Research on Green Supply Chain Optimization of Fresh Food

e-Commerce Platform Under New Retail Mode: Taking Fresh Hema

as an Example

Lefan Chen

a

College of Mechanical Engineering, Zhejiang University of Technology, Liuxia Street, Hangzhou, China

Keywords: New Retail Mode, Fresh e-Commerce Platform, Supply Chain, Sustainability.

Abstract: With the advancement of information technology, including the Internet, and the rising living levels of the

Chinese people, more and more people choose to use online platforms to buy fresh food and other necessities

of life, with Fresh Hema as a representative of fresh food platform enterprises balancing online and offline,

practicing the new retail model, attracting a large number of consumers. As the concept of sustainable

development is gradually being emphasized, companies like Fresh Hema need to transition to environmental

protection and build a green supply chain. Taking the supply chain approach of Fresh Hema as an example,

to analyze the environmental issues and put forward effective measures to build a green supply chain to

provide reference for the majority of fresh food platform enterprises.

1 INTRODUCTION

Recent years have seen the e-commerce sector grow

quickly, Internet technology become more and more

popular and convenient, the product line has

continued to grow, and the new retail model centered

on O2O is emerging, occupying the consumer market

and becoming a new choice for consumers.

Consumers' willingness to buy online has increased,

and they are gradually getting used to online

shopping, and the demand for daily fresh products is

also increasing, which makes the scale of fresh food

e-commerce platforms expanding. Fresh products

have a very short shelf life and require efficient

supply chain transportation to ensure product quality.

However high efficiency is not the only requirement

for the supply chain. The Chinese government

mentioned the need to build a green supply chain in

the "Guiding Opinions of the State Council on

Accelerating the Establishment of a Sound Green,

Low-Carbon and Cyclic Economic System" issued in

2021, in which enterprises should take environmental

impact and resource efficiency into account in the

supply chain. However, the poor economic conditions

in recent years have led to a decline in people's

consumption power, coupled with fierce competition

a

https://orcid.org/0009-0004-1035-386X

from various fresh food platforms, how to implement

and optimize the green supply chain has become an

urgent issue for enterprises to consider.

New retail is a new mode of retailing that utilizes

the Internet, takes into account the ecological and

business structure through digital and intelligent

means, and integrates online and offline and modern

logistics.

The green supply chain was first proposed by the

Manufacturing Research Association of Michigan

State University in 1996, with a focus on resource

efficiency and environmental effect, this

contemporary management style is grounded in

supply chain management technology and green

manufacturing philosophy, which ultimately makes

the products in the supply chain, with the most

resource efficiency and the least amount of

environmental harm.

Green supply chain management can be defined

as the integration of an environmental management

system into the supply chain process, together with

cooperation between suppliers, customers, and

logistics service providers to exchange knowledge

and information to enhance environmental

performance (Tseng et al., 2019).

316

Chen, L.

Research on Green Supply Chain Optimization of Fresh Food e-Commerce Platform Under New Retail Mode: Taking Fresh Hema as an Example.

DOI: 10.5220/0012937400004508

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 1st International Conference on Engineering Management, Information Technology and Intelligence (EMITI 2024), pages 316-322

ISBN: 978-989-758-713-9

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

Fresh Hema is used as an example. The supply

chain model of Fresh Hema is analyzed in this article

under the new retail mode, and a supply chain

optimization path based on the green supply chain

idea is suggested. This paper's practical value lies in

its analysis of Fresh Hema's situation, which enables

the company to modernize its supply chain and create

a green supply chain that other fresh food retail

businesses can use as a model.

2 SUPPLY CHAIN

Supply chain refers to the production and distribution

process, involving the upstream and downstream

enterprises to provide products or services to the end-

user activities formed by the network chain structure,

that is, the product from the business to the hands of

consumers throughout the chain. For a fresh food

platform, the supply chain is the key to determining

whether the platform can run smoothly, China and

foreign fresh food platforms, always actively build to

improve the supply chain, to provide customers with

better quality service.

2.1 Situation in China

The vast territory and diverse topography and climate

make China's fresh products rich in variety. Because

fresh products are fresh, easily perishable, seasonal,

not easy to store, and in high demand, they have

higher requirements for the supply chain.

At present, China has nearly 230 million farmers,

and more than 91% of them are still in the "small farm

economy" production mode, i.e., production is

scattered, lack of unity, specialized management, and

low production efficiency, so the main distribution of

fresh agricultural products in China is still based on

the wholesalers' multilevel distribution in the place of

production and marketing. In terms of sales methods,

China has a variety of parallel supermarkets,

vegetable farms, and e-commerce.

China's current fresh food channels are still

dominated by farmers' markets, and because of its

high freshness, affordable prices, fast and safe, etc., it

will remain the primary method of selling fresh food

for a very long time. However, due to the in-depth

implementation of the policy of "farmers market to

the supermarket" and the penetration rate of new

channels such as fresh food e-commerce, the

proportion of farmer markets is decreasing, and the

coverage of online fresh food users is becoming more

and more extensive (Zheng & Zhu, 2024).

2.2 Situation in Other Countries

This part takes the United States as an example. The

U.S. fresh food B2B model is very successful, thanks

to the standardization of the macro-environment,

including the mechanical automation of upstream

agriculture and the scale of downstream catering

enterprises. From the source of upstream agricultural

products, the United States has a high degree of

agricultural scale, specialization, and mechanization,

with more concentrated planting sites and a large

production scale of individual farms. This has greatly

reduced procurement costs and operating costs for

fresh produce companies. B2B for intelligent fresh

food can be useful in the supply chain, integrating

downstream demand, determining production by

sales volume, guiding the upstream agricultural

production cycle and scale, and reducing the risk of

stagnation. From the downstream consumer situation,

large retailers in the United States for the wholesale

business opened the By-Pass system. The customer-

customized production model, specialty store sales

model, and national or global warranty service model

adopted by many producers have brought consumers

and manufacturers closer together directly.

2.3 Situation of Fresh Hema

Founded in 2015, Fresh Hema is a new retail platform

under Alibaba that is driven by data and technology

and is a benchmark company in China's new retail

industry. Different from traditional retail, Fresh

Hema integrates supermarkets, restaurants, and food

markets. Fresh Hema under the new retail model uses

technologies such as big data, mobile Internet, and

intelligent Internet of Things to match people, goods,

and fields to achieve optimization (Wang, 2023).

Fresh Hema uses the O2O model, i.e., online and

offline, but different from traditional O2O. In contrast

to traditional O2O, which is Online to Offline, Fresh

Hema's O2O is Offline to Online. This can be

understood as bringing offline traffic online, assisting

clients in using their offline shopping acumen to shop

online, encouraging the habit of online consumption,

and guaranteeing that the quality of both offline and

online products is the same. Products purchased

offline and online are of the same caliber (Zhu, 2022).

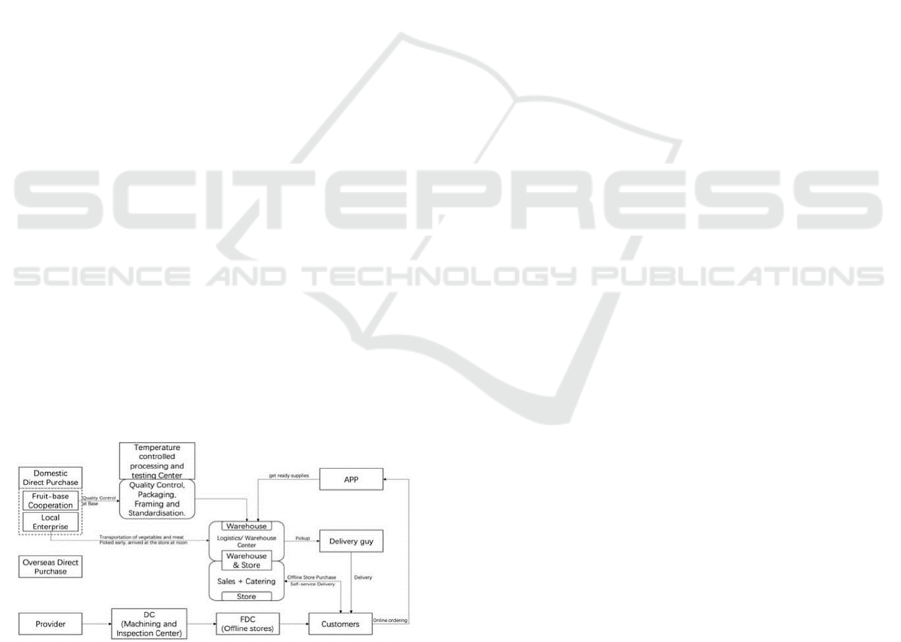

The current supply chain model used by Fresh

Hema is broken down into four sections, including the

supply side, the processing and inspection center

(DC), offline stores, and logistics.

On the supply side, Fresh Hema adopts a direct

sourcing model, purchasing high-quality fresh

products such as aquatic products, fruits and

Research on Green Supply Chain Optimization of Fresh Food e-Commerce Platform Under New Retail Mode: Taking Fresh Hema as an

Example

317

vegetables, and dairy products from all over the

world, and cooperating with Coles, NH Foods from

Australia, Migros from Switzerland, Driscoll's from

the U.S., and MOWI from Norway. At the same time,

Fresh Hema also purchases fruits and other products

from mature agricultural bases in China, such as

Sanya Mango Base and Lingshui Maidenhair Fruit

Base, and enters the bases directly to complete the

processing and inspection of the products. Meat and

vegetables are purchased from local enterprises and

cooperated with them, and they are often ordered in

the morning and delivered to offline stores for sale in

the afternoon.

The Processing and Inspection Center (DC) is

responsible for the processing or storage of

commodities. The Processing and Inspection Center

conducts quality inspections of globally procured

products, as well as transshipment and temporary

storage of live fish. Therefore, the Processing and

Inspection Center also has room-temperature and

low-temperature warehouses. Finally, the products

are packaged, standardized, and sent to offline stores.

The offline stores are based on the concept of

integrated stores and warehouses, with both sales and

warehousing functions. Customers can shop in person

at offline stores, which are equipped with a food

processing system that allows them to buy and eat the

raw materials directly from the staff. The offline

stores also serve as logistics centers for online

shopping. Customers can place an order through the

Fresh Hema APP, and the goods will be delivered to

their door by the nearest store. For the selection of

offline stores, Fresh Hema analyzes a large amount of

shopping data and courier addresses owned by

Taobao and Tmall to know the crowd density and

consumption habits. A schematic of the complete

supply chain of Fresh Hema is shown in Figure 1.

Figure 1: Fresh Hema’s Supply Chain (Photo/Picture credit:

Original).

In terms of logistics, Fresh Hema puts forward the

slogan of "30-minute delivery", relying on the

computing power of big data, a fully digitalized

system with hanging conveyor belts in the store,

which makes the process of goods from entering the

store to delivering them to the customers very

efficient, and the error rate are extremely low.

Deliveries within three kilometers of the store can be

made in about thirty minutes (Wang, 2023).

With the further pursuit of green business, the

concept of ESG (Environmental, Social, and

Governance) has come into the public's view. The

ESG governance concept emphasizes green and

sustainable development and focuses on the long-

term interests of enterprises, which can effectively

inhibit enterprises from pursuing short-term interests

due to internal and external pressures, reduce the

short-sighted behavior of managers, and enhance the

level of corporate risk-taking (Peng et al., 2024). In

exploring the path of ESG, Fresh Hema focuses on

the organic series, upgrading the organic series

products, restructuring the supply chain, assisting in

rural revitalization, and providing consumers with

high-quality experiences.

On June 5, 2023, Fresh Hema established a

Sustainable Development Department to focus on

promoting sustainable development in agriculture

and supply chain and established long-term

partnerships with more than one hundred organic

enterprises, with more than thirty "Organic Hema

Villages" across the country, where all fruits and

vegetables are free from the use of chemical

pesticides, to avoid exposing agricultural operators to

agricultural chemicals. All fruits and vegetables do

not use chemical pesticides, which prevents

agricultural workers from being exposed to

agricultural chemicals. Behind the low-priced and

high-quality organic vegetables, Fresh Hema uses the

order agriculture model to expand the supply chain's

upstream and downstream. protects the interests of

farmers with stable supply relationships, reduces

purchasing costs, and ultimately allows consumers

and farmers to benefit at the same time.

Fresh Hema is reducing resource waste, as well as

farmers' losses and agricultural wastage, through a

combined supply chain model that maximizes

utilization by grading. For example, the specification

and appearance of substandard Yunnan Menglian

avocado is made into ice cream; Beijing organic

Pinggu peaches of different sizes are processed into

freeze-dried peach crisp, which allows each

mu(a Chinese unit of area equal to 1/15 hectare) to

reduce the waste of fresh peaches by 400 jin (a

Chinese unit of mass equal to 0.5 kilograms) and

increase the net income of 1,200 yuan per mu.

Fresh Hema promotes eco-agriculture,

encouraging efficient and sustainable agricultural

operation modes such as intercropping, three-

dimensional agriculture, and multi-level recycling of

EMITI 2024 - International Conference on Engineering Management, Information Technology and Intelligence

318

materials and energy, to resolve the conflict between

human beings and the natural environment while

exploring more economical eco-agriculture modes.

Under this business philosophy, Fresh Hema actively

cooperates with international environmental

organizations. For example, Fresh Hema and IFAW

(International Fund for Animal Welfare) jointly

created the Zero Carbon Elephant Honey Project,

which helps local farmers increase their income and

alleviates the human-elephant conflict caused by

farmers going into the mountains at night to cut

rubber. Zero Carbon Elephant Honey is available in

stores nationwide, and a portion of the profits are used

to support the sustainable development of local

communities, including planting eco-friendly fruit

trees instead of rubber and installing photovoltaic

power generation equipment to neutralize carbon

emissions from the production process.

Fresh Hema actively participates in the practice of

circular economy and brings the concept of

environmental protection closer to consumers. On

World Environment Day 2023, Fresh Hema and

Corona jointly launched the "Zero Plastic Payment"

campaign, where consumers can bring recycled

plastics to offline stores, and exchange the plastics for

a corresponding amount of money.

3 OBSTACLES IN FRESH HEMA

Through the continuous development and

construction of Fresh Hema, Fresh Hema has

established a three-dimensional supply chain network

with a three-tier network and five major centers. The

three-tier network refers to the national central

warehouse, regional central warehouse, and city

warehouse. The five centers refer to the room-

temperature logistics center, low-temperature

logistics center, fresh food holding center, processing

center, and central kitchen.

In the concurrent creation of an entire supply

chain, the new retail model of Fresh Hema will be

online and offline integration, the reasonable use of

Alibaba's ecological data, in the data and technology

of the dual-support, and ultimately to form their

ecological circle. The perfect combination and

utilization of big data, the Internet, intelligent

equipment technology, and the commercial operation

of new technology help optimize the match between

logistics, people, goods, and the field, which has

become the biggest difference between Fresh Hema

and traditional offline stores. Furthermore, the

implementation of Fresh Hema's unmanned self-

checkout service model has resulted in the

replacement of the manual checkout mode in large

commercial supermarkets around the nation.

The concept and model of new retail has attracted

many customers to Fresh Hema, making it more and

more popular, and more and more city residents are

choosing Fresh Hema. However, as time goes on,

more and more problems such as "using rotten apples

to squeeze juice", "charging extra environmental

protection fees", "durian varieties falsified" and so on,

Fresh Hema has continuously encountered bumps in

the process of building a green supply chain, Fresh

Hema has been encountering bumps in the road.

3.1 High Level of Dependence on

Suppliers

Fresh Hema relies on global sourcing and direct

sourcing from production bases for its products and

has a high degree of dependence on its suppliers. If

suppliers have insufficient supply in terms of product

quantity or falsification in terms of product quality,

such as the incident of Fresh Hema's use of rotten and

decayed apples to squeeze juice from a juice supplier

on October 10, 2018, it will have a serious impact on

the entire Fresh Hema's supply chain, and after Fresh

Hema makes a swift move to take down the shelves

as well as to stop receiving the supply, it will result in

the out-of-stocking of the products related to apple

juice and the opening of a returns channel resulted in

a loss of finances and, in more serious cases, a loss of

consumers. Inappropriate disposal of existing stock

can also lead to environmental damage and waste of

resources.

3.2 Limited Cold-Chain Logistics

Technology

Cold chain logistics covering the whole store and the

demand for transportation of numerous fresh products

have led Fresh Hema to develop cold chain logistics

technology on a large scale, which requires high

capital. The development of cold chain logistics is

sluggish at this point due to Fresh Hema's lack of cold

chain logistics talent, although the quality of fresh

products is still affected. The operation of large-scale

refrigeration equipment consumes a large amount of

energy and generates a large amount of noise and a

large amount of waste, which has a considerable

impact on the environment.

3.3 Limited Store Coverage and Poor

Delivery Results

Fresh Hema's offline stores are mainly laid out in

Research on Green Supply Chain Optimization of Fresh Food e-Commerce Platform Under New Retail Mode: Taking Fresh Hema as an

Example

319

first- and second-tier cities. Due to the time

characteristics of fresh food, almost only the range

within 3km from the offline stores is an effective

logistics range, which determines that Fresh Hema's

logistic coverage across the country is not very large.

The distribution of Fresh Hema's offline stores can be

seen in Figure 2.

Figure 2: Fresh Hema’s Offline Store Distribution (Photo/

Picture credit: Original).

Consumers have reported that Fresh Hema's

claimed 30-minute delivery is difficult to reach

fulfillment in a certain portion of stores across the

country, and that certain orders have serious

overtime, ranging from one hour to five hours

overtime. Distribution focus delivery staff only

accounted for a part of the majority of stores rely on

the sea of people tactics, a large number of orders can

only rely on a large number of delivery staff stack,

and can only barely reach a general level of delivery.

3.4 Polluting Packaging Materials

In 2021, with the promulgation of the policy of

restricting plastics, some domestic head catering and

tea beverage enterprises have banned plastic straws

and plastic lunch boxes, which are mainly made of

PP, and switched to paper straws, aluminum foil

lunch boxes, and other more environmentally friendly

replacement products. However, in the field of

supermarkets, PP plastic film is still used in numerous

boutique fruit and vegetable products. This PP

material takes hundreds of years to fully degrade in

the natural environment and is therefore extremely

damaging to the environment.

3.5 Pompous and Excessive Packaging

Some fruit and vegetable products are over-packaged

on the outside to show off a sense of high class. Dutch

beans, millet peppers, carrots, and other fruits were

put into the plastic film, and oatmeal, spinach, celery,

and other leafy green vegetables were all packaged in

plastic bags. Even cabbage, cauliflower, and eggplant

were first set on a circle of sponge netting and put into

a square plastic box, the outside also needed to be

wrapped in several layers of plastic film, all unfolded

after more than 1 meter long. This fruit and vegetable

"dress" mode can enhance the price, and reduce the

damage rate of fruits and vegetables. For consumers,

sometimes excessive packaging, results in consumers

not being purchased on demand, and not finishing

eating caused by the waste of plastic bags and

vegetables.

4 DISCUSSIONS

In light of the supply chain issues that Fresh Hema is

currently facing and the notion of a "green supply

chain", this part gives some ideas of digitalization and

intelligence to promote the construction and

upgrading of a green supply chain, and provides

references to the question of "how to build a green

supply chain for fresh food platforms".

4.1 Digitization Builds Green Foundation

Relying on Alibaba, Fresh Hema has great

advantages in digital systems, big data analysis, cloud

computing, and other technology research and

development and application. Fresh Hema needs to

understand users' needs based on data, in all aspects

and from multiple angles, and utilize other Apps

under Alibaba, such as Tmall, Taobao, and Alipay, to

collect customers' data, and analyze users' profiles

through big data, and then understand the customers'

needs, so that every customer can see the push

information that meets his or her preference when

opening the Fresh Hema APP. After extensive

collection and analysis of customer needs and

consumption preferences, the logistics center will

unify the proportion of products in offline stores,

know what products should be placed on the shelves,

improve ping efficiency, and reduce the waste of

items with less customer demand.

Big data algorithms are used to plan the optimal

route to reduce transportation energy consumption, as

well as to shorten the delivery time and increase the

efficiency of delivery work. An Improved Ant

Colony Algorithm (ICAO) is proposed from the

perspective of takeaway delivery workers for

takeaway delivery path planning research. Firstly, the

initial planning path is obtained by solving the ACO

algorithm, then the initial planning path is optimized

by the large-scale neighborhood search algorithm,

EMITI 2024 - International Conference on Engineering Management, Information Technology and Intelligence

320

and the solution quality is improved by combining the

ACO and LNS algorithms. The IACO algorithm can

not only improve the intelligent level of distribution,

but also improve the distribution efficiency, and

realize the sustainable development of the

distribution network interconnected distribution

system (Tang et al.,2023).

4.2 Intelligence to Enhance Green

Capabilities

Intelligence is the first leap in the construction of a

green supply chain, which opens up the information

flow channels of each link through digitization and

intelligence. Digital resource coupling breaks down

the information silos of various information systems,

interconnects various nodes in the supply chain, and

realizes "physical-virtual" interoperability, to

improve the efficiency, environmental protection,

and security of the supply chain (Zhang et al., 2024).

In the processing and testing center, the use of

automated packaging production lines can improve

the production efficiency of packaging, reduce the

waste of packaging materials, and save labor costs

and raw material costs for enterprises.

The use of data analysis and prediction

technology, the implementation of food packaging

safety supervision and monitoring, and food

packaging safety of the safety hazards that exist

promptly to predict and alarm. The use of image

recognition and detection technology can monitor the

surface of the food packaging of foreign objects,

bacteria, or damage, and the use of automated means

to solve the problem, effectively preventing food

from being contaminated, which results in food

waste. Intelligent monitoring systems, blockchain

technology applications, automated processing and

decision support, and other technologies (Liu, 2023)

can also be used to replace the original manual

inspection and monitoring, reduce the rate of

misjudgment, improve supply chain efficiency,

automate the packaging production line, intelligent

decision-making, and promote the digital

transformation of processing and testing centers to

achieve lean production.

Learning from Jing Dong Logistics, the

development of intelligent insulation box technology,

Jing Dong’s independent research and development

with the U.S. FDA standards of the fifth generation of

VIP material insulation box can be recycled, better

than the industry norm in terms of insulating time,

storage space, etc., the service life or the industry's 2-

3 times, greatly saving the loss of packaging. Through

real-time monitoring of the location of fresh cold

chain packaging, the temperature of fresh

commodities inside the packaging, and other quality

control information, the development of intelligent

temperature control technology offers comprehensive

and superior logistics protection for fresh products.

Realize intelligent temperature control sharing

function, establish intelligent temperature control

system for the whole cold chain, realize

comprehensive monitoring of temperature change,

transportation speed, and distribution time in each

link of fresh storage, transportation, and distribution,

and guarantee the safety of fresh food (Yang & Wang,

2020).

Fresh Hema can also learn from Amazon Fresh to

set up receiving boxes, these boxes can be fixed on

the wall outside the buyer's door, according to the

characteristics of different fresh products set up three

chambers, room temperature, heat preservation, and

low temperature. To ensure that customers are unable

to receive products in time, fresh products remain

fresh (Aćimović et al., 2020).

4.3 Green Cooperation on the Supply

Side

On the supply side, cooperate with green suppliers,

cooperate with green agricultural bases, and purchase

green organic fruits and vegetables. In addition,

packaging suppliers should also choose

environmentally friendly packaging companies.

The materials for the packaging design of Fresh

Hema’s food are firstly, materials with natural

ecological properties, such as bamboo and rattan, and

secondly, artificial materials that reduce

environmental pollution to a greater extent, such as

kraft paper, corrugated paper, and non-toxic ABS

plastic. In terms of packaging, suppliers try to choose

green material companies, to ensure that the same

ecological properties in the production and

processing of materials, to facilitate secondary use, as

well as packaging is easy to degrade after the final

waste. At the same time, the geographical nature of

packaging materials should be considered to achieve

local conditions. Offline stores are mostly situated

around the Yangtze River Delta, and Anji, Zhejiang

Province, also located in the Yangtze River Delta

region, is rich in bamboo, which is a natural material

that can be recycled and naturally explained, and the

promotion of bamboo instead of paper materials is

conducive to the reduction of tree felling.

Improve the green recycling system based on the

"5R" principle (Reduce, Revaluate, Reuse, Recycle,

Rescue) with a third-party organization, and propose

more economical and environmentally friendly green

Research on Green Supply Chain Optimization of Fresh Food e-Commerce Platform Under New Retail Mode: Taking Fresh Hema as an

Example

321

recycling and disposal solutions for various

packaging boxes and residual agricultural products,

such as recycling of bamboo boxes, making bamboo

charcoal, expired fruits and vegetables can be

recycled to make fertilizers, etc. to achieve green and

sustainable development.

5 CONCLUSIONS

People's demand for environmental protection of

enterprises is constantly rising, and how fresh food e-

commerce platform conforms to the requirements of

the environment and build a green supply chain has

become extremely important.

This paper takes Fresh Hema as the research

object, by introducing Fresh Hema's supply chain

mode and green policy at the present stage to provide

a reference for peer company and then analyzing the

environmental protection problems that still exist at

the present stage of Fresh Hema, analyzing and

proposing solutions to them, and providing reference

direction for Fresh Hema to build a green supply

chain.

Fresh Hema's strong supply chain and new retail

model have made it a great success. However, under

the social background of pursuing environmental

protection, Fresh Hema, as a head enterprise of the

new retail fresh food industry, combines

digitalization, intelligence, and supply chain,

optimizes environmental protection from every link

of the supply chain, and promotes the implementation

of environmental protection policies and the

construction of green supply chain, which can

provide a reference standard for the whole industry.

However, the research in this paper relies on a

literature review and case study, without involving

original data, and the confirmation aspect is lacking.

Future research can apply empirical analysis to

analyze specific environmental indicators, use linear

regression and other models to analyze the impact of

different green supply chain measures on corporate

environmental protection, and further expand the

research related to the role of green supply chain

construction on the promotion of new retail

enterprises.

REFERENCES

Aćimović S., Mijušković V., &Milošević N., 2020.

Logistics Aspects of Goods Home Delivery: The Case

of Amazon Company. Marketing. 2020,51(01), 3-11.

DOI: 10.5937/markt2001003A.

Liu, Y., 2023. Research on Food Packaging Safety

Supervision Strategies Based on Artificial Intelligence.

Shanghai Packaging. 2023(08), 17-19. DOI:

10.19446/j.cnki.1005-9423.2023.08.006.

Peng B., Zhang Y., &Wang Z., 2024. A Study on the Impact

of Corporate ESG Performance on Green Innovation

Efficiency. Statistics & Decision. 2024,40(05), 172-176.

DOI: 10.13546/j.cnki.tjyjc.2024.05.031.

Tang, C., Zhang M., Li J., Wan Y., &Wei M., 2023.

Research on takeout delivery path planning based on

improved ant colony optimization algorithm. Journal of

Nanjing University of Information Science &

Technology (Natural Science Edition)1-14. DOI:

10.13878/j.cnki.jnuist.20230311001.

Tseng, M.-L., Islam M.S., Karia N., Fauzi F.A., &Afrin S.,

2019. A literature review on green supply chain

management: Trends and Future Challenges. Resources,

Conservation & Recycling. 141(2019), 145-162. DOI:

10.1016/j.resconrec.2018.10.009.

Wang, J., 2023. Research on the business model of fresh

food e-commerce under new retail--Taking Fresh Hema

as an example. China Circulation Economy. 2023(22),

4-7. DOI: 10.16834/j.cnki.issn1009-5292.2023.22.004.

Wang, Q., 2023. Retail Business Model Innovation from th

e Perspective of New Retail— A Case Study of Hema

Fresh. Economic Research Guide. 2023(13), 77-79. htt

ps://kns.cnki.net/kcms2/article/abstract?v=29axctaKF3

yJ0TIcw15YXAByMq-AHYehHH5fWMbYpkj0WTIf

lINS5fIJ8c2Y5InE02_uvjgRN0DCB2IE-q4cMnz_TTe

_Bc2MBs0VvwDYjWfaZxBB3Ufa1yn5yY5Tor5eyK

Jt4Ok41JXRp4feBDONwA==&uniplatform=NZKPT

&language=CHS.

Yang, S., &Wang H., 2020. Analysis and Optimization of

JD Cold Chain Logistics System. Logistics Technolog

y. 2020,39(09), 134-137. https://kns.cnki.net/kcms2/art

icle/abstract?v=29axctaKF3zbpCQYquML8MWRRaT

8PeJ78AJP1sAiGBSl3rO_IJZNJ8EfllLjxRupoMNlFz

FAH4SIIpS25VNHqi7sUzP0TV8p2GNr4AEFHlX0Z

p0Gq3jVCozktW63ezY8TckeXGjWfX_9HPY_0XOh

fg==&uniplatform=NZKPT&language=CHS.

Zhang, M., Sun Y., &Yang L., 2024. Digital Intelligence

Boosts Enterprises' Green Supply Chain Upgrade: A

Dual Case Study Based on Schneider and Lenovo

Group. Finance and Accounting Monthly. 2024,45(06),

28-35. DOI: 10.19641/j.cnki.42-1290/f.2024.06.004.

Zhu, Y., 2022. Research on Fresh Hema's New Retail

Model Supported by Data. Modern Business. 2022(02),

12-14. DOI: 10.14097/j.cnki.5392/2022.02.004.

Zheng, Y., &Zhu X., 2024. Fresh food e-commerce supply

chain status quo and development trend. China Storage

& Transport. 2024(01), 71-72. DOI:

10.16301/j.cnki.cn12-1204/f.2024.01.105.

EMITI 2024 - International Conference on Engineering Management, Information Technology and Intelligence

322