HyPredictor: Hybrid Failure Prognosis Approach Combining

Data-Driven and Knowledge-Based Methods

Miguel Almeida

1 a

, Eliseu Pereira

1,2 b

and Gil Gonc¸alves

1,2 c

1

Faculty of Engineering, University of Porto, Porto, Portugal

2

SYSTEC - ARISE, Faculty of Enginnering of the University of Porto, Porto, Portugal

Keywords:

Failure Prediction, Hybrid Approaches, Knowledge-Based Methods, Data-Driven Methods, Explainable

Artificial Intelligence.

Abstract:

In modern manufacturing, marked by an unprecedented surge in data generation, utilising this wealth of in-

formation to enhance company performance has become essential. Within the industrial landscape, one of the

significant challenges is equipment failures, which can result in substantial financial losses and wasted time

and resources. This work presents the HyPredictor framework, a comprehensive failure prediction and report-

ing system designed to enhance the reliability and efficiency of industrial operations by leveraging advanced

machine learning techniques and domain knowledge. Six machine learning algorithms were evaluated for

failure prediction. The predictions from the algorithms are then refined using rule-based adjustments derived

from domain knowledge. Additionally, Explainable Artificial Intelligence (XAI) techniques were incorpo-

rated, as well as the capability of users to customise the system with their own rules and submit failure reports,

prompting model retraining and continuous improvement. Integrating domain-specific rules improved the per-

formance by up to 28 percentage points in the F1 Score metric in some prediction models, with the best hybrid

approach achieving an F1 Score of 90% and a Recall of 92% in failure prediction. This adaptive, hybrid ap-

proach improves prediction accuracy and fosters proactive maintenance, significantly reducing downtime and

operational costs.

1 INTRODUCTION

In industrial operations, equipment failures cause sig-

nificant downtime and financial losses. Predictive

maintenance is a proactive strategy that anticipates

faults before they occur, minimising disruptions. In

the era of Industry 4.0, technologies like the Inter-

net of Things, Artificial Intelligence (AI), and Ma-

chine Learning enhance productivity and operational

intelligence by leveraging real-time data and combin-

ing data-driven and knowledge-driven methods, such

as analysing sensor data and incorporating expert in-

sights.

Integrating these advanced technologies and data-

driven insights promises to revolutionise industrial

operations but also presents challenges. The vast

quantity and complexity of data requires sophisticated

tools to avoid information overload and extract rel-

a

https://orcid.org/0009-0003-6559-6271

b

https://orcid.org/0000-0003-3893-3845

c

https://orcid.org/0000-0001-7757-7308

evant insights. Traditional machine learning meth-

ods may struggle with this complexity, and static

models may fail to capture the dynamic nature of

industrial processes. Relying solely on data-driven

or knowledge-driven approaches has inherent limita-

tions. Combining both methodologies offers a more

comprehensive understanding of equipment health

and enhances decision-making processes. Address-

ing these challenges is crucial for effectively utilising

the abundant data available.

By integrating data-driven and knowledge-driven

methodologies, this work aims to address these chal-

lenges and provide a comprehensive understanding

of the equipment’s health. By developing accurate

predictive models, this work also seeks to minimise

downtime, reduce maintenance costs, and promote

sustainable industrial practices by mitigating the en-

vironmental impact of equipment failures.

Data-driven methods process various sensor data,

extracting valuable insights from the information gen-

erated by industrial equipment. Concurrently, expert

knowledge will be integrated through knowledge-

Almeida, M., Pereira, E. and Gonçalves, G.

HyPredictor: Hybrid Failure Prognosis Approach Combining Data-Driven and Knowledge-Based Methods.

DOI: 10.5220/0012924300003822

In Proceedings of the 21st International Conference on Informatics in Control, Automation and Robotics (ICINCO 2024) - Volume 1, pages 245-252

ISBN: 978-989-758-717-7; ISSN: 2184-2809

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

245

specific rules, enriching the analytical framework

with insights and domain expertise. Finally, XAI

techniques will be deployed to provide transparent ex-

planations of the model’s predictions. This integrated

approach of data-driven methods, knowledge-driven

rules, and XAI forms a robust analytical framework

that leverages the unique advantages of each method,

aligning with the principles of Industry 4.0.

This paper is organised as follows: Section 2

presents the literature review, Section 3 describes the

dataset, Section 4 outlines the implementation, Sec-

tion 5 presents the results, and Section 6 concludes

and discusses potential future work.

2 LITERATURE REVIEW

This literature review section discusses predictive

maintenance and explores data-driven methodologies,

knowledge-driven strategies, and XAI methods.

2.1 Predictive Maintenance

In the realm of maintenance, as outlined by (Zonta

et al., 2020), four primary categories have been iden-

tified: corrective, preventive, predictive, and prescrip-

tive strategies. Predictive maintenance represents a

transformative shift in industrial asset management,

employing advanced data analytics, machine learn-

ing, and sensor technologies to anticipate equipment

failures proactively. By utilising extensive datasets

from sensors and other industrial sources, data-driven

methodologies uncover intricate patterns and anoma-

lies, forming the foundation of predictive mainte-

nance. Model-driven approaches utilise mathemati-

cal or computational models to simulate equipment

behaviour and optimise maintenance strategies. In

contrast, knowledge-driven methods integrate human

expertise, providing qualitative insights and contex-

tual understanding to enhance predictive accuracy, es-

pecially in scenarios requiring careful considerations

and predictions of rare events.

2.2 Data-Driven Methods

Data-driven methods in predictive maintenance utilise

the abundance of data generated in industrial en-

vironments to identify patterns, correlations, and

anomalies, facilitating the prediction of equipment

health and potential failures. This approach encom-

passes both supervised and unsupervised learning

techniques, with supervised methods like classifica-

tion and regression being particularly prevalent (An-

gelopoulos et al., 2020). Notably, machine learning

algorithms such as Random Forest (RF), Support Vec-

tor Machines (SVMs), Gradient Boosting (GB), Arti-

ficial Neural Networks (ANNs), and Logistic Regres-

sion (LR) are among the most widely utilised in pre-

dictive maintenance (Leukel et al., 2021).

Unsupervised methods operate without labelled

data, making them particularly valuable in scenarios

where the outcomes are not well-defined or unknown.

Clustering and anomaly detection are prevalent unsu-

pervised techniques in predictive maintenance, with

Principal Component Analysis (PCA) and K-Means

clustering being among the most widely used meth-

ods. Moreover, PCA was utilised to reduce the di-

mensionality of features (Canizo et al., 2017; Li et al.,

2014). In the study by (Bekar et al., 2020), a K-Means

clustering technique is employed to obtain diagnostic

information, which can be utilised for labelling the

data and supporting practitioners in predictive main-

tenance decision-making.

2.3 Knowledge-Drive Methods

Knowledge-driven methods in artificial intelligence

and machine learning play a pivotal role in decision-

making by utilising expert knowledge and domain

expertise. These methods contrast data-driven ap-

proaches, as they involve incorporating explicit rules,

ontologies, and logical reasoning into the decision-

making process.

One popular example of knowledge-based meth-

ods is the development of Rule-Based Systems, where

predefined rules guide decision-making (Sun and Ge,

2021). These rules can be derived from expert knowl-

edge, logical reasoning, or established guidelines

within a specific domain.

Ontologies, structured representations of knowl-

edge defining relationships and entities within a do-

main, are frequently used in knowledge-based meth-

ods (Chi et al., 2022). Expert Systems are a spe-

cialised category of knowledge-based methods de-

signed to emulate the decision-making capabilities of

human experts. However, traditional knowledge rep-

resentations built upon expert systems demand a spe-

cific data structure design, and most of these systems

possess intricate architectures, restricting the ease of

knowledge sharing and reuse (Chi et al., 2022).

2.4 Explainable Artificial Intelligence

XAI plays a crucial role in enhancing the transparency

and trustworthiness of failure prediction systems in

industrial settings. XAI techniques provide insights

into how and why specific predictions are made,

enabling humans to understand the underlying fac-

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

246

tors influencing the model’s decisions (Ahmed et al.,

2022; Barredo Arrieta et al., 2020).

Techniques such as Local Interpretable Model-

agnostic Explanations (LIME) and Shapley Additive

Explanations (SHAP) are commonly used to break

down model predictions into understandable compo-

nents, thus closing the gap between complex ma-

chine learning algorithms and practical, applicable in-

sights. Integrating XAI into failure prediction sys-

tems not only enhances their reliability but also em-

powers users to leverage these systems more effec-

tively, encouraging a proactive approach to main-

tenance and operational efficiency (Barredo Arrieta

et al., 2020).

2.5 Gap Analysis

Current predictive maintenance methodologies have

notable gaps. While data-driven approaches are

prevalent, they often overlook the valuable insights

domain experts provide. Moreover, the lack of trans-

parency in machine learning models poses a signif-

icant challenge, hindering trust and interpretability.

Additionally, many existing systems lack mechanisms

for continuous improvement based on real-time feed-

back, resulting in models that struggle to adapt to

changing operational environments. These gaps high-

light the need for innovative hybrid solutions that in-

tegrate data-driven methods with domain expertise

while also prioritising transparency and adaptability.

3 DATASET

This work utilised a public dataset from a metro

train of Porto in an operational context (Davari et al.,

2021). The dataset includes 15 signals, such as pres-

sure readings, temperature, motor current, and air in-

take valves, collected from a compressor’s Air Pro-

duction Unit between February and August 2020. The

data was logged at a frequency of 1Hz by an onboard

embedded device, resulting in 1,516,948 instances.

4 IMPLEMENTATION

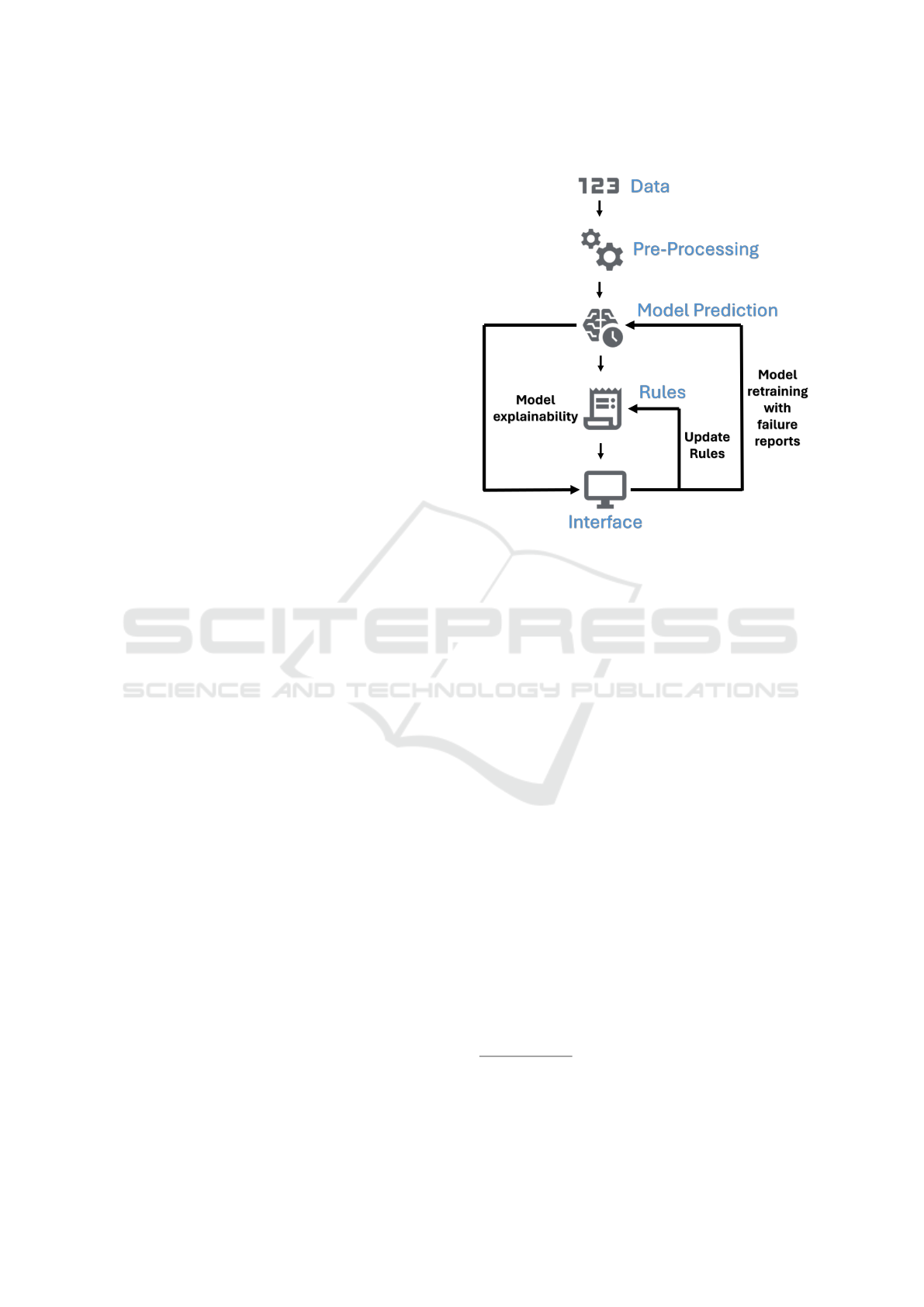

The HyPredictor methodology encompasses several

critical stages, including data reception and pre-

processing, model development, rule-based adjust-

ments, explainability through XAI, user-implemented

rules, and failure reporting with model retraining, as

can be seen in Figure 1. Each stage ensures robust,

accurate, and transparent predictions, promoting con-

tinuous improvement and user engagement.

1

Figure 1: Proposed implementation structure.

Given that the dataset was initially unlabeled, the

process began by labelling it using the failure reports

provided by the company. This involved correlat-

ing the collected sensor data with documented failure

events to create a labelled dataset. To allow operators

to address issues before an actual failure occurred, la-

bels were assigned to indicate a failure beginning two

hours before the reported failure time. This preemp-

tive labelling strategy aimed to provide a sufficient

lead time for operators to intervene and potentially

prevent failure, thereby enhancing the system’s effec-

tiveness in facilitating proactive maintenance. To en-

hance the model’s predictive capabilities, feature en-

gineering was performed. This process involved ag-

gregating the data into 15-minute intervals, comput-

ing the median value within each interval, and inte-

grating these median values into the original dataset.

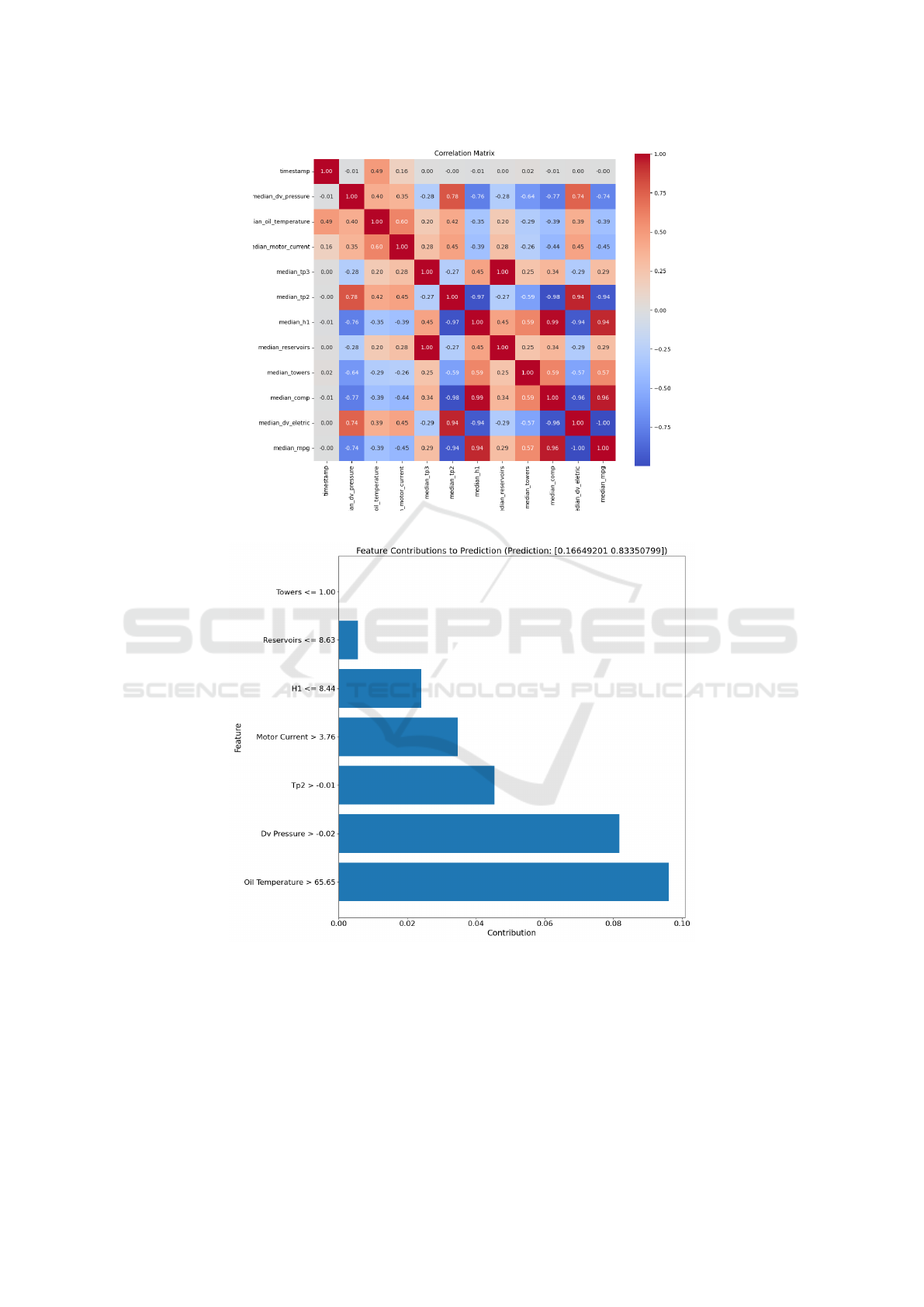

Moreover, a thorough analysis was conducted to

enhance the model’s predictive capabilities for fail-

ure prediction. Initially, the target variable was iden-

tified as ’Failure’, and correlation coefficients be-

tween this variable and all other features in the dataset

were calculated. The features most strongly asso-

ciated with failure occurrences were determined by

ordering these correlation coefficients by their abso-

lute values. Subsequently, a correlation threshold of

|

0.2

|

was applied to filter out features with low cor-

1

To access the code for this

project, please visit the repository at:

https://github.com/miguelalmeida8/HyPredictor-

Framework

HyPredictor: Hybrid Failure Prognosis Approach Combining Data-Driven and Knowledge-Based Methods

247

relation to the target variable. These low-correlation

features were then dropped from the dataset to opti-

mise the model’s training process. Additionally, to

mitigate multicollinearity issues, the correlation ma-

trix of the remaining features was visualised through

a heatmap, as can be seen in Figure 2, and pairs of

features with high correlation coefficients were iden-

tified using a threshold of

|

0.8

|

to denote high correla-

tion. Finally, the features that exhibit a high correla-

tion with others were removed. This feature selection

and multicollinearity mitigation process aimed to op-

timise the model’s predictive performance and ensure

the robustness of the failure prediction system for in-

dustrial applications.

This step involved dividing the dataset into train-

ing and testing sets using a temporal split. The test-

ing data, comprising 638,486 samples from June 4,

2020, onward, represented approximately 42% of the

dataset. Six machine learning algorithms were eval-

uated to determine the most suitable method for ac-

curate failure prediction: Random Forest, XGBoost,

CatBoost, Gradient Boosting Machine (GBM), Light-

GBM and a voting algorithm. The voting algorithm

was used to combine the strengths of multiple mod-

els, aiming to enhance overall prediction reliability.

Due to their strong overall performance, the four al-

gorithms chosen for the ensemble were XGBoost,

CatBoost, GBM, and LightGBM. The models were

trained using the pre-processed data, and k-fold cross-

validation was implemented to ensure that the model

generalises well to unseen data. Additionally, grid

search was employed to optimise the model param-

eters, enhancing its performance. Recall was used as

the primary metric to evaluate the model’s effective-

ness in accurately identifying failures, ensuring a fo-

cus on minimising false negatives in the predictions.

For the knowledge-driven approach, rules were

defined based on expertise and experience to adjust

the model’s predictions. These rules are crucial for

improving accuracy and handling edge cases, en-

suring that rare but critical scenarios are correctly

addressed. The system applies these rules post-

prediction, refining the initial outputs. The imple-

mented rules are designed to enhance the model’s pre-

dictive accuracy by incorporating domain-specific in-

sights, particularly concerning the median oil temper-

ature and pressure readings. These rules adjust the

model’s initial predictions based on predefined con-

ditions indicative of potential failures. The specific

rules applied are as follows:

• Rule 1: If the initial prediction is 0 (no failure)

but the median oil temperature exceeds 83°C, the

prediction is adjusted to 1 (failure).

• Rule 2: If the initial prediction is 1 (failure) but

the median oil temperature is below 67.25°C, the

prediction is adjusted to 0 (no failure).

• Rule 3: If the initial prediction is 0 (no fail-

ure) and both the median oil temperature exceeds

75.65°C and the median differential pressure ex-

ceeds -0.02 Bar, the prediction is adjusted to 1

(failure).

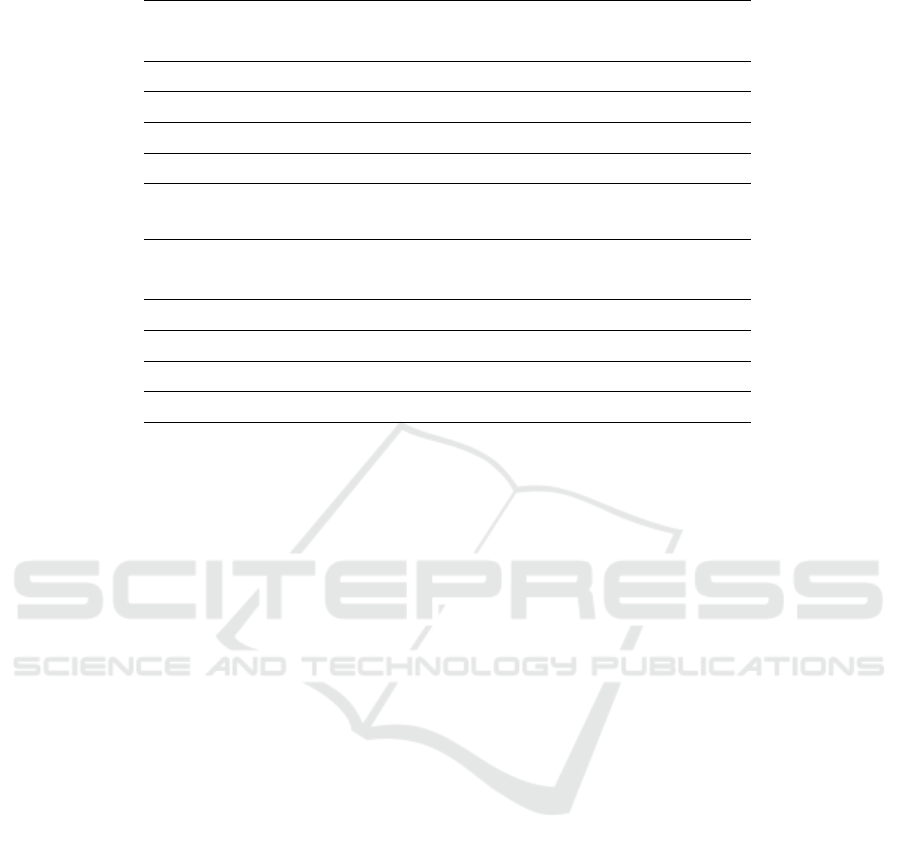

Subsequently, XAI methods like LIME reveal the

rules and contributions of individual features in pre-

dictions, as illustrated in Figure 3.

A user interface (UI) displays these explanations,

allowing experts to understand the model’s behaviour

behind specific predictions. The visual representa-

tion of feature contributions provides clear insights

into the factors influencing each prediction, making

the model’s decision-making process transparent and

comprehensible.

The system also empowers experts to implement

new rules based on their observations and insights

from the model explanations. These insights can then

be codified into new rules integrated into the system

to refine its predictive accuracy. This continuous feed-

back loop is crucial in enhancing the system’s perfor-

mance. As experts identify and address new scenar-

ios or anomalies, the rules evolve, making the model

more robust over time.

This dynamic interaction between the model and

the experts promotes a proactive maintenance strat-

egy. The system can predict failures more accu-

rately by preemptively adjusting the model based on

real-world observations, reducing downtime and op-

erational costs. This integration of human expertise

with machine learning not only optimises the pre-

dictive model but also ensures that the system re-

mains aligned with the evolving operational context

and complexities of the industrial environment.

The interface also allows experts to submit a fail-

ure report whenever they identify a failure. This re-

porting mechanism is crucial for maintaining the sys-

tem’s accuracy and responsiveness. When a failure re-

port is submitted, the system triggers a retraining pro-

cess for the model. The model adapts and learns from

recent occurrences by incorporating the new failure

data, continuously improving its predictive accuracy

and reducing future prediction errors. This process

not only updates the model with the latest data but

also enhances its ability to recognise similar patterns

and anomalies in the future. The integration of real-

time feedback ensures that the model remains relevant

and effective in an ever-changing operational environ-

ment. This capability is particularly important in in-

dustrial settings, where conditions and failure modes

can evolve rapidly.

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

248

Figure 2: Correlation matrix.

Figure 3: LIME explanation.

The described methodology ensures a comprehen-

sive and adaptative failure prediction and reporting

system. The system delivers accurate, transparent,

and continuously improving predictions by combin-

ing advanced data processing, machine learning, and

domain knowledge in the form of rules, XAI, and user

interaction.

5 RESULTS

This section presents the performance and results of

the failure prediction and reporting system.

HyPredictor: Hybrid Failure Prognosis Approach Combining Data-Driven and Knowledge-Based Methods

249

5.1 Model Performance Metrics

The model’s performance was assessed using sev-

eral key metrics: Accuracy, Precision, Recall, and

F1 Score. The evaluation results for the six differ-

ent models, Random Forest, XGBoost, LightGBM,

GBM, CatBoost and the voting algorithm, are pre-

sented in the ”Before” column of Table 1 and 2. This

comparison highlights the strengths and weaknesses

of each model, allowing for an informed selection

based on the specific requirements of the predictive

maintenance task.

The evaluation of the models showcased signifi-

cant variations in their performance metrics. While

XGBoost, GBM, LGBM, CatBoost and the voting al-

gorithm demonstrated good performance across mul-

tiple metrics, with high recall rates and F1 scores,

Random Forest fell short in terms of precision and F1

score, indicating a higher incidence of false positives.

5.2 Rule-Based Adjustments

Applying rule-based adjustments significantly en-

hanced the model’s performance in specific scenarios.

By integrating domain-specific rules, the system im-

proved its handling of rare but critical failure scenar-

ios. For instance, rules were implemented to address

conditions where certain sensor readings, when com-

bined, indicated an impending failure that the model

alone did not detect. The combination of machine

learning predictions and rule-based adjustments re-

sulted in an overall accuracy improvement.

Table 1 and 2 presents the performance metrics

before and after applying the rule-based adjustments.

The improvements in Recall, Precision, and F1 Score

across different models highlight the added value of

expert knowledge in enhancing predictive accuracy.

The decision to deploy GBM was primarily influ-

enced by its highest recall rate after applying the do-

main knowledge, indicating its effectiveness in cap-

turing a larger proportion of true positive instances.

While high recall rates are important for capturing as

many true positives as possible, the potential conse-

quences of false alarms must be carefully weighed,

especially in industrial settings where false positives

could lead to unnecessary maintenance interventions

and operational disruptions.

This hybrid approach not only improves the

model’s predictive accuracy but also ensures that crit-

ical, rare failure scenarios are effectively captured,

thereby enhancing the reliability and efficiency of the

failure prediction system. The system remains adap-

tive and robust in real-world operational contexts by

continuously refining the rules based on new data and

expert feedback.

5.3 Prediction and Explanation Time

The model’s prediction generation time was measured

to average 24.8 milliseconds per instance. This rapid

prediction time ensures the system can provide timely

alerts, allowing for rapid intervention and mitigation

measures. Similarly, the time required to generate ex-

planations using LIME averaged 233.8 milliseconds

per instance. While explanations took slightly longer

than predictions, this timeframe is considered accept-

able.

The relatively quick prediction and explanation

times contribute to enhanced operational efficiency.

Users can act on predictions and understand the un-

derlying reasons without significant delays, which is

crucial in time-sensitive environments.

5.4 Interface

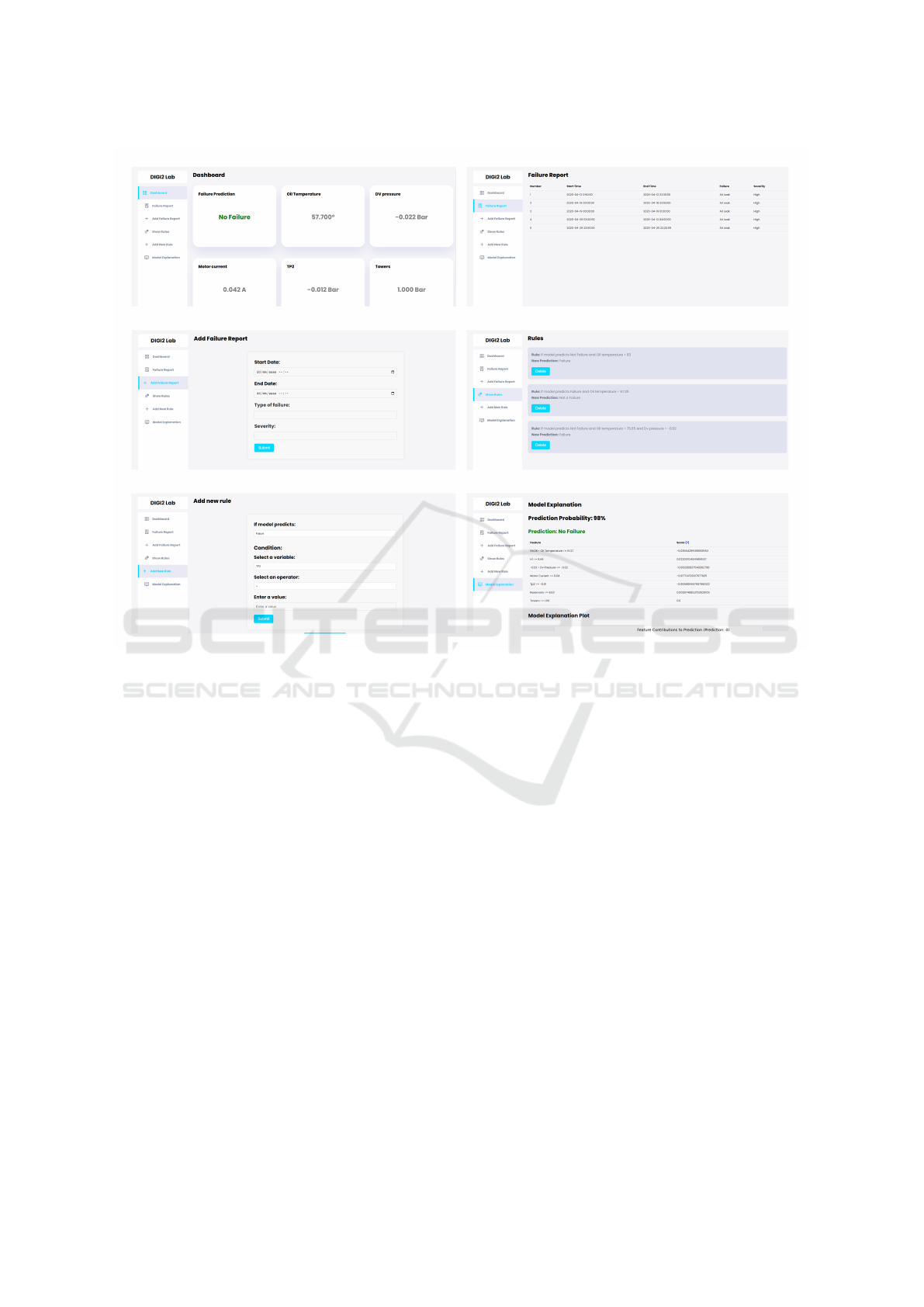

Transitioning from discussing the technical perfor-

mance of the predictive model, it’s important to high-

light the user interface, which is the primary means

through which users interact with the system. Images

of the interface, showcasing its various features and

capabilities, are provided in Figure 4.

To test the interface, raw data was sent via

Message Queuing Telemetry Transport (MQTT), a

lightweight messaging protocol ideal for real-time

data transmission. The interface efficiently processes

this incoming data and displays the system’s current

status on a user-friendly dashboard. Key features of

the interface include:

• Real-Time Failure Detection. The dashboard

displays whether a failure is predicted based on

the incoming data, allowing for immediate user

intervention.

• Sensor Data Visualization. Alongside the fail-

ure prediction, the values from various sensors,

such as pressure, temperature, motor current, and

air intake valve readings, are shown in real-time.

This gives users a comprehensive view of the op-

erational status and helps diagnose potential is-

sues.

• Failure Report Management. The UI can dis-

play existing failure reports and allows users to

create new failure reports when a failure is iden-

tified. This helps track and document failure in-

stances systematically.

• Rule Management. Users can view the rules in

place, organised by order of priority, ensuring that

the most critical rules are given top priority. Ad-

ditionally, the interface allows users to create new

rules based on their insights and observations.

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

250

Table 1: Comparison of model performance before and after rules (Part 1).

Metrics

RF XGBoost LGBM

Before After Before After Before After

Recall (%) 90.685 90.999 91.991 91.991 88.786 90.748

F1 Score (%) 64.655 93.093 90.104 90.471 92.144 92.232

Precision (%) 50.236 95.285 88.293 89.001 95.767 95.855

Accuracy (%) 96.586 99.535 99.305 99.333 99.479 99.547

Table 2: Comparison of model performance before and after rules (Part 2).

Metrics

CatBoost GBM Voting

Before After Before After Before After

Recall (%) 91.413 91.413 91.003 92.241 91.003 91.413

F1 Score (%) 89.303 90.771 89.576 90.245 91.055 91.278

Precision (%) 87.288 90.137 88.193 88.333 91.107 91.143

Accuracy (%) 99.247 99.547 98.886 98.950 99.059 99.081

• Model Explanation. The UI includes functional-

ity to show detailed model explanations, provid-

ing insights into the factors influencing each pre-

diction. This transparency helps users understand

the model’s decision-making process.

The combination of real-time failure alerts, de-

tailed sensor data visualisation, failure report man-

agement, rule management, and model explanations

ensures that users can quickly understand and react to

potential problems.

6 CONCLUSIONS AND FUTURE

WORK

In modern manufacturing, equipment failures can

cause extensive downtime, resulting in considerable

financial losses and wasted resources. This paper in-

troduces a methodology for a failure prediction and

reporting system designed to mitigate such risks by

proactively reducing instances of equipment failure.

The UI enables real-time failure detection, sen-

sor data visualisation, failure report management,

rule management, and model explanations, facilitat-

ing rapid understanding and response to potential is-

sues. Additionally, the integration of domain knowl-

edge in the form of rules significantly enhanced the

system’s performance. Notably, GBM, with the ap-

plied rules, emerged as the most effective approach in

the evaluation. Overall, the HyPredictor methodology

ensures a comprehensive and adaptive failure predic-

tion and reporting system, leveraging advanced data

processing, machine learning, and domain knowledge

to enhance operational efficiency and facilitate proac-

tive maintenance strategies in industrial settings.

Future work should focus on ensuring the scala-

bility of the failure prediction and reporting system to

deploy across various industrial environments.

ACKNOWLEDGEMENTS

This work was partially supported by the HORIZON-

CL4-2021-TWIN-TRANSITION-01 openZDM

project, under Grant Agreement No. 101058673.

REFERENCES

Ahmed, I., Jeon, G., and Piccialli, F. (2022). From artificial

intelligence to explainable artificial intelligence in in-

dustry 4.0: a survey on what, how, and where. IEEE

Transactions on Industrial Informatics, 18(8):5031–

5042.

Angelopoulos, A., Michailidis, E. T., Nomikos, N.,

Trakadas, P., Hatziefremidis, A., Voliotis, S., and Za-

hariadis, T. (2020). Tackling faults in the industry 4.0

era—a survey of machine-learning solutions and key

aspects.

Barredo Arrieta, A., D

´

ıaz-Rodr

´

ıguez, N., Del Ser, J., Ben-

netot, A., Tabik, S., Barbado, A., Garcia, S., Gil-

Lopez, S., Molina, D., Benjamins, R., Chatila, R.,

and Herrera, F. (2020). Explainable artificial intelli-

gence (xai): Concepts, taxonomies, opportunities and

challenges toward responsible ai. Information Fusion,

58:82–115.

Bekar, E. T., Nyqvist, P., and Skoogh, A. (2020). An intelli-

gent approach for data pre-processing and analysis in

HyPredictor: Hybrid Failure Prognosis Approach Combining Data-Driven and Knowledge-Based Methods

251

Figure 4: Images of the interface.

predictive maintenance with an industrial case study.

Advances in Mechanical Engineering, 12.

Canizo, M., Onieva, E., Conde, A., Charramendieta, S.,

and Trujillo, S. (2017). Real-time predictive mainte-

nance for wind turbines using big data frameworks. In

2017 IEEE International Conference on Prognostics

and Health Management (ICPHM), pages 70–77.

Chi, Y., Dong, Y., Wang, Z. J., Yu, F. R., and Leung, V. C.

(2022). Knowledge-based fault diagnosis in industrial

internet of things: A survey. IEEE Internet of Things

Journal, 9:12886–12900.

Davari, N., Veloso, B., Ribeiro, R. P., Pereira, P. M., and

Gama, J. (2021). Predictive maintenance based on

anomaly detection using deep learning for air produc-

tion unit in the railway industry. In 2021 IEEE 8th

International Conference on Data Science and Ad-

vanced Analytics (DSAA), pages 1–10. IEEE.

Leukel, J., Gonz

´

alez, J., and Riekert, M. (2021). Adoption

of machine learning technology for failure prediction

in industrial maintenance: A systematic review.

Li, H., Parikh, D., He, Q., Qian, B., Li, Z., Fang, D., and

Hampapur, A. (2014). Improving rail network veloc-

ity: A machine learning approach to predictive main-

tenance. Transportation Research Part C: Emerging

Technologies, 45:17–26.

Sun, Q. and Ge, Z. (2021). A survey on deep learning for

data-driven soft sensors. IEEE Transactions on Indus-

trial Informatics, 17:5853–5866.

Zonta, T., da Costa, C. A., da Rosa Righi, R., de Lima,

M. J., da Trindade, E. S., and Li, G. P. (2020). Pre-

dictive maintenance in the industry 4.0: A systematic

literature review. Computers and Industrial Engineer-

ing, 150.

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

252