Lucena et al., 2019;

Meira et al., 2023).

The aim of this work is to present a digital twin of

the 5G-based WCS elements using the Asset

Administration Shell. The paper will describe the

AAS model defined by the authors and will provide

an example of how the AAS model can be used in a

real 5G communication scenario.

2 RELATED WORK

The current literature offers a huge set of papers about

the use of the Asset Administration Shell for the

digital representation of industrial assets. In (Inigo et

al., 2020; Hu et al., 2023) the current state of the art

about realizations of digital twins by the AAS

metamodel is presented, proving the relevant

feasibility of representing heterogeneous industrial

assets. Among them, examples of use of AAS for

modelling communication subsystems are present.

Considering the modelling of 5G communication

systems by AAS, literature presents some

publications. One of the available documents is a

white paper written by 5G Alliance for Connected

Industries and Automation (5G-ACIA, 2021). It

points out the importance of integrating 5G into

Industry 4.0 by defining a 5G AAS. The document

does not present a detailed AAS model of the 5G

communication system, but it points out the main

features to be hold by a digital twin based on AAS, in

order to properly represent a 5G communication

system. A very general description of an AAS model

is proposed, formulating only the main components

that should be included in the model.

Another document available in the current

literature about 5G modelling by AAS is given by

(Cainelli et al., 2022). In the paper, the authors

present a proposal of AAS model of 5G WCS,

describing a communication submodel for a 5G-

enabled device. Two AAS submodel elements were

defined as the main relevant to a 5G device. The

proposal does not take into account the general

concepts given by (5G-ACIA, 2021).

As said in the Introduction, the aim of this paper

is the proposal of a AAS digital twin of 5G

communication system. On account of what written

about the current state-of-the-art, it seems that the

proposal here presented is original for two reasons.

The first is that it gives a very detailed definition of

the AAS model of 5G communication system, more

than the other works present in the current literature;

moreover, this proposal is fully based on the

considerations and architecture drawn in (5G-ACIA,

2021). This last point is very important according to

the authors’ point of view; 5G-ACIA brings together

widely varying 5G stakeholders and for this reason

the authors believe that including the relevant

considerations and vision of the AAS 5G model

should be important.

3 ASSET ADMINISTRATION

SHELL

The AAS is the implementation of the digital twin for

Industry 4.0 from the perspective of Plattform I4.0

(Gowtham et al., 2021; ZVEI, 2022). It is under

development by project 63278-1 of the International

Electrotechnical Commission.

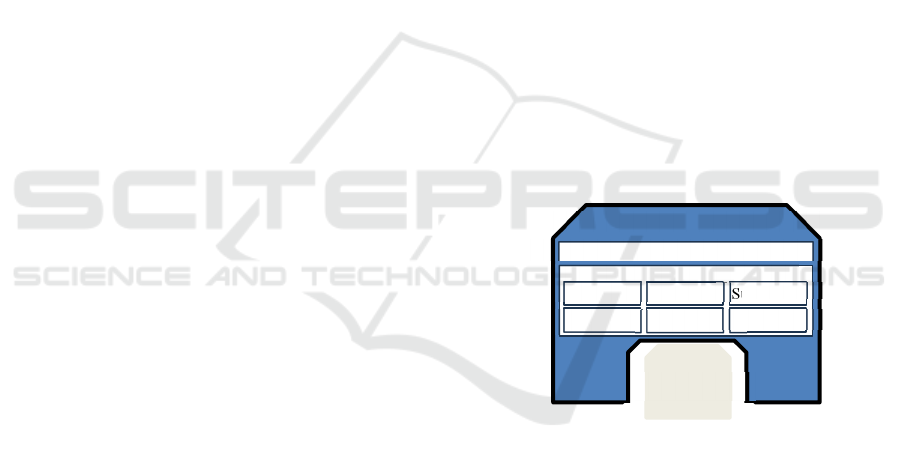

The AAS is composed of a passive part and an

active part, as shown by Figure 1.

Figure 1: Asset Administration Shell.

The passive part contains the properties of the

asset which are readable and/or modifiable. The

active part consists of functions performed by the

AAS; it incorporates decision-making functions and

interaction mechanisms that enable peer-to-peer

interaction.

The asset’s information is described in the AAS

as Submodels. Below the submodel level, there are

the submodel elements (SubmodelElements), which

store specific data related to the submodel. For

example, a property, which is a submodel element

type, can contain a value that represents a physical

variable of the asset. The

SubmodelElementCollection (SMC) plays a crucial

Active Part: Algorithms and Methods

Asset Administration Shell

Passive Part: Properties

Real Asset

Submodel

Submodel

Submodel

Submodel

Submodel Submodel

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

396

role in this context, as it is defined as a set or list of

SubmodelElements.

The AAS metamodel introduces an important

referencing mechanism to establish relationships

among the entities that make up the AAS. This

mechanism relies on the ReferenceElement, through

which structured navigation within the AAS becomes

possible. For example, if one submodel refers to

another through a ReferenceElement, it is possible to

follow this link to access the related information.

Navigation may be realized also among several AASs;

a ReferenceElement of a particular AAS submodel

may point to a different AAS.

One of the core entities of the AAS metamodel to

achieve interoperability is ConceptDescription; it is

used to define the semantics of entities inside the

AAS metamodel. Every element in AAS may have its

semantics described by a ConceptDescription.

In the Asset Administration Shell, Submodel

Templates allow for establishing a standardized and

consistent structure for submodels within an AAS

(ZVEI, 2020).

4 THE 5G AAS MODEL

The 5G-ACIA proposes two Asset Administration

Shell models called 5G Network AAS and 5G UE

AAS (5G-ACIA, 2021).

The 5G Network AAS represents the enabling

networking function, which includes all nodes and

functions within the 5G RAN (Radio Access

Network) and CN (Core Network) that do not belong

to 5G-capable IIoT devices.

The 5G UE AAS describes the endpoint of the 5G

link located on the device, which corresponds to the

5G UE (User Equipment), and analyzes its

functionalities, capacities, and performances as

defined by 3GPP (3GPP, 2020).

The white paper (5G-ACIA, 2021) outlines the

main features of these two AASs, without specifying

the structures of the various submodels. The authors

have therefore undertaken further works to structure

these models and then to implement them. In the

following paragraphs, the details about the models

defined by the authors will be given, focusing more

on the 5G UE AAS, only for space reasons.

4.1 The 5G Network AAS

The 5G Network AAS presented in (5G-ACIA, 2021)

has been defined and implemented by the Asset

Administration Shell named AAS_5G_Network.

It was organized into the following submodels:

Asset Service Registry. It registers the services

offered by assets in the network and tracks

them to facilitate access and management.

5G Network ID. It handles the management of

a wide range of essential identifiers used for the

identification and management of users and

devices within the Radio Access Network and

the Core Network.

5G Network Data Sheet. It contains detailed

technical information about the 5G network,

including equipment specifications, network

configurations, and other crucial information

for network design and maintenance.

Physical & Logical Topology. It describes the

physical and logical configuration of the 5G

network, providing a comprehensive overview

of the network structure and interconnections

between its components.

PDU Sessions/QoS Flows. It contains

information about data transfer sessions and

quality of service, ensuring that network traffic

is efficiently managed and meets user needs.

Performance. It contains metrics on the

performance of the 5G network, allowing

evaluation of network efficiency and

reliability.

4.2 The 5G UE AAS

The 5G UE AAS presented in (5G-ACIA, 2021) has

been defined and implemented by the Asset

Administration Shell named AAS_5G_UE. In the

following subsections the submodels defined and

implemented by the authors, will be described.

4.2.1 Equipment Identifier Submodel

The Equipment Identifier Submodel maintains a wide

range of essential identifiers for user and device

identification and management within the network.

These identifiers, such as the Subscription Permanent

Identifier (SUPI), the Subscriber Concealed Identifier

(SUCI), the 5G Globally Unique Temporary Identity

(5G-GUTI), and others, play a fundamental role in

managing connections and services within the

network.

In addition to user and device identifiers, the

submodel also includes information such as the name

of the Access and Mobility Management Function

(AMF), the Data Network Name (DNN), and network

slice identifiers, which are needed for the proper

delivery of services and efficient network resource

management.

Asset Administration Shell Digital Twin of 5G Communication System

397

4.2.2 Certification Status Submodel

The Certification Status Submodel represents the set

of information related to the X.509 certificate

associated with a UE device within a 5G network.

This submodel provides a detailed view of the

various fields comprising the certificate, enabling

efficient and secure management of security in the 5G

environment. Among the fields included in this

submodel there are fundamental pieces of

information such as the certificate version, serial

number, signature algorithm used, and the issuing

authority. Additionally, details about the certificate's

validity, including the validity period and associated

policies, are also represented.

The structure of this submodel is designed using

the SMC to define fields composed of multiple

properties. For example, the Validity field, consisting

of two properties - notBefore and notAfter, is

implemented through a SMC.

Conversely, individual properties are represented

using SubmodelElements of type Property. A key

field is the Certificate field, represented through a

SubmodelElement of type Blob, allowing for the

retention of the actual certificate file. In addition to

details about the issuer and subject of the certificate,

the submodel also includes information about the

public key associated with the certificate, as well as

key usage restrictions and certificate extensions.

4.2.3 Network Access Restrictions Submodel

The Network Access Restrictions Submodel is

designed to manage network access restrictions

within a specific system or environment. This

Submodel is structured into two distinct SMCs:

GeofenceArea and ListOfCGIs.

GeofenceArea contains information related to

geographical areas defined as "geofences", which can

be used to restrict or allow network access in specific

geographical locations. Each element within this

SubmodelElementCollection represents a precise

geographical area defined by geographical

coordinates. Geographical coordinates are

represented through SubmodelElement of type

Property.

On the other hand, ListOfCGIs contains a list of

CGIs (Cell Global Identity), which are unique

identifiers for cells within a mobile network. CGIs

allow for the specific identification of a cell within a

cellular network and can be used to apply access

restrictions based on cell location. CGIs are formed

by sub-identifiers such as PLMNID, LAC, and CI,

and for this reason, each CGI is represented through

a SMC.

4.2.4 5G-UE Data Sheet Submodel

This submodel contains detailed specifications of the

user equipment, e.g., hardware capabilities, supported

5G bands, throughput capacities.

To implement the 5G UE Data Sheet submodel,

the Technical Data submodel template provided by

Industrial Digital Twin Association (IDTA) was used

(Industrial Digital Twin Association, 2024).

4.2.5 Connectivity QoS Requirement

Submodel

The submodel Connectivity QoS (Quality of Service)

Requirement submodel defines the expected level of

service quality that the network should provide to the

device, which could include parameters like latency,

bandwidth, and reliability.

The submodel was realized following the

VDI/VDE 2192 (VDI/VDE, 2020). This submodel

contains a main submodel collection called

“Subscription” composed by ten submodel

collections for supporting the quality-of-service-

parameters, e.g., “Response Time”, “Trasmission

Time”, “Update Time”. Each of these submodel

collections describes a couple of requested value and

guaranteed value parameters.

4.2.6 QoS Monitoring Submodel

This submodel allows to monitor the device's actual

performance against the QoS requirements,

potentially for adaptive network management or SLA

(Service Level Agreement) adherence.

In this submodel some characteristic parameters

such as transmission time and update time are

considered. As done for the previous submodel, it was

modeled following the VDI/VDE 2192 (VDI/VDE,

2020).

4.2.7 Positioning Data Submodel

The Positioning Data Submodel represents a crucial

set of information for the precise localization of User

Equipment (UE) devices within a 5G network. This

submodel provides data regarding the geographical

position of the UE, along with details about the

received signal quality.

The geographical coordinates, collected through a

SMC, include latitude and longitude, represented by

a SubmodelElement of type Property. Through these

coordinates, precise localization of the UE within the

geographical context is achieved. This information is

complemented by signal data, such as the Reference

Signal Received Power (RSRP), the Signal-to-Noise

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

398

Ratio (SNR), and the Channel Quality Indicator

(CQI), which are represented by SubmodelElements

of type Property and are contained within a SMC

called Signal Info. These properties provide

indications of the quality and intensity of the signal

received by the UE device.

5 CASE STUDY

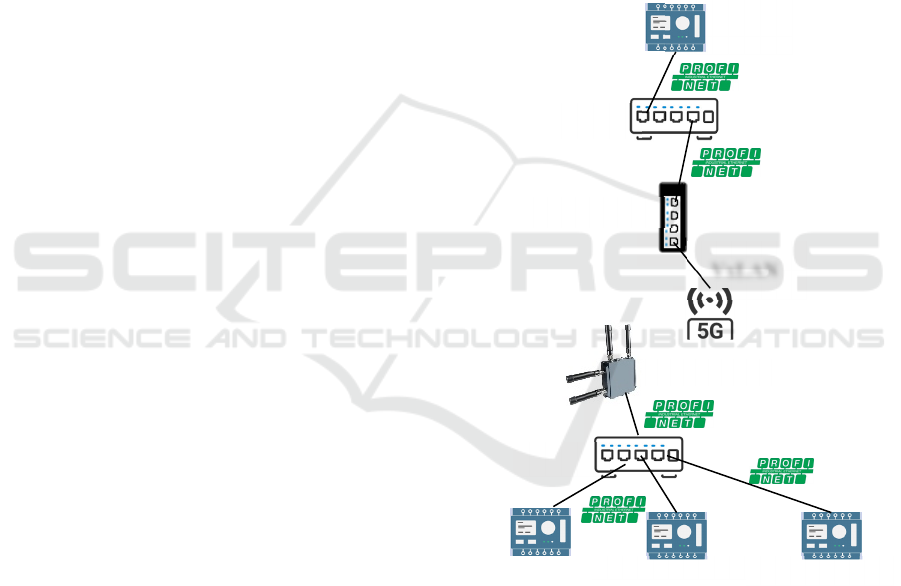

The aim of this section is to present an example of

application of the AAS-based modelling of the 5G

UE-5G Network System, proposed in this paper.

The scenario considered for the case study

features the use of a private 5G network to convey

communications between Programmable Logic

Controllers (PLCs) using the PROFINET

communication protocol (Pigan and Metter, 2015).

Wired communication systems like PROFINET

are widely used in industrial communication, mainly

for their capability to guarantee a reliable, real-time

deterministic data transmission. However, wired data

transmission may not be feasible where non-

stationary devices are involved; in this case, wireless

technologies such as 5G can be applied. To combine

wireless and wired transmission, suitable

communication protocols that allow the integration of

these technologies are needed.

Currently it is not possible to transmit PROFINET

frames directly over 5G without using tunneling

protocols; this because 5G communication system

use the IP as layer 3 protocol, whilst the PROFINET

protocol uses only layer 2 frames. A solution for this

is the use of protocols like Virtual Extensible LAN

(VxLAN) (Mahalingam et al., 2014) or Generic

Routing Encapsulation (GRE) (Yegani et al., 2011).

Tunnelling is commonly realized by the use of two

devices - one wired and the other wireless. A wired

Tunneling device is tailored to establish

communication with the 5G core network via an

Ethernet connection, and subsequently create a tunnel

for the transfer of PROFINET packets, while

ensuring that vital metadata and information related

to the packet’s type of service is preserved. The wired

Tunneling device establishes a transparent

connection between a PLC and slave devices, while

simultaneously informing the cellular network about

the priority level of each packet and allocating

distinct bearer channels for different types of traffic.

A 5G-wireless router fulfils high-speed wireless

connectivity requirements of industrial cabinets and

mobile devices, offering the traffic prioritization and

routing capabilities.

In the case study here considered, it has been

assumed that a PLC featuring the PROFINET

Controller role must communicate with one or more

PLCs with PROFINET Device role, through a 5G

network. For this reason, the PLC Controller is

connected to a Tunneling device (through a switch)

which is able to tunnel Layer 2 frames through Layer

3 protocol (assuming to use VxLAN protocol).

Figure 2 shows the case study here considered and

based on the wired (Tunneling device) and wireless

(5G-wireless router) devices just described. As shown

by the Figure 2, a 5G-wireless router allows the data

exchange between the PLC Controller and the PLC

Devices, featuring the traffic prioritization and

offering routing capabilities.

Figure 2: Case study scenario.

5.1 AAS Models

The scenario shown by Figure 2 includes the 5G

network and the 5G user equipment, whose AAS

models have been introduced in Section 4. But the

scenario contains other components, whose relevant

AAS models will be introduced in the following.

The AAS_ModularComputingSystem has been

defined by the authors to allow the digital

representation of modular computing systems such as

PLC

Switch1

PLC Device1 PLC Device2 PLC Device3

Switch2

Tunneling device

5G-wireless router

Controller

VxLAN

Asset Administration Shell Digital Twin of 5G Communication System

399

PLC, composed of interconnected modules with at

least one possessing computing capabilities.

The AAS_CommunicationSystem has been

designed to provide the digital representation of

network communication devices, e.g. switches.

The AAS_CommunicationProtocol has been

defined by the authors to represent each

communication protocol used in the communication

system. This AAS includes information about the

configuration and parameters required to implement

the protocol.

These AAS models have been introduced by the

authors in another paper (Cavalieri and Gambadoro,

2024); the reader may refer to it to have more details.

5.2 Digital Twin of the Case Study

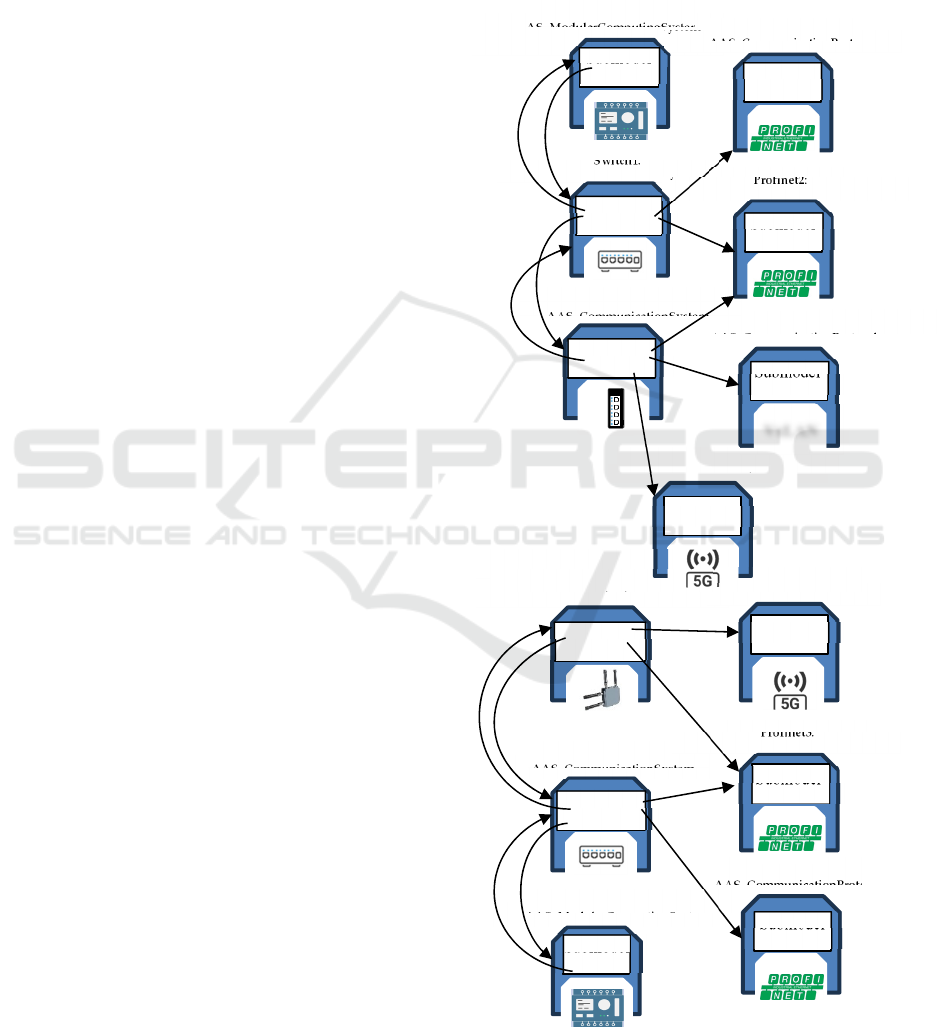

The aim of this sub-section is to present the AAS-

based Digital Twin of the communication scenario

shown by Figure 2. Figure 3 gives the graphical

representation of the AAS-based Digital Twin.

The case study features a PLC with PROFINET

Controller role and several PLCs with Device role.

The AAS_ModularComputingSystem has been used

to model each single PLC. Figure 3 shows the

instance modelling the PLC Controller; for space

reason, only one AAS model representing a PLC with

Device role has been represented (PLC Device1). In

each AAS modelling the PLC (both Device and

Controller), the Submodel Modules includes the

representation of the Ethernet port; a

ReferenceElement points directly from the PLC

Ethernet module to the AAS modelling the relevant

switch, as shown by Figure 3.

To model each of the two switches, the

AAS_CommunicationSystem model was used.

Through the Connections submodel, the

ReferenceElement Device allows to point to the AAS

model of the devices to which each switch is

connected. For example, considering the Switch1, the

reference will point to the AAS models relevant to the

PLC Controller and to the Tunneling device. In each

instance of the AAS_CommunicationSystem that

models a switch, the Connections submodel will

include the ReferenceElement DeviceProtocol, which

points to the AAS that models the communication

protocol used for communication between the switch

and each connected device. Considering both

switches in our case study, this reference will point to

the AAS model representing the PROFINET

communication protocol (described in the following).

In particular, Profinet1 is the AAS model of the

PROFINET protocol relevant to the communication

between the Switch1 and the PLC Controller;

Profinet2 is the AAS model of the PROFINET

protocol relevant to the communication between the

Switch1 and the Tunneling device. Profinet3 and

Profinet4 are the AAS models representing the

PROFINET protocol relevant to the communications

between Switch2 and 5G-wireless router and between

Switch2 and PLC Device1, respectively.

Figure 3: Digital Twin by AAS of the case study scenario.

AAS_ModularComputingSystem

Su

b

model

Modules

Switch1:

Su

b

model

Connections

AAS_CommunicationProtocol

Su

b

model

Parameters

AAS_5G_Network

Su

b

models

AAS_CommunicationSystem

Su

b

model

Connections

AAS_CommunicationSystem

Su

b

model

Connections

AAS_5G_UE

Su

b

models

AAS_ModularComputingSystem

Su

b

model

Modules

AAS_CommunicationProtocol

Su

b

model

Parameters

AAS_CommunicationProtocol

Su

b

model

Parameters

AAS_CommunicationSystem

Su

b

model

Connections

PLC Device1:

Switch2:

Profinet4:

5G_UE:

5G_WirelessRouter:

5G_Network:

VXLAN:

Profinet1:

AAS_CommunicationSystem

Tunneling Device:

Su

b

model

Parameters

Profinet3:

AAS_CommunicationProtocol

Profinet2:

AAS_CommunicationProtocol

Su

b

model

Parameters

PLC Controller:

VxLAN

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

400

The AAS model of the Tunneling Device has been

realized as an instance of the

AAS_CommunicationSystem type. Through the

Connections submodel, the ReferenceElement

Device allows to point to the AAS models of the

devices to which the Tunneling device is connected,

i.e. the Switch1 and the 5G network system. The

ReferenceElement DeviceProtocol will point to the

AAS modelling the communication protocol used for

the communication between the Tunneling device

and each device connected. In this scenario, a

DeviceProtocol reference will point to the Profinet2

AAS modelling the PROFINET protocol used

between the Tunneling device and the Switch1;

another DeviceProtocol reference will point to the

AAS describing the VxLAN protocol (described in

the following) used between the Tunneling device

and the 5G network.

The 5G network system has been represented

using an instance of the AAS_5G_Network type,

proposed in this paper. Through the AAS, a structured

representation of the 5G network is provided,

including all network nodes and their respective

functions. The AAS's capability to provide details on

the physical and logical topology of the network,

along with PDU sessions and QoS flows, ensures

excellent management of data traffic. Additionally,

the 5G Network AAS constantly monitors network

performance, allowing for continuous assessment of

the efficiency and reliability of wireless

communications in the production environment,

thereby facilitating optimization of operations within

the system.

The model of the 5G-wireless router device has

been done considering the router as a communication

system made up by an internal component realizing

the 5G UE. Based on this assumption, instances of the

AAS_CommunicationSystem and AAS_5G_UE

types were considered. The instance of

AAS_CommunicationSystem type (i.e.

5G_WirelessRouter in Figure 3) represents the router,

whilst the other instance (i.e. 5G_UE) is the digital

representation of the 5G UE component of the router.

Through the Connections submodel, the

ReferenceElement Device allows to create a

reference from the AAS modelling the 5G-wireless

router to the AAS 5G_UE. Another

ReferenceElement Device is contained in the

Submodel Connections, pointing to the AAS

modelling the Switch2, as the 5G-wireless router is

attached to the switch. In the AAS modelling the 5G-

wireless router, the Connections submodel will also

include the ReferenceElement DeviceProtocol, which

points to the AAS modelling the PROFINET

communication protocol used for communication

between the 5G-wireless router and the Switch2 (i.e.

Profinet3), as shown by Figure 3.

The AAS_CommunicationProtocol has been used

to represent the PROFINET protocol. For each pair of

devices connected by this protocol, an instance of the

AAS_CommunicationProtocol have been considered

to represent the main features of the PROFINET

communication. Among the parameters that can be

managed there are: IP address, SubnetMask,

SendClock, and UpdateTime.

The AAS_CommunicationProtocol has been

instantiated to represent the VxLAN protocol. This

protocol is used in the communication between the

Tunneling device and the 5G network system and

between the 5G network system and the 5G Wireless

Router. An instance of the

AAS_CommunicationProtocol is referenced by

DeviceProtocol ReferenceElement pointing from the

Submodel Connections of the AAS representing the

Tunneling device, as shown by Figure 3.

6 CONCLUSIONS

The paper pointed out the importance to realize a

digital twin of a 5G wireless communication system.

A solution based on the use of Asset Administration

Shell metamodel has been presented in this paper.

Originality of the proposed approach has been

pointed out, considering the current state-of-the-art.

A case study has been shown in order to better

understand the AAS model and to demonstrate the

feasibility of the proposal. The AAS model here

proposed has been implemented using the AASX

Package Explorer, that is a tool provided by the

Industry 4.0 consortium.

ACKNOWLEDGEMENTS

This work has been supported in part by the Research

Grants from European Union – NextGenerationEU –

PNRR within the project “RESearch and innovation

on future Telecommunications systems and networks,

to make Italy more smART” - RESTART, C.I.

PE00000001, CUP E63C22002070006, and in part

by the Research Grants from Fondo per la Crescita

Sostenibile – Accordi per l'innovazione "Fabbrica

Intelligente", within the project "Water 4.0", Prog n.

F/160041/03/X41 - CUP: B69J24001170005.

Asset Administration Shell Digital Twin of 5G Communication System

401

REFERENCES

3GPP TS 38.401: NG-RAN. (2020). Architecture

description. Rel16.

5G-ACIA. (2021). Using digital twins to integrate 5G into

production networks (White Paper). Accessed on line:

https://5g-acia.org//wp-content/uploads/2021/05/5G-A

CIA-Using-Digital-Twins-to-Integrate-5G-into-Produc

tion-Networks-single-pages.pdf

Cainelli, G. P., Underberg, L., Rauchhaupt, L., Pereira, C.

E. (2022). Asset administration shell submodel for

wireless communication system. IFAC PapersOnLine,

55(2), pp.120–125.

Cavalieri, S., Gambadoro, S. (2024). Digital Twin of a

Water Supply System Using the Asset Administration

Shell. Sensors, 24, 1360.

Cotrino, A., Sebastián, M.A., González-Gaya, G. (2020).

Industry 4.0 Roadmap: Implementation for small and

medium-sized enterprises. Appl. Sci., 10, 8566.

DIN. (2016). Reference Architecture Model Industrie 4.0

(RAMI4.0). DIN SPEC 91345:2016-04. Beuth Verlag

GmbH: Berlin, Germany.

Gowtham, V., Willner, A., Pilar von Pilchau, W., Hähner,

J., Riedl, M., Koutrakis, N. S., Polte, J., Uhlmann, E.,

Tayub, J., Frey, V. (2021). A Reference Architecture

enabling Sensor Networks based on homogeneous

AASs. In Proceedings of AUTOMATION 2021,

Volume VDI-Berichte-Nr. 2392, pp. 5–16.

Hu, F. F., Wang, W., Zhou, J. (2023). Petri nets-based

digital twin drives dual-arm cooperative manipulation.

Computers in Industry, 147, 103880.

Industrial Digital Twin Association. (2024). Submodels

Hub. Accessed on line: https://industrialdigital

twin.org/en/content-hub/submodels.

Inigo, M. A., Porto, A., Kremer, B., Perez, A., Larrinaga,

F., Cuenca, J. (2020). Towards an asset administration

shell scenario: A use case for interoperability and

standardization in Industry 4.0. In Proceedings of the

IEEE/IFIP Network Operations and Management

Symposium 2020: Management in the Age of

Softwarization and Artificial Intelligence, NOMS, pp.

1-6, Budapest, Hungary.

Javaid, M., Haleem, A., Suman, R. (2023). Digital Twin

applications toward Industry 4.0: A Review. Cogn.

Robot., 3, 71–92.

Mahalingam, M., et al. (2014). Virtual eXtensible Local

Area Network (VXLAN): A Framework for Overlaying

Virtualized Layer 2 Networks over Layer 3 Networks.

RFC 7348: 1-22.

Meira, J., Matos, G., Perdigão, A., Cação, J., Resende, C.,

Moreira, W., Antunes, M., Quevedo, J., Moutinho, R.,

Oliveira, J., et al. (2023). Industrial Internet of Things

over 5G: A Practical Implementation. Sensors, 23(11),

5199.

Mihai, S., Yaqoob, M., Hung, D.V., Davis, W., Towakel,

P., Raza, M., Karamanoglu, M., Barn, B., Shetve, D.,

Prasad, R.V., et al. (2022). Digital Twins: A Survey on

Enabling Technologies, Challenges, Trends and Future

Prospects. IEEE Commun. Surv. Tutor., 24, 2255–2291.

Ordonez-Lucena, J., Chavarria, J. F., Contreras, L. M.,

Pastor, A. (2019). The use of 5G Non-Public Networks

to support Industry 4.0 scenarios. In Proceedings of the

2019 IEEE Conference on Standards for

Communications and Networking (CSCN), pp. 1-7,

Granada, Spain.

Pigan, R., Metter, M. (2015). Automating with PROFINET

(2nd ed.). Hoboken, NJ, USA: Wiley.

Schroeder, G., Steinmetz, C., Pereira, C., Espíndola, D.

(2016). Digital twin data modeling with

AutomationML and a communication methodology for

data exchange. IFAC-PapersOnLine, 49(30), 12-17.

VDI/VDE. (2020). VDI/VDE 2192: Quality of Service –

Description and Examples.

Wagner, C., Grothoff, J., Epple, U., Drath, R., Malakuti, S.,

Gruner, S., Hoffmeister, M., & Zimermann, P. (2017).

The role of the Industry 4.0 asset administration shell

and the digital twin during the life cycle of a plant. In

Proceedings of the 22nd IEEE International

Conference on Emerging Technologies and Factory

Automation (ETFA), pp. 1–8, Limassol, Cyprus.

Wei, K., Sun, J. Z., Liu, R. J. (2019). A review of asset

administration shell. In Proceedings of IEEE

International Conference on Industrial Engineering

and Engineering Management (IEEM) (pp. 1460–

1465).

Xu, L.D., Xu, E.L., Li, L. (2018). Industry 4.0: State of the

art and future trends. Int. J. Prod. Res., 56, 2941–2962.

Ye, X., Hong, S. H. (2019). Toward Industry 4.0

components: Insights into and implementation of asset

administration shells. IEEE Industrial Electronics

Magazine, 13, 13–25.

Yegani, P., Leung, K., Lior, A., Chowdhury, K., Navali, J.

(2011). RFC 6245: Generic Routing Encapsulation

(GRE) Key Extension for Mobile IPv4. RFC Editor,

USA.

ZVEI. (2020). Submodel Templates of the Asset

Administration Shell—Generic Frame for Technical

Data for Industrial Equipment in Manufacturing

(Version 1.1). Platform Industrie 4.0. Accessed on line:

https://www.plattform-

i40.de/IP/Redaktion/EN/Downloads/Publikation/Subm

odel_templates-Asset_Administration_Shell-

Technical_Data.html.

ZVEI. (2022). Details of the Asset Administration Shell—

Part 1, Platform Industrie 4.0 v3. Accessed on line:

https://www.plattform-

i40.de/IP/Redaktion/EN/Downloads/Publikation/Detai

ls_of_the_Asset_Administration_Shell_Part1_V3.html

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

402