Nonlinear Control and State Estimation for the Hand Axes of a

Pneumatic Robot

Seyed Houman Mirafzal

Independent Researcher, Germany

Keywords: Mechatronics, Robotics, Predictive Control, Flatness-Based Methods, Pneumatic Muscle.

Abstract: This paper presents a nonlinear control for the hand axes of a robot with three pneumatic muscles. A vector-

based approach is employed for the modeling. Due to the structure of the system, a flatness-based control

method is chosen and used. A control system is designed in which three types of compensators, including

feedback, feedforward, and observer (estimator) are used to improve the trajectory tracking of the main joint

angles and the muscle force control. The Kalman Filter is used to estimate the disturbance friction torque in

the system. Through a combination of theoretical analysis and experimental validation, the proposed methods

demonstrate significant improvements in control accuracy and system stability. As a result, the control system

tracks the desired trajectories very well, as various trajectories are implemented to test the tracking behavior

of the control system.

1 INTRODUCTION

The integration of automatic control systems has

become pivotal in modern industries, enhancing both

efficiency and precision across a wide range of

applications. While open-loop control systems suffice

for the operation of simpler devices, such as

household appliances, the demand for increasingly

complex feedback control systems has steadily

grown. Feedback control systems, which

continuously monitor and adjust outputs to align with

desired set points, are essential for high-precision

tasks, ranging from industrial automation to delicate

surgical procedures.

Although control using electric actuators is more

common due to its processing flexibility, pneumatic

control, which operates based on the pressure and

force of compressed air, remains crucial in modern

industry (Franklin et al., 2019). Pneumatic actuators

are commonly used in automation and robotics due to

their lightweight and naturally compliant behavior,

which comes from air's compressibility. This

compliance, adjustable through pressure control, is

essential for safe human-machine interactions and

delicate tasks like handling fragile objects. In

contrast, hydraulic and electric systems are more rigid

and require relatively more complex feedback control

to achieve similar flexibility (Daerden et al., 2002). In

addition, because pneumatic muscles can produce

relatively big forces and make these forces last long

without much effort, using them is also advantageous

(Schindele et al., 2013).

Pneumatic robots, characterized by their inherent

compliance and safety, present unique challenges in

control due to their nonlinear behavior and dynamic

uncertainties. These robots are particularly

advantageous in environments where human-robot

interaction is frequent, as their compliant nature

reduces the risk of injury. However, the nonlinear

dynamics of pneumatic actuators necessitate

advanced control strategies to achieve precise and

reliable performance.

This experiment addresses the critical need for

robust nonlinear control and state estimation

techniques for the hand axes of a pneumatic robot, in

which the axes of the three pneumatic muscles are

regarded as the axes of the robot hand. The

experiment aims for optimization of the control

process by merging all the compensators (feedback,

feedforward, and observer) together, while the model

is also considered as similar as possible to the real

physical system.

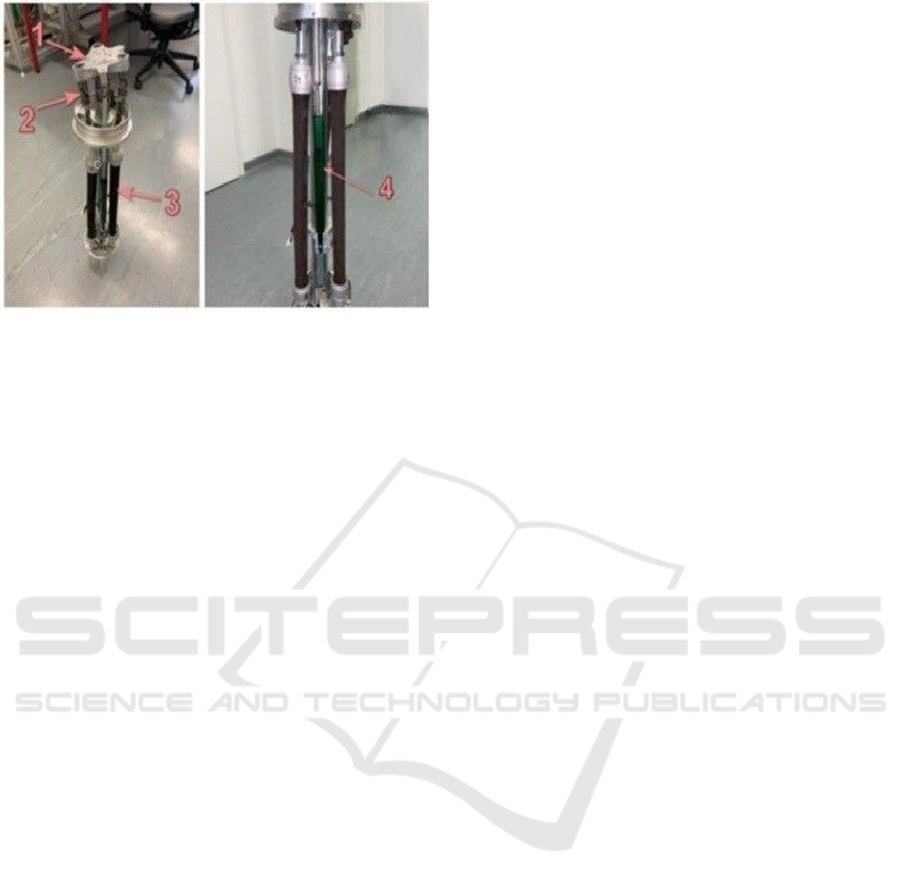

Figure 1 shows two images of the robot, in which

its main components are introduced, while the

muscles are still not filled with the compressed air. A

comprehensive approach is proposed that includes the

development

of nonlinear controllers designed to

236

Mirafzal, S. H.

Nonlinear Control and State Estimation for the Hand Axes of a Pneumatic Robot.

DOI: 10.5220/0013006500003822

In Proceedings of the 21st International Conference on Informatics in Control, Automation and Robotics (ICINCO 2024) - Volume 2, pages 236-247

ISBN: 978-989-758-717-7; ISSN: 2184-2809

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

Figure 1: The pneumatic robot. The system consists of four

major parts: the joint top plate (1), the joint level (2), the

three pneumatic muscles (3) and the two measuring

cylinders or potentiometer sensors (4).

enhance trajectory tracking and force control

accuracy.

This paper is structured as follows: First, the

system is modeled using vectors and various

coordinate systems to simplify calculations. While

some components, like the chains and fully realistic

top plate, are approximated, the model closely

represents the real system, resulting in minimal

residual errors. Multiple coordinate systems, tailored

to the shape, degrees of freedom, and movement

directions, make the modeling and logic easier to

understand. Transformation matrices facilitate easy

variable transfers between coordinate systems. Next,

the equations for modeling the pneumatic muscles,

including required coefficients, are derived

experimentally.

New coefficients and muscle

characteristics specific to this system are calculated.

Furthermore, flatness-based controllers are designed

for the desired control response. Initial controllers

manage angles that approximate the rotated top plate

angles. Secondary controllers manage the pneumatic

system, controlling muscle forces based on desired

torques and mean force. Moreover, the desired

trajectories and feasible variable ranges, considering

the real physical system, are explained. Movement,

pressure, and force limitations in the pneumatic

system are detailed, such as restricted rotation angles

of the top plate and pressure limits affecting muscle

forces. As the air mass flow rate 𝑚 is considered the

manipulated variable of the control system, the initial

and the maximum air pressure in the muscles are

considered 1 bar and 8 bars, respectively.

Additionally, data derived from plotting the results in

MATLAB/Simulink indicate that the desired mean

force should not fall below 15 newtons to ensure

logical system responses. Observers are also used to

estimate and compensate for friction as a disturbance.

The Kalman Filter is chosen as an optimal method

among various observer options. Finally, the entire

control system model is evaluated regarding its

responses and results, comparing them to expected

outcomes. As a result, it is shown that the desired

trajectories are being tracked fast with a high

accuracy, due to the precise design of the control

system, including different compensators. The paper

concludes by summarizing the thesis aims and

discussing system applications.

2 MULTI-BODY MODELING

As discussed in the introduction, the kinematic

modeling of the robot is based on vectors and

different coordinate systems, corresponding to the

system's parts and their movement directions. The

bottom plate, located at the base of the pneumatic

muscles, remains stationary, so the initial point (O

1

)

of the primary coordinate system (system 1) is set at

the center of this plate.

The main joint, which allows two perpendicular

angular rotations, is located in the middle of the joint

level. These rotation angles are the main controlling

angles. The center of this joint is the center point (O

2

)

of the next coordinate system (system 2), formed by

rotating system 1 around the x-axis by angle 𝜑

1

. The

final coordinate system is created by rotating system

2 around its y-axis (y

2

-axis) by angle 𝜑

2

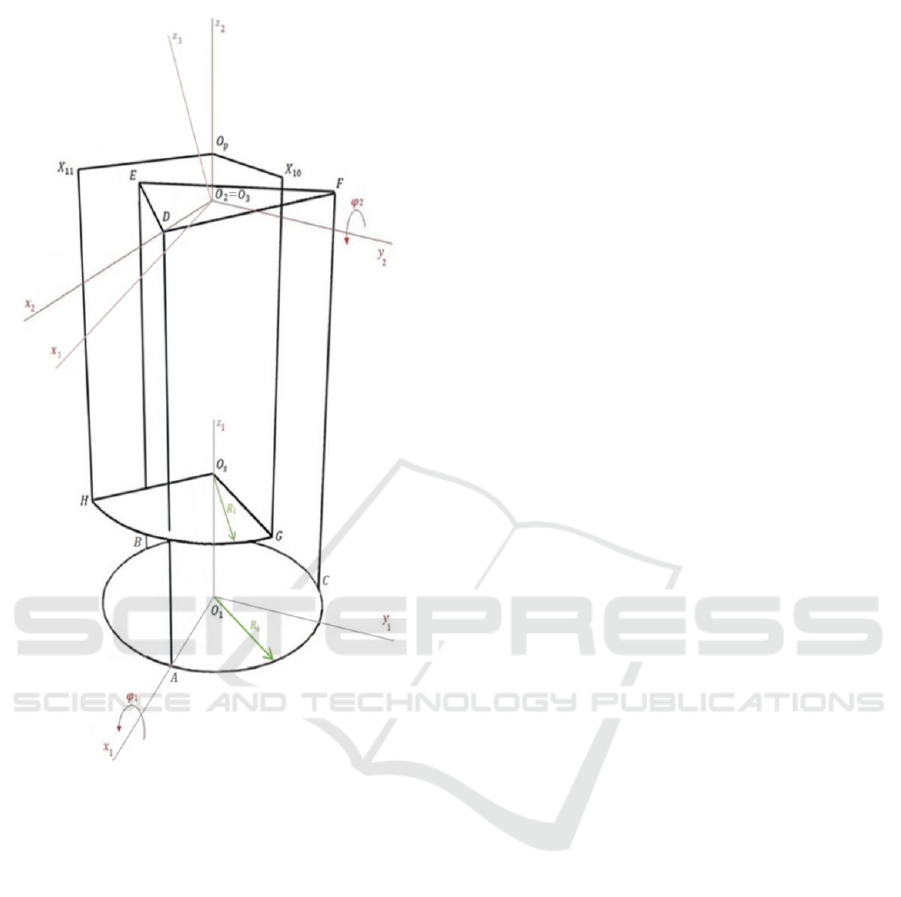

. Figure 2

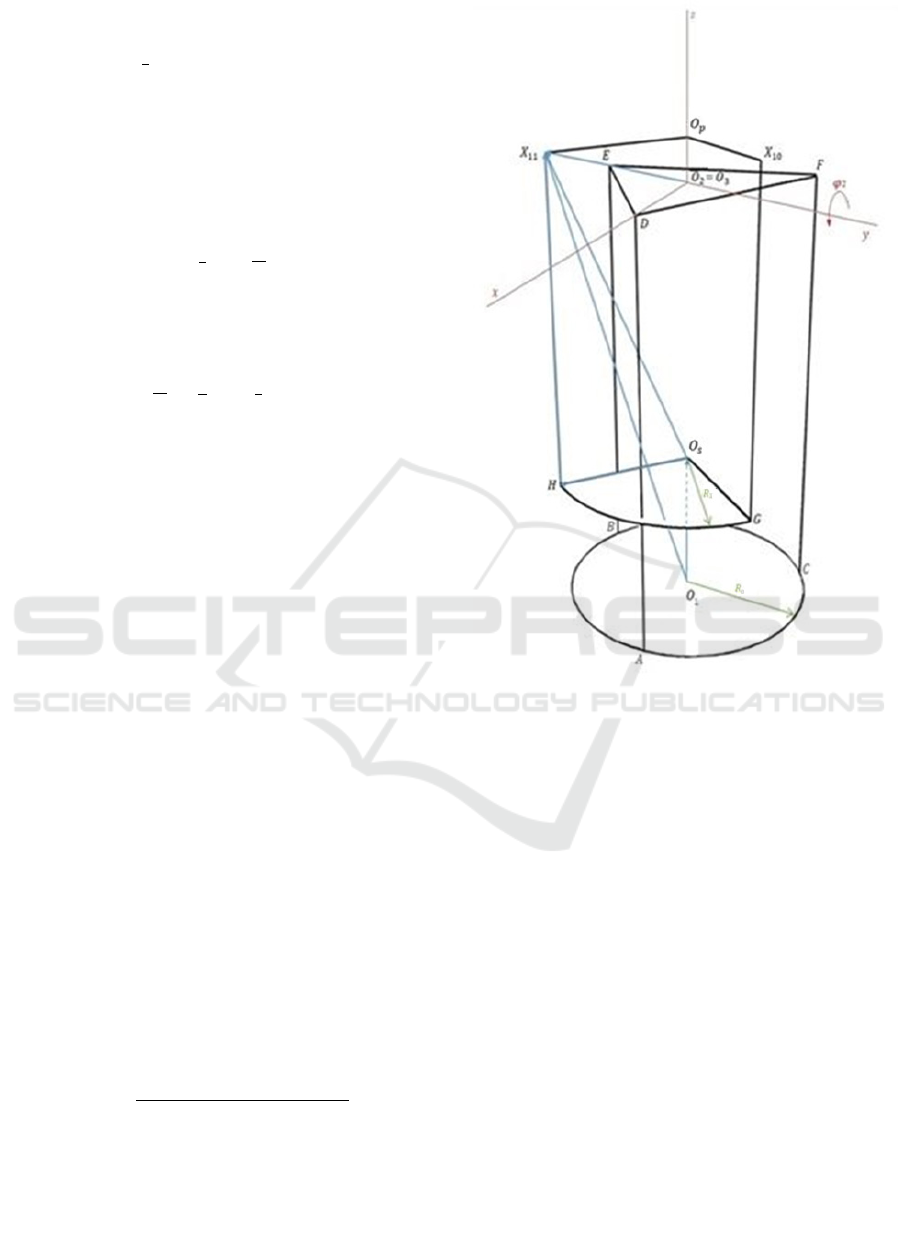

shows the simplified system model, including the

three coordinate systems.

The robot hand axes design benefits from

symmetry, simplifying calculations and modeling.

Additionally, the end joints of the pneumatic muscles

are aligned with the main joint's center, further easing

the modeling process.

2.1 Modeling the Hand Axes and the

Pneumatic Actuators

The primary goal in modeling the robot hand axes is

to determine the relationship between the vectors of

the model's different parts, the rotation angles, and the

changes in the lengths of the two potentiometer

sensors, X

10

and X

11

, as shown in figure 1. Since X

10

and X

11

are the only means of measuring the current

positions or lengths of other components, establishing

this relationship is crucial. The modeling process is

conducted in several steps, as described in the

following sections.

Nonlinear Control and State Estimation for the Hand Axes of a Pneumatic Robot

237

Figure 2: The simplified model, including the bottom

surface of the muscles, top triangular surface and the

sensors’ bottom and top positions.

2.1.1 Selecting Different Coordinate Systems

As mentioned briefly earlier, the modeling involves

three coordinate systems. To explain the system's

behavior better, the second and third coordinate

systems are placed at the main joint just below the top

surface. Key points for calculations include the

centers of the pneumatic muscle top joints (D, E, and

F), as shown in figure 2.

2.1.2 Vector-Based Modeling

In the modeling approach, muscles and their chains

together are treated as vectors in three-dimensional

space for calculations and coding purposes. As

previously mentioned, the goal is to relate these

vectors to the rotation angles of the main central joint,

O

2

,

to the outputs from sensors X

10

and X

11

. For this

purpose, a vector must represent each pneumatic

muscle.

The secondary coordinate system, system 2,

centered at the main joint with origin O

2

, simplifies

calculations for vectors such as

1

𝑟⃗

D 1

, which represent

distances like O

1

to D. These vectors are transformed

into the initial coordinate system using a

straightforward multiplication by a transformation

matrix explained in section 2.1.3.

2.1.3 Derivation of the Transformation

Matrix

In subsection 2.1.2, the concept of representing

vectors in different coordinate systems is introduced.

In order to calculate each vector component in a new

coordinate system, a transformation matrix is

required. The transformation matrix to form a new

coordinate system 3, after two consequent rotations

about x- and y-axes, can be stated as (Woernle,

2016)

13

T =

𝑐𝑜𝑠 𝜑

0𝑠𝑖𝑛 𝜑

𝑠𝑖𝑛 𝜑

𝑠𝑖𝑛 𝜑

𝑐𝑜𝑠 𝜑

− 𝑠𝑖𝑛 𝜑

𝑐𝑜𝑠 𝜑

− 𝑐𝑜𝑠 𝜑

𝑠𝑖𝑛 𝜑

𝑠𝑖𝑛 𝜑

𝑐𝑜𝑠 𝜑

𝑐𝑜𝑠 𝜑

.

(1)

Similarly, this 2 degrees of freedom (DOF)

system involves rotations around the main center joint

along x- and y-axes. Thus, analogous to the equation

(1), separate transformation matrices are developed:

12

T,

23

T, and

13

T, representing movements between

coordinate systems. Therefore, each vector can be

calculated in the third coordinate system to ease the

calculations, by having its components in the first

coordinate system as follow

1

𝑟⃗ =

13

T .

3

𝑟⃗ .

2.2 Experimental Identification of

Unknown Parameters

Pneumatic systems involve diverse muscle types,

each with specific characteristics like air pressure

requirements for contraction. A key challenge in

pneumatic muscles is hysteresis. This effect in

pneumatic muscles arises from the relative motions

occurring during muscle inflation or deflation, which

increase the system's nonlinearities and complexities

(Vo et al., 2010). Internal friction between the aramid

fibers and the surrounding elastic material also

contributes to hysteresis (Deaconescu et al., 2016).

Despite its potential impact, hysteresis is negligible in

(2)

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

238

this experiment and is omitted in the pneumatic

control model design.

The complete force characteristic F

Mi

can be

stated as (Schindele et al., 2013)

F

Mi

= F

Mi,st

+ F

Mi,hys

,

where F

Mi,st

, and F

Mi,hys

denote the static muscle force

and the hysteresis effect, respectively.

Because the hysteresis effect, F

Mi,hys

, is negligible

in this experiment, therefore, complete force

characteristic F

Mi

is considered approximately equal

to the static muscle force F

Mi,st

. As a result,

F

Mi

≈ F

Mi,st

.

The muscle force depends on internal pressure

𝑝

and contraction length Δ𝑙

approximated by

𝐹

,

(

𝑝

,Δ𝑙

)

=

𝐹

(

𝑝

,Δ𝑙

)

𝑖𝑓 𝐹

0

0 𝑒𝑙𝑠𝑒

,

The amounts of the coefficients 𝑎

and b

n

can be

defined experimentally. The Recursive Least Squares

(RLS) method is a reliable approach for parameter

estimation (Xie et al., 2011), requiring extensive data

collection—about 20,000 states of p

Mi

, 𝛥𝑙

Mi

, and F

Mi

are practically analyzed in the university laboratory.

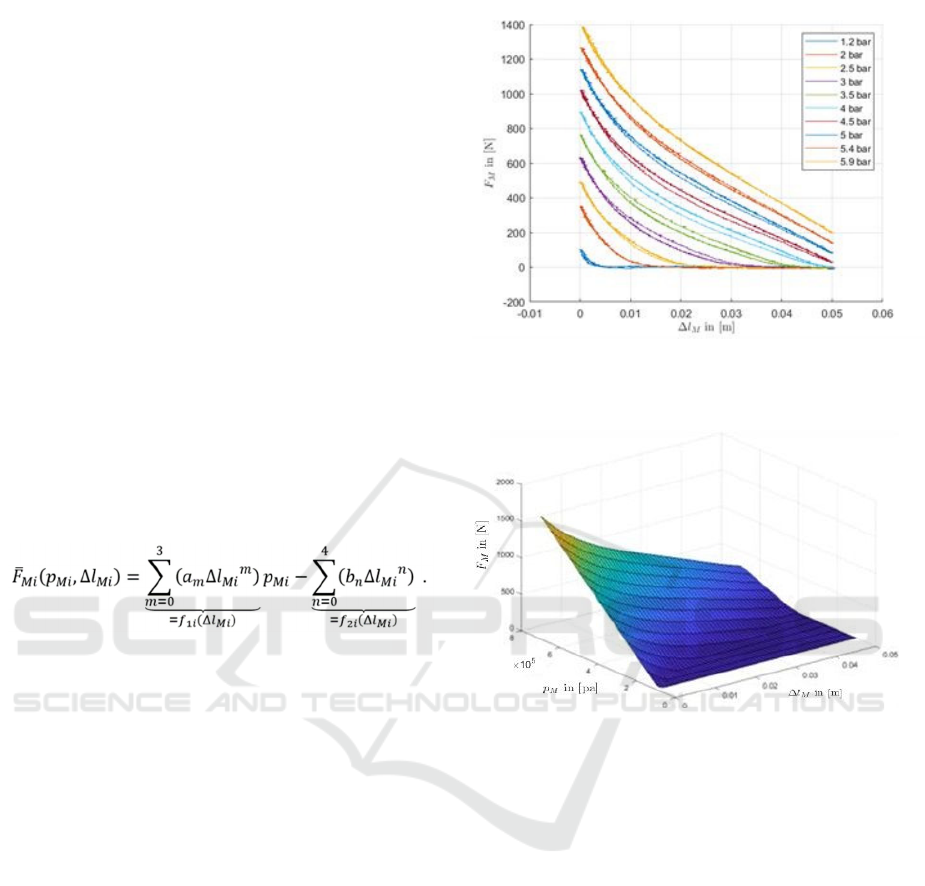

Figure 3 illustrates results for 10 internal muscle

pressures.

By using the RLS method, the quantities for 𝑎

and bn can be calculated.

Consequently, the resulting three-dimensional

figure for the identified force characteristic of the

pneumatic muscle can be plotted as figure 4.

3 DESIGN OF THE NONLINEAR

MIMO AND INVERSE SYSTEM

MODEL

The flatness-based control approach is chosen, due to

the suitable trajectory tracking structure and inclusion

of the feedforward compensator, as it is discussed in

more detail in section 3.

Figure 3: The resulting curves, including the relationship

between the created muscle force and the contraction length

for 10 different pressures.

Figure 4: The force characteristic of the pneumatic muscle.

In order to design a complete flatness-based

feedback cascade control for a Multiple-Input

Multiple-Output (MIMO) system, it is necessary to

design not only the MIMO system model, but also the

nonlinear inverse system model. The inputs of the

MIMO system model are the controlled outputs of the

nonlinear inverse model.

The design of the MIMO system and the inverse

system models is discussed in this section, however,

the design of the flatness-based controllers is

discussed in the next section, as mentioned earlier.

3.1 Design of the Nonlinear MIMO

System Model

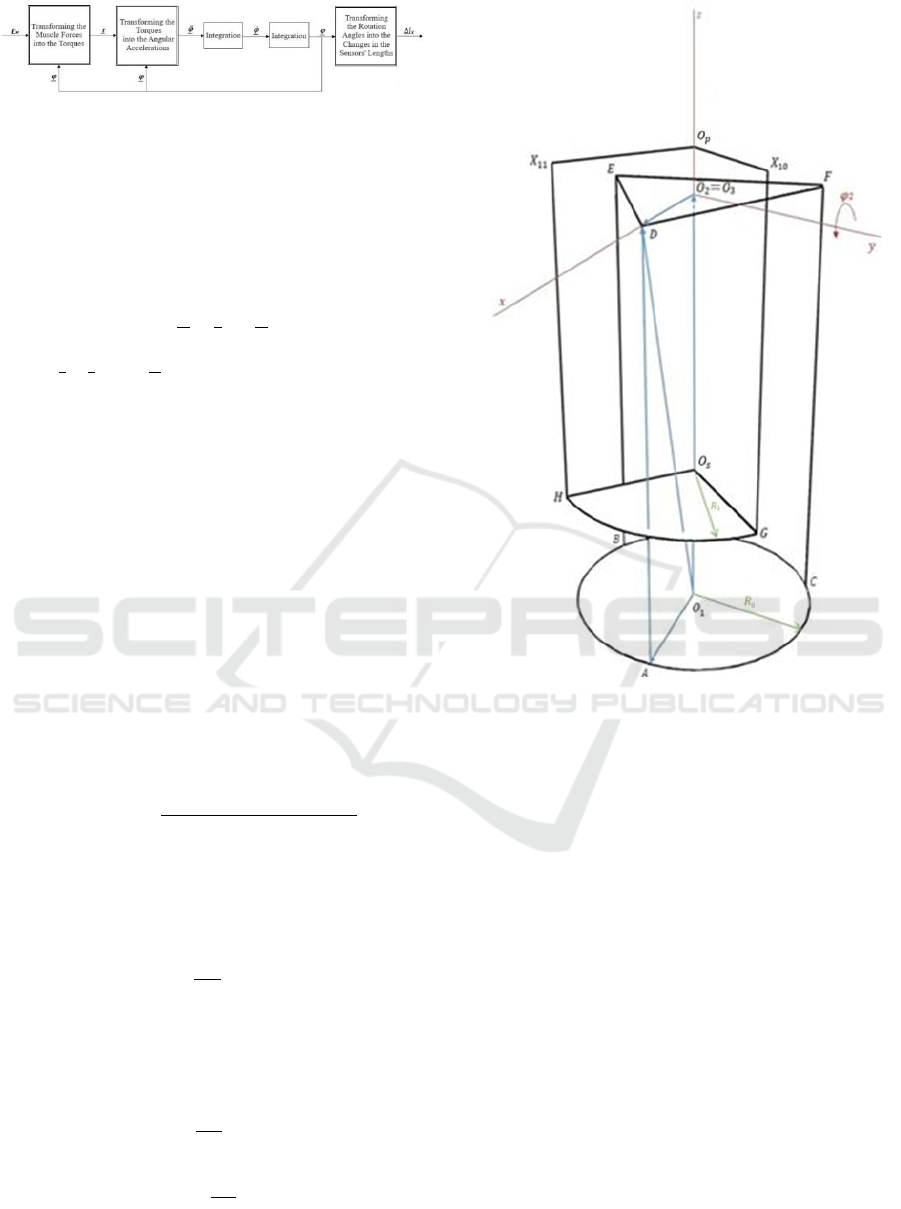

The initial inputs of the MIMO system model are the

controlled muscle forces, which must sequentially be

transformed into the torques, rotation angles, and

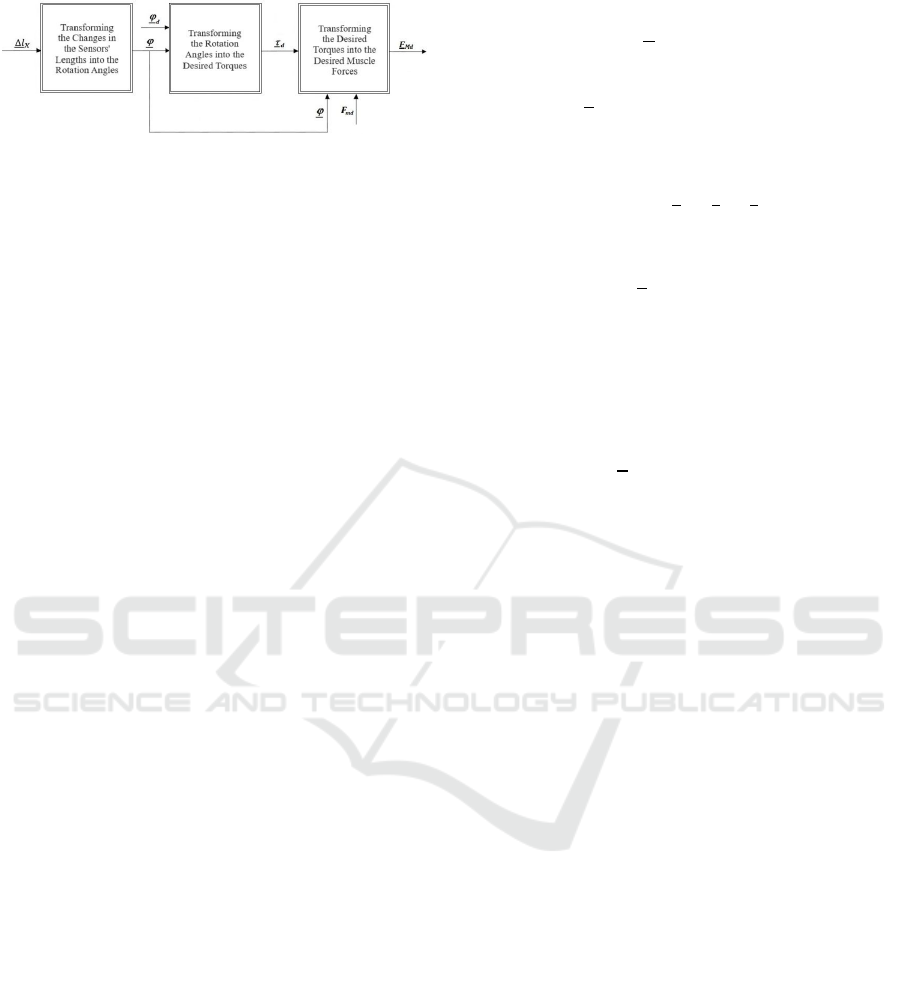

sensors' lengths change. Figure 5 shows the schematic

block diagrams of the whole MIMO system model.

(3)

(4)

(5)

(6)

Nonlinear Control and State Estimation for the Hand Axes of a Pneumatic Robot

239

Figure 5: The block diagrams of the whole MIMO system

model.

3.1.1 Transforming the Muscle Forces into

the Toques

Based on the physical laws of angular rotation, the

corresponding torques can be calculated as follows

τ

= r × F ,

where τ , r and F represent the resulting torques

matrix, the distance vector and the muscles forces

matrix, respectively. Figure 6 shows the simplified

model of the robot hand axes in which the related

vectors to calculate the first muscle vector are shown

in blue.

The step-by-step calculations to get the first

muscle vector are as follows

1

𝑟⃗

D 3

=

13

T .

3

𝑟⃗

D 3 ,

1

𝑟⃗

D 1

=

1

𝑟⃗

3 1

+

1

𝑟⃗

D 3 ,

1

𝑟⃗

D A

=

1

𝑟⃗

D 1

-

1

𝑟⃗

A 1 .

If the coordinates of the first muscle force vector

1

𝑟⃗

D A

along x- , y- and z-axis are considered

𝑟

,

,𝑟

,

, and 𝑟

,

, respectively, the whole length

of 𝑟⃗

DA

can be stated as

𝑙

D A

=

𝑟

,

+𝑟

,

+𝑟

,

.

Therefore, the unit vector of the first muscle

force vector in the first coordinate system can be

expressed as

1

𝑒

D A

=

.

1

𝑟⃗

D A

.

Similarly, the unit vector of the second and third

muscle vector in the first coordinate system can be

determined by the following equations

1

𝑒

EB

=

.

1

𝑟⃗

EB

,

1

𝑒

FC

=

.

1

𝑟⃗

FC

.

Figure 6: The simplified system model to calculate the first

muscle vector, 𝑟⃗

D A

.

To correctly show the pulling direction of the

muscle forces, the unit matrices must be multiplied by

-1, resulting in the following vector

1

𝐹

⃗

M 1

= - F

M 1

.

1

𝑒

D A

,

where F

M 1

denotes the scalar value of the produced

forces of the first pneumatic muscle.

To simplify the further calculations, the related

vectors must be brought into the third coordinate

system, therefore

3

𝐹

⃗

M 1

=

13

T

-1

.

1

𝐹

⃗

M 1

,

Consequently, based on the equation (7) the

produced torque of the first muscle can be calculated

as follows

3

𝜏⃗

1

=

3

𝑟⃗

1

×

3

𝐹

⃗

M 1

,

The corresponding vectors of the second and the

third muscles can be calculated similarly. As a result,

(8)

(9)

(10)

(11)

(12)

(13)

(14)

(15)

(16)

(17)

(7)

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

240

the aggregate torque can be stated as

∑ τ =

3

𝜏⃗

1 +

3

𝜏⃗

2 +

3

𝜏⃗

3

.

3.1.2 Transforming the Torques into the

Angles

According to the physical laws of rotation, the

relationship between the angular velocity and the

corresponding torque stated as

∑ τ = J

⋅

𝜑 ,

where J denotes the moment of inertia of the mass to

which the torque has been applied. Therefore, the

angular velocity can be stated as

𝜑 = J

-1

. ∑ τ .

In order to calculate J, the top plate is considered

a triangular prism. The detailed calculations can be

found in (Mirafzal, 2023).

Correspondingly, the matrix of the rotation

angles can be calculated easily by two consecutive

integrator blocks in Simulink.

3.1.3 Transforming the Angles into the

Changes in the Sensors' Lengths

To calculate the sensors' lengths change, each of the

corresponding sensor vectors must be calculated

separately. Figure 7 shows the simplified model of the

robot hand axes in which the related vectors to

calculate the X

11

sensor vector are shown in blue.

Consequently, the

X

11

sensor vector, 𝑟⃗

11H

, can be

calculated by the following equations.

1

𝑟⃗

11 3

=

13

T .

3

𝑟⃗

11 3

,

1

𝑟⃗

11 1

=

1

𝑟⃗

3 1

+

1

𝑟⃗

11 3

,

1

𝑟⃗

11 S

=

1

𝑟⃗

11 1

-

1

𝑟⃗

S 1

,

1

𝑟⃗

11 H

=

1

𝑟⃗

11 S

-

1

𝑟⃗

H S

.

As a result, the length of the X

11

sensor can be

stated as

𝑙

X 11

=

𝑟

,

+𝑟

,

+𝑟

,

.

Accordingly, if the initial sensor length is

considered 𝑙

s0,

the length change of the X

11

sensor

can be stated as

𝛥𝑙

X 11

= 𝑙

X 11

- 𝑙

s 0

.

Figure 7: The simplified system model to calculate the X

11

sensor vector, 𝒓

⃗

11H

.

A similar approach can be followed to calculate

the length change of the X

10

sensor, 𝛥𝑙

X 10

.

3.2 Design of the Nonlinear Inverse

System Model

As shortly discussed previously, it is necessary to

design an inverse system model to complete the

flatness-based control block diagram. As the first

inverse block, the output values for the changes in the

sensors’ lengths, 𝛥𝑙

X 11

and

𝛥𝑙

X 10

, must be converted

into the corresponding rotation angle values, 𝜑

1

and

𝜑

2

. These output rotation angles as well as the desired

rotation angles are the inputs of the first flatness-

based angle controller, which is explained in more

detail in section 4. Figure 8 shows the schematic

block diagrams of the whole inverse system model.

(18)

(19)

(20)

(21)

(22)

(23)

(24)

(25)

(26)

Nonlinear Control and State Estimation for the Hand Axes of a Pneumatic Robot

241

Figure 8: The block diagrams of the whole inverse system

model, in which 𝜑

d

,

𝜏

, 𝐹

, and 𝐹

represent the desired

rotation angle, torque, mean force, and muscle force,

respectively.

3.2.1 Transforming the Changes in the

Sensors’ Lengths into the Rotation

Angles

Although the changes in the sensors’ lengths can be

analytically calculated from the rotation angles in the

MIMO system model, the rotation angles cannot be

calculated analytically by the MATLAB “solve”

function, due to the complexity of the nonlinear

inverse model to calculate the angles. Therefore, a

lookup table is employed in Simulink to output the

rotation angles from the inputs, which are the changes

in the sensors’ lengths, numerically.

3.2.2 Transforming the Rotation Angles into

the Desired Torques

Given the rotation angles, that result from the lookup

table, the desired torques can be outputted. To do this,

the designed angle controller, which is described in

the equation (32) in section 4, must take the rotation

angles from the lookup table, as well as the desired

angles, that can be chosen by considering the system

limitations. Next, the controller outputs the second

derivative of the rotation angles, as the controlled

values. Then, the desired torques can be calculated,

having the moment of inertia, as described in the

equation (33) in section 4.

3.2.3 Transforming the Desired Torques

into the Desired Muscle Forces

The conversion of the desired torques to the desired

muscle forces could be challenging, due to the

complex nonlinear structure of the equations.

Nevertheless, by using an innovative approach, the

problem is solved completely analytically.

Due to the fact that the coefficients of the desired

muscle forces,

F

M1

, F

M2

and

F

M3

, can be totally

separated from the muscle forces in the matrix of the

desired torques, the desired torques matrix can be

rewritten as follows

A

f

∙ F

Md

=

𝜏

𝜏

𝐹

,

where

A

f

and

F

Md

can be written as

A

f

=

𝑎

𝑏

𝑐

𝑑

𝑒

𝑓

,

F

Md

=

𝐹

𝐹

𝐹

,

,

and 𝐹

denotes the desired mean muscle force.

As a result, the desired muscle force matrix can be

calculated by

F

Md

=

A

f

-1

∙

𝜏

𝜏

𝐹

.

The desired muscle forces are used as the

reference values for the flatness-based force

controller, which is discussed in section 4.

4 SYSTEM ANALYSIS AND

DESIGN OF A NONLINEAR

TRAJECTORY TRACKING

CONTROL

Flatness-based control is a method that offers a cost-

effective and straightforward approach for nonlinear

models, enabling easy tracking of desired inputs with

the inclusion of feedforward as a compensator.

The general formula to design a flatness-based

controller can be stated as (Lévine, 2009)

𝜈=𝑦

(

)

+𝑎

𝑦

(

)

−𝑦

(

)

,

where 𝜈 denotes the control input to the system, 𝑦

represents the desired flat output or the reference

trajectory, 𝑎

refers to the feedback coefficient

ensuring stability (typically chosen to form a Hurwitz

polynomial), and n is the relative degree of the

system.

This approach effectively controls angles and

muscle forces (or pressures) and is implemented in

the control system, detailed in this section.

(27)

(28)

(29)

(30)

(31)

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

242

4.1 Design of the Flatness-based Angle

Controller

The angles 𝜑

1

and 𝜑

2

are determined using sensor

feedback and the relationship between its length

change to the other components of the robot by means

of the vector-based modeling. Using numerical

methods, including lookup tables in

MATLAB/Simulink, sensor data can be converted

into controlled outputs.

For systems suitable for flatness-based control,

like this system, the design is straightforward. As the

relative degree of the angels in the system is 2,

according to equation (31), the control equations for

the main joint angles can be stated as

𝜑

i

= 𝜑

id

+ 𝑎

. (𝜑

id

– 𝜑

i

) + 𝑎

. (𝜑

id

– 𝜑

i

) .

Here, i={1, 2} for each of the angles and 𝜑

id

is the

desired angular acceleration, also acting as the

feedforward compensator, while 𝑎

and 𝑎

are

positive constants ensuring system stability.

Desired angle trajectories, e.g. varying sine

functions, can be freely chosen within physical

constraints, detailed further in section 5.

Next, torques are computed from the angular

accelerations, which are used to calculate total

torques about x- and y-axes

𝜏

𝜏

=

𝐽

𝐽

𝐽

𝐽

.

𝜑

𝜑

,

where 𝐽 denotes the moment of inertia of the mass at

the top of the robot hands to which the torques have

been applied, that has been approximated by a

triangular prism. This process is implemented in the

angle controller.

4.2 Design of the Flatness-based Force

Controller of the Pneumatic

Muscles

In addition to rotation angles, it is crucial to control

the pneumatic muscle forces through a separate

tracking controller.

The muscle force 𝐹

comprises the static force

𝐹

,

and the hysteresis force 𝐹

,

, with the latter

being negligible, as written in equation (4) in section

2.

As mentioned earlier, the static force is calculated

using coefficients 𝑎

and 𝑏

determined via the

Recursive Least Squares (RLS) method, as described

in section 2, equations (5) and (6). The derivative of

muscle pressure 𝑝

Mi

is expressed as (Schindele et al.,

2013)

𝑝

Mi

=

𝑅

𝑇

𝑚

−

𝑧

𝑝

=𝑘

(

Δ𝑙

,𝑝

)

𝑚

− 𝑘

Δ𝑙

,Δ𝑙

,𝑝

𝑝

,

where i = {1, 2, 3}, 𝑉

denotes the volume of the

pneumatic

muscles, R

L

= 287 the air gas constant,

n = 1.26

the identified polytropic exponent,

T

Mi

= 294 K the internal temperature, and Δ𝑙

the

contraction length.

The volume of the pneumatic muscles 𝑉

is

defined as

𝑉

(

Δ𝑙

,𝑝

)

=𝑎

Δ𝑙

𝑝

+ 𝑏

Δ𝑙

,

where the coefficients 𝑎

and 𝑏

can be identified

experimentally, just like the polynomial function of

the muscle forces.

The mass flow rate 𝑚

is given by:

𝑚

=

,

where 𝑓

and 𝑓

are derived from the equation (6).

By considering 𝜈

=𝐹

, similar to designing the

angle controller based on equation (31), and

considering that the relative degree of the muscle

forces in the system is 1, the flatness-based force

controller can be formulated as

𝐹

=𝐹

+𝑎

.

(

𝐹

− 𝐹

)

.

Here, i={1, 2, 3} for each of the muscles, and 𝐹

act as the feedforward compensator, while 𝑎

must be

chosen positive to ensure the system stability.

5 DETERMINATION OF THE

DESIRED TRAJECTORIES

The robot pneumatic system has restrictions such as

the rotation angles, 𝜑

1

and 𝜑

2

, of the main joint and

the maximum pressure from the pneumatic control

unit (PCU), due to its physical characteristics. These

(32)

(33)

(34)

(36)

(37)

(35)

Nonlinear Control and State Estimation for the Hand Axes of a Pneumatic Robot

243

limitations must be incorporated into the model for

realism. Typically, a target polynomial is used for the

desired angles to improve control response and

derivatives (Mirafzal, 2023). This section details

these system restrictions, methods, and resulting

trajectories.

5.1 Minimum Force/Pressure

Requirements

The pulling force of the pneumatic muscles is limited

by the compressed air pressure. The initial pressure is

approximately 1 bar, while the laboratory maximum

is 8 bars due to the pneumatic control unit's

constraints. Additionally, the muscle forces have

minimum and maximum limits. Tests showed that the

desired mean force, F

m

, should not fall below 15

newtons, as lower values result in unrealistic negative

forces. Consequently, the maximum forces and

torques are functions of the compressed air pressure,

which is capped at 8 bars, limiting the corresponding

forces and torques.

5.2 Feasible Trajectories for the end

Effector Rotation Angles

The primary constraints of the pneumatic robot

system include the feasible rotation angles due to

physical limitations. Rotations about the z-axis are

not allowed, and rotations about the x- and y-axes are

limited and cannot approach e.g. 90 degrees. Not all

combinations of the main angles, 𝜑

1

and 𝜑

2

, are

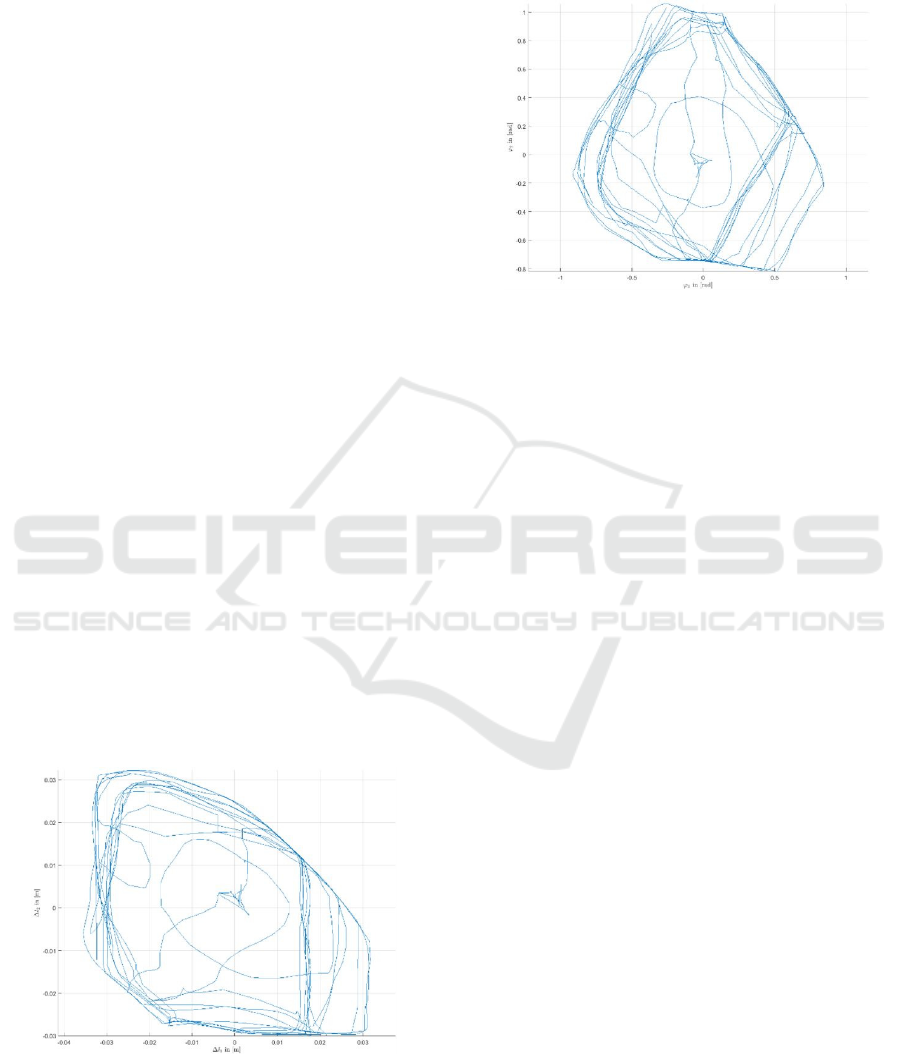

practically achievable. Practical trajectory plots for

the changes in the sensors’ length are created in the

laboratory to determine the possible angles from 1377

different states, as shown in figure 9.

Figure 9: The possible trajectories for the changes in the X

10

and X

11

sensors’ lengths that are measured practically in the

laboratory for 1377 reachable points.

As a result, the corresponding 𝜑

1

and 𝜑

2

angles

can be plotted using MATLAB, as shown in figure

10.

Figure 10: The corresponding trajectories for the main

angles for all of the 1377 measured points resulting from

the sensors data.

Some maximum points in Figure 10 are achieved

manually, not through full compressed air pressure,

indicating some unreachable points. In addition, the

plot should be symmetric, due to the symmetric

structure of the system, revealing missing points.

6 ESTIMATION OF THE STATE

AND DISTURBANCE

In advanced control systems, feedback alone is often

insufficient for achieving quick and accurate

responses due to errors, noise, and disturbances.

Feedback compares current outputs with set points to

identify errors but compensates only after errors

occur, leading to potential delays. In addition to

feedback, two main compensators, including

feedforward and observer (estimator), are typically

employed to address the mentioned issues.

Feedforward, as explained briefly in the flatness-

based control design, anticipates errors using prior

knowledge of disturbances, compensating before

errors are detected by feedback. Furthermore, the

observer, or estimator, is used when employing

sensors is impractical or costly, as it estimates system

states and reduces noise and cost, making it essential

for complex systems where direct measurement is

impossible. These strategies work together to enhance

error correction and improve system performance.

The system model described earlier is idealized

and does not account for real-world disturbances,

particularly friction, which significantly affects

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

244

mechanical systems. The nonlinear friction model for

such systems can be expressed as (Mirafzal, 2023)

𝜏

=𝜏

.𝑡𝑎𝑛ℎ

,

where 𝜏

denotes the nonlinear friction, 𝜏

and ε are

constants, with ε typically set to a small value, such

as 0.01, based on experience. Damping, especially

speed-proportional damping, also affects the system

and is represented as b. 𝜑, where b is a constant

relating angular velocity to friction.

Thus, the total friction torque can be stated as

𝜏

= 𝑏.𝜑+ 𝜏

.𝑡𝑎𝑛ℎ

.

In this experiment, the constants are considered

b = 0.1, 𝜏

= 0.0015, and 𝜀= 0.01 The state space

representation for the torque about each rotation axis

is given by

𝜑

𝜑

=

𝜑

−

𝜑−

𝜏

.𝑡𝑎𝑛ℎ

,

where

,

and

.

Here, y

m

refers to the state vector. Equation (40)

can be applied separately to each rotation angle,

𝜑

and 𝜑

, with 𝜏 representing the torque about the x-

and y-axes, respectively.

Therefore, this friction will be estimated and used

as a compensator in the control system model.

In this system model, various states, such as the

main angles of the central joint, can be estimated.

However, compensating friction disturbances has

higher priority. Given that friction influences the

aggregate torques and the model uses a linear

approach for these calculations, the Kalman Filter can

estimate friction in this system (Welch et al., 2006).

Consequently, it is employed to estimate the

disturbance torque attributed to friction. The detailed

design of the Kalman Filter can be found in (Mirafzal,

2023).

The next section will compare the estimation

results with the noisy model disturbance torque and

analyze the overall model control response.

7 SIMULATIVE

INVESTIGATION AND

EVALUATION

To evaluate the control system’s response,

adjustments are made to simulate real-world

conditions with disturbances, noise, and initial

conditions. Potentiometers and pressure sensors

received noise with specified variances. System limits

and delays are also set. Friction is estimated and

compensated using a Kalman Filter.

The system's response is evaluated against desired

trajectories for both angles and muscle forces. The

next step is to tune the controllers to receive a

satisfactory response of the system. Effective tuning

of flatness-based controllers is achieved by adjusting

coefficients iteratively. To adjust the coefficients of

the controllers, the eigenvalues should be chosen for

each controller. Through multiple rounds of trial and

error and examining how well the outputs can track

the desired trajectories in Simulink, the eigenvalues

of -225 and -1100 are chosen for the angle controller

and the force controller, respectively. As a result, the

characteristic polynomial for the angle controller can

be stated as

𝑃(𝑆)=(𝑆 + 225)

=𝑆

+ 450 𝑆+ 50625 .

Therefore, the coefficients of the flatness-based

angle controller in equation (32) can be chosen as

𝑎

= 50625 and 𝑎

= 450.

Similarly, the characteristic polynomial for the

force controller can be stated as

𝑃

(

𝑆

)

=𝑆+ 1100

.

As a result, the coefficient of the flatness-based

force controller in equation (37) can be chosen as

𝑎

= 1100.

After implementation of the selected control

coefficients, the tracking behavior of the system

shows high accuracy and fast response to the desired

trajectories.

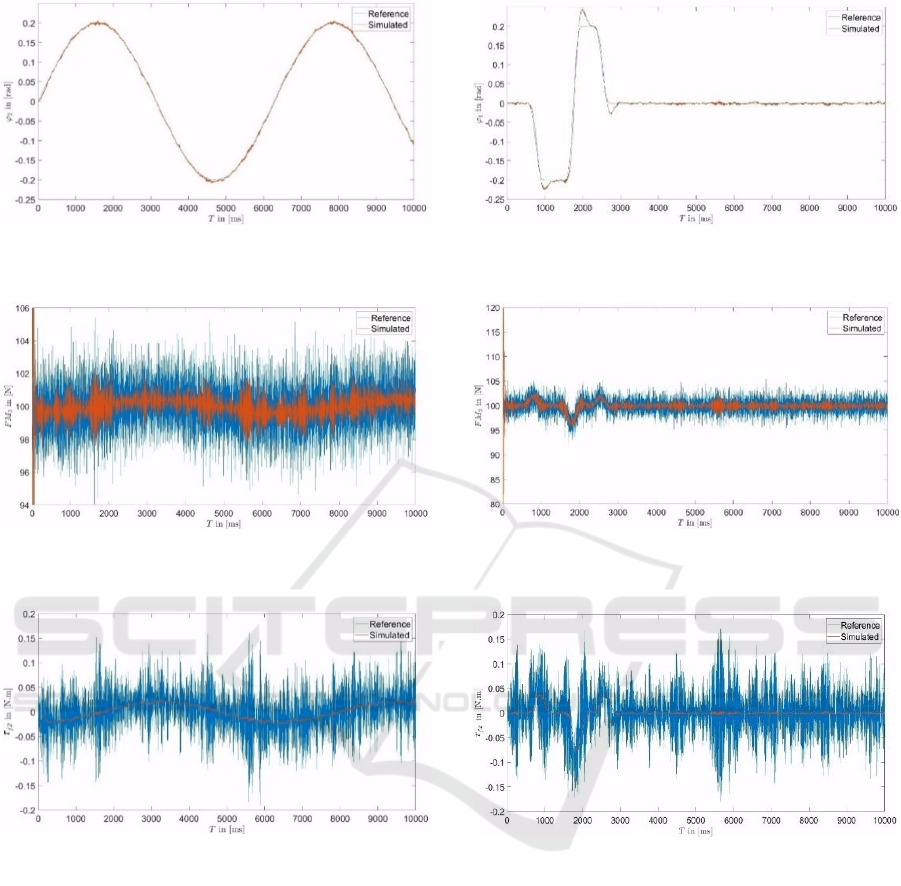

Figures 11 and 12 show the tracking behavior of

the system as a response to the desired sine wave

trajectories. Figure 13 also illustrates how well the

Kalman Filter estimates the friction torques.

(38)

(39)

(40)

(43)

(44)

(41)

(42)

Nonlinear Control and State Estimation for the Hand Axes of a Pneumatic Robot

245

Figure 11: The output of the second angle, 𝜑

2,

compared to

sample reference sine wave trajectories.

Figure 12: The output of the third muscle force, F

M3

,

compared to the reference values.

Figure 13: The estimated friction torque about y-axis

compared to the reference values.

Similarly, figures 14 and 15 illustrate how well

the system follows more complex desired trajectories

for the first rotation angle and the third muscle force,

respectively, demonstrating effective control despite

assumed disturbances. The Kalman Filter also

effectively estimates friction torques, as shown in

Figures 16, aligning closely with real values under

various conditions.

Overall, the simulation results validate the proper

determination of the physical conditions, as well as

the suitability of the controller designs and the

coefficient selections, ensuring the system performs

well under different operating conditions, in which

factors such as friction torque play important roles in

the system’s response.

Figure 14: The output of the first angle, 𝜑

1,

compared to

sample reference trajectories.

Figure 15: The output of the third muscle force, F

M3

,

compared to the reference values.

Figure 16: The estimated friction torque about y-axis

compared to the reference values.

8 CONCLUSIONS

This experiment focuses on modeling and controlling

a pneumatic robot hand axes system, with a key

emphasis on central joint rotation angles and

pneumatic muscle forces. Using transformation

matrices simplifies kinematic relationships, while

Recursive Least Squares helps characterize

pneumatic muscle behavior.

A flatness-based control approach is chosen for its

ability to effectively track desired trajectories despite

system non-linearities.

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

246

To enhance realism, disturbances like friction

torques and sensor noise are introduced and mitigated

using a Kalman Filter observer. Tuning controller

coefficients through iterative testing optimizes

system response, ensuring outputs closely matches

desired values.

In conclusion, this research demonstrates the

practicality and efficiency of pneumatic actuators in

generating substantial forces, supported by robust

flatness-based controllers. Future work could explore

alternative actuators and control strategies like the

Backstepping or the Sliding-Mode-Control for

further system enhancement.

REFERENCES

Daerden, F., and Lefeber, D. (2002). Pneumatic artificial

muscles: Actuators for robotics and automation.

European Journal of Mechanical and Environmental

Engineering, Vol. 47, No. 1, pages 11–22.

Deaconescu, T., and Deaconescu, A. (2016). Study

Concerning the Hysteresis of Pneumatic Muscles,

Applied Mechanics and Materials, Trans Tech

Publications, Switzerland. Vol. 841, pages 209-214.

Franklin, Powell, and Emami-Naeini. (2019). Feedback

Control of Dynamic Systems, Pearson. 8th edition.

Lévine, J. (2009). Analysis and Control of Nonlinear

Systems: A Flatness-based Approach, Springer.

Mirafzal, S. H. (2023). Nonlinear Control and State

Estimation for the Hand Axes of a Pneumatic Robot.

Master’s thesis at the Faculty of Mechanical

Engineering and Ship Technology, University of

Rostock.

Schindele, D., and Aschemann, H. (2013). Comparison of

Cascaded Backstepping Control Approaches with

Hysteresis Compensation for a Linear Axis with

Pneumatic Muscles. IFAC, Vol. 46, No. 23, pages 773-

778.

Vo, T. M., Kamers, Ramon, H., and Van Brussel, H. (2010).

Characterization of Hysteresis in a Pneumatic Muscle

Manipulator with Accounting for the Creep Effect,

IFAC, Vol. 43, No. 21, pages 296-302.

Welch, G., and Bishop, G. (2006). An Introduction to the

Kalman Filter. Department of Computer Science,

University of North Carolina at Chapel Hill.

Woernle, C. (2016). Mehrkörpersysteme. Eine Einführung

in die Kinematik und Dynamik von Systemen starrer

Körper, Springer-Vieweg. Wiesbaden. 2

nd

edition.

Xie, L., Yang, H., and Ding, F. (2011). Recursive least

squares parameter estimation for non-uniformly

sampled systems based on the data filtering.

Mathematical and Computer Modelling No. 54, pages

315–324.

Nonlinear Control and State Estimation for the Hand Axes of a Pneumatic Robot

247