A Study on Optimizing Signal Path in Model Predictive Control and

Fault Detection System of Three-Tank Pilot System Using Reference

Architecture

Jukka Kortela

1 a

, Yared Tadesse

2

and Kim Miikki

2

1

Aalto University School of Chemical Engineering, P.O. Box 16100, FI-00076 Aalto, Espoo, Finland

2

Bellmer Finland Oy, Vanha Messil

¨

antie 6, 15860 Hollola, Finland

fi fi

Keywords:

Cyber Physical System, Industrial Internet of Things, Rami, Iira, Model Predictive Control, Three Tank

System, Model, Experiment, Fault Detection, Fault Diagnosis, Parity Equations.

Abstract:

This paper presents the model predictive control and fault detection and diagnosis system of a three-tank pilot

within a novel cloud-integrated industrial automation framework. The system architecture includes a state-

of-the-art NodeJS-based gateway facilitating communication between the cloud service and the automation

system. OPC DA has not been updated to function with the latest programming libraries and operating systems,

which significantly reduces the performance of automation systems. The optimized signal path through the

OPC DA is developed and compared to the OPC UA tunneller implementation through experiments on a real

three-tank pilot system with an industrial ABB 800xA automation system. The results demonstrate that the

optimized signal path significantly reduces the control interval by a factor of 5, leading to a quicker controller

response. In fault detection and diagnosis, the delay is only 22 milliseconds with an optimized signal path

compared to 408 milliseconds when using OPC UA tunneler software.

1 INTRODUCTION

Since the invention of the Programmable Logic Con-

troller (PLC) in 1968, industrial automation has

passed through milestones marked by advances in in-

formation technology. The first milestone is the link-

ing of the PLC with the personal computer (PC) in

1986. The next main milestone was reached in 1992

with the introduction of Ethernet and Transmission

Control Protocol and Internet Protocol (TCP/IP) con-

nectivity for PLCs. The current trend in industries is

the transformation from industrial Ethernet and wire-

less communications to advanced information tech-

nology (IT) solutions where traditional automation is

merged with cyber-physical systems (CPS) combin-

ing communications, information and communication

technology (ICT), data and physical elements and the

ability to connect devices to one another. This trans-

formation results in what is now known as Industrial

Internet of Things (IIoT) or the 4th Industrial Revolu-

tion (Industry 4.0) where every step of a manufactur-

ing process is interconnected. Cloud computing and

a

https://orcid.org/0000-0001-7831-1413

data analytics are among the technologies driving the

IIoT. (IEC, 2015)

According to IEEE, the term architecture in the

context of information technology is ”the fundamen-

tal organization of a system embodied in its compo-

nents, their relationships to each other, and to the en-

vironment, and the principles guiding its design and

evolution”. (IEEE, 2022)

A reference architecture in the context of infor-

mation technology documents such things as hard-

ware, software, processes, specifications and config-

urations, logical modules and interrelationships. Ac-

cording to IBM Rational Unified Process, a reference

architecture “is, in essence, a predefined architectural

pattern, or set of patterns, possible partially or com-

pletely instantiated, designed, and proven for use in

particular business and technical contexts, together

with supporting artifacts to enable their use. Often,

these artifacts are harvested from previous projects”.

(Evensen, 2013)

A reference architecture for IIoT serves the pur-

pose of providing common and consistent definitions

for the IIoT, its subsystems and design patterns, and a

Kortela, J., Tadesse, Y. and Miikki, K.

A Study on Optimizing Signal Path in Model Predictive Control and Fault Detection System of Three-Tank Pilot System Using Reference Architecture.

DOI: 10.5220/0012995400003822

In Proceedings of the 21st International Conference on Informatics in Control, Automation and Robotics (ICINCO 2024) - Volume 1, pages 351-358

ISBN: 978-989-758-717-7; ISSN: 2184-2809

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

351

common lexicon and taxonomy for discussing

specification of implementations of IIoT.

Currently, there are several reference architectures

that can be employed for deploying Factory of Fu-

ture (FoF). Two of the most popular reference archi-

tectures, RAMI 4.0 and IIRA, and their interoper-

ability will be discussed in the following paragraphs.

RAMI 4.0 is the product of Industrie 4.0, which is

a national project of the German government initi-

ated in 2011 through German’s Ministry of Education

and Research (BMBF) and the Ministry for Economic

Affairs and Energy (BMWI) (European Commission,

2017), which has since been joined by industries and

academia to form a consortium called Plattform In-

dustrie 4.0. Industrie 4.0 aims to increase value in

manufacturing and decrease waste by transforming

the way products are developed, produced, managed,

and consumed. The project focuses on the industrial

manufacturing sector and connects value chains by in-

tegrating things and processes to form cyber physical

systems (CPS). The novelty of Industrie 4.0 results

from the combination of already existing and new

technologies such as embedded computers, intelligent

sensors, mobile broadband internet access, and Radio

Frequency Identification (RFID) in the industrial en-

vironment into a uniform, integrated solution through

standardized communication. (VDI Verein Deutscher

Ingenieure e.V., 2015) The Industrie 4.0 concept is

implemented through RAMI 4.0; a service-oriented

architecture that has been designed for efficient shar-

ing of data and information between all the sharehold-

ers taking part in the Industrie 4.0 ecosystem. RAMI

4.0 (registered DIN SPEC 91345 in Germany) en-

sures that all participants in Industrie 4.0 share a com-

mon perspective and build a common understanding.

(DIN, 2016)

The Industrial Internet Consortium (IIC) first pub-

lished IIRA in the form of a Technical Report in

2015. Founded by AT&T, Cisco, General Electric,

IBM, and Intel, the mission of IIC is to reach indus-

trial interoperability and consensus on IIoT platforms.

The IIC is a part of the Object Management Group

(OMG) and today has 19 working groups and over

250 members of industrial and academic background.

In July 2019, the latest version of IIRA, IIRA v1.9,

was published by the Industrial Internet Consortium

Architecture Task Group, which is a subset of the

IIC Technology Working group. (Industrial Internet

Consortium, 2019) IIRA is a reference architecture

of what IIC calls Industrial Internet Systems (IIS).

These systems are defined as end-to-end application

systems for industrial tasks. They include technical

components as well as interactions with users. Ac-

cording to the IIC, IIRA is a ”business-value-driven

and concern-resolution-oriented” reference architec-

ture for the IIoT. (Industrial Internet Consortium,

2019) IIRA itself is based on the Industrial Internet

Architecture Framework (IIAF), which provides ba-

sic conventions, principles and definitions. The IIAF

builds on the international standard ISO / IEC / IEEE

42010: 2011 and performs basic architectural descrip-

tion constructs, such as Concern, Stakeholders, and

Viewpoint. The viewpoints are one of the key build-

ing blocks of IIS. There are four viewpoints: Busi-

ness, Usage, Functional, and Implementation. (Indus-

trial Internet Consortium, 2019)

1.1 Industrial Data Protocols

The goal of the Industry 4.0 research initiative is to

enable networked, flexible and therefore adaptive pro-

duction. The challenge here is that production data is

often very distributed and heterogeneous. As a solu-

tion to this, the OPC Unified Architecture (OPC UA)

standard provides a context-based data description

model alongside its communication protocol specifi-

cation. In OPC UA, metadata is defined with stan-

dardized data models that enable a uniform under-

standing of the data in the value chain.

There are several technologies that provide the

functionality needed to bridge the operational tech-

nology (OT) and information technology (IT) gap

(Bonomi et al., 2012), such as, time-sensitive net-

working (TSN), cloud computing and OPC Unified

Architecture (OPC UA). Although TSN has received

a lot of attention, a suitable technology such as OPC

UA PubSub was only recently explored for its poten-

tial to meet tight timing guarantees [5], [6]. How-

ever, an open issue is that the timing guarantees are

only valid if the OPC UA PubSub is isolated from the

OPC UA client-server communication model. The

reason is that both communication paradigms use a

shared data model, which raises issues related to si-

multaneous data access that need to be addressed. A

client-server instance may prevent access to PubSub

data or change the value during a read operation with

unexpected consequences. Analysis in (Denzler et al.,

2022) includes the overall RT-TSN-OPC UA concept,

an analysis of common concurrent data access mech-

anisms for their suitability, and identifying critical

code segments in the open62541 OPC UA stack.

The work in (Großmann et al., 2014) describes

an approach to modeling the information of an ag-

gregated OPC UA server to combine the representa-

tion of a single entity in different data models. The

work in (M

¨

uller et al., 2022) presents a methodology

for the integration of standardized information mod-

els into existing OPC UA servers. However, the prob-

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

352

lem is the overhead brought by the automatic OPC

UA adapter in time-critical systems.

In (Reiswich and Fay, 2012), the authors outline

a method for migrating an OPC DA (Data Access)

server to the OPC UA standard. The integration of

the data model existing in the DA server is done by

manually mapping each of the corresponding nodes.

The work in (Reiswich and Fay, 2012) is suitable for

model integration in this context of paper, but its dis-

advantage is the lack of automatic mapping. To meet

above challenges, this paper implements the OPC DA

and OPC UA NodeJS libraries, which enable auto-

matic mapping and an optimized connection to time-

critical systems.

1.2 The Control of the Three-Tank

System

A comparison of Model Predictive Control (MPC)

with Proportional-Integral-Derivative (PID) control

has been conducted in (Kortela, 2022). The perfor-

mance can also be compared with Internal Model

Control (IMC) using a similar interval of 100 ms, as

presented in (Ujjwal Manikya Nath and Mudi, 2023).

Newer methods beyond classical PID include Adap-

tive Safe Experimentation Dynamics (ADED) (Ghaz-

ali, 2019) and methods utilizing Nonlinear Constraint

Optimization (Govind et al., 2023). Both linear and

nonlinear schemes were able to achieve the primary

objective of controlling the liquid level of the system.

However, when choosing the appropriate scheme to

apply, stakeholders must consider a trade-off between

accurate system representation and the ease or cost

of implementation (Samuel Emebu, 2023). In (Alhas-

san Osman and Arıcı, 2023), the Adaptive Pole Place-

ment Controller (APPC) method is extended by incor-

porating it with a Sliding Mode Controller (SMC) to

enhance system robustness. Nevertheless, in real im-

plementations, the data transfer rate has a significant

effect on performance.

The rest of this paper is structured as follows:

The optimized signal path and the three-tank sys-

tem are utilized in both Model Predictive Control

(MPC) and fault detection, and have been presented

in Section II and Section III, respectively. Section IV

presents the model predictive control of the three-tank

system, while Section V introduces the fault detection

method applicable to this system. In Section VI, the

architecture of the proposed method is detailed. Sec-

tion VII presents the test results of the MPC and fault

detection system using the optimized signal path. Fi-

nally, Section VI presents the conclusions of the pro-

posed method.

2 OPTIMIZED SIGNAL PATH

WITH OPC DA

This document proposes an approach that makes it

possible to make the data of an already existing OPC

DA server available for an optimized OPC UA server.

The structure consists of four components: Wireless

Arduino MKR WiFi 1010 + Raspberry Pi 3 Model

B+ (2.1), optimized OPC DA client 2.2), NodeJS DA

Client (2.3), and Gateway PC + Spring framework

(2.4).

Fig. 1 shows the Arduino MKR WiFi 1010, where

3 level measurements are connected to the analog in-

puts of the Arduino.

2.1 Wireless Arduino MKR WiFi 1010

+ Raspberry Pi 3 Model B+

1. In Arduino code, the value of the tank level 1, for

example, is read from the first pin with the call

sensorValue = analogRead(A0);

2. The value is scaled by executing the command

outputValue = map(sensorValue, 0, 1023, 0,

255);

3. Finally, the scale and value are written to the serial

port with commands:

Serial.print("sensor = ");

Serial.print(sensorValue);

Serial.print("\t output = ");

Serial.print(outputValue);

4. The OPC UA server is created by calling

new opcua.OPCUAServer()

5. Correspondingly, to read the serial port input, an

object is created with the call

new SerialPort( { path: ’/dev/ttyACM0’,

baudrate: 9600 } )

6. To read the serial port, an object is created with

the

new ReadlineParser()

command, and writing data to the port triggers the

”on” event for the object.

7. The object ”ThreeTank” is added to addressSpace

with command addObject and its component as

nodeId ”Level 1” is added with command

namespace.addVariable

8. When the ”on” event occurs, a new value is writ-

ten to the ”Level 1” component.

A Study on Optimizing Signal Path in Model Predictive Control and Fault Detection System of Three-Tank Pilot System Using Reference

Architecture

353

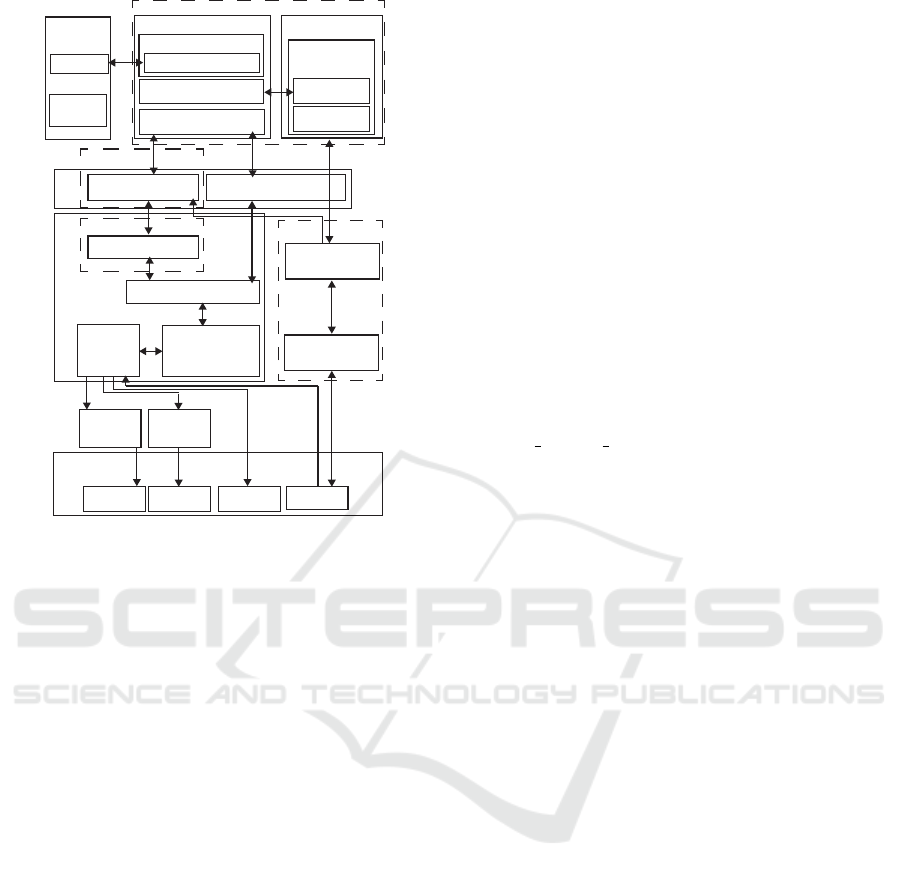

NodeJS OPC UA Client

NodeJS OPC UA Server

NodeJS OPC DA Client

OPC UA Tunneller

MPC

C++ OPC DA Client

ABB OPC Server

Gateway PC (NodeJS)

express web server

io sockets

Web browser

User

interface (UI)

io sockets

Cloud

Java Spring

Application

Parity equations

async JSON

ABB System 800xA

ABB PM856A PLC

ABB AO820

ABB AI801

ABB DO801

Inverter 1 Inverter 2

Pump 1 Pump 2

Valves

Level

sensors

Amira DTS200

three-tank system

Wireless Arduino

MKR WiFi 1010

Raspberry Pi 3

Model B+

Figure 1: The architecture of the model predictive control

and fault detection system in the cloud.

2.2 Optimized OPC DA Client

In this paper an OPC DA client has been implemented

and it has been compiled with Visual Studio 2019 so

that it would be available on the latest Windows op-

erating system such as 10 and 11 and, for example,

the latest NodeJS. Corresponding branches in the tar-

get OPC DA server must be found and listed. In an

optimized way, the branch should be interpreted only

when it is opened.

1. First, the position is moved to the root with the

command

ChangeBrowsePosition(OPC_BROWSE_TO,

W2OLE(const_cast<wchar_t *>(

parentItemPath.c_str() ) ) );

2. With the method

ChangeBrowsePosition(OPC_BROWSE_DOWN,

itemPath)

we go down the branch.

3. All branch leaves are read with

BrowseOPcitepmIDs(OPC_BRANCH, emptyString,

VT_EMPTY, 0, &iEnum );

and the name of the list with

GetItemID(itemName, &FullName);

4. The item is first added to the group of type

IOPcitepmMgt with the command

AddItems(1, &itemDef, &pResults, &pErrors);

5. After that, the value can be written with the

IOPCSyncIO object with the command

Write(1, &hServer, &value, &pErrors)

and read with command

Read(OPC_DS_DEVICE, 1, &hServer,

&pItemState, &pErrors)

2.3 NodeJS OPC DA Client

With NAN module of NodeJS you can use a tem-

plate to wrap C++ functions and data structures within

JavaScript objects so that they can be manipulated

from JavaScript. In this document, NodeJS calls to

the C++ OPC DA Client were implemented, so that

branches of the OPC DA server can be called through

the NodeJS OPC UA server in an optimized way.

1. NAN MODULE INIT() sets entry points for Node

add-ons. It makes an object that corresponds to

JavaScript’s export command object.

2. Nan::Set(target, New<string>( \\

"ReadOPCDAValue").ToLocalChecked(), \\

GetFunction(New<functionTemplate>( \\

ReadOPCDAValue)).ToLocalChecked());

add a NodeJS method to read the OPC DA proto-

col value.

2.4 Gateway PC + Spring Framework

1. The gateway PC reads the data from the OPC UA

server and sends the data so that the header con-

tains the names of the data columns and the data as

a whole is a table. Compared to name-value pairs,

the data takes up significantly less space and can

be created directly as a data table for the native

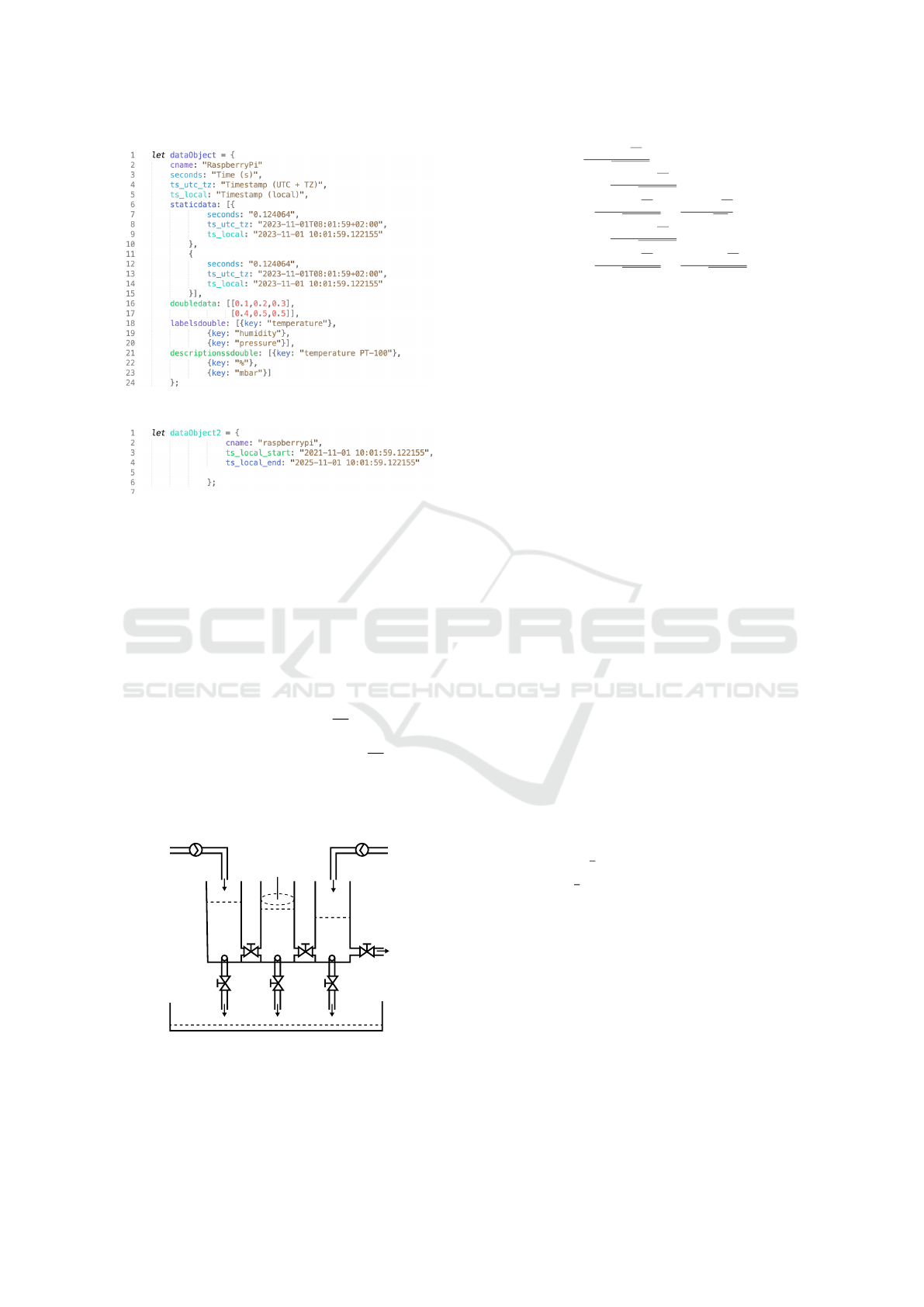

language as shown in Fig. 2 and Fig. 3.

2. Spring framework automatically converts json-

string into Java objects.

3 MODELLING OF THE

THREE-TANK SYSTEM

The development and validation of the three-tank sys-

tem are detailed in (Kortela, 2022). The three-tank

system consists of tanks T

1

, T

3

, and T

2

with the same

cross-sectional area A

b

, as shown in Fig. 4. These

cylindrical tanks are connected in series by a cylindri-

cal pipe with cross-sectional area A

c

. Liquid is col-

lected in a reservoir and is pumped back into tanks T

1

and T

2

using pumps 1 and 2 to maintain their levels.

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

354

Figure 2: Optimized data structure to save data.

Figure 3: Optimized data structure to retrieve data.

All tanks are equipped with a piezo-resistive pressure

transducer that measures the liquid level in the tank.

The flow rates of pumps 1 and 2 are represented by

Q

1

and Q

2

, respectively. The flow rate provided by a

pump is proportional to the DC voltage applied to its

motor. In the tested system, valves V

13

, V

32

, and V

3O

were open and leakage valves V

L1

, V

L3

, and V

L2

were

closed. The linearized state-space model parameters

are given by

A =

a

11

a

12

a

13

a

21

a

22

a

23

a

31

a

32

a

33

,B =

1

A

b

0

0

1

A

b

0 0

C =

1 0 0

0 1 0

,D = 0

(1)

T

1

T

3

T

2

V

13

V

32

V

2O

V

L1

V

L3

V

L2

Pump 1

Pump 2

A

b

Q

1

h

1

h

3

h

2

Q

2

Figure 4: Three-tank system.

a

11

= −

α

13

A

c

√

2g

2A

b

√

h

1s

−h

3s

,a

12

= a

21

= 0,

a

13

= a

31

=

α

13

A

c

√

2g

2A

b

√

h

1s

−h

3s

,

a

22

= −

α

32

A

c

√

2g

2A

b

√

h

3s

−h

2s

+

α

2O

A

c

√

2g

2A

b

√

h

2s

,

a

23

= a

32

=

α

32

A

c

√

2g

2A

b

√

h

3s

−h

2s

a

33

= −

α

13

A

c

√

2g

2A

b

√

h

1s

−h

3s

+

α

32

A

c

√

2g

2A

b

√

h

3s

−h

2s

(2)

where A is the state matrix, B is the input matrix, C

is the output matrix, D is the matrix that describes

which inputs affect directly the outputs, α

i j

∈ [0,1]

denotes the outflow coefficient between tank i, j and

out from the tank 2, g is the gravity constant, and h

1s

,

h

2s

and h

3s

are the operating points of the three levels,

respectively.

4 MODEL PREDICTIVE

CONTROL FOR THE THREE

TANK PILOT SYSTEM

4.1 State-Space Model Based MPC

As a detailed physical model of the three-tank system

was available, it was a natural choice to use the lin-

earized version of that model directly with MPC. The

inputs to the MPC are the reference values for the two

water levels (r) and the measured process outputs for

the levels (y). The outputs of the MPC are the manip-

ulated variables, the speeds of the two water pumps

(u). The linear state space system for the MPC is as

follows (Maciejowski, 2002):

x(k + 1) = Ax(k) + Bu(k) + Ed(k)

z(k) = Cx(k)

(3)

where x are the states, E is the disturbance matrix

and d are the disturbances. The regularized l

2

out-

put tracking problem with the input, the input rate of

movement, and the output constraints is formulated as

minφ =

1

2

∑

N

p

k=1

∥z(k) −r(k)∥

2

Q

z

+

1

2

∑

N

p

−1

k=1

∥∆u(k)∥

2

S

s.t.x(k + 1) = Ax(k) + Bu(k) + Ed(k),

k = 0,1, . . . ,N

p

−1

z(k) = Cx(k), k = 0,1,..., N

p

u

min

≤ u(k) ≤ u

max

,k = 0, 1, . . .,N

p

−1

∆u

min

≤ ∆u(k) ≤ ∆u

max

,k = 0, 1, . . .,N

p

−1

z

min

≤ z(k) ≤ z

max

,k = 1, 2, . . .,N

p

(4)

where ∆u(k) = u(k) −u(k −1) and N

p

is the predic-

tion horizon, r is the future target vector, Q

z

is the

tracking error weight matrix, and S is the move sup-

pression factor weight matrix. Sizes of the stacked

matrices Z, R, U and D depend on the prediction hori-

zon N

p

.

A Study on Optimizing Signal Path in Model Predictive Control and Fault Detection System of Three-Tank Pilot System Using Reference

Architecture

355

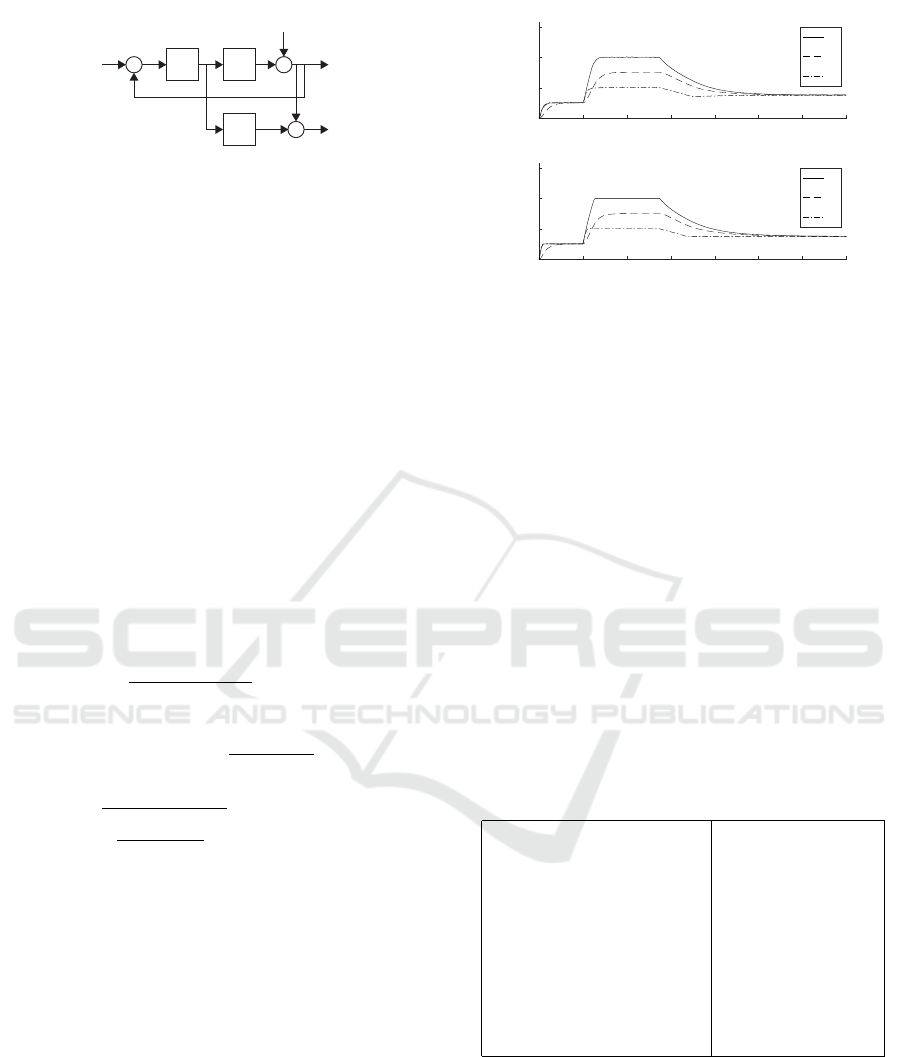

G

c

e

n

yw

G

m

r’

-

-

+

u

G

p

Figure 5: Fault detection of closed loop with parity equa-

tions and output error r

′

.

5 FAULT DETECTION WITH

PARITY EQUATIONS

Parity equations were also chosen to identify the fault

because the exact model of the three-tank system was

available (Isermann, 2006).

5.1 Model-Based Methods for

Closed-Loop Supervision

Application of parity equations in closed-loop is con-

sidered. As shown in Fig. 5 a residual r is generated

by using a fixed model. The calculation of the output

error is as follows:

r

′

(s) = y

p

(s) −y

m

(s) = y

p

(s) −G

m

(s)u(s) (5)

y

p

(s) = G

p

(s)u(s) + n(s) (6)

u(s) =

G

c

(s)

1 + G

c

(s)G

p

(s)

(w(s) −n(s)) (7)

r

′

(s) = (G

p

(s) −G

m

(s))u(s) + n(s)

= (G

p

(s) −G

m

(s))

G

c

(s)

1+G

c

(s)G

p

(s)

(w(s) −n(s))

+n(s)

=

G

c

(s)(G

p

(s)−G

m

(s))

1+G

c

(s)G

p

(s)

w(s)

+

1+G

c

(s)G

m

(s)

1+G

c

(s)G

p

(s)

n(s)

(8)

If the model agree with the real process, G

p

(s) =

G

(

s), it holds

r

′

(s) = n(s) (9)

6 THE ARCHITECTURE OF THE

MODEL PREDICTIVE

CONTROL FOR THE THREE

TANK PILOT SYSTEM IN THE

CLOUD

The experimental setup consists of a cloud with a Java

Spring Application and MPC and the fault detection

system implemented in Java. Apache Commons Math

3.6.1 API and oj! Algorithms (ojAlgo) were utilized

0 200 400 600 800 1000 1200 1400

time (s)

0

0.2

0.4

0.6

height (m)

h

1

h

3

h

2

0 200 400 600 800 1000 1200 1400

time (s)

0

0.2

0.4

0.6

height (m)

h

1

h

3

h

2

Figure 6: Levels’ response in experimental setup utilizing

OPC UA tunneller (above). Levels’ response in experimen-

tal setup utilizing NodeJS OPC UA server and OPC DA

client (below).

to implement MPC, as shown in Fig. 1. The gateway

PC reads the level measurements and writes the values

of the pumps via the NodeJS OPC UA Server and al-

ternatively through the OPC UA tunneller software. It

communicates with the cloud through the JSON pro-

tocol. The web browser receives the new pump and

level values through the IO socket and draws them to

the user interface using HTML 5 canvas. The connec-

tions of the ABB PM856A PLC and cards are defined

in ABB Control Builder M Professional.

7 EXPERIMENTAL RESULTS OF

THE OPTIMIZED SIGNAL

PATH

Table 1: Three tank system parameters.

Cross section (tanks) (A

b

) 0.0154m

2

Cross section (pipes) (A

c

) 5 ·10

−5

m

2

Valve opening (α

i j

) α

i j

= 0.84

Max flow rate (Q

max

) 1.2 ·10

−4

m

3

/s

Maximum level (h

max

) 0.63m

Operating point Q

1

= 7 ·10

−5

m

3

/s

Q

2

= 4 ·10

−5

m

3

/s

h

1

= 0.45m

h

2

= 0.25m

h

3

= 0.35m

7.1 Experimental Results of MPC of

Three-Tank System

The MPC was tested on Heroku Cloud with ps:scale

web=1, on a cloud server with an Intel Xeon Gold

6248 CPU and 16 GB of memory, as well as on a

Macbook Pro with an Apple M1 processor and 16

GB of memory. The execution time of MPC on these

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

356

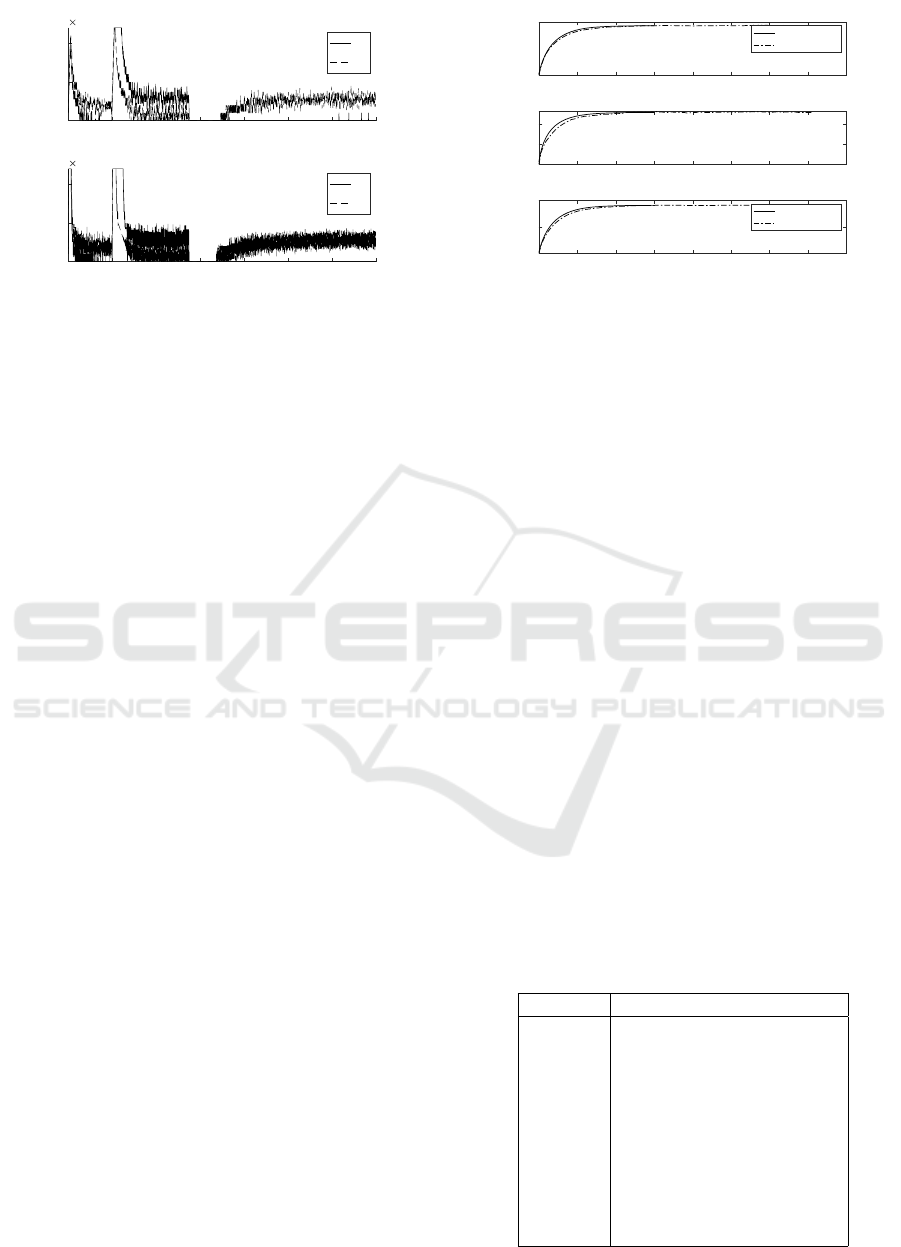

0 200 400 600 800 1000 1200 1400

time (s)

0

0.5

1

flow [m

3

/s]

10

-4

Q

1

Q

2

0 200 400 600 800 1000 1200 1400

time (s)

0

0.5

1

flow [m

3

/s]

10

-4

Q

1

Q

2

Figure 7: Input flow rates in experimental setup utilizing

NodeJS OPC UA server and OPC DA client (above). Input

flow rates in experimental setup utilizing OPC UA tunneller.

(below).

systems was approximately 100 ms, which was the

limiting factor for the speed of MPC. The OPC UA

tunneller software and ABB OPC Server with their 3

level variables and 2 pump variables limited the con-

trol interval to around 0.5 second. The parameters

were substituted by The MPC was discretized with

a sampling interval of 200 milliseconds when using

the NodeJS OPC UA and OPC DA path, and a sam-

pling interval of 1 second when using the OPC UA

tunneller path. The model used the parameters de-

fined in Table 1. Figures 6 and 7 show the response

of the three tank levels and input flow rates using the

NodeJS OPC UA and OPC DA path and the path with

OPC UA tunneller. Due to its smaller control interval

of 200 milliseconds, the former controller provides a

faster response.

7.2 Experimental Results of Fault

Detection and Diagnosis System

The testing of the fault detection and diagnosis sys-

tem was conducted using the same system as for test-

ing MPC, additionally including a Wireless Arduino

MK WiFi 1010 device and a Raspberry Pi 3 Model

B+ device. The mA data for the surface heights h

1

, h

3

and h

2

were calibrated so that they showed the correct

millimeter value at the top and bottom of the tank with

an accuracy of about a millimeter. Pump 1 and Pump

2 were calibrated with 1% percent interval to obtain

an exact calibrated equation for the pumps. This was

done for both pumps. In addition, with the help of

the collected data, the α

i j

parameters were accurately

identified. The validation between digital twin and

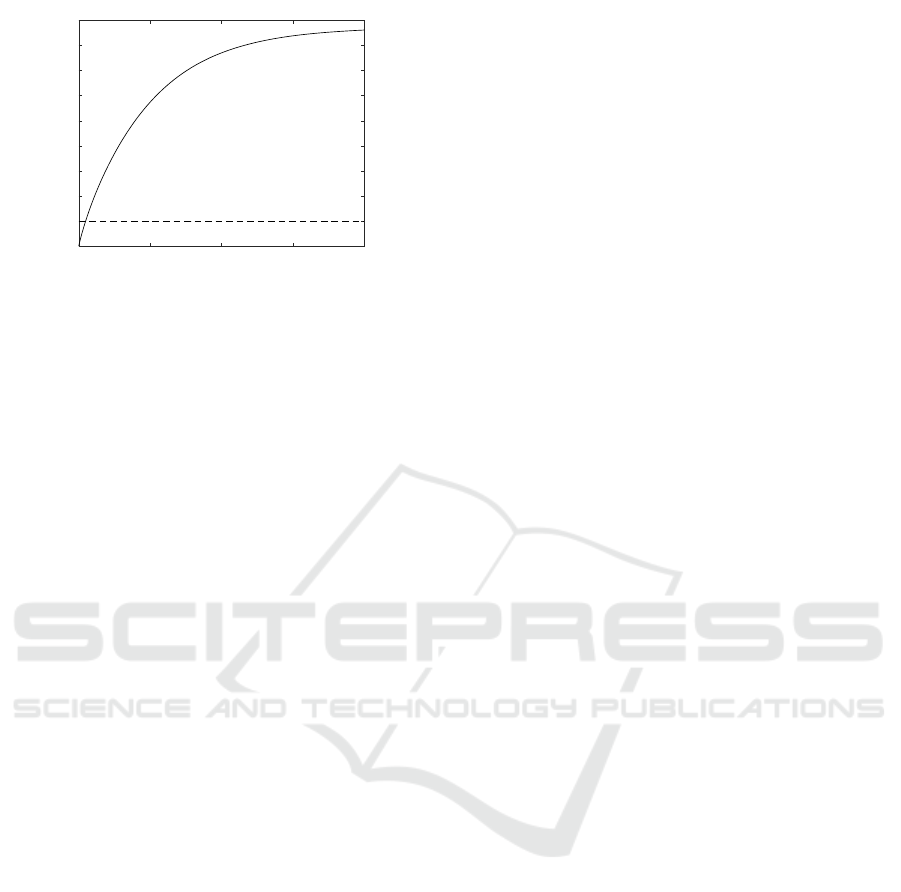

data is shown in Fig. 8. The parameters are show in

Table 2. In the first test, the delay was measured

by measuring how long it takes to read and write the

measurement value to the cloud. Test results show

0 1000 2000 3000 4000 5000 6000 7000 8000

t[seconds]

0

0.5

h

1

simulation

measurement

0 1000 2000 3000 4000 5000 6000 7000 8000

t[seconds]

0

0.1

0.2

h

3

0 1000 2000 3000 4000 5000 6000 7000 8000

t[seconds]

0

0.2

0.4

h

2

simulation

measurement

Figure 8: Accurate calibration of three tank system.

that the delay is 409 milliseconds when using OPC

UA tunneller software. When reading data utilizing

the Arduino MK WiFi 1010, the delay is 36 millisec-

onds. The delay is only 22 milliseconds when the

Gateway pc reads data through the C++ OPC DA and

NodeJS combination. In the second test, the signal

path is tested with the three-tank system with the par-

ity equations with transfer functions implemented in

the cloud. The Gateway PC read the values utiliz-

ing a combination of C++ OPC DA and NodeJS and

wrote them to the cloud service. The set point values

of 0.4 and 0.2 were set for level 1 and level 2, respec-

tively. Test results show that the digital twin detects a

fault in 56 seconds. To conclude, OPC DA no longer

meets current safety standards, however by combin-

ing it with OPC UA, an optimized and safe signal path

even for the latest Windows version is achieved.

8 CONCLUSIONS

OPC DA has not been updated earlier to function with

the latest programming libraries and operating sys-

tems, which significantly reduced the performance of

automation systems. The developed optimized signal

path using C++ OPC DA and NodeJS was compared

Table 2: Accurate model of the faulty pumps.

Variable Value

U

Signal1

0 −100

U

Signal2

0 −100

a

1

−32.41

b

1

1.475

a

2

−33.34

b

2

1.440

U

P

ump1 a

1

+ b

1

∗U

Signal1

U

P

ump2 a

2

+ b

2

∗U

Signal2

f low1 1.0 ∗10e −6 ∗U

Pump1

∗0.1

f low2 1.0 ∗10e −6 ∗U

Pump2

∗0.1

A Study on Optimizing Signal Path in Model Predictive Control and Fault Detection System of Three-Tank Pilot System Using Reference

Architecture

357

0 500 1000 1500 2000

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

Figure 9: Fault in the pump 1 and pump 2 in the closed loop

three-tank system.

to the OPC UA tunneler implementation through ex-

periments conducted on a real three-tank pilot system.

Due to the optimized signal path, the control interval

of MPC is 5 times smaller, resulting in a faster re-

sponse from the controller. In fault diagnosis and de-

tection, the delay is only 22 milliseconds compared to

408 milliseconds when using OPC UA tunneller soft-

ware. Test results show that the fault detection system

detects a fault in 56 seconds.

ACKNOWLEDGEMENTS

Pumps calibration was implemented by Otacilio Bez-

erra Leite Neto.

This work has received funding from the Eu-

ropean Union’s Horizon Europe research and in-

novation programme under grant agreement No.

101057083 – Zero-SWARM.

REFERENCES

Alhassan Osman, T. K. and Arıcı, M. (2023). Robust adap-

tive control of a quadruple tank process with sliding

mode and pole placement control strategies. IETE

Journal of Research, 69(5):2412–2425.

Bonomi, F., Milito, R., Zhu, J., and Addepalli, S. (2012).

Fog computing and its role in the internet of things. In

MCC ’12: Proceedings of the first edition of the MCC

workshop on Mobile cloud computing, pages 13–16.

Denzler, P., Ashjaei, M., Fr

¨

uhwirth, T., Ebirim, V. N., and

Kastner, W. (2022). Concurrent opc ua information

model access, enabling real-time opc ua pubsub. In

2022 IEEE 27th International Conference on Emerg-

ing Technologies and Factory Automation (ETFA).

DIN (2016). Din spec 91345:2016-04, reference architec-

ture model industrie 4.0 (rami4.0). Technical report.

European Commission (2017). Digital transformation mon-

itor. Technical report. Accessed 5 December 2022.

Evensen, L. (2013). Why a reference architecture is impor-

tant for you. Technical report. Accessed 5 December

2022.

Ghazali, M. R., A. M. A. . R. I. R. M. T. (2019). Adap-

tive safe experimentation dynamics for data-driven

neuroendocrine-pid control of mimo systems. IETE

Journal of Research, 68(3):1611–1624.

Govind, K. R. A., Mahapatra, S., and Mahapatro, S. R.

(2023). Design of an optimal control strategy for cou-

pled tank systems using nonlinear constraint optimiza-

tion with kharitonov-hurwitz stability analysis. IEEE

Access, 11:72618–72629.

Großmann, D., Bregulla, M., Banerjee, S., Schulz, D., and

Braun, R. (2014). Opc ua server aggregation - the

foundation for an internet of portals. In Proceedings

of the 2014 IEEE Emerging Technology and Factory

Automation (ETFA).

IEC (2015). Factory of the future. Technical report. Ac-

cessed 5 December 2022.

IEEE (2022). Systems and software engineering – archi-

tecture description. Technical report. Accessed 5 De-

cember 2022.

Industrial Internet Consortium (2019). The industrial in-

ternet of things volume g1: Reference architecture.

Technical report.

Isermann, R. (2006). Fault-Diagnosis Systems, An In-

troduction from Fault Detection to Fault Tolerance.

Springer, Berlin.

Kortela, J. (2022). Model-predictive control for the three-

tank system utilizing an industrial automation system.

ACS Omega, 7(22):18605–18611.

Maciejowski, J. M. (2002). Predictive Control with Con-

straints, 1st ed. Prentice Hal, Harlow.

M

¨

uller, A., Schnieders, T., Storms, S., and Herfs, W. (2022).

Integration method of custom information models into

existing opc ua servers. In 2022 IEEE 27th Interna-

tional Conference on Emerging Technologies and Fac-

tory Automation (ETFA).

Reiswich, E. and Fay, A. (2012). Strategy for the amend-

ment of plant information models by means of opc ua.

In IEEE 10th International Conference on Industrial

Informatics.

Samuel Emebu, Marek Kubal

ˇ

c

´

ık, C. J. B. D. J. (2023).

A comparative study of linear and nonlinear optimal

control of a three-tank system. ISA Transactions,

132:419–427.

Ujjwal Manikya Nath, C. D. and Mudi, R. K. (2023). Re-

view on imc-based pid controller design approach

with experimental validations. IETE Journal of Re-

search, 69(3):1640–1660.

VDI Verein Deutscher Ingenieure e.V. (2015). Reference

architecture model industrie 4.0 (rami4.0). Technical

report. Accessed 5 December 2022.

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

358