Identification of Piezoelectric Actuator

Using Bayesian Approach and Neural Networks

Lenka Kukli

ˇ

sov

´

a Pavelkov

´

a

a

and Kv

ˇ

etoslav Belda

b

Department of Adaptive Systems,

The Czech Academy of Sciences, Institute of Information Theory and Automation,

Pod Vod

´

arenskou v

ˇ

e

ˇ

z

´

ı 4, CZ-182 00, Prague 8, Czech Republic

Keywords:

Piezoceramic Actuator, Hammerstein Model, Hysteresis, ARX Model, Bounded Noise, Bayesian Estimation,

Physical Modelling, Continuum Mechanics, Euler–Bernoulli Beam Theory.

Abstract:

The paper deals with a modelling and identification of a class of piezoelectric actuators intended for mecha-

tronic and bio-inspired robotic applications. Specifically, a commercial piezoelectric bender PL140 from

Physik Instrumente Co. is used. Considering catalogue/datasheet parameters, a physical model of PL140 is

derived using Euler-Bernoulli beam theory. This model serves as a substitution of reality to generate proper

data without potentially damaging the real actuator. However, due to its complex structure, this model cannot

be used for control design. For this purpose, a Hammerstein model is proposed. It consists of a static nonlin-

ear part describing the hysteresis and a dynamic linear part that is represented by the auto-regressive model

with exogenous input (ARX model). The nonlinear part of the Hammerstein model is identified by a neural

network. The Bayesian approach is used for the estimation of the ARX model parameters.

1 INTRODUCTION

Continuous progress in science and technology stim-

ulates the demand for novel materials and devices.

Piezoelectric actuators represent such a device. They

have great potential in various fields such as micro-

robotics, precision instruments or biomedicine (Gao

et al., 2024).

Piezoelectric actuator (PEA) uses electro-

mechanical coupling (inverse piezoelectric effect)

to convert input electrical energy into output force

or motion. Piezoelectric materials can be classified

into single crystals, piezoelectric ceramics (PZT) and

polymers. For a precision positioning, PZT is mostly

used (Zhou et al., 2024). However, the accuracy of

the generated motion is significantly impacted by the

intrinsic non-linearity of PEAs under dynamic work-

ing conditions. This non-linearity arises mainly from

hysteresis. Therefore, suitable modeling approaches

that are able to model this nonlinearity are required

to achieve higher motion accuracy (Kanchan et al.,

2023).

The mechanical behavior of materials can be mod-

elled by means of continuum mechanics. Never-

a

https://orcid.org/0000-0001-5290-2389

b

https://orcid.org/0000-0002-1299-7704

theless, the respective partial differential equations

are too complex to be solved analytically. There-

fore, a numerical technique called the finite element

method (FEM) is used to solve these equations for

complex systems in a computationally feasible man-

ner (Hughes, 2003). However, the obtained model is

still too complex for the control tasks. Thus, alterna-

tive models are used for nonlinear modeling of PZT

actuators. They incorporate a black-box modeling to-

gether with a physical understanding of the hysteretic

system (Ismail et al., 2009).

A hysteresis can by modelled either by using op-

erator superposition or by differential equations (Dai

et al., 2023). In the context of piezo actuators, the

Bouc-Wen (BW) model, which belongs to the second

group, is often used (Ismail et al., 2009).

However, the BW model only provides a static

description, so it is often supplemented with a dy-

namic linear part such as auto-regressive model with

exogenous input (ARX model). This combination of

static non-linear and dynamic linear parts corresponds

to the concept of Hammerstein’s model (Dai et al.,

2023).

Currently, the required control model is also of-

ten identified by artificial neural networks (ANNs)

(Uralde et al., 2023).

Kuklišová Pavelková, L. and Belda, K.

Identification of Piezoelectric Actuator Using Bayesian Approach and Neural Networks.

DOI: 10.5220/0013011700003822

In Proceedings of the 21st International Conference on Informatics in Control, Automation and Robotics (ICINCO 2024) - Volume 1, pages 591-599

ISBN: 978-989-758-717-7; ISSN: 2184-2809

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

591

Figure 1: PEA bender PL140.

L

a

b

z

y

x

Figure 2: Main dimensions of PEA bender PL140.

This paper aims to provide a nonlinear data-driven

model of the commercial piezoelectric bender PL140

of Physik Instrumente (PI) Co. The model is intended

for a subsequent use in the micro-position control

tasks. The proposed model will be based on a Ham-

merstein model.

Simultaneously, a physically based model is de-

veloped as a substitute of the real piezo bender.

It is meant to simulate data for the identification

of the above mentioned data-driven model with-

out the need for an actual piezoelectric actuator.

The paper is organized as follows. In Section 2,

a physical model of the piezoelectric bender PL140

is introduced. In Section 3, a relevant data-driven

model is presented and the estimation of its param-

eters is proposed. The simulation experiments using

both physical and data-driven models are described in

Section 4.

2 PHYSICAL MODEL

This section summarises physical model of the PEA

including the related theory. Namely the PICMA

Bender PL140 is considered, see Figure 1. The simu-

lation model is realized using MATLAB/Simulink en-

vironment and serves as a substitute for the real PEA.

2.1 Beam Theory for Piezo Bender

Physical bodies can be described using the gen-

eral theory of continuum mechanics (Bruno et al.,

2018). In the case of a prism-shaped piezo bender,

i.e. a beam, a simplification in the form of Euler-

Bernoulli beam theory can be used (Tadmor and

K

´

osa, 2003). This theory will be considered and ap-

plied to model construction in this section. The ob-

tained model is considered as a model substitut-

ing a real piezo ceramic beam. We consider that

used piezo bender actuator is built from a homo-

geneous isotropic linear elastic piezoceramic mate-

rial. Its stress σ is related to the strain ε by σ = E ε,

where E is the Young’s modulus. Then, general con-

stitutive equations (Bruno et al., 2018) considering

strains in space are as follows

σ = C ε− e

T

E

◦

(1)

d = e ε + ϵ E

◦

(2)

where E

◦

, C, ε, e, d and ϵ are the electric field,

compliance tensor, strain field, electric displacement

field, piezo stress coefficient tensor and permittivity

tensor at constant or zero strain, respectively. The re-

quired beam equations can be separated from (1) and

(2). Let us proceed from strain along axis x (simpli-

fying a general three-dimensional problem to a one-

dimensional one, ◦ → (x ∧ z), i.e. corresponding di-

rections):

ε → ε

xx

(x,z) = −z

dφ

y

dx

(x) (3)

E

◦

→ E

z

=

u

b

(4)

σ → σ

xx

(x,z) = −c

11

z

dφ

y

dx

(x) − e

31

u

b

(5)

where c

11

= E and E

z

is electric field perpendic-

ular to plane xy and u is input voltage between

surface electrodes of PEA. Then, bending moment

from the stress field is

M

y

(x) = −

¨

z σ

xx

(x,z) dS (6)

By performing a double integral in (6), the bending

moment is expressed as follows

M

y

(x) = E I

dφ

y

dx

(x) + abe

31

u (7)

where I =

1

12

ab

3

is the second moment of area

of the rectangular cross-section.

Let us continue by developing the equation

for electric displacement (2), again simplifying

to the relevant one-dimensional subspace, as:

d

z

(x,z) = e

31

ε

xx

(x,z) + ϵE

z

(8)

d

z

(x,z) = −e

31

z

dφ

y

dx

(x) + ϵ

u

b

(9)

dq =

"

d

z

dS = e

31

a b dφ

y

(10)

where dq is infinitesimal accumulated charge

at a bend characterized by a bend angle change.

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

592

Thus, the charge q for a specific bend can be ex-

pressed as follows

q = e

31

ab(φ

y

(x

k+1

) − φ

y

(x

k

)) (11)

Then, the resulting Euler-Bernoulli beam equations

for torque and charge are as follows

M

y

(x) = E I

dφ

y

dx

(x) + abe

31

u (12)

q = e

31

ab(φ

y

(x

k+1

)−φ

y

(x

k

))+

ϵaℓ

b

u (13)

The set of equations (7)-(13) leads to the state-space

finite-element form (16) of one element of the mod-

elled beam divided into n elements:

F

C

τ

C

F

R

τ

R

= K

z

C

φ

C

z

R

φ

R

(14)

¯

M 0

0 0

¨

x

0

+

K υ

piezo

−υ

T

piezo

δ

piezo

x

u

=

f

q

(15)

where

K =

E I

ℓ

3

12 6ℓ −12 6ℓ

6ℓ 4ℓ

2

−6ℓ

2

2ℓ

2

−12 −6ℓ 12 −6ℓ

6ℓ 2ℓ

2

−6ℓ 4ℓ

2

¯

M =

m

420

156 22ℓ 54 −13ℓ

22ℓ 4ℓ

2

13ℓ −3ℓ

2

54 13ℓ 156 −22ℓ

−13ℓ −12ℓ −22 ℓ 4 ℓ

2

υ

piezo

= [ 0 e

31

ab 0 − e

31

ab]

T

δ

piezo

=

ϵaℓ

b

with added dumping matrix B, the final form is

M

¨

x

0

+ B

˙

x

0

+

¯

K

x

u

=

f

q

(16)

where m = ρabℓ is the element mass with den-

sity ρ and ℓ as element length and L = nℓ total

beam length, a and b are cross-sectional parameters

– width and thickness respectively (see Figure 2),

x = [z

C

φ

C

z

R

φ

R

]

T

is generalized coordinate vector,

e

31

is a piezoelectric stress-charge coupling element

and ϵ is electrical permittivity.

The set (16) can be numerically solved in n-

element chain, where terms K, M, B (= zero matrix

but b

11

̸= 0), q and f = [F

C

τ

C

F

R

τ

R

]

T

are stiffness

matrix, mass matrix, stiffness finite element matrix,

damping matrix, accumulated charge trough PEA and

generalized force effects, respectively, with right di-

mensions (Benjeddou et al., 1997).

The relations between available datasheet

parameters and material parameters, which can

be equally used in the equations and MAT-

LAB/Simulink/Simscape blocks for Piezo Bender

simulation, are summarised as follows (Tadmor and

K

´

osa, 2003)

e

31

= −

2ℓF

block

3ab u

rated

(17)

E = −

4F

block

ℓ

3

y

free

ab

(18)

ϵ =

b

aℓ

C

piezo

+

4F

block

y

free

y

free

ab

3

(19)

where parameters on the right side of equations:

F

block

, a, b, u

rated

, y

free

and C

piezo

– blocking force,

dimensions, rated drive voltage and free deflection

at u

rated

, beam capacitance, respectively – can be

found in specific datasheet of PI Co.

The following section will focus on the modelling

based on Simulink block models that can consider

both the parameter types above.

2.2 Simscape Model

In the context of physical analysis above, to construct

a suitable simulation model representing a real beam,

MATLAB/Simulink with Simscape block libraries of-

fers a simple start (user-friendly pre-arranged alterna-

tive to programming the mathematical equations de-

fined in Section 2.1) for experimental research and

development, see Figure 3. This model has several

advantages such as structural clarity, fast implemen-

tation considering real physical parameters and con-

stants contained in data sheets of producers.

Identification of Piezoelectric Actuator Using Bayesian Approach and Neural Networks

593

Piezo Bender Actuator

f(x) = 0

Solver

Configuration

Electrical

Reference

Rotational

Free End

Piezo Bender

PS-Simulink

Converter z = z(t)

Translational

Free End

Mechanical

Rotational

Reference

Mechanical

Translational

Reference

Ideal

Translational

Motion Sensor

Mechanical

Translational

Reference1

PS-Simulink

Converter

v = v(t) = dz/dt

Voltage

Sensor

PS-Simulink

Converter u [V]

Controlled

Voltage

Source

Simulink-PS

Converter

Ideal

Rotational

Motion Sensor

Mechanical

Rotational

Reference1

PS-Simulink

Converter fi = fi(t)

PS-Simulink

Converter

omg = dfi/dt

Scope:

Piezo

Ideal

Force Sensor

PS-Simulink

Converter F = F(t)

Scope:

Force Fr

Ideal

Torque Sensor

PS-Simulink

Converter T = T(t)

Scope:

Torque Tr

XY Graph

Sine Wave

Uniform Random

Number

From

Workspace

Multiport

Switch

Random

Number

Relay

Constant

z

dz

voltage

dphi

phi

F

T

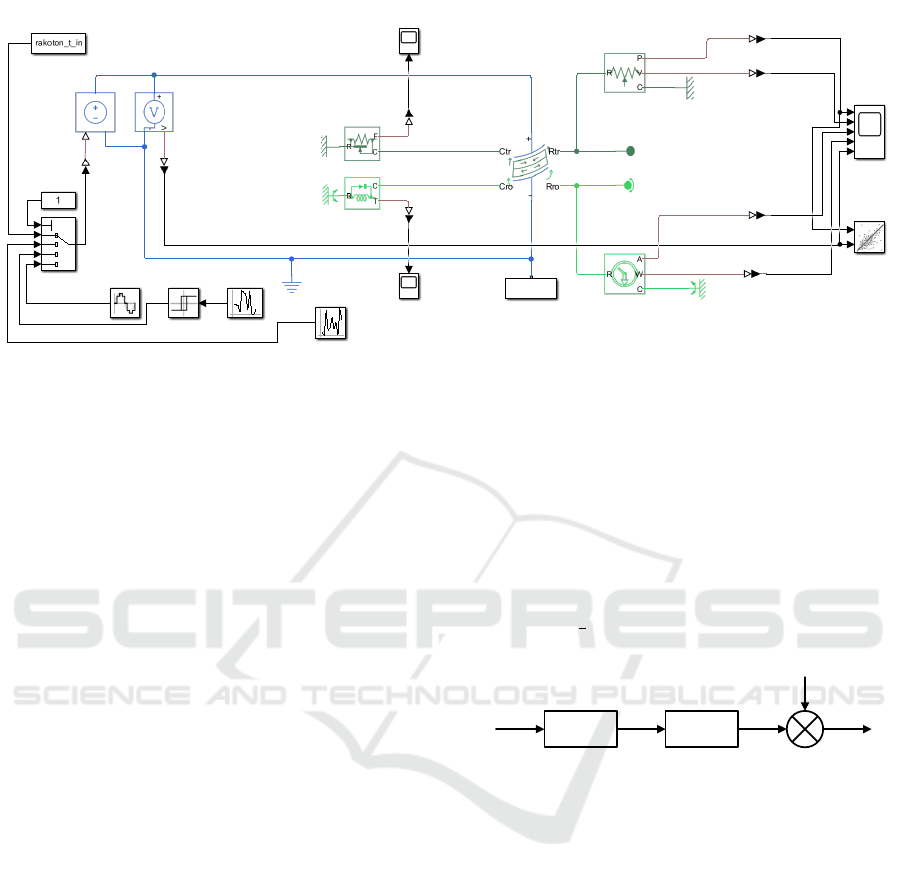

Figure 3: Simulink model comprising Simscape blocks.

The Simulink model can be described as fol-

lows. The main block is Piezo Bender block (Math-

Works, 2021). It represents piezoelectric bimorph

beam of rectangular cross-section that is connected

trough mechanical translational and rotational refer-

ence via ideal force and torque sensors to the ground

on one side and on other side leaved free via transla-

tional and rotational free ends. They are connected

with ideal translational and rotational motion sen-

sors. Input voltage of PEA is provided by controlled

voltage source.

The function of Piezo bender block is as follows:

it bends when an electrical potential is applied across

its layers. Conversely, when a piezo bender is bended,

it generates an electrical potential.

3 DATA DRIVEN MODEL

This section presents a data-driven model of the piezo

bender PL140 that is aimed to be used in microposi-

tion control tasks.

3.1 Hammerstein Model

The Hammerstein model describes a dynamics of

nonlinear systems by combining a static nonlinearity

followed by a linear dynamic model. In the context

of PEA, it concatenates various basic (static) hystere-

sis models with dynamic transfer functions, giving the

model better dynamic description ability (Dai et al.,

2023). Using the Hammerstein model for a descrip-

tion of a PZT actuator simplifies the analysis because

it separates the nonlinear hysteresis component from

the linear dynamic behavior. It is also easy to use in a

various control algorithms and simulation tools (Gao

et al., 2015).

A block diagram of the model is shown in Fig-

ure 4. The block NLS describes the rate-independent

(static) hysteresis nonlinearity and the block LD de-

scribes rate-dependent (dynamic) linear part charac-

teristic of the piezoelectric actuator. The involved sig-

nals u

t

, z

t

, ν

t

, and y

t

represents an input, hidden un-

measurable variable, noise, and output, respectively;

t∈ {1,2,·· · ,t} denotes a discrete time.

NLS LD

u

t

z

t

y

t

ν

t

+

+

y

t

~

Figure 4: Block diagram of Hammerstein model

Generally, there is a coupling between the lin-

ear part and the nonlinear part of Hammerstein

model. Nevertheless, under certain conditions, the lin-

ear part can be separated from the nonlinear one dur-

ing the identification.

The paper (Bai, 2004) proposes such an identifica-

tion algorithm. In the first step, the system is excited

by the pseudo-random binary sequences (PRBS) in-

put. Under this input, the nonlinearity will not appear

as it is not excited. Then, z

t

= u

t

and the linear part

LD can be identified independently of the non-linear

one.

On the other side, to identify the nonlinear part

NLS, the input has to be sufficiently rich. There-

fore, a new input–output data set {u

t

, y

t

} needs to

be generated. We consider that NLS is unknown but

static. Therefore, if u

t

and z

t

are available (see Fig-

ure 4), the structural information on the unknown

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

594

NLS can be derived from their graphical representa-

tion (Bai, 2004). We will estimate the unmeasurable

z

t

using the mentioned rich input–output data set and

already identified linear part LD.

3.2 Uniform ARX Model

The LD part of Hammerstein model (Figure 4) is of-

ten represented by an ARX model (Dai et al., 2023).

Here, we will consider the ARX model with an adi-

tive bounded noise, as it is suitable for real application

(d’Onofrio, 2013). Namely, we will consider a uni-

formly distributed noise. When considering a model

with uniform noise, we do not need to know the sta-

tistical properties of the noise, but only its bounds.

The ARX model with a uniform noise is defined

as follows

y

t

= ψ

T

t

θ + ν

t

, ν

t

∼ U

ν

(−r, r) (20)

where

y

t

is an observable output,

u

t

is an optional known input,

ψ

t

is a finite-dimensional regression vector,

ψ

t

= [y

t−1

,.. .,y

t−m

, u

t−1

,.. .,u

t−m

]

T

,

θ is a vector of unknown regression coefficients,

θ = [a

1

,.. .,a

m

,b

1

,.. .,b

m

]

T

, m is model order,

T denotes the transposition,

ν

t

is a uniformly distributed i.i.d. white noise, i.e.,

zero mean and uncorrelated with older observa-

tions,

U

ν

(−r, r) denotes a uniform distribution of ν; r > 0

is a noise range.

To estimate the regression coefficients of ARX

model (20), we use the Bayesian framework (K

´

arn

´

y

et al., 2006). There, a system of interest is described

by the following probability density functions (pdfs):

prior pdf f(Θ) ≡ f(Θ|d(0)),

observation model f(y

t

|u

t

,d(t − 1), Θ),

(21)

where Θ is an unknown parameters vector.

Bayesian parameter estimation consists in the re-

cursive evolution of the posterior pdf f(Θ|d(t)) that

starts from the prior pdf f(Θ):

f(Θ|d(t))∝ f(y

t

|u

t

,d(t−1),Θ)f(Θ|d(t−1)) (22)

where d(t) = [d

t

,d

t−1

,.. .,d

1

], t = 1,2,.. .,

t, is a se-

quence of observed data records, d

t

= (y

t

,u

t

), ∝

means the equality up the normalising constant. Note

that here is no formal distinction of a random variable,

its realization and pdf argument.

Considering the ARX model (20) in the role of

the observation model (21) with Θ comprising both

θ and r, then the use of (22) leads to the increasing

complexity of the support of f(Θ|d(t)) ≡ f(Θ|ψ

t

).

In (Pavelkov

´

a and K

´

arn

´

y, 2012), the approximate

estimation is proposed that recursively circumscribe

this complex support by a feasible set. The follow-

ing expected values of both the model parameters θ

and the noise bound r are provided:

ˆ

θ = ˆrv

−1

ψ

[I

n−1

,0]

u + l

2

− v

−1

ψ

v

y

, (23)

v =

v

ψ

v

y

0 1

ˆr =

ν + 1

ν

1 − γ

ν

1 − γ

ν+1

u

−1

n

, γ =

max(l

n

,0)

u

n

.

where ν corresponds to the number of processed data,

[I

n−1

,0] denote n − 1 rows of unit n matrix,

column vectors l, u and the square matrix v are the ap-

proximate statistics that define the approximate sup-

port

ˆ

S

t

of f(Θ|d(t)) as follows:

ˆ

S

t

= {Θ : Θ

n

> 0, l ≤ v Θ ≤ u}, (24)

Θ

n

= 1/r is the n-th entry of the vector Θ, Θ =

[−θ

T

Θ

n

, Θ

n

]. The matrix v has the upper triangu-

lar form with unit diagonal.

The update of

ˆ

S

t

includes extension of v by one

row corresponding to the vector Ψ

t

= [ψ

T

,y

t

] and ex-

tension of l by −1 and u by 1 followed by the orthog-

onal rotation that zeroes the last rows of l, v, u and

keep the triangular form of v (Pavelkov

´

a and K

´

arn

´

y,

2012).

Note that we do not need to know the noise range

r because it is estimated together with the model pa-

rameters.

3.3 Static Nonlinearity

To identify NLS, the static nonlinear part of the Ham-

merstein model, we need a data set of u

t

and z

t

, see

Figure 4. The inputs u

t

are available. The hidden

variables z

t

can be estimated using the inverse esti-

mated ARX model representing LD part and from the

known y

t

generated by the Simscape model, Figure 3.

Considering that LD is represented by the ARX

model (20), the inverse model with input y

t

and out-

put z

t

has the following form:

z

t

= ˆz

t

−

1

b

1

v

t+1

=

=

1

b

1

(y

t+1

− a

1

y

t

− · ·· − a

m

y

k−m+1

−

−b

2

z

t−1

− · ·· − b

m

z

t−m+1

) −

1

b

1

v

t+1

(25)

Identification of Piezoelectric Actuator Using Bayesian Approach and Neural Networks

595

where a

i

, b

i

, i = 1,2,.. .,m, corresponds to the pa-

rameters of the ARX model (20). Considering the

noise v

t+1

, z

t

is uniformly distributed on the support

[ˆz

t

− r/b

1

, ˆz

t

+ r/b

1

] with the mean ˆz

t

.

To identify the NLS block of Hammerstein model,

we use the generated inputs u

t

together with es-

timated means ˆz

t

of hidden variable z

t

(25). As

a mapping function, a neural network idNeuralNet-

work from MATLAB was chosen. This function

is designed to identify nonlinear ARX models and

Hammerstein-Wiener models and requires Statistics

and Machine Learning Toolbox or Deep Learning

Toolbox (MathWorks, 2023).

Mathematically, idNeuralNetwork is a function

that maps vector of regressors X

t

to a single scalar

output y

t

using the relationship

y

t

= S(X

T

t

Q) (26)

where X

t

= [ψ

T

1

,.. .,ψ

T

t

]

T

, Q is a projection ma-

trix, S(.) represents a neural network object. This

object is defined by the number of hidden layers in-

cluding number of nodes and activation function for

each layer.

3.4 Identification Procedure

Consider the Hammerstein model in Figure 4. Then,

the identification of data-driven model of PL140 is as

follows:

a) generate PRBS data using Simscape model de-

picted in Figure 3

b) estimate the parameters of the block LD

in Hammerstein model represented by the ARX

model (20) according to (23) using the generated

PRBS data

c) generate new rich data (with sin waveform, ran-

dom or (Rakotondrabe, 2021) inputs)

d) estimate the z

t

in Hammerstein model as the out-

put of inverse ARX model (25) where the gener-

ated outputs y

t

from c) serve as inputs

e) identify the NLS block in Hammerstein model as

described in Subsection 3.3 using input data u

t

from c) and output data ˆz

t

from d) together with

the mapping function (26)

f) generate new rich data set as described in c) to test

the identified Hammerstein model accuracy.

4 EXPERIMENTS

This section presents a performance of the proposed

identification scheme, Subsection 3.4, applied to the

piezoelectric bender PL140.

The real-like data are generated by the Simscape

model of piezoelectric bender PL140, see Figure

3. The following input sources corresponding the ap-

plied voltage are available:

PRBS - pseudorandom binary sequence with param-

eter C

P

, i.e. sequence of random numbers from

the set {−C

P

,C

P

}

RAND - data uniformly distributed within a given in-

terval [−C

R

,C

R

]

SINE - sine wave signal of tunable amplitude and fre-

quency

RAKO - input data from the Matlab example “Piezo-

electric Actuator Model Identification Using Ma-

chine Learning” (Rakotondrabe, 2021)

The experiments were performed in accordance

with the proposed identification scheme (Subsection

3.4) with the sampling frequency T

s

= 10

−3

s.

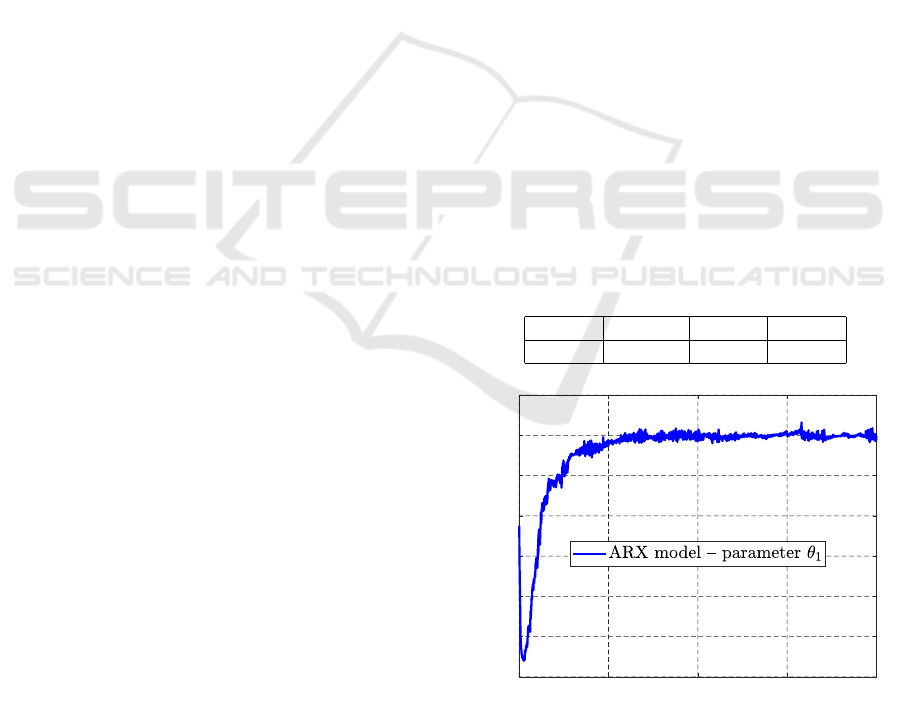

First, the PRBS data with C

P

= 1 were generated

and subsequently used to estimate the parameters of

the ARX model (20). The time course of the regres-

sion coefficients estimates are depicted in Figures 5

– 8. It can be seen that although the estimates con-

verge to a particular values, they do not stabilize and

oscillate around these values.

For further use, we set the point parameter esti-

mates as the mean values from the steady-state part

of the relevant time courses. The estimates are shown

in the Table 1.

Table 1: Point estimates of the ARX model (20).

a

1

a

2

b

1

b

2

1.1980 -0.9719 0.0042 0.0021

0 1000 2000 3000 4000

0

0.2

0.4

0.6

0.

8

1

1.2

1.

4

Figure 5: Time course (in 10

−3

s) of the parameter estimate

θ

1

= a

1

in ARX model (20).

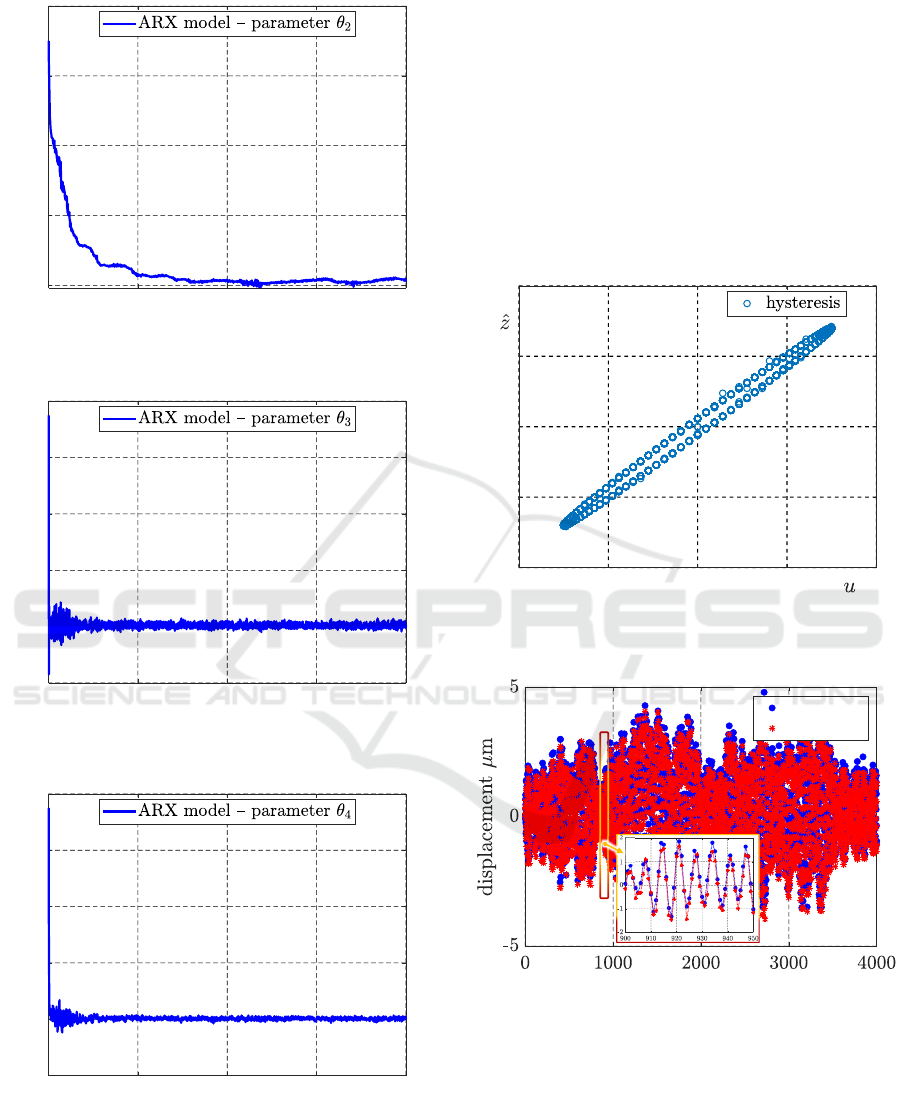

Then, the new input-output data with SINE input

was generated to be used for estimating the hidden

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

596

0 1000 2000 3000 4000

-1

-0.5

0

0.5

1

Figure 6: Time course (in 10

−3

s) of the parameter estimate

θ

2

= a

2

in ARX model (20).

0 1000 2000 3000 4000

-0.2

0

0.2

0.4

0.6

0.

8

Figure 7: Time course (in 10

−3

s) of the parameter estimate

θ

3

= b

3

in ARX model (20).

0 1000 2000 3000 4000

-0.2

0

0.2

0.4

0.6

0.

8

Figure 8: Time course (in 10

−3

s) of the parameter estimate

θ

4

= b

4

in ARX model (20).

variable z

t

and the subsequent identification of the

nonlinear part NLS represented by (26). In the exper-

iment, we have used neural network with three hid-

den layers and the hyperbolic tangent activation func-

tion. Model parameters were obtained using the Mat-

lab function nlarx. The estimated hysteresis curve,

i.e. relationship between the applied input voltage

u and the mean of the hidden variable ˆz is depicted

in Figure 9.

To test the performance of identified Hammerstein

model, we generated another rich input-output data

sets with RAND inputs and used them for the predic-

tion task. A sample example of the simulated outputs

and their predictions is shown in Figure 10.

-40 -20 0 20 40

-100

-50

0

50

100

Figure 9: NLS part of Hammerstein model – identified hys-

teresis between u and ˆz.

simulated

predicted

Figure 10: Time course (in 10

−3

s) of predicted (red) and

simulated (blue) outputs with a zoomed part for the Ham-

merstein model excited by random inputs.

5 CONCLUSION

This paper deals with the construction of a physical

model of the commercial piezoelectric bender PL140

as well as with the identification of the correspond-

ing data-driven model. Nevertheless, the presented re-

sults can be easily adapted to other beam PZT actua-

Identification of Piezoelectric Actuator Using Bayesian Approach and Neural Networks

597

tors. The explanation of these models provides inter-

ested readers with the necessary background to carry

out their own experiments.

The Simscape model is based on a physical anal-

ysis and it is intended as a substitute for the real

piezoelectric actuator. It serves as an experimental

data source. It has the advantage that various experi-

ments can be performed without expensive measuring

equipment and without the risk of damaging the real

actuator.

The identified data-driven model is intended for

a subsequent model-based micro-positioning control

design. This control design will be tuned on the de-

veloped Simulink model and then verified on a real

bender PL140.

The used identification scheme, i.e. Hammerstein

model, with an independent estimation of the linear

dynamic and the nonlinear static parts, offers freedom

in the choice of both the linear model and a function

representing the nonlinear static part.

Our choice of uniform ARX model was motivated

by the facts that models with a bounded noise are suit-

able for a real applications, and that the estimation al-

gorithm is simple and not time-consuming. Moreover,

we do not need to know the noise bound r, because it

is estimated together with the model parameters.

A function representing the nonlinear static part

was conveniently identified by the means of a neural

network MATLAB toolbox.

The proposed model offers a good prediction re-

sults with isolated outliers. The achieved result could

be further improved by tuning the network param-

eters. Another increase in model accuracy can be

achieved by a creep modelling. After hysteresis, the

creep is another factor responsible for nonlinearity in

the piezoelectric actuator. It is a time-dependent ef-

fect that causes a slow drift of the output displacement

when the input voltage changes suddenly (Kanchan

et al., 2023).

Future research will focus on incorporating

the proposed data-driven model into a model predic-

tive control task and on a testing the developed algo-

rithms on a real piezo actuator.

ACKNOWLEDGEMENTS

This work was supported by The Czech Academy

of Sciences, Institute of Information Theory

and Automation under the project No. 23-04676J

of the Czech Science Foundation: Controllable

Gripping Mechanics: Modelling, Control and

Experiments.

REFERENCES

Bai, E.-W. (2004). Decoupling the linear and nonlinear

parts in Hammerstein model identification. Automat-

ica, 40(4):671–676.

Benjeddou, A., Trindade, M. A., and Ohayon, R. (1997).

A unified beam finite element model for extension

and shear piezoelectric actuation mechanisms. Jour-

nal of Intelligent Material Systems and Structures,

8(12):1012–1025.

Bruno, B. P., Fahmy, A. R., St

¨

urmer, M., Wallrabe, U.,

and Wapler, M. C. (2018). Properties of piezoceramic

materials in high electric field actuator applications.

Smart Materials and Structures, 28(1):015029.

Dai, Y., Li, D., and Wang, D. (2023). Review on the non-

linear modeling of hysteresis in piezoelectric ceramic

actuators. Actuators, 12(12).

d’Onofrio, A. (2013). Bounded Noises in Physics, Biology,

and Engineering. Springer.

Gao, T., Liao, Q., Si, W., Chu, Y., Dong, H., Li, Y., Liao,

Y., and Qin, L. (2024). From fundamentals to future

challenges for flexible piezoelectric actuators. Cell

Reports Physical Science, 5(2):101789.

Gao, X., Ren, X., Zhu, C., and Zhang, C. (2015). Iden-

tification and control for Hammerstein systems with

hysteresis non-linearity. IET Control Theory & Appli-

cations, 9(13):1935–1947.

Hughes, T. J. (2003). The finite element method: linear

static and dynamic finite element analysis. Courier

Corporation.

Ismail, M., Ikhouane, F., and Rodellar, J. (2009). The hys-

teresis Bouc-Wen model, a survey. Archives of com-

putational methods in engineering, 16:161–188.

Kanchan, M., Santhya, M., Bhat, R., and Naik, N. (2023).

Application of modeling and control approaches of

piezoelectric actuators: A review. Technologies,

11(6):155.

K

´

arn

´

y, M., B

¨

ohm, J., Guy, T. V., Jirsa, L., Nagy, I., Ne-

doma, P., and Tesa

ˇ

r, L. (2006). Optimized Bayesian

Dynamic Advising: Theory and Algorithms. Springer,

London.

MathWorks (2021). Piezo bender. www.mathworks.com/

help/sps/ref/piezobender.html. Accessed: 2024-06-

30.

MathWorks (2023). Available mapping functions for non-

linear ARX models. www.mathworks.com/help/ident/

ref/idneuralnetwork.html. Accessed: 2024-06-30.

Pavelkov

´

a, L. and K

´

arn

´

y, M. (2012). Approxi-

mate Bayesian recursive estimation of linear model

with uniform noise. IFAC Proceedings Volumes,

45(16):1803–1807.

Rakotondrabe, M. (2021). Piezoelectric actuator

model identification using machine learning.

www.mathworks.com/help/ident/ug/machine-

learning-based-identification-of- piezoelectric-

actuator.html. Accessed: 2024-02-08.

Tadmor, E. B. and K

´

osa, G. (2003). Electromechanical cou-

pling correction for piezoelectric layered beams. Jour-

nal of Microelectromechanical Systems, 12(6):899–

906.

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

598

Uralde, J., Artetxe, E., Barambones, O., Calvo, I.,

Fernandez-Bustamante, P., and Martin, I. (2023). Ul-

traprecise controller for piezoelectric actuators based

on deep learning and model predictive control. Sen-

sors, 23(3).

Zhou, X., Wu, S., Wang, X., Wang, Z., Zhu, Q., Sun, J.,

Huang, P., Wang, X., Huang, W., and Lu, Q. (2024).

Review on piezoelectric actuators: materials, classifi-

cations, applications, and recent trends. Frontiers of

Mech. Engin., 19(1):6.

Identification of Piezoelectric Actuator Using Bayesian Approach and Neural Networks

599