EMG-Based Shared Control Framework for Human-Robot

Co-Manipulation Tasks

Francesca Patriarca

a

, Paolo Di Lillo

b

and Filippo Arrichiello

c

Department of Electrical and Information Engineering, University of Cassino and Southern Lazio,

Via G. Di Biasio 43, 03043 Cassino (FR), Italy

fi

Keywords:

Physical Human-Robot Interaction, Human-Robot Collaboration, Shared Control.

Abstract:

The paper presents a shared control architecture designed for human-robot co-manipulation tasks, that allows

the human to switch among robot’s operational modes through surface electromyography (sEMG) signals

from the user’s arm. A support vector machine (SVM) classifier is employed to process the raw EMG data to

identify two classes of contractions that are fed into a finite state machine algorithm to trigger the activation

of different sets of admittance control parameters corresponding to the envisaged operational modes. The

proposed architecture has been experimentally validated using a Kinova Jaco

2

manipulator, equipped with

Force/Torque sensor at the end-effector, and with a user wearing Delsys Trigno Avanti EMG sensors on the

dominant upper limb.

1 INTRODUCTION

Collaborative robotics involves robotic systems inter-

acting directly with humans in a shared workspace to

complete tasks together, combining the versatility and

decision-making capabilities of human workers with

the precision, strength, and repeatability of robots

and improving task quality and productivity. Intuitive

user interfaces, advanced sensors, and control sys-

tems are crucial for smooth cooperation and safe op-

eration close to humans (Villani et al., 2018). Unlike

industrial robots, collaborative robots (cobots) dy-

namically adapt to people and objects that enter their

workspace (Matheson et al., 2019), without the need

for physical barriers, making them suitable for var-

ious applications like logistics, assembly, and med-

ical procedures (Sladi

´

c et al., 2021). However, de-

veloping effective human-robot teams presents chal-

lenges such as robots situational awareness, clear

communication protocols, and ensuring safety with-

out limiting robot’s speed or motion (Sharifi et al.,

2022). To address these challenges, shared control,

which involves both the robot and the human as ac-

tive parts in the control loop (Abbink et al., 2018),

has emerged as a promising solution in collaborative

robotics by enabling smoother interactions and im-

a

https://orcid.org/0009-0005-5849-6162

b

https://orcid.org/0000-0003-2083-1883

c

https://orcid.org/0000-0001-9750-8289

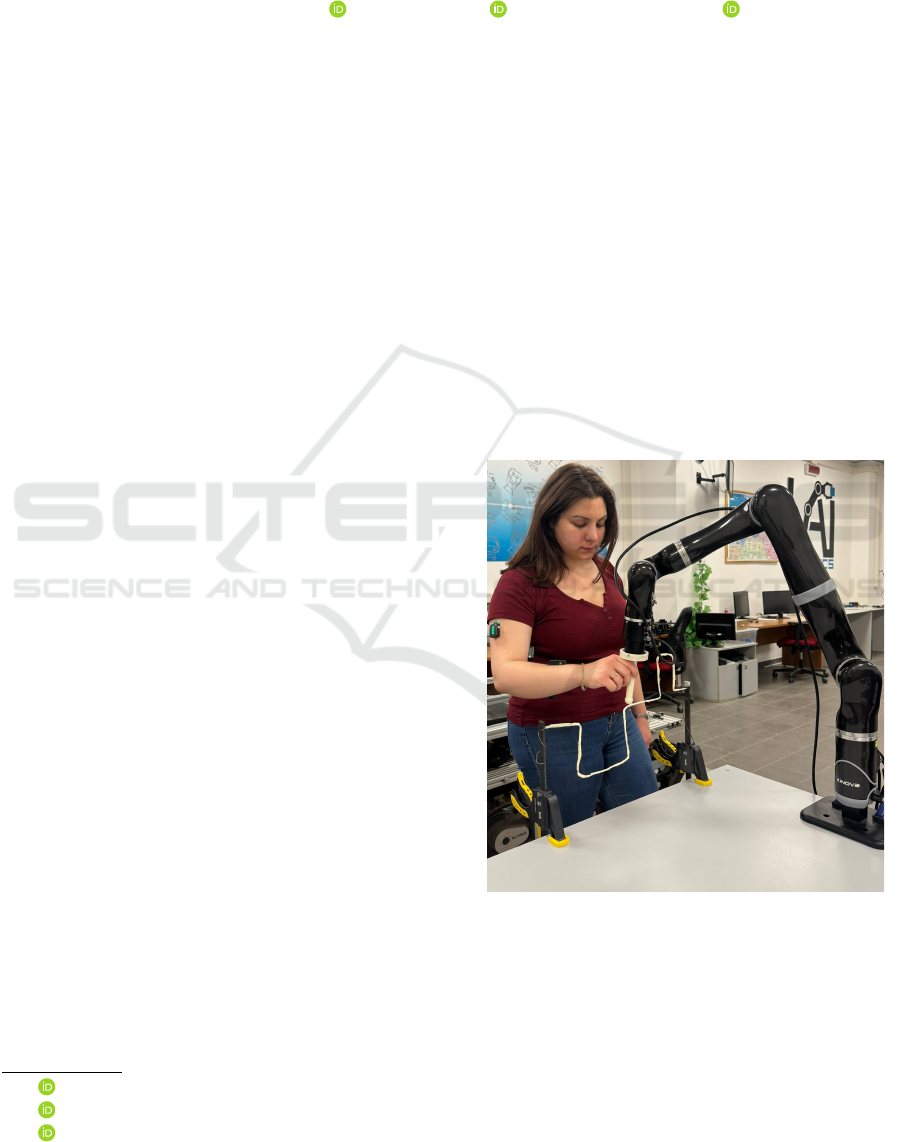

Figure 1: The scenario shows the experimental setup in

which a human operator performs a co-manipulation task

wearing four EMG sensors and using a Jaco

2

manipulator.

proving task efficiency and safety. To achieve this,

impedance/admittance control strategies can be em-

ployed for controlling robots to behave as virtual dy-

namic systems with adjustable impedance parame-

ters (Cacace et al., 2019). This allows the robot to

adapt its compliance and motion synchronization ca-

pabilities to better interact with their environment (Fi-

46

Patriarca, F., Di Lillo, P. and Arrichiello, F.

EMG-Based Shared Control Framework for Human-Robot Co-Manipulation Tasks.

DOI: 10.5220/0012943600003822

In Proceedings of the 21st International Conference on Informatics in Control, Automation and Robotics (ICINCO 2024) - Volume 2, pages 46-53

ISBN: 978-989-758-717-7; ISSN: 2184-2809

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

cuciello et al., 2015). The rates of change of inter-

action force and human arm admittance parameters

can be used to modify the variable admittance param-

eters (Wang and Zhao, 2023); while predicting human

motion trajectories enables robots to anticipate move-

ments and adapt accordingly, optimizing task comple-

tion (Losey and O’Malley, 2018). In order to estimate

user movement intentions, surface electromyography

(sEMG) sensors, which capture muscle electrical ac-

tivity, are essential (Grafakos et al., 2016). These

sensors help to adapt virtual online damping, leading

to the integration of EMG signals with adaptive ad-

mittance control in robotic manipulation, skill learn-

ing, and rehabilitation devices (Gonzalez-Mendoza

et al., 2022). Integration of human motion predic-

tion, adaptation algorithms, and virtual guidance also

enhances the quality of assistance (Li et al., 2022),

as demonstrated in applications like exoskeleton con-

trol (Zhuang et al., 2021). Furthermore, the sEMG

signals also play a crucial role in encoding stiffness

and movement patterns to improve robotic skill learn-

ing and adaptive behavior (Zeng et al., 2021).

This paper presents a shared control architecture

for human-robot co-manipulation tasks that allows the

human operator to dynamically change the robot’s op-

erational mode using sEMG signals from the user’s

arm and hand. These signals are classified by a Sup-

port Vector Machine (SVM) (Hearst et al., 1998)

algorithm, which detects various contractions and

movements. The output of the classifier is then fed

into a finite state machine algorithm, which adjusts

the parameters of a variable admittance controller to

allow for better human-robot interaction. Since the

dynamic behavior of the manipulator is not unique,

managing different types of interactions in a unified

way ensuring optimal co-manipulation experiences is

not easy. Key factors in determining admittance pa-

rameters include the robot’s compliance with forces

applied by human, the fluidity and intuitiveness of

the manual driving experience, and the speed and ac-

curacy of task execution. Lower damping improves

maneuverability but can cause instability or inaccu-

racy, while higher damping enhances precision but

reduces compliance, making co-manipulation more

difficult and slower. Using sEMG signals to adjust

admittance parameters is a novel approach that en-

sures stable robot behavior, contrasting with previ-

ous methods relying on heuristics (Ferraguti et al.,

2019) or specific stable region of parameters for spe-

cific interaction (Ficuciello et al., 2015). Wrench sen-

sor readings make complex to distinguish intentional

operator’s gestures from unintentional collisions be-

cause the user holds the end-effector after the sen-

sor that can not detect the forces between the contact

point and the environment if the forces are exerted

by the user; while integrating musculoskeletal activ-

ity allows to recognize such interactions that would

be indistinguishable otherwise.

The paper presents a shared control architecture

that dynamically changes the variable admittance

controller parameters based on the operator’s EMG

signals to enhance precision in task performance by

reducing downtime, improving human-robot interac-

tions for a more intuitive co-manipulation experi-

ence. The approach’s effectiveness and robustness

have been experimentally validated with a user wear-

ing four sEMG sensors on his/her dominant upper

limb and using a 7DOF manipulator equipped with

a Force/Torque sensor for admittance control, despite

not being torque-controlled.

2 SHARED CONTROL

ARCHITECTURE

The proposed architecture includes two possible op-

erational modes:

• Low-Damping mode: hand-guidance of the end-

effector in the free space to allow the operator to

move the end-effector, e.g., to reach a workpiece;

• High-Damping mode: hand-guidance of the end-

effector near a surface or a workpiece to perform

operations such as welding or painting.

To achieve this, the gains of the admittance con-

troller of the manipulator are changed between two

sets corresponding to each operational mode. A fi-

nite state machine algorithm handles the switching

between these sets based on the movements or con-

tractions of the operator’s arm, which are recognized

through an EMG-based classifier.

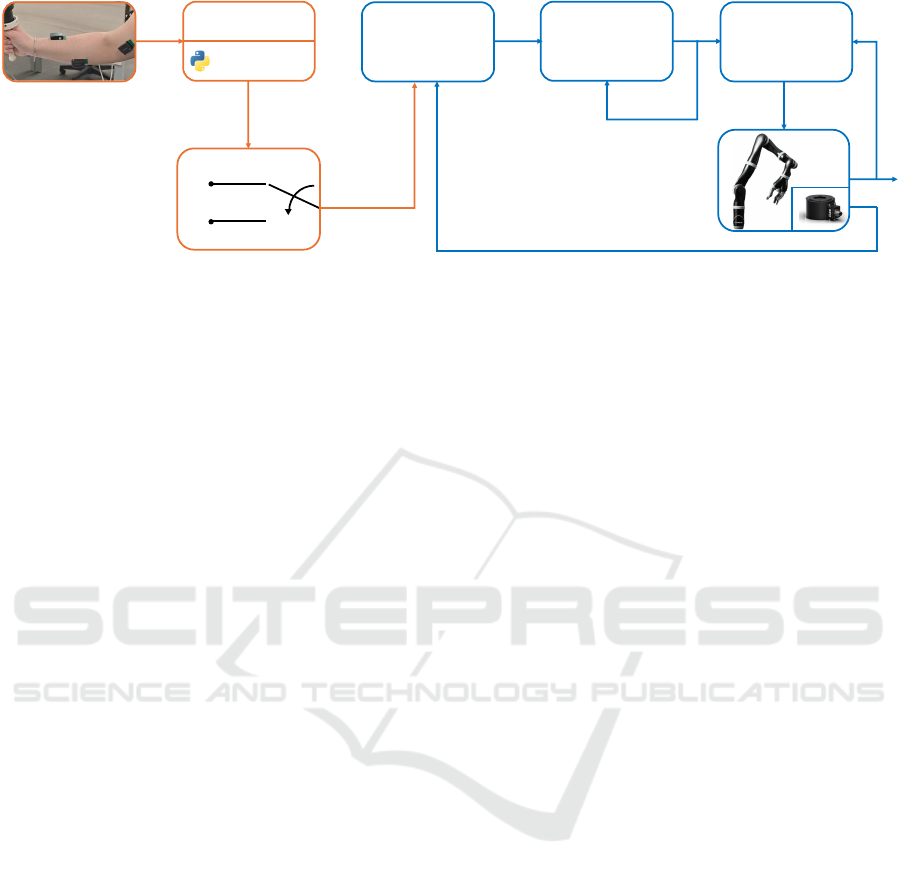

Figure 2 shows the block diagram of the entire

shared control architecture. The High-level layer in-

cludes all the functional blocks that generate specific

sets of admittance gains, while the Low-level layer in-

cludes all the blocks that concern the motion control

of the manipulator. The raw EMG signals go as in-

put to a SVM classifier that recognizes two possible

classes of motions/contractions of the operator. The

finite state machine algorithm receives this informa-

tion and it sets the admittance gains based on the oper-

ational mode; then, an admittance controller (Di Lillo

et al., 2021) outputs a desired trajectory for the end-

effector, which is finally tracked by computing the

needed joint velocity with an inverse kinematics al-

gorithm (Di Lillo et al., 2023). In the following sec-

tions, details about all the functional blocks are given

in a bottom-up order.

EMG-Based Shared Control Framework for Human-Robot Co-Manipulation Tasks

47

A

D

n

L

C

I

K

g

h

l

m

k

e

f

a

b

d

z

c

High-Level

Layer

Low -level

Layer

F

E

P

G

P

Figure 2: Proposed shared control architecture. The High-Level layer is responsible for the EMG signal acquisition and

classification. Then, the recognized class is used into a finite-state machine algorithm that outputs a set of admittance gains.

The Low-Level layer is responsible for the motion control of the manipulator, and it employs a variable admittance controller,

an inverse kinematics algorithm and a joints controller.

3 LOW-LEVEL LAYER

The low-level layer implements the robot control al-

gorithm and consists of three blocks: i) the joints con-

troller, that generates actual joint velocity commands

based on joint encoder readings and the inverse kine-

matics controller output; ii) the inverse kinematics

controller, which computes the desired joint velocities

that make the end-effector track the desired trajectory;

and iii) the variable admittance controller, that modi-

fies the input reference trajectory for the end-effector,

using wrench sensor readings, to achieve a desired dy-

namic behavior, and outputs a new desired trajectory

for the end-effector.

3.1 Inverse Kinematics and Joints

Controller

Considering a serial manipulator with n Degrees of

Freedom (DOFs), the state of the system is described

by the vector q

q

q = [q

1

, q

2

, ·· · , q

n

]

T

∈ R

n

, which con-

tains the joint positions. Define the vector that gathers

the end-effector configuration as x

x

x =

p

p

p

T

o

o

o

T

T

∈ R

7

,

where p

p

p = [p

x

, p

y

, p

z

]

T

∈ R

3

represents the coordi-

nates of the end-effector expressed in the arm base

frame, while o

o

o = [o

x

, o

y

, o

z

, o

w

]

T

∈ R

4

is the quater-

nion that expresses the orientation of the end-effector

with respect to the arm base frame. The velocity

of the end-effector can be described by the vector

v

v

v =

˙

p

p

p

T

ω

ω

ω

T

T

∈ R

6

, where

˙

p

p

p = [ ˙p

x

, ˙p

y

, ˙p

z

]

T

∈ R

3

and

ω

ω

ω = [ω

x

, ω

y

, ω

z

]

T

∈ R

3

represent the end-effector lin-

ear and angular velocities, respectively. The differ-

ential relationship between the end-effector velocity

and the joint velocity vector

˙

q

q

q = [ ˙q

1

, ˙q

2

, ·· · , ˙q

n

]

T

can

be expressed as v

v

v = J

J

J

˙

q

q

q, where J

J

J ∈ R

6×n

is the robot

Jacobian matrix.

Assuming a redundant manipulator, i.e. n > 6, and

the availability of a desired end-effector trajectory ex-

pressed as:

x

x

x

d

=

p

p

p

d

o

o

o

d

∈ R

7

v

v

v

d

=

˙

p

p

p

d

ω

ω

ω

d

∈ R

6

a

a

a

d

=

¨

p

p

p

d

α

α

α

d

∈ R

6

,

(1)

where x

x

x

d

represents the desired position and quater-

nion, v

v

v

d

gathers the desired linear and angular ve-

locities and a

a

a

d

represents the desired linear and an-

gular accelerations. The desired joint velocity that

makes the end-effector track the desired trajectory can

be computed by resorting to the Closed-Loop Inverse

Kinematics (CLIK) algorithm:

˙

q

q

q

d

= J

J

J

†

(v

v

v

d

+ K

K

K

ik

˜

x

x

x) , (2)

where J

J

J

†

is the Moore-Penrose pseudoinverse of the

Jacobian matrix, K

K

K

ik

∈ R

6×6

is a positive-definite ma-

trix of gains and

˜

x

x

x is the error vector, defined as:

˜

x

x

x =

˜

p

p

p

˜

o

o

o

=

p

p

p

d

− p

p

p(q

q

q

d

)

o

o

o

−1

d

⋆ o

o

o(q

q

q

d

)

∈ R

6

, (3)

where

˜

p

p

p and

˜

o

o

o are the position and quaternion errors,

respectively, q

q

q

d

is the vector of desired joint position

obtained by numerically integrating the desired joint

velocity vector

˙

q

q

q

d

, p

p

p(q

q

q

d

) and o

o

o(q

q

q

d

) are the position

and orientation of the end-effector obtained by con-

sidering q

q

q

d

as joint positions in the direct kinematics

computation.

Finally, the desired joint velocity vector is passed

to the joints controller, which computes the actual

command to send to the manipulator by resorting to

a proportional controller including a feedforward ac-

tion as:

˙

q

q

q

r

=

˙

q

q

q

d

+ K

K

K

jc

˜

q

q

q , (4)

where K

K

K

jc

∈ R

n×n

is a positive-definite matrix of gains

and

˜

q

q

q = q

q

q

d

− q

q

q is the joint position error computed

with respect to the actual readings of the joint en-

coders.

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

48

3.2 Admittance Control

The admittance controller aims to assign a virtual dy-

namics to the manipulator, characterized by a desired

mass, damping, and stiffness. More in detail, assum-

ing to have a wrench sensor mounted on the wrist of

the manipulator and to have a certain reference tra-

jectory for the end-effector, the desired end-effector

trajectory must have the following dynamics:

K

K

K

m

˜

a

a

a

r,d

+ K

K

K

d

˜

v

v

v

r,d

+ K

K

K

k

˜

x

x

x

r,d

= h

h

h , (5)

where the positive-definite matrices:

K

K

K

m

=

K

K

K

p

m

O

O

O

3×3

O

O

O

3×3

K

K

K

o

m

(6)

K

K

K

d

=

K

K

K

p

d

O

O

O

3×3

O

O

O

3×3

K

K

K

o

d

(7)

K

K

K

k

=

K

K

K

p

k

O

O

O

3×3

O

O

O

3×3

K

K

K

o

k

, (8)

represent the virtual mass, damping, and stiffness,

respectively, where the position K

p

(·)

and orientation

K

K

K

o

(·)

gains are highlighted, h

h

h =

f

f

f

T

µ

µ

µ

T

T

∈ R

6

is the

vector stacking the linear force and moments mea-

sured by the wrench sensor, and:

˜

x

x

x

r,d

=

˜

p

p

p

r,d

˜

o

o

o

r,d

=

p

p

p

r

− p

p

p

d

o

o

o

−1

r

⋆ o

o

o

d

(9)

˜

v

v

v

r,d

= v

v

v

r

− v

v

v

d

(10)

˜

a

a

a

r,d

= a

a

a

r

− a

a

a

d

, (11)

are the operational space configuration, velocity and

acceleration errors computed between the reference

and the desired trajectories. The desired acceleration

in output from the admittance controller can be com-

puted by folding Eqs (9)-(11) in Eq. (5) and rearrang-

ing the terms, obtaining:

a

a

a

d

= K

K

K

−1

m

[K

K

K

m

a

a

a

r

+ K

K

K

d

˜

v

v

v

r,d

+ K

K

K

k

˜

x

x

x

r,d

− h

h

h] . (12)

The desired end-effector velocity v

v

v

d

and configura-

tion x

x

x

d

to be tracked by the inverse kinematics con-

troller in Eq. (2) can then be obtained by numerical in-

tegration of the desired acceleration. It is worth notic-

ing that the virtual mass, damping and stiffness can be

varied, obtaining a variable admittance controller.

Each one of the operational modes listed in Sec. 2

has a corresponding set of admittance gains that ad-

just the robot’s behavior to successfully execute them.

In detail, with reference to Eqs. (6)-(8), when in Low-

Damping mode the K

K

K

k

gain is set to O

O

O

6×6

to allow

the operator to freely change the end-effector posi-

tion and orientation. The matrix K

K

K

p

d

is set as K

K

K

p

d

=

diag{k

p

d,low

, k

p

d,low

, k

p

d,low

}, with low element k

p

d,low

to

assure smooth teleoperation to the user; similarly,

for the orientation, the matrix K

K

K

o

d

is set as K

K

K

o

d

=

diag{k

o

d,low

, k

o

d,low

, k

o

d,low

}, with low element k

o

d,low

.

Regarding the virtual mass, the matrix K

K

K

p

m

is set to

diag = {k

p

m,low

, k

p

m,low

, k

p

m,low

}, while the matrix K

K

K

o

m

is

set to diag = {k

o

m,low

, k

o

m,low

, k

o

m,low

}.

When in High-Damping mode the K

K

K

k

gain

is still set to O

O

O

6×6

, while K

K

K

p

d

is set as K

K

K

p

d

=

diag{k

p

d,high

, k

p

d,high

, k

p

d,high

} with high element k

p

d,high

to ensure slow and precise movements, for ex-

ample when painting a thin element. Regard-

ing the orientation, the matrix K

K

K

o

d

is set as K

K

K

o

d

=

diag{k

o

d,high

, k

o

d,high

, k

o

d,high

}, with high element k

o

d,low

.

Finally, the virtual mass, the matrix K

K

K

p

m

is set to

diag = {k

p

m,high

, k

p

m,high

, k

p

m,high

}, while the matrix K

K

K

o

m

is set to diag = {k

o

m,high

, k

o

m,high

, k

o

m,high

}.

4 HIGH-LEVEL LAYER

The high-level layer is composed of three main func-

tional blocks: i) the EMG sensors, ii) the operator’s

motion classifier, and iii) the finite state machine al-

gorithm.

4.1 EMG Signal Analysis

Electromyography (EMG) signals, produced by mus-

cle contractions and relaxations, are detected us-

ing surface or needle-based electrodes, and need to

be amplified and filtered to remove noise. In this

works EMG signals are used to detect muscle activ-

ity and patterns. The proposed solution refers to a

Support Vector Machine classifier, a common super-

vised learning algorithm for classification tasks, that

processes features extracted from EMG signals seg-

mented into time windows (or epochs), specifically

using three commonly time-domain features: Root

Mean Square (RMS), Mean Absolute Value (MAV)

and Average Amplitude Change (AAC) (Li et al.,

2022).

To train the SVM classifier, a dataset of feature

vectors with associated class labels, obtained with a

predetermined acquisition procedure, is used. The

SVM algorithm learns a decision boundary to sep-

arate different classes by finding an optimal hyper-

plane in the feature space, governed by two main hy-

perparameters: the regularization parameter C, which

prevents overfitting by limiting misclassification, and

γ, which determines how much far points influence

the hyperplane calculation. During the training, the

SVM adjusts the parameters by solving a quadratic

programming problem to identify the support vectors,

i.e., the points closest to the decision boundary.

EMG-Based Shared Control Framework for Human-Robot Co-Manipulation Tasks

49

In the proposed scenario, the classifier is trained

to discriminate between two classes: free (movements

made by the operator in various directions with mini-

mal resistance) and contraction (generated by the op-

erator by tightening his hand).

4.2 Finite State Machine

The two classes in output from the SVM classifier are

fed into a finite state machine algorithm to automati-

cally switch between the operational modes, as shown

in Figure 3.

C

m

c

u

F

m

f

f

Figure 3: Finite State Machine.

In detail, the system starts in Low-Damping mode;

when the operator executes the contraction class for at

least 1.5s, the state switches to High-Damping mode,

corresponding to a set of admittance gains that allow

the operator to move the end-effector to follow a pre-

defined path, without touching it, with lower speed

and higher accuracy due to the increased damping.

By generating the contraction class for at least 3s, the

state returns to the Low-Damping mode, in which the

operator can move the end-effector more easily and

faster towards the starting point to execute the path

again.

5 EXPERIMENTAL VALIDATION

5.1 Experimental Setup

To validate the effectiveness of the proposed shared

control architecture, experiments of human-robot co-

manipulation tasks were conducted using a 7DOF Ki-

nova Jaco

2

manipulator

1

equipped with a Bota Sys-

tems Rokubimini force/torque sensor

2

. Four non-

invasive Delsys Trigno Avanti active sensors

3

with a

frequency of 1.78 kHz were placed on the dominant

1

https://www.kinovarobotics.com/product/gen2-robots

2

https://www.botasys.com/force-torque-sensors/rokubi

3

https://delsys.com/trigno-avanti/. These sensors have

an integrated pre-amplification circuit to reduce input noise

and do not require amplifying and filtering signals.

arm of the human operator. Following Seniam guide-

lines

4

, they were put on the biceps and triceps brachii,

flexor carpi radialis and extensor carpi ulnaris mus-

cles, as much as possible in the center of muscles.

The streaming of EMG data was done through a

Python GUI on a Windows PC, while the control soft-

ware and the SVM classifier, developed using Python

and the Scikit-learn library (Kramer, 2016), were im-

plemented in the ROS (Robotic Operating System)

framework running on Linux. To allow the two work-

stations to communicate TCP/IP sockets were used.

5.2 Training and Test of the Classifier

To train the SVM classifier described in section 4.1,

EMG signals from a human operator’s arm were

recorded while performing specific movements or

contractions interacting with a manipulator. Two in-

teractions were considered for data collection: in the

first, the robot’s behavior was made compliant, using

the Low-Damping mode parameters, and the operator

moved the end-effector in random directions to col-

lect data related to the free class; in the second, the

robot had a rigid behavior, obtained by referring to

a standard position controller, and the operator tight-

ened the hand on the end-effector handle to collect

data related to the contraction class. A Matlab GUI

told the operator which movements or contractions to

perform and automatically labeled the data to obtain

two datasets: one for training and one for testing the

classifier. For each of the four EMG sensors, three

time-domain features were extracted, resulting in a

12-element feature vector, with an associated class la-

bel. The SVM model is trained using the hyperpa-

rameters in Table 1. The confusion matrix for binary

problems, where the rows represent the expected class

distribution and the columns the predicted distribution

by the classifier, was used to evaluate classifier perfor-

mance and to compute class metrics such as Accuracy,

Precision, Recall, and F1-score, yielding the follow-

ing indexes:

A =

T P

T P + T N +FP + FN

P =

T P

T P + FP

R =

T P

T P + FN

F1 =

T P

T P +

FN + FP

2

where T P, T N, FP and FN are true posi-

tives/negatives and false positives/negatives taken

from the binary problem confusion matrix, respec-

tively. True positives and negatives are the correctly

4

http://seniam.org

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

50

identified positive/negative classes, while false pos-

itives and negatives are the incorrectly classified val-

ues. The accuracy measures how many instances were

correctly classified, the precision measures the accu-

racy of the positive predictions, the recall is the ratio

of positive instances that are correctly detected, and

the F1-score is the harmonic mean of precision and

recall.

In the on-line use of the classifier, the statistical

mode of the predicted classes calculated over the last

1.5s is sent to the finite state machine to increase the

robustness in terms of misclassifications.

5.3 Experimental Results

To validate the overall architecture by triggering all

the envisioned state transitions, a series of experi-

ments were performed in which a subject

5

(female,

aged 29) wearing EMG sensors had to guide the robot

end-effector several times along a predefined path, as

if she were performing a painting operation on a thin

element, as shown in Figure 1. The path consists of a

cylindrical filament whose shape is similar to a square

wave. The user repeated the designed experiment 15

times to test the reproducibility of the approach.

Table 1: Experimental parameters used in the proposed ar-

chitecture.

Control parameters

Parameter Value Description

K

K

K

ik

diag{20 I

I

I

3

, 15 I

I

I

3

} Inverse kinematics gain

K

K

K

jc

diag{3 I

I

I

4

, 2 I

I

I

3

} Joints controller gain

k

p

d,low

40 Low-damping position gain

k

o

d,low

2 Low-damping orientation gain

k

p

m,low

3 Low-mass position gain

k

o

m,low

0.1 Low-mass orientation gain

k

p

d,high

120 High-damping position gain

k

o

d,high

4 High-damping orientation gain

k

p

m,high

5 High-mass position gain

k

o

m,high

0.1 High-mass orientation gain

Classifier parameters

Parameter Value Description

C 1 Regularization parameter

γ ’scale’

6

Parameter of a Gaussian Kernel

Kernel ’RBF’ Kernel used in the SVM Classifier

5

The experiments were taken in accordance with the

Declaration of Helsinki, the protocol has been approved by

the Research Ethics Committee at the university where the

study is conducted and the subject gave informed consent.

6

’scale’ is a parameter calculated as 1 divided by the

product of the features number and the variance of the fea-

ture vector.

Table 1 shows the parameters for the con-

trollers and the classifier used in the experiments,

where all the admittance parameters were experi-

mentally determined; while a video showing the

experiments is provided at the following link:

https://youtu.be/93u5i8HmsPY.

M

98.2% 1.8%

0.0% 100.0%

F C

f

c

Figure 4: The confusion matrix obtained after training the

classifier.

In the following, the results of the classifier perfor-

mances and the experimental execution are discussed.

In particular, the confusion matrix is shown in Fig-

ure 4, while Table 2 contains the classifier indexes.

All performance indexes exceed 99%, as indicated in

the confusion matrix, which has only 1.8% of mis-

classifications for contraction class. This means that,

in addition to the high classification performance at-

tested by the high accuracy value, the number of false

positives is also very low. The precision and recall

also indicate a solid balance confirmed by the F1-

score, whose value is close to the accuracy. Thus, the

numerical results attest a reliable and accurate classi-

fication capability, also supported by the use of only

two classes.

Table 2: Table containing performance evaluation metrics.

Accuracy (%) Precision (%) Recall (%) F1-Score (%)

99.20 99.28 99.12 99.19

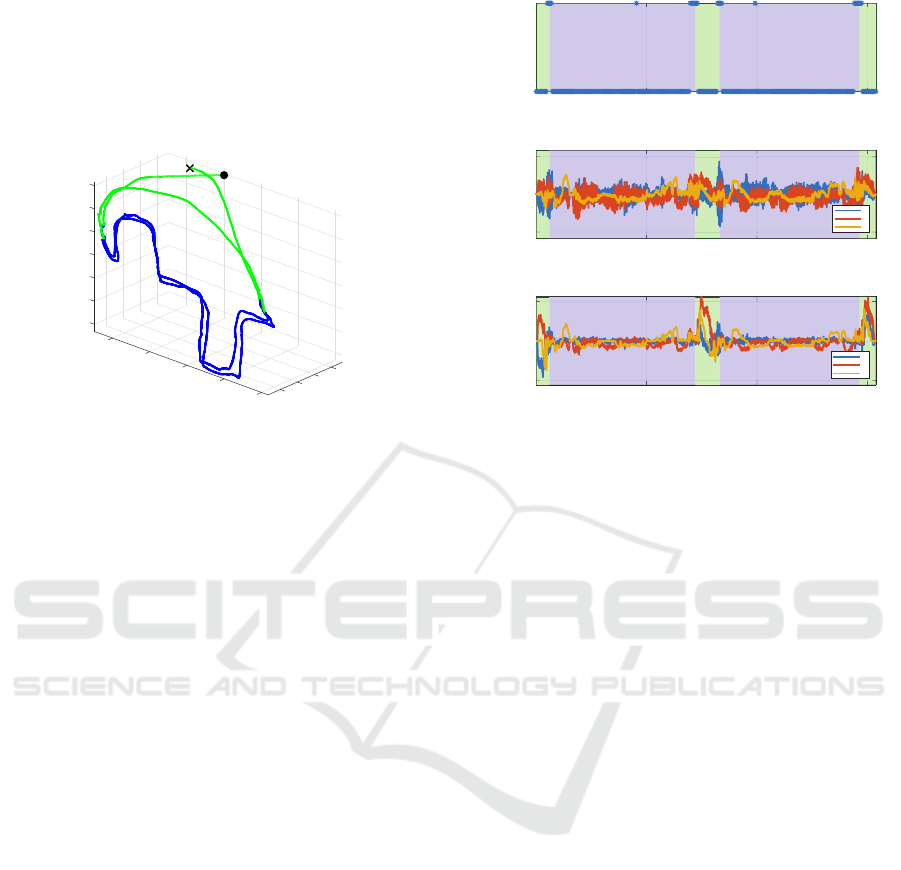

Figure 5 shows the path followed by the end-

effector during one of the experiments performed, in-

cluding the start and end points. Two different col-

ors were used to highlight the path followed by the

manipulator, depending on the corresponding active

operational mode: green and blue paths correspond

to Low-Damping and High-Damping modes, respec-

tively. The user drives the end-effector near the be-

ginning of the filament to be followed, generates the

contraction class for 1.5s to switch to High-Damping

mode, and moves the end-effector along the filament

without touching it using the free class. By generat-

ing contraction for at least 3s, the user switches the

FSM back to Low-Damping mode and quickly moves

the end-effector back to start point with the free class

(as can be seen by the green edge connecting the ends

of the blue lines). Then, the user generates contrac-

EMG-Based Shared Control Framework for Human-Robot Co-Manipulation Tasks

51

tion for 1.5s, returning the FSM to High-Damping

mode, and uses the free class to follow the filament

again; in fact, there are two blue lines in the shape

of a square wave. Finally, the user switches the FSM

back to Low-Damping mode using contraction for 3s

and moves the manipulator to the endpoint.

0.1

0.15

0.2

-0.1

0.25

z

0.3

S

0.35

E

-0.2

0.4

p

y

-0.3

-0.25

-0.3

x

-0.4

-0.35

-0.4

-0.5

Figure 5: The path followed by the manipulator’s end-

effector in one of the experiments performed. The path is

highlighted with two colors based on the two operational

modes: Low-Damping mode is marked in green and High-

Damping mode is highlighted in blue.

The user was able to complete the experiment

without difficulty by easily changing the operational

modes, as outlined in the NASA-TLX questionnaire

she completed.

Figure 6 shows the time evolution of the classifier

output, the force measured by the F/T sensor, and the

linear velocity of the manipulator’s end-effector. Sim-

ilarly to what was highlighted in the performed path,

the colors green and blue indicate the Low-Damping

and High-Damping modes, respectively. In particu-

lar, Figure 6a shows the time evolution of the classi-

fier output, which provides information about how it

was able to distinguish between free and contraction

classes. The classifier output determines the transition

between the control modes, as highlighted by the dif-

ferent colored areas; in fact, after the first 6s (or after

83s) in which the operator is in free class, she gen-

erates contraction for 1.5s and the FSM switches to

High-Damping mode; the FSM remains in the same

state until the operator stops following the filament;

then, the operator generates a 3s contraction (after 72

or 146s) and the FSM returns to Low-Damping mode.

Instead, the time evolution of the force and linear ve-

locity of the end-effector are shown in Figures 6b and

6c, respectively. The velocity increases significantly

in the green areas, corresponding to a mode with low

damping values, compared to the blue areas where,

since the damping is higher, the manipulator becomes

less compliant and moves more slowly during the co-

manipulation.

0 50 100 150

t

f

c

e

0 50 100 150

t

-10

0

10

N

F

x

y

z

0 50 100 150

t

-0.1

0

0.1

l

V

X

Y

Z

Figure 6: Experimental results: a) EMG Classifier Output;

b) Force measured by the F/T sensor; c) End-Effector Lin-

ear Velocity. The different colored areas on all graphs cor-

respond to the two different control modes: green and blue

represent the Low-Damping and the High-Damping modes,

respectively.

Oscillations in the force trend also increase in the

green areas corresponding to Low-Damping, espe-

cially when the user generates the contraction class to

switch modes. In the transition from Low-Damping

to High-Damping this happens because, before the

transition occurs, the force sensor perceives the user’s

hand as a rigid external environment; while in the

transition from High-Damping to Low-Damping the

operator does not stop contracting immediately after

the transition because of his reflexes, and the lower

damping is not sufficient to reduce the oscillations due

to residual contractions.

6 CONCLUSIONS

In this work, a shared control architecture is proposed

that allows changing the admittance parameters of a

manipulator using sEMG sensors in a human-robot

co-manipulation scenario. A dedicated classifier rec-

ognizes the human movements and contractions to

switch among two sets of admittance parameters cor-

responding to two robot behaviors. The robustness

of the approach is validated using a Jaco

2

manipula-

tor and four Trigno Avanti EMG sensors through a

series of experiments. The interaction with external

environment can produce oscillations that can cause

resonance phenomena (known in the literature), espe-

cially when the robot comes into contact with more

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

52

rigid environments. Future work will be devoted to

analyze these phenomena in order to extend this ap-

proach to more complex scenarios where both human-

robot and robot-environment interactions are consid-

ered. This will require an increase in the number of

operational modes to handle complex scenarios and,

consequently, the introduction of a greater number of

classes from EMG signals.

ACKNOWLEDGEMENTS

The research leading to these results has re-

ceived funding from Project COM

3

CUP

H53D23000610006 funded by EU in NextGen-

erationEU plan through the Italian “Bando Prin

2022 - D.D. 104 del 02-02-2022” by MUR, from

H2020-ICT project CANOPIES (Grant Agree-

ment N. 101016906), and by Project “Ecosistema

dell’innovazione - Rome Technopole” financed by

EU in NextGenerationEU plan through MUR Decree

n. 1051 23.06.2022.

REFERENCES

Abbink, D. A., Carlson, T., Mulder, M., de Winter, J. C. F.,

Aminravan, F., Gibo, T. L., and Boer, E. R. (2018). A

topology of shared control systems—finding common

ground in diversity. IEEE Transactions on Human-

Machine Systems, 48(5):509–525.

Cacace, J., Caccavale, R., Finzi, A., and Lippiello, V.

(2019). Variable admittance control based on virtual

fixtures for human-robot co-manipulation. In 2019

IEEE International Conference on Systems, Man and

Cybernetics (SMC), pages 1569–1574.

Di Lillo, P., Simetti, E., Wanderlingh, F., Casalino, G., and

Antonelli, G. (2021). Underwater intervention with

remote supervision via satellite communication: De-

veloped control architecture and experimental results

within the dexrov project. IEEE Transactions on Con-

trol Systems Technology, 29(1):108–123.

Di Lillo, P., Vito, D. D., and Antonelli, G. (2023). Merging

global and local planners: Real-time replanning algo-

rithm of redundant robots within a task-priority frame-

work. IEEE Transactions on Automation Science and

Engineering, 20(2):1180–1193.

Ferraguti, F., Talignani Landi, C., Sabattini, L., Bonfe, M.,

Fantuzzi, C., and Secchi, C. (2019). A variable admit-

tance control strategy for stable physical human–robot

interaction. The International Journal of Robotics Re-

search, 38(6):747–765.

Ficuciello, F., Villani, L., and Siciliano, B. (2015). Variable

impedance control of redundant manipulators for intu-

itive human–robot physical interaction. IEEE Trans-

actions on Robotics, 31(4):850–863.

Gonzalez-Mendoza, A., Quinones-Uriostegui, I., Salazar-

Cruz, S., Perez Sanpablo, A. I., L

´

opez, R., and

Lozano, R. (2022). Design and implementation of a

rehabilitation upper-limb exoskeleton robot controlled

by cognitive and physical interfaces. Journal of Bionic

Engineering, 19.

Grafakos, S., Dimeas, F., and Aspragathos, N. (2016). Vari-

able admittance control in pHRI using EMG-based

arm muscles co-activation. In 2016 IEEE Interna-

tional Conference on Systems, Man, and Cybernetics

(SMC), pages 001900–001905.

Hearst, M. A., Dumais, S. T., Osuna, E., Platt, J., and

Scholkopf, B. (1998). Support vector machines. IEEE

Intelligent Systems and their applications, 13(4):18–

28.

Kramer, O. (2016). Scikit-learn. Machine learning for evo-

lution strategies, pages 45–53.

Li, J., Li, G., Chen, Z., and Li, J. (2022). A novel emg-

based variable impedance control method for a tele-

operation system under an unstructured environment.

IEEE Access, 10:89509–89518.

Losey, D. P. and O’Malley, M. K. (2018). Trajectory defor-

mations from physical human–robot interaction. IEEE

Transactions on Robotics, 34(1):126–138.

Matheson, E., Minto, R., Zampieri, E. G. G., Faccio, M.,

and Rosati, G. (2019). Human–robot collaboration in

manufacturing applications: A review. Robotics, 8(4).

Sharifi, M., Zakerimanesh, A., Mehr, J. K., Torabi,

A., Mushahwar, V. K., and Tavakoli, M. (2022).

Impedance variation and learning strategies in hu-

man–robot interaction. IEEE Transactions on Cyber-

netics, 52(7):6462–6475.

Sladi

´

c, S., Lisjak, R., Runko Luttenberger, L., and Musa,

M. (2021). Trends and progress in collaborative robot

applications. Politehnika, 5:32–37.

Villani, V., Pini, F., Leali, F., and Secchi, C. (2018). Survey

on human–robot collaboration in industrial settings:

Safety, intuitive interfaces and applications. Mecha-

tronics, 55:248–266.

Wang, C. and Zhao, J. (2023). Based on human-like vari-

able admittance control for human–robot collabora-

tive motion. Robotica, 41(7):2155–2176.

Zeng, C., Yang, C., Cheng, H., Li, Y., and Dai, S.-

L. (2021). Simultaneously encoding movement and

sEMG-based stiffness for robotic skill learning. IEEE

Transactions on Industrial Informatics, 17(2):1244–

1252.

Zhuang, Y., Leng, Y., Zhou, J., Song, R., Li, L., and

Su, S. W. (2021). Voluntary control of an an-

kle joint exoskeleton by able-bodied individuals and

stroke survivors using emg-based admittance control

scheme. IEEE Transactions on Biomedical Engineer-

ing, 68(2):695–705.

EMG-Based Shared Control Framework for Human-Robot Co-Manipulation Tasks

53