Advanced Nonlinear Control for an Omnidirectional Spherical Robot

Integrating Aerial and Ground Mobility

Davide Spitaleri

1a

, Gianluca Pepe

1b

, Maicol Laurenza

2c

, Silvia Milana

1d

,

Flavio Ceccarelli

1

and Antonio Carcaterra

1e

1

Department of Mechanical and Aerospace Engineering, University “La Sapienza”, Eudossiana street, 18, Rome, Italy

2

Department of Engineering, Niccolò Cusano University, Don Carlo Gnocchi street, 3, Rome, Italy

Keywords: Spherical Drone, Rolling Robot, Nonlinear Control, Model-Based Control, Hybrid Dynamic System.

Abstract: This paper presents an innovative control strategy for an overactuated omnidirectional spherical drone,

capable of both flying and rolling on the ground. The control system, based on Feedback Local Optimality

Control (FLOP), utilizes a comprehensive dynamic model that facilitates smooth transitions between flight

and rolling modes, optimizing energy efficiency and enhancing maneuverability. Key features include an

advanced decision-making mechanism for contact detection and a constrained control allocation algorithm

that respects physical limitations. Virtual simulations have demonstrated the control system's robustness and

responsiveness. This spherical drone design not only extends the capability to navigate complex environments

but also enables energy conservation during ground transport.

1 INTRODUCTION

In recent years, mobile robotics has increasingly

focused on spherical robots due to their agility and

stability in complex scenarios, making them ideal for

industrial inspections, exploration of rugged terrains,

urban search and rescue operations in difficult

environment (Diouf et al., 2024). Integrating in a single

system the flight capabilities of traditional multicopters

with the ability to roll on surfaces offers unique

versatility and energy-saving modes during ground

transport. However, the realization of such systems

remains challenging, necessitating innovations in

mechanics, sensing, and control. Current solutions

often present significant limitations that hinder the

widespread adoption of such robots in real

applications. Simpler designs mount traditional coaxial

or quadrotor UAVs inside a protective cage using

connecting rods, but these underactuated

configurations typically suffer from low control

capability, especially in rolling maneuvers (Hou et al.,

a

https://orcid.org/0009-0009-4285-7567

b

https://orcid.org/0000-0002-1444-7765

c

https://orcid.org/0000-0002-3493-0965

d

https://orcid.org/0000-0001-9484-0315

e

https://orcid.org/0000-0002-0355-3925

2013; Zhou et al., 2010). Quadrotors with variable-

pitch propellers, offer versatile operations on land,

water and in the air, but are complex to manage and

maintain (Yao et al., 2021). Improved maneuverability

can be achieved with configurations allowing relative

rotation between the quadrotor and the shell along a

connecting rod equipped with ball bearings, but this

solution favours rolling in one direction (Dudley et al.,

2015; Kalantari & Spenko, 2014). Complete

omnidirectional motion in flight and rolling can be

attained with spherical flying robots equipped with a 3-

axis gimbal mechanism. This design absorbs impacts

by allowing the external cage to rotate passively,

though it introduces high mechanical complexity (Atay

et al., 2021; Briod et al., 2014). Finally, a hybrid aerial

and ground mobility robot with a fully actuated

multirotor system rigidly connected to the spherical

shell offers promising omnidirectional mobility but

requires further development to fully evaluate control

and maneuverability in real-world scenarios (Sabet et

al., 2019).

684

Spitaleri, D., Pepe, G., Laurenza, M., Milana, S., Ceccarelli, F. and Carcaterra, A.

Advanced Nonlinear Control for an Omnidirectional Spherical Robot Integrating Aerial and Ground Mobility.

DOI: 10.5220/0013020300003822

In Proceedings of the 21st International Conference on Informatics in Control, Automation and Robotics (ICINCO 2024) - Volume 1, pages 684-691

ISBN: 978-989-758-717-7; ISSN: 2184-2809

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

Among the various solutions, omnidirectional

flying spherical robots with reversible propellers,

over-actuated and gimbal-less, represent an emerging

and promising area of research, offering high

versatility with reduced mechanical complexity and

improved structural robustness. However, this

configuration requires more sophisticated control to

manage impact moments and transitions between

flight and ground rolling movement, such as in

landing and take-off operations. To pursue this

objective, in this study we implemented a nonlinear

control algorithm that optimizes performance both in

flight and rolling, and that can effectively manage the

transitions during landing and take-off operations.

The Feedback Local Optimality Principle (FLOP)

control, belonging to a special class of optimal

controllers named Variational Feedback Controllers

(Pensalfini et al., 2017; Pepe et al., 2018; Pepe et al.,

2023; Pepe et al., 2019), allows for the integration of

nonlinear behaviors, typical of spherical attitude

control (Spitaleri et al., 2024), and for following

assigned trajectories in feedback. The validation of

the algorithm has been carried out through numerical

simulations in a multibody environment, testing the

robustness of the controller. The control hardware is

emulated in the Simulink MathWorks virtual

environment, where both the hardware and its

integrated sensors are simulated, allowing for

comprehensive testing and development without the

need for physical components.

The paper is organized as follows: Section 2

describes the design of the newly assembled drone;

Section 3 presents the equations of motion that

characterize a rolling-flying sphere; Section 4 details

the control system design; and Section 5 presents

numerical results through simulations in flight,

rolling and mixed modes.

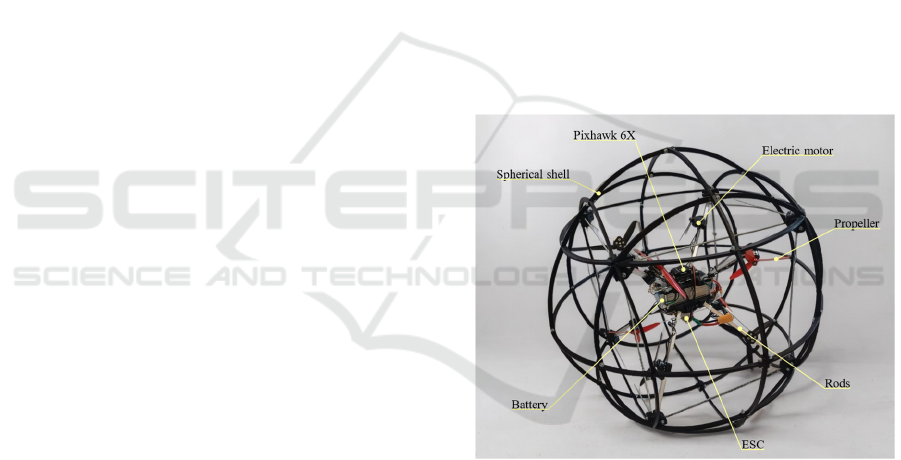

2 SPHERICAL ROBOT DESIGN

The spherical robot developed in this study features a

structure composed of three main elements, as

depicted in Figure 1: an internal central unit, an

external spherical frame, and eight cross-shaped rods.

The internal central part houses the battery and

electronic components, while the external spherical

frame allows for rolling and provides protection. The

aluminium rods connect the internal part to the

external frame of radius 𝑅, ensuring structural

rigidity and enabling the mounting of eight rotors in

a star configuration, one for each rod, as proposed in

(Brescianini & D’Andrea, 2018). The over actuation

and the specific arrangement allow the motors to push

uniformly in different directions, ensuring

omnidirectional control. The other parts of the robot's

chassis are 3D printed from polymer material (PLA),

with the spherical shell featuring a thin and lattice-

like geometry that provides both lightness and

robustness, minimize aerodynamic interference and

ensures smooth rolling. The central unit includes the

Pixhawk 6X flight computer running the open-source

PX4 control software. The onboard sensor system

comprises three six-axis MEMS inertial units, two

barometers, and a magnetometer, offering

stabilization and noise reduction. The robot's rotors

consist of brushless outrunner motors connected to

fixed-pitch, three-blade symmetric propellers capable

of generating variable thrust in both rotational

directions. The electric motors are controlled by two

ESCs, each with four independent outputs that

modulate the voltage applied to the motors via pulse-

width modulation (PWM) control and can reverse the

direction of motor rotation. The six-cell 3300 mAh

lithium polymer battery provides approximately ten

minutes of hover time, delivering a peak power of 6.5

kW.

Figure 1: The newly assembled spherical robot prototype,

featuring a 0.32 m radius spherical shell with a total weight

of 2.3 kg. The robot is equipped with eight thrust motors

and eight reversible three-bladed propellers. The onboard

hardware is centrally positioned within the shell.

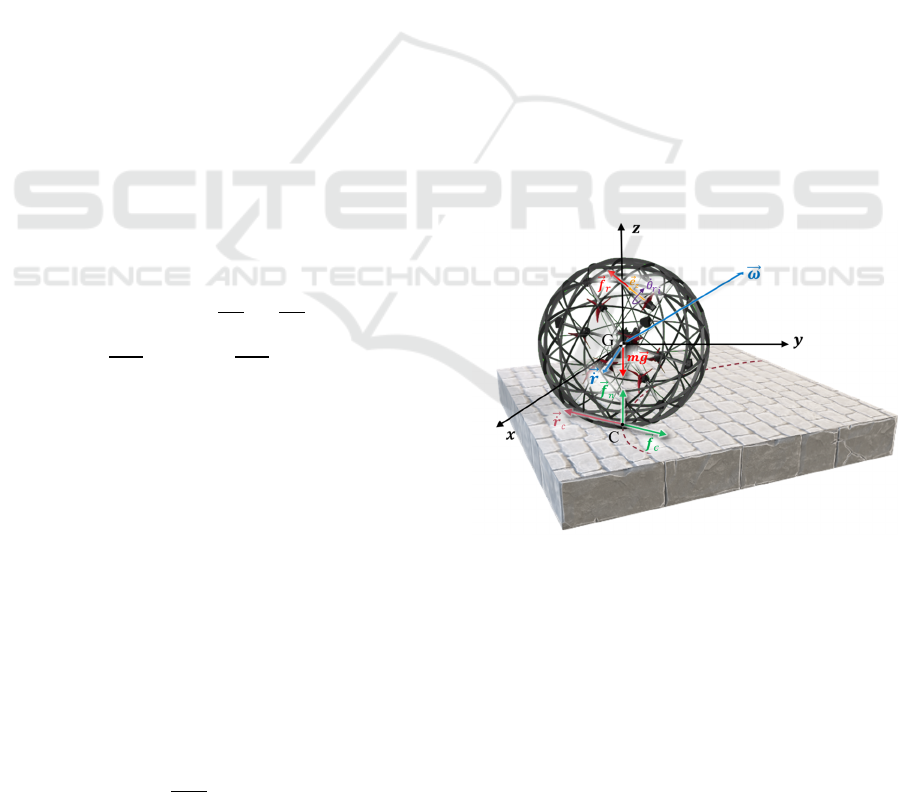

3 DYNAMIC MODEL

The dynamic model of a spherical drone capable of

flying and rolling requires an adaptive modeling

approach depending on the operational conditions: (i)

during flight, the model must account for the mass,

inertial and aerodynamic forces. This involves

analyzing the flight dynamics, which includes the

Advanced Nonlinear Control for an Omnidirectional Spherical Robot Integrating Aerial and Ground Mobility

685

thrust of the rotors; (ii) during rolling, it is necessary

to introduce a holonomic constraint that allows

replicating the reaction force of the support plane and

the tangential friction force. The entire dynamic

model serves a dual purpose: on one hand, it enables

testing and validation of the system in a simulated

environment; on the other hand, it is crucial for

implementing the model-based nonlinear control,

described in the following sections. Given the

omnidirectional spherical behavior of the robot, it is

convenient to express the equations of motion using

quaternions𝒒=

𝑞

,𝑞

,𝑞

,𝑞

⊤

, refer to (Nikravesh

et al., 1985). Consequently, the rotation matrix 𝑹

from the body frame

𝑏

to the inertial frame

𝑛

(East-North-Up, ENU) is defined as function of

quaternions. Being 𝝎=𝜔

,𝜔

,𝜔

the body

angular velocity expressed in the inertial reference

frame, the body’s rotational kinematics is described

using quaternions as well through the transformation

matrix 𝑬, i.e.

𝒒

=

𝑬(𝒒)𝝎

. The absolute angular

velocity 𝝎

of the 𝑟

-th rotor comprises two

components: the relative rotation of the electric motor

𝜃

oriented along the unit vector e

⃗

of each rotating

frame

𝑟

and the angular velocity component of the

drone 𝝎 (see Figure 2 for further details), leading to:

𝝎

=𝑹

(𝒒)𝑹

(

𝜃

)

𝜃

e

⃗

+𝝎=𝜃

e

⃗

+2𝑬

𝒒

(1)

Where e

⃗

=𝑹

e

⃗

now indicates the direction of the

action unit vector of the motor's relative rotation,

expressed in reference frame

𝑛

. The rotation matrix

𝑹

allows transformation from the rotating rotor

reference frame

𝑟

to the body reference frame

𝑏

and is defined by an XYZ rotation sequence 𝑹

=

𝑹

(

𝛼

)

𝑹

(

𝛽

)

𝑹

(

𝜃

)

, with the constant parameters

𝛼

e 𝛽

describing the specific mounting orientation

of the individual stator 𝑟

.

From the outset, we choose to divide the vector of

generalized coordinates into two parts, namely the

body and the rotors, as we intend to use only the body

dynamics, while still including the gyroscopic effects

arising from the rotor dynamics. The differential

equations of the dynamic model are derived using the

Euler-Lagrange formulation with the vector of

generalized coordinates 𝜼=

𝜼

,𝜼

.

Here, 𝜼

=

𝑥,𝑦,𝑧,𝑞

,𝑞

,𝑞

,𝑞

is associated to the rigid body

dynamics, including the coordinates 𝒓=

𝑥 𝑦 𝑧

of

the center of mass G and the orientation described by

quaternions. The rotor rotation coordinates are

collected in 𝜼

= 𝜃

,…,𝜃

. The kinetic energy

𝑇 and potential energy 𝑈 of the body and the N-rotors

𝑟

are:

𝑇=

1

2

𝑚𝒓

𝒓

+

1

2

𝝎

𝑹

𝑰

𝑹

𝝎+

+

1

2

𝑚

𝒓

𝒓

+

1

2

𝝎

𝑹

𝑰

𝑹

𝝎

(2)

𝑈=−𝑚𝒓

𝒈− 𝑚

𝒓

𝒈

(3)

where 𝑚 and 𝑰

are respectively the mass and inertia

matrix of the robot, including the spherical shell,

frame, stator part of the electric motors, onboard

electronics and batteries; 𝑚

and 𝑰

are the mass and

inertia matrix of the rotor part of the electric motors,

including the propeller; 𝒈=

0 0 𝑔

is the

gravitational acceleration vector; 𝒓

=𝒓+𝑹

𝒅

represents the position of the center of mass of the

rotating parts, with 𝒅

the fixed geometric

arrangement vector of the i-th rotor relative to the

barycenter G, expressed in the body frame

𝑏

.

The Lagrangian ℒ is defined as the difference

between the kinetic and potential energy of the

system ℒ=𝑇−𝑈, and is associated with the

problem's constraint conditions. For this reason, the

extended Lagrangian ℒ

∗

, which includes holonomic

constraints, is introduced:

ℒ

∗

(𝜼,𝜼

˙

,𝜆,𝑡)=

ℒ

(𝜼,𝜼

˙

,𝑡)+𝜆

𝜓

(𝜼,𝑡)

(4)

where the Lagrange multipliers 𝜆

are associated

with the constraint equations 𝜓

(𝜼,𝑡)=0 . It is

important to note that, when representing the motion

of a rigid body in 3D-space using quaternions, a

holonomic constraint must be introduced to ensure

the quaternion unit norm condition:

𝜓

q

(

𝜼

)

=

‖

𝒒

‖

−1=0

(5)

In rolling mode, an additional holonomic constraint is

required to express the contact with a support plane,

assumed in this case to be horizontal:

𝜓

c

(

𝜼

)

=𝑧−𝑅=0

(6)

Proceeding with the Euler-Lagrange formulation,

the following differential equations are obtained:

⎩

⎪

⎨

⎪

⎧

𝑑

𝑑𝑡

∂

ℒ

∂𝜼

˙

−

∂

ℒ

∂𝜼

=𝜆

𝜕𝜓

𝜕𝜼

+𝜆

𝜕𝜓

𝜕𝜼

+𝝉

𝑑

𝜓

𝑑𝑡

=0 ,

𝑑

𝜓

𝑑𝑡

=0

(7)

Where 𝝉 is the vector of generalized forces acting on

the robot, detailed in the following paragraph. The

first system equation (7) can be rearranged in the

classic form, comprising the mass matrix 𝑴(𝜼), the

Coriolis matrix 𝑪(𝜼,𝜼

˙

), the gravitational force vector

𝜻(𝜼), and the matrix 𝚿(𝜼) associated to the vector of

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

686

Lagrange multipliers 𝝀=𝜆

,𝜆

for the

corresponding holonomic constraints:

𝑴

(

𝜼

)

𝜼

+𝑪

(

𝜼,𝜼

)

𝜼

+𝜻

(

𝜼

)

=𝚿

(

𝜼

)

𝝀+𝝉

(8)

The first seven rows of equation (8) describe the rigid

body dynamics, while the remaining rows pertain to

the rotor dynamics. The vector 𝝉 expresses the

generalized forces acting on the robot, coming from:

the thrust forces 𝒇

=𝑓

𝑒⃗

generated by propellers

along their respective axes of rotation; the contact

forces 𝒇

generated by the rolling surface and the

spherical shell through the contact point C (see Figure

2); the aerodynamic resistance torques from the

propellers 𝒕

=𝑡

𝑒⃗

and the torques from the

electric motors 𝒕

=𝑡

𝑒⃗

. In our case, the

contribution produced by aerodynamic drag force

acting on the sphere is neglected because of the low

operating translational speed. Due to the typically

high values of the rotors, around tens of thousands of

RPM, the body is significantly influenced by the

Coriolis terms associated to 𝜼

. In contrast, the

rotors’ dynamics is not directly affected by Coriolis

terms and is typically faster than the body's dynamics

because of a shorter transient time. To develop a

model suitable for the controller, we streamline the

system by substituting 𝜼

, obtained from the last

eight rows of equation (8), into the first rows related

to body dynamics. In the end, the new compact

system model, along with the corresponding

constraint equations, takes the form:

⎩

⎨

⎧

𝑴

𝜼

+𝑪

𝜼

+𝑪

𝜼

+𝜻

=

𝜕𝜓

q

𝜕𝜼

𝜆

q

+

𝜕𝜓

𝜕𝜼

𝜆

+𝝉

+𝝉

𝑑

𝜓

q

𝑑𝑡

=0 ,

𝑑

𝜓

𝑑𝑡

=0

(9)

with 𝑴

=𝑴

−𝑴

𝑴

𝑴

. The remaining

forces and torques include those generated by contact

interactions and by the electromotive torques 𝒕

:

𝝉

=

𝒇

,2𝑬

(

𝒅

𝒇

)

(10)

𝝉

=

⎣

⎢

⎢

⎡

𝑘𝒕

2𝑬 𝒅

𝑘𝒕

−𝒕

⎦

⎥

⎥

⎤

(11)

In fact, experimental bench tests show a linear

relationship 𝑓

=𝑘𝑡

between the thrust forces of

the rotors and their electromotive torque through a

constant parameter 𝑘 (as further explained in Section

4.2). The contact force vector 𝒇

is simply the

tangential friction force, directed along the velocity of

the contact point 𝒓

and defined as:

𝒇

=

𝒓

‖

𝒓

‖

𝜇

(

𝜎

)

𝜆

(12)

Where the Lagrange multiplier 𝜆

represents the

normal reaction force of the plane, while the friction

coefficient

𝜇

is selected as a nonlinear function of the

relative slip 𝜎=

‖

𝒓

‖

given by 𝜇

(

𝜎

)

=𝜇

tanh

(

𝜖𝜎

)

,

with 𝜇

the dynamic friction coefficient and 𝜖 a

smoothing coefficient.

When the drone is in flight, the governing

equation (9) is simplified by removing the contact

constraint 𝜓

with the corresponding Lagrange

multiplier 𝜆

, and the vector of contact interaction 𝝉

.

Finally, the set of second-order differential equations

describing the robot’s motion in rolling and flight

modes can be reduced to affine first-order systems to

optimally utilize the FLOP control algorithm

described in the next section. Defining the state vector

as 𝒙=𝜼

,𝜼

,

𝜆

𝑑𝑡,

𝜆

𝑑𝑡

∈ℝ

for the

rolling mode and 𝒙=𝜼

,𝜼

,

𝜆

𝑑𝑡

∈ℝ

for

the flying mode, we have:

𝒙

=𝝓𝒙,𝜼

𝑟

+𝑫

(

𝒙

)

𝒕

(13)

Where 𝒕

=𝑡

,…𝑡

,…,𝑡

collects the

rotors’ electromotive torques and is considered the

control action of our system. Here, 𝝓𝒙,

𝜼

𝑟

highlights the parametric dependence on the motor

RPMs, appropriately estimated from the commands

sent to the electric motor controllers.

Figure 2: Model of the flying-rolling sphere, showing the

inertial coordinate system 𝑥,𝑦,𝑧 translated in G; the

sphere velocity vectors 𝒓

, 𝝎; the i-th rotor axis 𝑒⃗

along

with its relative velocity 𝜃

; the contact point velocity 𝒓

;

and the contact, thrust and gravity forces.

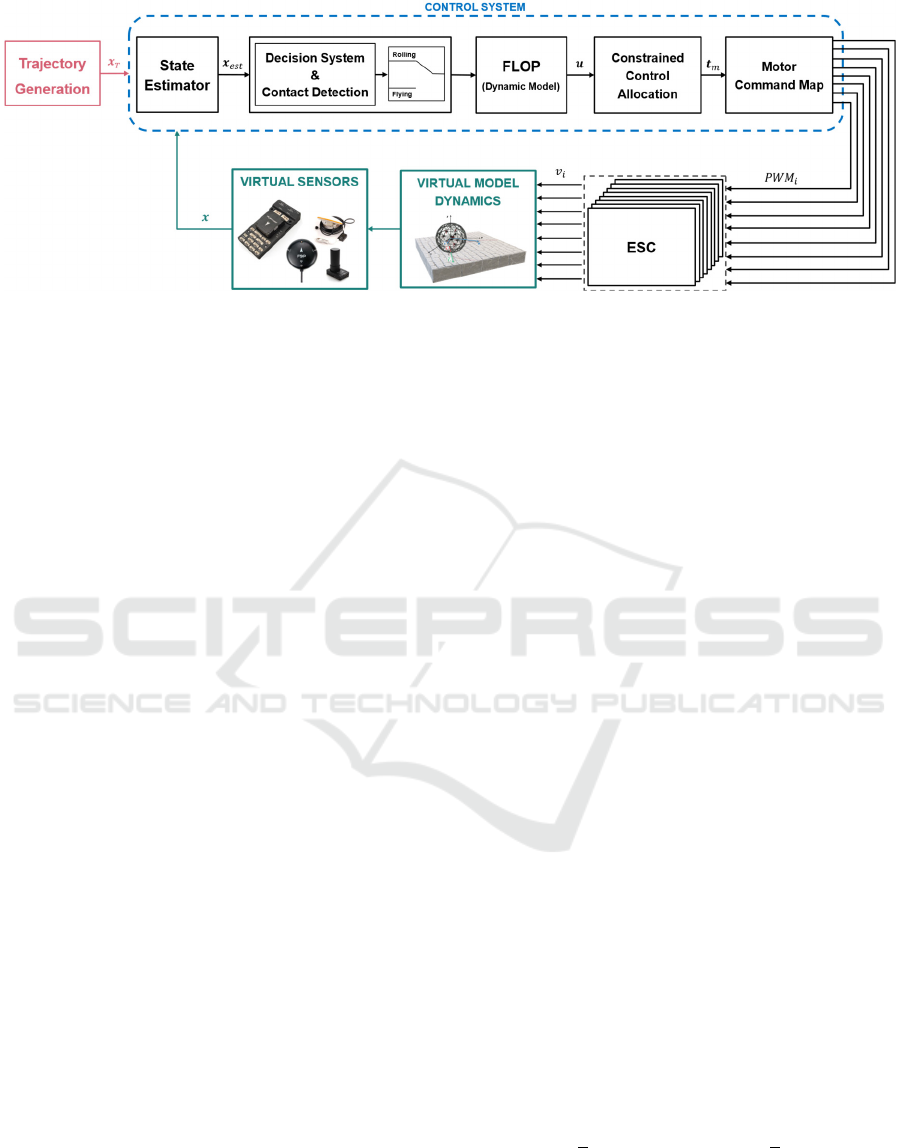

4 CONTROL SYSTEM DESIGN

The control architecture designed for the autonomous

navigation of the drone is illustrated in Figure 3. The

flight operator can plan a trajectory 𝒙

(𝑡), that

Advanced Nonlinear Control for an Omnidirectional Spherical Robot Integrating Aerial and Ground Mobility

687

Figure 3: Architecture of the Control System designed for the spherical drone, which receives as input the target trajectory to

be followed and the virtualized onboard sensor data and gives as output the PWM signal to the virtual model.

includes both flight segments and rolling segments.

The control system receives this trajectory and

onboard sensor data as inputs and outputs PWM

commands to the electric motors controllers. The

control system consists of five sequential blocks: (i)

the State Estimator assesses the drone's position,

orientation, and translational and rotational

velocities; (ii) the Decision System and Contact

Detection determines whether the drone is in flight,

rolling, landing, or take-off phases; (iii) the FLOP

Control Algorithm calculates the desired "fictitious"

force and torque actions needed to follow the

trajectory; (iv) the Constrained Control Allocation

Algorithm converts the desired actions into physical

actions, specifically the rotors’ electromotive torques

𝑡

, while respecting actuators limits; (v) the Motor

Commands maps the electromotive torques to

commands for the ESCs. To test and tune the control

system, we developed a virtual reference model that

simulates the dynamics in a multibody environment.

In the State Estimator block, the drone's state

estimation is achieved by properly processing data

from the sensors. Specifically, the system's

orientation is estimated using accelerometer,

gyroscope, and magnetometer data from the IMU

platform, implementing filtering and data fusion

techniques typical of the Attitude and Heading

Reference System (AHRS) To enhance the position

and velocity estimates, a Kalman filter was

implemented, integrating accelerometer data and

GPS data from an RTK (Real-Time Kinematic) dual-

antenna system, which provides centimeter-level

accuracy with an update frequency of 10 Hz.

The Decision System, based on onboard sensor

measurements and the output from the Contact

Detection System, determines the operating state of

the drone, such as being in free flight or in rolling

contact. The Contact Detection System analyzes the

vertical acceleration data provided by the IMU and

compares it with the acceleration predicted by both

the rolling contact model (9) and the associated free-

flight model. The system then identifies the state

based on which predicted acceleration value is closest

to the measured data and select the corresponding

model to employ in the control algorithm. A properly

defined moving average filter helps the evaluation

system to reduce false positives caused by noisy

measurements and potential signal oscillations.

4.1 Nonlinear FLOP Control

The control system designed for guiding and

controlling the drone is a nonlinear control type

known as FLOP (Pepe et al., 2018). Instead of

directly providing the 𝑁 electromotive torques 𝑡

as

control variables, this system uses seven fictitious

actions 𝒖=

𝑢

,…,𝑢

⊤

. These actions include three

translational forces along the drone's body axes 𝑥𝑦𝑧

and four pseudo-torque actions affecting the

orientation described by quaternions. This approach

allows for the subsequent resolution of a control

allocation problem for the electromotive torque

variables, taking into account the actual constraints

that exist. This process is explained in more detail in

the following section. As illustrated in (Pepe et al.,

2018), the FLOP technique utilizes an affine

reference dynamic model of the type (13), linear in 𝒖,

to provide an approximate solution to the optimal

local control problem of a constrained minimization

problem of the form:

min

𝒖

J =

1

2

(

𝒙−𝒙

)

𝑸

(

𝒙−𝒙

)

+

1

2

𝒖

𝑹𝒖 𝑑𝑡

Subject to: 𝒙

=𝝓

(

𝒙

)

+𝑩𝒖

(14)

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

688

The control vector 𝒖 is premultiplied by the input

matrix 𝑩, properly derived by introducing the

fictitious actions in our model. The solution provided

by the FLOP technique yields an explicit feedback

control formulated as:

𝒖=𝑹

𝑩

𝜕𝝓

𝜕𝒙

−

1

Δ𝑡

𝑰

𝑸

(

𝒙−𝒙

)

+𝑩

𝒙

−𝝓

(

𝒙

)

(15)

Here, 𝑸 and 𝑹 are matrices containing the control

tuning gains, Δ𝑡 is a positive control parameter, and

the symbol + denotes the pseudo-inverse of matrix

𝑩.

4.2 Constrained Control Allocation

and Motor Command

To determine the necessary electromotive torques for

controlling the drone, a constrained allocation

problem is solved, which involves a linear

programming problem outlined as follows:

min

𝒕

𝜒

‖

𝑩𝒖 − 𝑫𝒕

‖

+

𝜒

‖

𝒕

−𝒕

∗

‖

Subject to: 𝒕

≤

|

𝒕

|

≤𝒕

(16)

The goal is to minimize the sum of two terms, each

weighted by a scaling factor, 𝜒

. The first term, the

most critical, requires that the electromotive torques

𝒕

multiplied by the associated Jacobian matrix 𝑫

closely match the "fictitious" components 𝒖

suggested by the FLOP through 𝑩. The second term

ensures that the new 𝒕

is as close as possible to the

𝒕

∗

determined in the previous time step to obtain a

smoother control action. Moreover, the minimization

problem (16) is constrained by the hard limits that the

electromotive torques 𝒕

must be within the actual

maximum and minimum values, denoted by 𝒕

and

𝒕

, representing the lower and upper boundaries,

respectively.

Finally, the Motor Command block is responsible

for mapping the electromotive torques from the

Constrained Control Allocation to the corresponding

PWM commands to be sent to the ESCs, defined here

in percentage terms. Based on the hypothesis

described in (Brescianini & D’Andrea, 2018), the

PWM signal can be expressed as a polynomial

function of the electromotive torque, defining the

conversion map:

𝑃𝑊𝑀

=𝑐

𝑡

+𝑐

𝑡

⋅𝑠𝑖𝑔𝑛𝑡

+𝑐

(17)

Using a load cell, a series of experimental

measurements were conducted directly on the motor-

propeller assembly to determine the operating points

related to thrust force and transmitted torque. The

conversion map was then analytically calculated by

determining the values of 𝑐

=218.98 Nm,𝑐

=

41.96

√

Nm

and 𝑐

=50 through a least-squares

problem. Additionally, the coefficient 𝑘=131.14

introduced in (11) was evaluated.

5 NUMERICAL SIMULATION

The system was tested using numerical simulations in

the Simscape multibody environment within

MATLAB & Simulink, serving as a tool for design

support and verification of the control system. The

virtual model comprises a multibody setup with 14-

degree-of-freedom, six for the sphere and eight for the

rotors, and with specific modifications that introduce

misalignments compared to the model used in the

control algorithm. This testing and validation

approach allowed us to assess the robustness of the

algorithm under the following conditions: uncertainty

in the system's mass and inertia of about 5%; actual

electromotive torques with a random variation of

around 10%; thrust forces and aerodynamic torques

on the blades misaligned by up to 10%; contact

dynamics calculated using the penalty method, where

the normal force 𝒇

and tangential friction force 𝒇

are modelled differently:

𝒇

=

0,0,

𝑓

⊤

,

𝒇

=

𝒓

‖

𝒓

‖

𝜇

𝑓

𝑓

=

𝑘

𝛿+𝑐

𝛿

𝛿≥0, 𝛿

≥0

𝑘

𝛿𝛿≥0,𝛿

<0

0𝛿<0

(18)

where 𝛿=𝑅−𝑧 is the virtual penetration of the

sphere into the plane, 𝑘

and 𝑐

are the contact

stiffness and damping, respectively, and the friction

coefficient 𝜇 is defined as a piecewise linear function

of the slip. The virtualization of the sensors was

implemented by introducing noise signals into the

state measured from the virtual system to emulate the

real onboard sensors of the Pixhawk 6X.

The numerical simulations include three types of

tests: flight mode control, ground rolling mode

control, and a mixed mode with landing and take-off.

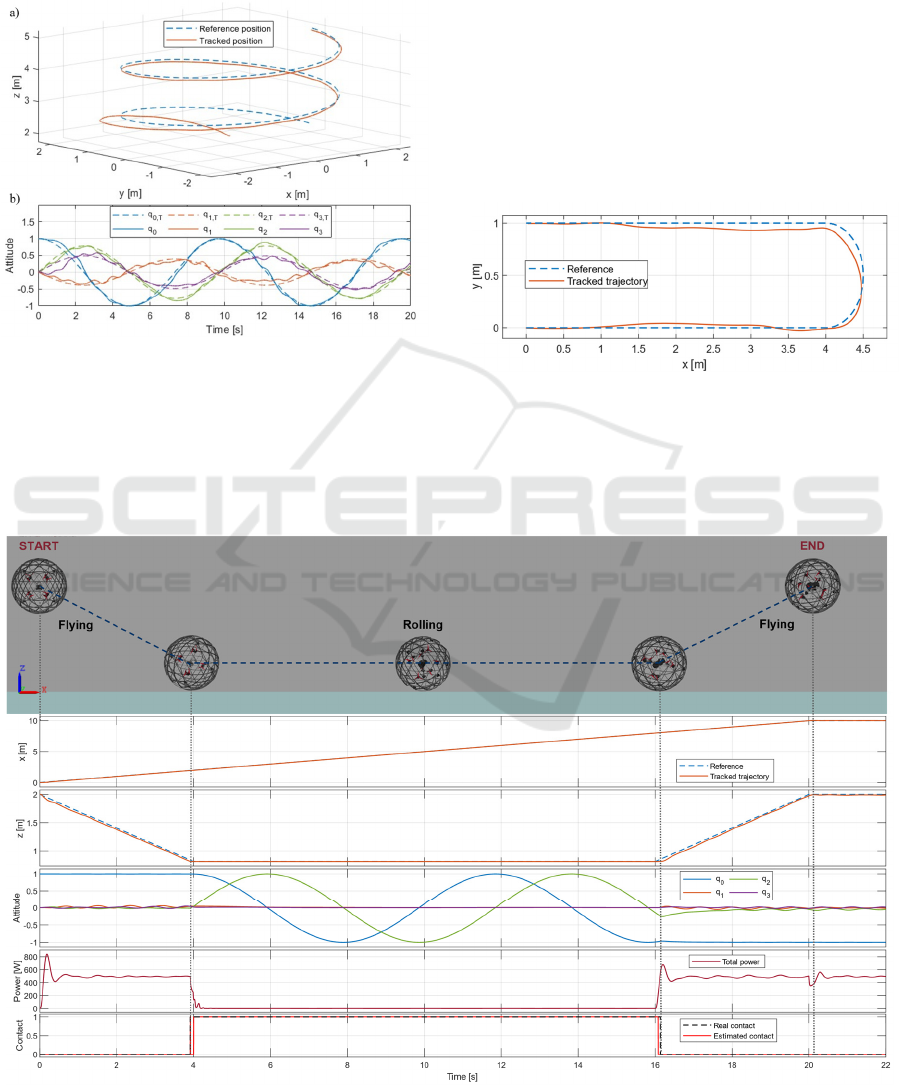

5.1 Flying Mode Test

The first test was conducted to verify the drone's

performance in flight mode, independently

controlling its position and orientation along a

predetermined trajectory. The drone was tasked with

following a helical trajectory with a oscillation period

of 10 s, while maintaining a constant arbitrary angular

velocity

𝝎

. The simulation results, shown in Figure

Advanced Nonlinear Control for an Omnidirectional Spherical Robot Integrating Aerial and Ground Mobility

689

4 demonstrate that the robot can follow the assigned

trajectory well, both in position and orientation, with

a settling position error less than 0.3 m despite

starting from an initial condition different from the

trajectory's start point.

Figure 4: Flying mode test results, showing the position

trajectory in 3D view (a) and the attitude via quaternion (b).

5.2 Rolling Mode Test

A second simulation was conducted to assess the

performance of ground rolling mobility. In this case,

the robot was subjected to a hard maneuvering test

under low-traction conditions, simulating an icy

surface with a dynamic friction coefficient of 0.1.

Additionally, the control system was assumed to be

unaware of the actual traction conditions, considering

a dynamic friction coefficient of 0.5 into (12). This

allows to test the system's robustness under

unexpected slippery conditions. The target trajectory

involved a sharp curve of radius 0.5 m, to be

navigated at a speed of 2 m/s. The results shown in

Figure 5 indicate that the maximum deviation from

the target was about 20 cm, considered satisfactory

given the challenging conditions of the test.

Figure 5: Tracked trajectory in rolling mode.

5.3 Mixed Mode

The final test evaluated the drone's ability to

transition between flight and rolling modes. The robot

Figure 6: Results of the simulation in mixed mode, showing the behavior of the spherical drone during the three phases of

landing, rolling on ground and take-off.

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

690

was tasked with three phases: landing, rolling, and

take-off, while maintain a constant target speed 𝑥

of

0.5 m/s (Figure 6Figure 6). During landing and take-

off, a controlled vertical speed 𝑧

of 0.3 m/s was

required at specific key times. Before landing, the

control system did not have information about the

contact plane's location and imposed a constant

descent speed, until the Decision and Contact

Detection system identified contact around the 4th

second mark, and promptly switched to rolling

control. Due to the low speed of impact, there was no

noticeable bounce, and the motors were managed by

the controller to achieve the desired rolling motion,

resulting in a significant drop in the required power.

At the 16th second mark, the take-off phase was

initiated and the Contact Detection system, unaware

of the take-off command, automatically recognized

the new flight state and subsequently enabled the free

flight control, where the orientation became stable

again and the required power increased accordingly.

6 CONCLUSIONS

This study presents a comprehensive approach to the

design and control of a flying-rolling spherical drone.

The key contributions include the development of a

nonlinear control system, referred to as FLOP, which

effectively manages the drone’s complex dynamics in

both aerial and ground-based operations. The control

architecture integrates state estimation, decision-

making, and force allocation to achieve precise

control in varying operational modes, including

flight, rolling, landing, and take-off. Numerical

simulations validated the proposed control methods,

demonstrating the drone's ability to follow planned

trajectories and maintain stability under different

conditions. Future work involves applying the FLOP

algorithm to the newly constructed prototype and

conducting experimental tests to validate its

performance and robustness in real-world scenarios.

REFERENCES

Atay, S., Bryant, M., & Buckner, G. (2021). The Spherical

Rolling-Flying Vehicle: Dynamic Modeling and

Control System Design. Journal of Mechanisms and

Robotics, 13(5).

Brescianini, D., & D’Andrea, R. (2018). An omni-

directional multirotor vehicle. Mechatronics, 55, 76-93.

Briod, A., Kornatowski, P., Zufferey, J.-C., & Floreano, D.

(2014). A Collision-resilient Flying Robot. Journal of

Field Robotics, 31(4), 496-509.

Diouf, A., Belzile, B., Saad, M., & St-Onge, D. (2024).

Spherical rolling robots—Design, modeling, and

control: A systematic literature review. Robotics and

Autonomous Systems, 175, 104657.

Dudley, C. J., Woods, A. C., & Leang, K. K. (2015). A

micro spherical rolling and flying robot. 2015

IEEE/RSJ International Conference on Intelligent

Robots and Systems (IROS),

Hou, K., Sun, H. X., Jia, Q. X., Zhang, Y. H., Wei, N. Z.,

& Meng, L. (2013). Analysis and Design of Spherical

Aerial Vehicle's Motion Modes. Applied Mechanics

and Materials, 411-414, 1836-1839.

Kalantari, A., & Spenko, M. (2014). Modeling and

Performance Assessment of the HyTAQ, a Hybrid

Terrestrial/Aerial Quadrotor. IEEE Transactions on

Robotics, 30(5), 1278-1285.

Nikravesh, P. E., Wehage, R. A., & Kwon, O. K. (1985).

Euler Parameters in Computational Kinematics and

Dynamics. Part 1. Journal of Mechanisms,

Transmissions, and Automation in Design, 107(3), 358-

365.

Pensalfini, S., Coppo, F., Mezzani, F., Pepe, G., &

Carcaterra, A. (2017). Optimal control theory based

design of elasto-magnetic metamaterial. Procedia

Engineering, 199, 1761-1766.

Pepe, G., Antonelli, D., Nesi, L., & Carcaterra, A. (2018).

Flop: Feedback local optimality control of the inverse

pendulum oscillations. Proceedings of ISMA 2018 -

International Conference on Noise and Vibration

Engineering and USD 2018 - International Conference

on Uncertainty in Structural Dynamics, Leuven.

Pepe, G., Doria, A., Roveri, N., & Carcaterra, A. (2023).

Vibration energy harvesting for cars: semi-active piezo

controllers. Archive of Applied Mechanics, 93(2), 663-

685.

Pepe, G., Laurenza, M., Antonelli, D., & Carcaterra, A.

(2019). A new optimal control of obstacle avoidance for

safer autonomous driving. 2019 AEIT International

Conference of Electrical and Electronic Technologies

for Automotive, AEIT AUTOMOTIVE 2019,

Sabet, S., Agha-Mohammadi, A. A., Tagliabue, A., Elliott,

D. S., & Nikravesh, P. E. (2019). Rollocopter: An

Energy-Aware Hybrid Aerial-Ground Mobility for

Extreme Terrains. 2019 IEEE Aerospace Conference,

Spitaleri, D., Pepe, G., Laurenza, M., Milana, S., &

Carcaterra, A. (2024). Enhancing Spherical Rolling

Robot Control for Slippery Terrain. 2024 13th

International Workshop on Robot Motion and Control

(RoMoCo),

Yao, Y., Deng, Z., Zhang, X., & Lv, C. (2021). Design and

Implementation of a Quadrotor-Based Spherical Robot.

2021 IEEE 5th Advanced Information Technology,

Electronic and Automation Control Conference

(IAEAC),

Zhou, Q. L., Zhang, Y., Qu, Y. H., & Rabbath, C. A. (2010).

Dead reckoning and Kalman filter design for trajectory

tracking of a quadrotor UAV. Proceedings of 2010

IEEE/ASME International Conference on Mechatronic

and Embedded Systems and Applications,

Advanced Nonlinear Control for an Omnidirectional Spherical Robot Integrating Aerial and Ground Mobility

691