A Taxonomy for Complexity Estimation of Machine Data in Machine

Health Applications

Lukas Meitz

1 a

, Michael Heider

2 b

, Thorsten Sch

¨

oler

1 c

and J

¨

org H

¨

ahner

2 d

1

Hochschule Augsburg, An der Hochschule 1, Augsburg, Germany

2

Universit

¨

at Augsburg, Am Technologiezentrum 8, Augsburg, Germany

Keywords:

Predictive Maintenance, Condition Monitoring, Complexity, Taxonomy, Product Automation Systems.

Abstract:

The Machine Health (MH) sector—which includes, for example, Predictive Maintenance, Prognostics and

Health Management, and Condition Monitoring—has the potential to improve efficiency and reduce costs for

maintenance and machine operation. This is achieved by data-driven analytics applications, utilising the vast

amount of data collected by sensors during machine runtime. While there are numerous possible fields of ap-

plication, the overall complexity of machines and applications in scientific publications is still low, preventing

MH technologies from being implemented in many real-world scenarios. This may be the result of a diffuse

understanding of the term complexity in the publications of this field, which results in a lack of focus towards

the core problems of real-world MH applications. This article introduces a new way of discerning complexity

in data-driven MH applications, enabling an effective discussion and analysis of present and future MH ap-

plications. This is achieved by creating a new taxonomy based on observations from relevant literature and

substantial domain knowledge. Using this newly introduced taxonomy, we categorise recent applications of

MH to demonstrate the usefulness of our approach and illustrate a still-prevalent research gap based on our

findings.

1 INTRODUCTION

The sector of Machine Health (MH), whose more

prominent elements are, for example, Predictive

Maintenance (PdM), Prognostics and Health Man-

agement, and Condition Monitoring, has the potential

to revolutionise modern machinery-related applica-

tions. In theory, MH technologies, such as estimating

a machine’s Remaining Useful Lifetime (RUL), are

able to reduce downtime, cost, and resource consump-

tion of maintenance and can improve overall machine

efficiency by using data that is continuously collected

and analysed (Serradilla et al., 2022).

However, as current surveys repeatedly find, there

are still numerous open challenges and research gaps

in the domain, preventing its technologies from be-

ing widespread and commonplace (Nunes et al.,

2023)(Gashi and Thalmann, 2020)(Serradilla et al.,

2022). Most important, there is a lack of generalisa-

a

https://orcid.org/0000-0001-7409-2401

b

https://orcid.org/0000-0003-3140-1993

c

https://orcid.org/0000-0001-5487-1862

d

https://orcid.org/0000-0003-0107-264X

tion in current research, with each research project be-

ing a solution to the specific machine at hand (Nunes

et al., 2023). Applications that are reported in sci-

entific literature are not as diverse as they could be;

published articles are still mostly staying at the level

of system components (Gashi and Thalmann, 2020).

The overall complexity of actual MH applications is

often said to be low, while—at the same time—there

is a lack of common understanding of the term com-

plexity in MH.

For the scope of this article, a first definition of

complex applications references applications, that are

hard or impossible to implement using existing stan-

dard components and algorithms. To aid future re-

search on implementing this type of applications, the

aim of this article is to further refine this definition,

and describe what exactly makes an application com-

plex. This refined definition is presented and intro-

duced as a new taxonomy in Section 4.

This taxonomy allows identifying and addressing

the parts of an application that introduce the most

complexity, thereby guiding the research field towards

removing the most relevant barriers to the adoption of

MH methods in practice.

Meitz, L., Heider, M., Schöler, T. and Hähner, J.

A Taxonomy for Complexity Estimation of Machine Data in Machine Health Applications.

DOI: 10.5220/0012994900003822

In Proceedings of the 21st International Conference on Informatics in Control, Automation and Robotics (ICINCO 2024) - Volume 1, pages 341-350

ISBN: 978-989-758-717-7; ISSN: 2184-2809

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

341

The contributions of this article are:

• Collection of related articles dealing with com-

plexity

• Introduction of a taxonomy for the term complex-

ity

• Categorisation of multiple applications using this

taxonomy

• Discussion of current applications, their complex-

ity level and research gaps

The structure of this work is the following: In Sec-

tion 2 the foundations for the remainder of this article

are introduced to enable an effective discussion. Sec-

tion 3 comprises a review of how the term complexity

has been used in recent applications, and summarises

the building blocks of related work. Afterwards, the

proposed taxonomy is explained in detail in Section 4

and used to classify multiple recent applications and

illustrate the findings in Section 5. Lastly, a discus-

sion about the selected applications and the usage of

the taxonomy is provided in Section 6 followed by an

outlook to future research.

2 FOUNDATIONS AND

PROBLEM DEFINITION

An application is a concrete implementation of a

paradigm, such as Predictive Maintenance, for a given

machine. Applications differ from machines in that

different applications are possible for one machine.

One application of MH for CNC Mill’s might be RUL

estimation of the used tool. Another application may

be the monitoring of vibrations from the same CNC

mill’s spindle. As can be seen from this, application

complexity is related not only to a machine, but to

each specific application.

In the context of this paper, we define Machine

Data as data that is created by or related to the oper-

ation of machinery. This not only encompasses pro-

duction machinery, but any type of machine that is

subject to continuous monitoring. Mostly, this data

is gathered by connected sensors attached to or built

into the machine or by logging signals that control the

machine or parts of it. However, different additional

sources of information can be present in an MH appli-

cation, such as meta-information about the operation

of the machinery. The data usually takes the form of

time series, as samples are recorded periodically from

sensors and other information sources.

We assume that the collection of data follows a

purpose beyond purely internal use, e.g. for control

systems: Engineers and/or Data Scientists want

to use that data for a variety of applications. Here,

extracting machine-related information from the

collected data is the main goal of MH. We can

distinguish between direct consumption by humans,

e.g. for remote condition monitoring, dashboarding,

or remote control, and (semi-)intelligent data-driven

applications, such as Prognostics and Health Man-

agement, which is often also known under the

term Predictive Maintenance and the main type of

application we focus on in this study.

To give an intuitive understanding of the problem

found in recent literature, we give a short example of

what complexity encompasses. One prominent appli-

cation example in the MH domain is fault detection

on ball bearings of rotating machinery. This can be a

straightforward affair and has seen exhaustive atten-

tion in recent publications, which are summarised for

example in (Farooq et al., 2024). The vibration data

in form of time series, generated by the ball bearing

in operation, can be analysed using off-the-shelf mod-

els. However, implementing the same fault detection

application is not as straightforward for more complex

machinery. Take the example of a robotic arm, which

consists of multiple jointed components monitored by

sensors. This setup is generating multiple different

time series with additional dependencies, in contrast

to the ball bearings application. Naturally, providing

the same fault detection mechanism for such an arm is

much more difficult and comes with more challenges

than in the simple ball-bearing application. In other

words, the robotic arm application is more complex,

but the way in which it is more complex is not prop-

erly defined.

This lack of specific understanding of complex-

ity leads to problems for implementing Predictive

Maintenance for sophisticated machinery. Solving

the example application with existing off-the-shelf so-

lutions is unlikely but of course highly desired. In

recent literature every application needed its own re-

search for finding suitable methods, as there is no

detailed description of the problem of complexity at

hand and comparison of different machines is not triv-

ial.

In this context, the consideration of data properties

is an important aspect, as we presume that it will aid

further research. Considering the sources and type of

complexity of an application can be used to estimate

the complexity of an application, help focus on the

core problems for implementation, and enables the

comparison of different settings. This in turn lends

an idea of what models or modelling approaches and

pipelines are applicable for any specific use case. To

achieve all this, we propose the creation of a new tax-

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

342

onomy that enables a mapping of complexity levels to

ways to process and model data.

3 DISCUSSION OF THE TERM

COMPLEXITY

Complexity is a term regularly used in multiple publi-

cations, especially to characterise systems that cannot

be easily described. In consequence, there are varying

definitions of the term complex in the context of MH.

To shed some light and give an overview of popular

definitions, we dive into the relevant literature based

on a short survey we performed.

3.1 Usage in Related Literature

In their work, Gashi et al. (Gashi and Thalmann,

2020) state that recent PdM applications mostly con-

sists of single-component-system solutions, which

neglect the dependency of components on each other

and therefore lacking complexity. The authors coint

the term multi-component systems (MCS) and give

four types of component interdependence, in order to

communicate which type of complexity could be part

of future research. Some publications use the term

complexity without explicit definition, such as Fos-

sier et al. (Fossier and Robic, 2017) and Dai et al. (Dai

et al., 2008), missing out on the opportunity to clarify

the exact challenges faced in their work.

In contrast to these, there are articles which ex-

plicitly deal with the term complexity and establish

isolated descriptions. Miller and Dubrawski (Miller

and Dubrawski, 2020) for example give an overview

of multiple different applications and group them by

similarity, which is useful for illustrating the range

of different implementations. As an additional re-

sult of their work, they analyse research gaps regard-

ing the complexity of current scenarios. To better

communicate their findings, they introduce the terms

component-level and system-level Predictive Main-

tenance, referring to the scope of implementations.

They find two gaps: First, in component-level scenar-

ios, there is mostly two distinct states of operation,

which are faulty and healthy. Second, most of the

more elaborate applications do not incorporate the in-

terdependence of components into their analysis and

fail to observe the system as a whole. Their termi-

nology using component-level and system-level gives

a solid starting point to where complexity might be

introduced in applications.

Nguyen et al. (Nguyen et al., 2015) set the focus

of their article on a decision policy rather than data

analysis. They introduce their own description of sys-

tem complexity as being inter-dependencies of differ-

ent kinds for a MCS.

Van Horenbeek et al. (Van Horenbeek and Pin-

telon, 2013) similarly introduce complexity in the

form of MCS with different kinds of dependencies

between components. They further state that there

are stochastic, structural and economic dependencies

between components of one machine. In their pa-

per, they address the problem of modelling such types

of dependencies and choosing a maintenance strategy

suited for a given system.

The approach of considering component depen-

dencies is adapted in a clear definition by Ahmed et

al. (Ahmed et al., 2021). They describe complex sys-

tems as systems with multiple components with de-

pendencies that are either unknown or hard to incor-

porate into a model. As examples of domains con-

taining complex applications they mention aerospace,

automotive, oil and gas, as well as industrial applica-

tions.

3.2 Basic Aspects of Complexity in

Applications

There are multiple publications that describe small as-

pects of complexity in the context of MH, whose in-

sights form a solid basis for discussion. To under-

stand their impact onto the proposed taxonomy, they

are referenced and described shortly.

Klein et al. (Klein and Bergmann, 2019) worked

on the subject of complexity in machines from the

perspective of data. Their publication tackles the

problem of complex data generation for PdM ap-

plications, with complexity being defined as multi-

variability. They give an overview of datasets that

are commonly used for benchmark purposes, describe

their attributes and finally introduce their own method

of generating multivariate time series data based on

a Fischertechnik factory model. The main aspect of

complexity they introduced is the use of multivariate

time series, which is considered an important attribute

in the further scope this article.

Blancke and Combette (Blancke et al., 2019) use

the term complex to mean that there are many possi-

ble modes of failure for the equipment being moni-

tored. They used expert knowledge to create a causal

graph of failure causes and symptoms in order to im-

plement PdM. They intuitively refer to complexity as

a high variance of possible machine states, but do

not give a formal definition. We, too, incorporate the

amount and difference in possible failure modes into

our taxonomy.

Lee and Pan (Lee and Pan, 2017) published a

A Taxonomy for Complexity Estimation of Machine Data in Machine Health Applications

343

way of implementing PdM for complex systems with

probabilistic dependencies. They list publications

addressing PdM for multi-component machines and

single-component applications, and give a possible

implementation of PdM. While their dataset does not

consist of time series data and is quite outdated, they

do define their understanding of a complex system

explicitly: They characterise it as multi-leveled hi-

erarchical system with multiple components and un-

known component dependencies. These dependen-

cies are another way of introducing complexity to a

multi-component system, which will be relevant in

the course of this article as well.

Z

¨

ufle et al. (Z

¨

ufle et al., 2021) also deal with the

complexity of data, but do not explicitly explain their

understanding of it. They introduce a workflow for

anomaly detection on machine tool data. Instead of

relying on benchmark datasets, they use real-world

data collected from a machining centre and process it

in order to implement supervised anomaly detection.

To achieve this, they used a segmentation approach on

the complex real-world data to make it suitable for the

anomaly detection task. Their publication introduces

a conception of especially relevant in real-world PdM

applications, which is variance in form of multiple

steps in a process.

As can be seen, all named publications implic-

itly or explicitly deal with data complexity, but they

lack a common understanding in their applications.

The majority only take the mechanical properties of

a machine into account when referring to complex-

ity, making them too specific for comparison among

different MH applications. However, as stated in the

foundations section, different applications can be im-

plemented for a given machine, introducing complex-

ity in a second field: the process being executed by

the machine.

There is still a lack of sophisticated applications,

as stated for example by (Z

¨

ufle et al., 2021) or (Gashi

and Thalmann, 2020). We think this is a direct result

of the research gap at hand, which is the matter of

clearly describing complexity in MH. In order to fill

this research gap, our article will further characterise

the term complexity and provide a way of estimating

and comparing application complexity by introducing

a novel taxonomy that can be used for all types of MH

applications.

3.3 Challenges of Complexity

Complexity influences not only the feasibility of im-

plementation for some applications, but also the nec-

essary steps for properly working with the data. More

complexity in the data generally means models might

not perform well or at all. More complexity in terms

of machine hardware will introduce more feature di-

mensions, data types, component dependencies and

general data heterogeneity. Higher complexity in the

observed process also leads to longer time series,

possible deviations in length, more possible machine

states, different types of machine states and more pos-

sible environmental influences. Increased complexity

in either attribute means more states and variance to

consider, with only a small part of the data relevant to

maintenance decisions, bringing off-the-shelf models

to their performance limit. Most models cannot work

well with high amounts of variance, as they are only

trained to learn one specific function or classification,

not a combination of multiple ones. The taxonomy,

which will be now introduced, can be used for a cat-

egorisation of an application in terms of its complex-

ity, and therefore help with selecting the proper opera-

tions for actual data preprocessing and models for the

implementation, mitigating some of these challenges.

4 A NOVEL TAXONOMY FOR

COMPLEXITY

Essentially, the previously mentioned publications re-

ferring to complexity describe attributes like volume

and variance in the application’s data. This is already

a common understanding in the domain of big data,

where the five Vs (Volume, Velocity, Veracity, Vari-

ety, and Value) are often addressed as the main chal-

lenges (Naeem et al., 2022).

However, in contrast to the specific definitions of

our related work, the definition given in Big Data pub-

lications is too general for the subject of Machine

Health. There is no deeper look at where the volume

or variance is introduced, missing out on the possibil-

ity of solving problems at their core. The core prob-

lem of complex applications is handling or reducing

the complexity in/to a form that existing models can

handle. To successfully achieve this, the source and

type of complexity needs to be found and dealt with

in the implementation.

When looking at the data recorded from Ma-

chines, two major factors contribute to an applica-

tion’s complexity: the machine and the process be-

ing implemented. The first factor solely describes the

hardware aspect of an application, while the second

one focuses on the technical process that is imple-

mented by the machine.

To illustrate this, we get back to the previously in-

troduced example of Section 2. By being a machine

consisting of more than one component, the robot arm

introduces more volume of data, simply by needing

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

344

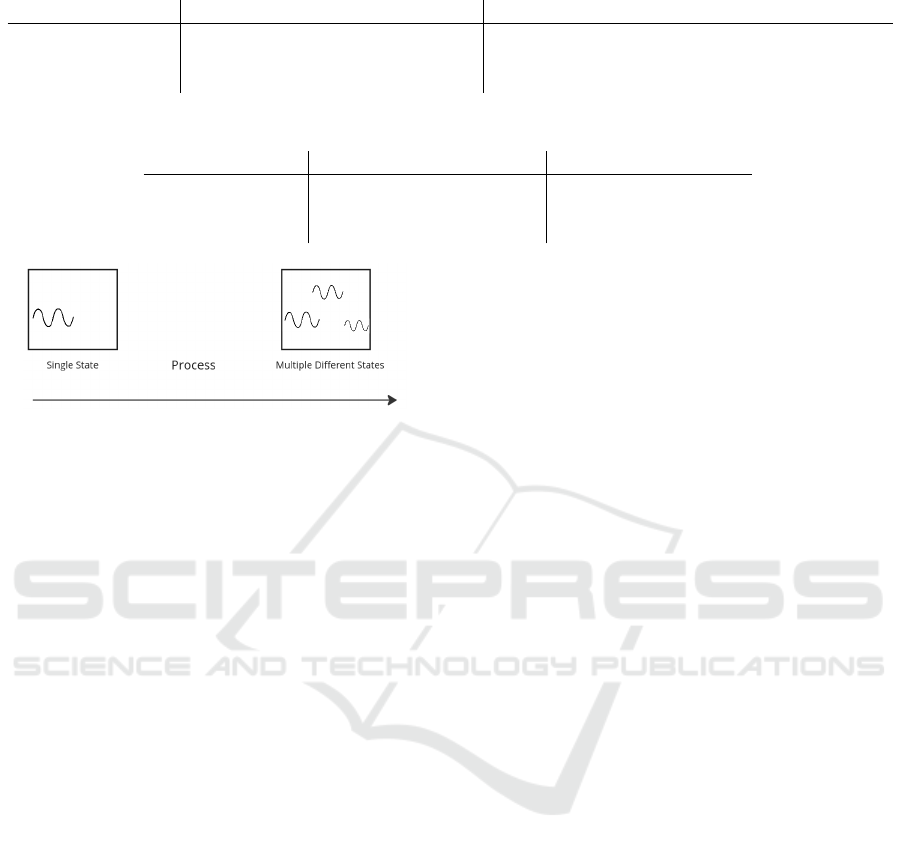

Figure 1: Machine Complexity Illustration.

more sensors to monitor all of its components. Ad-

ditionally, the robot arm can perform tasks that are

more complicated or inherently different from each

other, which increases the variance in recordings for

each process. While this is intuitively understood, a

definition of the two factors machine and process will

help in aiding the discussion about complexity.

4.1 Machine-Induced Complexity

By looking at the hardware part of an application,

complexity can be found in the number and type of

components that are the building blocks of the ma-

chine or system. With more components, there are

more possible interactions and dependencies. Addi-

tionally, with many different components there are

a wider variety of observable properties. Differ-

ent types of sensors create heterogeneous time se-

ries data, with multiple observations that have to be

treated differently. This increases volume and vari-

ance of the recorded data, creating the aforemen-

tioned challenges.

Depending on the application setup, a single ma-

chine or a batch of machines can be subject to the

approach. For a single machine, an observation of op-

erating condition over time is the only way to imple-

ment monitoring. This way, degradation and trends

over time can be extracted from the observations. For

multiple machines, deviations from the behaviour of

the bulk of machines can be the mode for detection.

This enables detection of failures without trend or

degradation attributes, as there is no need to compare

a history of observations.

Another factor to consider is that machine degra-

dation is not always linear. Components can fail spon-

taneously or degrade exponentially, among other pos-

sibilities, which may not be easily modelled. Differ-

ent components may fail differently, all inside of one

machine, which makes the task of failure detection

and diagnosis even harder for complex machines. For

this taxonomy, the type of degradation is not among

the properties for complexity estimation, as the inter-

actions of components are considered the prime cause

for complexity.

The scale of machine complexity ranges from a

single component to a system of multiple different

interdependent components, with single component

machines being the least complex type of applica-

tions. This scale is further defined in Table 1 and is

illustrated in Figure 1.

Machine complexity in PdM applications is cru-

cial to incorporate into preprocessing. As machine

complexity increases, so does the possible depen-

dence and interaction of the components. With high

machine complexity, components may not be able to

be monitored separately, but need to be seen as a

whole system. In addition, some models may not be

able to learn the complexity of circular dependencies.

The complexity of the monitored machine is the

main focus of relevant publications. While this is one

big aspect of complexity, there is another important

factor which has not seen too much attention in recent

research.

4.2 Process-Induced Complexity

In addition to the machine complexity, the imple-

mented process itself has significant impact on data

complexity and needs to be considered as an addi-

tional source of complexity in applications. The main

influence on process complexity is the number of ma-

chine states that can be observed in the data.

Simple processes can range from stamping or

pressing a part to driving a shaft or tool. For these

cases, only a single state is enough to define the nor-

mal operating conditions of the process. However, in

most real-world applications the processes have more

than one or two states. For example, the manufac-

turing of a complicated shape from a piece of stock

involves manipulating material in a sequence of dif-

ferent operations. For sequences with multiple steps,

there are multiple different states for each one, result-

ing in turn in a higher complexity of the application.

In recording or monitoring, the process can have

an influence on the form of data. Some processes or

segments can deviate in their length, making direct in-

stance comparison infeasible. Processes can, depend-

ing on their nature, produce periodic and non-periodic

data. For some algorithms or models, non-periodicity

can be a problem during learning or inference.

Control signals recorded in the time series data,

can be beneficial and enable more sophisticated anal-

ysis approaches. In the absence control signals, a

black box approach is used, where measurements, or

observations, depict to the machine condition. With

the presence of control signals a grey-box approach

can be implemented, in which the desired machine

state can (partially) be extracted from control signals

and more precise assumptions about the normality are

possible. However, another form of information/data

A Taxonomy for Complexity Estimation of Machine Data in Machine Health Applications

345

Table 1: Scale of complexity for the Machine Part.

Low Complexity Medium Complexity High Complexity

Single Component Multiple Independent Components Many inter-dependent Components

Single Sensor Multiple Sensors Many Heterogeneous Sensors

Single Machine Multiple similar Machines Multiple Machines w/ Environmental Influences

Table 2: Scale of complexity for the Process Part.

Low Complexity Medium Complexity High Complexity

Single State Multiple known States Many Unknown States

Uniform Length Uniform Length Non-Uniform Length

Periodic Data Periodic and Non-Periodic Non-Periodic

Figure 2: Process Complexity Illustration

introduces even further complexity to the application.

The levels of process complexity range from a

single-state, continuous process up to a multi-state se-

quenced process containing multiple modes of failure.

The summary of these levels can be found in Table 2

and are illustrated in Figure 2.

Process-attributes contribute a lot to the overall

complexity of an application, but has not seen at-

tention in related publications. By considering this

second aspect as an important one, our taxonomy

presents a new and effective way of describing the

overall complexity of a MH application.

5 USING THE PROPOSED

TAXONOMY

After introducing and explaining the two types of

complexity sources, this section will demonstrate the

usage of the taxonomy on different published applica-

tions to give a brief overview over recent research ef-

forts. By using it to categorise and compare multiple

data sets, a better overview of the current complex-

ity of applications can be given for the set of selected

applications.

5.1 Literature Search for Applications

The next goal of this article is to give an overview of

some of the existing applications and categorise them

using the proposed taxonomy. In order to give an un-

biased image, a structured literature search for appli-

cation publications is needed to create a dataset that

can be used as a basis for the demonstration.

One method of looking for applications is to ap-

ply numerous keyword-searches to scientific search

engines. However there are existing surveys that col-

lect applications in PdM or CM in order to give an

overview of the recent advances. For the purpose of

this article, taking a collection of applications from an

already published survey-paper is sufficient.

In the following, the findings of Mallioris et

al. (Mallioris et al., 2024) will be used for further dis-

cussion. Using the proposed approach, a set of appli-

cations has been collected from their survey and will

be described in the following subsection. As there

were multiple similar listings in their overview tables,

representative examples have been selected to be in-

cluded in this illustration of our taxonomy.

Table 3 gives an overview of all the selected appli-

cations for the scope of this article. On the first col-

umn of the table, the referenced application is named

and cited. In the next column, the used features are

presented to give an impression of the application

scope.

For the application of our taxonomy, one column

per feature is present in the table. The estimations

were retrieved by comparing the authors description

in the publications with our introduced scales for

machine- and process-induced complexity. The first

aspect, machine complexity, is described by the Ma-

chine Setup column. Here, a brief description of the

selected machine components and used sensors are

given, followed by an estimation of the complexity

based on these attributes. Process complexity is pre-

sented in another dedicated column named Process

Setup. Here, the type of process is described briefly,

how many different states it involves and if it is con-

tinuous or periodic. This column also contains the

complexity estimation for the given process.

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

346

Table 3: Overview of the selected applications with the taxonomy applied. The Machine Setup and Process Setup columns

describe and categorise the two complexity sources.

Machine Type Data Features Machine Setup Process Setup

Pressing Machine

(Serradilla et al., 2021)

Rotational Speed,

Power Consumption,

Force, Position

Motor Connected over Gearbox to friction clutch;

Multiple Sensors of different kind;

Medium Complexity

Stamping a Part in one Motor Rotation;

Non-periodic time series and Single Normal State;

Low Complexity

Centrifugal Fan

(Lis et al., 2021)

Vibration

Single Motor driving a Fan;

Single Component and Sensor;

Low Complexity

Turning a Fan at constant RPM;

Single Normal State of a constant signal;

Low Complexity

Conveyor Belt

(Elahi et al., 2022)

Power Consumption

Single Motor driving a conveyor

belt with tensioning mechanism;

Single Component and Measurement;

Low Complexity

Turning a Conveyor Belt at constant speed;

Low Complexity

Hydraulic Machinery

(Roosefert Mohan et al., 2023)

Vibration, Oil Pressure,

Contamination

Motor Driving hydraulic Pump

Single Measurement and Autoregression;

Low Complexity

Hydraulic system monitoring (e.g. oil pressure);

Single healthy state with degradation;

Low Complexity

CNC Milling Machine

(Z

¨

ufle et al., 2021)

Vibration, movements,

temperature, speed, torque,

power, acoustics

3 Axis CNC Machine with one spindle;

Monitoring Sensor with multiple different signals;

incorporation of control signals;

Medium Complexity

Manufacturing Process with multiple steps;

multiple possible states;

Medium to High Complexity

CNC Spindle

(Hesser and Markert, 2019)

Vibration

CNC Machine Spindle;

Single vibration sensor;

Low Complexity

Test Process with single healthy state;

Low Complexity

Industrial Robot Joint

(Izagirre et al., 2020)

Torque Signal

Robot arm with multiple Joints;

Torque Readings from Two joints;

Low to Medium Complexity

Fixed test trajectory on the same Machine;

Non-periodic time series;

Medium Complexity

Nasa Turbofan

(Wang and Zhao, 2022)

Temperature, pressure,

ratio flow, fan speed,

coolant bleed

Turbofan Engine with many components

Multiple heterogeneous sensor signals;

High Complexity

Continuous usage in varying conditions;

Single Healthy State with Degradation and RUL;

Low to Medium Complexity

CFRP Drilling Machine

(Dom

´

ınguez-Monferrer

et al., 2022)

Energy Consumption,

Cutting Time

Drill with different Tool inserts;

Power Consumption and Statistical Features;

Low to Medium Complexity

Drilling Operation with 4 Phases;

Non-Periodic Time Series;

Medium Complexity

A Taxonomy for Complexity Estimation of Machine Data in Machine Health Applications

347

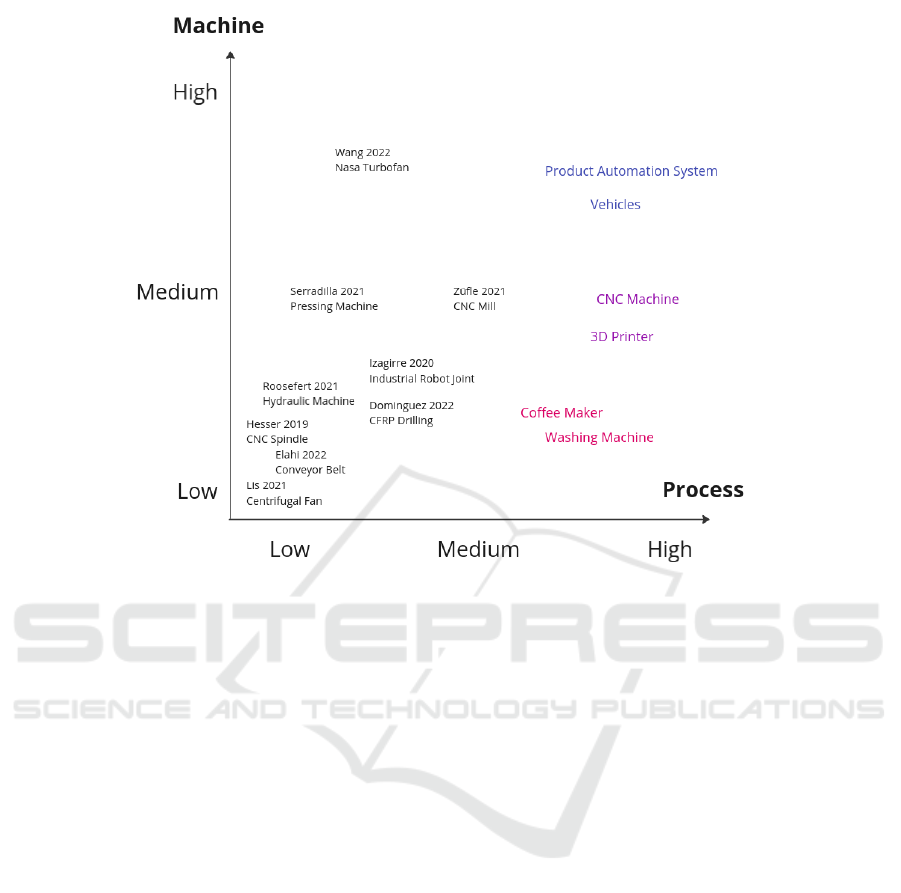

Figure 3: Complexity of related applications.

5.2 Illustration of the Dataset

In order to get a comprehensive illustration of the

complexity of different applications, it is useful to

combine the two introduced factors, machine and pro-

cess, into a two-dimensional plot. When applied to

multiple data points, this creates an illustrative way of

comparing complexity among the given applications.

For each application, an estimate of relative com-

plexity in Machine and Process has been made. These

data points have been placed in a graph displaying the

machine complexity in its X-axis and process com-

plexity in its Y -axis. Figure 3 shows the plot of the se-

lected and classified applications. Applications from

the list of selected publications are shown in black.

Additionally, there are coloured data points, which

are examples of possible future applications and will

be introduced in the following discussion.

6 DISCUSSION

The illustration of our proposed taxonomy yields in-

teresting insights into the current application spec-

trum as given by (Mallioris et al., 2024). In this sec-

tion, a discussion of the findings will be presented, as

well as a discussion of the approach itself.

6.1 Observations from the Taxonomy

When looking at Figure 3, two conclusions can be

drawn from the illustration: 1. Clusters of similarly

complex applications can be established, and 2. There

is a lack of applications with high process complex-

ity. These two observations are an important subject

for further discussion.

First, by using the taxonomy on a set of applica-

tions, clusters of similar complexity have been cre-

ated. This enables the observer, or an interested en-

terprise, to find similar solutions to their own prob-

lem, based on the characteristics of the application. It

therefore aids the development of real-world imple-

mentations by giving a starting point to look for when

it comes to preprocessing techniques and model se-

lection.

Second, evident through a lack of data points on

the right side of the graph, process complexity in the

observed applications is still low. This means that the

currently published types of solutions are only suit-

able for simple processes or kept simple for ease of

implementation. Processes of such type have only

few known states or a single healthy state, which is

distinctly different to most real-world scenarios.

Figure 3 illustrates the complexity of selected ap-

plications in black. In addition to those points, there

are coloured instances, which are examples of pos-

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

348

sible applications that could be implemented to fit

those complexity. These can be summarised as a spe-

cific type of machinery, called Product Automation

Systems (PAS). PAS automate a technical process for

manufacturing or production of goods in a single ma-

chine. As can be seen in the illustration, this can

be simple machines such as a washing machine or

a coffee maker, but is also true for 3d printers and

CNC machines. What these machines introduce by

automating a complicated technical process is a high

complexity in the process-axis. The difference of the

examples in the illustration to existing research is the

scope of the application, which often does not con-

sider all of the possible process-induced complexity.

6.2 Identified Research Gap and

Relevance

The main research gap that can be observed by ap-

plying the proposed taxonomy to recent implementa-

tions in the MH setting is a lack of process-induced

complexity.

A possible cause of this could be the lack of

process-complex datasets in the field. Benchmark

datasets are popular and seen as a solid way to com-

pare performance over different models. However,

these benchmark datasets are neither optimised to be

as close as possible to real scenarios, nor complex

enough to make current algorithms struggle, as has

been demonstrated for the case of time series anomaly

detection (Wu and Keogh, 2022). Without read-

ily available datasets only industry-partnered projects

have access to complex data, which are then often re-

stricted by NDA policies. The result of such a lack

in complex datasets is a lack of research concerning

process complexity. Exactly this complexity is an es-

sential part and challenge of using MH technology in

real-world scenarios. Without being able to research

this field, complex applications will ultimately stay

out of reach for the MH community, and applications

will stay on the component level of machinery.

In order to mitigate this scarcity, some preliminary

steps should be taken. First, industrial co-operations

should be able to publish and share their data in a

scope that allows researchers from different institu-

tions to work together and compare their results, or to

develop methods for dealing with complex applica-

tions. Second, the creation of synthetic data based on

real-world applications should be researched to cre-

ate publicly available benchmark datasets that con-

tain various aspects process complexity. Third, the

effort to implement MH applications for PAS ma-

chinery should be increased. This type of machine

is widespread and not only reserved for big indus-

trial partnerships. Small machines such as CNC ma-

chines, 3d printers or coffee makers are available for

consumers and can build an important foundation for

research applications. Improvements in these areas

would foster the efforts of dealing with the process-

induced complexity and aid future efforts of imple-

menting sophisticated real-world applications.

6.3 Limits of the Proposed Approach

There are some fields of machinery, where this taxon-

omy is more suitable than for others. Industrial ma-

chinery, especially PAS are now part of the discus-

sion in MH. Overall, the taxonomy can be used for

comparing most applications that can be found in the

domain of Machine Health, as it is general enough to

encompass not only industrial machines.

Additionally, unsupervised learning is the mode of

operation for most applications. For supervised learn-

ing, the complexity of the application is not the first

consideration. When labels are present, most of the

issues that arise through complexity become less im-

portant.

One limitation of our taxonomy is that there is

no exact numerical quantification of complexity, but

more of a continuous scale that can vary slightly de-

pending on the observer. This makes it hard to give

a precise estimation for some applications, which can

however be resolved in discussions.

7 CONCLUSION

This article introduced a novel way of characterising

machine data in the context of Machine Health appli-

cations, which was described in detail as a two-feature

taxonomy containing machine- and process-induced

complexity. Using this taxonomy, selected applica-

tions from a well-crafted survey article have been

classified and illustrated using a two-dimensional

plot.

Based on observations from the plot, two impor-

tant topics have been identified and discussed: The

possibility to find clusters of similar applications in

the illustration, as well as the lack of high-complexity

processes in recent publications. The type of ma-

chines and research that could fill this gap in the future

have been introduced as Product Automation Systems.

The introduced taxonomy is an important step to-

wards fostering the discussion about complex, real-

world Machine Health applications. Using this well-

defined baseline for discussion, two improvements to

the state of the art are now possible. First, comparing

existing applications to another and to planned imple-

A Taxonomy for Complexity Estimation of Machine Data in Machine Health Applications

349

mentations of MH. Second, applications with previ-

ously unsolved challenges can be identified as such

and targeted specifically in future research. Imple-

mentation can focus on core sources of complexity

for tackling future problems.

REFERENCES

Ahmed, U., Carpitella, S., and Certa, A. (2021). An inte-

grated methodological approach for optimising com-

plex systems subjected to predictive maintenance. Re-

liability Engineering & System Safety, 216:108022.

Blancke, O., Combette, A., Amyot, N., and Komljenovic,

D. (2019). A predictive maintenance approach for

complex equipment based on a failure mechanism

propagation model. International Journal of Prognos-

tics and Health Management, 10.

Dai, J., Chen, C. L. P., Xu, X.-Y., and Hu, P. (2008). Condi-

tion monitoring on complex machinery for predictive

maintenance and process control. In 2008 IEEE Inter-

national Conference on Systems, Man and Cybernet-

ics, pages 3595–3600.

Dom

´

ınguez-Monferrer, C., Fern

´

andez-P

´

erez, J., De Santos,

R., Migu

´

elez, M., and Cantero, J. (2022). Machine

learning approach in non-intrusive monitoring of tool

wear evolution in massive cfrp automatic drilling pro-

cesses in the aircraft industry. Journal of Manufactur-

ing Systems, 65:622–639.

Elahi, M., Afolaranmi, S. O., Mohammed, W. M., and Mar-

tinez Lastra, J. L. (2022). Energy-based prognostics

for gradual loss of conveyor belt tension in discrete

manufacturing systems. Energies, 15(13).

Farooq, U., Ademola, M., and Shaalan, A. (2024). Compar-

ative analysis of machine learning models for predic-

tive maintenance of ball bearing systems. Electronics,

13(2).

Fossier, S. and Robic, P.-O. (2017). Maintenance of com-

plex systems — from preventive to predictive. In 2017

12th International Conference on Live Maintenance

(ICOLIM), pages 1–6.

Gashi, M. and Thalmann, S. (2020). Taking complex-

ity into account: A structured literature review on

multi-component systems in the context of predictive

maintenance. In Themistocleous, M. and Papadaki,

M., editors, Information Systems, pages 31–44, Cham.

Springer International Publishing.

Hesser, D. F. and Markert, B. (2019). Tool wear monitor-

ing of a retrofitted cnc milling machine using artificial

neural networks. Manufacturing Letters, 19:1–4.

Izagirre, U., Andonegui, I., Egea, A., and Zurutuza, U.

(2020). A methodology and experimental implemen-

tation for industrial robot health assessment via torque

signature analysis. Applied Sciences, 10(21).

Klein, P. and Bergmann, R. (2019). Generation of complex

data for ai-based predictive maintenance research with

a physical factory model. In ICINCO (1), pages 40–

50. Scitepress.

Lee, D. and Pan, R. (2017). Predictive maintenance

of complex system with multi-level reliability struc-

ture. International Journal of Production Research,

55(16):4785–4801.

Lis, A., Dworakowski, Z., and Czubak, P. (2021). An

anomaly detection method for rotating machinery

monitoring based on the most representative data.

Journal of Vibroengineering.

Mallioris, P., Aivazidou, E., and Bechtsis, D. (2024). Pre-

dictive maintenance in industry 4.0: A systematic

multi-sector mapping. CIRP Journal of Manufactur-

ing Science and Technology, 50:80–103.

Miller, K. and Dubrawski, A. (2020). System-level predic-

tive maintenance: Review of research literature and

gap analysis.

Naeem, M., Jamal, T., Diaz-Martinez, J., Butt, S. A., Mon-

tesano, N., Tariq, M. I., De-la Hoz-Franco, E., and

De-La-Hoz-Valdiris, E. (2022). Trends and future per-

spective challenges in big data. In Pan, J.-S., Balas,

V. E., and Chen, C.-M., editors, Advances in Intelli-

gent Data Analysis and Applications, pages 309–325,

Singapore. Springer Singapore.

Nguyen, K.-A., Do, P., and Grall, A. (2015). Multi-level

predictive maintenance for multi-component systems.

Reliability Engineering & System Safety, 144:83–94.

Nunes, P., Santos, J., and Rocha, E. (2023). Challenges in

predictive maintenance – a review. CIRP Journal of

Manufacturing Science and Technology, 40:53–67.

Roosefert Mohan, T., Preetha Roselyn, J., and Annie Uthra,

R. (2023). Lstm based predictive maintenance ap-

proach for zero breakdown in foundry line through in-

dustry 4.0. In Kumar, H., Jain, P. K., and Goel, S., ed-

itors, Recent Advances in Intelligent Manufacturing,

pages 29–51, Singapore. Springer Nature Singapore.

Serradilla, O., Zugasti, E., Ramirez de Okariz, J., Ro-

driguez, J., and Zurutuza, U. (2021). Adaptable and

explainable predictive maintenance: Semi-supervised

deep learning for anomaly detection and diagnosis in

press machine data. Applied Sciences, 11(16).

Serradilla, O., Zugasti, E., Rodriguez, J., and Zurutuza,

U. (2022). Deep learning models for predictive

maintenance: a survey, comparison, challenges and

prospects. Applied Intelligence, 52.

Van Horenbeek, A. and Pintelon, L. (2013). A dynamic

predictive maintenance policy for complex multi-

component systems. Reliability Engineering & Sys-

tem Safety, 120:39–50.

Wang, Y. and Zhao, Y. (2022). Multi-scale remaining useful

life prediction using long short-term memory. Sustain-

ability, 14(23).

Wu, R. and Keogh, E. J. (2022). Current time series

anomaly detection benchmarks are flawed and are cre-

ating the illusion of progress (extended abstract). In

2022 IEEE 38th International Conference on Data

Engineering (ICDE), pages 1479–1480.

Z

¨

ufle, M., Moog, F., Lesch, V., Krupitzer, C., and Kounev,

S. (2021). A machine learning-based workflow for au-

tomatic detection of anomalies in machine tools. ISA

Transactions, 125.

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

350