Motion Control Unit Design for Control Prototyping

of Modern BLDC/PMSM Drives and Piezo Actuators

Kv

ˇ

etoslav Belda

1 a

, Pavel P

´

ı

ˇ

sa

1,2 b

and

ˇ

St

ˇ

ep

´

an Pressl

1,2 c

1

Department of Adaptive Systems, The Czech Academy of Sciences, Institute of Information Theory and Automation,

Pod Vod

´

arenskou v

ˇ

e

ˇ

z

´

ı 4, 182 00 Prague 8, Czech Republic

2

Department of Control Engineering, Czech Technical University in Prague, Faculty of Electrical Engineering,

Karlovo n

´

am

ˇ

est

´

ı 13, 120 00 Prague 2, Czech Republic

Keywords:

BLDC/PMSM Drives, Motion Control, Power Supply, Mechatronic Systems, PysimCoder, Real-Time

Generated Code, NuttX RTOS, Piezoelectric Bender Actuators, Rapid Prototyping.

Abstract:

This paper deals with the design and construction of an open-software and open-hardware motion control

unit intended for experimental development and rapid prototyping of advanced drive control for mechatronic

systems and robotic applications such as smart production lines, manipulators, and robotic machine tools.

The control unit is designed for high dynamic drives, both modern permanent magnet synchronous motors

and piezoelectric drives and actuators promising for the near future. The concept and construction of the con-

sidered control unit are presented both from the hardware and software point of view. This includes cus-

tom printed circuit boards, electronic components for communication and power outputs, the microcontroller,

firmware as well as software used to generate control application code. The presented experimental research

and development is illustrated by figures and records of measured data.

1 INTRODUCTION

Many motion controllers work in industrial and home

applications such as robots-manipulators, production

lines and machines, unmanned vehicles and oth-

ers. Therefore, the motion control matter is well

known among engineers and the amount of motion

controllers in industry is vast. On the market, the sup-

ply ranges from controllers working only with a spe-

cific actuator (motor) with closed firmware to more

affordable and available controllers.

However, in the early stages of developing or re-

searching new control algorithms, it can be advanta-

geous to have a generic prototyping platform. Thus,

for fast application development, controllers are re-

quired to enable rapid prototyping using model-based

design, capable of running the designed control al-

gorithms (Tachiquingutierrez et al., 2023). In this pa-

per, we propose a modular and extensible, yet rel-

atively low-cost, embedded platform with a strong

emphasis on running control applications built us-

ing model-based design tools that generate real-

time code. Firstly, we discuss the existing solutions

and then we introduce the main parameters of a pro-

posed control unit.

a

https://orcid.org/0000-0002-1299-7704

b

https://orcid.org/0000-0003-3476-5151

c

https://orcid.org/0009-0006-5364-8961

1.1 Existing Tools and Platforms

Let us analyse available solutions like ODrive

(ODrive Robotics, 2024), VESC (Vedder, 2022)

and SOLO (SOLO Motor Controllers SRL, 2024)

controllers that all focus on the control of Permanent

Magnet Synchronous Motors (PMSM) and Brush-

less Direct Current (BLDC) drives. These controllers

share a few similarities: i ) they use mostly the same

interfaces, such as UART, SPI, I

2

C, CAN, and USB;

however, for rapid prototyping, the Ethernet interface

can be useful for convenient data logging and config-

uration, even from all over the world; ii ) the other

similarity is that each controller features its API

to configure control algorithms; on our proposed plat-

form, we intend not to come with a custom API but

rather provide a nonrestrictive environment, where

the generated code of control algorithms could be run;

iii) the last similarity is the lack of more than three

phases per axis, making control of stepper motors

or other types of actuators not possible.

There are already several solutions avail-

able for Rapid Control Prototyping (RCP), such

as Speedgoat (Speedgoat GmbH, 2024) and dSPACE

(dSPACE GmbH, 2024). However, these systems

are expensive and are tightly linked up to MAT-

LAB/Simulink. In contrast, we propose a unit based

on an open and free code generation tool.

Belda, K., Píša, P. and Pressl, Š.

Motion Control Unit Design for Control Prototyping of Modern BLDC/PMSM Drives and Piezo Actuators.

DOI: 10.5220/0012999300003822

In Proceedings of the 21st International Conference on Informatics in Control, Automation and Robotics (ICINCO 2024) - Volume 1, pages 579-590

ISBN: 978-989-758-717-7; ISSN: 2184-2809

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

579

1.2 Proposed Platform

The platform is intended to be fully open-source

and open-hardware to remain maintained and tech-

nologically sustainable. A large number of commu-

nication interfaces are also required for communi-

cating with sensors, interfacing with the microcon-

troller and logging purposes, such as Ethernet, I

2

C,

SPI, USB, CAN, etc., as well as functional parts

such as Pulse Width Modulation, Analog-to-Digital

Converter and Timer peripherals for the specific de-

sign of field oriented control BLDC/PMSM drives.

The generated code adds computational overhead, so

a microcontroller with a powerful core is required.

The main focus is on the control of PMSM/BLDC,

Stepper (even with feedback sensors), and Brushed

DC motors. However, the platform can also be used

for special actuators e.g. using inverse piezoelectric

effect and others in mechatronics (Gao et al., 2020).

We require the controller to be able to drive

at least two stepper motors, therefore eight control-

lable phases are needed. Eight phases are also enough

for BLDC/PMSM motors with more than three

phases. With a higher number of phases, a utilised

motor can be still operated when one or more phases

are failed. For these advantages, the multi-phase

BLDC motor is taken a good candidate for energy

saving or military application (Moon et al., 2015).

The controller is intended as a generic prototyping

platform with a large number of interfaces, the size

and weight are not a matter. If the control algorithms

are designed and verified on this platform, the hard-

ware can be redesigned to fit certain criteria, such

as size, weight, safety-critical, or space compliance,

keeping the same algorithms. Despite all the pro-

posed features, we strive for an affordable solution

within motion controllers such as ODrive controllers.

Finally, to make the generated code portable

across various platforms, a Real-Time Operating

System (RTOS) is considered. It provides a run-

time environment for multithreaded applications, net-

work stacks and a unified API for accessing hard-

ware dependent peripherals. In this paper, NuttX

RTOS is selected as a suitable OS. Furthermore,

as an experimental but open source code genera-

tion tool, pysimCoder is used, capable of generating

NuttX-compatible code from block diagrams and re-

motely tuning its internal parameters over the network

via the Silicon Heaven protocol (Lenc et al., 2023).

The paper is organised as follows. Hardware

and its implementation are in Sections 2 and 3. Then,

the hardware adaptation to NuttX is described along-

side the pysimCoder suite in Section 4. Finally,

the pysimCoder applications are shown in Section 5.

2 HARDWARE SPECIFICATION

Hardware (HW) design is inspired by the LX-RoCon

controller (PiKRON, 2014). One of the design rules

is to divide the motion controller into a Micro-

Controller Unit (MCU) board and a Power stage

board as two printed circuit boards. The complete

motion control unit then comprises of these two con-

nected boards.

This design rule allows to swap the less complex

Power stage board for a different one while keep-

ing the more complex MCU board the same. Since

the MCU board accommodates most of the used

connectors, it is placed above the power board.

The power board acts as the 5 V voltage source

for the MCU board as well.

2.1 Hardware Analysis

To design and specify motion control unit, a basis

for selecting a micro-controller, the intended periph-

erals and their use cases were summarised as fol-

lows: TTL UART for Simple console user inter-

face; RS232, RS422 or RS485 for Communication

with other devices, sensor data acquisition; (Q)SPI

for Ext. SPI memory, sensor data acquisition; I

2

C

for Ext. I

2

C memory, sensor data acquisition; Counter

for position measurement from quadrature encoders;

JTAG or SWD for program flashing and debugging;

CAN for communication with other devices; Eth-

ernet for data logging, remote access, pysimCoder

parameter tuning; SD slot for data logging; PWMs

for Control of power switches; ADCs for current

measurement for motor field oriented control (FOC)

and GPIOs for reading from hall sensors.

The motion controller should be capable of driv-

ing at least two stepper motors simultaneously since

we require the unit to be used for SCARA-like

or Cartesian robot topologies and axles with two in-

dependently driven wheels.

Since a stepper motor requires 4 half-bridge

switches, 8 half-bridge switches in total are re-

quired. BLDC/PMSM requires 3 half-bridge switches

to be controlled and a DC brushed motor requires

2 half-bridge switches (forming a H-bridge). Choos-

ing 8 half-bridge switches is enough for controlling

2 BLDC/PMSM and 4 DC brushed motors as well.

Furthermore, at least 8 PWM outputs for power

switches and at least 8 ADC channels for current mea-

surement are necessary with two counter peripherals

for encoder pulse counting and all the communica-

tion interfaces in paragraph above. Finally, all compo-

nents should operate in industrial temperature range

of at least −40 to 85

◦

C.

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

580

2.2 Microcontroller

ATSAMV71Q21B from Microchip, hereinafter ab-

breviated SAMV71 (Microchip, 2023), was cho-

sen as a suitable microcontroller (alternatives are

e.g. series STMicroelectronics STM32H7 or the NXP

imxRT). According to this selection, the control unit

has the label SaMoCon.

The microcontroller core is ARM Cortex M7

with support for single-precision and double-

precision floating point unit, making it feasible to use

alongside pysimCoder generated code with double

64bit type in calculations. The core is running

at 300MHz and features 2MB of Flash memory,

alongside 384kB of SRAM.

This microcontroller features all the desired pe-

ripherals, ranging from Ethernet, to two PWM pe-

ripherals featuring eight channels in total with com-

plementary outputs with configurable deadzones, two

Analog Front End Controller (AFEC) peripherals

each having up to 11 AD channels at disposal and four

TC (Timer/Counter) peripherals with encoder counter

logic. Besides that, CAN peripherals, the HSMCI pe-

ripheral for SD interfacing and many UARTs, SPIs,

TWIHSs (Microchip’s I

2

C) are present too.

3 HW IMPLEMENTATION

AS for the first power stage board prototype, Infineon

IFX007T half-bridge switches (Infineon, 2018) were

selected, see Figure 1. Since the maximum rated volt-

age is 40 V, this first power board has a nominal rating

of 24 V. To reduce the component cost, the common

ground is shared with the MCU board, as no galvanic

isolators are needed.

IFX007T is an all-in-one switch featuring two

N power-switching MOSFETs alongside gate drivers.

It includes built-in high and low-side current lim-

itations alongside over-temperature protection. This

IS

SR

INH

IN

GND

OUT

VS

Gate Driver

HS

Slewrate

Adjustment

Digital Logic

Undervolt.

detection

Overtemp .

detection

Current

Limitation

LS

Current

Limitation

HS

Current

Sense

Gate Driver

LS

LS off HS off

Figure 1: IFX007T structure (Infineon, 2018).

I

L

[A]

I

IS(lim)

I

IS

[mA]

I

CLx

Error Flag Mode

l

o

w

e

r

d

k

I

L

I

S

v

a

l

u

e

h

i

g

h

e

r

d

k

I

L

I

S

v

a

l

u

e

Current Sense Mode

(High Side)

I

IS(offset)

Figure 2: IS output current (Infineon, 2018).

makes the switch very easy to use, as it only requires

one PWM driving signal (IN) and an inhibit (INH)

input controlled by a GPIO.

The half-bridge also has an IS (current-sense)

output whose current is proportional to the current

flowing through the high-side transistor to the load.

The high-side current can then be measured by mea-

suring the voltage drop across the connected resistor.

The IS pin also serves the purpose of a fault indication

in case of over-current or high temperature. The char-

acteristics of IS output current are shown in Figure 2.

Even though the high-side current can be mea-

sured using the IS output, a decision was made

to measure the low-side transistor current using

a shunt connected to ground. However, IS high-side

value was used as an indicator of average current

by connecting a parallel capacitor, and the indicator

of a fault.

As Figure 2 suggests, the fault output current

is bigger than the expected current during normal op-

eration. This way, a fault voltage drop can be com-

pared with a reference on a comparator. Therefore

the comparator with open drain/collector outputs was

chosen for easy chaining with other comparators.

The low-side shunt is used for more precise mea-

surement of the motor winding current. The current

measurement and fault generation scheme is depicted

in Figure 3. If the voltage drop on the R

IS

resistor is

bigger than V

ref

, the comparator output goes low.

Since the operational amplifiers must be con-

nected to the analog ground, the measurement

of the shunt R

S

is done using a differential am-

plifier for R

S

is connected to the power ground,

which is affected by voltage drop caused by high cur-

rents in the power stage.

As the current passing through the transistors can

be negative, a bias voltage is applied to the differen-

tial amplifier, shifting the output voltage of the ampli-

fier. Fast voltage spikes on the R

IS

resistor are filtered

by the parallel C

IS

capacitor.

Motion Control Unit Design for Control Prototyping of Modern BLDC/PMSM Drives and Piezo Actuators

581

1 2 3 4 5 6

1 2 3 4 5 6

A

B

C

D

A

B

C

D

Date:

KiCad E.D.A. 8.0.1

Rev:

Size: A4

Id: 1/1

Title:

File:

Sheet: /

1

-

2

+

3

Comparator

GNDA

R3

R3

+

5

-

6

7

R4

R4

VCC

R2

Cis

GND

1

-

2

+

3

R1

GND

Ris

Rs

LS to MCU

BIAS

Fault

IFX007 GND

IFX007 IS

HS to MCU

REF

1

-

2

+

3

R1

Cis

VCC

R4

R4

+

5

-

6

7

Ris

Figure 3: HS and LS current sensing with fault generation.

The output voltage formulas of the amplifiers are

as follows according to Figure 3:

V

HS

=

1 +

R

1

R

2

R

IS

I

IS

, (1)

V

LS

=

R

4

R

3

R

S

I

RS

+ V

Bias

, (2)

where I

IS

is the current sourced by the IFX007T IS pin

and I

RS

is the current passing through the R

S

shunt,

which is in fact the low-side current.

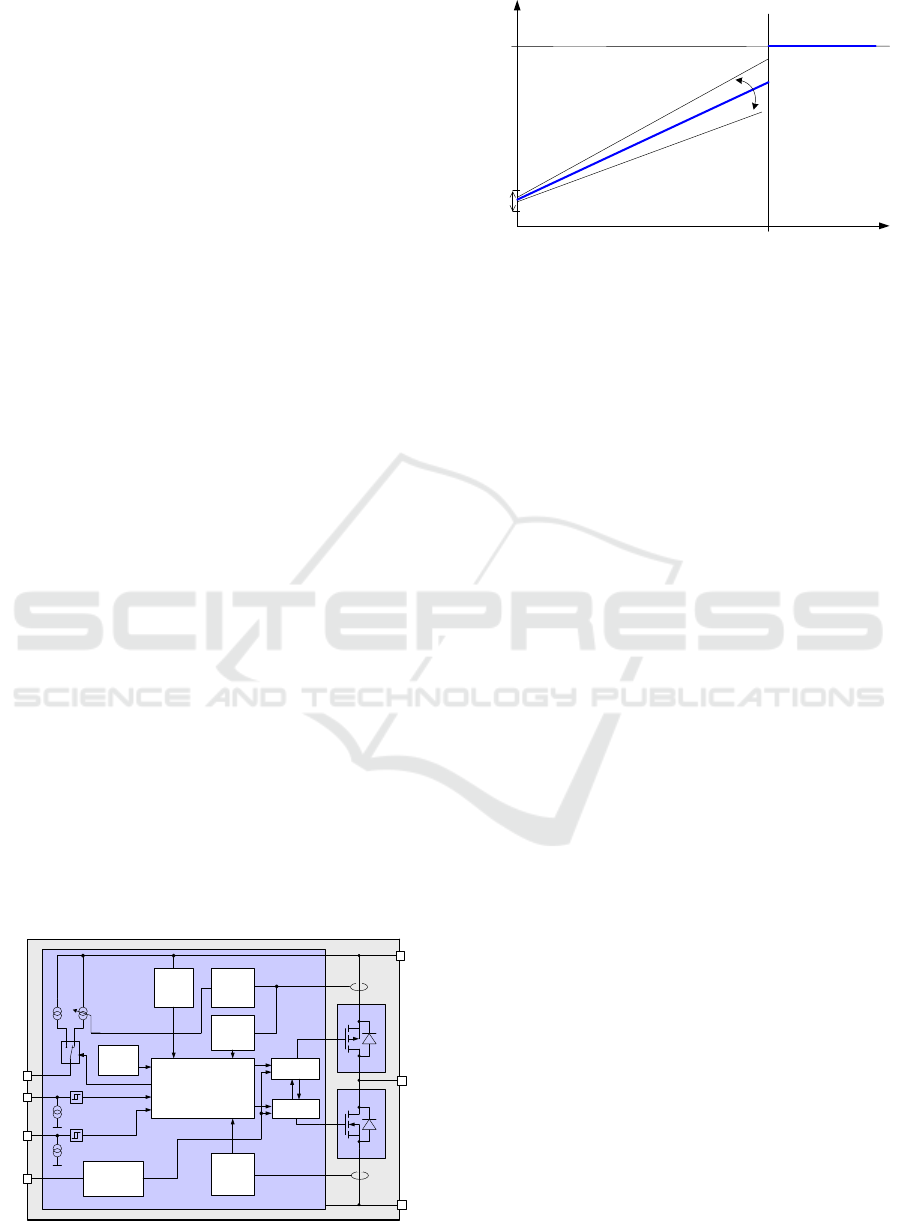

3.1 MCU Board Implementation

This section briefly describes the implementation

of the upper control MCU board, with all the pe-

ripherals shown in Figure 4. The connection of two

boards is placed on one of the longer sides of the PCB.

Extra GPIOs, SPI, and I

2

C are useful for future exten-

sions. There is another connector on top of the MCU

board with the same mirrored pinout as the lower

interconnection which can be used for expanding

boards placed above the MCU board and as an os-

cilloscope probing place. In the following sections,

the peripherals routed to the separate peripheral con-

nectors on the MCU board will be referred to as main

Ethernet

100 / 10

Mbit

I2C +

3.3 V

USB-C

Host,

Device

UART +

3.3 V

SD Card

2x Hall

trios in

SWD

debug

2x encoder

inputs

SPI + 3 CS

3.3 or 5V

RS232

RS485

2x

CAN FD

Winbond

SPI flash

External GPIOS, PWMs, ADCs, down and up mirror

5V to 3.3V

buck

24xxxx EEPROM

KSZ8081

Ethernet

PHY

2x CAN FD

drivers

Microchip

ATSAMV71Q21B

ARM Cortex M7

@ 300 MHz

2 MB flash

384 kB SRAM

5V power

2.5 V reference

Figure 4: Upper control MCU board with peripherals.

Table 1: Routed peripherals.

SaMoCon Peripheral SAMV7 peripheral

2x CAN MCAN0, MCAN1

SPI main & extra SPI0, SPI1

TTL Console UART3

RS232/RS485 USART2

Ethernet GMAC in RMII mode

USB-C HSUSB

2× IRC TC[0,2] (Timer/Counter)

SD Card HSMCI

H PWM out, Motor A PWM0 CH0-3

L PWM out, Motor A PWM0 CH0-3

H PWM out, Motor B PWM1 CH0, CH1, CH3

L PWM out, Motor B PWM1 CH0-3

8 ADC chn., Motor A AFEC0

8 ADC chn., Motor B AFEC1

3 extra ADC chn. AFEC1

2x 3 Hall inputs GPIOs on the same PIO

I

2

C main & extra TWIHS0, TWIHS1

peripherals whereas the peripherals routed to the in-

terconnection/expanding connector will be referred

to as the extra peripherals.

3.1.1 Microcontroller Pinout

There are many combinations of pin configurations

due to alternative functions of microcontroller pins.

However, for a high count of the desired peripher-

als, conflicts began to occur − two peripheral outputs

or inputs were on the same pin. See Table 1 for routed

peripherals and the corresponding SAMV71 periph-

eral. Each IFX007T half-bridge is controlled by one

PWM H (high-side) signal and one GPIO pin. Even

though we need 8 PWM H outputs, we also route all

remaining PWM L (low-side) outputs, because some

gate drivers require complementary PWM outputs.

In the case of IFX007T, the L output can be config-

ured as a simple output pin.

Unfortunately, the only one H output of PWM1

CH2 could not be routed due to collisions

with the HSMCI peripheral. A decision was

made to route the L channel output as the H channel,

because the PWM polarity can be configured in soft-

ware, resulting in a total of 7 complementary and one

non-complementary output.

3.1.2 MCU-Board Voltage Supplies

All the components on this PCB are powered

from the 5 V or 3.3 V rail. MCU board is de-

signed to be powered from the power board through

the interconnection. The 5V rail can also be sup-

plied from the USB-C connector. A buck regulator

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

582

(Texas Instruments TPS562207) is used to convert 5V

to 3.3 V. The CAN and RS232/RS485 peripherals are

galvanically isolated, so 5 V to 5 V small power sup-

plies are used. Also, a stable 2.5 V reference (Mi-

crochip MCP1525) was added for analog measure-

ments.

3.1.3 Ethernet

A Physical Layer (PHY) component was con-

nected to the microcontroller GMAC periph-

eral. The Microchip KSZ8081 IC was used,

working in the RMII mode with specific bit rates

up to 100 Mb/s. The design uses the recommen-

dations from the datasheet (Microchip, 2019)

with compatible magnetics. Communication activity

is indicated by two LED.

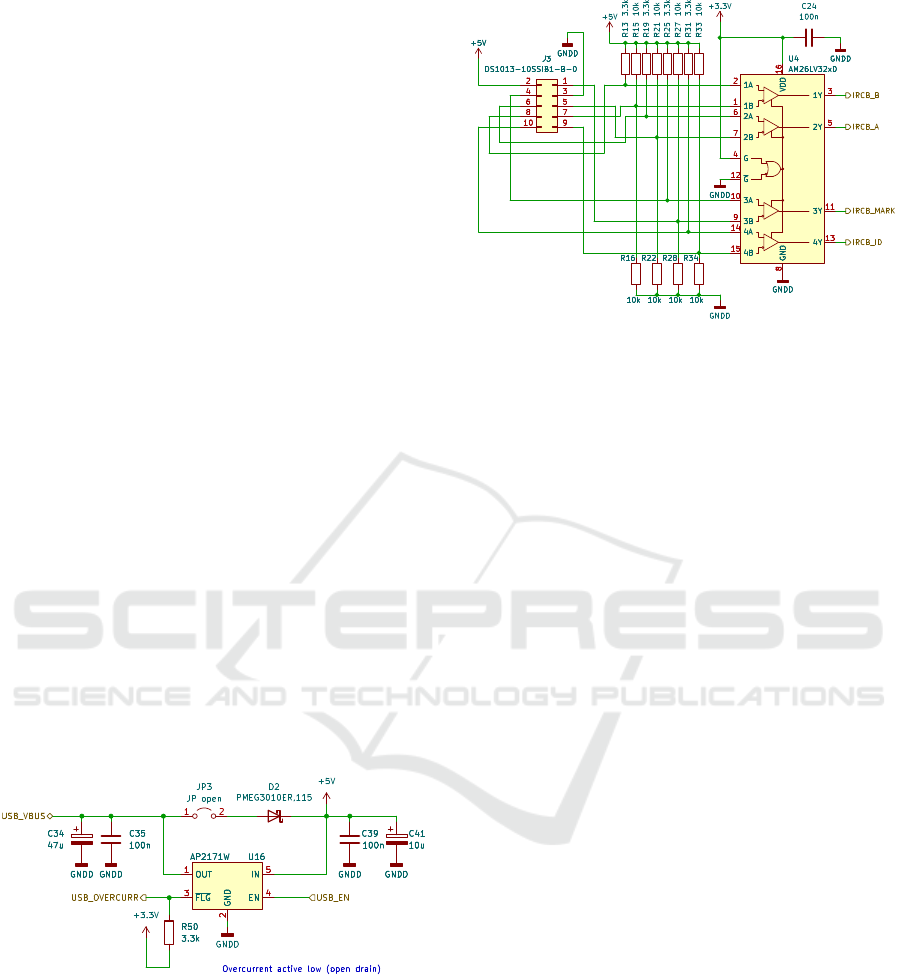

3.1.4 USB

The USB-C’s CC1 and CC2 pins are connected

to the Texas Instruments TUSB321 integrated cir-

cuit that negotiates host or device operation, given

voltage levels at certain pins. The data pins are con-

nected to the HSUSB SAMV71 peripheral. The board

was designed to act as a host or a device, using

an AP2171W power switch. If the controller acts

as a host, the enable pin (EN) is set high, enabling

the power switch. If over-current happens, an open

collector FLG output is used to indicate an error.

If connected to a USB power source, the current

passes through a Schottky diode with a low voltage

drop and bypasses the USB power switch, see Fig-

ure 5.

1 2 3 4 5 6

1 2 3 4 5 6

A

B

C

D

A

B

C

D

Date: 2024-01-17

KiCad E.D.A. 8.0.1

Rev: v1.0.0

Size: A4

Id: 4/6

Title: SaMoCon MCU Controller - Power, References

File: power.kicad_sch

Sheet: /POWER/

2024 þÿ©þÿ`tpán Pressl - bachelor thesis at FEE CTU in Prague

Supported and funded by: þÿÚTIAAV þÿR, PiKRON s.r.o.

This work is licensed under CERN-OHL-W.

R50

3.3k

H1

MountingHole

H4

MountingHole

+5V

GNDD

-Vin

1

+Vin

2

-Vout

3

+Vout

4

U17

TEA1-0505

-Vin

1

+Vin

2

-Vout

3

+Vout

4

U18

TEA1-0505

VBUS

GND2

VCOM

C44

100n

GNDD

H2

MountingHole

+3.3V

C35

100n

GNDDGNDD

GNDAGNDD

C34

47u

+3.3V

R51

31k

GNDD

C38

100n

D2

PMEG3010ER,115

+5V

1 2

JP3

JP open

C41

10u

C39

100n

GNDDGNDDOUT

1

GND

2

~{FLG}

3

EN

4

IN

5

U16AP2171W

R49

10k

VIN

1

SW

2

GND

3

BST

4

EN

5

FB

6

U15

TPS562208

C45

100n

C31

22u

C33

100n

GNDDGNDD

GNDD

GND1

+5V

GNDD

H5

MountingHole

H3

MountingHole

GNDA

C43

22u

+3.3V

GNDD

C40

100n

GNDD

GNDA

R52

10k

GNDA

C36

1u

C42

22u

C37

100n

C32

100n

Vin

1

Vout

2

Vss

3

U14

MCP1525-TT

L2

3.3u

GNDA

+5V

GNDD

USB_OVERCURR

ADC_REF

USB_EN

USB_VBUS

Serial Line

CAN

Overcurrent active low (open drain)

Connection of GNDD and GNDA is realised on this PCB

Diode for host and device operation simultaneously

Recommended values TPS562200:

R1 31k

R2 10k

L 3.3u

Cout = 22u + 22u No need to turn off

C37

100n

U14

MCP1525-TT

Vin

1

Vout

2

Vss

3

+3.3V

C36

1u

GNDAGNDA

C34

47u

GNDD GNDD

C35

100n

R50

3.3k

C38

100n

U15

TPS562208

VIN

1

SW

2

GND

3

BST

4

EN

5

FB

6

U16AP2171W

OUT

1

GND

2

~{FLG}

3

EN

4

IN

5

GNDD GNDD

C39

100n

C41

10u

Figure 5: USB power components.

3.1.5 Other Communication Interfaces

The MCU board features two CAN-FD peripher-

als with MCP2562FD transceivers. The board fea-

tures a circuit that either functions as the RS232

or the RS485 interface. The RS232 interface uses

a MAX232 converter and the RS485 uses the ST485

converter. CAN and RS interfaces are both isolated

by the ADuM1201AR isolators.

1 2 3 4 5 6

1 2 3 4 5 6

A

B

C

D

A

B

C

D

Date: 2024-01-17

KiCad E.D.A. 8.0.1

Rev: v1.0.0

Size: A4

Id: 3/6

Title: SaMoCon MCU Controller - Connectivity 1

File: connectors.kicad_sch

Sheet: /CONNECTORS1/

2024 þÿ© þÿ`tpán Pressl - bachelor thesis at FEE CTU in Prague

Supported and funded by: þÿÚTIAAV þÿR, PiKRON s.r.o.

This work is licensed under CERN-OHL-W.

GNDD

1

2

3

4

5

6

7

8

J6

NS25-W8P

+5V

1 2

3 4

J7

JP 2 rows

+3.3V

GNDD

GNDD

R43

3.3k

R25 3.3k

C25

100n

+3.3V

2

GND

3

4

VCC

5

U11

74HC1G04GW,125

R36

10k

+3.3V

R37

NC

R38

NC

GNDD

+3.3V

1

10

2

34

56

78

9

J4

DS1013-10SSIB1-B-0

GNDD

R12

2.2k

GNDD

1

2

3

4

J2

NS25-W4P

+3.3V

R11

2.2k

1B

1

3A

10

3Y

11

~{G}

12

4Y

13

4A

14

4B

15

VDD

16

1A

2

1Y

3

G

4

2Y

5

2A

6

2B

7

GND

8

3B

9

U4

AM26LV32xD

+3.3V C24

100n

GNDD

1

10

2

34

56

78

9

J3

DS1013-10SSIB1-B-0

GNDD

+5V

GNDD

R34

10k

GNDD

GNDD

C22

100n

R393.3k

R403.3k

R413.3k

R42

NC

1B

1

3A

10

3Y

11

~{G}

12

4Y

13

4A

14

4B

15

VDD

16

1A

2

1Y

3

G

4

2Y

5

2A

6

2B

7

GND

8

3B

9

U5

AM26LV32xD

GNDD

VDD1

1

VOA

2

VIB

3

GND1

4

GND2

5

VOB

6

VIA

7

VDD2

8

U6

ADuM1201AR

+3.3V

VDD1

1

VOA

2

VIB

3

GND1

4

GND2

5

VOB

6

VIA

7

VDD2

8

U7

ADuM1201AR

GNDD

1

2

3

4

J5

NS25-W4P

+3.3V

GND1

GND1

1

2

3

4

5

J10

NS25-W5P

LOGIC RS232

C1+

1

T2IN

10

T1IN

11

R1OUT

12

R1IN

13

T1OUT

14

GND

15

VCC

16

VS+

2

C1-

3

C2+

4

C2-

5

VS-

6

T2OUT

7

R2IN

8

R2OUT

9

U13

MAX232CSE

VCOM

C27 1u

C301u

C291u

C28

1u

GND1

VCOM

VCOM

GND1

GNDD

CC1

1

GND

10

DIR

11

VDD

12

CC2

2

CURRENT_MODE

3

PORT

4

VBUS_DET

5

~{VCONN_FAULT}

6

OUT1

7

OUT2

8

ID

9

U9

TUSB321

1 2

JP2

R46

820k

47k

R48

47k

GND1

RO

1

~{RE}

2

DE

3

DI

4

GND

5

A

6

B

7

VCC

8

GNDD

GND

1

I/O1

2

I/O2

3

VCC

4

D1

PRTR5V0U2X

1 2

JP1

Jumper 2 open

1

2

GND

3

4

VCC

5

U8

74HC1G08,125

A0

1

A1

2

A2

3

GND

4

SDA

5

SCL

6

WP

7

VCC

8

U3

24AA64

R30

10k

R24

10k

R18

10k

1

2

GND

3

4

VCC

5

U10

74HC1G08,125

VCOM

VCOM

GND1

VCOM

GNDD

R45

47k

VCOM

VCOM

GNDD GNDD

GND

A1

VBUS

A4

CC1

A5

D+

A6

D-

A7

SBU1

A8

CC2

B5

D+

B6

D-

B7

SBU2

B8

SHIELD

S1

J9

USBC Connector

FB1

BLM21PG331SN1D

R47

47k

1

2

J8

NS25-W2P

C26

1u

GND1

R22

10k

R16

10k

GNDD

+5V

R19 3.3k

R13 3.3k

GNDD

R15 10k

R21 10k

+5V

R28

10k

R33 10k

R31 3.3k

R27 10k

USART_TX

I2C_SDA

I2C_SCL

SPI_MOSI

USART_RX

SPI_CS1

SPI_CLK

SPI_CS0

SPI_MISO

USB_VBUS

SPI_CS2

USB_D-

USB_D+

USART_RTS

IRCA_ID

IRCA_A

IRCA_MARK

UART_TX

UART_RX

IRCA_B

USB_ID

IRCB_A USART_CTS

IRCB_B

IRCB_MARK

IRCB_ID

485+

485-

I2C

RS232

in case of some failures force usb for device operation

SPI

RS485

UART (TTL Console)

IRC A

PORT on Z: DRP (dual port mode)

ID open drain

R28

10k

R16

10k

R22

10k

GNDD

GNDDU4

AM26LV32xD

1B

1

3A

10

3Y

11

~{G}

12

4Y

13

4A

14

4B

15

VDD

16

1A

2

1Y

3

G

4

2Y

5

2A

6

2B

7

GND

8

3B

9

GNDD

J3

DS1013-10SSIB1-B-0

1

10

2

34

56

78

9

GNDD

+5V

R34

10k

GNDD

GNDD

U5

AM26LV32xD

1B

1

3A

10

3Y

11

~{G}

12

4Y

13

4A

14

4B

15

VDD

16

1A

2

1Y

3

G

4

2Y

5

2A

6

2B

7

GND

8

3B

9

U6

ADuM1201AR

VDD1

1

VOA

2

VIB

3

GND1

4

GND2

5

VOB

6

VIA

7

VDD2

8

+3.3V

J6

NS25-W8P

1

2

3

4

5

6

7

8

J7

JP 2 rows

1 2

3 4

+3.3V

GNDD

C25

100n

+3.3V

U11

74HC1G04GW,125

2

GND

3

4

VCC

5

R36

10k

GNDD

GNDD

J4

DS1013-10SSIB1-B-0

1

10

2

34

56

78

9

GNDD

R30

10k

R24

10k

R18

10k

U10

74HC1G08,125

1

2

GND

3

4

VCC

5

VCOM

VCOM

GND1

VCOM

U8

74HC1G08,125

1

2

GND

3

4

VCC

5

GNDD

J9

USBC Connector

GND

A1

VBUS

A4

CC1

A5

D+

A6

D-

A7

SBU1

A8

CC2

B5

D+

B6

D-

B7

SBU2

B8

SHIELD

S1

FB1

BLM21PG331SN1D

C26

1u

GND1

GND1

U13

MAX232CSE

C1+

1

T2IN

10

T1IN

11

R1OUT

12

R1IN

13

T1OUT

14

GND

15

VCC

16

VS+

2

C1-

3

C2+

4

C2-

5

VS-

6

T2OUT

7

R2IN

8

R2OUT

9

C27 1u

C301u

C291u

C28

1u

GND1

VCOM

VCOM

+3.3V

U9

TUSB321

CC1

1

GND

10

DIR

11

VDD

12

CC2

2

CURRENT_MODE

3

PORT

4

VBUS_DET

5

~{VCONN_FAULT}

6

OUT1

7

OUT2

8

ID

9

JP2

1 2

R48

47k

GND1

GNDD D1

PRTR5V0U2X

GND

1

I/O1

2

I/O2

3

VCC

4

JP1

Jumper 2 open

1 2

Figure 6: Routed optical encoder with HEDL series pinout.

There are also main and extra TWIHS (I

2

C) inter-

faces routed. The main TWIHS peripheral has a Mi-

crochip 24AA64 EEPROM connected and the signals

are routed to a 4 pin Molex connector alongside 3.3 V

and GND. There is an another separate 4-pin Molex

connector for a basic LVTTL console user interface,

with 3.3 V, GND and RX and TX signals.

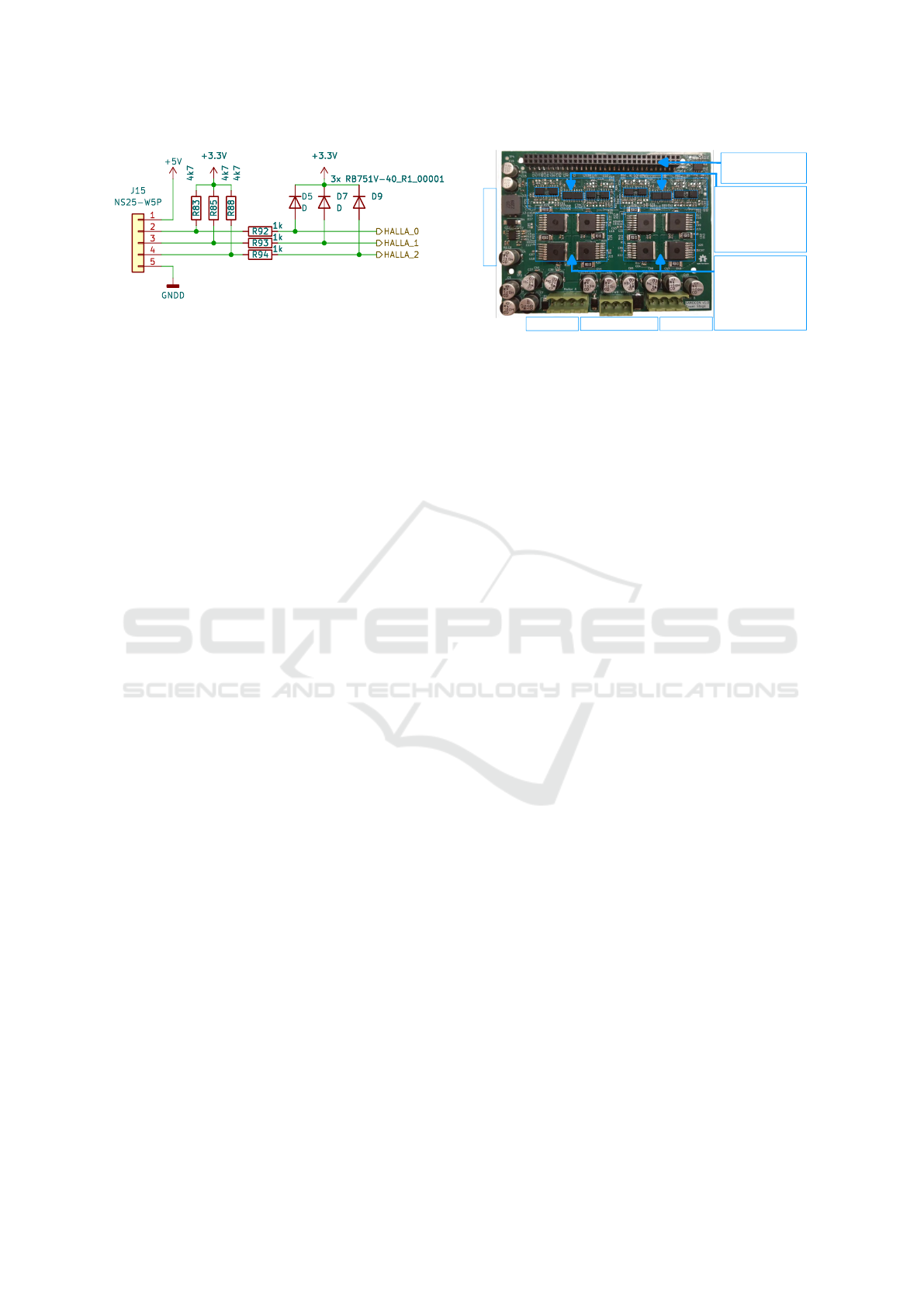

3.1.6 Feedback from the Actuators

The board has 2 connectors for incremental encoders

and 2 Hall input trios at its disposal. The optical en-

coder connector is compatible with the HEDL en-

coder series with a 2×5 pin socket. The HEDL se-

ries connector incorporates differential two optical

phases, a differential zero-cross index, grounding

and a 5 V power output too.

The differential signals are decoded by the Texas

Instruments AM26LV32 receiver. A so-called mark

signal is used too, acting as another user-defined help-

ful synchronising signal. The scheme of the decoder

circuit is in Figure 6.

Since the voltage level for the inverted signals

in the disconnected state is defined by voltage di-

viders, then an encoder with single-ended outputs can

be connected to the positive inputs. All the inputs

have a pull-up in case of open drain/collector outputs.

The decoded signals from the receiver are connected

to the SAMV71 TC0 and TC2 (Timer/Counter) pe-

ripherals.

The Hall outputs can be read by a GPIO pin.

In our implementation, a standard 5-pin Molex con-

nector (5 V power, GND, and 3 Hall outputs) is used.

In general, the outputs can be either push-pull

or open-drain. However, the 5 V push-pull output

could potentially destroy the microcontroller, mean-

ing precautions must be taken. The way Hall inputs

are routed is shown in Figure 7.

Motion Control Unit Design for Control Prototyping of Modern BLDC/PMSM Drives and Piezo Actuators

583

1 2 3 4 5 6

1 2 3 4 5 6

A

B

C

D

A

B

C

D

Date: 2024-01-17

KiCad E.D.A. 8.0.1

Rev: v1.0.0

Size: A4

Id: 5/6

Title: SaMoCon MCU Controller - Connectivity 2

File: connectors2.kicad_sch

Sheet: /CONNECTORS2/

2024 þÿ©þÿ`tpán Pressl - bachelor thesis at FEE CTU in Prague

Supported and funded by: þÿÚTIAAV þÿR, PiKRON s.r.o.

This work is licensed under CERN-OHL-W.

VDD1

1

VOA

2

VIB

3

GND1

4

GND2

5

VOB

6

VIA

7

VDD2

8

U19

ADuM1201AR

R72

22R

R65

22k

GNDD

C59

22p

L3

1uH

R66

22k

R74

22k

C58

22p

GNDD

R73

22R

+3.3V

GNDD

GND2

+3.3V

GND2

TXD

1

VSS

2

VDD

3

RXD

4

Vio

5

CANL

6

CANH

7

STBY

8

U22

MCP2562-E-SN

GND2

VDD1

1

VOA

2

VIB

3

GND1

4

GND2

5

VOB

6

VIA

7

VDD2

8

U20

ADuM1201AR

VBUS

C62

10u

GNDD

GNDD

C57

22u

+3.3V

C55

100n

L4

470R @ 100 MHz

GNDD

R64

22k

R67

22R

C48

100n

GNDD

GNDD

C60

100n

C61

2.2u

+3.3V

R68

22R

R71

22R

R70

22R

R69

22R

R62

6k49

R55

560R

GNDD

R58

75R

R59

75R

C52

100n

TXD

1

VSS

2

VDD

3

RXD

4

Vio

5

CANL

6

CANH

7

STBY

8

U21

MCP2562-E-SN

R60

120R

GND2

C51

100n

GNDD

GNDD

1

2

3

J13

Conn_01x03

1 2

JP5

JMP 2 Open

1

2

3

J12

Conn_01x03

1 2

JP4

JMP 2 Open

GND2

C50

100n

GND2

VBUS

1

10

11

12

2

3

4

5

6

7

89

SH

J11

RJHSE-5384

GND2

GNDD

RX

TX

1

10

11

14

15

16

2

3

6

7

89

T1

HX1188NL

GND2

R61

120R

+3.3V

GNDD

R56

75R

R57

75R

GNDD

C47

100n

VBUS

GNDD

R54

560R

R53

4k7

C46

1n (2kV)

C49

100n

VBUS

C63

10u

C54

2.2u

R86 1k

R95 1k

R89

1k

R91

1k

D5

D

D7

D

R88

4k7

R85

4k7

R92

1k

1-DAT2

1

2-CD/DAT3

2

3-CMD

3

4-VDD

4

5-CLK

5

6-VSS

6

7-DAT0

7

8-DAT1

8

SW-A

CD

SW-B/GND

G

K1

112J-TDAR-R01

R93

1k

R94

1k

1

2

3

4

5

J14

NS25-W5P

+3.3V

+3.3V

R90

1k

GNDD

D9

3x RB751V-40_R1_00001

R84

4k7

+3.3V

R63

22k

R87

4k7

R82

4k7

D6

D

D4

D

D8

3x RB751V-40_R1_00001

C53

100n

GNDD

GNDD

+3.3V

+5V

+3.3V

+3.3V

R80 1k

R75

22k

R76

22k

1

2

3

4

5

J15

NS25-W5P

+5V

+3.3V

R77 1k

D3

1N4148WS

R79 1k GNDDGNDD

GNDD

1

2

3

4

Y2

3225-25M-SR

VDD_1.2

1

MDIO

10

MDC

11

RXD1

12

RXD0

13

VDDIO

14

CRS_DV/PHYAD[1:0]

15

REF_CLK

16

RXER

17

INTRP

18

TXEN

19

VDDA_3.3

2

TXD0

20

TXD1

21

GND

22

LED0/ANEN_SPEED

23

~{RST}

24

RXM

3

RXP

4

TXM

5

TXP

6

XO

7

XI

8

REXT

9

U23

KSZ8081RNA

GNDD

R78 10k

R83

4k7

C56

2.2u

R81 4k7

HALLA_2

HALLB_2

SD_CLK

HALLA_1

HALLA_0

ETH_LED

SD_DA2

SD_CMD

SD_DA3

SD_DET

CAN1_RX

SD_DA1

SD_DA0

HALLB_0

ETH_MDC

ETH_INT

ETH_EN

ETH_RXER

ETH_MDIO

ETH_CLK

ETH_RX0

ETH_TX1

ETH_RX1

ETH_TX0

ETH_PHYAD

CAN0_RX

CAN0_TX

CAN1_TX

HALLB_1

E_RX+

E_TX-

E_TX+

PHY_RX+

E_RX-

PHY_TX-

PHY_RX-

PHY_TX+

diode for fast shutdown

CAN B

120 R terminator

2.1V forward voltage (at 2 mA)

PHY INT and MDIO require external 1k

HALL B

CAN A

datasheet PHY: pinstate==low => led==high

SD Card slot

120 R terminator

HALL A

Ethernet

K1

112J-TDAR-R01

1-DAT2

1

2-CD/DAT3

2

3-CMD

3

4-VDD

4

5-CLK

5

6-VSS

6

7-DAT0

7

8-DAT1

8

SW-A

CD

SW-B/GND

G

R63

22k

GNDD

U23

KSZ8081RNA

VDD_1.2

1

MDIO

10

MDC

11

RXD1

12

RXD0

13

VDDIO

14

CRS_DV/PHYAD[1:0]

15

REF_CLK

16

RXER

17

INTRP

18

TXEN

19

VDDA_3.3

2

TXD0

20

TXD1

21

GND

22

LED0/ANEN_SPEED

23

~{RST}

24

RXM

3

RXP

4

TXM

5

TXP

6

XO

7

XI

8

REXT

9

Y2

3225-25M-SR

1

2

3

4

+3.3V

GNDD

GNDD

R65

22k

L3

1uH

GND2

U22

MCP2562-E-SN

TXD

1

VSS

2

VDD

3

RXD

4

Vio

5

CANL

6

CANH

7

STBY

8

GND2

R61

120R

+3.3V

R56

75R

J11

RJHSE-5384

1

10

11

12

2

3

4

5

6

7

89

SH

R54

560R

R53

4k7

U21

MCP2562-E-SN

TXD

1

VSS

2

VDD

3

RXD

4

Vio

5

CANL

6

CANH

7

STBY

8

R60

120R

GND2

C50

100n

GND2

VBUS

J12

Conn_01x03

1

2

3

R62

6k49

C52

100n

R59

75R

VBUS

C49

100n

C46

1n (2kV)

GNDD

VBUS

T1

HX1188NL

1

10

11

14

15

16

2

3

6

7

89

GNDD

VBUS

U20

ADuM1201AR

VDD1

1

VOA

2

VIB

3

GND1

4

GND2

5

VOB

6

VIA

7

VDD2

8

+3.3V

GNDD

+3.3V U19

ADuM1201AR

VDD1

1

VOA

2

VIB

3

GND1

4

GND2

5

VOB

6

VIA

7

VDD2

8

GNDD

C58

22p

C59

22p

GNDD

R72

22R

R73

22R

R69

22R

R70

22R

R71

22R

R68

22R

+3.3V

R67

22R

L4

470R @ 100 MHz

+3.3V

+3.3VD3

1N4148WS

GNDD

R81 4k7

+3.3V

D7

D

R88

4k7

R85

4k7

R92

1k

R93

1k

R94

1k

R84

4k7

R87

4k7

R82

4k7

D8

3x RB751V-40_R1_00001

D6

D

+3.3V

D9

3x RB751V-40_R1_00001

R90

1k

R91

1k

R89

1k

+3.3V

R83

4k7

Figure 7: Open drain/collector output: the output is 3.3 V

or GND due to the pull-up to 3.3 V. Push-pull: the voltage

limitation is done by shorting the output to 3.3 V through

diodes. The shorting current is limited by series resistors.

3.1.7 Interconnection Pinout

The interconnection between the two boards is re-

alized by a standard 2×32 header pin connector

with a 2.54 mm pitch. The MCU board contains

the pin connector heading down towards the power

board and a socket heading up. The pinouts of these

connectors are the same, mirrored only, and are

of SMD type, allowing us to route tracks in the inner

layers.

Some pins provide the 5 V source and the power

digital ground to power the MCU board. In gen-

eral, the power board may contain 3.3 V powered

circuits, so we need to route 3.3 V too, as well

as the 2.5 V reference. The lower board may also con-

tain analog circuitry so we route the analog ground

too. The connection of the analog and digital ground

is done on the MCU board nearby the ADC reference

and ground pins.

All 15 (7 complementary and one non-comple-

mentary) PWM outputs must be routed alongside 16

ADC channels (IFX007 high and low side sensing)

for two motors. An extra I

2

C, GPIOs and SPI or 3 ex-

tra ADC channels are routed too.

3.2 Power Stage Board Implementation

As already discussed during the analysis, the power

board also serves the purpose of a step-down to 5 V.

The rated current per phase is a continuous 10 A

minimum, achieving a 20 A peak is possible too.

The board must perform the current measurement

and amplification. These analog signals are then pro-

cessed by the MCU board placed above. The power

board is in Figure 8.

The power to the half-bridge switches is routed

on the PCB upper side, while the outputs are routed

on its back side. The IFX007 output with an ex-

posed solder pad is connected to a high area cop-

per, on which a heatsink can be placed to cool down

the switches.

4 phases A

4 phases B

5 V power out,

PWM inputs,

output of opamps

GND, VPWR, VCTRL

24 V to 5V buck

Pair of 4

Infineon IFX007s

Half bridges with

integrated HS and

LS drivers

Opamps for current

measurement of HS

and LS switches.

Comparators used

for fault signal

generation. 2x

MCP6022

MCP6022

LM2903

LM2903

MCP6022

MCP6022

Figure 8: Power stage board

3.2.1 Power Components

The power board features a 3-pin power connector,

one pin being the common ground pin, the other

ones are the positive voltage rails, one for the MCU

board, and the other for the motors. The used

buck regulator IC is AOZ1284, used in accordance

with the datasheet’s recommendations. The total

power consumption of the MCU board is supposed

around 0.5A, the MCU board’s USB power switch

handles 1A continuous at maximum and we suppose

the expanding board consumes another 1A. The IC

provides up to 4A, enough for our requirements.

All the analog circuitry powered from 5 V or 3.3 V

(provided by the MCU board) is first filtered

with an LC filter. The power rail for the IFX007

switches contains decoupling electrolytic capacitors.

3.2.2 Low Side Shunt Current Measurement

Let us consider the formula (2). Let V

Bias

be 1.25V,

in the middle of the voltage reference. This volt-

age is obtained by choosing a 1:1 voltage divider

with a buffer to lower the output impedance of the di-

vider. R

s

was chosen to be 10mΩ because higher

resistance values would lead to big power losses.

The power loss of this at 10 A is 1 W, so a 3 W

2512 resistor has been chosen. To use the whole

ADC bandwidth, we amplify the voltage by at least

10×. This can be achieved by setting R

3

= 1 kΩ

and R

4

= 10kΩ.

3.2.3 IS Current Measurement

Since the IFX007T IS output indicates a fault, we

need to set the threshold value first which should

equal to the point where I = 20 A. Referring to Ta-

ble 11 in (Infineon, 2018), the maximum analog sense

current in fault condition is I

IS(lim)

= 6.1mA. To be

sure, the voltage drop on R

IS

must not be higher than

3.3 V to not damage the operational amplifier, pow-

ered from the 3.3 V rail. We choose a R

IS

= 510 Ω

resistor from the E24 series. The maximum voltage

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

584

drop across this resistor is

V

IS(lim)

= 3.111V < 3.3V. (3)

The differential current sense ratio in static on-

condition is on average (Infineon, 2018)

dI

L

dI

S

= 19500. (4)

Then, a threshold value for the comparator at I = 20A

can be computed as follows:

V

th

=

20

19500

510V = 0.52V. (5)

Since the differential ratio varies significantly and it

also has a non-negligible offset, we set V

th

= 0.655 V,

provided by a divider made out of 2.2 kΩ and 6.2 kΩ

resistors. This compare value is again amplified

by a buffer to lower the output impedance.

The last value that needs to be set is C

IS

.

This value was supposed to be in the range of hun-

dreds of pF, so only the high-frequency noise would

be filtered. Unfortunately, during testing, we spotted

a high fault rate on the comparator’s output due to fast

voltage spikes on R

IS

which were always caused after

switching off the PWM signal. The reasons of this

problem are unknown to us and will require further

investigation. Currently C

IS

is 22 nF, as a trade-off

between suppressing the spikes and fast-rising times.

3.2.4 Analog Components

Used operational amplifiers are Microchip MCP6022,

a low offset and rail-to-rail operational amplifier.

The used comparator is Texas Instruments LM2903,

a dual differential comparator with open-drain out-

puts. That means all comparators from 4 half bridges

can be chained together. If at least one switch faults,

the line goes low. Finally, the complete motion con-

trol unit is shown in Figure 9 assembled of MCU

and power boards. This ends the issue of HW design

and implementation.

Figure 9: Connected boards forming the controller.

4 NuttX AND pysimCoder

This section briefly introduces NuttX and its adapta-

tion to the SaMoCon hardware and pysimCoder suite.

NuttX is an open-source real-time operating sys-

tem written in C and released under Apache 2.0

license was introduced by Gregory Nutt in 2007,

(ASF, 2023). Currently, the project is maintained

on GitHub (ASF, 2024c). The primary governing

standards in NuttX are POSIX and ANSI standards

(ASF, 2024a).

Since NuttX aims to conform to Portable Op-

erating System Interface (POSIX) (Group, 2024),

all the interaction with the microcontroller periph-

erals is done by accessing the peripherals’ regis-

tered /dev files (for example, an AD converter may

be registered as /dev/adc0). The files are ac-

cessed using system calls like open, close, read

or write. As many peripherals do not share many

similarities with each other, ioctl calls are com-

monly used to change the underlying device pa-

rameters. The project’s directory structure is similar

to the Linux Kernel’s one (Torvalds, 2024), as well as

the process of configuration and building. The project

must be first configured by choosing Kconfig options

and then built using make or CMake.

4.1 NuttX Adaptation

To build NuttX, a custom BSP (board sup-

port package) is needed. The samv71-xult BSP

for the SAMV71 Xplained Ultra Evaluation Kit was

used as the baseline. Multiple source files were added

to initialize and register the peripherals, the most

important are AD converters (/dev/adc0,1), PWM

(/dev/pwm0,1), quadrature decoders of rotary en-

coders (/dev/qe0,1) and GPIOs for HALL reading

and IFX007T INH activation.

Furthermore, the NuttX build needs to be con-

figured so all the peripherals work properly, i.e.

console driver to output on the SAMV71 UART3

peripheral; SAMV71 GMAC peripheral to com-

municate with the KSZ8081 PHY and enabling

the UDP/IP and TCP/IP, alongside helper applications

like ping or telnet. Also the SAMV71 quadrature

decoder, PWM and ADC drivers needed to be con-

figured. Changes to SAMV71 quadrature decoder

and PWM drivers were made, which also made it

into the GitHub mainline repository.

By default, a NuttX configuration uses a pe-

riodic timer interrupt that drives all system tim-

ing. The timer is provided by architecture-spe-

cific code that calls into NuttX at a rate con-

trolled by CONFIG USEC PER TICK. The default value

Motion Control Unit Design for Control Prototyping of Modern BLDC/PMSM Drives and Piezo Actuators

585

of CONFIG USEC PER TICK is 10000 microseconds

which corresponds to a timer interrupt rate of 100Hz

((ASF, 2024b), Tickless OS). This configuration must

be turned on for control applications because it in-

troduces a freerunning timer, where each counter

increment corresponds to the smallest measurable

time slice. If time slice is small, high precision de-

lays can be made, useful in a fast periodic sampling

of the pysimCoder-generated real-time applications.

4.2 Introduction to pysimCoder

PysimCoder is an open-source rapid control ap-

plication development tool designed by Professor

Roberto Bucher from the University of Applied Sci-

ences and Arts of Southern Switzerland, (Bucher,

2024). It uses an extended python-control library

for the integration of methods as full or reduced state

space observer, anti-windup mechanism and discrete

linear quadratic regulator. Apart from that, pysim-

Coder offers a graphical editor with a code genera-

tor. This combination allows the user to design the de-

sired application graphically using predefined blocks

and then generate a C code that can be run on target

hardware. Details and pysimCoder setup and compi-

lation is in (Lenc et al., 2023).

PysimCoder supports code generation for var-

ious platforms using custom APIs, like STMi-

croelectronic’s STM32H7, Microchip SAMD21,

or Linux. Simulations of control systems can be done

if the code is generated for Linux. In the con-

text of this paper, the ability of code generation

for the OSIX-compatible NuttX RTOS is more impor-

tant. As with NuttX, the generated code runs in a high-

priority task, with a periodic control loop. The sam-

pling time of the control loop can be set in pysim-

Coder GUI before the code generation. Runtime

monitoring and tuning of model parameters that al-

low the user to display and edit parameters, inputs,

and outputs of individual blocks, is solved using Sili-

con Heaven infrastructure (SHV) (Elektroline, 2024)

and (Lenc et al., 2023).

5 pysimCoder APPLICATIONS

This section presents the control applications and its

pysimCoder diagrams. The behavior of the con-

trol system can be remotely tuned using the Sili-

con Heaven protocol, like the references or the val-

ues of the PID controllers. Unfortunately, the cur-

rent build of NuttX is only capable of achieving sam-

pling rates below 1kHz, probably due to the NuttX

scheduler limitations or a long-lasting interrupt, mak-

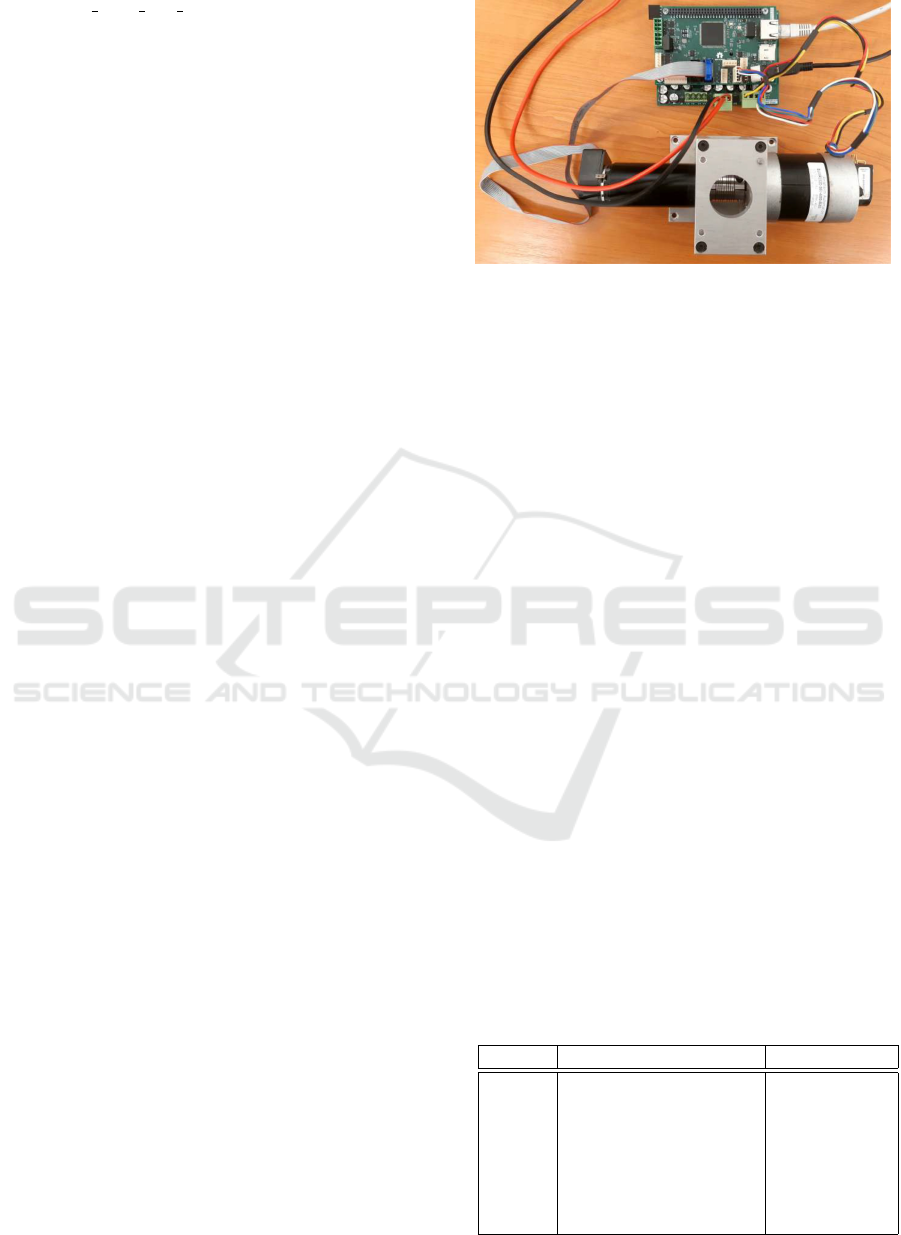

Figure 10: The control unit with a PMSM and an unused

DC motor serving as a brake.

ing it unusable for the control of fast-moving sys-

tems or the field oriented control. This issue will re-

quire further investigation in the future. Fortunately,

there are ways to debug the control applications, ei-

ther using the low-level ARM Cortex-M profiling fea-

tures using the Instrumented Trace Macrocell or using

NuttX internal profiling tools (ASF, 2023).

The purpose of this section is to show that pysim-

Coder is ready to create control applications, even

the ones used for PMSM field oriented control,

as well as its logging capabilities.

5.1 Control of PMSM

The unit connected to PMSM is shown in Fig-

ure 10. The parameters of the used PMSM are in Ta-

ble 2. The PMSM was tested simply in (Belda and

P

´

ı

ˇ

sa, 2021). Despite the sampling issues, a diagram

of the current PI controller of dq axes is presented,

showing that pysimCoder is ready to create FOC ap-

plications. Afterward, we present a simple non-vector

PMSM control.

5.1.1 Current Controllers

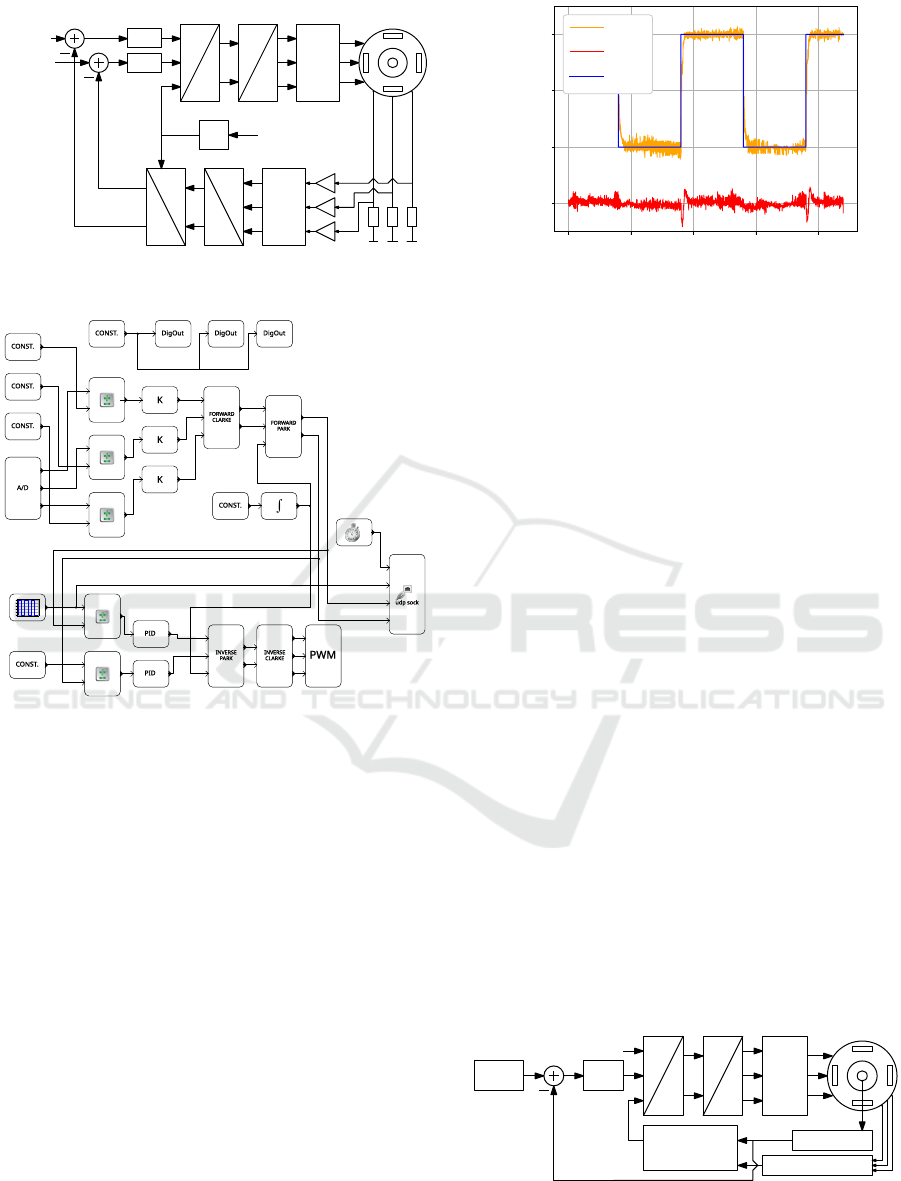

To verify and tune current PI control, synchronous

current-constant mode is used (see diagram Fig-

ure 11). The rotor is rotated in a synchronous way by

generating an angle from an integrating angular ve-

Table 2: Parameters: PMSM BLWR233D-36V-4000

Symbol Description Value

P rated power 95W

R

S

stator resistance 0.64Ω

L

S

stator inductance 0.0021 H

Ψ

M

PM rotor magnetic flux 0.0200077 Wb

B viscous friction coef. ≈ 0kgm

2

s

−1

p number of pole pairs 4

J moment of inertia 1.2·10

−5

kgm

2

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

586

u

d

u

q

dq

αβ

αβ

abc

u

α

u

β

NuttX

PWM

PMSM

u

a

u

b

u

c

PI

PI

αβ

dq αβ

abc

NuttX

ADC

i

a

i

b

i

c

Op. Amps

ω

const

i

q,ref

= 0

i

d,ref

ϕ

i

q

i

d

Shunts

ClarkePark

Inv. Park Inv. Clarke

Figure 11: A simplified diagram of current controllers.

Timer

QRef

PWM3

PWM1

PWM0

ADC

SubQ

SubD

PIDQ

PIDD

L3toI3

L1toI1

L0toI0

L3off

L1off

ForwardPark

ForwardClarke

PWM

InversePark

InverseClarke

SubL0

SubL1

SubL2

L0off

EnablePWM

AngularVelocity

Integral

PulseGenerator

UDPTx

Figure 12: PysimCoder diagram of dq current control.

locity (see the integrator) while applying action only

in the d-axis, while q-axis action is zero. The an-

gular velocity must be set low. The measured cur-

rents i

a

, i

b

and i

c

are acquired by reading the volt-

age drop on the current shunts with an AD converter.

These readings are recalculated to obtain the i

q

and i

d

currents using the Clarke and Park transformations.

The angle used in the Park transformation comes

from the integrator.

These quantities are subtracted from the ref-

erences and passed to inner PI controllers. After-

ward, the Inverse Park and Inverse Clarke transfor-

mations are used to obtain the actions used to con-

trol the IFX007 switches. The angle used in the In-

verse Park transformation is also from the integra-

tor. The implementation in pysimCoder is depicted

in Figure 12. In this figure, the ADC outputs are also

passed to subtract and gain blocks, mapping an ADC

number to the real currents using linear regression.

The calibration procedure was done beforehand by fit-

ting measured data using a custom Python script.

0 1 2 3 4

t [s]

0.0

0.5

1.0

1.5

i [A]

i

d

i

q

i

d,ref

Figure 13: The PI dq currents control, i

q,ref

= 0.

The output of the reference i

d,ref

and measured

i

d

and i

q

currents is sent by using a NuttX UDP

Socket to a given IP address, which can be configured

in the block itself. Using the Silicon Heaven protocol,

the user can tune the constants of the PI controllers

remotely while watching the changing waveforms.

Figure 13 presents the captured data visualisation.

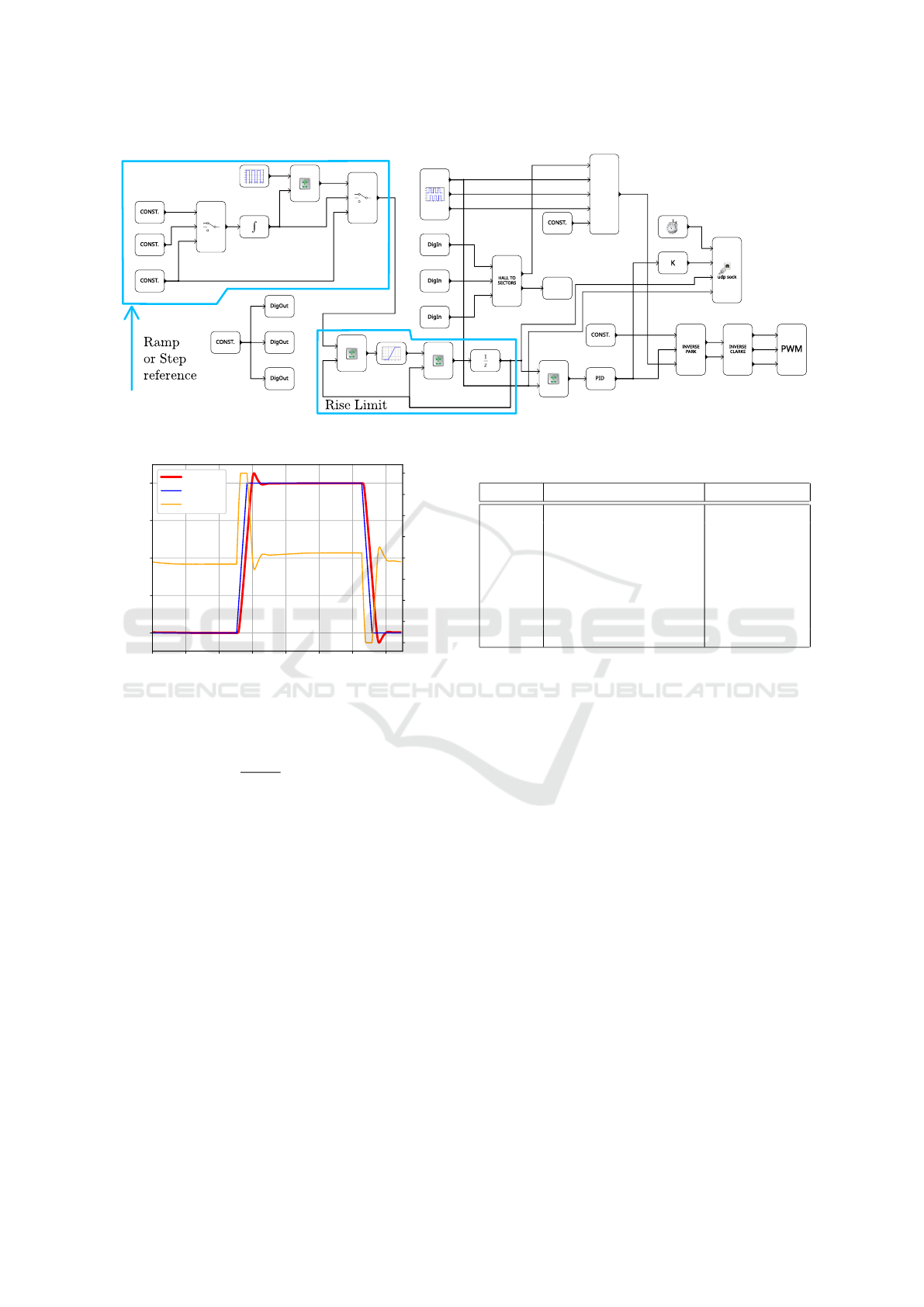

5.1.2 Simple Closed-Loop Control

A simplified diagram of the closed-loop control

is shown in Figure 14. The difference between the tar-

get and the current incremental encoder count (NuttX-

specific block) goes into the PID controller, setting

the q-axis action for the highest torque while the d

input is set to zero. The inverse Park transformation

requires the rotor angle to be estimated. This is per-

formed by the electrical angle estimation block using

current IRC count and Hall sensors.

The realisation of this control diagram in pysim-

Coder is shown in Figure 15. The Hall To 6 Sectors

block reads the GPIOs (NuttX-specific) of the Hall

outputs and transforms them into the 6 sectors (a sim-

ple integer). The Encoder block outputs the current

encoder count (C) the encoder count of the last hit

index (C

I

) and the number of hit indexes. The angle

estimation is performed by the PMSM Align block.

When the number of hit indexes is zero, the estima-

tion is done only using Hall sensors, and the block

outputs multiples of π/3. When a first index is hit,

Target

IRC

0

u

d

u

q

dq

αβ

αβ

abc

u

α

u

β

NuttX

PWM

PMSM

Current IRC

u

a

u

b

u

c

Electrical Angle

Estimation

(PMSM Align)

3 Hall to 6 Sectors

PID

ϕ

Inv. Park

Inv. Clarke

Figure 14: A simplified diagram of the closed-loop control.

Motion Control Unit Design for Control Prototyping of Modern BLDC/PMSM Drives and Piezo Actuators

587

Rise Sub 0

PWMInverse Clarke

Hall to 6 Sectors

NULL

Discrete PID

HALL_A

HALL_B

HALL_C

Inverse Park

PWM_B_EN

PWM_C_EN

PWM_A_EN

Enable PWM

D Zero

Feedback Sub

Electrical Angle Estimation

Encoder

Align reset

Control Mode Switch

Pulse Generator

Int Switch

Int Sum

Integral

Pulse or Int Control

Max Rise

Rise Sub 1

Delay

Ramp Slope

Zero

Timer

Gain

UDP Tx

0

PMSM

Align

Figure 15: PysimCoder of the closed-loop control diagram with a selectable reference.

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4

t [s]

0

1000

2000

3000

4000

Position [IRC]

−100

−75

−50

−25

0

25

50

75

100

PWM [%]

Cur.Pos

Ref. Pos

PWM

Figure 16: The step response to 4000 encoder counts.

the following formula is used:

ϕ

Est

=

C −C

I

C

Turn

2π + ϕ

Offset

, (6)

where C

Turn

denotes the number of encoder counts per

one electrical turn and ϕ

Offset

denotes an offset be-

tween the start of electrical angle and index. Values

C

Turn

and C

Offset

must be set in the PMSM Align block.

The diagram in Figure 15 also features a selectable

reference between a ramp and a step. The reference

is chosen by setting the constant remotely using Sili-

con Heaven (Lenc et al., 2023).

Furthermore, the rise time of the ramp is limited

with a saturated sumator. Again, this diagram features

a NuttX UDP Socket sending the PID action, the ref-

erence, and the actual position. Figure 16 shows a step

response of the used motor.

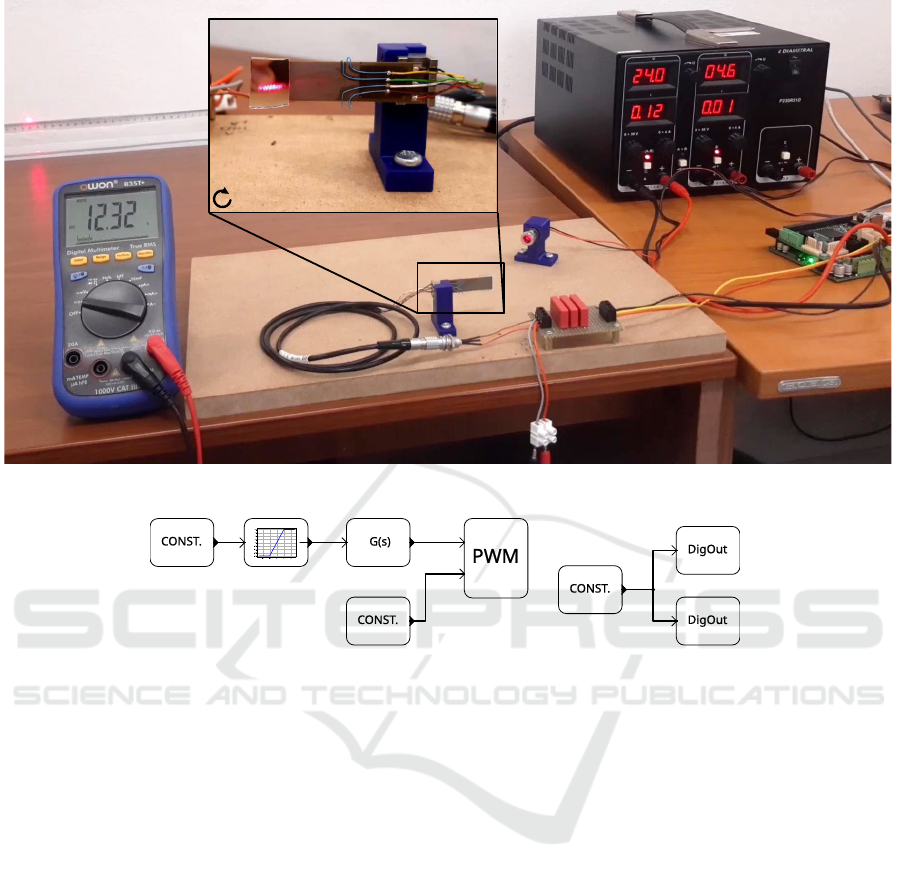

5.2 Control of a Piezoelectric Actuator

This section presents a simple pysimCoder diagram

capable of controlling a piezo actuator P-871.140, (PI,

Table 3: Parameters: PL140 - PIC251

Symbol Description Value

l

t

length 40 mm

w width 11 mm

d thickness 0.55 mm

c capacitance 8.2 µF

u

rated

rated voltage range ±30 V

z

f

free deflection at u

rated

±1 mm

f

b

blocking force at u

rated

±0.5 N

f

n

first natural frequency 160 Hz

2008). The parameters of this piezo bender actuator

are listed in Table 3, where the used piezo material

is PIC251 ceramic. The purpose is to demonstrate

simple control applications that can be quickly de-

veloped in research environments. Despite this actua-

tor having a tensometer, an optical approach has been

chosen as proof of the movement. There is a mirror

placed at the tip of the actuator. If this place is illumi-

nated by a laser beam, the incidence angle changes,

thus the reflection angle changes too. The experiment

setup is shown in Figure 17.

The piezo actuator is controlled by a linear volt-

age. In our case, we have constructed an LC low-

pass filter, turning the PWM voltage into a DC voltage

which depends on the duty. Although the power board

supplies 24 V at most, this voltage was used for initial

tests, despite the rated voltage range of the piezo actu-

ator. The pysimCoder diagram is shown in Figure 18.

The only block that is to be controlled over Silicon

Heaven is the CONST block with the Duty descrip-

tion in the range of [-1, 1].

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

588

Figure 17: Experimental unit with piezo bender actuator P-871.140.

LTI

VCC

EnINH

PWM

INH1

INH0

Duty

Saturation

Figure 18: Inputs and outputs of piezo bender actuator.

6 CONCLUSIONS

This paper introduces the design of an extensible pro-

totyping unit with an emphasis on motion control

of modern BLDC/PMSM drives and piezo actuators.

Proposed power stage is rated up to 24 V.

The hardware was successfully tested with pysim-

Coder with generated code running on NuttX real-

time operating system including remote tuning model

parameters using Silicon Heaven. The adaptations

of NuttX peripheral drivers for the platform have

been merged by NuttX maintainers into the main-

line repository. We have observed limits of maximum

achievable sampling frequency of the NuttX sched-

uler, which requires future investigation.

Despite the indicated issues, we demonstrated

the advantage of open-source and block-based graph-

ical environment pysimCoder that control applica-

tions can be created very quickly without writing

code. It was proven in the simple PID PMSM con-

trol and the piezo actuator control. Compared to fully

professional commercial solutions for universal use,

e.g. dSPACE, the presented solution is feasible

with components at an affordable cost and free open

source software. In addition, other operating sys-

tems like Zephyr and RTEMS support the selected

family of SAMV71 microcontrollers as well. Thus,

they represent another alternatives for real-time con-

trol applications. In the future, the adequate selection

of the operating system is important for the sampling

frequency.

Hardware and pysimCoder model diagrams are avail-

able in the public repository:

https://gitlab.fel.cvut.cz/otrees/motion/samocon

ACKNOWLEDGEMENTS

This work was supported by The Czech Academy

of Sciences, Institute of Information Theory and Au-

tomation under project No. 23-04676J of the Czech

Science Foundation: Controllable Gripping Mechan-

ics: Modelling, Control and Experiments.

Motion Control Unit Design for Control Prototyping of Modern BLDC/PMSM Drives and Piezo Actuators

589

REFERENCES

Belda, K. and P

´

ı

ˇ

sa, P. (2021). Explicit model predictive

control of PMSM drives. In 2021 IEEE 30th Int. Sym-

posium on Indus. Electron. (ISIE), pages 1–6.

Bucher, R. (2024). pysimCoder – Block diagram ed-

itor and real time code generator for Python.

https://github.com/robertobucher/pysimCoder. Ac-

cessed: 2024-07-10.

dSPACE GmbH (2024). dSPACE rapid prototyping sys-

tems. Accessed: 2024-09-22.

Gao, X., Yang, J., Wu, J., Xin, X., Li, Z., Yuan, X.,

Shen, X., and Dong, S. (2020). Piezoelectric actua-

tors and motors: materials, designs, and applications.

Advanced Materials Technologies, 5(1):1900716.

Group, A. (2024). POSIX IEEE std 1003.1-2024. https:

//posix.opengroup.org/. Accessed: 2024-07-10.

Lenc, M., P

´

ı

ˇ

sa, P., and Bucher, R. (2023). pysimcoder –

open-source rapid control prototyping for GNU/Linux

and NuttX. In 2023 24th Int. Conf. Process Control,

pages 102–107.

ASF, Apache Software Foundation. (2023). Apache NuttX,

rtos. https://nuttx.apache.org/. Accessed: 2024-07-10.

ASF, Apache Software Foundation. (2023). NuttX task

trace. https://nuttx.apache.org/docs/latest/guides/

tasktrace.html. Accessed: 2023-11-18.

ASF, Apache Software Foundation. (2024a). NuttX docu-

mentation. https://nuttx.apache.org/docs/latest/. Ac-

cessed: 2024-07-10.

ASF, Apache Software Foundation. (2024b). NuttX doc-

umentation - system time and clock. https://nuttx.

apache.org/docs/latest/reference/os/time clock.html.

Accessed: 2024-07-10.

ASF, Apache Software Foundation. (2024c). Reposi-

tory of NuttX source code. https://github.com/apache/

nuttx. Accessed: 2024-07-10.

Elektroline (2024). The repository of Silicon Heaven Pro-

tocol source code. https://github.com/silicon-heaven.

Accessed: 2024-07-10.

Infineon,Technoilogies. (2018). High current pn half bridge

with integrated driver. https://www.infineon.com/

dgdl/Infineon-IFX007T-DS-v01 00-EN.pdf?fileId=

5546d46265f064ff0166433484070b75. Accessed:

2023-09-10.

Microchip, Technology. (2019). 10BASE-T/100BASE-TX

PHY with RMII support.

https://ww1.microchip.com/downloads, note = Ac-

cessed: 2023-10-10.

Microchip, Technology. (2023). SAM e70/s70/v70/v71

family data sheet. https://ww1.microchip.com/ down-

loads/aemDocuments/ documents/MCU32/Product

Documents/DataSheets/ SAM-E70-S70-V70-V71-

Family-Data -Sheet- DS60001527.pdf. Accessed:

2023-10-10.

PI, Physik Instrumente, GmbH. (2008). P-871 PICMA®

piezo bender actuators. https://www.pi-usa.us/

fileadmin/user upload/pi us/files/product datasheets/

P871 Piezo Bimorph Bender.pdf. Accessed: 2024-

02-08.

Moon, J.-J., Lee, W., Park, S.-W., and Kim, J.-M. (2015).

Fault tolerant control method of seven-phase bldc mo-

tor in asymmetric fault condition due to open phase.

In 2015 9th International Conference on Power Elec-

tronics and ECCE Asia (ICPE-ECCE Asia), pages

1591–1596.

ODrive Robotics (2024). The ODrive website. https:

//odriverobotics.com/. Accessed: 2024-09-20.

PiKRON (2014). Lx RoCon − Robot Motion Controller.

https://pikron.com/pages/products/motion control/

lx rocon.html. Accessed: 2024-07-10.

SOLO Motor Controllers SRL (2024). The SOLO con-

trollers website. https://www.solomotorcontrollers.

com/. Accessed: 2024-09-20.

Speedgoat GmbH (2024). Speedgoat rapid control

prototyping. https://www.speedgoat.com/solutions/

testing-workflows/rapid-control-prototyping. Ac-

cessed: 2024-09-22”.

Tachiquingutierrez, R. T., Lay-Ekuakille, A., Chiffi, C.,

Singh, S. P., and Rao, K. S. (2023). Design, fab-

rication, and testing of a microelectronic controller

for sensing and actuating in robotic neurorehabilita-

tion. IEEE Sensors Journal, 23(16):18700–18707.

Torvalds, L. (2024). Linux kernel. https://kernel.org/. Ac-

cessed: 2024-07-10.

Vedder, B. (2022). The VESC project website. https:

//vesc-project.com/. Accessed: 2024-09-20.

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

590