Implementation of 12 Transition Controls for Rotary Double Inverted

Pendulum Using Direct Collocation

Doyoon Ju

a

, Taegun Lee

b

and Young Sam Lee

c

Department of Electrical and Computer Engineering, Inha University, Incheon, Korea

{seiko.kr, dlxorjs815}@gmail.com, lys@inha.ac.kr

Keywords:

Rotary Double Inverted Pendulum, Transition Control, Direct Collocation, Optimal Control.

Abstract:

The rotary double inverted pendulum system has one stable and three unstable equilibrium points due to

its kinematic properties. This paper extends the traditional swing-up control problem by defining a novel

transition control problem among these points. We formulate the system’s dynamic equations and boundary

conditions for different equilibrium points to minimize energy consumption during transitions, resulting in a

two-point boundary value optimal control problem. This problem is solved offline to calculate the feedforward

trajectory for feedforward control. To convert the continuous optimal control problem with constraints into a

nonlinear optimization problem, we employ the direct collocation method. A time-varying Linear Quadratic

controller is used as the feedback controller to accurately track the generated feedforward path during real-time

control, compensating for uncertainties. Previous studies on rotary double inverted pendulums have focused on

the swing-up problem, with no research addressing transition control between the four equilibrium points. This

paper defines the transition control problem for the rotary double inverted pendulum and proposes a control

strategy. The method’s effectiveness and practicality were validated through the design and implementation

of 12 transition trajectories in experimental settings, successfully demonstrating its feasibility and utility.

1 INTRODUCTION

The inverted pendulum system, with its unstable dy-

namic characteristics, incorporates both nonlinear and

non-minimum phase properties, making it a widely

used educational tool for teaching control theory.

Additionally, it serves as a popular testbed for re-

searchers to validate new control techniques. Ma-

jor studies on the inverted pendulum system include

swing-up control, which transitions the pendulum

from an initial state where it points downward to an

upright state(

¨

Astr

¨

om and Furuta, 2000; Meta et al.,

2014), and balance control, which aims to maintain

stability in the upright state after the swing-up(Oh and

Lee, 2018). Among these, swing-up control is consid-

ered a more challenging research topic compared to

balance control because it requires designing a con-

troller that accounts for the system’s nonlinearity, in-

stability, and input/output constraints.

In the case of the rotary inverted pendulum sys-

tem, unlike the linear inverted pendulum where the

a

https://orcid.org/0000-0001-7011-6779

b

https://orcid.org/0009-0007-3107-2735

c

https://orcid.org/0000-0003-0665-1464

pendulum is fixed to rotate in a single plane, the

powered arm of the rotary inverted pendulum also

rotates. This characteristic allows the pendulum to

move within a three-dimensional space, introducing

additional challenges in performing swing-up control.

To address the swing-up problem of such a rotary in-

verted pendulum system, various methods have been

applied, including self-tuning techniques(Ratiroch-

Anant et al., 2004), PID controllers(Rahairi et al.,

2011), and methods utilizing sliding observers(Thein

and Misawa, 1995). Recently, research has also

been conducted to solve this problem using artifi-

cial intelligence-based controllers(Brown and Strube,

2020; Baek et al., 2024).

However, in the case of the rotary double inverted

pendulum, most studies have implemented swing-

up control using only simulation environments(Liang

et al., 2023; Tran et al., 2024; Singh and Swarup,

2021; Zied et al., 2020). Rarely, when physical

systems were used, research was primarily limited

to balance control after manually performing the

swing-up(Ibrahim et al., 2019; Sondarangallage and

Manukid, 2019). A common limitation in these stud-

ies is the absence of a physical rotary double inverted

pendulum system capable of performing swing-up

92

Ju, D., Lee, T. and Lee, Y.

Implementation of 12 Transition Controls for Rotary Double Inverted Pendulum Using Direct Collocation.

DOI: 10.5220/0012994200003822

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 21st International Conference on Informatics in Control, Automation and Robotics (ICINCO 2024) - Volume 1, pages 92-100

ISBN: 978-989-758-717-7; ISSN: 2184-2809

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

control. Even if such a system exists, there is a lack of

documented successful implementations of swing-up

control in academic literature.

Building on the research laboratory’s extensive

experience in developing various inverted pendulum

systems over many years, the authors aim to solve

the problem by constructing a physical system them-

selves, instead of purchasing a commercially avail-

able rotary inverted pendulum. The most critical ob-

jective in this process is to ensure that the arm of the

rotary inverted pendulum can rotate infinitely, a char-

acteristic feature of the system. To address this, previ-

ous research successfully utilized a slip ring structure

to overcome the rotational displacement constraints

and perform swing-up control(Oh and Lee, 2018).

Building on this experience, the authors’ research lab-

oratory seeks to directly construct a rotary double in-

verted pendulum and implement swing-up control us-

ing the physical system.

In the case of a single-link inverted pendulum sys-

tem, there is only one type of swing-up problem. This

involves moving from the stable equilibrium point

where the pendulum hangs downward to the unstable

equilibrium point in the upright position. However,

when the pendulum has two links, there are two addi-

tional unstable equilibrium points determined by the

angles of each link. These are in addition to the sta-

ble equilibrium points where both links point down-

ward and the unstable equilibrium points where both

links are upright. This introduces not only the simple

swing-up problem but also a newly defined ‘transition

control’ problem between these equilibrium points.

The transitions between the four equilibrium points

created by the two links result in 11 different types of

transitions, excluding the traditional swing-up. This

paper experimentally addresses all 12 transition con-

trols, including swing-up control.

The transition control among the four equilib-

rium points of the rotary double inverted pendulum

used in the experiments can be designed by refer-

encing the swing-up control strategy of the linear in-

verted pendulum. In 2007, Graichen effectively ad-

dressed the swing-up control problem by introducing

a two-degree-of-freedom (2-DOF) control structure

that combines feedforward and feedback control, tak-

ing into account the rail length constraints of the lin-

ear double inverted pendulum(Graichen et al., 2007).

The basic concept of the 2-DOF control structure used

by Graichen involves using the dynamic equations of

the multi-link inverted pendulum to calculate the state

and control input trajectories offline that lead the pen-

dulum to an upright position. The calculated feed-

forward trajectory is then applied to guide the pendu-

lum to the upright state. During the operation of the

system, the difference between the actual trajectory

and the calculated feedforward trajectory is corrected

through feedback control. This ensures successful

swing-up by closely following the feedforward tra-

jectory. Based on this study, the present paper uses

the direct collocation method(Kelly, 2017) to numer-

ically solve the nonlinear optimal control problem to

find the feedforward trajectory for the rotary double

inverted pendulum. The feedback controller design

follows a similar approach to Graichen’s method and

employs Linear Quadratic(LQ) control, an optimal

control technique for time-varying systems. Unlike

Graichen’s method, which assumes a specific form for

the trajectory, the direct collocation method imposes

no constraints on the trajectory shape, increasing the

likelihood of finding a numerical solution for the tra-

jectory.

This paper aims to implement all 12 types of tran-

sition control using the physical rotary double in-

verted pendulum system. In Chapter 2, we first derive

the dynamic equations of the system using the Euler-

Lagrange equations based on the structural character-

istics of the rotary double inverted pendulum used in

the experiments. Chapter 3 defines each equilibrium

point and transition control problem and proposes a

method to obtain the feedforward trajectory using the

direct collocation method, which numerically solves

the nonlinear optimal problem. In Chapter 4, we per-

form the 12 transition control experiments using a 2-

DOF controller designed with time-varying LQ con-

trol. Finally, in Chapter 5, we analyze the results to

verify the effectiveness of the proposed method.

2 MATHEMATICAL MODEL OF

THE ROTARY DOUBLE

INVERTED PENDULUM

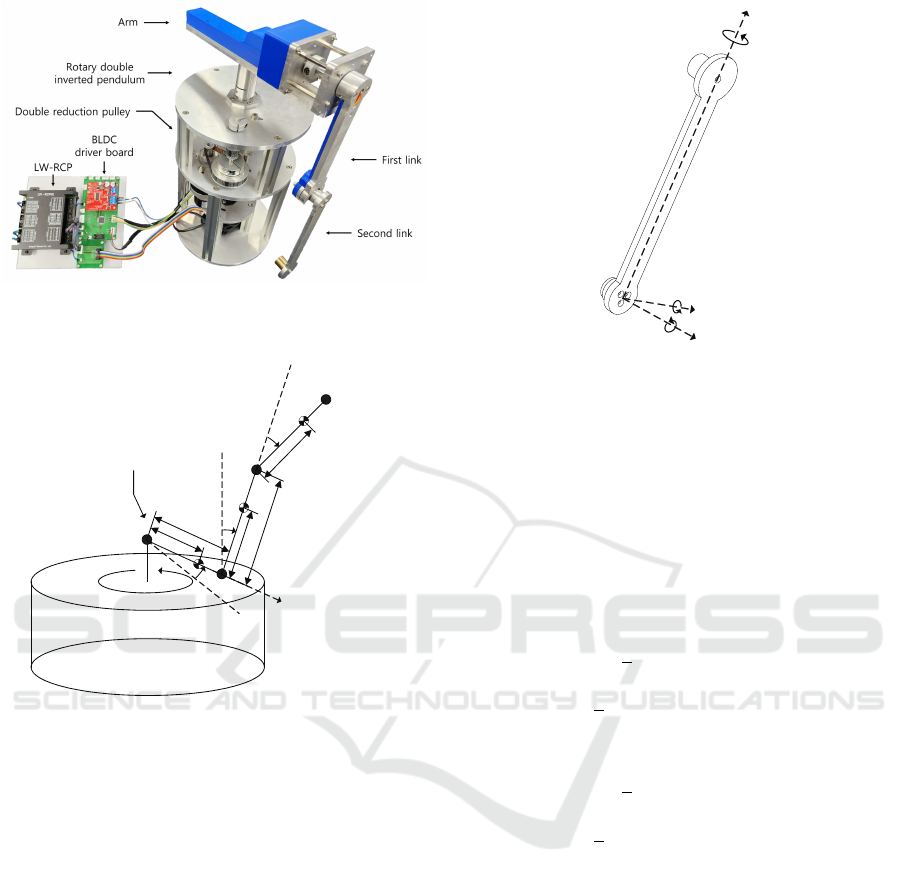

The rotary double inverted pendulum used in this pa-

per is shown in Figure 1, and Figure 2 illustrates the

mechanical concept of the system.

The unit system used in this paper is the Interna-

tional System of Units (SI), and all variables and pa-

rameters are defined accordingly. Here, θ represents

the rotational displacement from the initial position of

the arm, and u denotes the angular acceleration of the

arm. R

1

is the distance between the arm and the first

pendulum, while r

1

and r

2

represent the x-axis direc-

tional distances from the arm to the center of mass of

the first and second pendulums, respectively. M

1

and

M

2

are the masses of the first and second pendulums,

l

1

and l

2

are the lengths from the rotational axis to the

center of mass of each pendulum, and L

1

is the length

Implementation of 12 Transition Controls for Rotary Double Inverted Pendulum Using Direct Collocation

93

Figure 1: Rotary double inverted pendulum system con-

structed by the laboratory.

Arm

a

b

q

u

q

=

0

q

=

0

a

=

0

b

=

1

L

1

l

2

l

1

R

1

r

2

r

1

M

2

M

First link

Second link

x

1

c

2

c

Figure 2: The conceptual diagram of a rotary double in-

verted pendulum.

from the rotational axis of the first pendulum to the ro-

tational axis of the second pendulum. α is defined as

the rotational displacement of the first pendulum with

respect to the normal of the ground, and β is defined

as the relative rotational displacement of the second

pendulum with respect to the first pendulum. Addi-

tionally, c

1

and c

2

denote the friction coefficients at

the rotational axes of the first and second pendulums,

respectively. Figure 3 illustrates the rotations of the

first and second pendulums, and expressions like I

xx1

represent the moments of inertia of the pendulums(Oh

and Lee, 2018). The dynamic model of the rotary

double inverted pendulum can be derived using the

Euler-Lagrange equation and is expressed as follows.

n

1

n

2

¨

θ +

m

11

m

12

m

21

m

22

¨

α

¨

β

+

d

1

d

2

= 0. (1)

Each component of Equation (1) is defined as follows.

x

I

y

I

z

I

x

y

z

Figure 3: Rotation and inertia I of the first and second links.

n

1

= h

1

cos(α) + h

2

cos(α + β),

n

2

= h

2

cos(α + β),

m

11

= h

3

+ h

6

+ 2h

4

cos(β),

m

12

= h

6

+ h

4

cos(β),

m

21

= h

6

+ h

4

cos(β),

m

22

= h

6

,

d

1

= −h

4

sinβ(2

˙

α

˙

β +

˙

β

2

) − h

5

sinα

− h

7

sin(α + β) + c

1

˙

α

−

˙

θ

2

{

1

2

h

8

sin(2α) + h

4

sin(2α + β)

+

1

2

h

9

sin(2α + 2β)},

d

2

= h

4

sinβ(

˙

α

2

) − h

7

sin(α + β) + c

2

˙

β

−

˙

θ

2

{

1

2

h

9

sin(2α + 2β)

+

1

2

h

4

(sin(2α + 2β) − sin β)}.

h

1

to h

9

are defined as follows, and g represents the

gravitational acceleration of 9.81 [m/s

2

].

h

1

= M

1

l

1

r

1

+ M

2

L

1

(R

1

+ r

2

) − I

xz1

,

h

2

= M

2

l

2

(R

1

+ r

2

) − I

xz2

,

h

3

= I

xx1

+ M

1

l

2

1

+ M

2

L

2

1

,

h

4

= M

2

L

1

l

2

,

h

5

= g(M

1

l

1

+ M

2

L

1

),

h

6

= I

xx2

+ M

2

l

2

2

,

h

7

= M

2

gl

2

,

h

8

= M

1

l

2

1

+ M

2

L

2

1

+ I

yy1

− I

zz1

,

h

9

= M

2

l

2

2

+ I

yy2

− I

zz2

.

Thus, Equation (1) can be rearranged as follows.

¨

α

¨

β

= −

m

11

m

12

m

21

m

22

−1

n

1

n

2

¨

θ +

d

1

d

2

.

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

94

By solving this,

¨

α =

(−m

22

n

1

+ m

12

n

2

)

¨

θ + (−m

22

d

1

+ m

12

d

2

)

Φ

,

¨

β =

(m

21

n

1

− m

11

n

2

)

¨

θ + (m

21

d

1

− m

11

d

2

)

Φ

,

Φ = m

11

m

22

− m

12

m

21

.

In this context, the state vector is defined as x

1

= θ,

x

2

= α, x

3

= β, x

4

=

˙

θ, x

5

=

˙

α, x

6

=

˙

β, x

7

=

R

t

0

θ(τ)dτ,

and the angular acceleration

¨

θ is represented as u.

Consequently, the model equation of the double in-

verted pendulum can ultimately be expressed as the

following nonlinear state equation. The last element

of the state variable,

R

t

0

θ(τ)dτ, is an additional term

introduced to eliminate the steady-state error in the

position of the arm.

˙x

1

˙x

2

˙x

3

˙x

4

˙x

5

˙x

6

˙x

7

| {z }

˙x

=

x

4

x

5

x

6

u

(−m

22

n

1

+m

12

n

2

)

¨

θ+(−m

22

d

1

+m

12

d

2

)

Φ

(m

21

n

1

−m

11

n

2

)

¨

θ+(m

21

d

1

−m

11

d

2

)

Φ

x

1

| {z }

f (x,u)

.

(2)

The dynamic model derived in this manner is subse-

quently used as the feedforward trajectory generation

model when applying the direct collocation method.

3 DESIGN AND

IMPLEMENTATION OF

TRANSITION CONTROL

3.1 Transition Control Design

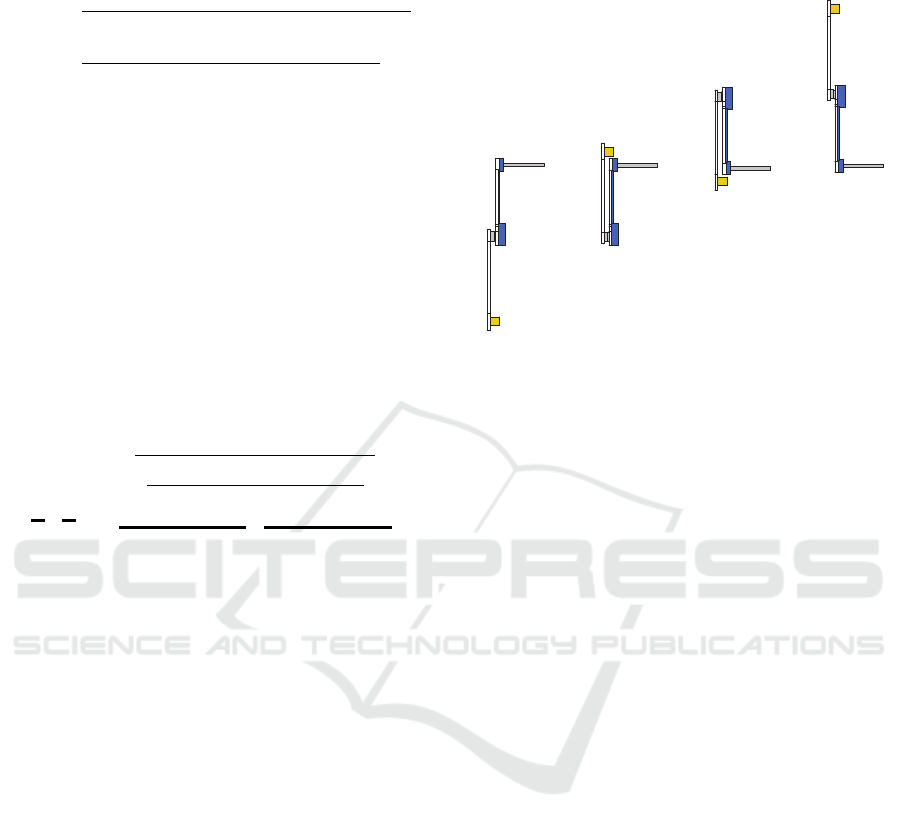

The four possible equilibrium points of the rotary

double inverted pendulum, determined by the states

of the first and second pendulums, are depicted in Fig-

ure 4. In this paper, the numbering of equilibrium

points is represented using a binary notation, where

the states Up and Down are designated as 1 and 0, re-

spectively. If the numbering is assigned starting from

the first pendulum, the equilibrium point where both

the first and second pendulums are in the Down-Down

state corresponds to the binary number 00 and is de-

noted as EP0. Similarly, the equilibrium point corre-

sponding to the Up-Down state is represented by the

binary number 10 and is denoted as EP2. In this pa-

per, the equilibrium points of the inverted pendulum

will be denoted as EP0 (Down-Down), EP1 (Down-

Up), EP2 (Up-Down), and EP3 (Up-Up) according to

this method.

EP 0 EP 1 EP 2 EP 3

Figure 4: Four equilibrium points of a rotary double in-

verted pendulum.

The implemented transition control follows three

steps:

1. Linear control at the current equilibrium point.

2. Transition control from the current equilibrium

point to the next equilibrium point.

3. Linear control at the next equilibrium point.

Each transition process is structurally similar to

the swing-up problem, which involves moving the

pendulum from its initial state (EP0) to the upright

state (EP3). First, linear control is performed to en-

sure the stability of the current state before transition-

ing between the four equilibrium points. Next, tran-

sition control is executed to move from the current

equilibrium point to the next equilibrium point. Upon

reaching the new equilibrium point, additional linear

control is required to maintain stability at that point.

Thus, each transition process must satisfy both ma-

jor elements: linear control at the equilibrium points

and transition control between the equilibrium points.

Since there are a total of 12 different transition trajec-

tories for the double inverted pendulum, experiments

must be designed and conducted for each trajectory to

meet the required conditions.

The 12 transition trajectories presented in this pa-

per are configured according to the sequence diagram

in Figure 5.

3.2 Implementation of Transition

Control

To calculate the optimal state x

∗

and control input u

∗

required for generating transition control trajectories,

Implementation of 12 Transition Controls for Rotary Double Inverted Pendulum Using Direct Collocation

95

lG

wGW

OkTP

lG

wGX

OkTP

lG

wGZ

O|TP

lG

wGY

O|TP

X

Y

Z

[

\

]

^

_

`

XW

XX

XY

Figure 5: 12-step transition diagram for the double inverted

pendulum.

it is essential to accurately estimate the parameters of

the system depicted in Figures 2 and 3. Parameters

such as M

1

, M

2

, I

xx1

, I

xx2

, l

1

, l

2

, c

1

, and c

2

can be es-

timated using the parameter estimation techniques for

the linear double inverted pendulum(Ju et al., 2022).

The estimation of the inertia tensor can be performed

by referring to the research conducted by Oh(Oh and

Lee, 2018). The parameters of the rotary double in-

verted pendulum obtained through these estimation

processes are summarized in Table 1.

Table 1: Model parameters of the rotary double inverted

pendulum used in the experiments.

Parameter Value

M

1

0.187 [kg]

M

2

0.132 [kg]

I

xx1

1.0415e-03 [kgm

2

]

I

xx2

8.8210e-04 [kgm

2

]

I

yy1

4.3569e-03 [kgm

2

]

I

yy2

4.9793e-03 [kgm

2

]

I

zz1

3.3179e-03 [kgm

2

]

I

zz2

4.8178e-03 [kgm

2

]

I

xz1

3.7770e-04 [kgm

2

]

I

xz2

1.9823e-04 [kgm

2

]

l

1

0.072 [m]

l

2

0.133 [m]

c

1

2.4100e-06

c

2

1.0900e-06

L

1

0.1645 [m]

The transition control between the equilibrium

points of the pendulum is performed using a 2-DOF

control technique that combines nonlinear feedfor-

ward control and feedback control as proposed in

(Graichen et al., 2007). Figure 6 illustrates the 2-

DOF control structure. In the control process, the pre-

computed ideal angular acceleration trajectory u

∗

(t)

is combined with the correction input ∆u(t), which

is calculated based on the error ∆x(t) = x

∗

(t) − x(t)

between the predicted state variables of the inverted

pendulum system and the actual output values. This

generates the actual angular acceleration input u(t) =

u

∗

(t)+∆u(t). In this paper, the feedforward trajectory

is generated by considering the dynamic constraints

and setting up a nonlinear optimal control problem

that numerically minimizes the desired cost function

while satisfying various constraints. The direct collo-

cation method is used to numerically solve this prob-

lem(Kelly, 2017). This method effectively estimates

the control inputs and state variable paths of contin-

uous dynamic systems and is a proven technique for

obtaining the optimal trajectory to achieve control ob-

jectives.

Signal

generator

Feedback

control

Double

Inverted

Pendulum

+

-

+

+

*

x

uD

u

*

u

x

Feedforward control

xD

Figure 6: 2-DOF control framework for the double inverted

pendulum.

The direct collocation method is an iterative nu-

merical solution implemented using a nonlinear opti-

mization solver. This method is characterized by the

influence of the initial trajectory provided by the de-

signer on the solution time of the numerical method

and the resulting trajectory’s shape. By considering

these characteristics and selecting an appropriate ini-

tial trajectory, the designer can effectively apply the

direct collocation method to derive a suitable trajec-

tory for specific transition control problems. In this

paper, the initial trajectory is designed using the sim-

plest form of a straight-line trajectory connecting the

start and end boundary conditions. Additionally, a

cost function is designed to satisfy all set constraints

and boundary conditions, forming a general nonlinear

optimal control problem. Equation (3) below repre-

sents the optimal control problem set to calculate the

optimal trajectory.

Minimize

u(t) J(x(t), u(t))

subject to input/output constraint,

dynamic equations,

boundary conditions.

(3)

In the above equation, J(x(t),u(t)) represents the

cost function and is defined as an optimal control

problem that satisfies the constraints set using the

model parameters of the actual system as listed in Ta-

ble 1. The cost function can be used either to mini-

mize time or to optimize the cost over a given period.

The constraints and limitations applied to this cost

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

96

function include the dynamic equations of the rotary

double inverted pendulum (2) and the limits specified

by equation (4), which restrict the maximum distance

the arm can move during the control process, as well

as the maximum angular velocity and input angular

acceleration of the arm within the operational range

of the actuator. These conditions play a crucial role in

ensuring the practical operability and stability of the

control system.

|

x

∗

1

|

≤ θ

limit

,

|

x

4

∗

|

≤

˙

θ

limit

,

|

u

∗

|

≤ u

limit

.

(4)

The set limit values are all defined as positive, with

θ

limit

> 0,

˙

θlimit > 0, and ulimit > 0 specifying the

maximum allowable values for the arm’s output dis-

placement, output angular velocity, and input angular

acceleration, respectively. These limit values reflect

the actual operational constraints of the rotary double

inverted pendulum used in the experiments, and these

constraints are explicitly stated in equation (5).

θ

limit

= 1.5[rad],

˙

θ

limit

= 7.0[rad/s],

u

limit

= 50[rad/s

2

].

(5)

To satisfy various constraints during the 12 differ-

ent transition control processes, additional constraints

can be applied to the pendulum’s rotation angles α

and β as well as their angular velocities

˙

α and

˙

β.

Furthermore, at the start (t = 0) and end (t = T ) of

the transition control, the boundary conditions cor-

responding to the specific equilibrium points for the

transition must be satisfied. For example, if the cur-

rent equilibrium point is EP0 and the target equilib-

rium point for the transition is EP3, this situation can

be expressed as shown in equation (6).

x

∗

(0) =

0,−π,0,0, 0, 0,0

T

,

x

∗

(T ) =

0,0,0,0, 0, 0,0

T

,

u

∗

(0) = 0,u

∗

(T ) = 0.

(6)

By utilizing the direct collocation method, the transi-

tion trajectories implemented can be optimized to sat-

isfy the set constraints and boundary conditions dur-

ing the transition process, as illustrated in Figure 7.

4 EXPERIMENTAL VALIDATION

AND RESULTS

The design of the feedback controller for trajec-

tory tracking is similar to the method proposed by

Graichen(Graichen et al., 2007), mentioned in the in-

troduction. However, a key difference in this study

is the application of the optimal control technique,

Figure 7: Feedforward transition trajectory from EP0 to

EP3.

linear-quadratic (LQ) control, for time-varying sys-

tems throughout the entire process. In Graichen’s

study, it was determined that high compensation val-

ues in intervals where the gain coefficient increases

rapidly could lead to a loss of controllability, prompt-

ing the decision to suspend feedback in certain in-

tervals. In contrast, this study maintains a consis-

tent control strategy by utilizing the calculated time-

varying LQ control gain values across all intervals

during the implementation of transition control. The

design of this time-varying LQ controller is based on

the linearized dynamic system centered around the

swing-up trajectory of the double inverted pendulum

system. The state equations used in this process,

which vary with time, used in this process are mod-

eled in a form where the values of A and B are time-

varying, as shown in equation (7).

A(t) =

∂ f

∂x

x

∗

(t),u

∗

(t)

, B(t) =

∂ f

∂u

x

∗

(t),u

∗

(t)

. (7)

In this context, x

∗

(t) and u

∗

(t) represent the feed-

forward trajectories for the state and input obtained

using the direct collocation method. The difference

between the obtained feedforward trajectory and the

actual state variable values is calculated as ∆x(t) =

x

∗

(t) − x(t), and the correction input ∆u(t) generated

to compensate for this error is defined by equation (8).

∆u(t) = −K(t)∆x(t). (8)

In this case, the time-varying state equation can be

expressed as equation (9).

∆ ˙x(t) = A(t)∆x(t) + B(t)∆u(t). (9)

The cost function used is given by equation (10).

Implementation of 12 Transition Controls for Rotary Double Inverted Pendulum Using Direct Collocation

97

J = ∆x

T

(T )H

Tr

∆x(T ) +

R

T

0

∆x(t)

T

Q

Tr

∆x(t)

+∆u(t)

T

R

Tr

∆u(t)dt.

(10)

Here, the subscript Tr is used to indicate the design

variables of the transition process. In equation (10),

the variables with this subscript must satisfy H

Tr

≥ 0,

Q

Tr

≥ 0, and R

Tr

> 0. The matrix H

Tr

represents the

weight on the terminal state, the matrix Q

Tr

repre-

sents the weight on the system state, and the matrix

R

Tr

represents the weight on the control input. These

weights are set to the values of equation (11) through

an experimental process.

Q

Tr

= diag(1,300,500,1, 1, 1,1),

R

Tr

= 1.

(11)

Additionally, to calculate the time-varying gain K(t),

the differential Riccati equation presented in equation

(12) must be solved.

˙

P(t) = −A(t)

T

P(t) − P(t)A(t)

+PB(t)R

−1

Tr

B

T

(t)P(t) − Q

Tr

,

P(T ) = H

Tr

.

(12)

Ultimately, the time-varying gain K(t) can be calcu-

lated using equation (13). The LQ control gain K(t)

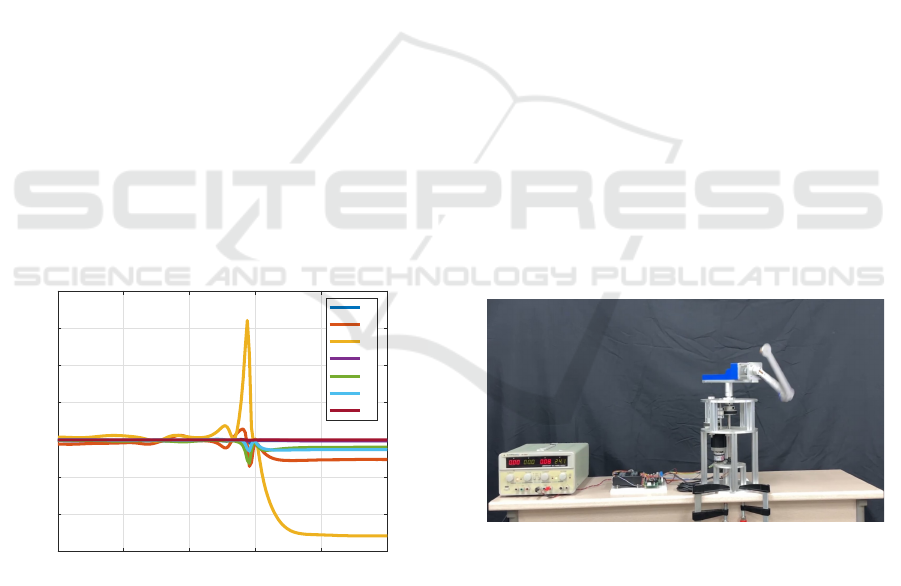

applied in the earlier Figure 7 can be seen in Figure 8.

K(t) = R

−1

Tr

B

T

(t)P(t). (13)

0 0.5 1 1.5 2 2.5

time(sec)

-1500

-1000

-500

0

500

1000

1500

2000

time-varying feedback gain

K

1

K

2

K

3

K

4

K

5

K

6

K

7

Figure 8: Time-varying LQ gain of feedforward transition

trajectory from EP0 to EP3.

To conduct the experiments, the swing-up trajec-

tory obtained using the direct collocation method pre-

sented in Chapter 3 is combined with the LQ control-

based feedback controller to implement the 12 differ-

ent transition controls. The trajectory paths are con-

figured according to the flowchart in Figure 5, and

the transition paths between each equilibrium point

are designed to move only once. The duration of one

cycle of state transition and linear control at the equi-

librium point is set to 5 seconds, with the time taken

for state transitions varying from a minimum of 1.8

seconds to a maximum of 3 seconds, as shown in

Table 2. After each transition, linear control is per-

formed at the corresponding equilibrium point until

the next transition control begins, to stabilize the sys-

tem. Figure 9 shows a captured image of a YouTube

video that presents the experimental results of 12 tran-

sition controls. The actual YouTube video can be ac-

cessed at https://youtu.be/J8vRJtQ-t3I (Video title: 12

transition controls of a rotary double inverted pendu-

lum (with double reduction timing pulleys), Channel

name: Embedded Control Lab.), where the experi-

mental results can be viewed in detail.

The first state transition begins at the 5-second

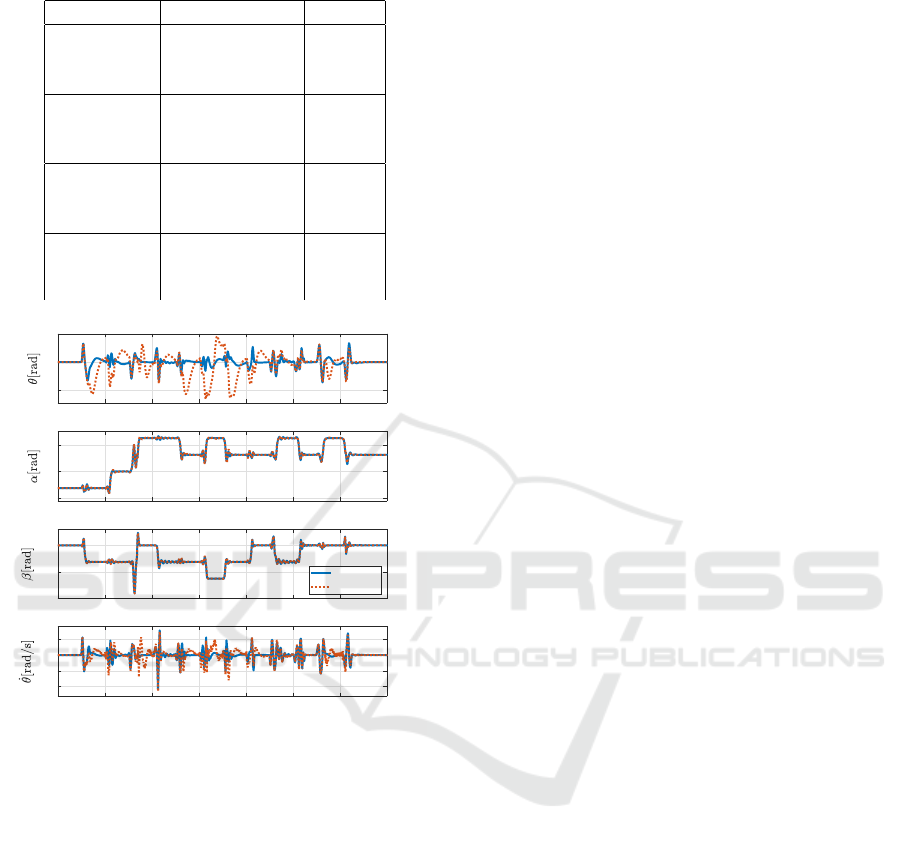

point, and Figure 10 shows the continuous results of

all transition controls. Each line represents the sim-

ulation model trajectory depicted by solid lines and

the actual experimental trajectory shown by dashed

lines. Due to the compensation effect of the closed-

loop control, the arm’s rotation angle θ and angular

velocity

˙

θ exhibit significant differences immediately

after the state transition, but the result graphs for α

and β, which are the most critical variables in transi-

tion control, demonstrate that the predicted paths are

followed with high accuracy. Following this, linear

control at the equilibrium point gradually adjusts the

θ value to approach zero, helping to limit the random

movement of the double pendulum and enabling all

12 transition controls to be successfully executed.

Figure 9: The Youtube video for 12 transition controls of

the RDIP.

5 CONCLUSION AND FUTURE

WORK

In this paper, we established an experimental envi-

ronment using a physically constructed rotary dou-

ble inverted pendulum system to address 12 transition

control problems, including swing-up control. We

introduced a method for generating feedforward tra-

jectories using the direct collocation technique and

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

98

Table 2: Transition times used in the experiments.

Starting EP Destination EP T [sec]

EP0 EP1 2.000

EP2 3.000

EP3 2.500

EP1 EP0 1.800

EP2 2.500

EP3 2.500

EP2 EP0 2.500

EP1 2.000

EP3 2.921

EP3 EP0 2.500

EP1 2.000

EP2 2.000

0 10 20 30 40 50 60 70

-2

0

2

0 10 20 30 40 50 60 70

-5

0

5

0 10 20 30 40 50 60 70

-10

-5

0

simulation

true data

0 10 20 30 40 50 60 70

Time

-10

-5

0

5

Figure 10: 12-step transition trajectories of the rotary dou-

ble inverted pendulum: simulated trajectory (solid line) and

actual trajectory (dot-dashed line).

implemented these trajectories with a 2-DOF con-

troller incorporating time-varying LQ control. This

approach effectively addressed the complex transition

control problem by combining feedforward trajec-

tory generation and feedback control. The efficiency

and feasibility of the proposed method were demon-

strated through continuous control of the 12 transi-

tion paths among the four equilibrium points of the

double inverted pendulum. The main contributions

of this study include the novel definition and experi-

mental implementation of the transition control prob-

lem between equilibrium points, extending the exist-

ing swing-up problem, and the practical applicability

of the proposed control strategy validated through ex-

perimental results.

Future research can consider several directions

to further develop the transition control method pre-

sented in this paper. First, the application of a Distur-

bance Observer (DOB) technique could enhance the

robustness of the system against disturbances. Sec-

ond, incorporating artificial intelligence-based con-

trol techniques such as Reinforcement Learning could

lead to the development of more intelligent and adap-

tive control systems. Third, introducing advanced

control strategies, such as nonlinear control tech-

niques or Model Predictive Control (MPC), could be

a promising direction to improve the performance of

the controller.

As additional research, it is necessary to evaluate

the performance of the transition control under vari-

ous experimental environments and conditions to ver-

ify the generality of the proposed method. In the fu-

ture, this transition control strategy will be applied to

multi-dimensional and multi-body systems to explore

the controllability of more complex dynamic systems.

Through this, it is expected that the method can be de-

veloped into a universal control technique applicable

not only to the rotary double inverted pendulum sys-

tem but also to other complex dynamic systems.

ACKNOWLEDGEMENTS

This work was supported by the National Research

Foundation of Korea(NRF) grant funded by the Korea

government(MSIT)(RS-2024-00347193).

REFERENCES

Baek, J., Lee, C., Lee, Y. S., Jeon, S., and Han, S. (2024).

Reinforcement learning to achieve real-time control of

triple inverted pendulum. Engineering Applications of

Artificial Intelligence, 128:107518.

Brown, D. and Strube, M. (2020). Design of a neural con-

troller using reinforcement learning to control a rota-

tional inverted pendulum. In 2020 21st International

Conference on Research and Education in Mechatron-

ics (REM), pages 1–5.

¨

Astr

¨

om, K. J. and Furuta, K. (2000). Swinging up a pendu-

lum by energy control. Automatica, 36(2):287–295.

Graichen, K., Treuer, M., and Zeitz, M. (2007). Swing-up

of the double pendulum on a cart by feedforward and

feedback control with experimental validation. Auto-

matica, 43:63–71.

Ibrahim, M. M., Ubaid, M. A., Rachid, M., and Maamar,

B. (2019). Stabilization of a double inverted rotary

pendulum through fractional order integral control

scheme. International Journal of Advanced Robotic

Systems, 16(4).

Ju, D., Choi, C., Jeong, J., and Lee, Y. S. (2022). Design

and parameter estimation of a double inverted pendu-

lum for model-based swing-up control. Journal of In-

Implementation of 12 Transition Controls for Rotary Double Inverted Pendulum Using Direct Collocation

99

stitute of Control, Robotics and Systems (in Korean),

28(9):793–803.

Kelly, M. (2017). An introduction to trajectory optimiza-

tion: How to do your own direct collcation. SIAM

Review, 59(4):849–904.

Liang, F., Xin, X., and Li, Y. (2023). Swing-up and balance

control of rotary double inverted pendulum. In Pro-

ceedings of the 2023 3rd International Conference on

Robotics and Control Engineering, page 65–70.

Meta, T., Gyeong, G. Y., Park, J. H., and Lee, Y. S. (2014).

Swingup control of an inverted pendulum subject to

input/output constraints. Journal of Institute of Con-

trol, Robotics and Systems (in Korean), 20:835–841.

Oh, Y. and Lee, Y. S. (2018). Robust Swing-up Control of

a Rotary Inverted Pendulum Subject to Input/Output

Constraints. Journal of Institute of Control, Robotics

and Systems (in Korean), 24(5):423–430.

Rahairi, M., H.Selamat, Zamzuri, H., and Ahmad, F.

(2011). Pid controller optimization for a rotational

inverted pendulum using genetic algorithm. In 2011

Fourth International Conference on Modeling, Simu-

lation and Applied Optimization, pages 1–6.

Ratiroch-Anant, P., Anabuki, M., and Hirata, H. (2004).

Self-tuning control for rotational inverted pendulum

by: eigenvalue approach. In 2004 IEEE Region 10

Conference TENCON 2004., volume D, pages 542–

545.

Singh, S. and Swarup, A. (2021). Control of rotary dou-

ble inverted pendulum using sliding mode controller.

In 2021 International Conference on Intelligent Tech-

nologies (CONIT), pages 1–6.

Sondarangallage, D. A. and Manukid, P. (2019). Control of

rotary double inverted pendulum system using mixed

sensitivity h∞ controller. International Journal of Ad-

vanced Robotic Systems, 16(2).

Thein, M.-W. and Misawa, E. (1995). Comparison of the

sliding observer to several state estimators using a ro-

tational inverted pendulum. In Proceedings of 1995

34th IEEE Conference on Decision and Control, vol-

ume 4, pages 3385–3390.

Tran, N., Nguyen, V., Le, C., Lai, A., Nguyen, T., Huynh,

M., Phan, V., Tong, G., Nguyen, L., and Ngo, T.

(2024). Lqr control for experimental double rotary in-

verted pendulum. Journal of Fuzzy Systems and Con-

trol, 2(2):104–108.

Zied, B. H., Mohammad, J. F., and Zafer, B. (2020). De-

velopment of a Fuzzy-LQR and Fuzzy-LQG stabil-

ity control for a double link rotary inverted pendu-

lum. Journal of the Franklin Institute, 357(15):10529–

10556.

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

100