Automated Detection of Defects on Metal Surfaces Using Vision

Transformers

Toqa Alaa

1

, Mostafa Kotb

1

, Arwa Zakaria

1

, Mariam Diab

1

and Walid Gomaa

1,2

1

Department of Computer Science and Engineering, Egypt-Japan University of Science and Technology, Alexandria, Egypt

2

Faculty of Engineering, Alexandria University, Alexandria, Egypt

Keywords:

Vision Transformers, Classification, Localization, Convolution Neural Networks, GC10-DET, NEU-DET,

Multi-DET.

Abstract:

Metal manufacturing often results in the production of defective products, leading to operational challenges.

Since traditional manual inspection is time-consuming and resource-intensive, automatic solutions are needed.

The study utilizes deep learning techniques to develop a model for detecting metal surface defects using Vision

Transformers (ViTs). The proposed model focuses on the classification and localization of defects using a

ViT for feature extraction. The architecture branches into two paths: classification and localization. The

model must approach high classification accuracy while keeping the Mean Square Error (MSE) and Mean

Absolute Error (MAE) as low as possible in the localization process. Experimental results show that it can

be utilized in the process of automated defects detection, improve operational efficiency, and reduce errors in

metal manufacturing.

1 INTRODUCTION

The manufacturing and reshaping of metal surfaces

are critical processes in various industries, including

automotive, aerospace, and construction. These pro-

cesses often result in products with defects such as

cracks, dents, scratches, and other surface irregular-

ities. Such defects can compromise the structural

integrity and performance of metal products, posing

significant challenges to quality control and prod-

uct usability. Detecting and addressing these defects

is crucial to ensure the production of high-quality

metal products and to prevent costly operational fail-

ures (Wang et al., 2021; Murakami, 2019; Leibfried

and Breuer, 2006).

Traditionally, defect detection on metal surfaces

has relied heavily on manual inspection, where hu-

man experts visually examine surfaces for abnormal-

ities. This method is not only time-consuming and

labor-intensive but also highly subjective and incon-

sistent. It is prone to errors and often fails to detect

subtle defects that are not easily visible to the human

eye. Consequently, there is a compelling need for au-

tomated defect detection systems that can accurately

and efficiently identify and classify defects on metal

surfaces (Li et al., 2022; Fang et al., 2020).

Significant progress has been made in developing

automated defect detection techniques. Traditional

computer vision methods, such as edge detection,

thresholding, Hough transfrom, and image segmenta-

tion, have been extensively explored. These methods

typically rely on handcrafted features and rule-based

algorithms to identify defects based on predefined cri-

teria. Although these approaches have achieved some

success in detecting specific types of defects, they are

limited in their ability to handle complex and varied

defect patterns. They depend heavily on the expertise

of domain-specific engineers and lack the adaptabil-

ity to new or varied defect types (Sharifzadeh et al.,

2009).

With the advent of deep learning techniques and

the availability of large-scale annotated datasets, there

has been a paradigm shift towards employing neural

networks for automated defect detection. Convolu-

tional Neural Networks (CNNs) have demonstrated

remarkable performance in various computer vision

tasks, including image classification, object detec-

tion, and semantic segmentation. CNNs can auto-

matically learn discriminative features from raw in-

put data, making them well-suited for defect detec-

tion on metal surfaces. Several studies have success-

fully applied CNNs to detect defects on metal sur-

faces, achieving high accuracy and demonstrating the

36

Alaa, T., Kotb, M., Zakaria, A., Diab, M. and Gomaa, W.

Automated Detection of Defects on Metal Surfaces Using Vision Transformers.

DOI: 10.5220/0012936300003822

In Proceedings of the 21st International Conference on Informatics in Control, Automation and Robotics (ICINCO 2024) - Volume 2, pages 36-45

ISBN: 978-989-758-717-7; ISSN: 2184-2809

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

potential of deep learning in this domain. For exam-

ple, U-Net-based CNN architectures have been ap-

plied to metal surface defect detection, showing im-

proved performance in capturing fine-grained details

of surface defects (Konovalenko et al., 2022).

Despite their promise, CNNs have limitations in

defect detection. They typically rely on local recep-

tive fields and hierarchical feature extraction, which

may not adequately capture long-range dependencies

and global context in images. Studies have shown

that varying lighting conditions can impact the perfor-

mance of neural network models in detecting defects,

which highlights the importance of surface illumina-

tion factor to ensure a reliable performance of models

(Maruschak et al., 2024).

This limitation is particularly critical when deal-

ing with complex defect patterns that span significant

portions of metal surfaces. Additionally, CNNs re-

quire large amounts of labeled training data, which

can be challenging and time-consuming to acquire for

specific defect types or rare occurrences (Tao et al.,

2018).

To address these limitations, we propose the use of

Vision Transformers (ViTs) for automated defect de-

tection on metal surfaces. ViTs, originally introduced

for image classification, (Dosovitskiy et al., 2020)

have gained attention for their ability to capture global

context and long-range dependencies through self-

attention mechanisms (Vaswani et al., 2017). This

makes them well-suited for capturing intricate defect

patterns on metal surfaces.

To address the limitations of the current datasets

used in metal surface detection, a new dataset called

Multi-DET is built. Current datasets don’t accurately

simulate real-world conditions, as metal surfaces typ-

ically have more overlapping and higher number of

defects per image. Our new dataset, Mult-DET, ad-

dresses these limitations by introducing diversity and

increased density per image.

The primary objectives of this research are

twofold: defect classification and defect localization.

Defect classification aims to accurately identify the

type and nature of each defect. Defect localization

aims to precisely predict the boundaries of each de-

fect, facilitating targeted treatment and repair. The

proposed model should be able to detect multiple de-

fects in the input image.

Leveraging the power of pre-trained ViTs on

large-scale image datasets like Imagenet, the pro-

posed model utilizes transfer learning to benefit from

the learned representations of ViTs, which capture

rich visual features. This pre-trained model is able to

effectively extract meaningful defect-related features

from raw metal surface images. So, we propose using

Vision Transformers and deep learning techniques to

automate defect detection on metal surfaces, aiming

to enhance product quality and reduce costly errors in

metal manufacturing.

The paper is organized as follows. Section 1 is an

introduction, offering an overview of the problem and

the undergoing research. Section 2 discusses related

work. Section 3 explores the used datasets and our

new dataset. Section 4 discusses the methodologies

used for defect detection and localization. Section 5

gives the experimental work to validate our approach

along with analyzing the results, illustrating as well

the limitations of our approach. Section 6 summa-

rizes our work and provides an outlook on future di-

rections.

2 RELATED WORK

Metal defects detection is a critical task in industrial

applications. Over the years, researchers have devel-

oped methods to identify and classify these defects

using machine learning and computer vision (Wang

et al., 2021). The advancement of these methods in-

creases the efficiency and accuracy of the process to

ensure quality and reliability of metal products in in-

dustries.

2.1 Traditional Approaches

Metal defects initially relied on manual inspection,

including Magnetic Particle Inspection (MPI), Ultra-

sonic Testing (UT), and Dye Penetrant Inspection

(DPI) (Lovejoy, 1993). While these approaches have

been fundamental in ensuring the quality of metals,

they come with limitations such as inconsistency and

potential human error.

2.2 CNN

A compact Convolutional Neural Network was used

alongside a cascaded autoencoder (CASAE) in the

task of metal defects detection (Tao et al., 2018). The

compact CNN architecture aimed to classify defects,

while the CASAE was used to localize and segment

defects. The usage of CASAE resulted in accurate

and consistent results even under complex lighting

conditions or with irregular defects. The pipeline of

the architecture started with passing the input image

to the CASAE, which outputs a segmented image of

the defects. The segments are then cropped and fed

to the compact CNN to obtain classification results.

Nevertheless, the architecture had limitations, as the

input data must be manually labelled as segments, not

Automated Detection of Defects on Metal Surfaces Using Vision Transformers

37

as bounding boxes, which takes a lot of time and ex-

pense.

2.3 RepVGG

The authors of (Li et al., 2022) provided a reference

for solving the problem of classifying aluminum pro-

file surface defects. Defective images for training

were obtained by means of digital image processing,

such as rotation, flip, brightness, and contrast trans-

formation. A novel model, RepVGG, with a convolu-

tional block attention module (RepVGG-CBAM) was

proposed. The model was used to classify ten types

of aluminum profile surface defects.

2.4 Faster R-CNN

Another novel approach proposes a method combin-

ing a classification model with an object recogni-

tion model for metal surface defects detection (Wang

et al., 2021). An improved, faster R-CNN model is

used to detect multi-scale defects better by adding

spatial pyramid pooling (SPP) (Mikołajczyk et al.,

2017) and enhanced feature pyramid networks (FPN)

modules (Girshick et al., 2017). The model aims

to increase the detection accuracy of crazing defects

by modifying the aspect ratio of the anchor. Non-

maximum suppression is used to get the bounding box

faster and better. Improved ResNet50-vd model is in-

corporated as the backbone of the classification model

and object recognition model (He et al., 2019). Detec-

tion accuracy and robustness are increased by adding

the deformable revolution network (DCN) (Zhu et al.,

2018).

2.5 YOLOv5

Among the deep learning models, the You Only Look

Once (YOLO) algorithm stands out for its capabilities

for object detection (Redmon et al., 2016). YOLO re-

frames object detection as a single regression prob-

lem, predicting bounding boxes and class probabil-

ities directly from full images in one evaluation.

YOLOv5 (Bochkovskiy et al., 2020) is a famous ver-

sion among the YOLO versions, as it was the first ver-

sion with ultralytics support. YOLOv5 was used as a

base model in metal defects detection (Wang et al.,

2022), while adding a focus structure to the base net-

work of the Darknet. Additionally, GIOU loss was

chosen over L1 loss to focus on accuracy. The back-

bone feature extraction network of the YOLOv5 was

retrained to improve the performance of the model.

However, this model faced limitations due to its in-

ability to detect small defects on metal surfaces.

3 DATASETS

Several datasets have been created to provide research

with standardized data for training and evaluating de-

fects detection algorithms. This section focuses on

three datasets - NEU-DET, GC10-DET and Multi-

DET that were used for the work done in this research.

3.1 Training Datasets

GC10-DET is a dataset for surface defects collected

in a real industry (Lv et al., 2020). The dataset con-

tains 2300 high-resolution images of surfaces with 10

different classes of defects, which are punching, weld

line, crescent gap, water spot, oil spot, silk spot, in-

clusion, rolled pit, crease, and waist folding.

NEU-DET is the Northeastern University (NEU)

surface defect dataset (Dixit, 2020). It contains 1800

grayscale images with 6 different classes of surface

defects and 300 images per defect type. The de-

fects’ classes include rolled-in scale, patches, inclu-

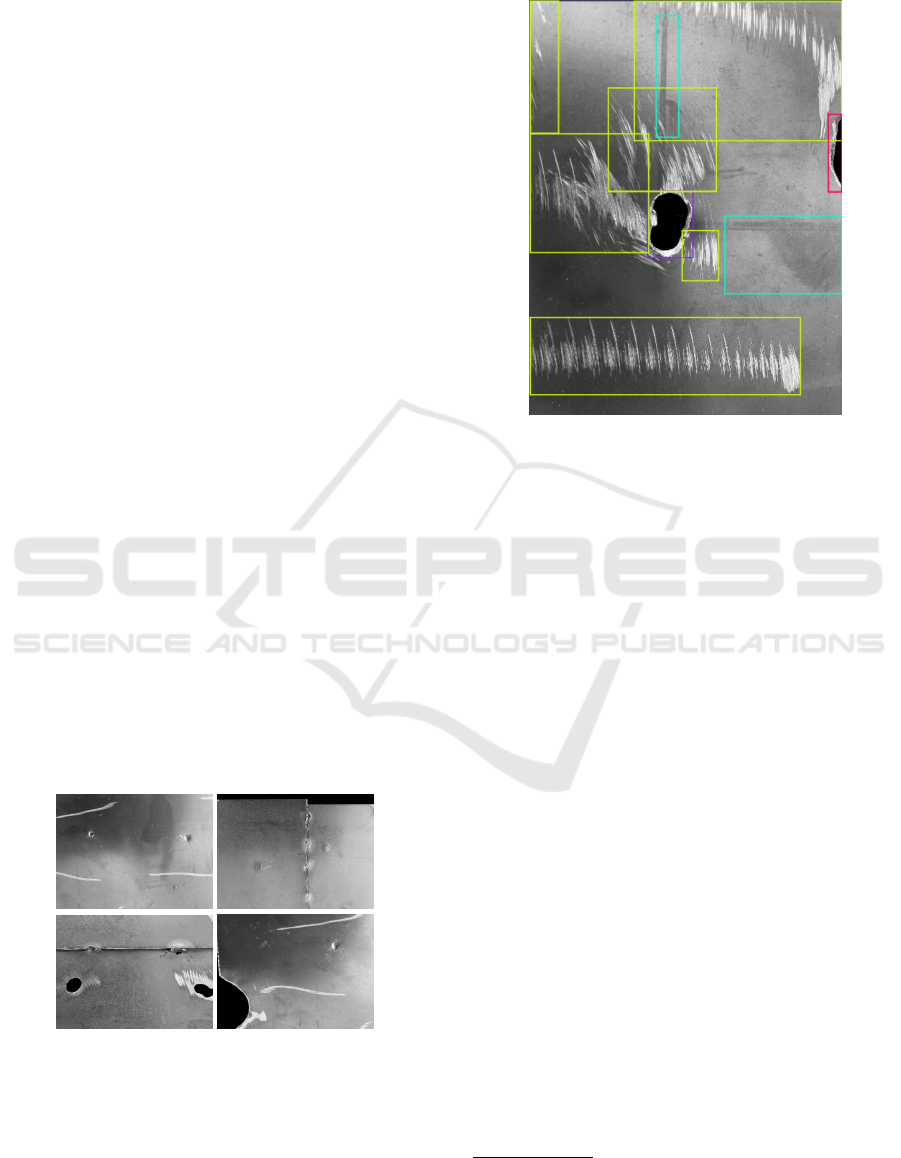

sion, scratches, crazing, and pitted surface. Figure 1

shows different classes from the two datasets.

Figure 1: Defect Classes from GC10-DET and NEU-DET.

3.2 Multi-DET

We introduce a new dataset called Multi-DET in or-

der to address the limitations of the current datasets.

The proposed dataset surpasses current datasets by of-

fering increased diversity and density of defects per

photo.

Multi-DET contains 300 high-resolution images

for 8 classes. Unlike traditional datasets that feature

repetitive defect types per image, our dataset covers

a wide range of defects, including scratches, welding

line, inclusion, water spot, oil spot, crescent gap , and

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

38

variations in texture and color. Our approach mimics

real-world conditions, where metal surfaces exhibit

complex and overlapping defects. Figure 2 represents

some samples of Multi-DET dataset.

3.2.1 Dataset Collection

The dataset collection process started with surface

preparation, where metal samples were cleaned and

smoothed to ensure a uniform pattern. Following this,

different defects were introduced using various tools.

Scratches were made using sharp instruments, weld-

ing lines were simulated using a welding machine,

crescent gap were made using precise cutting tools,

and inclusions were created using contaminant ma-

terials. Oil and water spots were applied using con-

trolled droplets.

3.2.2 Dataset Pre-Processing

The pre-processing of photos in Multi-DET is a cru-

cial step in order to ensure quality and the unifor-

mity in terms of resolution, lighting, and color bal-

ance. Pre-processing involves adjusting the bright-

ness and contrast to compensate for any variations.

In addition, image denoising is used to remove any

unwanted noise that may interfere with the detection

process. Image cropping is performed to focus on rel-

evant parts of the metal, excluding information that

does not contribute to the analysis. Images are con-

verted to grayscale to enhance the feature extraction

process. Data augmentation techniques are utilized to

increase the variability of the dataset. This includes

rotating, flipping, and scaling. These transformations

represent the diversity of real-world conditions, there-

fore it was avoided to reach extreme levels of these

changes.

Figure 2: Sample photos of Multi-DET dataset.

3.2.3 Data Annotations

For annotating Multi-DET dataset, Roboflow serves

as the primary tool for creating the annotations for

our dataset. Figure 3 illustrates the process of annota-

tions.

Figure 3: Defects bounding boxes annotation.

4 EXPERIMENTAL WORK

4.1 Methodology

This research presents an automated approach for de-

tecting defects on metal surfaces utilizing the Vision

Transformer (ViT) architecture. ViTs achieve en-

hanced accuracy via the self-attention mechanism in-

herent in transformer encoders. We utilize the ViT’s

encoder as a feature extractor, which is then for-

warded to a CNN, followed by a couple of Multi-

Layer Perceptron (MLP) models for classification and

localization. For the detection mechanism, we imple-

ment the anchor boxes method in order to dynami-

cally detect any number of defects within the input

image. This repository includes the source code for

our implementation

*

.

4.2 Vision Transformers

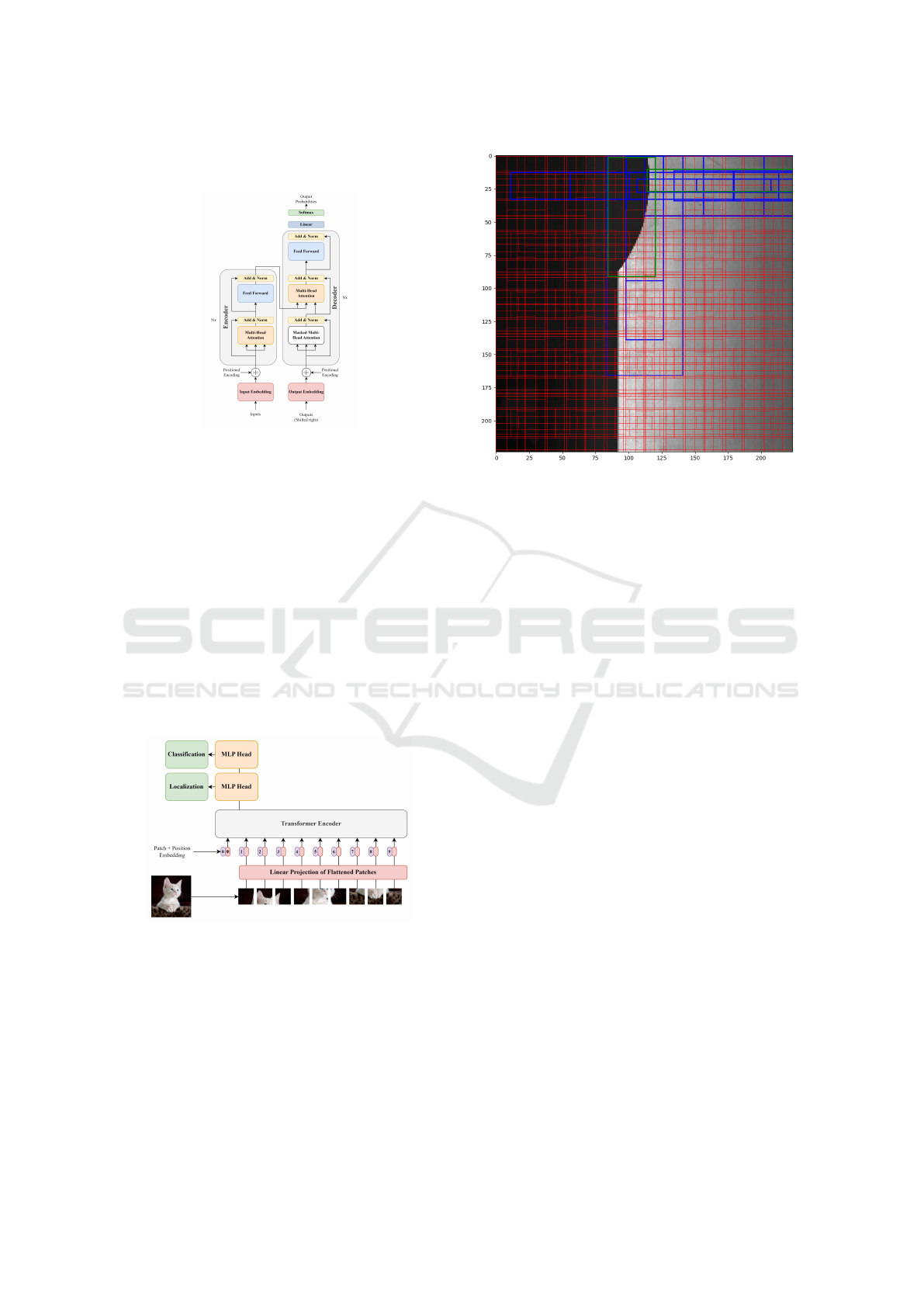

The architecture, Figure 4, of the ordinary trans-

former (Vaswani et al., 2017) was initially applied in

Natural Language Processing (NLP). The main pur-

pose of the transformer was to detect the relationships

between the tokens through the self-attention mecha-

nism. The architecture also added positional encoding

to the input of the multi-head attention layers, which

*

https://github.com/toqaalaa20/Metal-surface-defects-

detection

Automated Detection of Defects on Metal Surfaces Using Vision Transformers

39

allowed the transformer to keep track of the order of

the tokens.

Figure 4: Transformer architecture.

The architecture in Figure 5 of the Vision Trans-

former (ViT) used the same basic structure of the

transformer with the multi-head attention layers fol-

lowed by the MLPs and the normalization lay-

ers (Dosovitskiy et al., 2020). However, the mod-

ification was on the input of the model, as the in-

put was modified to take an image instead of a se-

quence of words. To use the same structure of the

transformer, an input image is divided into patches

and flattened. Positional embedding is added to the

patches to keep track of the position of each patch.

The encoded patches are fed to the ViT encoder. In

order to perform any task of classification or localiza-

tion, a learnable MLP is added to the output of the

encoder.

Figure 5: Vision Transformer Architecture.

4.3 Anchor Boxes

In order to dynamically detect any number of defects

in an image without being limited to a fixed number of

defects per image, the anchor boxes method was used.

The mechanism of anchor boxes was first introduced

as a part of the You Only Look Once (YOLO) model

architecture (Redmon et al., 2016). At first, a set of

pre-defined anchor boxes (Figure 6) is defined.

Figure 6: Initialized pre-defined anchor boxes. Red boxes

are background boxes. Blue boxes are selected boxes before

offset correction. Green boxes are the ground truth.

During training, each anchor box is assigned to a

ground truth label depending on the Intersection over

Union (IOU) value. If the IoU value is higher than

an upper threshold, the anchor box gets assigned to a

ground truth label. If the IoU is lower than a lower

threshold, it is marked as background. If it is between

the two thresholds, it is marked as discarded.

After that, the offset in position from the ground

truth is calculated for the assigned anchor boxes and

set to zero for the background and discarded boxes.

The class of the ground truth is also passed to the

assigned anchor boxes. During prediction, a non-

maximal suppression is applied on the predicted an-

chor boxes in order to choose the most suitable an-

chor box from the overlaying boxes with the same

predicted class.

4.4 Data Pre-Processing

In order to fit our model architecture, all images were

resized and normalized to fit the input of the ViT en-

coder. Then, they were passed to an image processor,

which prepares the images to be a suitable input for

the ViT. The image processor ensures that the input

data is in the correct format suitable for the ViT. It

handles image transformations such as resizing, nor-

malization, and conversion to TensorFlow tensors.

After that, offsets are calculated for each image

as the distance between the anchor box point and the

ground truth point and divided by either the width or

the height of the anchor box according to the orien-

tation. This makes the offsets invariant to different

scales of anchor boxes. Afterwards, the offsets are

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

40

normalized by passing on a min-max scaler which

subtracts the minimum value from the offset and di-

vides the result by the range. All these normaliza-

tions were made to ensure the stability of the model

and help it predict the values without overshooting or

overfitting.

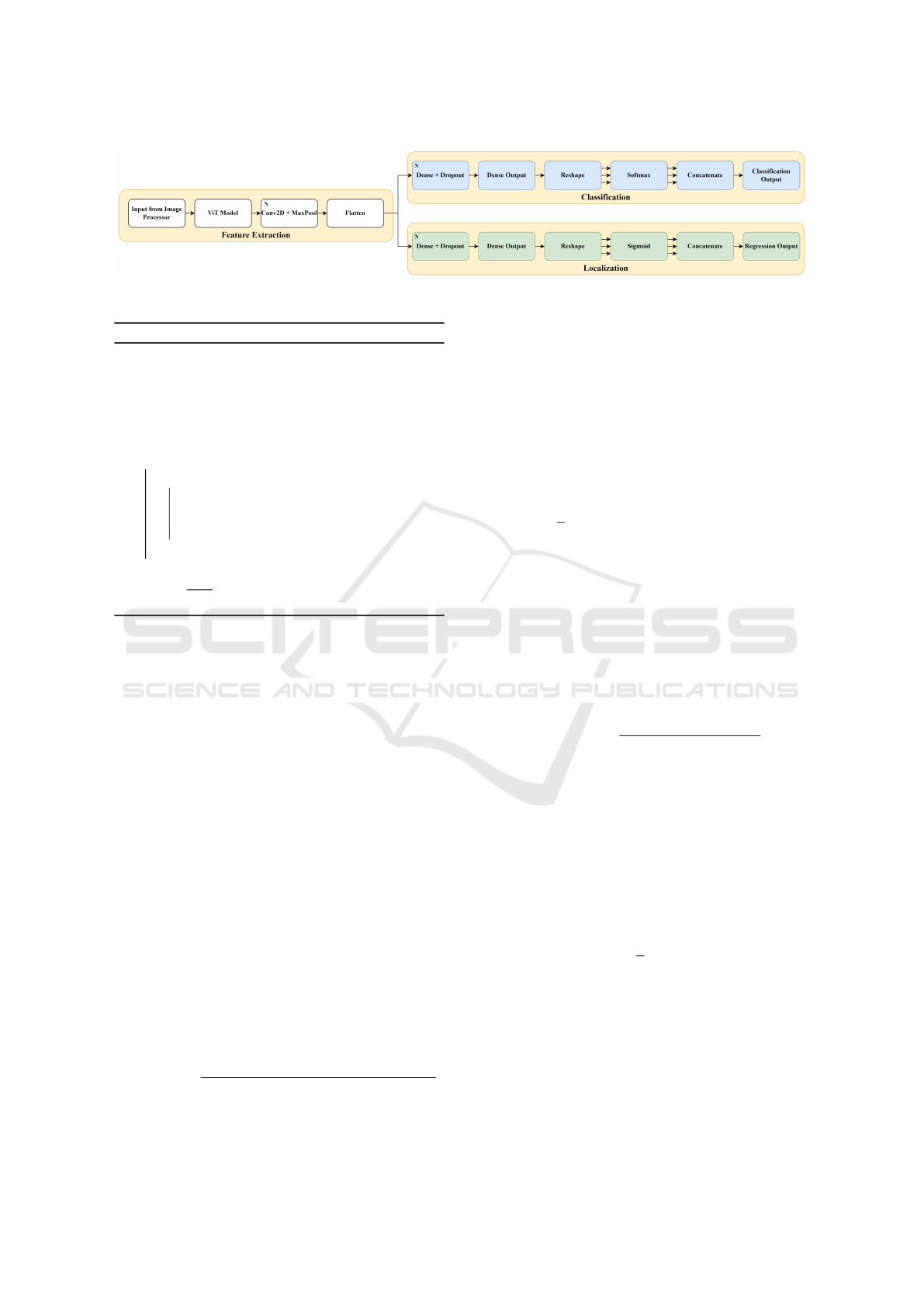

4.5 Model

Our model architecture (Figure 7) consists mainly of

4 parts: ViT encoder, CNN, Classification MLP, Re-

gression MLP.

4.5.1 Feature Extraction

After the image is pre-processed using the image pro-

cessor, it is passed to the encoder of the ViT model.

The output embeddings of the encoder are then passed

on a CNN to process these embeddings and extract the

features from them.

The output of the CNN is then flattened and shared

to two different MLPs. The share mechanism is se-

lected over using two different models for classifi-

cation and localization to allow the model’s CNN to

learn the common features between classification and

localization. This will allow the model to understand

the image features better and connect the two parts of

detection together.

4.5.2 Detection

Each MLP consists of multiple dense and dropout lay-

ers followed by an output layer. The output layer is

then reshaped to (number of anchor boxes, number

of classes) in the classification MLP and reshaped to

(number of anchor boxes, 4) in the regression MLP.

This is done to apply Softmax in classification and

sigmoid in regression individually on each sample

(anchor box). Sigmoid is used as the values of the off-

sets are limited between 0 and 1 after scaling. This re-

shape will yield more meaningful results as applying

Softmax on the whole number of samples will yield

false results.

The output of the Softmax layers and sigmoid lay-

ers is then concatenated and reshaped to match the

output shape, which is [(number of anchor boxes,

number of classes), (number of anchor boxes, 4)].

4.6 Loss Functions

The model is compiled with modified versions of

Categorical Cross-Entropy and Mean Square Error

(MSE) for classification and regression, respectively.

4.6.1 Classification Head

In categorical cross-entropy, the modification aimed

to handle the fact that most anchor boxes will be as-

signed to the background class, as found in the train-

ing datasets, which will lead towards extreme bias to-

wards the background class. In other words, it would

be easier for the model to predict all classes as back-

ground than actually spotting features in the image.

To eliminate this bias, the categorical cross-entropy

is performed individually on each detection (instead

of grouping by all defects in the image) only if the

true value is not a background class. This is to mimic

a two-level categorical cross-entropy, a lower level

on each sample, and a higher level on the whole im-

age with all samples. This modification aims to stop

giving the model a positive score on detecting the

background class, which prevents bias towards this

class. Algorithm 1 describes how the modified func-

tion works.

Algorithm 1: Modified Categorical Cross-entropy.

Data: y

true

, y

pred

Result: Categorical Cross Entropy Value

N ← len(y

true

);

M ← len(y

true

[0]);

loss ← 0;

for i ← 0 to N do

for j ← 0 to M do

if argmax(y

true

[i][ j]) ̸= background

then

loss ← loss +

∑

M

m=1

y

true

[i][ j][m]log(y

pred

[i][ j][m]);

end

end

end

return loss

4.6.2 Localization Head

In MSE, the modification aimed to handle the prob-

lem that most offsets will be 0, due to the fact that

most anchor boxes are from the background class, as

found in the training datasets. The modification was

to iterate over all detections and calculate the MSE

individually for each detection only if the true values

are not zeros (background class, and then output the

total MSE. This modification results in lowering the

bias towards the background class of offset 0. Algo-

rithm 2 describes how the modified function works.

Automated Detection of Defects on Metal Surfaces Using Vision Transformers

41

Figure 7: Our Model Architecture.

Algorithm 2: Modified Mean Squared Error.

Data: y

true

, y

pred

Result: Mean Squared Error Value

N ← len(y

true

);

M ← len(y

true

[0]);

loss ← 0;

count ← 0;

for i ← 0 to N do

if

∑

M

m=1

(y

true

[i][m]) ̸= 0 then

loss ← loss +

∑

M

m=1

(y

true

[i][m] − y

pred

[i][m])

2

;

count ← count + 1;

end

end

loss ←

loss

count

;

return loss

5 EVALUATION

This section discusses the evaluation metrics used to

assess our model, the obtained results, the strengths,

and the limitations of our approach.

5.1 Metrics

Evaluation metrics are essential for assessing the per-

formance our model. In this study, we employ three

key metrics: a modified version of accuracy for de-

fect classification, a modified version of Mean Abso-

lute Error for bounding box regression, and Mean In-

tersection over Union (Mean IOU) for bounding box

localization.

5.1.1 Accuracy: Defect Classification

The modification on accuracy followed the same pro-

cedures mentioned in Algorithm 1. The accuracy

measures the proportion of the correctly classified de-

fect instances out of the total instances.

Accuracy =

Number of correctly classified defects

Total number of defects

(1)

5.1.2 Mean Absolute Error: Bounding Box

Regression

The modification on MAE followed the same pro-

cedures mentioned in Algorithm 2. MAE quanti-

fies the average absolute distance between predicted

bounding box coordinates

ˆ

B

i

= (x

ˆ

B

i

, y

ˆ

B

i

, w

ˆ

B

i

, h

ˆ

B

i

),

and ground truth bounding box coordinates B

i

=

(x

B

i

, y

B

i

, w

B

i

, h

B

i

) for each instance i.

MAE =

1

n

n

∑

i=1

|x

ˆ

B

i

− x

B

i

| + |y

ˆ

B

i

− y

B

i

|

+ |w

ˆ

B

i

− w

B

i

| + |h

ˆ

B

i

− h

B

i

|

(2)

where n is the total number of instances.

5.1.3 Mean IOU

Mean IOU measures the spatial overlap between pre-

dicted and ground truth bounding boxes across all de-

fect instances.

IOU(B

i

,

ˆ

B

i

) =

Area of overlap(B

i

,

ˆ

B

i

)

Area of union(B

i

,

ˆ

B

i

)

(3)

where:

• Area of overlap(B

i

,

ˆ

B

i

) is the area where the pre-

dicted and ground truth bounding boxes overlap.

• Area of union(B

i

,

ˆ

B

i

) is the area encompassed by

both the predicted and ground truth bounding

boxes.

Mean Intersection over Union (Mean IOU) is calcu-

lated as the average IOU across all bounding boxes:

Mean IOU =

1

n

n

∑

i=1

IOU(B

i

,

ˆ

B

i

) (4)

5.2 Results

This section emphasizes the results of the loss func-

tions, and the evaluation metrics illustrated earlier.

The figures compare the results obtained by training

our data on our model with and without using the ViT

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

42

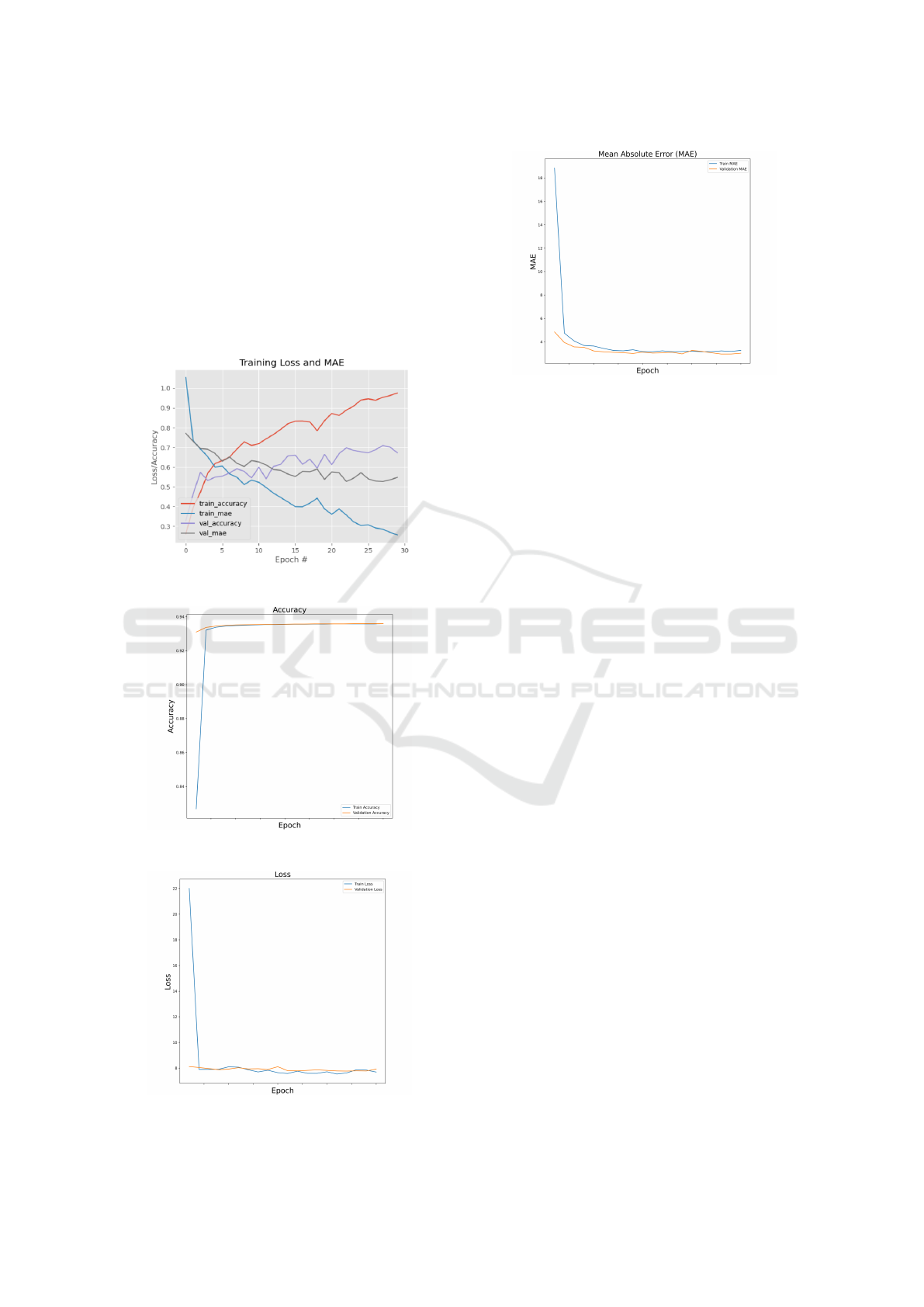

as our base feature extractor. Figure 8 shows the train-

ing versus validation accuracy and MAE without us-

ing ViT as a feature extractor. As shown in the fig-

ure, the model is overfitting our data as there is a

significant gap between the training and the valida-

tion results. Figure 9 shows the training and the val-

idation accuracy using the ViT. Figure 10 shows the

loss using the ViT. Figure 11 shows the MAE using

ViT. As the figures show, using ViT as the feature ex-

tractor has addressed the problem of over-fitting and

achieved high performance.

Figure 8: Evaluation metrics without using ViT.

Figure 9: Model accuracy using ViT.

Figure 10: Model loss using ViT.

Figure 11: MAE using ViT.

5.3 Discussion

In this study, we evaluated a metal surface detec-

tion algorithm using classification accuracy, MAE for

bounding box regression, and Mean IOU for bound-

ing box localization. Our findings indicate significant

achievements and some areas for improvement.

5.3.1 Performance Evaluation

Our model has achieved a high accuracy of 93.5% in

classifying metal surface defects. This high accuracy

emphasizes the effectiveness of our classification ap-

proach in detecting and distinguishing between differ-

ent defects.

For bounding box regression, we calculated MAE

to assess the accuracy of predicted bounding box co-

ordinates compared to ground truth. The calculated

MAE of 3.2 pixels suggests that our model can rea-

sonably predict the dimensions and positions of the

bounding boxes representing the defects.

Mean Intersection over Union (Mean IOU) was

used to evaluate the spatial overlap between pre-

dicted and ground truth bounding boxes. Our model

achieved a Mean IOU score of 0.72, indicating strong

performance in accurately localizing metal defects

within the bounding boxes.

The model has achieved State-of-the-Art results,

as shown in Table 1. Our proposed methodology

achieved a mean average precision (mAP) score of

0.732, which indicates the strong ability of our model

to classify different types of defects. It has beaten the

YOLO-backbone methods as indicated in the table.

5.3.2 Strengths and Limitations

Our study demonstrates several strengths, including

robust classification accuracy and effective bounding

box localization capabilities. These strengths high-

light the potential of our approach to contribute to au-

Automated Detection of Defects on Metal Surfaces Using Vision Transformers

43

Table 1: Comparison with State-of-the-Art Methods.

Model mAP Score

SSD 0.634

Faster-RCNN 0.627

YOLOv5 0.573

YOLOv6 0.666

Proposed Model 0.732

tomated quality control processes in metal manufac-

turing industries.

However, our approach also has limitations. For

instance, the current model may struggle with detect-

ing highly irregular defects due to limitations in the

training data. In addition, the localization and the

classification processes are not fast enough due to

the complex details of the transformer architecture.

The multi-head attention mechanism and the numer-

ous layers in the transformer architecture significantly

increase computational overhead, which further slows

down the processing speed and decreases computa-

tional efficiency.

Addressing these limitations could involve adding

more samples to Multi-DET dataset to introduce these

variations and incorporating further development on

the vision transformer to optimize the detection and

classification processes.

6 CONCLUSIONS

Automated defect detection on metal surfaces is a cru-

cial research area as it contributes to various indus-

tries, like automotive and construction. Manual in-

spection methods are slow and subjective, calling for

automated systems. This study proposes using Vi-

sion Transformers to overcome the limitations of tra-

ditional methods. ViTs, with their attention mech-

anisms, can capture complex defect patterns effec-

tively. The research focuses on defect classification

and localization, using pre-trained ViTs and transfer

learning. By automating defect detection, the ap-

proach aims to improve product quality and reduce

errors in metal manufacturing. The study addresses

a research gap in applying ViTs to metal surface de-

fect detection, contributing to the field. The promis-

ing results demonstrate accurate defect classification

and precise defect localization. The proposed model

achieved 93.5% accuracy in defect detection outper-

forming YOLO-based methods with a mean average

precision of 0.732. These results demonstrate the

model’s performance and its potential impact across

multiple industries.

Our methodology offers a promising approach for

addressing the challenges posed by metal defects in

manufacturing and reshaping industries. However,

there is still room for improvement, particularly in

addressing the model’s capability for detecting ex-

tremely overlapping and irregular shapes of defects.

This can be done by adding degrees of freedom to the

model while augmenting the training dataset. In ad-

dition, optimizing the model to work in real-time will

levitate the model’s performance. This limitation is

due to the complexity of the ViT. Despite the effec-

tiveness, ViTs are known for their high computational

demands in terms of memory and processing power.

This can be challenging when deploying the model in

real-time industrial settings.

Ultimately, this research paves the way for more

effective defect detection, ensuring the production of

high-quality metal products, and reducing operational

challenges in various industries.

ACKNOWLEDGEMENTS

We would like to extend our sincere gratitude to Eng.

Fatma Youssef, for her invaluable help and guidance

throughout this project. Her expertise and thoughtful

advice have played a crucial role in shaping the path

and achievements of this research.

REFERENCES

Bochkovskiy, A., Wang, C.-Y., and Liao, H.-Y. M. (2020).

Yolov4: Optimal speed and accuracy of object detec-

tion.

Dixit, K. (2020). Neu-det neu surface defect database.

Dosovitskiy, A., Beyer, L., Kolesnikov, A., Weissenborn,

D., Zhai, X., Unterthiner, T., Dehghani, M., Min-

derer, M., Heigold, G., Gelly, S., Uszkoreit, J., and

Houlsby, N. (2020). An image is worth 16x16 words:

Transformers for image recognition at scale. CoRR,

abs/2010.11929.

Fang, X., Luo, Q., Zhou, B., Li, C., and Tian, L. (2020).

Research progress of automated visual surface defect

detection for industrial metal planar materials. Sen-

sors, 20(18):5136.

Girshick, R., Lin, T., Dollar, P., Belongie, S., et al. (2017).

Feature pyramid networks for object detection. Face-

book AI Research (FAIR)(19 April 2017).

He, T., Zhang, Z., Zhang, H., Zhang, Z., Xie, J., and Li,

M. (2019). Bag of tricks for image classification with

convolutional neural networks. In Proceedings of the

IEEE/CVF conference on computer vision and pattern

recognition, pages 558–567.

Konovalenko, I., Maruschak, P., Brezinov

´

a, J., Pren-

tkovskis, O., and Brezina, J. (2022). Research of u-

net-based cnn architectures for metal surface defect

detection. Machines, 10(5).

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

44

Leibfried, G. and Breuer, N. (2006). Point defects in metals

I: introduction to the theory, volume 81. Springer.

Li, Z., Li, B., Ni, H., Ren, F., Lv, S., and Kang, X.

(2022). An effective surface defect classification

method based on repvgg with cbam attention mech-

anism (repvgg-cbam) for aluminum profiles. Metals,

12(11):1809.

Lovejoy, M. (1993). Magnetic particle inspection: a prac-

tical guide. Springer Science & Business Media.

Lv, X., Duan, F., Jiang, J.-j., Fu, X., and Gan, L. (2020).

Deep metallic surface defect detection: The new

benchmark and detection network. Sensors, 20(6).

Maruschak, P., Konovalenko, I., Osadtsa, Y., Medvid, V.,

Shovkun, O., Baran, D., Kozbur, H., and Mykhai-

lyshyn, R. (2024). Surface illumination as a factor in-

fluencing the efficacy of defect recognition on a rolled

metal surface using a deep neural network. Applied

Sciences, 14(6).

Mikołajczyk, T., Nowicki, K., Kłodowski, A., and Pimenov,

D. Y. (2017). Neural network approach for automatic

image analysis of cutting edge wear. Mechanical Sys-

tems and Signal Processing, 88:100–110.

Murakami, Y. (2019). Metal fatigue: effects of small defects

and nonmetallic inclusions. Academic Press.

Redmon, J., Divvala, S., Girshick, R., and Farhadi, A.

(2016). You only look once: Unified, real-time object

detection. In Proceedings of the IEEE conference on

computer vision and pattern recognition, pages 779–

788.

Sharifzadeh, M., Alirezaee, S., Amirfattahi, R., and Sadri,

S. (2009). Detection of steel defect using the image

processing algorithms. pages 125 – 127.

Tao, X., Zhang, D., Ma, W., Liu, X., and Xu, D. (2018). Au-

tomatic metallic surface defect detection and recogni-

tion with convolutional neural networks. Applied Sci-

ences, 8(9):1575.

Vaswani, A., Shazeer, N., Parmar, N., Uszkoreit, J., Jones,

L., Gomez, A. N., Kaiser, L. u., and Polosukhin,

I. (2017). Attention is all you need. In Guyon,

I., Luxburg, U. V., Bengio, S., Wallach, H., Fer-

gus, R., Vishwanathan, S., and Garnett, R., editors,

Advances in Neural Information Processing Systems,

volume 30. Curran Associates, Inc.

Wang, K., Teng, Z., and Zou, T. (2022). Metal defect detec-

tion based on yolov5. Journal of Physics: Conference

Series, 2218(1):012050.

Wang, S., Xia, X., Ye, L., and Yang, B. (2021). Auto-

matic detection and classification of steel surface de-

fect using deep convolutional neural networks. Met-

als, 11(3):388.

Zhu, X., Hu, H., Lin, S., and Dai, J. (2018). Deformable

convnets v2: More deformable, better results. 2019

ieee. In CVF Conference on Computer Vision and Pat-

tern Recognition (CVPR), pages 9300–9308.

Automated Detection of Defects on Metal Surfaces Using Vision Transformers

45