Towards a Modular Human-Robot Safety Control System Using Petri

Nets

Philipp Kranz

a

, Fabian Schirmer

b

, Marian Daun

c

and Tobias Kaupp

d

Center for Robotics (CERI), Technical University of Applied Sciences W

¨

urzburg-Schweinfurt, Schweinfurt, Germany

Keywords:

Human-Robot Collaboration, Safety, Modularity, Petri Nets.

Abstract:

In industrial human-robot collaboration, where humans and robots operate in a shared workspace, the

paramount concern is the safety of the human operator. The prevailing safety practices evaluate safety based

on the overall assembly sequence, with the most critical task within the sequence being the limiting factor for

all other tasks. This approach often results in significant limitations and the potential exclusion of collabora-

tive interaction. However, the integration of human and robotic capabilities can facilitate the automation of

processes, enhancing overall flexibility. The modular safety control system presented in this work employs

a decentralized approach using Petri nets to evaluate the safety of humans and robots on a task-basis. This

enables bridging the gap between the current, static regulatory framework and the necessary adaptivity of

modern production systems.

1 INTRODUCTION

The concept of human-robot collaboration (HRC)

represents a production paradigm that is designed

to enhance flexibility within the context of Indus-

try 4.0 production landscapes (Kr

¨

uger et al., 2009).

However, the increased flexibility that HRC affords

also gives rise to an elevated risk of safety incidents.

In the case of conventional robot applications, the

workspaces between humans and robots are separated

by safety fences, which effectively eliminate the ma-

jority of safety risks. In contrast, the safety assess-

ment process assumes a pivotal role in HRC, as hu-

mans and robots have to solve assembly tasks together

and interact in the same workspace simultaneously

(Manjunath et al., 2024).

Safety assessment is a critical issue and an ongo-

ing research challenge in HRC (Arents et al., 2021).

The objective of safety assessment is to eliminate the

majority of potential risks at design time. While this

approach works for traditional robot and automation

solutions, it significantly constrains the dynamic as-

pects of human-robot collaboration, impeding the ac-

ceptance of such applications. HRC should therefore

a

https://orcid.org/0000-0002-1057-4273

b

https://orcid.org/0000-0002-7032-8242

c

https://orcid.org/0000-0002-9156-9731

d

https://orcid.org/0000-0003-3017-5816

use passive measures wherever possible, but these

should be complemented by active measures backed

up by an intelligent monitoring strategy.

This is particularly important as most accidents in

HRC occur during process and maintenance opera-

tions (Lee et al., 2021). The causes of these accidents

are often malfunctions, untrained operators, improper

methods, or operator fatigue. However, what is not

considered in many safety assessment approaches is

a system-wide view resulting from the interaction be-

tween human and robot (Berx et al., 2022). Human-

robot interaction is therefore both a driver of the flex-

ibility of HRC, but also introduces new risks that are

difficult to detect with current safety control systems.

Robot safety standards provide limited support for the

implementation of such flexible automation solutions

and do not take human factors and the trade-off be-

tween various industrial requirements and safety into

account (Hanna et al., 2022).

This work presents a model-based approach that

serves as a foundation for the development of a mod-

ular safety control system for HRC assembly. The

system uses a fully decentralized adaptive control

scheme in which independent sub-systems (human

and robot) coordinate with each other. The control

scheme is based on the four MAPE activities: Mon-

itor (M), Analyze (A), Plan (P), and Execute (E).

(Weyns et al., 2013). To this end, this work constructs

a state-space model in the form of Petri nets, which is

384

Kranz, P., Schirmer, F., Daun, M. and Kaupp, T.

Towards a Modular Human-Robot Safety Control System Using Petri Nets.

DOI: 10.5220/0013011900003822

In Proceedings of the 21st International Conference on Informatics in Control, Automation and Robotics (ICINCO 2024) - Volume 1, pages 384-391

ISBN: 978-989-758-717-7; ISSN: 2184-2809

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

capable of evaluating the status of the human and the

robot on an assembly task level and calculating the

current hazard potential in the form of a Safety Risk

Indicator (SRI).

The paper is structured as follows: Section 2 re-

views the literature on HRC risk management and

model-based approaches, including the use of Petri

nets. Section 3 explains the proposed modular safety

control system and how to calculate a Safety Risk In-

dicator. Section 4 details the Petri Net models for

human, robot, and safety control systems. Section 5

evaluates the approach in an industrial use case, and

Section 6 concludes with a discussion, a summary,

and future research directions.

2 RELATED WORK

This section summarizes the research underlying this

work. It first reviews current safety regulations for

HRC and highlights their limitations. Next, the bene-

fits of a modular design for safety control systems are

presented, followed by the use of Petri nets for mod-

eling and their applications in HRC.

2.1 Safety Standards and Regulations

for HRC

Under the European Union’s legal framework, man-

ufacturers, integrators, and end users must ensure

robotic systems comply with the Machinery Direc-

tive’s health and safety requirements. Compliance can

be achieved by adhering to the directive or harmo-

nized standards like ISO 10218 and ISO/TS 15066.

While these standards are not legally binding, a

mandatory risk assessment must identify hazards, es-

timate severity, analyze risks, monitor continuously,

and implement risk mitigation measures (Hanna et al.,

2022). Unlike the automotive sector, which follows

ISO 26262 for safety analysis, no definitive proce-

dures exist for robotics. Techniques such as Fault

Tree Analysis (FTA) and Failure Mode and Effects

Analysis (FMEA) are common but often oversimplify

system behavior, leading to unreliable reliability as-

sessments. There exists a notable gap between the ex-

isting static safety regulations and procedures and the

necessary adaptability required by modern production

systems (Hanna et al., 2022).

2.2 Modular Safety Control in HRC

The modular design of assembly systems allows for

greater flexibility and versatility in their utilization

(Siegert et al., 2021). However, the introduction of

a new or modified application to such a system ren-

ders it a novel and potentially hazardous system from

a safety perspective, necessitating a reassessment of

the associated risks. A modular design of a safety

control system would be advantageous for HRC, as it

would allow for compensation in the event of devia-

tions in the interaction between humans and robots,

as well as enabling a more flexible response to dan-

gerous situations. In their study, (Hillen et al., 2022)

present an initial approach to addressing the discrep-

ancy between the current static safety regulations and

the requisite flexibility of modern production systems.

The modular safety approach allows for comprehen-

sive coverage of the design, development and run-

time phases of risk assessment. In the runtime phase,

a multitude of safety-related variables, including the

present configuration and parameters of the systems,

can be evaluated automatically.

2.3 Petri Nets for Safety Modeling

A Petri net (PN) is a formal model used to describe

and analyze information flow and control systems,

particularly for asynchronous and concurrent activ-

ities (Peterson, 1977). PNs have a long history in

safety control, with Leveson and Stolzy using time

PNs to model failures in safety-critical real-time soft-

ware systems, focusing on fault tolerance and risk

mitigation (Leveson and Stolzy, 1987). Recently, PNs

have gained traction for safety, reliability, and risk as-

sessment due to their formal, graphical, and mathe-

matical nature, which enables realistic modeling of

dynamic behaviors (Kabir and Papadopoulos, 2019).

However, PNs can face state space explosion issues,

limiting their use in large systems. Modularization

has been proposed as a solution (Yevkin, 2011; Chi-

acchio et al., 2013). Given the complexity of human-

robot collaboration (HRC) in assembly tasks, this

work adopts a modular approach to enhance the scal-

ability of the PNs used.

2.4 Petri Nets in HRC

Chao and Thomaz utilize time PNs to create a sys-

tematic model for reciprocal human-robot turn-taking

(Chao and Thomaz, 2016). Their modular ap-

proach maps various resources and social actions, like

speech, gaze, and gestures, enabling the robot to per-

form pick-and-place tasks while adapting to the hu-

man operator. This results in quicker reactions and

improved task completion compared to simpler state-

based methods. Similarly, Casalino et al. use time

PNs to enhance scheduling in collaborative assembly

Towards a Modular Human-Robot Safety Control System Using Petri Nets

385

(Casalino et al., 2019). Their model allows for adap-

tive adjustments based on runtime data, responding

to variations in human task durations and optimizing

assembly activities. The principles of modularity and

adaptivity can also inform the development of a safety

control system for HRC. This work builds on the PNs

in (Casalino et al., 2019), extending their approach to

include a safety control loop.

3 MODULAR HRC SAFETY

CONTROL SYSTEM

This section presents a modular safety control sys-

tem for HRC. Firstly, the overall architecture based

on MAPE principles is explained. The most common

hazards for HRC assembly are then classified, and

a SRI is calculated as a safety metric for task-based

safety assessment.

3.1 Overall Architecture

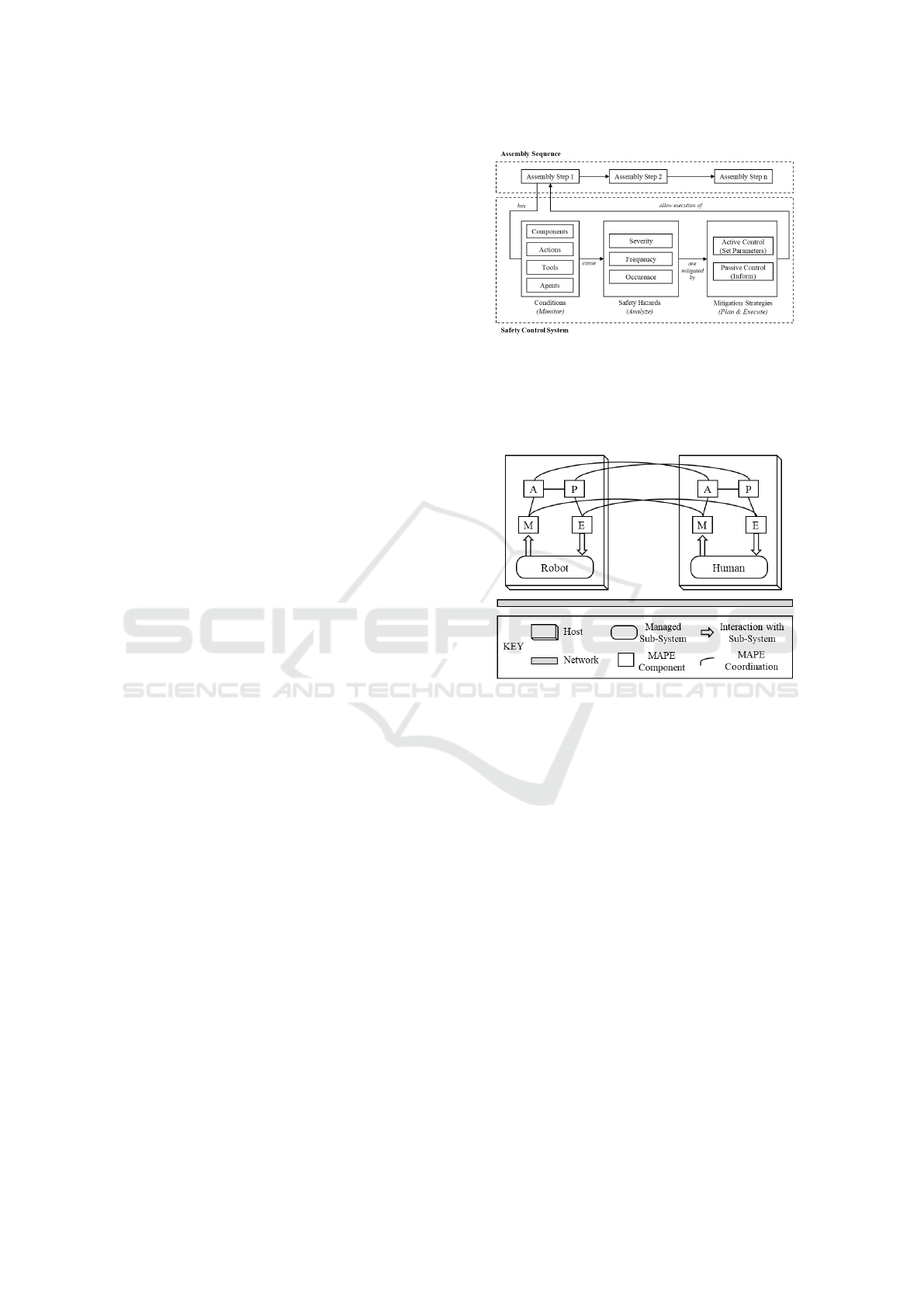

The system architecture overview is depicted in Fig-

ure 1. In human-robot interaction during assembly,

each step (1 to n) involves specific conditions related

to components, actions, tools, and agents. These con-

ditions, alongside environmental factors, can lead to

safety hazards (accidents or losses) (Leveson, 2016).

Hazards are categorized by severity, frequency, and

likelihood of occurrence. To mitigate risks, we can

use active controls that adjust system parameters or

passive controls that raise awareness of potential haz-

ards. Our safety control system employs a MAPE

(Monitor, Analyze, Plan, and Execute) loop to contin-

uously monitor conditions, analyze safety risks, and

implement mitigation strategies, ensuring customized

safety precautions for each assembly step (De Lemos

et al., 2013).

To enhance modularity, we implemented a decen-

tralized safety control system based on the MAPE

loop, as shown in Figure 2. In this fully decentral-

ized approach, each host operates its own MAPE loop

(De Lemos et al., 2013). The local M, A, P, and E

components coordinate with corresponding peer com-

ponents from other hosts, facilitating flexible infor-

mation exchange on system status and analysis re-

sults. The local P components manage adjustment

actions that activate their local E components to ex-

ecute actions on the sub-systems. In HRC assembly,

these sub-systems correspond to the agents involved,

which include both the human and the robot.

Figure 1: Overview of the proposed system with the two

main components, the assembly sequence and the safety

control system. Each assembly step is associated with spe-

cific conditions that give rise to different safety hazards.

These hazards are analyzed to apply appropriate mitigation

strategies, which legitimize execution of the assembly step.

Figure 2: Decentralized pattern of a collaborative

workspace, consisting of two sub-systems, the human and

the robot, adapted from (De Lemos et al., 2013). The

MAPE components of the human sub-system communi-

cate with the MAPE components of the robot sub-system,

making the overall system modular and adaptable to future

changes.

3.2 Hazard Sources in HRC Assembly

In order to conduct a safety assessment for Human-

Robot Collaboration (HRC), it is essential to identify

potential risk factors. Most accidents in HRC occur

during the execution of tasks (Lee et al., 2021). Each

task involves components, actions, tools, and agents,

all of which contribute to safety hazards. In adverse

scenarios, a combination of these elements and envi-

ronmental conditions may lead to safety risks (Leve-

son, 2016). Therefore, hazards are attributed to these

conditions, forming the basis for calculating a risk in-

dicator for specific tasks. This study focuses on task-

specific safety hazards, assuming that the robot and

workspace are inherently safe.

In assembly, components are the individual parts

that are combined, while sub-assemblies consist of at

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

386

least two components. The final product represents

the highest level, incorporating both sub-assemblies

and components. Handling components, especially

by robots, can create various hazards, such as sharp

edges posing risks to workers and difficult-to-grip

geometries that increase the likelihood of dropping

heavy components. An ordinal rating system catego-

rizes components as low, medium, or high risk based

on their characteristics.

Actions are operations necessary for assembling

components into sub-assemblies or final products,

performed by either robots or humans. This study fo-

cuses on the following actions: 1) Pick: the robot or

human grasps a component, 2) Place: the robot or

human moves and releases a component at a specific

point, 3) Join: the robot or human connects compo-

nents or sub-assemblies with the required force, 4)

Hold: the robot or human fixes a component in po-

sition, often with the robot acting as a third hand in

collaborative tasks, and 5) Screw: the robot or human

drives a screw using a screwdriver, with the appropri-

ate tool.

Tools are objects required for specific actions,

used by either humans (e.g., screwdrivers, hammers)

or robots (as end-effectors or gripped tools). How-

ever, tools can also introduce safety risks, influenced

by their geometry (e.g., piercing by a screwdriver bit)

or function (e.g., crushing or entanglement).

Agents in HRC include humans, robots, or both,

and the interaction modes depend on the task. For

tasks performed exclusively by humans or robots,

only their respective risk indicators are considered.

In collaborative tasks, the interactions must be eval-

uated, as safety risks can escalate with certain in-

teraction types. This work recognizes five interac-

tion modalities as proposed by (Bauer et al., 2016):

1) Human-Robot Cell: Humans and robots work in

separate areas, with the robot fenced off, preventing

contact, 2) Human-Robot Coexistence: Humans and

robots work in separate areas without a safety fence,

with no direct contact, 3) Human-Robot Synchro-

nized: Humans and robots share a workspace, work-

ing on the same component but at different times, 4)

Human-Robot Cooperation: They work on different

components in the same space simultaneously, with

possible but unnecessary contact, and 5) Human-

Robot Collaboration: Both work on the same com-

ponent in the same space at the same time, with nec-

essary contact.

3.3 Safety Metrics in HRC

In human-robot collaboration, safety hazards are usu-

ally assessed at design time, not at runtime, as it

is proposed in this work. One of the most com-

monly used metrics for design time safety assessment,

the risk priority number, is typically used to assess

hazards, prioritize them and identify the most criti-

cal ones so that targeted mitigation strategies can be

found (Afefy, 2015). The risk priority number is made

up of the severity of a hazard, its occurrence prob-

ability and its detectability. As it is not possible to

objectively measure detectability at runtime, the met-

ric is adjusted accordingly and the frequency at which

the actor is exposed to a hazard is used instead. The

three components of our Safety Risk Indicator (SRI)

are then defined as follows: 1) Severity (S): The po-

tential impact or seriousness of a failure on the system

is evaluated. Higher severity means more significant

consequences, 2) Frequency (F): This measure the

number of exposures to a situation where a potential

hazard can occur, and 3) Occurrence (O): This as-

sesses how likely it is for a particular failure to hap-

pen. A higher occurrence rate indicates that the fail-

ure is more common.

The defined conditions of an assembly task af-

fect the SRI variables: Components and tools impact

severity, the number of actions affects frequency, and

the agents and their interaction modalities influence

occurrence. All variables are scaled as low, medium,

or high and weighted as follows: severity (S) [3], oc-

currence (O) [2], and frequency (F) [1]. The SRI is

calculated as: SRI = 3 x S + 2 x O + 1 x F

4 HRC SAFETY CONTROL

MODEL

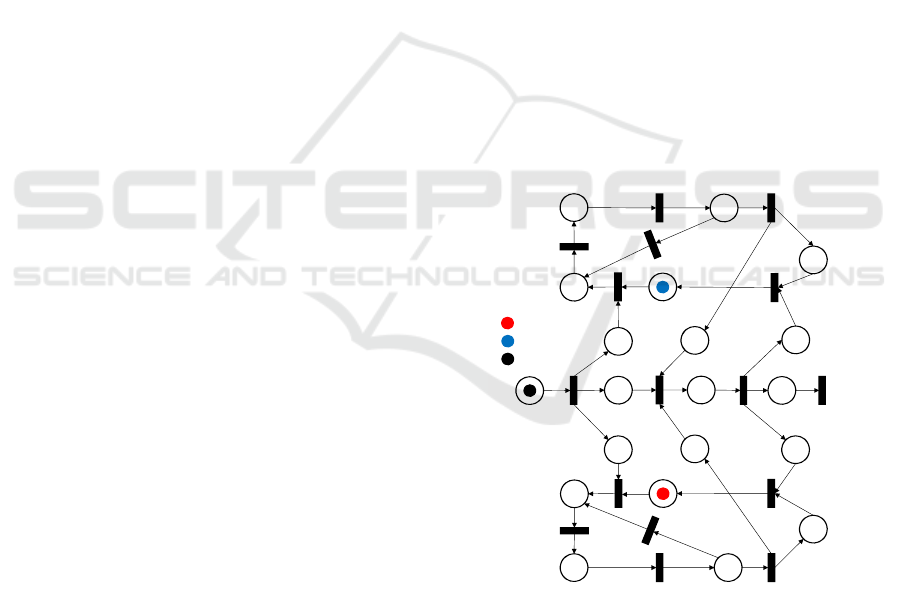

The modular HRC safety control system is modeled

using PNs. The MAPE loops of the human and robot

are integrated into a PN to model the control of a hu-

man, a robot and a human-robot task (Figure 3). The

PN models in this paper are based on the work of

(Casalino et al., 2019).

4.1 Model of a Robot Control System

To control a robot task, only the upper two compo-

nents of the PN are used: the assembly task and the

robot control loop. The robot status is represented

by a blue token linked to the assigned task. Before

starting the robot task, a condition check is initiated,

providing all relevant information (components, tools,

etc.). When T0 (Figure 3) is triggered, the safety con-

trol process begins.

The token first moves to ”Check Environment,”

where current parameters of the robot and its environ-

ment are assessed. Using these values, an SRI value

Towards a Modular Human-Robot Safety Control System Using Petri Nets

387

is calculated to establish a task-specific safety metric,

as detailed in Section 3.3. Robot parameters are then

adjusted to meet the SRI safety requirements. If the

requirements are satisfied, T8 fires and the robot pro-

ceeds to the assembly step and returns to ”Wait/Idle”

afterward. If not, T7 fires and the token moves to

”Check Environment,” and the safety control loop re-

evaluates the conditions for potential task execution.

The robot token consists of both unchangeable

and changeable values. Unchangeable values include

the robot type and the end-effector or tool, which

may vary depending on configuration or if a gripper

change system is used. Changeable values involve

current robot parameters (speed and force) and task-

specific conditions, such as 1) components to be han-

dled for the assembly step, 2) required actions, and

3) the interaction modality with the human operator.

These variable values can be modified throughout the

safety control cycle. Initially, task-specific conditions

are recorded during the monitoring phase, followed

by SRI calculation and adjustments to robot parame-

ters. Thus, the value composition for the robot’s place

type includes:

Robot = Type × CurrentSpeed × CurrentForce ×

Components × Actions × Tools × Interaction × SRI

4.2 Model of a Human Control System

The safety control system for the human operates sim-

ilarly to that of the robot (Figure 3, lower part). After

T0 is fired, the control loop starts, and the red human

status token moves to ”Check Environment.” Depth

cameras assess the human’s availability and position

at the collaborative workplace, while specific assem-

bly step information is gathered. An SRI value for the

human operator is calculated, mirroring the robot’s

process.

Due to the non-deterministic nature of human be-

havior, we can only passively control the human by

informing them of the calculated SRI and associated

risks. If T12 is satisfied, the task execution is con-

firmed, and the human receives assembly instructions.

The token then moves to ”Human Task” during exe-

cution and returns to ”Wait/Idle” afterward. If T14 is

fired, the token moves to ”Check Environment”, and

the safety control loop is re-triggered.

The human token consists of both changeable

and immutable values. Immutable values include the

employee ID, job description, and relevant training,

which help identify whether the individual is a trained

assembly or maintenance operator or a non-specialist,

the latter posing a higher safety risk. Like robots, hu-

man operators are assigned appropriate working con-

ditions based on the task. However, the tool used is

a variable value, while other conditions align with the

robot’s task-specific parameters. Since humans lack

directly adjustable parameters, only passive mitiga-

tion strategies can be employed. Thus, the value com-

position for the human’s place type includes:

Human = EmployeID × Jobtitle × Trainings ×

Components × Actions × Tools × Interaction × SRI

4.3 Model of a Human-Robot Control

System

In collaborative assembly situations, both, human and

robot execute an assembly step together (Figure 3).

For this purpose, both safety control systems work in

parallel. When T0 fires, both systems are triggered

and start their respective control loops, like they do

when the safety for a pure robot or a pure human step

is checked. As intended for the decentralized system

and as described in Section 3.1, the corresponding

MAPE components of the human and the robot con-

trol system are in close interaction to cover the over-

all safety hazards regarding the shared assembly step.

Transition T1 to start the actual Human-Robot Task

can only be fired, if both, the robot parameters are

met and the residual risk for the human is tolerable.

P1 (Check Task

Conditions)

P2 (Robot/Human

Task)

P9 (Confirm

Execution

/Execute)

P6 (Check

Environment

/Monitor)

P7

(Calculate

SRI

/Analyze)

P8 (Set Robot

Parameters/

Plan)

T8 robot.SRI <=

robot.parameter

P4 (Wait/Idle)

T7 (robot.SRI >

robot.parameter)

Robot

P0 (Start Task)

P3 (End Task)

Task

P5 (Aux 1

Robot)

P16 (Confirm

Execution

/Execute)

P13 (Check

Environment

/Monitor)

P14 (Calculate

SRI

/Analyze)

P15 (Inform Human

about Risks /Plan)

T12 (human.SRI <=

Human.risk)

P17 (Wait/Idle)

T14 (human.SRI >

Human.risk)

P12 (Aux 1

Human)

Human

P11 (Aux 3

Robot)

P10 (Aux 2

Robot)

P18 (Aux 2

Human)

P19 (Aux 3

Human)

T0

T1 T2

T3

T4

T5

T6

T9

T10

T11

T13

T15

Figure 3: Petri net for the control structure of a human-

robot task. Top: Robot safety control loop. Middle: HRC

assembly step. Bottom: Human safety control loop.

In the human-robot tasks, the token values associ-

ated with both the robot and the human are integrated

to compute the SRI. The aforementioned values com-

prise the employee ID, job title and trainings for the

human, and the type, current speed and current force

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

388

Figure 4: Exploded view of the product consisting of a

base (cabin, load carrier, and chassis), a front axle, a rear

axle, and four sub-assembly 1 (axle holder and two screws)

(Schirmer et al., 2024).

for the robot. Task-specific values, including the com-

ponents, actions and tools, are combined for both ac-

tors, thereby creating a new interaction modality. The

calculated SRI is then applied to the human and the

robot. In conclusion, the value composition for the

place type of human-robot task is as follows:

Human-Robot = Type × CurrentSpeed ×

CurrentForce× EmployeID × Jobtitle × Trainings ×

Components × Actions × Tools × Interaction × SRI

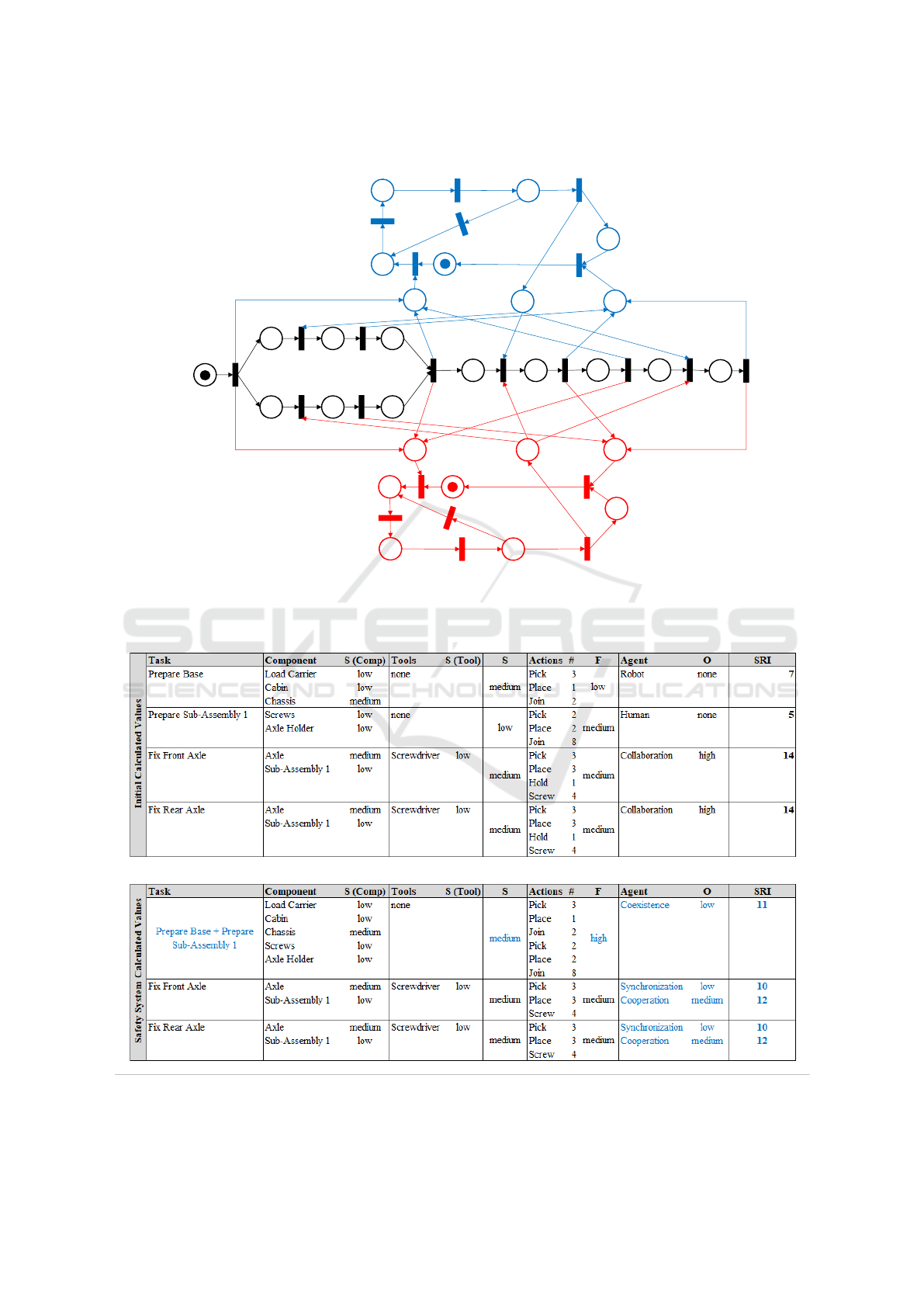

5 APPLICATION

The safety control system, as previously created, is

now applied to an industrial use case: the collabo-

rative assembly of a toy pick-up truck. This paper

demonstrates how the interaction between the MAPE

components of the robot and human affect the SRI

score, and how this can be manipulated by adjusting

the human and robot parameters.

5.1 Experimental Setup

The collaborative assembly of a toy pick-up truck,

shown in Figure 4, is employed as a case study

(Schirmer et al., 2024). The assembly sequence com-

prises tasks that are performed exclusively by hu-

mans, exclusively by the robot, or by an interaction

of the two actors.

In the initial assembly phase, the robot prepares

the truck base, consisting of the load carrier, cabin,

and chassis, by positioning them upside-down in an

assembly bracket. The human operator prepares sub-

assembly 1 by inserting two screws into each axle

holder. They then collaborate to fix the front axle: the

robot positions it, and the operator secures it with two

sub-assembly 1 using an electric screwdriver. This

process is repeated for the rear axle.

The SRI of the truck assembly tasks was initially

determined using the evaluation criteria set out in Sec-

tion 3 (Figure 6 top). The severity is determined by

the severity of the components and the severity of the

tools used in the task. The number of actions is trans-

lated into the frequency, and the type of interaction

between the agents is translated into the occurrence.

5.2 Safety Control System of the Toy

Pick-Up Truck

Figure 5 shows the safety control of the toy truck

modeled by using the PN from Section 4. The three

main components are color-coded: the assembly se-

quence in black, the robot’s safety control in blue,

and the human’s in red. Once the assembly starts and

T0 is activated, the tasks ’Prepare Base’ and ’Pre-

pare Sub-Assembly 1’ are initiated simultaneously,

engaging both agents’ safety control systems. As they

progress through their MAPE cycles, their monitor

components update to recognize that both agents are

working in the same collaborative space, effectively

merging the tasks. This results in an increased SRI

from 7 (Prepare Base) and 5 (Prepare Sub-Assembly

1) to 11 (Figure 6 bottom).

The ’Fix Front Axle’ and ’Fix Rear Axle’ tasks

require interaction, initially planned as collaborative.

After T0 fires, both safety control systems activate

and go through their MAPE loops. Their identical

initial SRI of 14 (Figure 6 top) is too high for execu-

tion. To lower the SRI, the interaction can be adjusted

to synchronization (SRI 10) or cooperation (SRI 12)

(Figure 6 bottom). The synchronization option is

chosen for execution due to its lower SRI, though

other factors like execution time or ergonomics could

change this decision.

6 DISCUSSION AND

CONCLUSION

The presented safety control system can conduct

safety assessments for collaborative assembly se-

quences on a task basis, allowing for more dynamic

evaluations compared to existing EU-standard sys-

tems, which require full assembly assessments. This

task-based approach promotes modular HRC systems

and enables the reuse of safety assessments across dif-

ferent sequences. However, the current system has a

limitation in its discrete assessment of safety hazards,

which cannot account for safety-critical factors occur-

ring during task execution.

In summary, this paper introduces a modular

safety control system based on the MAPE cycle, en-

abling decentralized safety evaluations for both robot

and human agents. By using Petri nets to represent the

system, we demonstrate the behavior of the MAPE

Towards a Modular Human-Robot Safety Control System Using Petri Nets

389

P0 (Start

Assembly)

P1 (Check Task

Conditions)

P2 (Prepare

Base)

P9 (Check Task

Conditions)

P10 (Prepare Sub-

Assembly 1)

P4 (Check Task

Conditions)

P5 (Fix Front

Axle)

P8 (Fix Rear

Axle)

P7

P19 (Wait/Idle)

P15 (Check

Environment

/Monitor)

P16 (Calculate SRI

/Analyze)

P17 (Set Robot

Parameters

/Plan)

P18

(Confirm

Execution

/Execute)

T12

(Robot.SRI >

robot.parameter)

T13 (Robot.SRI <=

robot.parameter)

P27 (Wait/Idle)

P23 (Check

Environment

/Monitor)

P26 (Give

Assembly

Instructions

/Execute)

P24 (Calculate SRI

/Analyze)

P25 (Inform Human

about Risks

/Plan)

T18 (human.SRI >

human.risk)

T19 (human.SRI <=

human.risk)

Blue = Robot Safety Control System

Red = Human Safety Control System

Black = Assembly Sequence

P20 (Aux 1 Human)

P12 (Aux 1 Robot)

T9

P13 (Aux 2 Robot)

P14 (Aux 3 Robot)

P3 (End

Task)

P21 (Aux 2 Human)

P22 (Aux 3 Human)

T0

T1 T2

T3

T4

T5

T6

T7

T8

T10

T11

T14

T15

T16

T17

T20

P6

P11 End

Task

T21T22

Figure 5: Petri net for the toy truck assembly. Different colors are used to distinguish between the three major parts of the

PN: black for the assembly task, blue for the safety control system of the robot, and red for the safety control system of the

human.

Figure 6: Calculated SRI values for the truck use case. Top: Initially calculated values. Bottom: Calculated values from the

safety control systems. Changes from the initial values are marked in blue.

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

390

components and their connection to the assembly se-

quence. Evaluations in an industrial context show the

system’s ability to discern various interaction modal-

ities and adjust parameters to keep safe robot interac-

tions within acceptable ranges.

In future work, in addition to a general risk assess-

ment of the current task, we intend to integrate the

detection and mitigation of more specific safety risks

into our system. These will be continually reviewed

to overcome our current limitation of discrete safety

assessment, which can only identify risks before, but

not during, task execution.

ACKNOWLEDGEMENTS

This research was partly funded by the Bayerische

Forschungsstiftung under grant no. AZ-1512-21. We

thank our industry partners Fresenius Medical Care,

Wittenstein SE, Uhlmann und Zacher, DE software &

control and Universal Robots.

REFERENCES

Afefy, I. H. (2015). Hazard analysis and risk assess-

ments for industrial processes using fmea and bow-tie

methodologies. Industrial Engineering and Manage-

ment Systems, 14(4):379–391.

Arents, J., Abolins, V., Judvaitis, J., Vismanis, O., Oraby,

A., and Ozols, K. (2021). Human–robot collaboration

trends and safety aspects: A systematic review. Jour-

nal of Sensor and Actuator Networks, 10(3):48.

Bauer, W., Bender, M., Braun, M., Rally, P., and Scholtz,

O. (2016). Lightweight robots in manual assembly–

best to start simply. Frauenhofer-Institut f

¨

ur Ar-

beitswirtschaft und Organisation IAO, Stuttgart, 1.

Berx, N., Decr

´

e, W., Morag, I., Chemweno, P., and Pin-

telon, L. (2022). Identification and classification

of risk factors for human-robot collaboration from a

system-wide perspective. Computers & Industrial En-

gineering, 163:107827.

Casalino, A., Zanchettin, A. M., Piroddi, L., and Rocco,

P. (2019). Optimal scheduling of human–robot col-

laborative assembly operations with time petri nets.

IEEE Transactions on Automation Science and Engi-

neering, 18(1):70–84.

Chao, C. and Thomaz, A. (2016). Timed petri nets for flu-

ent turn-taking over multimodal interaction resources

in human-robot collaboration. The Int. Journal of

Robotics Research, 35(11):1330–1353.

Chiacchio, F., Cacioppo, M., D’Urso, D., Manno, G., Tra-

pani, N., and Compagno, L. (2013). A weibull-

based compositional approach for hierarchical dy-

namic fault trees. Reliability Engineering & System

Safety, 109:45–52.

De Lemos, R., Giese, H., M

¨

uller, H. A., Shaw, M., Ander-

sson, J., Litoiu, M., Schmerl, B., Tamura, G., Ville-

gas, N. M., Vogel, T., et al. (2013). Software engi-

neering for self-adaptive systems: A second research

roadmap. In Software Engineering for Self-Adaptive

Systems II, pages 1–32. Springer.

Hanna, A., Larsson, S., G

¨

otvall, P.-L., and Bengtsson,

K. (2022). Deliberative safety for industrial intel-

ligent human–robot collaboration: Regulatory chal-

lenges and solutions for taking the next step towards

industry 4.0. Robotics and Computer-Integrated Man-

ufacturing, 78:102386.

Hillen, D., Huck, T. P., Laxman, N., Ledermann, C., Re-

ich, J., Schlosser, P., Schmidt, A., Schneider, D.,

and Uecker, D. (2022). Plug-and-produce... safely!

end-to-end model-based safety assurance for recon-

figurable industry 4.0. In Int. Symposium on Model-

Based Safety and Assessment, pages 83–97. Springer.

Kabir, S. and Papadopoulos, Y. (2019). Applications of

bayesian networks and petri nets in safety, reliabil-

ity, and risk assessments: A review. Safety science,

115:154–175.

Kr

¨

uger, J., Lien, T., and Verl, A. (2009). Cooperation of

human and machines in assembly lines. CIRP Annals,

58(2):628–646.

Lee, K., Shin, J., and Lim, J.-Y. (2021). Critical hazard fac-

tors in the risk assessments of industrial robots: causal

analysis and case studies. Safety and health at work,

12(4):496–504.

Leveson, N. and Stolzy, J. (1987). Safety analysis using

petri nets. IEEE Transactions on Software Engineer-

ing, SE-13(3):386–397.

Leveson, N. G. (2016). Engineering a safer world: Systems

thinking applied to safety. The MIT Press.

Manjunath, M., Raja, J. J., and Daun, M. (2024). Early

model-based safety analysis for collaborative robotic

systems. IEEE Transactions on Automation Science

and Engineering.

Peterson, J. L. (1977). Petri nets. ACM Comput. Surv.,

9(3):223–252.

Schirmer, F., Kranz, P., Rose, C. G., Schmitt, J., and Kaupp,

T. (2024). Holistic assembly planning framework

for dynamic human-robot collaboration. In Intelli-

gent Autonomous Systems 18, pages 215–227, Cham.

Springer Nature Switzerland.

Siegert, J., Krispin, L., Ramez, A., El-Shamouty, M.,

Schlegel, T., Zarco, L., Roth, F., and Mannuß, O.

(2021). Model-based approach for the automation and

acceleration of the ce-conformity process for modular

production systems: Future requirements and poten-

tials. ESSN: 2701-6277.

Weyns, D., Schmerl, B., Grassi, V., Malek, S., Mirandola,

R., Prehofer, C., Wuttke, J., Andersson, J., Giese, H.,

and G

¨

oschka, K. M. (2013). On patterns for decen-

tralized control in self-adaptive systems. In Software

Engineering for Self-Adaptive Systems II, pages 76–

107. Springer.

Yevkin, O. (2011). An improved modular approach for dy-

namic fault tree analysis. In Annual Reliability and

Maintainability Symposium, pages 1–5.

Towards a Modular Human-Robot Safety Control System Using Petri Nets

391