Model-Based Digital Twin for Collaborative Robots

Jeshwitha Jesus Raja

a

, Shaza Elbishbishy

b

, Yanire Gutierrez

c

, Ibrahim Mohamed,

Philipp Kranz

d

and Marian Daun

e

Center of Robotics, Technical University of Applied Sciences W

¨

urzburg-Schweinfurt, Schweinfurt, Germany

Keywords:

Collaborative Robot, Digital Twin, Model-Based Engineering, Conceptual Modeling.

Abstract:

Industry 4.0 is reshaping the way individuals live and work, with significant impact on manufacturing pro-

cesses. Collaborative robots, or cobots-designed to be easily programmable and capable of directly interacting

with humans-are expected to play a critical role in future manufacturing scenarios by reducing setup times,

labor costs, material waste, and processing durations. However, ensuring safety remains a major challenge in

their industrial application. One promising solution for addressing safety, as well as other real-time monitoring

needs, is the digital twin. While the potential of digital twins is widely acknowledged in both academia and

industry, current implementations often face several challenges, including high development costs and the lack

of a systematic approach to ensure consistency between the physical and virtual representations. These lim-

itations hinder the widespread adoption and scalability of digital twins in industrial processes. In this paper,

we propose a model-based approach to digital twins, which emphasizes the reuse of design-time models at

runtime. This ensures a coherent relationship between the physical system and its digital counterpart, aiming

to overcome current barriers and facilitate a more seamless integration into industrial environments.

1 INTRODUCTION

While there is still no consensus on a concrete def-

inition for a digital twin (Zhang et al., 2021), it is

commonly understood that a digital twin is a virtual

representation of a physical object or system that ac-

curately reflects its real-world counterpart. Initially

defined by IBM to encompass an object’s entire life

cycle, a digital twin is continuously updated with real-

time data. The applications of digital twins include

real-time monitoring, design and planning, optimiza-

tion, maintenance, and remote access. The use of

digital twin technology is expected to grow exponen-

tially in the coming decades (Tao et al., 2022). How-

ever, the current literature on digital twins primarily

focuses on technical approaches, analysis methodolo-

gies, and the challenges associated with data collec-

tion and integration into digital twins (VanDerHorn

and Mahadevan, 2021). Despite these advancements,

there is a notable lack of structured approaches for

creating digital twins and visual representations that

a

https://orcid.org/0009-0008-7886-7081

b

https://orcid.org/0009-0002-0975-272X

c

https://orcid.org/0009-0007-2959-7241

d

https://orcid.org/0000-0002-1057-4273

e

https://orcid.org/0000-0002-9156-9731

foster better understanding and usability of a system

(cf. (Sandkuhl and Stirna, 2020)).

In this paper, we address this challenge by propos-

ing a concept for a model-based digital twin. This

approach allows us to reuse design time artifacts

and highlight system execution, predicted defects,

and other analysis results within the existing arti-

facts. This enables runtime inspection of the digital

twin—and thereby the system monitored—and sup-

ports iterative development and continuous improve-

ment of the robotic application. Reusing conceptual

models from the design phase also has the advantage

as descriptive tools for highlighting data input are al-

ready in existence (Ca

˜

nas et al., 2021).

Therefore, in this paper, we introduce our con-

cept for a model-based digital twin for a collabora-

tive robot used in a manufacturing scenario. By using

standard interfaces of the robot and other monitor-

ing systems and connecting them with current stan-

dard model editors, we can reuse design models for

runtime monitoring and analysis. This contributes to

the enhancement of system development effectiveness

through a model-based digital twin, which facilitates

continuous system improvement and reduces devel-

opment costs by iteratively reusing design artifacts.

This paper is structured as follows: In Section 2,

256

Raja, J. J., Elbishbishy, S., Gutierrez, Y., Mohamed, I., Kranz, P. and Daun, M.

Model-Based Digital Twin for Collaborative Robots.

DOI: 10.5220/0013016400003822

In Proceedings of the 21st International Conference on Informatics in Control, Automation and Robotics (ICINCO 2024) - Volume 2, pages 256-263

ISBN: 978-989-758-717-7; ISSN: 2184-2809

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

research related to the concept of digital twin archi-

tecture and conceptual modeling, as well as its imple-

mentation in industry automation, is discussed. Sec-

tion 3 introduces the use case to be used through-

out the remainder of the paper. Section 4 introduces

the approach. Finally, Section 5 concludes the paper

along with future work.

2 RELATED WORK

Digital twins replicate real systems in a virtual space

to improve performance through advanced analy-

sis and prediction techniques (Zhang et al., 2021).

Driven by data and models, digital twins can per-

form tasks like monitoring, simulation, prediction,

and optimization (Tao et al., 2022). Specifically, dig-

ital twin modeling is crucial for accurately portray-

ing the physical entity, enabling the digital twin to de-

liver functional services and meet application require-

ments. Challenges include creating reliable models,

ensuring real-time communication, and developing

deep analysis methods (VanDerHorn and Mahadevan,

2021).

However, as Kritzinger et al. (Kritzinger et al.,

2018) noted, the development of digital twins is still

in its initial stages, with literature mainly present-

ing conceptual ideas without concrete case studies.

While digital twin technology has advanced since

Kritzinger’s investigation in 2018, it still requires

more structure and planning to achieve its full poten-

tial (Ramasubramanian et al., 2022). Although there

are many papers on digital twins for manufacturing

systems, there is still insufficient definitive evidence

of digital twin implementation and evaluation in the

industry (Redelinghuys et al., 2020). One reason for

this is the lack of systematic approaches to developing

digital twins (Sandkuhl and Stirna, 2020).

Current approaches like AutomationML(Drath,

2021) and Asset Administration Shell (AAS)(Tantik

and Anderl, 2017) offer frameworks for integrating

various aspects of industrial automation systems. Au-

tomationML, for instance, facilitates the exchange of

plant engineering information, while AAS serves as

a digital representation of an asset’s lifecycle. Our

work differentiates itself from the above-mentioned

approaches by focusing on a model-based digital twin

specifically designed for collaborative robots in man-

ufacturing scenarios.

AutomationML primarily addresses data ex-

change rather than real-time monitoring and dynamic

interaction between physical and virtual entities. In

contrast, our model-based digital twin approach not

only ensures data consistency and integration but also

supports real-time updates and interaction, which are

critical for the continuous improvement of robotic ap-

plications. Similarly, the Asset Administration Shell

(AAS) framework, as part of the Industry 4.0 initia-

tive, provides a robust structure for asset management

as it often requires extensive customization to suit

specific applications and lacks inherent support for

runtime monitoring and predictive analysis tailored to

collaborative robots.

In the industrial domain, there already are model-

based artifacts from the specification and develop-

ment of a system. Models can contain the potential

to depict a system’s functions, structure, or even its

behavior (Davis, 1993). Some existing modeling lan-

guages that have proven useful for modeling robotic

systems are goal models (Mussbacher and Nuttall,

2014) and process models (Petrasch and Hentschke,

2016). The Goal-Oriented Requirements Language

(GRL(ITU Int. Telecommunication Union, 2018))

can be used to elaborate and document the require-

ments of a physical system in the early stages of de-

velopment (Daun et al., 2019; Daun et al., 2021).

Business Process Model and Notation (BPMN), on

the other hand, can play an important role in docu-

menting the operations and requirements of a process

during its operation in industry. Both modeling lan-

guages also contain potential with respect to safety

analysis (Khan et al., 2015).

In previous work, we have successfully extended

the GRL to support early safety assessment of human

robot collaborations (Daun et al., 2023; Manjunath

et al., 2024). As a digital twin is also seen as an im-

portant safety mechanism in the field, we also already

proposed the use of goal models to systematically de-

velop digital twins (cf. (Jesus Raja et al., 2024)). In

this paper, we propose to go one step further, by using

the design time models as runtime models monitored

by the digital twin.

3 RUNNING EXAMPLE

Our case example explores the collaborative dynam-

ics between human operators and cobots in assembly

processes. The assembly process includes operations

ranging from picking and preparing components to

screwing and placing them. In the exemplary pro-

duction process, a toy truck is produced through the

collaboration between a human and a robot. The as-

sembly process is as follows:

1. Cabin (C2) and load carrier (C1) are lying up-

side down in the mounting bracket: Cobot be-

gins by carefully picking the load carrier from

the storage area and positioning it upside down in

Model-Based Digital Twin for Collaborative Robots

257

the collaborative workspace. It then picks up the

cabin and places it in the workspace next to the

load carrier with precision.

2. Chassis (C3) is placed on top: After placing the

structure of the truck (C1 and C2) on the col-

laborative area, the cobot picks up the chassis

and places it carefully with precision on the truck

structure.

3. Screws (C7) are placed inside the axle hold-

ers (C6): While the cobot manages the initial

tasks, the human operator prepares the parts for

screwing by inserting two screws into each axle

holder, repeating this process for all four holders.

The finished product of this process is called sub-

assembly 1. Once the human operator completes

the task, they signal the computer that the work is

finished by pressing a virtual button.

4. Front axle (C4) and rear axle (C5) are aligned

on top of the chassis: The cobot retrieves the

front axle and places it on the chassis, aligning

with the screw’s entries. The cobot securely holds

the front axle in place and waits for the human op-

erator’s intervention. After the completion of sub-

assembly 1, the operator moves to the collabora-

tive area and with the use of the screwdriver then

screws the axle holders, starting with the front

right side, followed by the front left side. After

this process is completed, the human operator sig-

nals the computer through the virtual button that

the work is finished and so, the same process is

again repeated for the rear axle. First, the cobot

picks up the rear axle and then secures it in place

on top of the chassis, aligning it with the holes for

the screws. After that, the human enters the col-

laborative area to screw the axle holder, starting

from the right side.

4 MODEL-BASED DIGITAL TWIN

4.1 Problem Statement

In industrial environments, collaborative robots are

increasingly deployed to enhance productivity and

adaptability. However, current monitoring systems

predominantly rely on basic status updates and data

logging, which provides limited visibility into the

cobots’ real-time operations and interactions with hu-

man operators (Das et al., 2009). These traditional

systems often lack to offer an in-depth, dynamic rep-

resentation of ongoing tasks, making it challenging to

optimize workflows, predict issues, and ensure seam-

less collaboration (Bruno and Antonelli, 2018).

4.2 Solution Idea

To address these limitations, we propose the introduc-

tion of a model-based digital twin for collaborative

robots, represented through detailed conceptual mod-

els that dynamically illustrate the entire process and

highlight the current tasks. This approach leverages

real-time data obtained via the standard robot inter-

face provided by the robot manufacturer. The digital

twin utilizes models created using a standard model

editor. Currently, we are developing the digital twin

mainly for monitoring and real-time analysis, with-

out making changes to the physical twin. ”Digital

shadow” is a more precise term for this one-way flow

of information (Bergs et al., 2021). However, for the

future we plan to develop the digital shadow into a

real digital twin with advanced analysis and the abil-

ity for interventions and adaptations in the physical

twin.

The proposed digital twin will employ BPMN and

GRL goal models to represent different aspects of the

workflow. BPMN models will be used to map out

the entire process flow, detailing each step and deci-

sion point. The reason we choose BPMN is that it

provides a standardized, visual representation of the

workflow, detailing each step of the cobot as it picks,

places and holds components. This clarity facilitates

better communication and process improvement.

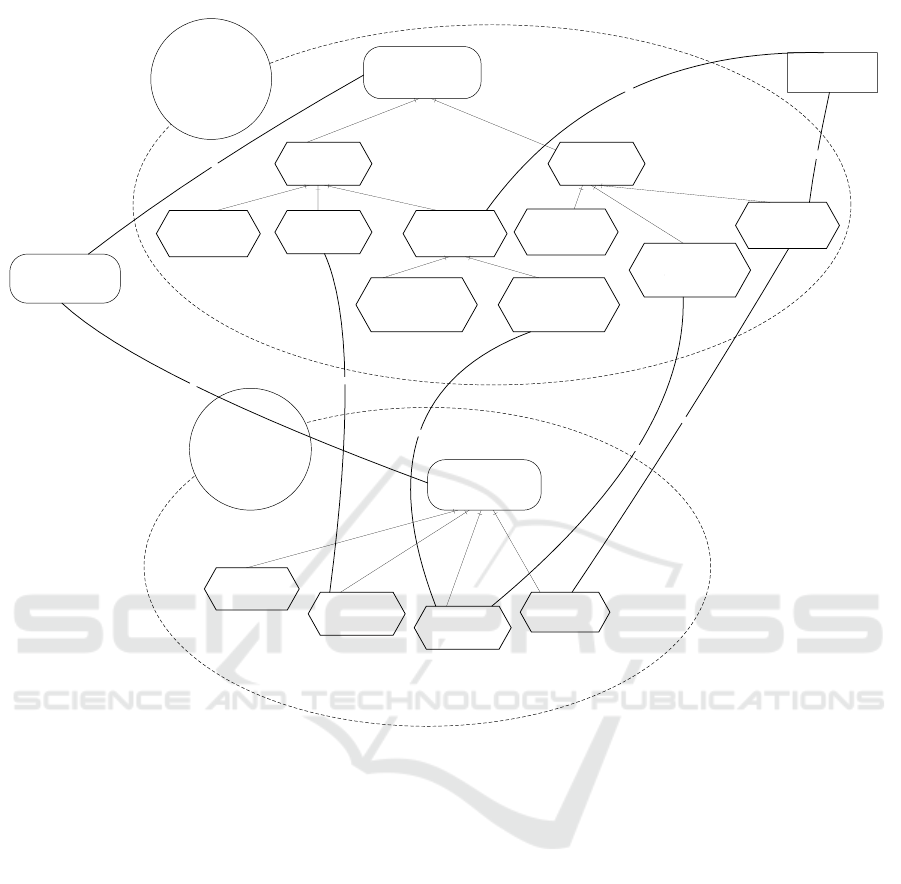

Figure 1 shows the basic GRL goal model that

showcases the goals, actors, tasks and dependencies

of the use case introduced in Section 3. The process

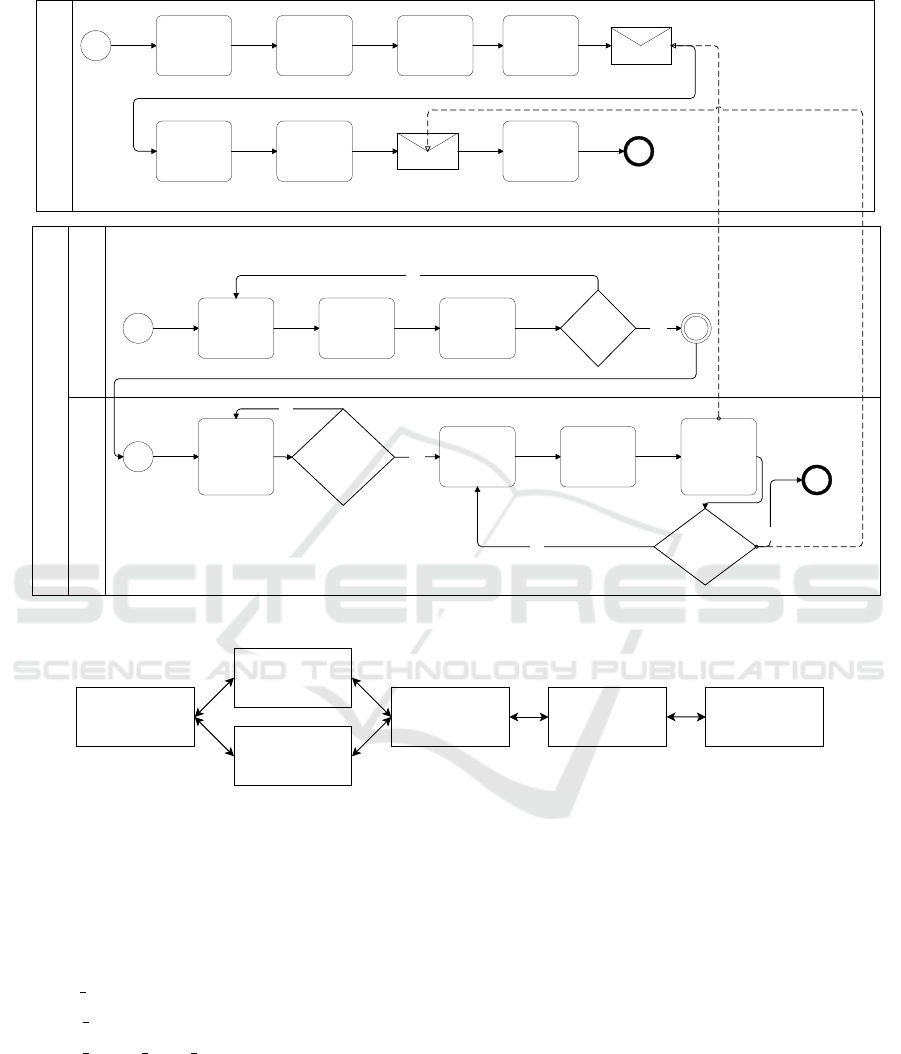

for the execution of tasks can be seen in the BPMN

process model shown in Figure 2. The two actors

are the human and the robot, and their tasks are di-

vided based on the parts they handle. This process in-

volves collaborative human-robot interaction, which

can be visualized through dependencies in the GRL

goal model.

Goal models will be employed to focus on spe-

cific objectives and their achievement. Goal models

focus on specific objectives. The advantage of using

these models lies in their ability to enable real-time

progress tracking and decision support, allowing dy-

namic adjustments based on the current state of as-

sembly.

4.3 Architecture

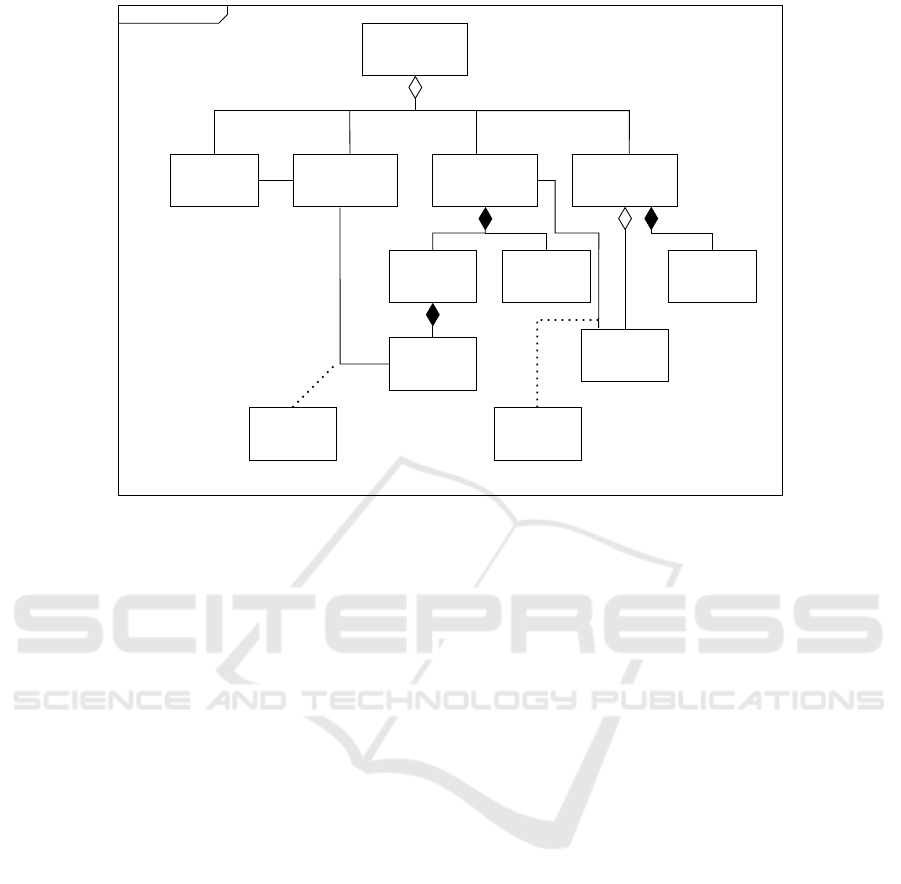

The current concept for creating the model-based dig-

ital twin can be seen in Figure 3 and is described in

detail in the following subsection.

The architecture of the physical twin is shown in

Figure 4. It begins with the complete system, the

‘Spatial Augmented Reality System’, which is later

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

258

Successfully assemble

toy truck

Mount front axle

holders

Pick 2 prepared

axle holder

Place 2 axle

holder is the given

position

Grab screwdriver

Screw 2 screws to the

left axle holder

Human

Successfully assemble

toy truck

Mount front axle

Robot

Assist during

collaboration

AND

AND

Screw 2 screws to the

right axle holder

Mount rear axle

holders

Pick 2 prepared

axle holder

Place 2 axle holder is the

given position

Grab screwdriver

AND

Screwdriver

D

D

Mount rear axle

D

D

D

D

Successfully

assemble toy truck

D

D

AND

AND

Assemble base

Figure 1: Goal Model of the Truck Assembly use case.

divided into four components: ‘Screwdriver’, ‘Hu-

man Operator’, ‘Monitoring System’, and ‘Cobot’.

The monitoring system consists of a projector and

a camera. This projector contains a depth sensor,

and together with the human operator, it facilitates

Human-Computer communication. The cobot also

includes a control tablet and a torque sensor. The

control tablet, along with the monitoring system, fa-

cilitates Robot-Computer communication. This illus-

trates that there is no direct communication between

the human and the robot but rather through the moni-

toring system.

4.4 Collection of Input and Output Data

Analyzing and understanding the architecture pro-

vides information on the data needed to build the dig-

ital twin. Therefore, the second step (shown in Figure

3) is to collect output data from the cobot and the hu-

man operator for runtime analysis and monitoring. In

our case, we use a Universal Robot with an RTDE

(Real Time Data Exchange) interface to control and

receive data from the cobot. Data from human ac-

tions is collected from a depth sensor integrated with

a virtual green button that the human clicks after each

task. This data, along with RTDE information, must

be processed through the interface and provided to the

models. For now, we only use the information from

the robot for processing and visualizing the models.

4.5 Data Pre-Processing

The data collected from cobot and human operator

can be exported and processed for use in the mod-

els through Python, which is shown as the third step

in Figure 3. A Python adapter software serves as the

interface between the physical twin and the model-

based digital twin. The RTDE interface that was used

to collect the needed data from the cobot can be uti-

lized with Python through the provided Python bind-

Model-Based Digital Twin for Collaborative Robots

259

Human Operator

Cobot

Prepare PartsScrew parts through collaboration

Picks and

Place parts

Assemble base

Mount front

axle

Message to continue

the process received

Holds front

axle

Picks and

Places back

axle

Holds back

axle

Message to continue

the process received

Goes back to

initial position

Picking and placing

all parts completed

Picks axle

holder

Holds axle

holder

Puts a screw in

each axle

holder slot

All slots

filled with a

screw?

Yes

No

Picks and

Places

prepped axle

holder

Axle holders

placed?

Yes

Grabs

screwdriver

Screws axle

holders

No

Clicks button

to send the

cobot to

continue the

process

All 4 axle

holders

screwed in?

No

Yes

All 4 axle holders

are screwed in

Figure 2: Business Process Model of the Truck Assembly use case.

Collect Data from

Cobot

Data exchange

format generation

(Microsoft Excel)

Model Highlighting

and Analysis

(Microsoft Visio)

Collect Data from

Depth Sensor

Data Pre-processingPhysical Twin

Figure 3: Concept for developing a model-based digital twin.

ings. The required data from the cobot can be indi-

vidually collected using predefined functions and then

compiled. Some of the data variables that can be col-

lected and used include:

• timestamp

• target q (target position)

• actual q (current position)

• actual digital input bits

Next, the data is exported into a format to be re-

used as standard input by the chosen standard model

editor. In our case, we chose to use Microsoft Visio as

Model Editor, as it is commonly available and acces-

sible in academia and industry.

Therefore, we generate a Microsoft Excel file from

the processed RTDE data, which is then automatically

imported into Microsoft Visio. Using Python and the

RTDE interface, we collect the specified variable, and

with this data, we create two columns in the Excel

document. The first column corresponds to the times-

tamp, and the second column corresponds to the cur-

rent task. The current task is labeled based on the cur-

rent position, and differentiation between human and

robot tasks is achieved using digital input bits. After

extracting the data into the Excel document, it can be

used in Microsoft Visio.

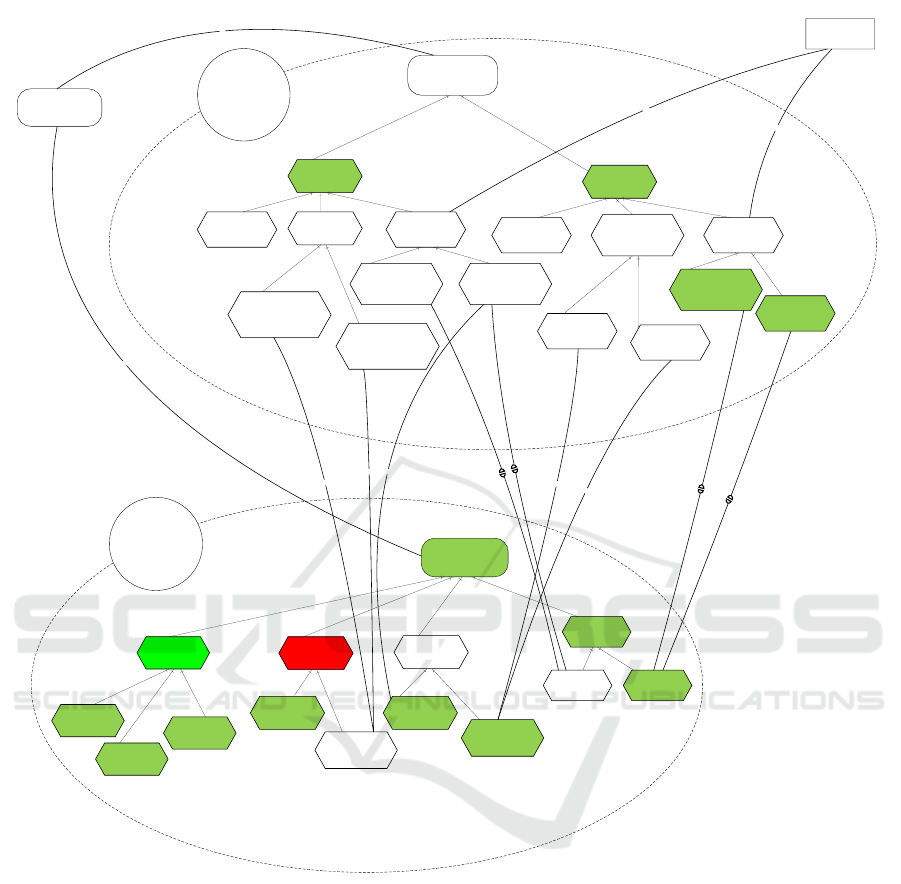

4.6 Model Highlighting

The representation of the models (GRL goal model

and BPMN) is shown in Microsoft Visio. Model

highlighting to show runtime representations can be

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

260

BDD

Spatial augmented

reality system

Collaborative RobotMonitoring systemHuman Operator

CameraProjector

Depth Sensor

Control tablet

Screwdriver

Torque sensor

Cobot-Computer

Communication

Human-Computer

Communication

Figure 4: The architecture of the physical system of the collaborative workspace.

achieved directly in Microsoft Visio using the ‘Link

data to shapes’ function. These shapes are assigned

conditions, and based on those conditions, the cur-

rently implementing task or process can be high-

lighted. This means that the model created fulfills the

properties of a digital shadow. In order to develop

this into a digital twin in our future work, more ad-

vanced analyses can also be directly implemented in

Microsoft Visio using C#-implemented add-ons.

Figure 5 shows how tasks can be highlighted in

the goal model. Here, bidirectional dependencies in-

dicate tasks where both actors are involved and mutu-

ally dependent on each other. For instance, tasks such

as the human performing ‘Screw 2 screws to the right

axle holder’ and the robot holding the ‘rear axle’ are

collaborative and connected by bidirectional depen-

dencies.

Tasks highlighted in green indicate that they are

currently being executed. Other colors can be used

to show different statuses of the tasks, such as ‘com-

pleted,’ ‘waiting,’ and ‘needs attention.’ For example,

the task ‘place one axle holder on the right of the front

axle’ is currently being executed and is highlighted

green. The colors and semantics can be customized

based on the type of process execution and monitor-

ing.

To achieve this, we utilize Visio’s ‘Link Data to

Shapes’ feature. After uploading the Excel document

to the Visio file, this feature allows us to link a cell

to either a main task or a sub-task. By utilizing this

capability, we ensure that the displayed statuses accu-

rately reflect the current state of each task.

Furthermore, the use of colors such as blue, yel-

low, and red serves to signify additional statuses

within the assembly process. These colors provide in-

tuitive visual cues for tasks that are completed, await-

ing action, or requiring attention, thereby enhancing

the overall clarity and effectiveness of process moni-

toring.

Shapes can be connected and highlighted simi-

larly with BPMN. This approach aligns with princi-

ples of re-use and iterative development, leveraging

standardized interfaces and model editors. It allows

for monitoring other assembly processes or general

processes from the cobot with simpler modifications

to the models.

5 CONCLUSION

In conclusion, digital twins offer immense potential to

design, plan, optimize, and monitor systems in real-

time throughout their lifecycle. The development of

a model-based digital twin allows for the replication

of physical system characteristics within a virtual en-

vironment, similar to traditional digital twins. How-

ever, our approach focuses on leveraging model-based

techniques to extend the capabilities of digital twins

for collaborative robots (cobots), providing the ability

to reuse design artifacts. This promotes the iterative

Model-Based Digital Twin for Collaborative Robots

261

Successfully assemble

toy truck

Mount front axle

holders

Pick 2 prepared

axle holder

Place 2 axle

holder is the given

position

Grab screwdriver

Place one axle holder on

the left of front axle

Place one axle holder on

the right of front axle

Screw 2 screws to the

left axle holder

Human

Successfully assemble

toy truck

Mount front axle

Pick front axle

Place front axle in

the front of the

chassis

Pick rear axle

Robot

Place rear axle in

the back of the

chassis

Assist during

collaboration

Hold front axle Hold rear axle

AND

AND

AND

AND

AND

Screw 2 screws to the

right axle holder

Mount rear axle

holders

Pick 2 prepared

axle holder

Place 2 axle holder is the

given position

Grab screwdriver

Place one axle

holder on the left

of rear axle

Place one axle

holder on the right

of rear axle

Screw 2 screws to the

left axle holder

AND

AND

AND

Screw 2 screws to

the right axle

holder

Screwdriver

D

D

Mount rear axle

AND

D

D

D

D

D

D

D

D

D

Successfully

assemble toy truck

D

D

AND

AND

Assemble base

Pick and place

cabin

Pick and place

chassis

Pick and place

load carrier

AND

Figure 5: GRL Goal Model for the truck use case with highlighting.

and continuous development of the system over time.

A key advantage of model-based digital twins is

their ability to enhance understanding during the early

stages of development. By facilitating the early detec-

tion of potential issues, they enable proactive safety

monitoring, improving both efficiency and reliabil-

ity. In this paper, we introduced a model-based digital

twin framework that utilizes GRL (Goal-oriented Re-

quirement Language) goal models and BPMN (Busi-

ness Process Model and Notation). Our approach em-

phasizes reusability by integrating standard interfaces

of cobots and existing industrial systems, as well as

employing widely accepted model editors. This en-

sures efficient integration, reducing development time

and cost while leveraging current technologies and

frameworks.

The contributions of this paper pave the way for

the development of a model-based digital twin that

can be directly implemented in industrial settings. As

part of our future work, we will focus on creating

conceptual models using standard model editors and

evaluating the system with our monitoring implemen-

tation. In addition, we plan to apply different work-

flows and conduct in-depth safety analyses to further

validate the system’s capabilities.

Moving forward, we aim to enhance the func-

tionality of our model-based digital twin by incor-

porating advanced features such as goal reasoning,

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

262

which would allow the system to autonomously ad-

just based on evolving objectives. We also intend to

explore modeling pattern analysis, enabling more effi-

cient reuse of design artifacts across different applica-

tions. These enhancements will not only improve the

twin’s adaptability but also contribute to the broader

adoption of digital twins in complex industrial envi-

ronments.

REFERENCES

Bergs, T., Gierlings, S., Auerbach, T., Klink, A.,

Schraknepper, D., and Augspurger, T. (2021). The

concept of digital twin and digital shadow in manu-

facturing. Procedia CIRP, 101:81–84.

Bruno, G. and Antonelli, D. (2018). Dynamic task classifi-

cation and assignment for the management of human-

robot collaborative teams in workcells. Int. Journal

Advanced Manufacturing Technology, 98:2415–2427.

Ca

˜

nas, H., Mula, J., D

´

ıaz-Madro

˜

nero, M., and Campuzano-

Bolar

´

ın, F. (2021). Implementing industry 4.0

principles. Computers & industrial engineering,

158:107379.

Das, A. N., Popa, D. O., Ballal, P. M., and Lewis, F. L.

(2009). Data-logging and supervisory control in wire-

less sensor networks. Int. Journal of Sensor Networks,

6(1):13–27.

Daun, M., Brings, J., Krajinski, L., Stenkova, V., and

Bandyszak, T. (2021). A grl-compliant istar exten-

sion for collaborative cyber-physical systems. Re-

quirements Engineering, 26(3):325–370.

Daun, M., Manjunath, M., and Jesus Raja, J. (2023). Safety

analysis of human robot collaborations with grl goal

models. In International Conference on Conceptual

Modeling, pages 317–333. Springer.

Daun, M., Stenkova, V., Krajinski, L., Brings, J.,

Bandyszak, T., and Weyer, T. (2019). Goal model-

ing for collaborative groups of cyber-physical systems

with grl: reflections on applicability and limitations

based on two studies conducted in industry. In Pro-

ceedings of the 34th ACM/SIGAPP Symposium on Ap-

plied Computing, pages 1600–1609.

Davis, A. M. (1993). Software requirements: objects, func-

tions, and states. Prentice-Hall, Inc.

Drath, R. (2021). Automationml: A practical guide . Walter

de Gruyter GmbH & Co KG.

ITU Int. Telecommunication Union (2018). Recommenda-

tion itu-t z.151: User Requirements Notation (URN).

Technical report.

Jesus Raja, J., Manjunath, M., and Daun, M. (2024). To-

wards a goal-oriented approach for engineering digital

twins of robotic systems. In ENASE, pages 466–473.

Khan, F., Rathnayaka, S., and Ahmed, S. (2015). Methods

and models in process safety and risk management:

Past, present and future. Process safety and environ-

mental protection, 98:116–147.

Kritzinger, W., Karner, M., Traar, G., Henjes, J., and Sihn,

W. (2018). Digital twin in manufacturing: A cat-

egorical literature review and classification. Ifac-

PapersOnline, 51(11):1016–1022.

Manjunath, M., Raja, J. J., and Daun, M. (2024). Early

model-based safety analysis for collaborative robotic

systems. IEEE Transactions on Automation Science

and Engineering.

Mussbacher, G. and Nuttall, D. (2014). Goal modeling for

sustainability: The case of time. In 2014 IEEE 4th

Int. Model-Driven Requirements Engineering Work-

shop (MoDRE), pages 7–16. IEEE.

Petrasch, R. and Hentschke, R. (2016). Process modeling

for industry 4.0 applications: Towards an industry 4.0

process modeling language and method. In 2016 13th

Int. Joint Conf. on Computer Science and Software

Engineering (JCSSE), pages 1–5. IEEE.

Ramasubramanian, A. K., Mathew, R., Kelly, M., Har-

gaden, V., and Papakostas, N. (2022). Digital twin for

human–robot collaboration in manufacturing: Review

and outlook. Applied Sciences, 12(10):4811.

Redelinghuys, A., Basson, A. H., and Kruger, K. (2020). A

six-layer architecture for the digital twin: a manufac-

turing case study implementation. Journal of Intelli-

gent Manufacturing, 31(6):1383–1402.

Sandkuhl, K. and Stirna, J. (2020). Supporting early phases

of digital twin development with enterprise modeling

and capability management: Requirements from two

industrial cases. In Int. Conf. Business-Process and

Information Systems Modeling, BPMDS, pages 284–

299. Springer.

Tantik, E. and Anderl, R. (2017). Integrated data model and

structure for the asset administration shell in industrie

4.0. Procedia Cirp, 60:86–91.

Tao, F., Xiao, B., Qi, Q., Cheng, J., and Ji, P. (2022). Digital

twin modeling. Journal of Manufacturing Systems,

64:372–389.

VanDerHorn, E. and Mahadevan, S. (2021). Digital twin:

Generalization, characterization and implementation.

Decision support systems, 145:113524.

Zhang, L., Zhou, L., and Horn, B. K. (2021). Building a

right digital twin with model engineering. Journal of

Manufacturing Systems, 59:151–164.

Model-Based Digital Twin for Collaborative Robots

263