Evaluation of the Contribution of Knowledge Management to

Efficiency in the Manufacturing Industry

Through Machine Learning

Juan Ibujés-Villacís

a

Facultad de Ciencias Administrativas, Escuela Politécnica Nacional, Quito, Ecuador

Keywords: Business Management, Efficiency, Knowledge Management, Manufacturing Industry, Machine Learning.

Abstract: Knowledge management (KM) has been instrumental for organizations to improve their efficiency. The

objective of this research is to determine the contribution of knowledge management (KM) to manufacturing

industry efficiency, using machine learning models to predict the relevant KM factors that should be taken

into account to improve efficiency. Given the quantitative nature of the research, in the first phase, data on

variables associated with KM factors and efficiency were collected and processed. In the second phase, four

supervised machine learning models were developed to predict which manufacturing companies are efficient

in their production process based on a set of KM factors. The study was based on information from 142

manufacturing companies in the province of Pichincha, Ecuador. The results show that the relevant KM

factors that contribute to business efficiency are policies and strategies, organizational structure, technology,

incentive systems and organizational culture. This pioneering study in Ecuador allows predicting the relevant

KM factors that impact the efficiency of manufacturing firms. This article contributes to the field of

knowledge management and provides information on the KM factors that manufacturing firms should focus

on to achieve greater efficiency.

1 INTRODUCTION

Enterprises are currently leveraging machine learning

(ML) technology to optimize various areas of

business management, such as analyzing purchase

history, personalizing product recommendations, and

predicting customer behaviors (Akerkar, 2019;

Hemachandran & Rodriguez, 2024). However, the

potential of ML is not limited to these applications; it

can also play a crucial role in strategic decision

making and improving operational efficiency.

Many companies in different economic sectors

have implemented artificial intelligence to increase

efficiency, improve their operations, and predict

future needs and behaviors in real time, allowing

them to offer better experiences to their customers

(Anshari et al., 2023; Pagani & Champion, 2024).

These technologies help companies optimize

resources and capabilities, contributing significantly

to their strategic objectives.

From a knowledge management (KM)

perspective, many companies develop strategies such

a

https://orcid.org/0000-0001-8439-3048

as knowledge exploitation, acquisition, sharing and

exploration to improve knowledge management

companies (Bolisani & Bratianu, 2018). However,

these strategies do not always translate into efficiency

gains, probably due to the lack of data for informed

decision making.

The purpose of this research is to design and

develop machine learning models that have an impact

on predictive analysis, identifying which

manufacturing companies are operationally efficient

based on practices associated with KM. This research

is pioneering in the Ecuadorian context, since there

are no studies in which machine learning is used to

predict business management results.

Methodologically, it has a quantitative approach

and a survey was used as a research technique, taking

142 manufacturing companies in Pichincha, Ecuador,

as a random sample. The survey collected data on

factors related to KM and efficiency based on

previous studies (Ibujés-Villacís & Franco-Crespo,

2022). With these data, several supervised machine

learning models were developed, including multiple

48

Ibujés-Villacís, J.

Evaluation of the Contribution of Knowledge Management to Efficiency in the Manufacturing Industry Through Machine Learning.

DOI: 10.5220/0012943500003838

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 16th International Joint Conference on Knowledge Discovery, Knowledge Engineering and Knowledge Management (IC3K 2024) - Volume 3: KMIS, pages 48-59

ISBN: 978-989-758-716-0; ISSN: 2184-3228

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

linear regression, where KM factors were considered

as independent variables and efficiency factors as

dependent variables.

Knowledge management brings numerous

benefits to companies such as the optimization of

efforts and the improvement of operational

efficiency. It allows identifying and leveraging best

practices, as well as avoiding errors and rework

(Pagani & Champion, 2024). This study, by training

algorithms with data from medium-sized

manufacturing companies, contributes to identify the

factors of KM that are relevant to determine

efficiency in the Ecuadorian manufacturing industry.

Its results will enable companies to develop strategies

to optimize resources and capabilities in achieving

business objectives.

The paper begins with an overview of knowledge

management, organizational efficiency and machine

learning. Then, four multiple linear regression models

are presented to predict variables associated with

business efficiency from KM-related variables.

Through machine learning, algorithms are developed

to identify significant KM variables that impact

efficiency. Finally, results are discussed, conclusions,

limitations and possible directions for future studies

are presented.

2 THEORETICAL ELEMENTS

2.1 Knowledge Management

Knowledge can be treated both as an object with

attributes and properties, and as a process involving a

set of cognitive activities performed by individuals or

organizations with the objective of creating or adding

value (Davenport & Prusak, 1998; Saulais & Ermine,

2019). In the organizational context, this value

manifests itself in various forms, such as the creation

of new business models, increased profitability,

improved organizational efficiency, innovations in

products and processes, and increased customer

satisfaction (Andreini & Bettinelli, 2017).

Knowledge management (KM) in organizations is

one of the most important collective capabilities, as it

is the key to professional growth and profitability

strength in the 21

st

century (Manning & Manning,

2020). In addition, it is fundamental to improve

efficiency and promote innovations in products and

processes (Newell, 2015).

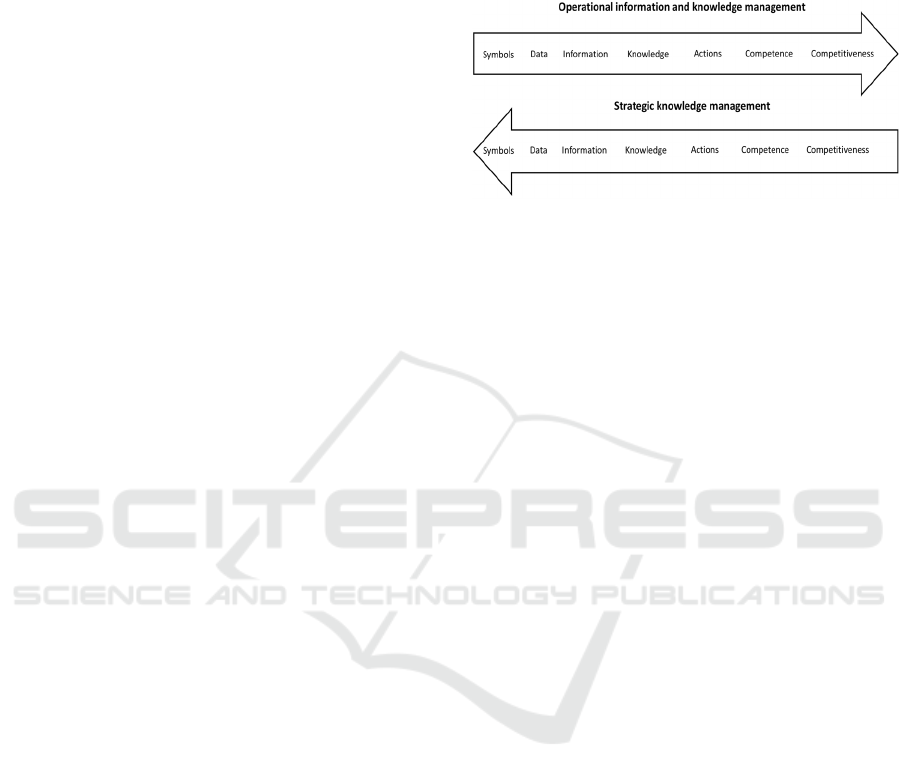

According to North & Kumta (2018), KM is

oriented in two main directions, as shown in Figure 1.

The first, focused on the operational management of

symbols until knowledge becomes a competitive

advantage. The second, focused on strategic

knowledge management, which consists of

determining what type of knowledge, data or symbols

the organization needs to realize its strategies.

Figure 1: Knowledge management and competitiveness.

Note: Image adapted from Knowledge Management. Value

Creation Through Organizational Learning (p. 35), by

Klaus North and Gita Kumta, 2018, Springer.

Knowledge management is multidimensional. In

the static dimension, the organization focuses on

maintaining, replicating and exploiting available

knowledge as an internal capability of the

organization, leveraging internal human talent and

existing technological infrastructure (Endres, 2018;

Kaur, 2019). In the dynamic dimension, the

organization performs activities to acquire, convert

and apply externally generated knowledge.

In recent years, due to the vast amount of data

available and the development of computer science,

KM has gained renewed importance in organizations.

This resurgence has been driven by advances in

machine learning and artificial intelligence (Bhupathi

et al., 2023; Uden et al., 2014; Weber, 2023).

2.2 Efficiency in the Industry

Efficiency is a key indicator that reflects a company's

ability to operate economically. The key indicators of

efficiency focus on physical-technical performance

and costs (Zanda, 2018). Efficiency assesses whether

resources are being utilized to their maximum

productive capacity, i.e., whether productive factors

are being utilized at one hundred percent or whether

there is idle capacity (Cachanosky, 2012).

In the context of Ecuadorian industry, efficiency

has also been studied as an indicator of innovation

and its relationship with sustainable development

objectives (Ibujés-Villacís & Franco-Crespo, 2019,

2023a, 2023b). These studies highlight the

importance of efficiency not only from an economic

perspective, but also from a sustainability and

innovation approach.

Several corporate performance factors are

specifically related to efficiency, and the application

Evaluation of the Contribution of Knowledge Management to Efficiency in the Manufacturing Industry Through Machine Learning

49

of these factors depends on the context and careful

management of each one (Albornoz, 2009). In this

study, relevant factors were selected for medium-

sized manufacturing companies in Pichincha, based

on previous studies conducted in these companies

(Ibujés-Villacís & Franco-Crespo, 2022).

This research focuses on the impact of knowledge

management (KM) on the efficiency of

manufacturing companies. For this purpose, a set of

factors were considered associated with both

knowledge management and efficiency. The

objective is to determine how certain KM factors can

predict efficiency in these companies. By

understanding the relationship between KM and

efficiency, organizations can develop more effective

strategies to optimize their operations and improve

their overall performance.

2.3 Machine Learning

Machine learning, predictive modeling and artificial

intelligence are closely related terms (Shmueli et al.,

2023). This field of study endows computers with the

ability to learn without the need to be explicitly

programmed. In machine learning, a computer

program learns from experience with respect to a set

of tasks, progressively improving its performance as

it accumulates experience (Akerkar, 2019).

Machine learning generally begins with the

simplified representation of reality using a model

(Burger, 2018). Models are mathematical tools that

describe systems and capture relationships in the data

provided (Kuhn & Silge, 2022). Unlike dashboards,

which provide a static picture of the data, models

allow understanding and predicting future trends

(Burger, 2018).

There are several machine learning models, such

as regression, clustering and neural networks, all

based on algorithms. The three main types of models

are: regression models, classification models and

mixed models combining both approaches.

To meet the objective of this research, a

supervised learning algorithm will be used to model

the relationships between KM input variables and

efficiency output variables. Machine learning is

currently a fundamental tool for decision making in

business (Pagani & Champion, 2024; Weber, 2023).

In particular, this research will employ a multiple

linear regression model to determine the relationship

between a set of corporate efficiency variables

(dependent variables) and another set of knowledge

management variables (independent variables).

Machine learning requires training a model with a

data set, which represents a percentage of the total

available data. The training results are evaluated to

determine if the errors decrease and if the model fits

correctly. If errors persist, the model needs to be

modified and refined (Burger, 2018).

Training data are crucial for fitting machine

learning models and, in many cases, are used to

perform cross-validation during the training phase of

the model. This validation consists of splitting the

data into two subsets, one for training and one for

testing, which allows further refinement of the model

(Burger, 2018; Hastie et al., 2023).

This research is based on supervised machine

learning, since it is required to make predictions about

the efficiency of companies based on a data set that

relates two defined categories: KM and corporate

efficiency. These data were obtained through surveys

of manufacturing companies in Pichincha, Ecuador.

2.4 Multiple Linear Regression

Multiple linear regression (MLR) is a statistical

technique used to model the relationship between a

dependent variable and two or more independent

variables. MLR seeks to find the best line (or

hyperplane in higher dimensions) that fits the data

optimally. This involves determining the coefficients

that minimize the difference between the values

predicted by the model and the actual values observed

in the data set.

Mathematically, the multiple linear regression

model is expressed as equation 1:

𝑌=𝛽

+𝛽

𝑋

+𝛽

𝑋

+⋯+𝛽

𝑋

+𝜀

(1)

Where

Y is the dependent variable.

𝑋

,𝑋

,……,𝑋

: independent variables.

𝛽

,𝛽

,𝛽

,….,𝛽

: coefficients representing the slope

of each independent variable.

ϵ: is the error term, which captures the variation not

explained by the model.

MLR is especially useful for understanding how

multiple independent factors contribute to a particular

outcome. In this study, MLR is used to analyze and

predict the relationship between dependent variables

related to company efficiency and set of independent

variables related to knowledge management.

In the scope of this research, which focuses on

medium-sized manufacturing companies in

KMIS 2024 - 16th International Conference on Knowledge Management and Information Systems

50

Pichincha, Ecuador, the dependent variables are

related to corporate efficiency, as shown in Table 2.

The independent variables, on the other hand, are

related to knowledge management, as shown in Table

1. The use of the MLR allows us to identify which

factors of knowledge management have a significant

impact on the efficiency of these companies.

3 METHODOLOGY

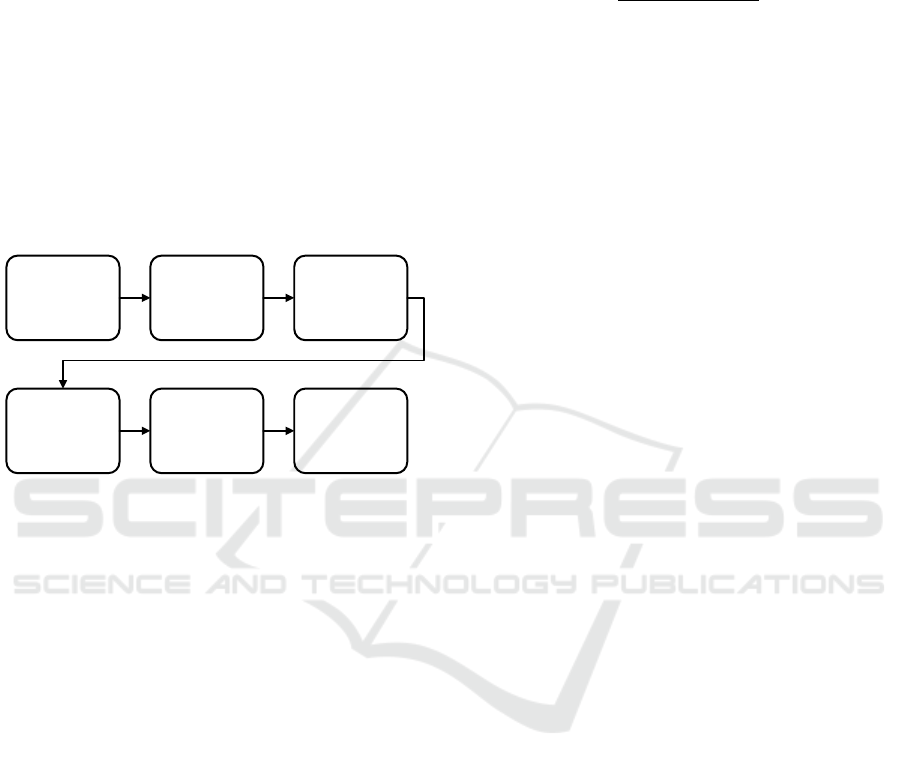

Figure 2 shows the complete process to achieve the

research objective, starting with the determination of

the sample and ending with the results obtained after

the application of machine learning.

Data collection

Data exploration

and preparation

Data modeling

and analysis

Training,

validation,

evaluation and

adjustment

Results and

actions

Sample

determination

Figure 2: Process for data analysis.

3.1 Sample Determination

The scope of the study is companies in the

manufacturing sector in the province of Pichincha,

where Quito, the capital of Ecuador, is located. This

economic sector was chosen because of its significant

contribution to the country's economy, contributing

14.2% to Ecuador's total production (MIPRO, 2021).

The study population includes medium-sized

manufacturing companies that are active and have

been operating for at least five years. These

companies have between 50 and 199 employees,

annual revenues between US$1 million and US$5

million, and an asset value of less than US$4 million

(SUPERCIAS, 2021). As of November 2020,

medium-sized manufacturing companies in Pichincha

that had submitted their economic and financial

reports for 2019 totaled 338 (SUPERCIAS, 2020).

To determine the sample size, proportional

sampling was used for a finite population. The

sampling was probabilistic and with equal

probabilities. The selection of companies was done

by simple random sampling, without replacement, to

ensure the greatest representativeness of the sample

(Latpate et al., 2021; Lohr, 2019).

To obtain a representative (n) and adequate

sample of the population, equation 2 (Lohr, 2019; Ott

& Longnecker, 2016) was applied.

𝑛=

𝑍

𝑁𝑝𝑞

𝐸

(

𝑁−1

)

+𝑍

𝑝𝑞

(2)

The parameters used to calculate the sample were:

N = 338 (study population), E = 10 % (sampling error

percentage), Z = 1.96 (95 % confidence level), p = 0.5

(probability of success) and q = 0.5 (probability of

failure). With these parameters it was determined that

n = 75 companies. The study was applied to 142

companies, exceeding the required sample size,

which reduced the sampling error to 6 % and

maintained the confidence level at 95 %.

3.2 Data Collection

Data collection was carried out by means of a survey

addressed to the top managers of the companies

included in the study sample. A closed-ended

questionnaire was used to evaluate 85 items

distributed in two main sections. The KM is

represented by 35 variables grouped into seven

factors, while the efficiency of the companies is

represented by four variables, as detailed in Tables 1

and 2.

This questionnaire was subjected to content

validation by experts, considering four categories:

coherence, relevance, clarity and sufficiency of the

questions. To ensure these qualities, a pilot test was

conducted with the participation of ten experts from

academia and industry. Based on the validation and

the comments received, the suggested improvements

were incorporated and the final version of the

questionnaire was prepared.

To respond to the questionnaire, company

managers were asked to rate each of the items using

the psychometric instrument called Likert scale

(Bertram, 2018). A 10-point scale was used, with 1

representing very low agreement and 10 representing

very high agreement with the argument presented in

each item.

The surveys were conducted using a Google form,

applied electronically from June to September 2021.

A total of 250 questionnaires were sent by e-mail to

the companies that were the subject of the study. Each

survey complied with ethical research standards:

informed consent, voluntary participation,

confidentiality and absence of physical or

psychological risk to participants.

Evaluation of the Contribution of Knowledge Management to Efficiency in the Manufacturing Industry Through Machine Learning

51

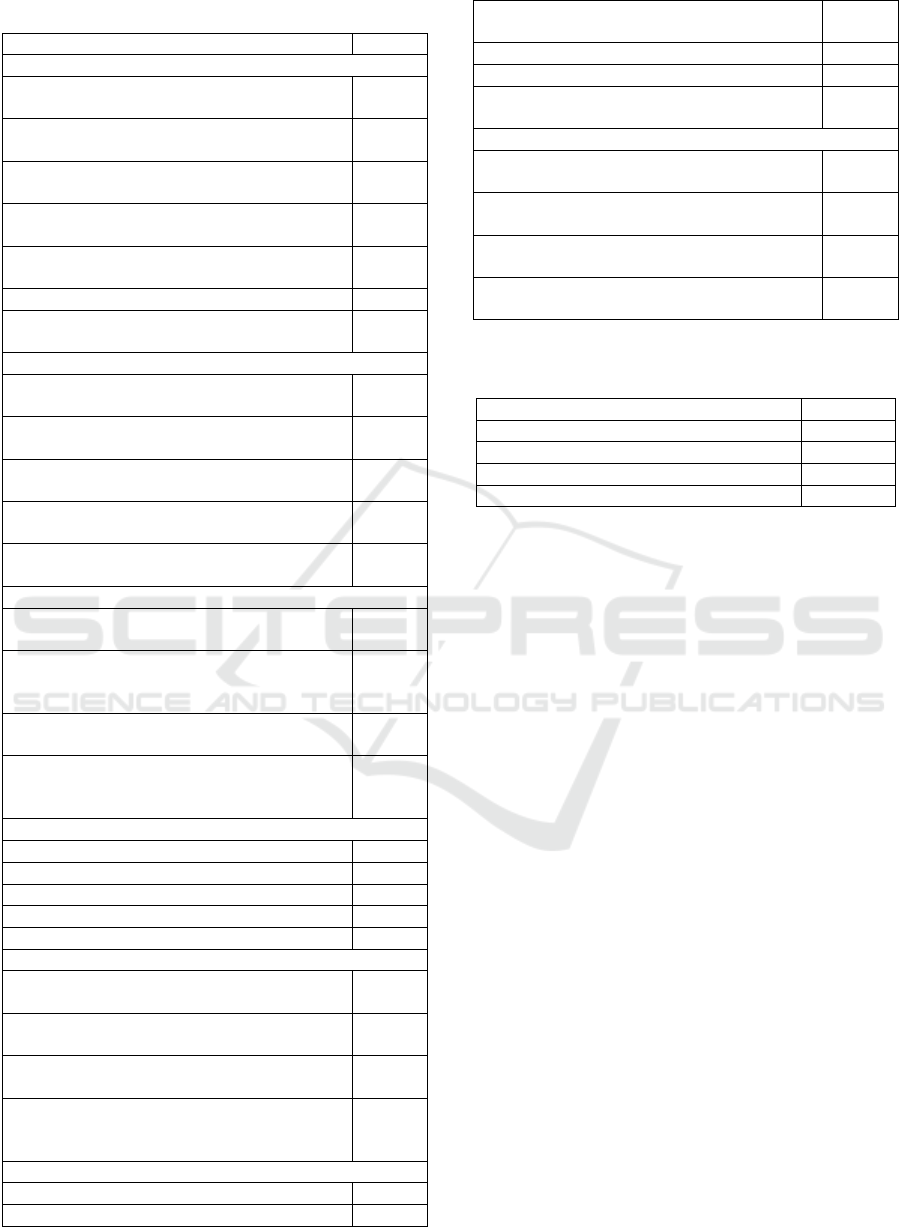

Table 1: Knowledge management factors and variables.

Knowled

g

e mana

g

ement variables Notation

Policies and strate

g

ies (PS)

Policies for the acquisition and generation of

organizational knowledge.

PS1

Policies for the storage, sharing and use of

knowledge organizational.

PS2

Implementation of properly documented

p

rocesses,

p

rocedures and routines

PS3

Establishment of alliances with public and

p

rivate organizations.

PS4

Development of dynamic plans to overcome

internal and external

b

arriers.

PS5

Permanent focus on continuous improvement. PS6

Systematic combination of existing and new

knowledge.

PS7

Organizational structure (OS)

Internal organizational structures dedicated to

research and develo

p

ment.

OS1

Regulations established for the access and use

of knowled

g

e.

OS2

Agility in the processes to access

organizational knowledge.

OS3

Facilities for the horizontal flow of knowledge

within the organization.

OS4

Facilities for the vertical flow of knowledge

within the or

g

anization.

OS5

Technolo

gy

(TG)

Use of technology for the methodical storage

of knowled

g

e.

TG1

Use of information systems for accessing,

sharing and utilizing the organizational

knowled

g

e.

TG2

Application of ICT for access, exchange and

use of knowled

g

e.

TG3

Utilization of corporate social networks for

collaboration and knowledge of the

environment.

TG4

Persons (PP)

Years of employee experience. PP1

Employees' level of education. PP2

Age of employees. PP3

Forei

g

n lan

g

ua

g

e

p

roficienc

y

of em

p

lo

y

ees. PP4

Gender diversit

y

amon

g

em

p

lo

y

ees. PP5

Incentive s

y

stems (IS)

Economic incentives for generating, sharing

and usin

g

knowled

g

e.

IS1

Training offered as an incentive for

generating, sharing and using the knowledge.

IS2

Days off granted as an incentive for

generating, sharing, and using the knowledge.

IS3

Public recognition as an incentive for

generating, sharing and utilizing the

knowledge.

IS4

Organizational culture (OC)

Im

p

ortance of

p

ersonal values. OC1

Positive attitude towards work. OC2

Respect for the company's principles and

re

g

ulations.

OC3

A

pp

lication of best

p

ractices. OC4

Staff em

p

owerment for decision makin

g

. OC5

Creation of a collaborative and synergistic

work environment.

OC6

Communication (CM)

Formal communication in the work

environment.

CM1

Informal communication in the work

environment.

CM2

Effective communication with all hierarchical

levels.

CM3

Fluent communication in physical and virtual

s

p

aces.

CM4

Note: ICT: Information and communication technologies.

Table 2: Efficiency variables.

Efficiency variables Notation

Reduced

p

roduction and marketin

g

costs. CS1

A

pp

lication of best

p

ractices. CS2

Reduced

p

roduct deliver

y

time. CS3

Increased benefit/cost ratio. CS4

3.3 Data Exploration and Preparation

Exploratory data analysis is a crucial phase in the

modeling process in machine learning, as it provides

valuable information about the nature and quality of

the data (Costa-Climent et al., 2023). This phase is

essential because its results can influence the

decisions made during the modeling process and

improve the effectiveness and interpretation of the

resulting models. In this research, the variables used

in supervised learning correspond to KM factors and

efficiency factors. In all cases, the variables are

quantitative.

The algorithm chosen to relate the KM variables

(inputs) to the efficiency variables (output) was

multiple linear regression. Since the responses to each

question range from 1 to 10, no outliers were found.

Therefore, no histograms, boxplots or scatter plots

were performed to visualize the distribution of the

data and detect possible outliers.

The relationships between each of the variables

that make up the seven KM factors were explored to

detect multicollinearity of the independent variables.

Multicollinearity occurs when two or more

independent variables in a model are highly

correlated with each other (Lantz, 2023). The

presence of multicollinearity can cause several

problems in regression analysis, including instability

in coefficient estimation, increased coefficient

variance, and unreliable coefficients.

KMIS 2024 - 16th International Conference on Knowledge Management and Information Systems

52

The correlation between the independent

variables made it possible to eliminate those with a

correlation coefficient greater than 0.7. These ten

variables were: PS1, PS6, OS3, TG1, TG2, OC2,

OC3, OC4, OC6, CM4; thus leaving 25 variables

corresponding to the KM for the analysis.

3.4 Data Modeling and Analysis

The approach chosen for the model in this research is

supervised machine learning. Supervised models are

those in which a machine learning model is trained

and fit with labeled data, i.e., known quantities

(Burger, 2018).

To evaluate the impact of KM on manufacturing

efficiency, a multiple linear regression model was

chosen. This model was selected for several reasons.

First, due to the nature of the data, since all variables

are quantitative. Second, the amount of data available

facilitates the application of the proposed model. The

model is represented by equation 3.

𝑌=

𝑓

(

𝑋

)

+𝜀 =𝛽

+𝛽

𝑋

+𝛽

𝑋

+⋯+𝛽

𝑋

+𝜀

(3)

The impact of the KM factors on four variables

related to efficiency was evaluated. For this reason,

four multiple linear regression models were

developed and are described in Table 3.

Table 3: Multiple linear regression models.

Model Y X

1 Y1= CS1

PS2, PS3, PS4, PS5, PS7

OS1, OS2, OS4, OS5

TG3, TG4

PP1, PP2, PP3, PP4, PP5

IS1, IS2, IS3, IS4

OC1, OC5

CM1, CM2, CM3

2 Y2= CS2

3 Y3= CS3

4 Y4= CS4

3.5 Training, Validation, Evaluation

and Adjustment

The database used contains 142 records and 31

variables, of which 25 are associated with KM and

four with efficiency. All variables are quantitative. To

evaluate the performance of the predictive model, the

data were divided into two subsets: training data (80

%) and test data (20 %).

Cross-validation is a technique used in machine

learning and statistics to evaluate the performance of

a predictive model. It consists of dividing the data set

into multiple training and test subsets, training and

evaluating the model on different combinations of

these subsets (Boehmke & Greenwell, 2020). In this

study, the K-fold technique with ten divisions (folds)

was used. This subdivision allowed obtaining more

stable estimates of the model performance, providing

a more robust evaluation by averaging the results

across the different data splits.

A recipe was used to define a set of preprocessing

steps that were applied to the data sets prior to

modeling. This recipe served as a template for data

preprocessing. Next, a workflow was created to

model the MLR, integrating the MLR model and the

preprocessing steps defined in the recipe, allowing to

train and evaluate the model in an integrated and

consistent way.

Model validation was performed using the root

mean squared error (RMSE) value, which measures

the level of dispersion of the residual values and

calculates the square root of the mean value of the

squared difference between the actual and predicted

value for all data points. The RMSE is calculated as

the square root of the mean of the squared errors

between the model predictions and the actual values

in the test set (Kuhn & Silge, 2022).

The RMSE formula is given in equation 4.

𝑅𝑀𝑆𝐸=

∑

(𝑦

𝑦

)

𝑛

(4)

Where n is the number of observations in the test

set,

𝑦𝑖

are the actual values of the dependent variable

and

𝑦

̂

𝜄

are the model predictions for the dependent

variable. A model performs well the lower the RMSE

value and the closer this value resembles the value

obtained between the training and test data (Kuhn &

Silge, 2022). Both modeling and data analysis were

performed using the RStudio programming language.

4 RESULTS

4.1 Relationship Between KM and

Reduction of Production and

Marketing Costs

The relationship between KM and cost reduction was

evaluated using a multiple linear regression model

CS1 = f (X)+ℇ. Table 4 shows that three KM variables

belonging to the factors of organizational structure,

incentive system and communication are significant

and have a direct relationship with cost reduction.

These results indicate that the model is viable.

Evaluation of the Contribution of Knowledge Management to Efficiency in the Manufacturing Industry Through Machine Learning

53

Table 4: KM variables that impact cost reduction.

KM variable Coefficient Pr(>|t|)

OS4 0.281 0.022

IS1 0.241 0.026

CM2 0.261 0.008

R

2

= 0.575, F = 4.61, p-value model = 6.1e-08

Notes:

OS4: Facilities for the horizontal flow of knowledge within

the organization, IS1: Economic incentives for generating,

sharing and using knowledge, CM2: Informal

communication in the work environment. Pr(>|t|):

Significance statistic of variable X, R

2

: Coefficient of

determination, F: Model relationship assessment statistic, p:

Significance statistic of the results.

The statistical results of the model indicate that it

is significant and viable as a whole. The model is

represented by the following function: CS1= 0.28

OS4 + 0.24 IS1 + 0.26 CM2.

The RMSE of the best model with the training

data is 2.79, a value similar to that obtained with the

test data, which is a positive sign that the model is

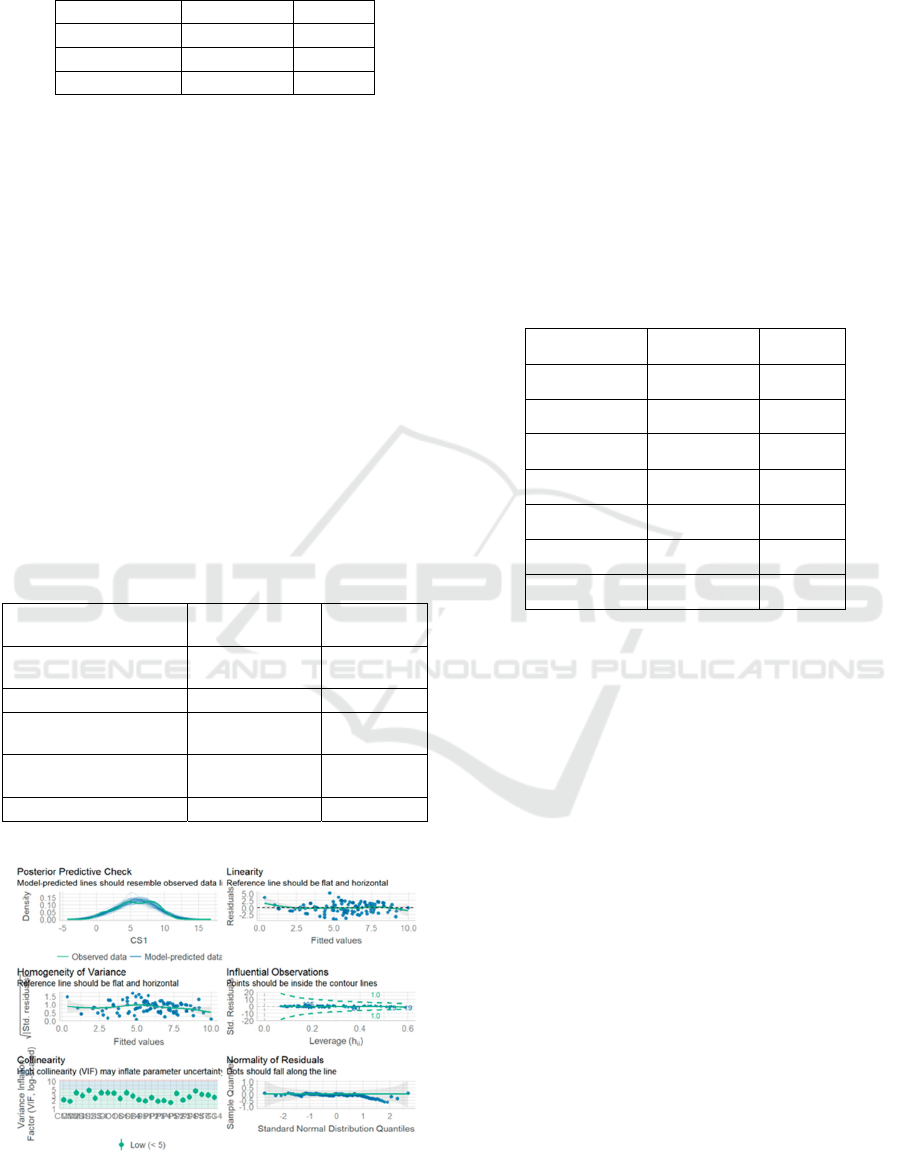

robust and has good generalizability. Table 5 reviews

the statistical assumptions of the model, while Figure

3 shows these results graphically.

Table 5: Statistical assumptions.

Supposed Value

obtained

Evaluation

Normality

of waste

p = 0.681

Ok.

Heteroscedasticity

p = 0.243

Ok.

Autocorrelated

residuals

p = 0.001

Warning

Multicollinearity All variables

<5

Low

Correlation

Outliers

None

OK

Note: Statistics obtained from RSudio.

Figure 3: Graphs of statistical assumptions.

Note: Image obtained from RSudio.

4.2 Relationship Between KM and the

application of best practices

The relationship between KM and the application of

best practices is evaluated using the multiple

regression model CS2 = f (X)+ℇ. Table 6 shows that

six knowledge management variables belonging to

factors such as technology, incentive system,

organizational culture and communication are

significant, and have a direct relationship with the

application of best practices. These results indicate

that the model is viable.

Table 6: KM variables impacting the application of best

practices.

KM variable Coefficient Pr(>|t|)

Intercept -1.643 0.039

TG3 0.284 0.017

TG4 0.183 0.025

IS1 0.214 0.011

OC5 0.309 0.006

CM2 0.244 0.001

CM3 0.393 0.000

R

2

= 0.728, F = 9.3, p-value model = 1.75e-15

Notes:

TG3: Application of ICT for access, sharing and use of

knowledge, TG4: Use of corporate social networks for

collaboration and leveraging knowledge of the

environment, IS1: Economic incentives for generating,

sharing and using knowledge, OC5: Empowerment of staff

for decision making, CM2: Informal communication in the

work environment, CM3: Effective communication with all

hierarchical levels, Pr(>|t|): Significance statistic of the

variable X, R

2

: Coefficient of determination, F: Model

relationship evaluation statistic, p: Significance statistic of

the results.

The statistical results of the model indicate that it

is significant and viable as a whole. The model is

represented by the function: CS2 = -1.64306 + 0.28

TG3 + 0.18 TG4 + 0.21 IS1 + 0.31 OC5 + 0.24 CM2

+ 0.39 CM3.

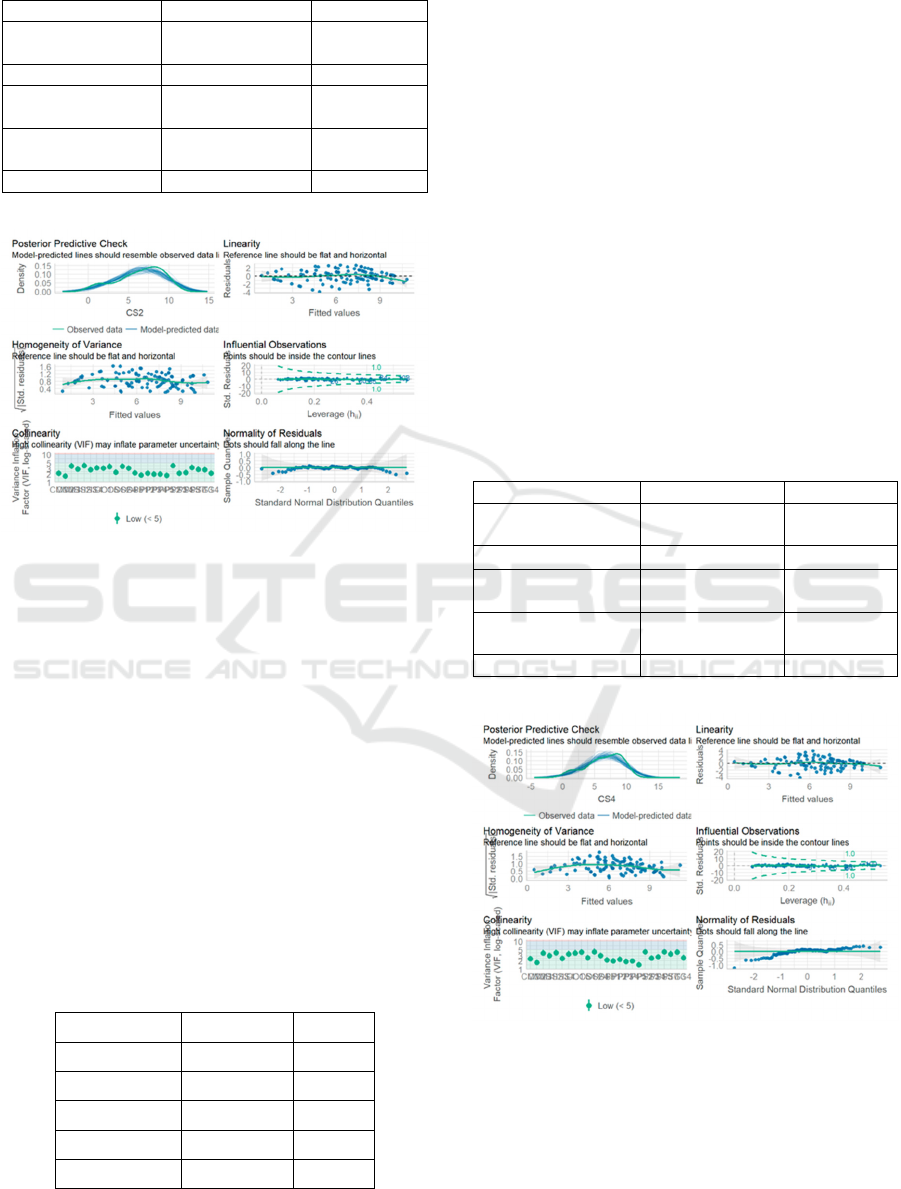

The RMSE of the best model with the training

data is 2.25, a value similar to that obtained with the

test data. This coincidence is a positive sign that the

model is robust and has good generalizability. Table

7 shows the statistical assumptions of the model,

while Figure 4 shows these results graphically.

KMIS 2024 - 16th International Conference on Knowledge Management and Information Systems

54

Table 7: Statistical assumptions.

Su

pp

osed Value obtained Evaluation

Normality

of waste

p = 0.433 Ok

Heteroscedasticity

p

= 0.405 O

k

Autocorrelated

residuals

p = 0.002 Warning

Multicollinearity All variables <5 Low

Correlation

Outliers None O

K

Note: Statistics obtained from RSudio.

Figure 4: Graphs of statistical assumptions.

Note: Image obtained from RSudio.

4.3 Relationship Between KM and

Reduction of Product Lead Time

The relationship between KM and product lead time

reduction is evaluated using the multiple regression

model CS3 = f (X)+ℇ. Table 8 shows that four KM

variables belonging to the factors: organizational

structure, organizational culture and communication

are significant and have a direct relationship with the

reduction of product lead time. Additionally, one

variable belonging to the policies and strategies

category is shown to have a significant and indirect

relationship. The results indicate that the model is

viable.

Table 8: KM variables impacting product lead time

reduction.

KM variable Coefficient Pr(>|t|)

PS2 -0.378 0.003

OS4 0.223 0.046

OC1 0.234 0.049

CM1 0.314 0.006

CM2 0.309 0.000

R

2

= 0.677, F = 7.11, p-value model = 3.46e-12

Notes:

PS2: Policies for the storage, sharing and use of

organizational knowledge, OS4: Facilities for the

horizontal flow of knowledge within the organization, OC1:

Importance of personal values, CM1: Formal

communication in the work environment, CM2: Informal

communication in the work environment, Pr(>|t|):

Significance statistic of variable X, R

2

: Coefficient of

determination, F: Model relationship evaluation statistic, p:

Significance statistic of the results.

The statistical results of the model indicate that it

is significant and viable as a whole. The model is

represented by the function: CS3 = -0.38 PS2 + 0.22

OS4 + 0.23 OC1 + 0.31 CM1 + 0.31 CM2.

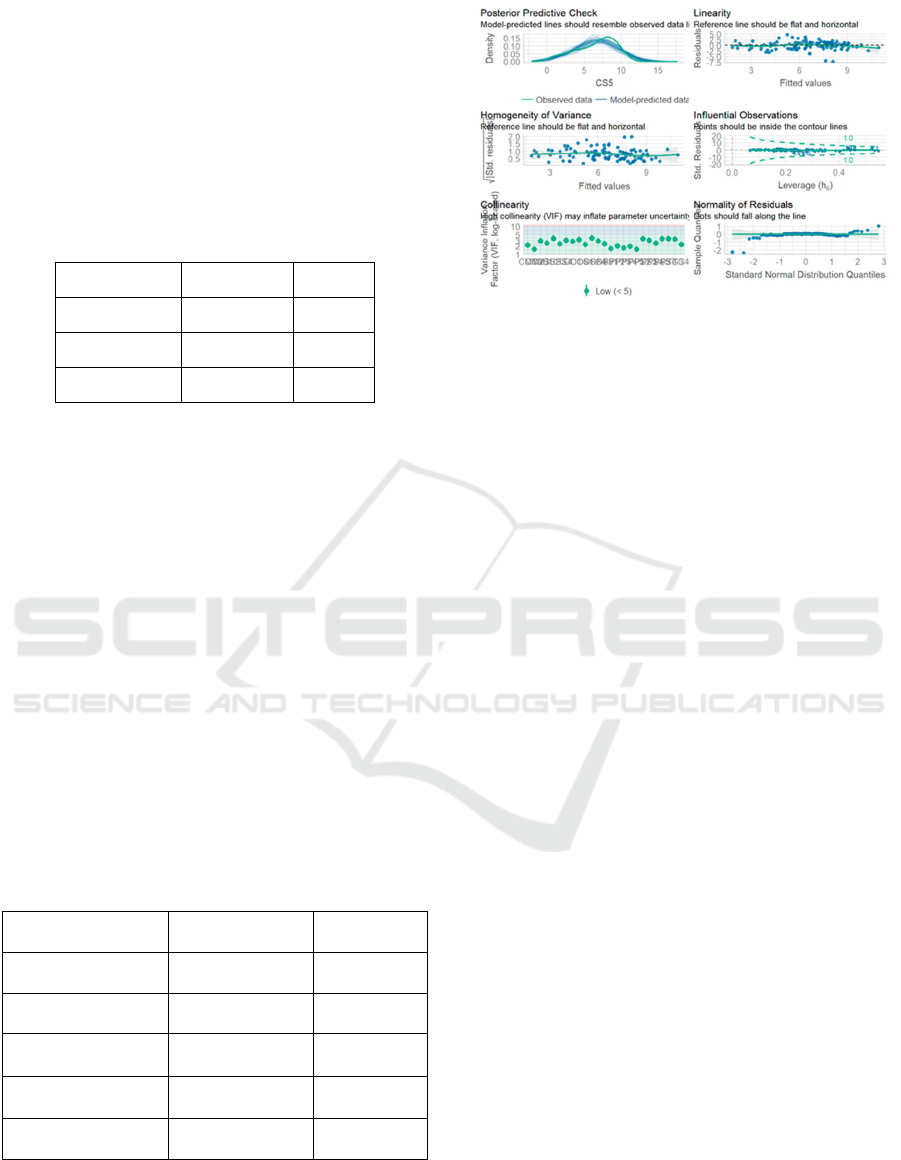

The RMSE of the best model with the training

data is 2.93, a value similar to that obtained with the

test data. This coincidence is a positive sign that the

model is robust and has good generalizability. Table

9 reviews the statistical assumptions of the model,

while Figure 5 shows these results graphically.

Table 9: Statistical assumptions.

Su

pp

osed Value obtained Evaluation

Normality

of waste

p = 0.386

Ok

Heteroscedasticity

p

= 0.134

Ok

Autocorrelated

residuals

p = 0.001

Warning

Multicollinearity All variables <5 Low

Correlation

Outliers None O

K

Note: Statistics obtained from RSudio.

Figure 5: Analysis of statistical assumptions.

Note: Image obtained from RSudio.

4.4 Relationship Between KM and

Increase in Benefit/Cost Ratio

The relationship between KM and the increase in the

benefit/cost ratio is evaluated using the multiple

Evaluation of the Contribution of Knowledge Management to Efficiency in the Manufacturing Industry Through Machine Learning

55

regression model CS4 = f (X)+ℇ. Table 10 shows that

two KM variables belonging to the factors: persons

and communication are significant and have a

significant and direct relationship with the increase in

the benefit/cost ratio. Additionally, it is shown that

one variable belonging to the policies and strategies

category has a significant and indirect relationship.

These results indicate that the model is viable.

Table 10: KM variables that have an impact on the increase

in benefit/cost ratio.

KM variable Coefficient Pr(>|t|)

PS2 -0.305 0.038

PP5 0.171 0.040

CM2 0.229 0.009

R

2

= 0.548, F = 4.18, p-value model = 3.76e-12

Notes:

PS2: Policies for the storage, sharing and use of

organizational knowledge, PP5: Development of dynamic

plans to overcome internal and external barriers, CM2:

Informal communication in the work environment, Pr(>|t|):

Significance statistic of variable X, R

2

: Coefficient of

determination, F: Model relationship evaluation statistic, p:

Significance statistic of the results.

The statistical results of the model indicate that it

is significant and viable as a whole. The model is

represented by the function: CS4 = -0.31 PS2 + 0.17

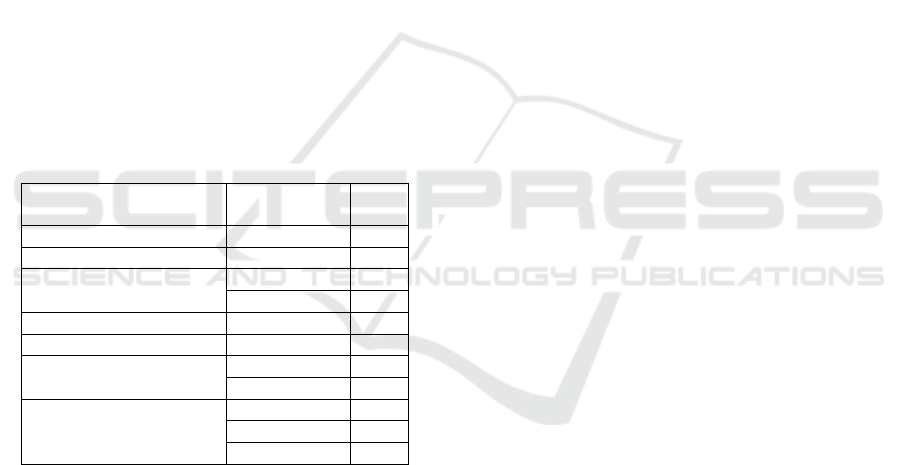

PP5 + 0.23 CM2. The RMSE of the best model with

the training data is 2.49, a value similar to that

obtained with the test data. This coincidence is a

positive sign that the model is robust and has good

generalizability. Table 11 reviews the statistical

assumptions of the model, while Figure 6 shows these

results graphically.

Table 11: Statistical assumptions.

Supposed Value obtained Evaluation

Normality of waste

p = 0.001

Warning

Heteroscedasticity

p = 0.943

Ok

Autocorrelated

residuals

p = 0.001

Warning

Multicollinearity All variables <5

Low

Correlation

Outliers None OK

Note: Statistics obtained from RSudio.

Figure 6: Analysis of statistical assumptions.

Note: Image obtained from RSudio.

5 DISCUSSION

Through the machine learning developed in this

research, it has been shown that the presence of

certain KM variables in business organizations can

predict efficiency in operational management.

Multiple linear regression was used to describe the

relationship between a target variable and a set of

explanatory characteristics, and to use this

relationship to predict the value of the target variable.

Evaluating the relationship between KM and the

reduction of production and marketing costs, the

MLR model showed that facilities for the horizontal

flow of knowledge within the organization, economic

incentives for generating, sharing and using

knowledge, and informal communication in the work

environment have a positive and significant impact on

cost reduction in manufacturing companies.

Regarding the relationship between KM and the

use of best practices, the results show that the

application of ICT, the use of social networks,

economic incentives to personnel, the empowerment

of personnel in decision making, and effective and

informal communication at all hierarchical levels

have a positive impact on the use of good practices in

the industrial sector.

Evaluating the relationship of KM with product

lead time reduction, it was shown that the level of

employee education, facilities for horizontal

knowledge flow within the organization, the

importance of personal values, and formal and

informal communication have an impact on the

optimization of product lead time.

Regarding the relationship between KM and the

increase in the benefit/cost ratio, it was shown that the

level of employee education, the development of

KMIS 2024 - 16th International Conference on Knowledge Management and Information Systems

56

dynamic plans to overcome internal and external

barriers, and informal communication in the work

environment have a direct impact on this relationship

in manufacturing companies.

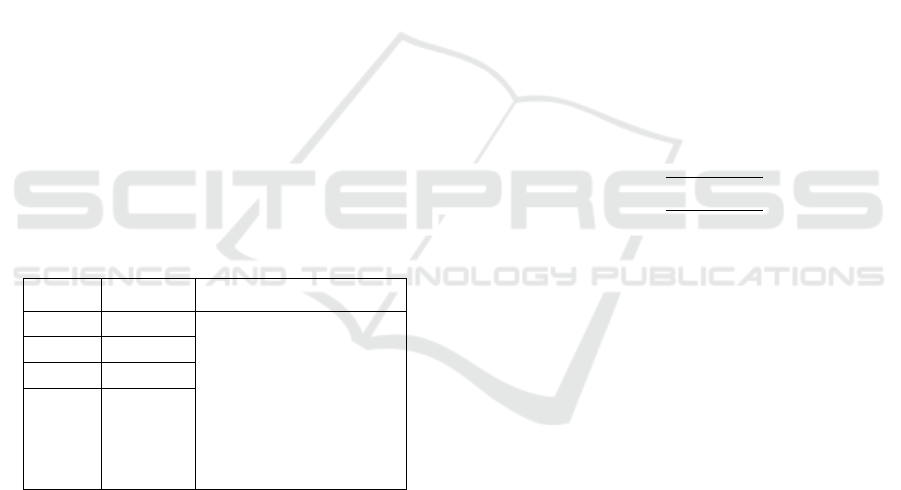

Table 12 shows that of the 35 KM variables

distributed in seven factors, 11 variables have a

significant impact on the efficiency of manufacturing

companies. In addition, the number of times these

variables appear in the models is shown. The KM

factor that contributes most to efficiency is

communication, followed by policies and strategies,

organizational structure, technology, incentive

systems, and organizational culture. The factor that

does not yet contribute substantially to KM is

persons.

The results obtained with each of the models are

consistent with the assertion that KM directly leads to

a reduction in operating costs (Piening & Salge, 2015)

and contributes to the development of innovations

(OECD & Eurostat, 2018). In addition, KM provide

more efficient and effective management of

companies, allowing informed decisions to be made

to meet customer needs by analyzing large data sets

(Hemachandran & Rodriguez, 2024).

Table 12: KM factors impacting efficiency.

Factors Significant

variables

n

Policies an

d

strate

g

ies PS2 2

Or

g

anizational structure OS4 2

Technology TG3 1

TG4 1

Persons PP5 1

Incentive s

y

ste

m

IS1 2

Organizational

culture

OC1 1

OC5 1

Communication CM1 1

CM2 3

CM3 1

Notes: n: Number of times the variables are present in the

models studied.

5.1 Theoretical Implications

Among the theoretical implications of this research, it

was determined that there are key factors related to

KM that impact the efficiency of companies. Of the

35 initial variables, 11 were found to be the most

influential on the efficiency of manufacturing

companies. This shows that the efficiency of

companies depends on a set of variables related to the

broad concept of knowledge management.

In the manufacturing industry it has been

concluded that all factors associated with KM should

be taken into account.

However, there are factors such as

communication, policies and strategies,

organizational structure, technology, personnel

incentives and organizational culture that are relevant

in predicting the efficiency of companies.

5.2 Practical Implications

The main practical contribution of this research lies

in the identification of the relevant factors of KM that

impact the efficiency of manufacturing companies.

This allows strategic decisions focused on cost

optimization, the application of best practices, the

reduction of product delivery time, and the

benefit/cost ratio.

By identifying these factors, companies can make

informed decisions in real time to focus on efficient

industrial processes by intervening in specific KM

variables. Learning from existing data will enable

companies to design solutions based on solid

information, aimed at solving efficiency problems.

In addition, these informed decisions will enable

companies:

• Design effective policies and strategies.

• Invest in appropriate technology.

• To optimally manage its human talent.

• Create motivating incentive policies.

• Establish beneficial strategic alliances.

• Modify its organizational structure to

improve efficiency.

These substantial components of KM, discussed

in this study, provide a practical framework for

manufacturing companies to improve their

operational efficiency and competitiveness in the

marketplace.

6 CONCLUSIONS

The purpose of this study was to design and develop

a series of machine learning models for predictive

analysis of the identification of operationally efficient

industries from the application of practices associated

with knowledge management. Multiple linear

regression models were used to demonstrate the

impact of KM in predicting company efficiency.

In each model the independent variables represented

the KM, and the dependent variables represented the

operating efficiency of the companies. After

eliminating correlated variables, 25 variables

associated with KM factors were used: policies and

strategies, organizational structure, technology,

persons, incentive system, organizational culture and

Evaluation of the Contribution of Knowledge Management to Efficiency in the Manufacturing Industry Through Machine Learning

57

communication. The variables related to efficiency

included cost reduction, application of best practices,

reduction of delivery time, and increase in the

benefit/cost ratio.

Four models were developed and 11 KM variables

were found to significantly impact the efficiency of

manufacturing companies. The KM factors that

contribute most to efficiency are policies and

strategies, organizational structure, technology,

incentive systems, and organizational culture.

Consequently, it has been shown that the application

of certain KM factors in organizations can predict

their efficiency and improve organizational

performance. These findings underscore the

importance of KM as a strategic tool for improving

operational efficiency in manufacturing companies,

providing a practical framework for informed

decision making and the implementation of effective

business practices.

6.1 Limitations and Future Studies

One of the limitations of this study is that knowledge

management is a relatively new topic for the

management of Ecuadorian business organizations.

To mitigate this limitation, the surveys included

sufficient introductory information to facilitate

respondents understanding and response to the

questionnaire.

The results of this research highlight the relevance

of KM in various aspects of business management

and provide a solid foundation for future research. It

is recommended that further studies explore the

impact of KM in areas such as the use of new

technologies, innovation, resilience, and business

sustainability, among others. These studies could

delve deeper into how KM can contribute more

comprehensively to improving the efficiency and

performance of manufacturing firms in Ecuador.

REFERENCES

Akerkar, R. (2019). Artificial Intelligence for Business.

Springer. https://doi.org/10.1007/978-3-319-97436-1_3

Albornoz, M. (2009). Indicadores de innovación: las

dificultades de un concepto en evolución. CTS: Revista

Iberoamericana de Ciencia, Tecnología y Sociedad,

5(13), 9–25. https://www.redalyc.org/articulo.oa?id=92

415269002

Andreini, D., & Bettinelli, C. (2017). Business Model

Innovation. From Systematic Literature Review to

Future Research Directions. In International Series in

Advanced Management Studies. Springer.

https://doi.org/10.1007/978-3-319-53351-3

Anshari, M., Syafrudin, M., Tan, A., Fitriyani, N., & Alas, Y.

(2023). Optimisation of Knowledge Management (KM)

with Machine Learning (ML) Enabled. Information

(Switzerland), 14(1), 1–15. https://doi.org/10.3390/in

fo14010035

Bertram, D. (2018). Likert Scales. http://poincare.matf.b

g.ac.rs/~kristina/topic-dane-likert.pdf

Bhupathi, P., Prabu, S., & Goh, A. P. I. (2023). Artificial

Intelligence-Enabled Knowledge Management Using a

Multidimensional Analytical Framework of

Visualizations. International Journal of Cognitive

Computing in Engineering, 4(January), 240–247.

https://doi.org/10.1016/j.ijcce.2023.06.003

Boehmke, B., & Greenwell, B. (2020). Hands-On Machine

Learning with R. Taylor & Francis.

Bolisani, E., & Bratianu, C. (2018). Generic Knowledge

Strategies. In Emergent Knowledge Strategies (4th ed.,

Vol. 4, Issue July, pp. 147–174). Springer.

https://doi.org/10.1007/978-3-319-60657-6

Burger, S. (2018). Introduction to machine learning with R :

rigorous mathematical analysis.

Cachanosky, I. (2012). Eficiencia técnica, eficiencia

económica y eficiencia dinámica. Procesos de Mercado:

Revista Europea de Economía Política, IX(2), 51–80.

Costa-Climent, R., Haftor, D. M., & Staniewski, M. W.

(2023). Using machine learning to create and capture

value in the business models of small and medium-sized

enterprises. International Journal of Information

Management, 73(January), 102637. https://doi.org/10.10

16/j.ijinfomgt.2023.102637

Davenport, T. H., & Prusak, L. (1998). Knowledge

Generation. In Working Knowledge: How Organizations

Manage What They Know (p. 226). Harvard Business

School Press.

Endres, H. (2018). Frameworks and Theories around

Dynamic Capabilities. In Adaptability Through Dynamic

Capabilities: How Management Can Recognize

Opportunities and Threats (pp. 13–28). Springer Gabler.

https://doi.org/10.1007/978-3-658-20157-9

Hastie, T., Tibshirani, R., James, G., & Witten, D. (2023). An

Introduction to Statistical Learning. In Springer Texts

(2nd ed., Vol. 102).

Hemachandran, K., & Rodriguez, R. (2024). Artificial

intelligence for business: An implementation guide

containing practical and industry-specific case studies. In

Artificial Intelligence for Business: An Implementation

Guide Containing Practical and Industry-Specific Case

Studies (1st ed.). Routledge. https://doi.org/10.4324/9

781003358411

Ibujés-Villacís, J., & Franco-Crespo, A. (2022). Determinant

factors of innovation management in the manufacturing

industry of Pichincha , Ecuador. Journal of Technology

Management & Innovation, 17(1), 50–70.

https://doi.org/10.4067/S0718-27242022000100050

Ibujés-Villacís, J., & Franco-Crespo, A. (2023a). La

eficiencia como indicador de innovación. El caso de las

compañías de manufactura en Pichincha, Ecuador.

Revista Innovar, 33. https://doi.org/10.15446/

innovar.v33n89.107039

KMIS 2024 - 16th International Conference on Knowledge Management and Information Systems

58

Ibujés-Villacís, J., & Franco-Crespo, A. (2023b).

Relationship between Productivity and Efficiency with

Sustainable Development Goals: The Case of the

Manufacturing Industry in Pichincha, Ecuador. Revista

de Métodos Cuantitativos Para La Economía y

Empresas, 35, 34–56. https://doi.org/10.46661/revmetod

oscuanteconempresa.5475

Ibujés-Villacís, J., & Franco-Crespo, A. A. (2019). Use of

ICT and its relationship with the Objectives of

Sustainable Development in Ecuador. RETOS. Revista de

Ciencias de La Administración y Economía, 9(17), 37–

53. https://doi.org/10.17163/ret.n17.2019.03

Kaur, V. (2019). Review of Literature. In Knowledge Based

Dynamic Capabilities. The Road Ahead in Gaining

Organizational Competitiveness (pp. 21–78). Springer.

https://doi.org/10.1007/978-3-030-21649-8

Kuhn, M., & Silge, J. (2022). Tidy Modelling with R (1st ed.).

O’Reilly Media, Inc. https://www.tmwr.org/

Lantz, B. (2023). Machine Learning with R (4th ed., Vol. 4,

Issue 1). Packt Publishing Pvt Ltd. www.packt.com

Latpate, R., Kshirsagar, J., Kumar Gupta, V., & Chandra, G.

(2021). Simple Random Sampling. In Advanced

Sampling Methods (pp. 11–36). Springer.

https://doi.org/10.1007/978-981-16-0622-9

Lohr, S. L. (2019). Simple Probability Samples. In Sampling.

Design and Analysis (2nd ed., pp. 25–72). CRC Press.

Manning, M. J., & Manning, M. S. (2020). Knowledge

Assets Management. In Total Innovative Management

Excellence (TIME). The Future of Innovation (pp. 354–

398). CRC Press.

MIPRO. (2021). Cifras de industrias. In Gobierno del

Ecuador. https://www.produccion.gob.ec/wp-content/

uploads/2021/06/Presentación-Industria-Junio-2021.pdf

Newell, S. (2015). Managing knowledge and managing

knowledge work: What we know and what the future

holds. Journal of Information Technology, 30(1), 1–17.

https://doi.org/10.1057/jit.2014.12

North, K., & Kumta, G. (2018). Knowledge in Organisations.

In Knowledge Management. Value Creation Through

Organizational Learning (2nd ed., pp. 33–66). Springer.

http://www.springer.com/series/10099

OECD, & Eurostat. (2018). Oslo Manual 2018: Guidelines

for Collecting, Reporting and Using Data on Innovation

(4th ed., Issue October). OECD. https://doi.org/

10.1787/9789264304604-en

Ott, R. L., & Longnecker, M. (2016). Inferences About

Population Central Values. In An Introduction to

Statistical Methods & Data Analysis (Seventh, pp. 232–

299). Cengage Learning.

Pagani, M., & Champion, R. (2024). Artificial Intelligence

for Business Creativity. Routledge. https://doi.org/

10.4324/9781003287582

Piening, E. P., & Salge, T. O. (2015). Understanding the

antecedents, contingencies, and performance

implications of process innovation: A dynamic

capabilities perspective. Journal of Product Innovation

Management, 32(1), 80–97. https://doi.org/10.1111/

jpim.12225

Saulais, P., & Ermine, J.-L. (2019). Knowledge Management

in Innovative Companies. Wiley. https://www.ptonline.

com/articles/how-to-get-better-mfi-results

Shmueli, G., Bruce, P., DeoKar, A., & Patel, N. (2023).

Machine Learning for Business Analytics (Vol. 5, Issue

1). Wiley.

SUPERCIAS. (2020). La eficiencia de las empresas

manufactureras en el Ecuador. In Investigación y estudios

sectoriales.

https://investigacionyestudios.supercias.gob.ec/wp-

content/uploads/2020/01/eficienciamanufactura_FINAL

.pdf

SUPERCIAS. (2021). Ranking de compañías.

Superintendencia de Compañías, Valores y Seguros.

https://appscvs.supercias.gob.ec/rankingCias/

Uden, L., Wang, L., Corchado, J., Yang, H.-C., & Ting, I.-H.

(2014). The 8th International Conference on Knowledge

Management in Organizations: Social and Big Data

Computing for Knowledge Management. Springer.

https://doi.org/10.1007/978-94-007-7287-8

Weber, F. (2023). Artificial Intelligence for Business

Analytics: Algorithms, Platforms and Application

Scenarios. In Artificial Intelligence for Business

Analytics: Algorithms, Platforms and Application

Scenarios. Springer. https://doi.org/10.1007/978-3-658-

37599-7

Zanda, S. (2018). The Compatibility of Effectiveness and

Efficiency: The Pillars of Barnard’s Theory of

Cooperation. In Building Efficient Management and

Leadership Practices, Innovation, Technology, and

Knowledge Management (pp. 109–128). Springer.

https://doi.org/10.1007/978-3-319-60068-0_8 109

Evaluation of the Contribution of Knowledge Management to Efficiency in the Manufacturing Industry Through Machine Learning

59