Human-Robot Cooperation in Disassembly: A Rapid Review

Sara Jacob

1,2

, Nathalie Klement

2

, Richard Bearee

2

and Marie-Pierre Pacaux-Lemoine

1

1

UPHF, CNRS, UMR 8201, LAMIH, F-59313 Valenciennes, France

2

Arts et M

´

etiers Institute of Technology, LISPEN, F-59000 Lille, France

Keywords:

Human-Robot Cooperation, Disassembly, Task Allocation, Optimization.

Abstract:

Despite the evolution of autonomous systems, manual disassembly of electrotechnical devices persists due

to the limitations associated with product variability. Effective cooperation between humans and robots is

essential to overcome the constraints of disassembly. This article presents a literature review focusing on

human-robot cooperation in disassembly, with the aim of summarizing existing research, identifying gaps,

and defining possible contributions. The state of the art includes methodologies for product representation,

task allocation between a human and a robot, and task scheduling optimization. Efficient cooperation would

integrate human adaptability, robot efficiency, and direct communication, to anticipate disassembly actions to

prioritize the well-being and involvement of the human at every stage of the process.

1 INTRODUCTION

Nowadays, the growing quantity of electronic waste

is a major challenge. The disassembly complexity of

these devices has an indicative impact on the environ-

ment and the economy. Despite the need for many

tasks to be carried out, manual disassembly persists,

affecting workers’ health and operational efficiency.

Humans have difficulty facing the workload imposed

and the inherent difficulty of disassembly tasks. At

the same time, even though autonomous systems are

evolving, their use in disassembly is limited by prod-

uct variability (Hjorth et al., 2022). This product vari-

ability requires a flexible and adaptable system. With

the respective limits and advantages of the agents, co-

operation between human and robot would offer pos-

sibilities for dealing with the constraints encountered

in manual disassembly and that with fully automated

systems. The question to be resolved is how to ensure

efficient cooperation between human and robot, while

encouraging the attractiveness of this new approach.

This article proposes a literature review focusing on

human-robot cooperation intended to roboticists, au-

tomaticians and the human sciences in the context

of disassembly. It aims to summarize the work that

has been done and to highlight current gaps, with a

view to highlighting our contribution and guiding our

study.

2 LITERATURE REVIEW

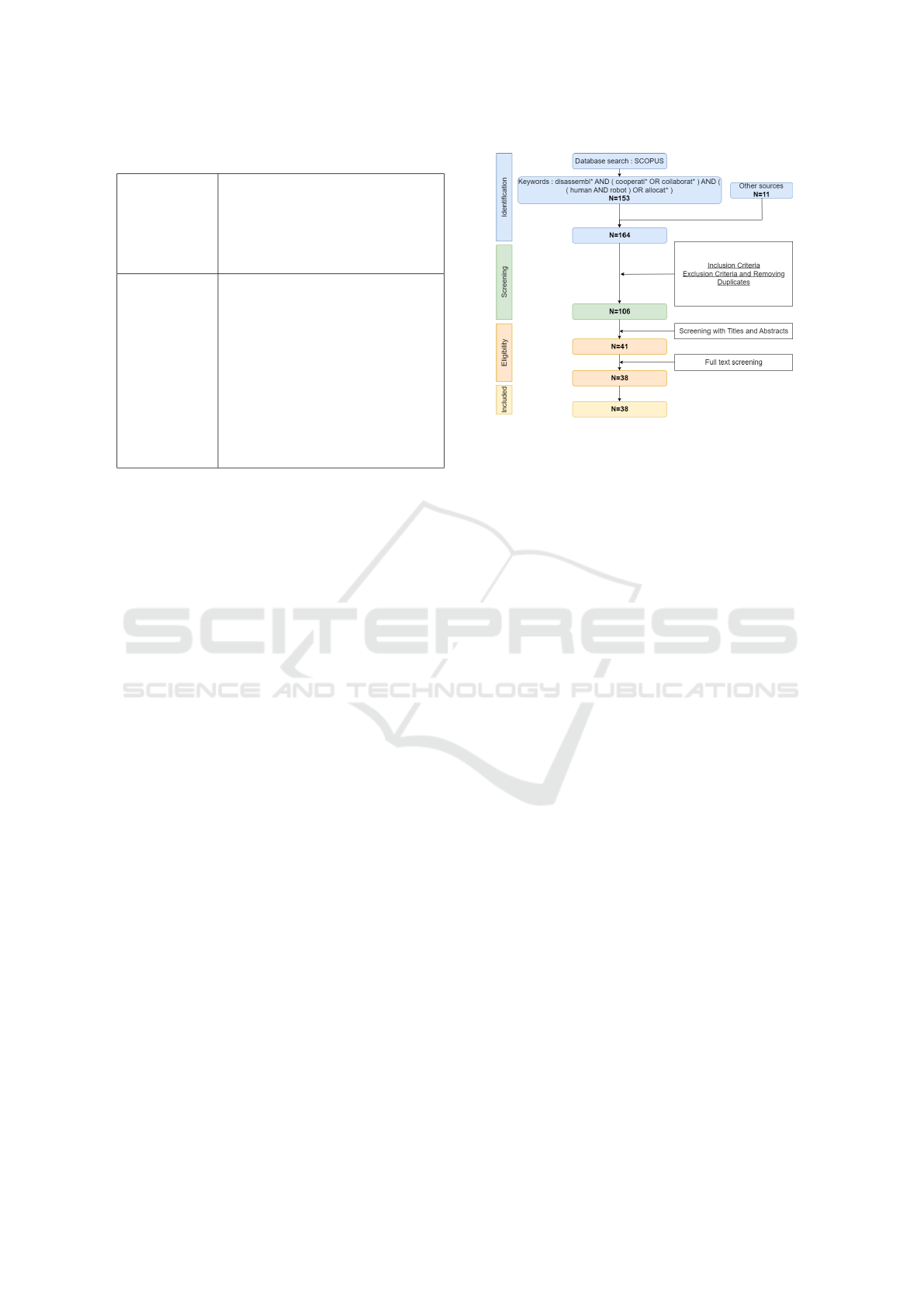

2.1 Methodology for a Review

The rapid review, conducted using the SCOPUS

database and providing an accelerated synthesis, aims

to outline interactions among various agents, partic-

ularly in cooperative contexts, and to review disas-

sembly methods and planning. Focusing on disassem-

bly and human-robot cooperation, we combined these

keywords to form the basis of our research:

disassembl* AND (cooperati* OR collaborat*) AND

((human AND robot) OR allocat*)

• Disassembl*: Focus on research and studies on

the disassembly process and its issues.

• Cooperati* OR Collaborat*: Include work that

considers aspects of cooperation between differ-

ent agents, detailing how they interact and mutu-

ally support each other in a shared work environ-

ment. The term ”collaboration” in robotics can be

synonymous with ”cooperation” in automation.

• (Human AND Robot) OR Allocat*: Focus on the

relationship between humans and robots, and on

the way in which tasks are allocated between these

two agents.

Before analyzing the titles and abstracts of documents

obtained, inclusion and exclusion criteria are defined

(Table 1).

212

Jacob, S., Klement, N., Bearee, R. and Pacaux-Lemoine, M.-P.

Human-Robot Cooperation in Disassembly: A Rapid Review.

DOI: 10.5220/0013000100003822

In Proceedings of the 21st International Conference on Informatics in Control, Automation and Robotics (ICINCO 2024) - Volume 2, pages 212-219

ISBN: 978-989-758-717-7; ISSN: 2184-2809

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

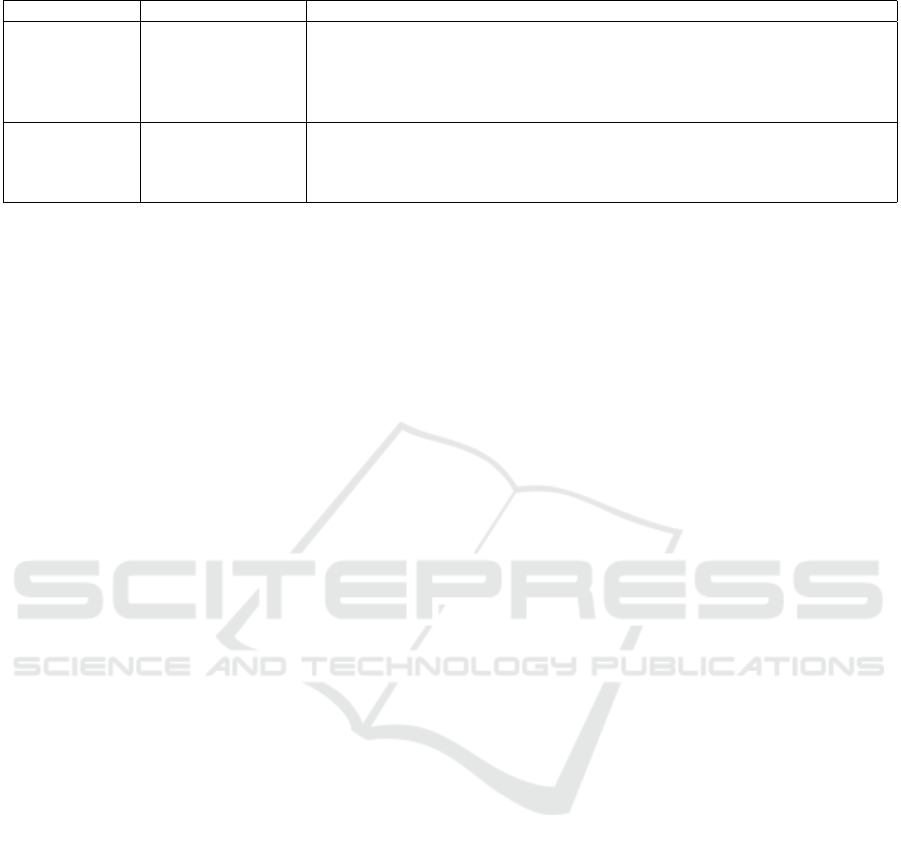

Table 1: Inclusion and Exclusion Criteria.

Inclusion Criteria

• Publication Year: From 2014 to 2024

• English language

• Document type: Conference paper, Article,

Conference Review, Review

Exclusion Criteria Subject areas not related to our research

• Physics and Astronomy

• Business

• Management and Accounting

• Chemical Engineering

• Chemistry

• Biochemistry

• Genetics and Molecular Biology

• Neuroscience

Research from the last 10 years until today has

been taken into account, excluding fields not related

to the research topic. Furthermore, only the docu-

ment types ”Conference Paper”, ”Article”, ”Confer-

ence Review” and ”Review” available on SCOPUS

have been included, thus excluding papers relating to

books. After that, a review of the titles and abstracts

allowed us to select only a limited number of articles

that seemed relevant to our question concerning the

efficient use of human-robot cooperation in disassem-

bly. A complete analysis of the texts is then carried

out, and a synthesis is presented, outlining the state of

the art on the subject of disassembly and cooperation,

as well as the methods used to allocate disassembly

tasks.

2.2 Results of Execution

A keyword search on SCOPUS allows us to visual-

ize 153 documents. Eleven documents from external

sources were added, which enabled us to familiarize

ourselves with the subject and which met the inclu-

sion and exclusion criteria (Table 1), finally making

it possible to study 164 documents in total. After ap-

plying inclusion and exclusion criteria, and removing

duplicates, 106 documents remained to be analyzed,

based on titles and abstracts. In the end, 41 documents

were studied, some of which were excluded after text

analysis (Fig. 1).

3 STATE OF THE ART

The methodology employed in disassembly efficiency

improvement, as seen across literature, typically com-

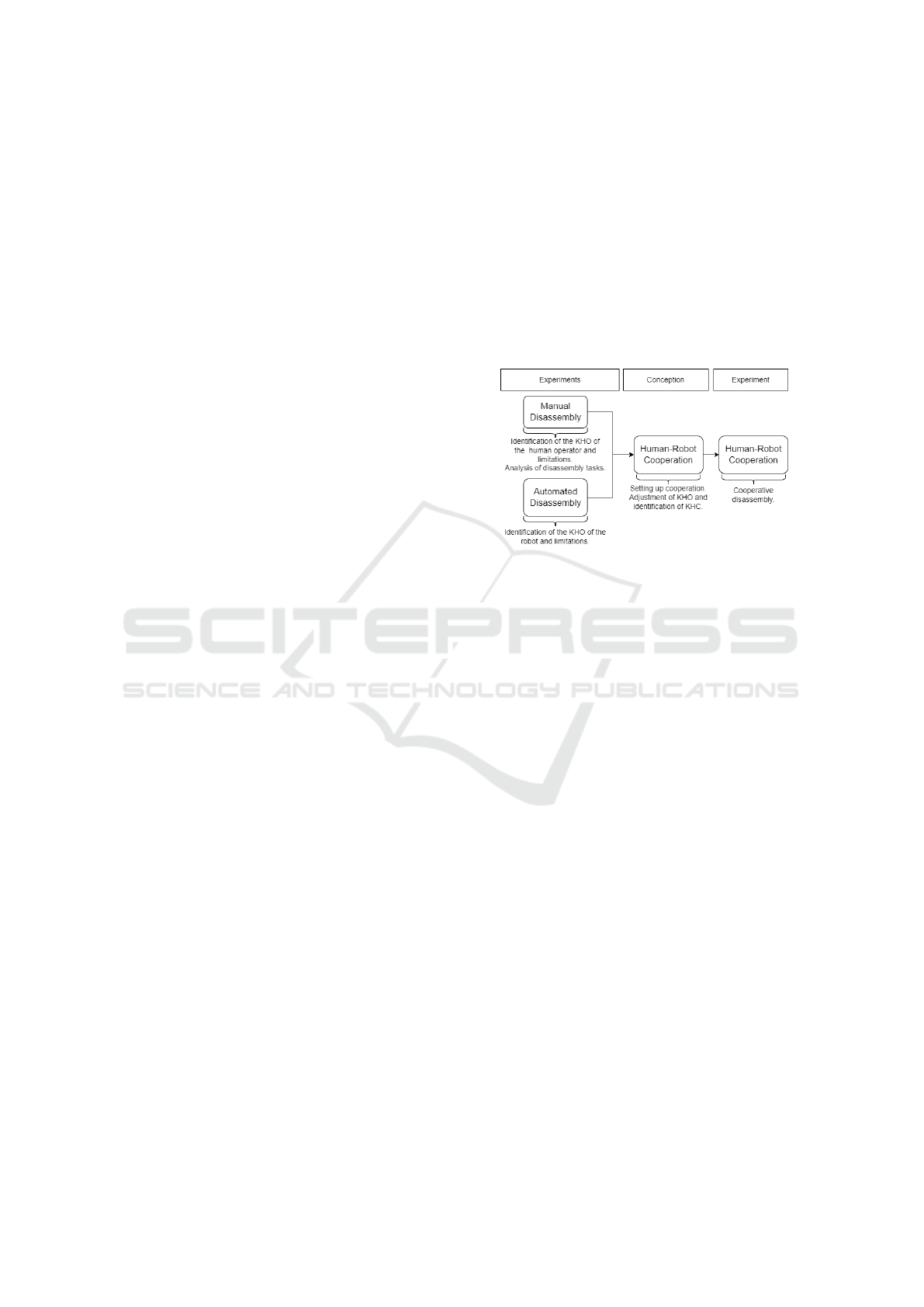

Figure 1: Rapid review.

prises three steps: product representation for task se-

quencing, task allocation based on predefined criteria

for human or robot involvement, and task scheduling

optimization using algorithms. This chapter is thus

structured accordingly to represent these steps.

3.1 Disassembly

In an era where technology is evolving, the quantity

of electrotechnical waste is growing rapidly. Disas-

sembling these products is part of the circular econ-

omy for their end-of-life treatment. This process has

the advantage of extending the life of equipment and

maximizing its value while reducing the environmen-

tal and economic impact of the constant production of

electrotechnical products (Lee et al., 2020b; Li et al.,

2019; Vongbunyong et al., 2017; Huang et al., 2019;

Wu et al., 2024). However, the question is how these

products can be disposed of. The following points can

be noted up to now (Table 2).

Defining product end-of-life could help to define

the tasks to be executed during disassembly. This

disassembly could be destructive or non-destructive,

and it would be easier to identify until which sub-

assemblies and components should be extracted. Guo

et al. (2023) went further, proposing partial destruc-

tive disassembly by representing the degree of degra-

dation of the product at end-of-life. These end-use

scenarios influence the disassembly process and the

methods used to recover components. In this way,

methods are proposed for classifying products and

representing them, so that the disassembly sequence

can then be determined. End-of-life products can be

represented using AND/OR graphs (Fang et al., 2023;

Xu et al., 2020a; Chu et al., 2023; Lou et al., 2024;

Parsa et al., 2021), oriented graphs (Lee et al., 2020b;

Jungbluth et al., 2017; Liao et al., 2023; Lee et al.,

Human-Robot Cooperation in Disassembly: A Rapid Review

213

Table 2: Product management.

Group Product Management Papers

Requalification Maintenance, Reuse,

Repairs,

Remanufacturing

Hjorth et al. (2022), Li et al. (2019), Huang et al. (2019), Wu et al. (2024), Ding et al. (2019), Jungbluth

et al. (2017), Sartori and Schlette (2021), Buhl et al. (2019), Liao et al. (2023), Fang et al. (2023), Chen

et al. (2023), Prioli and Rickli (2020), Chen et al. (2022), Xu et al. (2020a), Xu et al. (2020b) Guo

et al. (2023), Chu et al. (2023), Lou et al. (2024), Huang et al. (2021), Belhadj et al. (2022), Lee et al.

(2022)

Take-back and

Waste treatment

Recycling, Recovery,

Proper disposal

Lee et al. (2020b), Wu et al. (2024), Ding et al. (2019), Jungbluth et al. (2017), Liao et al. (2023), Fang

et al. (2023), Chen et al. (2023), Prioli and Rickli (2020), Chen et al. (2022), Guo et al. (2023), Chu

et al. (2023), Lou et al. (2024), Huang et al. (2021), Lee et al. (2022), Chatzikonstantinou et al. (2019),

Liu et al. (2023), Yuan et al. (2023), Lee et al. (2020a), Parsa et al. (2021), Renteria et al. (2019)

2020a), priority and constraint disassembly matrices

(Li et al., 2019; Xu et al., 2020b; Belhadj et al., 2022)

or vision systems for product recognition (Vongbuny-

ong et al., 2017; Ding et al., 2019; Bdiwi et al., 2017).

These representation methods are used to identify the

disassembly sequence.

Considering that two agents are going to coop-

erate together to perform these tasks, it is necessary

to determine which agent should be assigned which

task. In this way, a classification of tasks is estab-

lished (Antonelli et al., 2019), generally by evaluat-

ing their difficulty, and the variability of products in-

troduces challenges in task execution, necessitating

adaptive strategies. It is also possible to group prod-

ucts and their components in a class diagram, accord-

ing to their characteristics (Jungbluth et al., 2017).

This class diagram can also be completed by the data

set of the disassembly cell (Prioli and Rickli, 2020).

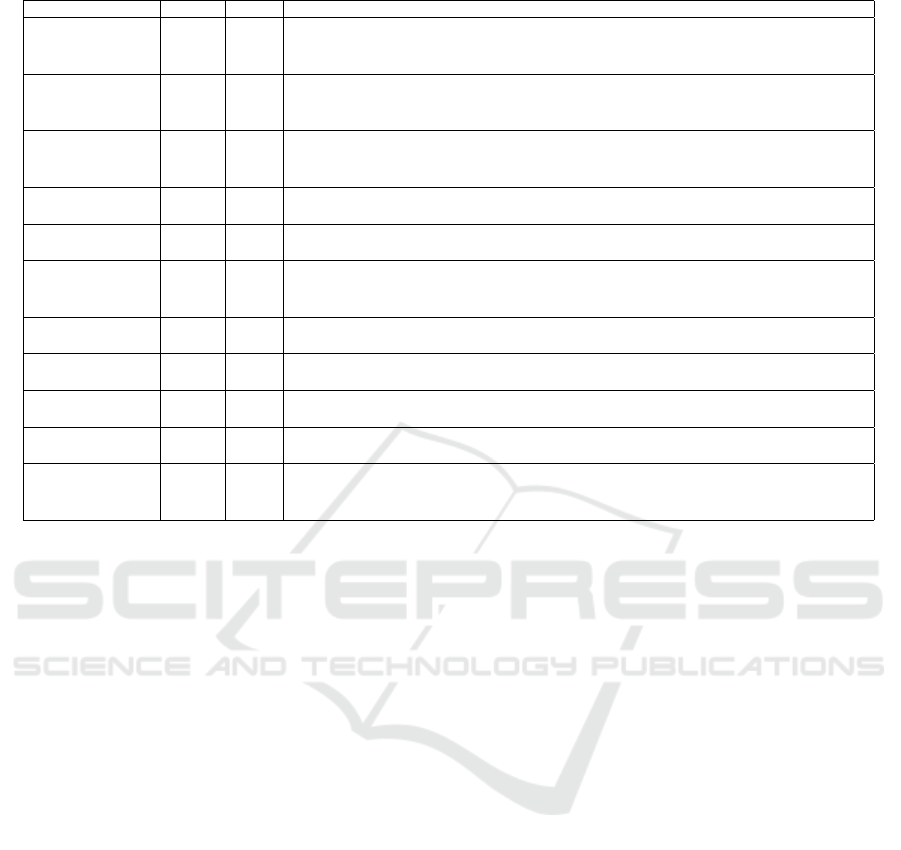

3.2 Human-Robot Cooperation

Despite the manual predominance of disassembly, co-

operation aims to improve efficiency by valorizing

human flexibility, dexterity, and knowledge, com-

bined with the precision and repeatability of robots

(Matsas et al., 2017). In the context of this coop-

eration, several authors propose to classify tasks ac-

cording to their difficulty (Liao et al., 2023; Xu et al.,

2020a,b; Lou et al., 2024; Parsa et al., 2021), in order

to finally determine if the task can be performed by

the human, the robot or both. However, it is neces-

sary to take into account the capabilities and skills of

the human, as well as their needs and preferences, in

order to keep the human at the center of the process

and promote the acceptability of this approach. A list

of the added values of each agent involved in the pro-

cess has been established based on a study of the lit-

erature (Table 3). For example, Chen et al. (2022) ex-

amined the impact of robot use on ergonomics and hu-

man workload, demonstrating the benefits of the robot

for these purposes and emphasizing the importance of

understanding how humans work with the robot.

On the one hand, table 3 confirms the human ad-

vantages in terms of physical and cognitive perfor-

mance, as well as his/her added value in terms of the

adaptability required by the complexity of disassem-

bly tasks. The robot, on the other hand, is highlighted

for its operational and economic performance, as well

as the comfort it brings to humans in terms of safety

and reduced health risks. Nevertheless, it is easy to

see that more positive points emerge from the use of

the robot. It is therefore possible to envisage the im-

plementation of weighting criteria in our future stud-

ies, based on the most important added values and en-

abling us to gain efficiency.

To ensure the acceptability of human-robot coop-

eration, safety measures must be taken. In particu-

lar, it is proposed to predict the intentions and ges-

tures of the robot and the human to make coopera-

tion safer and more transparent (Hjorth et al., 2022;

Liu et al., 2023, 2019). Tian et al. (2023) go a step

further, proposing motion prediction that takes uncer-

tainties into account. The advantage lies in the fact

that ”robots can react earlier based on the knowledge

of the human behavior provided by the prediction

model” (Liu et al., 2023). Furthermore, visual recog-

nition, including methods such as point cloud recog-

nition and instance segmentation, allows the robot to

be guided by human actions, enabling it to acquire

new skills and improve its performance (Vongbuny-

ong et al., 2017; Chen et al., 2023; Renteria et al.,

2019; Bdiwi et al., 2017; Duan et al., 2023). To

prevent disturbing noise and light conditions, Huang

et al. (2021) proposed interaction via tactile contact,

force and position control. In such an environment,

knowledge and skills need to be managed. Databases

and graphs can be created to ensure the acquisition,

availability, and sharing of skills between the two

agents (Ding et al., 2019). The integration of ac-

tive compliance control, as proposed by Huang et al.

(2019) and Huang et al. (2021), enables the robot to

adapt dynamically to variations and constraints en-

countered during product handling, thus enhancing

the precision and efficiency of human-robot cooper-

ation. The robot autonomy could be further enhanced

by equipping it with the knowledge and skills of an

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

214

Table 3: Added Values of Humans and Robots.

Human Robot Papers

Adaptability, Flexi-

bility

+ - Hjorth et al. (2022); Vongbunyong et al. (2017); Huang et al. (2019); Belhadj et al. (2022); Duan et al.

(2023); Liu et al. (2019); Li et al. (2019); Jungbluth et al. (2017); Liao et al. (2023); Xu et al. (2020a,b);

Guo et al. (2023); Huang et al. (2021); Belhadj et al. (2022); Parsa et al. (2021); Mateus et al. (2018)

Cognitive, Decision

Making, Learning,

Identification

+ - Huang et al. (2019); Jungbluth et al. (2017); Prioli and Rickli (2020); Lou et al. (2024); Huang et al.

(2021)

Complexity,

Uncertainty,

Unpredictable

+ - Hjorth et al. (2022); Huang et al. (2019); Wu et al. (2024); Jungbluth et al. (2017); Liao et al. (2023);

Guo et al. (2023); Huang et al. (2021); Lee et al. (2022); Yuan et al. (2023); Parsa et al. (2021); Liu

et al. (2019)

Cost, Economy - + Li et al. (2019); Vongbunyong et al. (2017); Huang et al. (2019); Jungbluth et al. (2017); Xu et al.

(2020a,b); Guo et al. (2023); Belhadj et al. (2022); Yuan et al. (2023); Parsa et al. (2021)

Dexterity, Sensory

motor

+ - Huang et al. (2019, 2021); Liu et al. (2019)

Efficiency, Time,

Speed, Precision

- + Li et al. (2019); Huang et al. (2019); Liao et al. (2023); Xu et al. (2020a,b); Guo et al. (2023); Belhadj

et al. (2022); Duan et al. (2023); Liu et al. (2019); Prioli and Rickli (2020); Huang et al. (2021); Bdiwi

et al. (2017); Mateus et al. (2018); Lee et al. (2022); Parsa et al. (2021)

Effort, Endurance,

Fatigue, Stress

- + Li et al. (2019); Jungbluth et al. (2017); Lou et al. (2024); Bdiwi et al. (2017); Liu et al. (2019); Tian

et al. (2023)

Ergonomic, Health,

Workload

- + Li et al. (2019); Jungbluth et al. (2017); Chen et al. (2022); Lou et al. (2024)

Hazardous, Safety - + Wu et al. (2024); Huang et al. (2019); Liao et al. (2023); Prioli and Rickli (2020); Huang et al. (2021);

Lee et al. (2022); Yuan et al. (2023); Renteria et al. (2019); Duan et al. (2023); Mateus et al. (2018)

Payload, Power,

Strength

- + Huang et al. (2019); Jungbluth et al. (2017); Sartori and Schlette (2021); Huang et al. (2021); Liu et al.

(2019); Mateus et al. (2018)

Monotony,

Patience, Tedious,

Repeatability

- + Liao et al. (2023); Renteria et al. (2019); Bdiwi et al. (2017); Liu et al. (2019); Li et al. (2019); Huang

et al. (2019); Sartori and Schlette (2021); Xu et al. (2020b); Lou et al. (2024); Huang et al. (2021);

Yuan et al. (2023); Parsa et al. (2021); Duan et al. (2023)

informed software agent. This would be based on the

product model (Jungbluth et al., 2017). Data man-

agement can also be carried out via a Cloud space,

bringing together real-time disassembly information.

In particular, it connects all the agents involved in the

process, capturing human and robotic inputs to share,

diffuse, and combine the knowledge and capabilities

of each agent. Finally, this information is used to dis-

tribute tasks in real-time (Prioli and Rickli, 2020).

Again to improve acceptability, and after evoking

proposals for knowledge sharing and motion predic-

tion, Alhaji et al. (2021) explored trust factors, such

as reliability, dependability, perceived predictability,

and confidence. Indeed, ”trust is the foundation of

successful human collaboration” (Alhaji et al., 2021).

These factors are examined to enable adaptation of

the robot’s dynamic behavior. Once again, to im-

prove robot capabilities, working with a robot with

two arms will not replace the work of the human, but

will improve robot flexibility, dexterity, and the safety

of disassembly operations (Buhl et al., 2019). How-

ever, defining a robot’s capabilities in advance is chal-

lenging due to their dependence on the use case, ap-

plication, and specific robot.

Additionally, it is essential to take into account the

variability of humans and the products handled. Hu-

man factors, such as skill level, cognitive load, and

physical condition, vary from one individual to an-

other and can have a significant impact on the effi-

ciency of human-robot cooperation. Some research

has already addressed the issue of human fatigue, by

incorporating models of human fatigue into optimiza-

tion algorithms for disassembly planning (Li et al.,

2019). The integration of an HMI as an assistant to

the human could facilitate robot programming, con-

trol, and agent coordination while offering a disas-

sembly sequence. In this respect, Sartori and Schlette

(2021) proposed developing a digital twin to repre-

sent the robot and its interactions and include human

actions. In this way, the aim is to have a digital repre-

sentation of what will be physically executed.

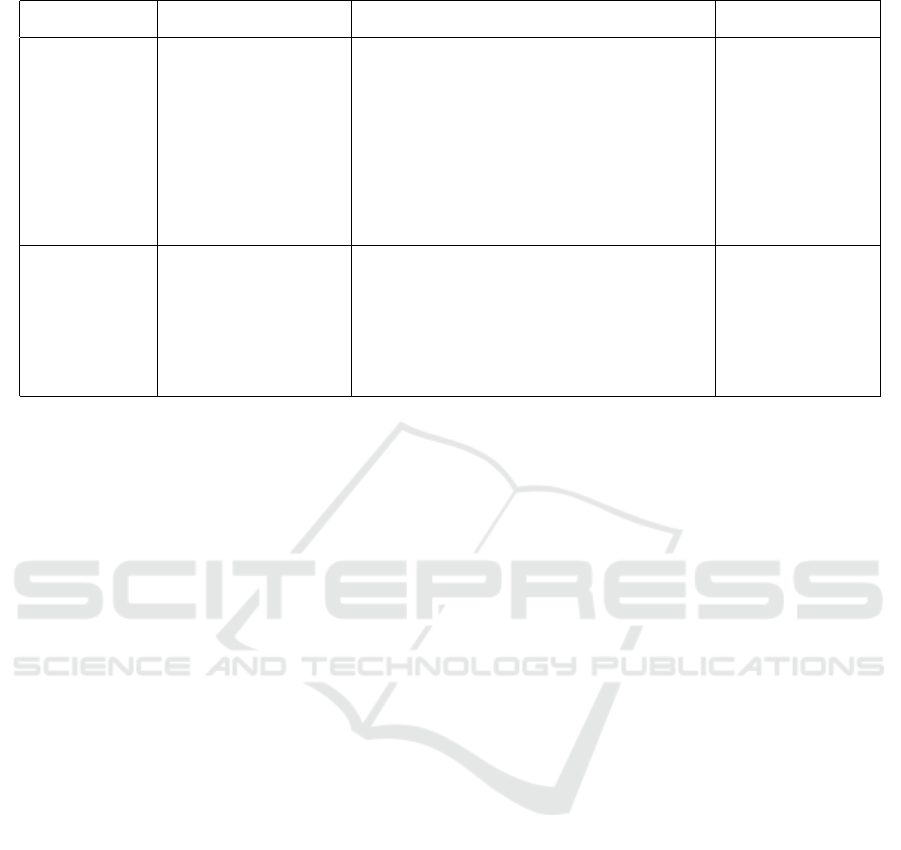

3.3 Task Allocation

In the context of human-robot cooperation in the dis-

assembly process, optimization techniques are used

to allocate tasks between these two agents. The aim

is to maximize process efficiency while taking into

account various resource and safety criteria and con-

straints. For this purpose, various algorithms have al-

ready been developed and tested in the literature (Ta-

ble 4).

Mathematical models optimize the disassembly

sequence, aiming to minimize the total execution time

with constraints such as transition times, safety, re-

source availability, and precedence rules (Lee et al.,

2022; Antonelli et al., 2019). These criteria (time,

safety, complexity) can also be grouped together in a

utility function to maximize overall utility (Liao et al.,

2023). Recently, metaheuristics have become more

Human-Robot Cooperation in Disassembly: A Rapid Review

215

Table 4: Optimization algorithms.

Population-based

meta-heuristics

Method Criterion Papers

Swarm Intelligence

1. Bees Algorithm

2. Bees Algorithm

3. Bees Algorithm

4. Particle Swarm Opti-

mization

5. Grey Wolves Optimiza-

tion

1. Time, Human fatigue

2. Profit, Energy Consumption, Difficulty, Number of

workstations

3. Time, Cost, Difficulty

4. Time with position-related and task assignment con-

straints

5. Profit, Complexity, Ergonomics, Time

1. Li et al. (2019)

2. Xu et al. (2020a)

3. Xu et al. (2020b)

4. Chu et al. (2023)

5. Lou et al. (2024)

Evolutionary com-

putation

1. Genetic Algorithm

2. Genetic Algorithm

3. Global Search -

Multi-objective

evolutionary algorithm

1. Time, Cost

2. Non-targeted component index, Time, Operator change

3. Makespan (Time), Cost with task assignment con-

straints

1. Guo et al. (2023)

2. Parsa et al. (2021)

3. Chatzikonstantinou

et al. (2019)

commonly used, with particular emphasis on the use

of the bee algorithm. This algorithm has been partic-

ularly promoted in recent years for the quality of the

solutions it produces, its greater convergence and di-

versity, and its faster execution time, compared with

other algorithms such as the genetic algorithm, the

grey wolf algorithm, and modified teaching-learning

optimization (Xu et al., 2020a,b). However, table 4

shows that these methods are often limited to mini-

mizing time and cost. The complex problems encoun-

tered in the disassembly process would require a re-

flection on the chosen criteria, representing more the

difficulties encountered by the human, such as work-

load, and those encountered during disassembly exe-

cution, such as variability. The advantages of cooper-

ation could then be put to the fore.

For example, Belhadj et al. (2022) proposed to

take human adaptability and efficiency into account

with the generation of disassembly plans. For this,

an inference engine assigns operations to the robot if

there is no interference with the human. Based on

the total disassembly time and the part wear, several

solutions are thus proposed until the end of disassem-

bly, with the advantage of leaving a certain amount

of flexibility in the decision-making process for the

execution plan. In order to retain the strengths of

each agent and divide tasks as effectively as possi-

ble, according to a sharing mode that gives the human

a degree of autonomy throughout execution, Mateus

et al. (2018) proposed a study of manual disassembly

to decompose tasks into movements. The compati-

bility and suitability of resources is then assessed by

moving from a qualitative to a quantitative descrip-

tion (time, part, process). This approach then enables

an allocation range to be established, with greater em-

phasis on the strengths of both agents. Faced with the

vulnerability and risks associated with the uncertainty

of disassembly tasks, Yuan et al. (2023) go one step

further by proposing an assessment of resilience, tak-

ing into account stability, redundancy, efficiency, and

adaptability. Thus, by visualizing resilience indexes,

rational decision-making can be made in the alloca-

tion of tasks between the human and the robot. While

some talk about adaptability, Lee et al. (2020b) pro-

posed a finite-horizon optimization problem, based on

the principle of a predictive control model. This min-

imizes cost by taking into account human and robot

movements during task execution.

These complementary approaches enrich the field

by offering solutions tailored to the specific needs of

disassembly processes, while highlighting the impor-

tance of considering a diverse range of methods for

task allocation, taking into account process efficiency

and quality, human fatigue and safety. While some are

trying to optimize the allocation of tasks between two

agents within the same work cell, others are seeking

methods to balance entire disassembly lines, primar-

ily aimed at reducing the number of workstations, im-

proving the fluidity of the load between different hu-

mans, and reducing production time (Wu et al., 2024).

3.4 Discussions

While significant advances are being made in the

management of end-of-life electrotechnical products

and in human-robot cooperation for disassembly, gaps

remain. Product diversity requires adaptive and opti-

mal management, with analytical approaches to guide

disassembly decisions. Algorithmic task allocation

optimizes efficiency while taking into account re-

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

216

source and safety constraints, but needs to incorporate

more criteria to reflect problem complexity and hu-

man willingness. The integration of human variability

is envisaged for his/her ability to adapt and make de-

cisions in variable and complex situations. Involving

humans right from the decision-making phase is cru-

cial for a more social approach to disassembly, valu-

ing their skills and combining them effectively with

those of the robot. The development of decision sup-

port systems is promising for gathering, sending and

supporting humans. To improve the efficiency and ac-

ceptability of this cooperation, it is essential to ac-

curately assess the skills required for each task, and

to foster direct communication between humans and

robots.

• H1: Defining product end-of-life, taking into ac-

count its variability, makes it easier to identify the

disassembly sequence.

• H2: Involving humans right from the decision

phase to determine the allocation of tasks, by

combining their specific skills with those of the

robots, helps to identify an optimized allocation

of functions.

• H3: Optimized allocation of disassembly tasks

between the human and the robot, taking into ac-

count a wide range of relevant criteria such as hu-

man flexibility, maximizes the efficiency of disas-

sembly operations.

• H4: A more precise assessment of the skills re-

quired for each task, and the encouragement of a

direct exchange between human and robot, will

enhance the attractiveness and human well-being.

4 COOPERATION FRAMEWORK

4.1 Definition and Application Proposal

To ensure the efficiency of human-robot cooperation

and encourage its attractiveness, it is proposed to in-

volve the human in task allocation and planning de-

cisions from the outset. A decision support system

would support this process, providing real-time feed-

back and enabling the human to use his/her skills

effectively, within his/her own limits. In this way,

it is possible to define the know-how-to-operate and

know-how-to-cooperate of both the human and the

robot for the execution of disassembly tasks. Prin-

ciples for evaluating ”Know-How-to-Operate” func-

tions (KHO) and ”Know-How-to-Cooperate” func-

tions (KHC) of agents guide the assignment of tasks

to the Human, the Robot, or both. KHO concerns the

ability to analyze and make decisions on the process,

while KHC is the ability to communicate, to decide

task allocation and build a model of the other agent.

Based on these assessments, it will be possible to al-

locate functions. In other words, ”levels of autonomy

can be identified for each capability of each agent, and

the combination of the levels of each agent defines the

levels of cooperation” (Pacaux-Lemoine et al., 2023).

On the one hand, it is crucial to highlight the impor-

tance of human adaptability in dealing with product

variability. On the other hand, robots play a crucial

role in enhancing efficiency and alleviating the human

workload.

Figure 2: Methodology.

Before setting up human-robot cooperation and

testing it through experiments, it is planned to test

manual disassembly on the one hand, and automated

disassembly on the other (Fig. 2). The aim is to as-

sess the efficiency, added values of each approach, as

well as to evaluate the disassembly tasks and their dif-

ficulty.

4.2 Expected Results

Manual disassembly aims to assess the analytical

skills of humans and their effectiveness in disassem-

bly tasks, highlighting adaptability, cognitive abili-

ties, dexterity, and flexibility. The analysis at this

stage also includes the tasks performed, the tools

used, and the difficulty and skills required for each

task. For automated disassembly, it is crucial to iden-

tify robot capabilities and limitations, focusing on

communication with the human and tasks that support

human work.

To take the added values of human and robot (Ta-

ble 3), we expect automated disassembly to be faster

and more efficient than manual disassembly, due to

the precision and repeatability of robots. However,

manual disassembly could offer greater flexibility and

adaptability to face product variability. The results of

this experiment will provide useful information on the

advantages and limitations of manual and automated

disassembly. These data can be used to guide the de-

cisions to be made when developing human-robot co-

Human-Robot Cooperation in Disassembly: A Rapid Review

217

operation. The aim is to take into account the skills

and limitations, wishes, and well-being of the human,

so as to keep him/her at the center of the process and

make his/her work more attractive after the addition

of the robot.

5 CONCLUSIONS

Although this rapid review has its limitations as a

preliminary overview, this paper addresses the persis-

tent problem of manual disassembly of electrotech-

nical devices, despite advances in autonomous sys-

tems. Efficient and optimized human-robot coopera-

tion is crucial to overcome the challenges associated

with disassembly tasks. A rapid review of the liter-

ature, focusing on human-robot cooperation in dis-

assembly, examines 38 articles, exploring the latest

methodologies. Products are generally represented by

graphs or matrices, enabling a disassembly sequence

to be defined. Tasks are then allocated according to

task difficulty and agent skills. Other proposals are

put forward to ensure safe and efficient cooperation.

In addition, several studies focus on optimizing plan-

ning and task allocation. Although this article focuses

on metaheuristics, future research could explore neu-

ral networks and reinforcement learning. By identi-

fying current gaps and outlining future research ap-

proaches, our aim is to steer human-robot cooperation

strategies toward maximizing operational efficiency

and satisfying human needs. Efficient cooperation

would combine the adaptability and cognitive abili-

ties of humans with the efficiency and assistance of

robots to lighten the workload of disassembly tasks.

Human involvement at every stage of the process is

crucial to progress towards social robotics. With this

in mind, it is useful to analyze both the human and the

robot in disassembly tasks before implementing coop-

eration. Future research will build on this initial ap-

proach by continuing the bibliographic monitoring to

ensure a comprehensive understanding of the evolv-

ing landscape of human-robot cooperation in disas-

sembly tasks.

ACKNOWLEDGEMENTS

This work is financially supported by the region

Hauts-De-France and Institut Carnot Arts.

Support of TEAM (cluster on circular economy).

REFERENCES

Alhaji, B., Prilla, M., and Rausch, A. (2021). Trust dy-

namics and verbal assurances in human robot physi-

cal collaboration. Frontiers in artificial intelligence,

4:703504.

Antonelli, D. et al. (2019). Dynamic distribution of assem-

bly tasks in a collaborative workcell of humans and

robots. FME Transactions, 47(4):723–730.

Bdiwi, M., Rashid, A., Pfeifer, M., and Putz, M. (2017).

Disassembly of unknown models of electrical vehicle

motors using innovative human robot cooperation. In

Proceedings of the Companion of the 2017 ACM/IEEE

Int. Conf. on Human-Robot Interaction, pages 85–86.

Belhadj, I., Aicha, M., and Aifaoui, N. (2022). Product dis-

assembly planning and task allocation based on hu-

man and robot collaboration. Int. J. on Interactive De-

sign and Manufacturing (IJIDeM), 16(2):803–819.

Buhl, J. F., Grønhøj, R., Jørgensen, J. K., Mateus, G., Pinto,

D., Sørensen, J. K., Bøgh, S., and Chrysostomou, D.

(2019). A dual-arm collaborative robot system for the

smart factories of the future. Procedia manufacturing,

38:333–340.

Chatzikonstantinou, I., Giakoumis, D., and Tzo-

varas, D. (2019). A new shopfloor orchestra-

tion approach for collaborative human-robot

device disassembly. In 2019 IEEE Smart-

World/SCALCOM/UIC/ATC/CBDCom/IOP/SCI,

pages 225–230. IEEE.

Chen, Y., Liao, H.-Y., Behdad, S., and Hu, B. (2023). Hu-

man activity recognition in an end-of-life consumer

electronics disassembly task. Applied Ergonomics,

113:104090.

Chen, Y., Luo, Y., Yerebakan, M. O., Xia, S., Behdad, S.,

and Hu, B. (2022). Human workload and ergonomics

during human-robot collaborative electronic waste

disassembly. In 2022 IEEE 3rd ICHMS, pages 1–6.

IEEE.

Chu, M. et al. (2023). Human-robot collaboration disassem-

bly planning for end-of-life power batteries. Journal

of Manufacturing Systems, 69:271–291.

Ding, Y., Xu, W., Liu, Z., Zhou, Z., and Pham, D. T. (2019).

Robotic task oriented knowledge graph for human-

robot collaboration in disassembly. Procedia CIRP,

83:105–110.

Duan, L., Li, J., Bao, J., Lv, J., and Zheng, H. (2023). A mr-

assisted and scene perception system for human-robot

collaborative disassembly of power batteries. In 2023

IEEE 19th Int. CASE, pages 1–8. IEEE.

Fang, Y. et al. (2023). Multi-source transfer-assisted evo-

lutionary optimization for dynamic human-robot col-

laborative disassembly planning. In 2023 Int. Conf.

on Frontiers of Robotics and Software Engineering,

pages 129–135. IEEE.

Guo, L., Zhang, Z., and Zhang, X. (2023). Human–

robot collaborative partial destruction disassembly se-

quence planning method for end-of-life product driven

by multi-failures. Advanced Engineering Informatics,

55:101821.

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

218

Hjorth, S. et al. (2022). Human–robot collaboration in in-

dustrial environments: A literature review on non-

destructive disassembly. Robotics and Computer-

Integrated Manufacturing, 73:102208.

Huang, J., Pham, D. T., Li, R., Qu, M., Wang, Y., Kerin,

M., Su, S., Ji, C., Mahomed, O., Khalil, R., et al.

(2021). An experimental human-robot collaborative

disassembly cell. Computers & Industrial Engineer-

ing, 155:107189.

Huang, J., Pham, D. T., Wang, Y., Ji, C., Xu, W., Liu, Q.,

and Zhou, Z. (2019). A strategy for human-robot col-

laboration in taking products apart for remanufacture.

Fme Transactions, 47(4):731–738.

Jungbluth, J., Gerke, W., and Plapper, P. (2017). An intelli-

gent agent-controlled and robot-based disassembly as-

sistant. In IOP Conf. Series: Materials Science and

Engineering, volume 235, page 012005. IOP Publish-

ing.

Lee, M.-L., Behdad, S., Liang, X., and Zheng, M. (2020a).

Disassembly sequence planning considering human-

robot collaboration. In 2020 American Control Con-

ference, pages 2438–2443. IEEE.

Lee, M.-L., Behdad, S., Liang, X., and Zheng, M. (2020b).

A real-time receding horizon sequence planner for dis-

assembly in a human-robot collaboration setting. In

Int. S. on Flexible Automation, volume 83617, page

V001T04A004. American Society of Mechanical En-

gineers.

Lee, M.-L., Behdad, S., Liang, X., and Zheng, M. (2022).

Task allocation and planning for product disassem-

bly with human–robot collaboration. Robotics and

Computer-Integrated Manufacturing, 76:102306.

Li, K., Liu, Q., Xu, W., Liu, J., Zhou, Z., and Feng, H.

(2019). Sequence planning considering human fatigue

for human-robot collaboration in disassembly. Proce-

dia CIRP, 83:95–104.

Liao, H.-y., Chen, Y., Hu, B., and Behdad, S. (2023).

Optimization-based disassembly sequence planning

under uncertainty for human–robot collaboration.

Journal of Mechanical Design, 145(2):022001.

Liu, W., Liang, X., and Zheng, M. (2023). Task-

constrained motion planning considering uncertainty-

informed human motion prediction for human–robot

collaborative disassembly. IEEE/ASME Transactions

on Mechatronics.

Liu, Z., Liu, Q., Xu, W., Liu, Z., Zhou, Z., and Chen,

J. (2019). Deep learning-based human motion pre-

diction considering context awareness for human-

robot collaboration in manufacturing. procedia cirp,

83:272–278.

Lou, S., Zhang, Y., Tan, R., and Lv, C. (2024). A human-

cyber-physical system enabled sequential disassem-

bly planning approach for a human-robot collabora-

tion cell in industry 5.0. Robotics and Computer-

Integrated Manufacturing, 87:102706.

Mateus, J. E. C., Aghezzaf, E.-H., Claeys, D., Lim

`

ere, V.,

and Cottyn, J. (2018). Method for transition from

manual assembly to human-robot collaborative as-

sembly. IFAC-PapersOnLine, 51(11):405–410.

Matsas, E. et al. (2017). Design of a virtual reality training

system for human–robot collaboration in manufactur-

ing tasks. Int. J. on Interactive Design and Manufac-

turing (IJIDeM), 11:139–153.

Pacaux-Lemoine, M.-P., Habib, L., and Carlson, T. (2023).

Levels of cooperation in human–machine systems: A

human–bci–robot example. Handbook of Human-

Machine Systems, pages 61–69.

Parsa, S. et al. (2021). Human-robot collaboration disas-

sembly planning for end-of-life product disassembly

process. Robotics and Computer-Integrated Manufac-

turing, 71:102170.

Prioli, J. P. J. and Rickli, J. L. (2020). Collaborative robot

based architecture to train flexible automated disas-

sembly systems for critical materials. Procedia Man-

ufacturing, 51:46–53.

Renteria, A. et al. (2019). Human-robot collaboration as a

new paradigm in circular economy for weee manage-

ment. Procedia Manufacturing, 38:375–382.

Sartori, A. and Schlette, C. (2021). Visual programming of

a human-machine interface for a multi-robot support

system. In 2021 4th IEEE Int. Conf. on ICPS, pages

387–392. IEEE.

Tian, S., Liang, X., and Zheng, M. (2023). An optimization-

based human behavior modeling and prediction for

human-robot collaborative disassembly. In 2023

American Control Conference, pages 3356–3361.

IEEE.

Vongbunyong, S., Vongseela, P., and Sreerattana-aporn, J.

(2017). A process demonstration platform for product

disassembly skills transfer. Procedia CIRP, 61:281–

286.

Wu, T., Zhang, Z., Zeng, Y., Zhang, Y., Guo, L., and

Liu, J. (2024). Techno-economic and environmen-

tal benefits-oriented human–robot collaborative disas-

sembly line balancing optimization in remanufactur-

ing. Robotics and Computer-Integrated Manufactur-

ing, 86:102650.

Xu, C., Wei, H., Guo, X., Liu, S., Qi, L., and Zhao, Z.

(2020a). Human-robot collaboration multi-objective

disassembly line balancing subject to task failure via

multi-objective artificial bee colony algorithm. IFAC-

PapersOnLine, 53(5):1–6.

Xu, W., Tang, Q., Liu, J., Liu, Z., Zhou, Z., and Pham, D. T.

(2020b). Disassembly sequence planning using dis-

crete bees algorithm for human-robot collaboration in

remanufacturing. Robotics and Computer-Integrated

Manufacturing, 62:101860.

Yuan, G., Liu, X., Zhang, C., Pham, D. T., and Li, Z. (2023).

A new heuristic algorithm based on multi-criteria re-

silience assessment of human–robot collaboration dis-

assembly for supporting spent lithium-ion battery re-

cycling. Engineering Applications of Artificial Intelli-

gence, 126:106878.

Human-Robot Cooperation in Disassembly: A Rapid Review

219