Automatic Placement of Digital Signals in Railway Digitalization: A

Constraint Approach

Sven L

¨

offler and Petra Hofstedt

Chair of Programming Languages and Compiler Construction,

Brandenburg University of Technology Cottbus - Senftenberg,

Konrad-Wachsmann-Allee 5, 03046 Cottbus, Germany

fl

Keywords:

Constraint Satisfaction, Planning and Scheduling, Digitalization, Logistics, Decision Support Systems,

Operation Scheduling Problem.

Abstract:

The aim of digitalization is to streamline operations and conserve resources; however, the process itself often

requires significant intellectual and resource investment. This paper addresses a digitalization challenge within

the German railway system, focusing on the placement of digital signals at appropriate distances from existing

switches along station track sections, replacing analog signals. This study serves as a feasibility analysis

demonstrating how constraint programming can resolve the problem. We first formulate a constraint problem

that defines the issue, then demonstrate methods to accelerate the solution process of the model, making it

suitable for larger problems. This approach is validated through a series of tests using generated scenarios to

illustrate its applicability to real-world challenges.

1 INTRODUCTION

The German railway network currently spans approx-

imately 39,200 kilometers, of which around 33,400

kilometers are operated by Deutsche Bahn. The com-

pany has set a goal to digitize its infrastructure. While

the outcome of digitalization aims to simplify opera-

tions and save resources, the actual process of digiti-

zation is itself often complex and resource-intensive.

One of Deutsche Bahn’s objectives is to replace ex-

isting analog signals with digital ones, necessitating

the installation of new signals and sensors. There are

specific guidelines controling the placement of these

components that must be adhered to. Currently, this

planning process is conducted manually, evaluated,

and, upon successful review, either implemented or

re-planned.

To streamline and accelerate this process, this pa-

per proposes a feasibility study demonstrating how

such challenges can be addressed using constraint

programming. The remainder of the paper is struc-

tured as follows: Section 2 begins by examining

the DB planning problem in detail and provides an

overview of constraint programming. Section 3 dis-

cusses related work and highlights the differences

from this study. Section 4 introduces our constraint-

based model for solving the DB planning problem.

However, for many practical problems, merely gen-

erating a valid constraint model is insufficient; ad-

justments must also be made to enhance the solution

speed of the problem. Therefore, the latter part of

Section 4 explores various optimizations for our con-

straint model. Section 5 encompasses our test series

and evaluation of the approach. Finally, the conclud-

ing Section 6 summarizes the key points of the paper

and outlines future directions.

2 PRELIMINARIES

Below, we briefly introduce the Deutsche Bahn Plan-

ning Problem and explain the fundamentals of con-

straint programming.

2.1 The DB Planning Problem

In the context of the ”Deutsche Bahn” (DB), the fol-

lowing problem arose during the digitalization pro-

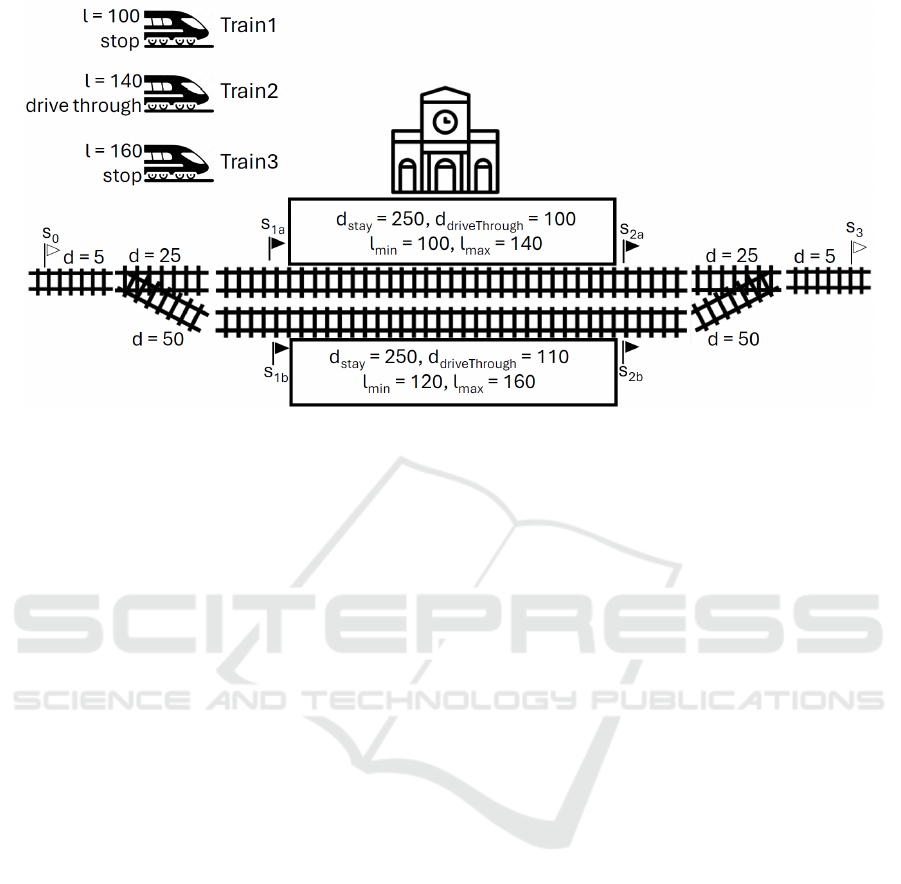

cess. We assume the following general setting, see

Figure 1. In general, for a given section of track that

includes a station, manual signals are to be replaced

with digital ones, whereby optimizing the train flow.

Trains (of different lengths) run on tracks. A

(main) track can be split into two (side) tracks by a

Löffler, S. and Hofstedt, P.

Automatic Placement of Digital Signals in Railway Digitalization: A Constraint Approach.

DOI: 10.5220/0012994800003822

In Proceedings of the 21st International Conference on Informatics in Control, Automation and Robotics (ICINCO 2024) - Volume 1, pages 101-112

ISBN: 978-989-758-717-7; ISSN: 2184-2809

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

101

switch, and two (side) tracks can also be joined by

a switch. Depending on the switch setting, a train

can thus move from the main track to one of the side

tracks or switch from a side track to the main track.

Switches and their positions are announced by sig-

nals. These signals usually announce the switch 70

meters in advance. The distance of 70 meters can be

reduced to a value of 50 meters in justified cases.

Figure 1 shows a diverging switch on the left and a

converging split on the right. The signals are marked

by s

i

. In the context of our considerations, only the

signals s

1a

, s

1b

and s

2a

, s

2b

are relevant (thus black).

There are also stations at which trains can stop or

drive through without stopping. A station usually has

several tracks. Trains can stop at platforms (marked

as boxes in Figure 1) on the tracks and pick up or drop

passengers. This means that there are often many

switches before and after stations to guide the trains

to the appropriate tracks. However, the signals of the

switches must not be located in the platform area. As

described above, switches can then be located at a dis-

tance of 70 meters (possibly less, but at least 50 me-

ters) after the signals.

A given railway network with corresponding

switches therefore has an influence on the maximum

length of platforms (in Figure 1: l

min

, l

max

) in the area

of the stations, depending on the placement of the sig-

nals, and therefore also on the maximum length of the

trains that are allowed to stop there.

The figure also shows durations (d in abstract time

units) for the passage or stop of trains in certain track

areas or at platforms.

The problem is that the trains passing through

the section have different lengths and require varying

amounts of time to traverse the individual segments.

Placing all digital signals at a distance of 70 meters

can result in some trains being unable to stop at cer-

tain platforms because the stopping area is too small

for the train’s length. Conversely, not all signals can

be uniformly set to a 50-meter distance to create the

largest possible stopping areas. It must be individu-

ally justified for each digital signal that a placement at

50 meters instead of 70 meters is necessary to achieve

maximum productivity.

This creates an optimization problem where the

digital signals must be positioned to maximize the

throughput rate of trains within the given time inter-

val while minimizing the deviation from the 70-meter

distance between all switches and their digital signals.

Determining the optimal throughput rate presents an

exponentially growing problem, which is rarely ver-

ifiable by hand. Currently, planning is done manu-

ally and subsequently reviewed by safety personnel,

resulting in numerous iterations in the planning and

control process until a satisfactory solution is found.

The quality of this solution in terms of the trains’

throughput rate is often not optimal.

Our approach initially focuses on a feasibility

study, hence we make some simplifications. We as-

sume that each train occupies each track component

for a specific duration d. This duration can vary de-

pending on the action performed during the traversal

of the track section. For example, whether a train

passes through a platform or stops and starts again.

Another initial simplification is that all trains come

from the same direction and continue in the same di-

rection. For our optimization problem, we consider

the following track components with their associated

parameters.

Tracks: Each track is occupied by a train for a spe-

cific duration d

Track

.

Switch (Diverging): A diverging switch splits a track

A into two other tracks B and C. Depending on the

switch setting, the train moves from track A to track

B or C. The occupancy duration d

switch

of the switch

depends on the setting (connection to track B or C)

d

split

∈ {d

B

,d

C

}.

Switch (Converging): Analogous to the diverging

switch, a converging switch merges two tracks A and

B into one track C. Depending on the switch set-

ting, the duration a train occupies it varies d

merge

∈

{d

A

,d

B

}.

Platform: Each platform has a minimum l

min

and

maximum length l

max

depending on whether the digi-

tal signal is 50 or 70 meters (or in between) from the

next switch. Trains can only use platforms that meet

the minimum length requirement. Trains have two op-

tions: either they stop at a platform, which takes a sig-

nificant amount of time, or they simply pass through

the platform. d

platform

∈ {d

driveT hrough

,d

stay

}

Train: A train has a specific length length and in-

formation stay about whether it needs to stop (stay =

true) at the platform or not (stay = f alse). If the train

needs to stop, it must stop at a platform that is long

enough and requires a corresponding amount of time.

If the train does not need to stop at the platform, it

will just pass through the platforms.

Thus, we face an optimization problem where

digital signals must be positioned to maximize the

throughput rate of trains within a given time inter-

val, while minimizing the deviation from the 70-meter

distance between all switches and a digital signal.

In our example DB Planning Problem in Fig-

ure 1, there are three incoming trains with differ-

ent lengths (l

Train1

= 100m, l

Train2

= 140m, l

Train3

=

160m) which must be navigated through a track net-

work with two switches and two platforms. Train 1

and Train 3 must stop at a sufficiently long platform,

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

102

Figure 1: A simple example DB PLanning Problem.

whereas Train 2 only needs to pass through the track

sections without stopping. The goal is for Train 1 to

pass over the first track before Train 2, and Train 2

before Train 3. A train can only enter a track seg-

ment if no other train occupies it at the same time.

For the initial track segment (far left in the figure),

each train requires d

Track

= 5 time units (TU) to tra-

verse it. Depending on the switch position, trains then

require either d

B

= 25TU to reach the upper platform

or d

C

= 50TU to reach the lower platform. Depend-

ing on whether a train stops at the upper platform, it

will occupy this track segment for d

stay

= 250TU or

d

driveT hrough

= 100TU. For the lower platform, the

times are d

stay

= 250TU and d

driveT hrough

= 110TU,

respectively. After the platform, the trains proceed

through the second switch and the final track segment.

The planning objective is to assign track segments

and times to the trains such that:

No two trains occupy the same track segment si-

multaneously. Each train stops at a valid platform if

required. Trains leave the track segments as quickly

as possible. Platform lengths are minimized, as min-

imal platform lengths correspond to a 70-meter dis-

tance of digital signals from the switches.

To adapt to real-world conditions beyond the fea-

sibility study, it would be necessary to allow trains to

pass through the station in both directions. Addition-

ally, it might be required to specify individual occu-

pancy times for each pair of train and track section.

These enhancements will ensure the optimization

model accurately reflects the complexity of real-world

train scheduling and track usage.

2.2 Constraint Programming

Constraint programming (CP) is a methodology used

for the declarative modeling and solving of complex

problems, especially those classified as NP-complete

and NP-hard. CP is applied in various problem do-

mains, including rostering, graph coloring, optimiza-

tion, and satisfiability (SAT) problems (Marriott and

Stuckey, 1998). In this section, we introduce the

fundamental concepts of constraint programming that

underpin our approach.

The general process of constraint programming

consists of two distinct phases:

1. The declarative formulation and representation of

a problem as a constraint model. This involves

defining constraints, variables, and their interre-

lationships, thereby establishing the logical struc-

ture of the problem or solution.

2. The resolution of the constraint model using a

dedicated constraint solver. The solver functions

independently, like a self-contained black box, ad-

dressing the complexities of the problem.

In essence, the CP user’s role is to craft the

application-specific problem model using constraints

and to set up and initiate the solver. The solver then

autonomously applies advanced techniques to explore

potential solutions and find an optimal or satisfac-

tory outcome. This separation of responsibilities sim-

plifies the problem-solving process, allowing domain

experts to focus on the abstract representation of their

real-world challenges.

A constraint satisfaction problem (CSP) is for-

mally defined as a 3-tuple P = (X, D,C), comprising

Automatic Placement of Digital Signals in Railway Digitalization: A Constraint Approach

103

the following components: X = {x

1

,x

2

,...,x

n

} rep-

resents a set of variables. D = {D

1

,D

2

,...,D

n

} is a

collection of finite domains, where D

i

denotes the do-

main of variable x

i

. C = {c

1

,c

2

,...,c

m

} constitutes a

set of constraints, with each constraint c

j

defined over

a subset of variables from X (Apt, 2003).

A constraint, denoted by a tuple (X

′

,R), consists

of a relation R and an ordered set of variables X

′

,

which is a subset of X , over which the relation R is

defined (Dechter, 2003). For instance, examples of

constraints include ({x, y}, x < y), ({x,y,z},x+y = z),

or ({A,B},A → B). Given that the variables involved

in a constraint are explicitly identifiable within their

corresponding relation, we solely specify the relation

in the subsequent sections of this paper.

A solution of a CSP involves the instantiation of

all variables x

i

with values d

i

from their respective

domains D

i

, such that all constraints are satisfied.

Additionally, a constraint optimization problem

(COP) extends the scope of a CSP. In a COP, an opti-

mization variable x

opt

is explicitly identified, and the

objective is to minimize or maximize this variable to

reach an optimal solution.

A specific constraint we use, in addition to many

simple and intuitive constraints, is the count con-

straint. For an ordered set of variables {x

1

,...,x

n

} =

X, this constraint specifies that a particular value v ∈

N must appear exactly occ ∈ X times among the vari-

ables.

count(X,occ,v) ⇔

∑

x∈X

(

0 x ̸= v

1 x = v

!

= occ (1)

An example of a valid assignment for the

count constraint count({x

1

,x

2

,x

3

},occ,2) with

D

1

,D

2

,D

3

∈ {1,2,3,4,5} and D

occ

∈ {1,3} is

x

1

= 2,x

2

= 1,x

3

= 3, and occ = 1, because the value

2 occurs once in the variable assignement. Another

solution is, e.g. x

1

= 2, x

2

= 2, and x

3

= 2, where the

value 2 occurs 3 times, i.e. occ = 3.

3 RELATED WORK

Related work primarily focuses on the Operation

Scheduling Problem (OSP), whose greatest challenge

lies in efficiently allocating limited resources to a

large number of train operations, especially during

peak demand periods (Zhong et al., 2024).

Both the quality and the speed of planning the

station operation schedules are crucial. While train

operations can be represented through resource allo-

cation, the OSP can be described as optimizing the

use of resources for a large number of train opera-

tions without conflicts at the station. Conflicts be-

tween two operations arise from the simultaneous use

of the same resource, and railway operations must be

entirely conflict-free. Generally, the resources refer to

railway infrastructure such as tracks, platforms, sig-

nals, and switches.

There are many publications focused on the OSP

in railway stations (Caimi et al., 2012; Rodriguez,

2007). These works primarily address the creation of

train routes through multi-track station areas but do

not consider the possibility that platform length can

vary due to digitalization and the associated recon-

struction.

Carey and Carville (Carey and Carville, 2000;

Carey and Carville, 2003) proposed and tested models

and algorithms for train scheduling at a single, heavily

trafficked, complex station. Their later work (Carey

and Crawford, 2007) extended scheduling from a sin-

gle station to a railway corridor. Freling et al. (Frel-

ing et al., 2005) assigned train units to marshalling

tracks through a column generation algorithm but did

not discuss potential routing conflicts between sched-

uled train paths within different station areas. These

methods have the advantage of being based on prac-

tical rules, making planning decisions understandable

and acceptable to the schedulers, thus beneficial for

their improvement.

Based on the creation of optimization models,

many methods have been proposed to solve the plat-

form problem or the reception-departure line assign-

ment problem, mainly including mathematical pro-

gramming software (Billionnet, 2003; Zhang et al.,

2019), branch-and-bound methods (Caprara et al.,

2011), and heuristic algorithms (Liu and Kozan,

2009), such as the ant algorithm-based method (Yue

et al., 2006), local search algorithm (Qi et al.,

2016), global neighborhood search algorithm (Mu

and Dessouky, 2011), and customized simulated an-

nealing algorithm (Kang et al., 2019).

In the past decade, heuristic algorithms have been

continuously improved and published (e.g., water

drop algorithms (Siddique and Adeli, 2014), particle

swarm optimization with selective search (Hossain

et al., 2019), and discrete spider monkey optimization

(Akhand et al., 2020)). However, heuristic algorithms

often require a large number of experiments to find

the best parameter settings for each case due to their

sensitivity to parameters, and the quality of their so-

lutions is easily affected by random factors, making

direct evaluation difficult.

In summary, none of these approaches consider

the flexible size of a platform by adjusting signals,

thereby affecting its usability for trains of varying

lengths.

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

104

4 A CONSTRAINT-BASED DB

APPROACH

In this section, we present our basic implementation

of the DB Planning Problem as a Constraint Opti-

mization Problem (COP). Fundamentally, we con-

sider the entire problem as a matrix of pairs of start

time and track segment of each train. This allows

to represent the concrete train sequence over a cer-

tain cutout of a railway net. The dimensions of

the matrix are the number of trains #Trains and

maximum number of track segments or components

maxComponents that each train must traverse to pass

through the entire track section. Subsequently, in

the tuple matrix M

i, j

= (component, startTime),i ∈

{1, 2, ..., #Trains}, j ∈ {1, 2, ..., maxComponents +

1}, we specify for each component when it is en-

tered by a respective train. The last component

maxComponent + 1 is needed to determine the time

when a train leaves the entire track section. If fewer

than the maximum number of components are needed

for a train, the tuples are filled with ”Completed”

components. See the following example which rep-

resents a solution for the problem given in Figure 1.

The maximum number of components that a train

must traverse in the example is 5 (which is also the

minimum number). Therefore, for three trains, we

generate a 3 × 6 matrix. A solution might look as

shown in Table 1.

In this solution, it is important to note that the first

and third trains must stop at a platform, while the sec-

ond train is allowed to pass through. This can be iden-

tified by the times at which a train enters a platform

and then moves on to the next component (stopping

requires at least 250 time units). At this point, nothing

has been said about the actual optimization value. The

goal is to minimize the sum of the platform lengths. In

this example, Platform 1 (upper platform) requires a

length of 100 meters and Platform 2 (lower platform)

requires 160 meters. All trains pass through and leave

the section after 495 TU. Both values (260 meters to-

tal length and 495 TU) are optimal for this example.

In the following sections, we will first present an

intuitive approach to modeling the DB Planning Prob-

lem. Additionally, we demonstrate improvements to

the model that increase its solution speed, making it

applicable to real-world problems.

4.1 An Intuitive COP for the DB

Planning Problem

Figure 2 illustrates our intuitive COP for the DB Plan-

ning Problem.

Variables and Domains (lines 1-12) This imple-

mentation reflects the previous considerations to store

the solution as a matrix. Specifically, there are

(#Trains × (maxComponents + 1)) component and

time variables X

C

i, j

(line 1) and X

T

i, j

(line 2), respec-

tively. These together represent the problem matrix

(as explained above, see e.g. Table 1) and indicate

which track components are traversed by train i in

what order, and the time when each component is

entered. These component variables can take val-

ues from 0 to number of existing components (line

7), where the values 1 to #Components are assigned

to real components, and the value 0 corresponds to

”Completed,” meaning no component. ”Completed”

can only occur when the train has completely left the

entire track section. The time variables X

T

i, j

take on

values between 0 and a precomputed maximum time

maxTime. The value for maxTime represents an upper

estimate of the total required time.

Since it is unclear whether and when a train will

reach a platform, an additional variable X

S

i, j

has been

introduced for each encounter of a train with a com-

ponent (line 3). Such a stop variable takes the value 0

if the corresponding component variable X

C

i, j

indicates

that it is not a platform. Otherwise, it takes the value

1 if a train stops at the platform, or the value 2 if all

trains passes through the platform without stopping

(line 9).

For each platform, an additional variable x

L

i

is in-

troduced (line 4), which indicates the length of the

platform i. The value range of this variable is between

the minimum length (l

min

i

) and the maximum length

(l

max

i

) of the platform, determined by the positioning

of the signals relative to the switch (line 10).

Finally, we need a variable x

Total

T

(line 5) that rep-

resents the total time required for all trains to traverse

the segment, and a variable x

Total

L

that represents the

total length of the platforms. We utilize our generated

COP twice to minimize both values. According to the

railway operator, the flow of trains has priority, so in

the first run, the COP is minimized with respect to the

total time x

Total

T

(line 26). In a second run, this to-

tal time is then fixed for x

Total

T

, and the problem is

optimized with respect to the length of the platforms

x

Total

L

(line 26). Thus, we first calculate a solution

where trains can pass through the segment as quickly

as possible, and then we seek a solution where the

trains can pass through the segment equally quickly,

but the platforms are as short as necessary.

Constraints (lines 13-26). The following section

explains the key constraints of the COP. Simplifica-

tions have been made in the representation in Figure

2 for better understanding.

Automatic Placement of Digital Signals in Railway Digitalization: A Constraint Approach

105

Table 1: A possible solution to the DB Planning Problem (Comp

i

denotes the corresponding component) from Figure 1.

Comp

1

Time

1

Comp

2

Time

2

Comp

3

Time

3

Comp

4

Time

4

Comp

5

Time

5

Comp

6

Time

6

Train 1 StartTrack 0 Switch1 5 Platform1 30 Switch2 280 EndTrack 305 Completed 310

Train 2 StartTrack 5 Switch1 30 Platform2 80 Switch2 190 EndTrack 240 Completed 245

Train 3 StartTrack 30 Switch1 80 Platform2 190 Switch2 440 EndTrack 490 Completed 495

P = (X,D,C, f ) with:

1 X = X

C

= {x

C

i, j

| ∀i ∈ {1,...,#Trains}, j ∈ {1,...,maxComponents + 1}} ∪ (Component variables)

2 X

T

= {x

T

i, j

| ∀i ∈ {1,...,#Trains}, j ∈ {1,...,maxComponents + 1}} ∪ (Time variables)

3 X

S

= {x

S

i, j

| ∀i ∈ {1,...,#Trains}, j ∈ {1,...,maxComponents + 1}} ∪ (Stop variables)

4 X

L

= {x

L

i

| ∀i ∈ {1,...,#Platforms}} ∪ (Length variables)

5 {x

Total

T

} ∪ (Total time variable)

6 {x

Total

L

} (Total length variable)

7 D = D

C

= {D

C

i, j

| D

C

i, j

= {0,1,...,#Components}} ∪

8 D

T

= {D

T

i, j

| D

T

i, j

= {0,1,...,maxTime}} ∪

9 D

S

= {D

T

i, j

| D

S

i, j

= {0,1,2}} ∪

10 D

L

= {D

L

i

| D

L

i

= {l

min

i

,l

min

i

+ 1,..., l

max

i

}} ∪

11 D

Total

T

= {0,1,...,maxTime} ∪

12 D

Total

L

= {0,1,...,maxLength}

13 C = C

Start

= {x

C

i,0

= StartTrack | ∀i ∈ {1, 2, ..., #Trains}} ∪ (Start constraints)

14 = C

End

= {count(EndTrack,{x

C

i,0

,x

C

i,1

,...,x

C

i,maxComponent

},1} | ∀i ∈ {1,2,...,#Trains}} ∪

(End constraints)

15 = C

Platform

= {x

C

i, j

̸= Platform ⇔ x

S

i, j

= 0 | ∀x

C

i, j

∈ X

C

} ∪ (Platform constraints)

16 C

Train

= {x

T

i,1

< x

T

i+1,1

| ∀ j ∈ {1, 2, ..., #Trains}} ∪ (Train sequencing constraints)

17 C

Time

= {(x

C

i, j

= Completed) ⇒ (x

T

i, j

= x

T

i, j+1

) | ∀x

C

i, j

∈ X

C

} ∪ (Time constraints)

18 {(x

T

i, j

+time(x

C

i, j

) ≤ x

T

i, j+1

) | ∀x

C

i, j

∈ X

C

} ∪

19 {(x

Total

T

= max(x

T

i,maxComponent

| ∀i ∈ {1,2,...,#Trains})} ∪

20 C

Component

= {(x

C

i, j

= EndTrack) ⇒ (x

C

i, j+1

= Completed) | ∀x

C

i, j

∈ X

C

} ∪ (Component order constraints)

21 {(x

C

i, j

= Component) ⇒ (x

C

i, j+1

= successor(Component)) | ∀x

C

i, j

∈ X

C

} ∪

22 C

Different

= {(x

C

i

1

, j

1

= x

C

i

2

, j

2

) ⇒ ((x

C

i

1

, j

1

= Completed) ∨ (x

T

i

1

, j

1

≥ x

T

i

2

, j

2

+1

) ∨ (x

T

i

2

, j

2

≥ x

T

i

1

, j

1

+1

))

| ∀x

C

i

1

, j

1

,x

C

i

2

, j

2

∈ X

C

,x

C

i

1

, j

1

̸= x

C

i

2

, j

2

} ∪ (Different component constraints)

23 C

Stop

= {(stay(Train

i

) ⇔ count(1, {x

S

i,0

,x

S

i,1

,...,x

S

i,maxComponent

},1} | ∀i ∈ {1,2,...,#Trains}} ∪

(Stop constraints)

24 C

Length

= {(x

C

i, j

= Platform) ⇒ (x

L

S

i

≥ l

i

) | ∀x

C

i, j

∈ X

C

} ∪ (Length constraints)

25 {(x

Total

L

= sum(x

L

i

| ∀i ∈ {1,2,...,#Platforms})} (Total length constraint)

26 minimize(x

Total

T

) or minimize(x

Total

L

)

Figure 2: A COP for the DB Planning Problem.

The start constraints C

Start

(line 13) specify that

each train must initially be at the StartTrack. Since

this COP is only a feasibility study, we have not in-

cluded multiple different StartTracks. This would

certainly be feasible in reality, where trains could

come from different origines.

The end constraints C

End

(line 14) serve a simi-

lar function, ensuring that each train ends up at the

EndTrack. The difference in this constraint is that

it is unclear at which point the EndTrack will appear

in the sequence of components. This depends on the

number of track segments in each parallel sequence of

platforms and other components. Since only ”Com-

pleted” can follow the EndTrack, it is sufficient to

require that the end component appears once in each

train’s component sequence. This is ensured by the

specified count constraint.

The platform constraints C

Platform

(line 15) ensure

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

106

that the stop variables take the value 0 precisely when

the component is not a platform. Conversely, these

variables must either take the value 1 (stop) or 2 (pass-

through).

The train constraints C

Train

(line 16) ensure that

the first train enters the StartTrack before the second

train, the second before the third, and so on.

The time constraints C

Time

encompass three dif-

ferent types of constraints. The first type (line 17)

ensures that if a component variable takes the value

”Completed,” the entry time for the following com-

ponent (which must also be ”Completed”) must be the

same. This propagates the final time within the tuple

matrix to the back, allowing the final arrival times to

be read from the last column.

The second type of constraint (line 18) ensures

that the following component (c

j+1

) can be entered

no earlier than when the previous component (c

j

) is

entered (x

T

i, j

) and is no longer blocked by passing

through or stopping (time(x

C

i, j

)). The function time

here is a simplified representation, as switch and plat-

form components may have different occupancy times

depending on whether the train is directed in one di-

rection or another or stops at a platform versus pass-

ing through. In the actual implementation, this con-

straint is represented by several other constraints that

are semantically equivalent to the one of Figure 2.

The third type of time constraint (line 19) ensures

that the variable x

Total

T

takes the maximum time of

all the last components. Since we specify one more

component in our set of variables than needed to tra-

verse the segment, the last component must always

be a ”Completed” component. This component has

an associated time value exactly equal to x

T

i, j

, the time

at which train i leaves the last real component.

The component constraints C

Component

specify that

only ”Completed” can follow the EndTrack (line 20),

and that each normal component can only be followed

by a component that logically succeeds it (line 21).

The successor function here is an abstraction. For a

switch, the successor depends on the switch’s setting.

Technically, this was implemented through various

constraints that are semantically equivalent to the one

described here. This constraint also ensures that only

other ”Completed” components can follow a ”Com-

pleted” component.

The different occupancy constraints C

Different

(line

22) state that each component can be occupied by

only one train at a time. If two trains i

1

and i

2

have

the same component, they must occupy it at differ-

ent times, unless the component is the ”Completed”

component, which can be occupied by all trains si-

multaneously.

The stop constraints C

Stop

(line 23) specify that if

a train Train

i

is to stop within the entire component

segment, it must do so at exactly one platform. This

is true if and only if one of the stop variables x

S

i, j

as-

signed to the train takes the value 1.

Finally, we have the length constraints C

Length

(line 24), which require that a train i can only stop

at or pass through a platform S

i

if the length of the

platform x

L

S

i

is greater than or equal to the length l

i

of

the train.

Additionally, there is a length constraint (line 25)

that sums the lengths of all platforms x

L

i

and assigns

the result to the variable x

Total

L

.

Finally, the objective function needs to be speci-

fied. In the case of the first COP, this involves min-

imizing the total time variable x

Total

T

. In the case

of the second COP, it involves minimizing the total

length of all platforms x

Total

L

(line 26).

4.2 Optimization of the COP for

Real-World Applications

Although the model presented in Figure 2 is correct, it

has some hidden weaknesses that prevent it from find-

ing solutions for real problems efficiently or proving

their feasibility quickly. These weaknesses in solving

arise from the manner in which a solver processes the

constraints.

Weak Propagation. Let us consider line 21. For

Switch1 (diverging) in the example from Figure 1, the

constraint (x

C

i, j

= Switch1) ⇒ ((x

C

i, j+1

= Platform1) ∨

(x

C

i, j+1

= Platform2)) holds. While this is correct,

there are hidden issues related to propagation in con-

junction with the time constraints x

T

i, j

+ time(x

C

i, j

) ≤

x

T

i, j+1

(line 18). Individually, both constraints are fine.

However, their combination leads to weaker propaga-

tion than expected.

In our example, according to the component con-

straint from line 21, if Switch1 is part of the com-

ponent sequence, the next component must be either

Platform1 or Platform2. Consequently, the next com-

ponent must occupy at least 100 TU (the minimum

occupancy time for either track). The problem is that

this cannot be immediately inferred by the COP. This

is because the variable x

C

i, j

is not yet uniquely deter-

mined and can still take on two possible values: either

Platform1 or Platform2. Therefore, the time function

cannot perform calculations, as it requires a definitive

variable assignment.

This problem can be circumvented by combin-

ing the two constraints from lines 18 and 21 into a

new constraint. Possible solutions include developing

a new, accurate constraint with appropriate propaga-

Automatic Placement of Digital Signals in Railway Digitalization: A Constraint Approach

107

tors or using model transformation methods such as

tabularization (Akg

¨

un et al., 2018) or regularization

(L

¨

offler et al., 2021; L

¨

offler, 2022).

In this work, we used both regularization and

transformation into element constraints to increase

the propagation strength.

The Direction of the Constraints. Normally, con-

straints are undirected. This means that from the con-

straint R = U/I, we can also derive U = R · I and

I = U/R. This is also true in our model; however,

the use of implications results in a forward propaga-

tion from the beginning to the end. The component

constraints (lines 20 and 21), as well as the time con-

straints (lines 17 to 19), always imply a subsequent

component or time for the current and the next seg-

ment. However, it is not possible to infer information

backward (from the next component to the previous

one).

In a solver search strategy that assigns variables

from front to back, this may not seem problematic at

first glance. However, first, we cannot assume such

a search strategy, and second, this overlooks the fact

that the last element is known (”Completed”) and that

only ”Completed” elements or the LastTrack can pre-

cede it. This means that, at least for the components,

we also need backward propagation.

For the temporal constraints, the need for back-

ward propagation is somewhat harder to see. How-

ever, since this is a COP, once we have found an

initial solution for our target value X

Total

T

, we will

only be searching for better solutions. Therefore, af-

ter finding an initial solution, we have a restriction

on the total time, which simultaneously constrains

the times for each train to leave the last segment

(x

T

i,maxComponents+1

). This means that, due to the nature

of how COP problems are solved, backward propaga-

tion is inherently necessary to propagate these con-

strained departure times to their preceding compo-

nents.

The problem of missing backward propagation in

the solution method of the solvers can be addressed

in both cases either by adding additional constraints

that consider the backward direction or by increasing

the level of consistency, e.g., by transforming the con-

straints (as mentioned in the previous paragraph using

regularization and tabularization).

To solve the problem for the components, we have

replaced all C

Component

constraints (lines 20 and 21)

affecting the same train with a regular constraint that

utilizes a deterministic finite automaton (DFA) rep-

resenting the entire track network. This automaton

ensures that components are automatically connected

in both directions. Specifically, if a component x

C

i, j

is known, it can be inferred that x

C

i, j+1

is the sub-

sequent component and x

C

i, j−1

is the preceding com-

ponent. For Platforms, Switches (converging), and

Tracks, the next component is always uniquely deter-

mined. In the case of Switches (diverging), there are

two possible successors. Conversely, for Platforms,

Switches (diverging), and Tracks, the predecessor is

always unique, whereas for Switches (converging),

there are two possible predecessors.

For the time constraints C

Time

, we have created an

additional constraint that, for each variable x

C

i, j

, deter-

mines and propagates the minimum required times of

all possible components (i.e., the remaining elements

in the domain of x

C

i, j

). Together, these constraints en-

sure that time can also be propagated backward (i.e.,

from later components to earlier components). This

leads to significant time savings, as it allows for the

rapid elimination of many time values that cannot be

part of a solution.

Parallelization of COPs. Parallelizing constraint

problems is a promising approach to accelerate the

solving of COPs. The most commonly used ap-

proaches are parallel search (R

´

egin et al., 2013) and

portfolio-based methods (R

´

egin and Malapert, 2018).

Both approaches can achieve superlinear speedup

in the solution time. Parallelizing COPs is gener-

ally challenging due to the high interaction of indi-

vidual components within a COP. However, the port-

folio approach offers a straightforward way for de-

velopers to parallelize the problem. In this approach,

a COP is solved independently in different versions,

and only the best optimization value found so far is

shared among them. This approach minimizes com-

munication overhead while allowing for quicker ex-

clusion of search space regions that yield worse opti-

mization values than those already known from other

versions.

Different versions of a model can involve using

various search strategies, different constraints, or dif-

ferent modeling approaches. It is even possible to

use different solvers in this way. The portfolio ap-

proach has proven to be very effective and easy to ap-

ply, making it widely used in real-world applications.

More information on the portfolio approach can be

found in (R

´

egin and Malapert, 2018). In our work,

we employed a portfolio approach with four different

search strategies.

The Search. As previously mentioned, the solution

speed of a COP heavily depends on the search strategy

used in the solver. For the DB Planning Problem, as-

signing component variables and time variables from

”front” to ”back” seems logical. However, classical

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

108

search strategies in solvers do not necessarily operate

this way. Some strategies, like wdeg and dom/wdeg,

follow conflict-driven approaches (Boussemart et al.,

2004). These approaches are based on complex cal-

culations to estimate future good decisions based on

decisions made so far or the underlying constraint net-

work. The resulting behavior typically does not re-

semble an ordered assignment of variables according

to their index order during creation.

For general problems, this approach is usually

very effective. However, as shown in other works

(L

¨

offler et al., 2024) , using problem-specific knowl-

edge in solver searches is a crucial factor for solution

speed. Therefore, it is advisable to design a targeted

problem-specific search strategy to explore the search

space as quickly as possible.

Currently, we have not yet developed a specific

search strategy to expedite problem-solving. How-

ever, we consider this a highly promising area for fu-

ture research.

Improving the Objective Function. It is possible

to further refine the objective function. For example,

when searching for a minimal end time x

Total

T

, we

encounter the problem that if a train A has to wait for

another train B to clear a track segment, train A can

wait directly at the previous component, at another

earlier component, or split the waiting time across

multiple components. This results in many equivalent

solutions that may all need to be explored. There-

fore, in our objective function, we assigned a high

weight w

high

to the final time and included the inter-

mediate times of individual components with a very

small weight w

small

.

minimize(w

high

∗ x

Total

T

+ w

small

∗ x

T

1,1

+ w

small

∗ x

T

1,2

+

... +w

small

∗ x

T

#Trains,maxComponents+1

)

(2)

The high weight w

high

must be chosen such that a

change in the total time x

Total

T

has a greater influence

than the weighted sum of the changes in the interme-

diate times x

T

i, j

.

This results in a prioritization of minimizing the

total time x

Total

T

over minimizing the individual in-

termediate times x

T

i, j

. This approach can also be

used to similarly include the minimization of platform

lengths x

Total

L

. By simply adding the weighted sum of

the total required length of the platforms, multiplied

by a similarly small weight, to the objective function:

x

Total

L

∗ w

small

. The search considers then also a min-

imal platform length (as well as a maximum distance

between switches and signals) with subordinate prior-

ity.

Due to the time limit of the search and the subordi-

nate priority of minimal length under minimal time, it

cannot be guaranteed that the shortest platform length

for the highest train throughput rate will always be

found. Therefore, it still makes sense to solve the sec-

ond constraint optimization problem (COP) with the

input of the maximum time and the minimization of

only the platform length x

Total

L

.

5 EXPERIMENTS AND RESULTS

All experiments were conducted on an LG Gram lap-

top with an 11th generation Intel(R) Core(TM) i7-

1165G7 quad-core processor running at 2.80GHz and

16GB of DDR3 RAM running at 2803MHz. The op-

erating system is Microsoft Windows 10 Enterprise.

The programming language used was Java with

JDK version 17.0.7 and the constraint solver Choco-

Solver version 4.10.7 (Prud’homme et al., 2017).

We generated 10 random station scenarios for

each combination of different numbers of trains (5,

10, 15, 20) and platforms (5, 10, 15, 20), resulting

in a total of 10 * 4 * 4 = 160 different test sce-

narios. For all problem instances, a time limit of 5

minutes was set for both determining a solution that

maximizes the throughput of trains through the track

section (minimize the total time x

Total

T

) and avoid-

ing distances under 70 meters between switches and

signals (minimize the total platform length x

Total

L

).

This previously introduced two-stage approach (first

minimizing x

Total

T

yieldings x

T

opt

, second minimizing

x

Total

L

with fixed x

T

opt

) ensures that initially, train flow

is maximized, followed by determining adjustments

to position signals closer than 70 meters to switches.

Table 2 presents the results of the 160 different

test runs. The first two columns indicate the num-

ber of trains and the number of Platforms in the track

segment. The column ∅DisArea shows the average

minimal and maximal summed platform length for

the 10 instances with the same number of trains and

platforms. The column ∅Dis represents the required

length for the fastest processing of the trains as calcu-

lated by our method. The time required for the trains

in Time Units (TU) is provided in the column ∅Time.

The last four columns provide insights into the so-

lution process. They indicate the average solution

time for computing the fastest processing of the trains

∅SolT(T) and for computing the shortest platforms

∅SolT(S). Additionally, the number of instances that

were completely and globally optimally solved is pro-

vided #comp(T) resp. #comp(L). The last row of

the Table 2 provides the average results across all in-

stances instances and the sums of the numbers of op-

Automatic Placement of Digital Signals in Railway Digitalization: A Constraint Approach

109

Table 2: Results of 160 different DB Planning Problems.

#Trains #Platforms ∅DisArea ∅Dis ∅Time ∅SolT(T) #Comp(T) ∅SolT(L) #Comp(L)

5 5 602-802 646 2039 248s 3 119s 7

5 10 1208-1608 1240 2124 265 s 2 166s 6

5 15 1786-2386 1856 3019 300 s 1 230s 3

5 20 2424-3224 2486 4067 300 s 0 199s 4

10 5 602-802 672 3922 300 s 0 150s 5

10 10 1208-1608 1302 3526 300 s 0 270s 1

10 15 1786-2386 1876 4438 300 s 0 271s 1

10 20 2424-3224 2516 5299 300 s 0 241s 2

15 5 602-802 676 4981 300 s 0 180s 4

15 10 1222-1622 1300 4389 300 s 0 271s 1

15 15 1786-2386 1898 5442 300 s 0 271s 1

15 20 2424-3224 2514 6278 300 s 0 243s 2

20 5 602-802 680 6052 300 s 0 181s 4

20 10 1222-1622 1314 5176 300 s 0 272s 1

20 15 1786-2386 1898 6379 300 s 0 273s 1

20 20 2424-3224 2522 7241 300 s 0 245s 2

12.5 12.5 1506-2006 1587 4648 298s 6 224s 45

timally solved instances (#Comp(T) and #Comp(L)),

resp.

First and foremost, it should be noted that the fact

that we were able to solve all 160 cases (though not

all globally optimal) represents a success for our fea-

sibility study. While these test cases were randomly

generated track segments, we believe that this solu-

tion method can be applied to comparably sized real-

world track segments. Ultimately, it needs to be eval-

uated with the railway employees who currently per-

form this process manually, to determine whether the

time units required for all trains to pass through are

better or worse than the manually determined ones.

In total, the fastest train passage was found in 6

cases (#Comp(T)). With further optimization of the

model, better search strategies, and more computa-

tion time (currently limited to 5 minutes), it is may

possible to achieve even better results.

The second computation step (calculating the min-

imal platform lengths to maximize the distance to

the signals) utilizes the results of the first calcula-

tion to set an upper bound on the maximum time and

then minimizes the platform lengths. This calculation

more frequently results in a global solution (in 45 out

of 160 cases). This means that in 45 cases, it was

proven that no better solution exists regarding the dis-

tance of the signals to the switches, where the trains

can pass just as quickly. In the other 115 cases, this

could not be definitively confirmed before reaching

the timeout, but no better solution was found either.

The result that the second computation is here un-

necessary (the second COP does not find a better so-

lution for x

Total

L

than the first COP in any case) is

due to the fact that we already incorporated platform

length into the objective function during the first com-

putation. Thus, the second computation served as a

verification of the first. It can be observed that the

calculated required platform lengths tend to be at the

lower end of the range (1587 in the range from 1506 to

2006), indicating a high quality of results. The lower

bound is unattainable because it simply represents the

sum of all minimal platform lengths, while the up-

per bound is the sum of all maximal platform lengths.

The lower bound cannot be reached because, by def-

inition, at least one platform must have a maximum

length for a train with a length of 180 meters.

A trend can be observed where an increase in the

number of trains more significantly reduces the num-

ber of problems that can be fully solved compared to

an increase in the number of platforms. From this, we

can infer that larger track segments can likely still be

managed as long as the number of trains does not in-

crease excessively. If the number of trains increases

significantly, it may be possible to divide them into

separate problems, first finding a solution for the first

20 trains, then for the next 20, and so on. This ap-

proach cannot guarantee a globally optimal solution;

however, we believe that the solution quality will still

be superior to that achieved through manual planning.

6 CONCLUSION AND FUTURE

WORK

We presented the Deutsche Bahn planning problem

for the digitization and placement of digital signals.

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

110

To address this, we developed a custom constraint

model, discussed and performed improvements (par-

allelization, model transformations, search strategies,

and objective functions) to make the model applica-

ble to real-world problems. It was demonstrated that

the approach works for generated (hypothetical) prob-

lems with up to 20 trains and 20 platforms.

Future work includes expanding the scenario to

incorporate additional components and various direc-

tions, as well as the consideration of real station sce-

narios. Furthermore, additional model optimizations

will be undertaken to enhance solution speed and,

consequently, solution quality within limited time

frames. Finally, it is essential to have the computed

solutions evaluated by railway experts.

REFERENCES

Akg

¨

un,

¨

O., Gent, I. P., Jefferson, C., Miguel, I., Nightin-

gale, P., and Salamon, A. Z. (2018). Automatic dis-

covery and exploitation of promising subproblems for

tabulation. In Principles and Practice of Constraint

Programming - 24th International Conference, CP

2018, Lille, France, August 27-31, 2018, Proceedings,

pages 3–12.

Akhand, M. A. H., Ayon, S. I., Shahriyar, S. A., Siddique,

N. H., and Adeli, H. (2020). Discrete spider monkey

optimization for travelling salesman problem. Appl.

Soft Comput., 86.

Apt, K. (2003). Constraint satisfaction problems: exam-

ples. Cambridge University Press. Principles of Con-

straint Programming: chapter 2.

Billionnet, A. (2003). Using integer programming to

solve the train-platforming problem. Transp. Sci.,

37(2):213–222.

Boussemart, F., Hemery, F., Lecoutre, C., and Sais, L.

(2004). Boosting systematic search by weighting con-

straints. In Proceedings of the 16th Eureopean Con-

ference on Artificial Intelligence, ECAI’2004, includ-

ing Prestigious Applicants of Intelligent Systems, PAIS

2004, Valencia, Spain, August 22-27, pages 146–150.

Caimi, G., Fuchsberger, M., Laumanns, M., and L

¨

uthi,

M. (2012). A model predictive control approach for

discrete-time rescheduling in complex central railway

station areas. Comput. Oper. Res., 39(11):2578–2593.

Caprara, A., Galli, L., and Toth, P. (2011). Solution of the

train platforming problem. Transp. Sci., 45(2):246–

257.

Carey, M. and Carville, S. (2000). Testing schedule perfor-

mance and reliability for train stations. J. Oper. Res.

Soc., 51(6):666–682.

Carey, M. and Carville, S. (2003). Scheduling and platform-

ing trains at busy complex stations. Transportation

Research Part A: Policy and Practice, 37(3):195–224.

Carey, M. and Crawford, I. (2007). Scheduling trains on a

network of busy complex stations. Transportation Re-

search Part B: Methodological, 41(2):159–178. Ad-

vanced Modelling of Train Operations in Stations and

Networks.

Dechter, R. (2003). Constraint networks. pages 25–49.

Elsevier Morgan Kaufmann. Constraint processing:

chapter 2.

Freling, R., Lentink, R. M., Kroon, L. G., and Huisman, D.

(2005). Shunting of passenger train units in a railway

station. Transp. Sci., 39(2):261–272.

Hossain, S. I., Akhand, M. A. H., Shuvo, M. I. R., Siddique,

N. H., and Adeli, H. (2019). Optimization of univer-

sity course scheduling problem using particle swarm

optimization with selective search. Expert Syst. Appl.,

127:9–24.

Kang, L., Lu, Z., and Meng, Q. (2019). Stochastic sched-

ule–based optimization model for track allocations in

large railway stations. Transportation Engineering,

Part A: Systems, 145(3).

Liu, S. Q. and Kozan, E. (2009). Scheduling trains as a

blocking parallel-machine job shop scheduling prob-

lem. Comput. Oper. Res., 36(10):2840–2852.

L

¨

offler, S. (2022). Optimierung und Regularisierung von

Constraint Satisfaction-Problemen (CSPs). PhD the-

sis, Brandenburg University of Technology, Cottbus,

Germany.

L

¨

offler, S., Becker, I., and Hofstedt, P. (2024). Enhancing

constraint optimization problems with greedy search

and clustering: A focus on the traveling salesman

problem. In Rocha, A. P., Steels, L., and van den

Herik, H. J., editors, Proceedings of the 16th Inter-

national Conference on Agents and Artificial Intelli-

gence, ICAART 2024, Volume 3, Rome, Italy, Febru-

ary 24-26, 2024, pages 1170–1178. SCITEPRESS.

L

¨

offler, S., Becker, I., Kroll, F., and Hofstedt, P. (2021).

A survey of constraint transformation methods. In

51. Jahrestagung der Gesellschaft f

¨

ur Informatik, IN-

FORMATIK 2021 - Computer Science & Sustain-

ability, Berlin, Germany, 27. September - 1. Okto-

ber, 2021, volume P-314 of LNI, pages 1107–1120.

Gesellschaft f

¨

ur Informatik, Bonn.

Marriott, K. and Stuckey, P. J. (1998). Programming with

Constraints - An Introduction. MIT Press, Cambridge.

Mu, S. and Dessouky, M. (2011). Scheduling freight trains

traveling on complex networks. Transportation Re-

search Part B: Methodological, 45(7):1103–1123.

Prud’homme, C., Fages, J.-G., and Lorca, X. (2017). Choco

documentation.

Qi, J., Yang, L., Gao, Y., Li, S., and Gao, Z. (2016). In-

tegrated multi-track station layout design and train

scheduling models on railway corridors. Transporta-

tion Research Part C: Emerging Technologies, 69:91–

119.

R

´

egin, J. and Malapert, A. (2018). Parallel constraint pro-

gramming. In Hamadi, Y. and Sais, L., editors, Hand-

book of Parallel Constraint Reasoning, pages 337–

379. Springer.

R

´

egin, J., Rezgui, M., and Malapert, A. (2013). Embarrass-

ingly parallel search. In Principles and Practice of

Constraint Programming - 19th International Confer-

ence, CP 2013, Uppsala, Sweden, September 16-20,

2013. Proceedings, pages 596–610.

Automatic Placement of Digital Signals in Railway Digitalization: A Constraint Approach

111

Rodriguez, J. (2007). A constraint programming model for

real-time train scheduling at junctions. Transporta-

tion Research Part B: Methodological, 41(2):231–

245. Advanced Modelling of Train Operations in Sta-

tions and Networks.

Siddique, N. H. and Adeli, H. (2014). Water drop algo-

rithms. Int. J. Artif. Intell. Tools, 23(6).

Yue, Y., Zhou, L., Sun, Q., and Yue, Q. (2006). An ant

algorithm for the reception-departure line assignment

problem. International Conference on Mechatronics

and Automation, pages 2284–2289.

Zhang, Q., Zhu, X., and Wang, L. (2019). Track alloca-

tion optimization in multi-direction high-speed rail-

way stations. Symmetry, 11(4):459.

Zhong, M., Yue, Y., Zhou, L., and Zhu, J. (2024). Paral-

lel optimization method of train scheduling and shunt-

ing at complex high-speed railway stations. Comput.

Aided Civ. Infrastructure Eng., 39(5):731–755.

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

112