Using Imitation Learning to Implement Control Orchestration for

Smart Chassis

Sarah Imene Khelil

1

, Bruno Monsuez

1

, Maud Geoffriault

2

and Anh Lam Do

2

1

Department of Computer and System Engineering (U2IS), ENSTA Paris,

Institut Polytechnique de Paris, Palaiseau, France

2

Chassis Systems Department, Groupe Renault, Guyancourt, France

Keywords: Behavioral Cloning, Control Allocation, Imitation Learning, Deep Reinforcement Learning,

Supervised Learning.

Abstract: Despite the advances in control allocation for over-actuated systems, the need for a comprehensive, optimized,

and safe solution remains ongoing. Traditional methods, though mature, struggle with the complexities of

coupled non-linear allocation and the need for extensive computational resources. Machine learning may

provide significant advantages through its generalization and adaptation capabilities, especially in scenarios

where linear approximations are employed to reduce computational burdens or when the effectiveness of

actuators is uncertain. Recent advances in imitation learning, particularly behavioral cloning, and deep

reinforcement learning have demonstrated promising results in addressing these challenges. This paper aims

to determine the potential of using machine learning in control orchestration for smart chassis to go beyond

allocation issues to include interaction management across systems, resource balance, and safety and

performance limits. We present a set of techniques that we believe are relevant to experiment to address

potential challenges like prediction and complexity for control allocation in smart chassis systems, which will

be tested in the upcoming articles.

1 INTRODUCTION

Chassis system design prioritizes safety, stability, and

performance. Initially, these systems aimed to

enhance individual vehicle parameters by utilizing

longitudinal tire forces for longitudinal control and

lateral tire forces for lateral control. Over time, more

sophisticated methods emerged, such as differential

steering between the right and left tires for

longitudinal control and differential acceleration

between the front and rear tires for lateral control,

electronic stability programs and torque vectoring are

examples of such techniques. The integration of

multiple subsystems that are critical for reinforcing

safety, and that drive the same physical quantity in

over-actuated vehicles raises the problem of how to

orchestrate those subsystems without degrading

neither the dynamic safety nor the vehicle

performance.

Traditionally, rule-based strategies based on

expert knowledge of vehicle dynamics are employed

to address these issues, under what we call the

downstream approach. Unlike traditional approaches,

optimization-based control allocation methods ensure

stability while leveraging the unique strengths of each

system, promising better performance and reliability

across diverse driving conditions (Kissai, 2019). We

call this the upstream approach.

Integrated Chassis Control (ICC) (Skrickij, Kojis,

Šabanovič, Shyrokau, & Ivanov, 2024) depends on

the upstream approach playing an important role in

harmonizing these active sub-systems to optimize

vehicle dynamics, safety, comfort, and energy based

on current conditions and actuator limitations.

Orchestration goes beyond that by managing the

coordination, and planning of subsystems over longer

timeframes, considering strategic goals and future

states.

The two terms will be used interchangeably as the

current state-of-the-art swings between the two terms.

Going back to ICC, it follows a modular strategy

for orchestration as it separates the tracking aspect of

control from the distribution perspective. As

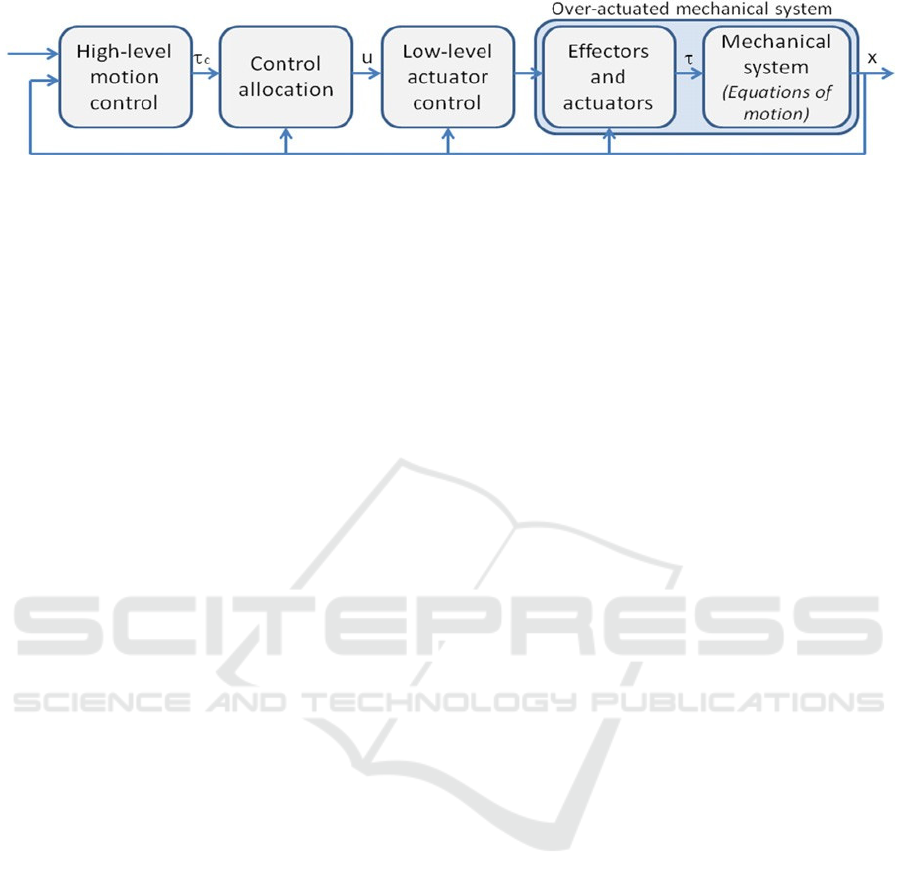

illustrated in Figure 1, the high-level control specifies

the desired control. A control allocator distributes this

effort among various actuators to produce the desired

462

Khelil, S. I., Moonsuez, B., Geoffriault, M. and Do, A. L.

Using Imitation Learning to Implement Control Orchestration for Smart Chassis.

DOI: 10.5220/0013049300003822

In Proceedings of the 21st International Conference on Informatics in Control, Automation and Robotics (ICINCO 2024) - Volume 1, pages 462-471

ISBN: 978-989-758-717-7; ISSN: 2184-2809

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

Figure 1: Control system structure including control allocation (Johansen & Fossen, 2013).

effect while optimizing for additional objectives such

as minimizing energy consumption (multi-objective

optimization).

Currently, researchers assume a linear

relationship between actuator actions and resulting

control outcomes to use computationally efficient

algorithms such as daisy chaining, redistributed

pseudo-inverse or cascaded generalized inverse, and

methods based on linear programming and quadratic

programming for control allocation (CA) (Johansen

& Fossen, 2013). However, the CA problem in cars is

inherently coupled and nonlinear suffering from

discontinuities as the system behavior changes

according to the changes in the environment and

changes in the system itself. The dependencies

between the vehicle states make the study even more

complex.

As the objective is to have a control orchestration

that predicts the saturation of the actuators by taking

into account their dynamics while keeping track of

the change in the environment and behaving

accordingly, preview capabilities are of a big interest

to such a problem.

Predictive nonlinear control allocation is

challenging necessitating significant onboard

computational power and accurate models of the

effectiveness function to find the optimal actuator

combination. Here comes machine learning (ML)

offering solutions to optimization and generalization

needs. Depending on the neural nets used in the

generation of the cloner, this latter can be enhanced

by predicting future states and behaviors based on

past data if such neural nets have a memory (e.g. long

short-term memories). It captures complex,

nonlinear, and time-varying vehicle dynamics and

accounts for uncertainty and variability in real-world

driving conditions, improving reliability. Also, ML

personalizes control strategies to individual driver

behavior and preferences.

The use of a cloner causes big challenges as the

same level of performance and the same quality of

results should be ensured while addressing the big

problem of the computational burden of the already

existing solutions. A comparative study should be

carried out during the development phase.

Recent advances in imitation learning and deep

reinforcement learning show promising capabilities

that may be used in CA formulation. Recent work by

Khan, Mobeen, Rajput, and Riaz (2024) explored the

use of a neural network (NN) in CA to account for the

nonlinear CA problem formulation and compared it

to quadratic programming (QP) allocation. The two

approaches have similar performance with reduced

run time for the proposed scheme of ANN-based

control allocator. From another part, the optimization

problem has been studied by Skulstad, Li, Fossen, and

Zhang (2023) who proposed a deep learning

technique for the problem of dynamic positioning in

marine vessels. The study used behavioral cloning to

capture the intricate relationships between control

inputs and system responses. The solution was as

performant as a sequential QP-based CA however the

constraints were violated leading to another research

by the same authors comprising the addition of a

costume NN layer to enforce hard constraints

(Raghunathan, Skulstad, Li, & Zhang, 2023). Wu and

Litt (2023) explored the use of deep reinforcement

learning (RL) for controlling an aircraft equipped

with distributed electric propulsion (DEP). The

research demonstrates that RL can efficiently manage

the allocation of thrust among multiple electric

engines, achieving stable flight even under conditions

of actuator failure without a knowledge of the

efficiency matrix of the CA.

Through this article, we aim to highlight the

potential of utilizing machine learning in control

allocation, especially for coupled non-linear

problems.

This paper is organized as follows. Section 2

introduces the CA problem formulation for a simple

chassis problem. Section 3 presents the existing

learning techniques of CA. The study conducted by

the state of the art is demonstrated through the

methodologies and results in section 4. In section 5, a

simple automotive-related example is presented. It is

followed by concluding remarks in section 6.

Using Imitation Learning to Implement Control Orchestration for Smart Chassis

463

2 CONTROL ALLOCATION

THEORY

Nothing is better than introducing a problem through

an example like controlling yaw rate for better

steering and stability. Active Front Steering (AFS)

and Active Rear Steering (ARS) have been proposed

as lateral methods that can directly affect the

parameter in question. However, physics laws proved

the possibility of using braking-based systems to

generate yaw moments, which gives rise to the

problem of managing both longitudinal, through the

Vehicle Dynamics Control (VDC) system, and

lateral, through ARS, controls to achieve the desired

behavior. Such a system is called an over-actuated

system, and the CA aims here to find the optimal

combination of the actuator distribution to achieve the

desired behavior.

As has been presented by Kissai (2019) the

upstream CA approach generates more realistic

commands as it takes into account the tire dynamic

couplings and constraints.

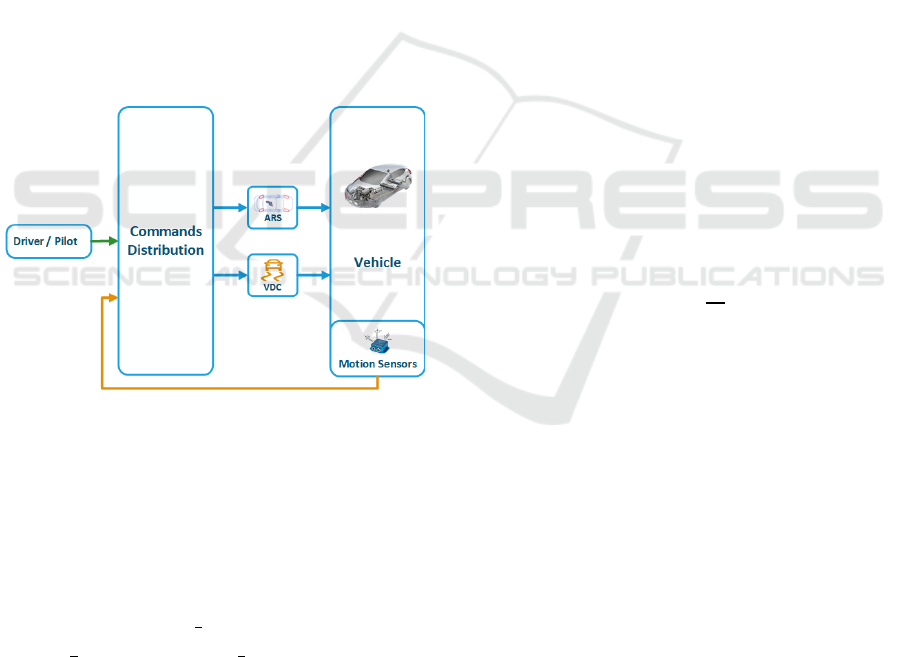

Figure 2: Structure of the upstream coordination approach

(Kissai, 2019).

We want to control the yaw rate rate ψ

using the

forces generated by the existing actuators. To

synthesize this control allocator we take the yaw

moment 𝑀

generated as a high-level command,

the following equation should be considered:

𝑀

=𝐹

,

𝑙

sin𝛿

−

cos𝛿

+𝐹

,

𝑙

sin𝛿

+

cos𝛿

+𝐹

,

−𝐹

,

−𝐹

𝑙

(1)

where:

𝑑: vehicle’s track,

𝑙

: distance between the axle k and the

vehicle’s center of gravity, where k

designates the front or the rear,

𝐹

: overall lateral force at the axle k,

𝐹

,

: longitudinal force of each tire, where j

designates left or right,

𝛿

: initial steering angle before the

application of the tire force.

Illustrated in Figure 1, the control system

structure prominently features control allocation.

CA of over-actuated systems functions through

three distinct stages:

2.1 High-Level Control

This initial stage involves generating virtual control

commands 𝜏

, without necessitating detailed actuator

information, relying on a simplified linear model.

𝑥 =𝑓

(

𝑥,𝑡

)

+𝑔

(

𝑥,𝑡

)

𝜏 (2)

where:

𝑓

,

𝑔

are functions,

𝑥 ∈𝑅

is the state vector,

𝑡 is time,

𝜏 ∈𝑅

is the virtual input vector.

Let us take ψ

as the high-level controlled state 𝑥

and 𝑀

as the virtual command, from the global

vehicle model, we get:

ψ

(

𝑠

)

=

(3)

where:

𝐼

: inertia moment,

𝑠: Laplace operator.

2.2 Control Allocation

Following high-level control, this stage coordinates

various effectors, accounting for input constraints and

fault tolerance, and maps the vector of virtual input

forces and moments 𝜏

into individual effector forces

or moments 𝜏.

𝜏 =ℎ(𝑢,𝑥,𝑡) (4)

where:

ℎ

is a function,

𝑢 ∈ 𝑈 ⊂ 𝑅

is the control input, with 𝑈

representing control constraints due to

saturation and other physical constraints.

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

464

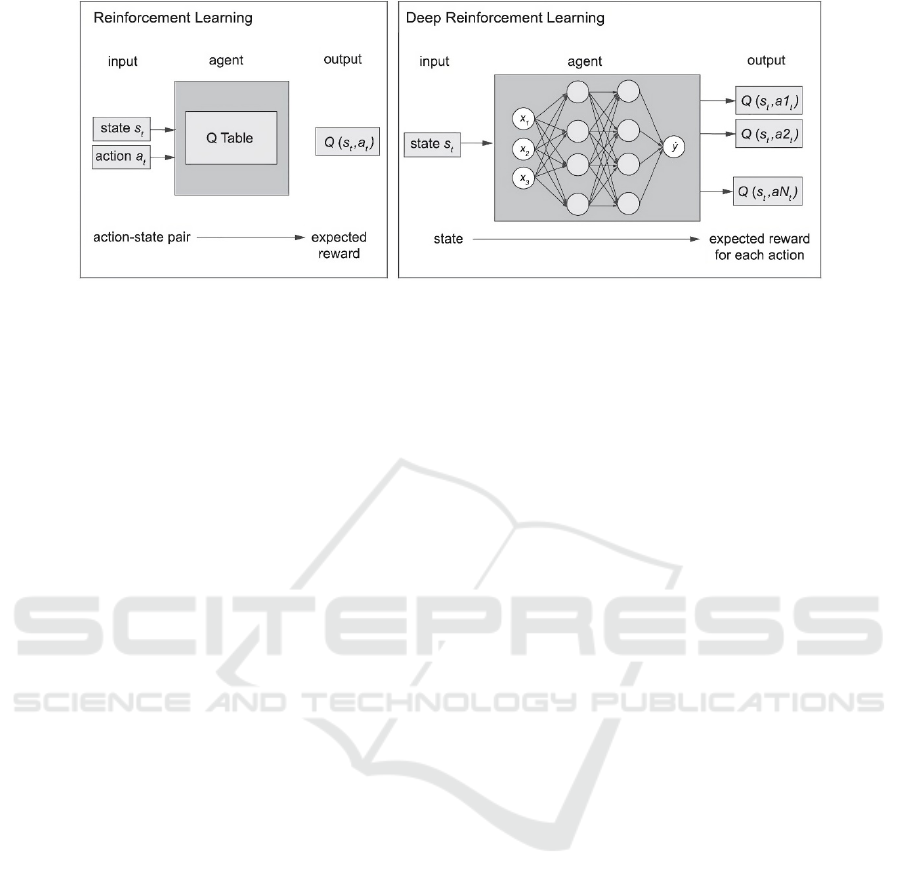

Figure 3: The reinforcement and imitation learning paradigms (Davila Delgado & Oyedele, 2022).

Commonly, effector models are linear in 𝑢:

𝜏 = ℎ

(

𝑢,𝑥,𝑡

)

=𝐵

(

𝑥,𝑡

)

𝑢 (5)

By taking the forces generated by the existing

actuators as 𝑢and 𝑀

as the virtual command, we get

the following effectiveness matrix:

𝐵 = [𝑙

sin𝛿

−

cos𝛿

,𝑙

sin𝛿

+

cos𝛿

,

−

,

,−𝑙

]

(6)

Clearly, by looking at the effectiveness matrix,

there is

a nonlinear relationship between the CA in-

out pair as

𝛿

depends on the forces and vice-versa

through the tire model.

The model can be complexified more by

including the actuators’ dynamics and delays.

2.3 Low-Level Control

This stage focuses on controlling each effector via its

actuators.

Control allocation computes a control input 𝑢

that ensures 𝜏

=ℎ(𝑢,𝑥,𝑡) at all times 𝑡.

If a feasible 𝑢 cannot be found, the control

allocation searches for a control input that minimizes

the allocation error 𝜏

−𝜏.

min

∈

𝑄(𝜏

−𝜏) (7)

Incorporated within this process are actuator

rate and position limits to ensure stability and

performance.

3 EXISTING APPROACHES OF

MACHINE LEARNING IN

CONTROL ALLOCATION

As presented through the example, the CA problem in

cars is inherently nonlinear and coupled. This

behavior can be made more complex as the system

behavior changes according to the changes in the

environment (preferred actuators depending on the

grip) and changes in the system itself (change in the

number of the actuators) making it suffer from

discontinuities. To achieve effective control

orchestration that predicts actuator saturation while

accounting for their dynamics and adapting to

environmental changes, preview capabilities are

essential. This task demands substantial onboard

computational power and precise models of actuator

effectiveness to find the optimal combination.

Machine learning (ML) provides powerful solutions

to these optimization and generalization challenges.

By predicting future states and behaviors from

past data, ML can handle complex, nonlinear, and

time-varying vehicle dynamics. It improves

reliability by addressing uncertainty and variability in

real-world driving conditions. Furthermore, ML can

tailor control strategies to match individual driver

behaviors and preferences.

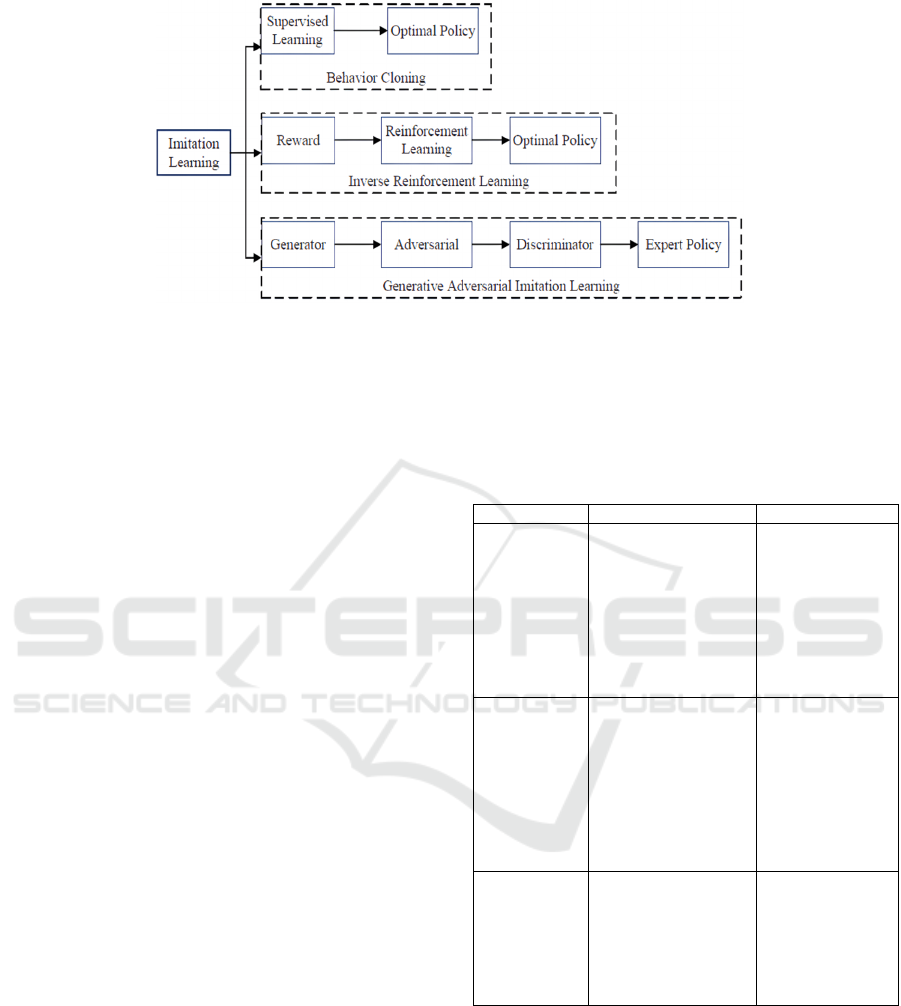

Depending on the expert used for the learning, we

can distinguish two existing approaches of learning in

control allocation, as illustrated in Figure 3.

3.1 Learning of a Non-Existing Control

Allocator Using Deep

Reinforcement Learning

Deep reinforcement learning (DRL) combines

reinforcement learning (RL) and deep learning (DL)

to enable learning expert behavior.

3.1.1 Reinforcement Learning

It is a mapping between states and actions with the

goal of maximizing a reward function.

In short the learning is achieved through

environment exploitation.

Using Imitation Learning to Implement Control Orchestration for Smart Chassis

465

Figure 4: Main differences between RL and DRL (Davila Delgado & Oyedele, 2022).

It is constructed from (Manuel Davila Delgado &

Oyedele, 2022):

Agents, Environments, Actions, and States: An

agent observes the state 𝒔

𝒕

of the environment then

takes actions 𝒂

𝒕

and receives feedback on the

outcome of the choices made.

Rewards: A scalar that indicates the level of success

to reach the goal every time the agent takes an action.

Value Function: The 𝑸 value of a state is the total

reward that an agent can expect in the future starting

from that given state. Rewards determine immediate

success, while value 𝑸 indicates long-term

accumulated success.

Policy: The policy 𝝅 is a state-action mapping

that maximizes the reward:

𝜋

∗

(𝑎) = max

𝑄(𝑠,𝑎)

(8)

3.1.2 Deep Learning

It defines the use of a neural network with a large

number of hidden layers.

In DRL, deep neural networks are used to

discover state-action mappings instead of a relational

table known as a Q-table to map states to actions

(Manuel Davila Delgado & Oyedele, 2022).

It can be categorized into model-based and model-

free approaches:

Model-Based Methods: These methods involve

learning a model of the environment and using it to

plan actions.

Model-Free Methods: These methods learn

policies directly from interactions with the

environment without explicitly modeling them.

DRL presents one of the most needed features as

it can generalize from specific training examples to

unseen situations, given sufficient data diversity

during training.

However, as opposed to imitation learning, as there

is no expert the DRL algorithms typically require a

large number of interactions with the environment to

learn effective policies, leading to high computational

costs. Designing appropriate reward functions can be

complex and task-specific, and the exploration-

exploitation trade-off presents a big limitation often

leading to suboptimal exploration strategies (Zare,

Kebria, Khosravi, & Nahavandi, 2023).

3.2 Learning of an Existing Control

Allocator Through Supervised

Learning

We call the use of supervised learning, Table 1, to

clone the behavior of an expert imitation learning

(IL).

IL aims at mimicking an agent that is considered

to perform well in a particular task. This is essentially

learning to map observations to actions.

Imitation learning is useful in fields like

autonomous vehicles, robotics, and other industries

where large sensory data of expert demonstrations are

available (Dey, Marzullo, Zhang, & Henze, 2023).

Such an approach is used whenever a well-

developed expert, in our case a CA, exists and needs

to be replaced because of its optimization burden, and

complex relation formulation between the in-out pairs

(coupling between in-out pairs, non-linearity for

example).

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

466

Table 1: Types of machine learning approaches (Manuel

Davila Delgado & Oyedele, 2022).

Type Supervised

Learning

Unsupervised

Learning

Reinforcement

Learning

Data

Labelle

d

data: (x, y)

x is data, y

is the

label.

Data: (

x

)

x

is

unlabelled

data.

D

ata:

(

s

t

,a

t

)

s

t

is state, a

t

is

action.

Goal

Learn

function to

map:

x → y

.

Learn an

underlying

structure to

find

relationships.

Maximize

future reward

over many time

steps through

interaction with

the environment

or with an

expert.

IL can be classified into:

3.2.1 Behavioral Cloning (BC)

It is a mapping of states 𝒔

𝒕

to actions 𝒂

𝒕

as shown

bellow:

𝑎

=𝜋(𝑠

) (9)

The policy π can be learned by a supervised

learning method from a dataset of pairs 𝐷 =

𝑠

,𝑎

.

The neural network mimics the expert behavior

by learning state-action pairs.

3.2.2 Inverse Reinforcement Learning (IRL)

In inverse reinforcement learning the reward function

is unknown and this needs to be recovered from the

existing expert demonstration.

The neural network infers the underlying reward

function (positive reward when the error between the

setpoint and the output of the system gets smaller)

from the expert demonstrations and then uses RL to

learn the optimal policy.

In these approaches the objective is to learn the

reward function –instead of the policy– directly from

an expert’s trajectory, and then find the optimal

policy using an RL approach (Manuel Davila

Delgado & Oyedele, 2022).

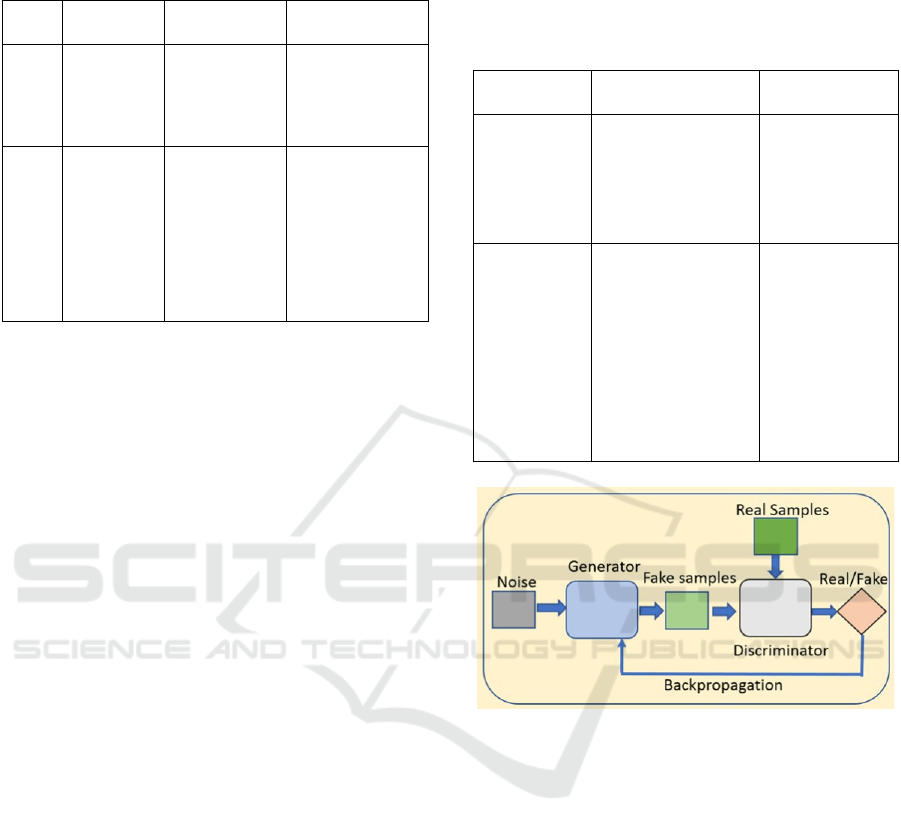

The Table 2 summarizes the main advantages and

disadvantages of the two principal IL approaches.

3.2.3 Adversarial Imitation Learning (AIL)

This approach involves training a policy (generator)

and a discriminator in an adversarial setup, where the

discriminator learns to distinguish between the

agent’s actions and the expert’s actions, while the

policy learns to fool the discriminator by producing

actions that are indistinguishable from those of the

expert, as illustrated in Figure 5:

Table 2: Benefits and disadvantages of imitation learning

approaches (Manuel Davila Delgado & Oyedele, 2022).

Type Benefits Disadvantages

Behavioral

Cloning

-Simple

implementation.

-Effective for

small state spaces.

Requires

almost total

coverage of

the state

space.

Inverse

Reinforceme

nt Learning

-No need to

specify reward

function.

-Improved

generalization.

-Robust against

changes in the

environment.

Very high

computational

costs for

relatively

small state and

action spaces.

Figure 5: Graphical illustration of the working principle of

adversarial imitation learning (Latif et al., 2021).

Illustrated in Figure 6, are the imitation learning

techniques.

In short, using adversarial training, the generator

(policy network) improves its ability to produce

expert-like actions, thereby learning the mapping

between states and actions effectively.

Clearly, imitation learning requires fewer

interactions with the environment as it has pre-

collected expert data. In IRL, the reward functions are

learned from expert demonstrations.

However, such an approach suffers from the need

for a collection of diverse and large-scale

demonstrations, in our case the in-out pairs of CA in

different scenarios. So, performance heavily depends

on the quality and diversity of the provided

demonstrations.

Using Imitation Learning to Implement Control Orchestration for Smart Chassis

467

Figure 6: Classification of imitation learning (Hua, Zeng, Li, & Ju, 2021).

3.3 Learning of a Control Allocator

Using Transfer Learning

Transfer Learning (TL) involves transferring

knowledge gained from one task to improve learning

in another related task, this can be achieved by

transferring models or policies learned.

Such an approach is so efficient as it reduces the

data and the training time by providing pre-trained

models or knowledge from related tasks.

However, transferred models may perform poorly

if the source and target domains differ significantly.

While each learning paradigm has its strengths,

they also come with significant challenges.

Combining these approaches (e.g., applying transfer

learning to adapt DRL policies to new tasks) can

leverage their advantages while mitigating individual

limitations. As an example, BC can be used to mimic

the existing CA, and DRL can be used to achieve a

generalization of the behavior of the cloner through

TL.

The choice of the technique will depend on the

needs and the suitability of whether the expert exists

or not and the quality of the data used in the learning,

Table 3.

4 CURRENT RESEARCHES

Concerning the work that has been conducted in

learning CA, researchers used BC and DRL till now.

Recent work by Khan, Mobeen, Rajput, and Riaz

(2024), explored the use of an ANN in CA to account

for the nonlinear CA problem formulation and

compared it to quadratic programming (QP)

allocation. They tested the two approaches on an

aircraft equipped with redundant control effectors.

The two approaches showed similar performance with

reduced run time for the proposed scheme of ANN-

based control allocator.

Table 3: Comparison of Learning Types: Imitation

Learning, Deep Reinforcement Learning, and Transfer

Learning.

Type Pros Cons

Imitation

Learning

-Facilitates rapid skill

acquisition.

-Effective in

structured

environments.

-Limited to

mimicking

demonstrated

behaviors.

-Challenges in

dealing with

unstructured

data.

Deep

Reinforcement

Learning

-Enables

autonomous

decision-making.

-Suitable for

complex, dynamic

environments.

-Requires

extensive

computation and

training time.

-Prone to

instability and

convergence

issues.

Transfer

Learning

-Leverages pre-

existing knowledge

for new tasks.

-Reduces data

requirements for

trainin

g

.

-Performance

heavily

depends on

source-target

similarity.

The optimization problem has been studied by

Skulstad, Li, Fossen, and Zhang (2023) in their article

“Constrained control allocation for dynamic ship

positioning using deep neural network” where they

proposed a deep Learning Technique for the problem

of dynamic positioning in marine vessels and trained

to perform low-speed maneuvering and

stationkeeping in a simulated environment. The study

used behavioral cloning to capture the intricate

relationships between control inputs and CA output.

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

468

Using custom loss functions, the network ensures

motion objectives and thruster constraints are met.

The solution was as performant as an SQP-based CA

however the constraints were violated leading to

another research by the same authors comprising the

addition of a costume NN layer to enforce hard

constraints (Raghunathan, Skulstad, Li, & Zhang,

2023). The layers use a specific activation function

that inherently respects the constraints.

Wu and Litt (2023) explored the use of deep

reinforcement learning (RL) for controlling an

aircraft equipped with tributed electric propulsion

(DEP) in their article “Reinforcement Learning

Approach to Flight Control Allocation With

Distributed Electric Propulsion”. The research

demonstrates that RL can efficiently manage the

allocation of thrust among multiple electric engines,

achieving stable flight even under conditions of

actuator failure without a knowledge of the efficiency

matrix of the CA.

As with any data-based approach, the learning-

based CA goes through the following steps:

4.1 Data Collection and Preprocessing

All studies emphasize the importance of

comprehensive data collection and preprocessing.

The state of art precised clearly the relationship

between the quality of the data processed and the

generalization capability of the resulting CA.

For the BC, neither change in the number of

actuators nor failure scenarios were considered in the

data collection (Skulstad, Li, Fossen, & Zhang,

2023), (Khan, Mobeen, Rajput, & Riaz, 2024). For

the DRL case, coordinated turns and one-wing fan

failure were taken into the data collection scenarios

and tested afterward.

4.2 Model Design and Training

From the previously presented learning methods, only

two approaches have been used in the state of the art:

4.2.1 Behavioral Cloning

This approach has been used because a well-working

CA already exists.

The neural network models for BC contained

multiple layers to capture complex nonlinear

relationships between in-out pairs. Recurrent neural

nets have been used to facilitate constraining rates

(Zare, Kebria, Khosravi, & Nahavandi, 2023).

Specific attention was given to preventing overfitting

through techniques such as dropout and

regularization.

Constraints were taken into account in the

development of the NN by introducing them as

penalties in the loss function, or by clipping the

outputs violating the constraints.

Multi-objective optimization was also taken into

account to achieve secondary objectives such as

minimizing power consumption and maximizing

comfort. A deep autoencoder network was used to lay

a hand on both the tracking and the allocation

capabilities of the NN.

A small study on the change of the parameters of

the neural network has been done to show the effect

of the number of layers and their dimensions on the

convergence of the output.

4.2.2 Deep Reinforcement Learning

The DRL has been used because no CA was

developed for such a system. The DRL agent was

trained by interacting with the system model in a

high-fidelity simulation.

Proximal Policy Optimization (PPO) was used

with a reward function designed to encourage the

minimization of the tracking error.

4.3 Results

The integration of deep learning and reinforcement

learning into control allocation systems offers

significant advantages as it leverages better handling

of complexities and non-linearities plus an adaption

to actuator failures if covered in the training phase.

The reviewed studies collectively demonstrate

that learning-based control allocation methods reach

similar performances to traditional approaches in

terms of allocation and better performances in terms

of multi-objective optimization.

Comparing the execution time of both approaches

doesn’t seem to give a collective answer about the

real-time performance of the two approaches.

5 APPLICATION CASE TO

SMART CHASSIS

As all the blocks are presented, there is nothing left

but to assemble them.

Let’s retake the same example used by Kissai,

Monsuez, Mouton, Martinez, and Tapus (2019);

control of the yaw rate ψ

using the forces generated

by the existing actuators (VDC and ARS).

Using Imitation Learning to Implement Control Orchestration for Smart Chassis

469

The relationship between the yaw moment 𝑀

and

the different longitudinal and lateral forces were

shown in (1). The non-linearities and coupling are

clearly seen in the equation. What if forces in the Z-

direction are considered, or a different set of actuators

is used, or a change in the vehicle parameters (e.g.:

mass) or the environment parameters happens, or

prediction needs for a more comfortable ride are

desired? Such needs clearly cause coupled, highly

changing control allocation formulations.

Here comes machine learning (ML) in solving

optimization and generalization concerns. Add the

fact that if the neural nets have memory capabilities

like long short-term memory (LSTM), then predicting

future states and behaviors based on past data can be

possible. Complicated nonlinear and time-varying

vehicle dynamics can be considered, under significant

uncertainty and variability in real-life driving

conditions, providing better reliability. ML also has

the ability to personalize control strategies to the

driver.

As with any ML problem, the following steps

should be followed:

Data collection: As the driving environment is

so dynamic and restrictive, these limitations

can oppose with the big performance and

comfort expectations. High safety and

adaptability should be guaranteed. So,

extensive driving data should be gathered for

the training of the NN model under various

conditions, including sensor readings, actuator

inputs, and responses.

Model training: The NN should be trained to

produce the optimal output by taking into

consideration all the constraints and objectives

of the developer.

Integration: The trained ML models should be

embedded into the CA algorithm with the

high-level controller and the actuator.

Allocation and tracking performance should

be checked. For the RL implementation, the

ML model continuously learns by the

interaction with the environment.

Testing and validation: A detailed comparison

with hopefully an already developed CA

should be made.

5.1 Reinforcement Learning for

Control Allocation

Reinforcement Learning (RL) is used when the

efficiency matrix is uncertain. This can be the case

with complex dynamics of the system studied. Here,

the solution would be learned from the interaction

with the environment.

Define the environment: The hardest part is

the choice of a suitable reward function.

Depending on the objectives, reward can

include factors like maintaining vehicle

stability, minimizing tire slip, and ensuring

passenger comfort.

Model design: An RL algorithm should be

selected to learn the optimal control policy.

Model training: The RL agent interacts with

the simulated environment, learning to

optimize control actions based on rewards.

Model deployment: The trained RL model is

deployed in the vehicle’s control system,

continuously refining its strategy based on

real-time data.

5.2 Behavioral Cloning for Control

Allocation

This Behavioral Cloning (BC) can effectively learn

and replicate the control strategies of an already-

developed expert CA.

The main steps that should be followed are:

Define the environment: As opposed to the

plants used in the current state-of-the-art, the

driving environment is so dynamic pushing

the car to its functional limits more often. So,

we should ensure that the data capture a wide

range of driving scenarios to train a robust

model.

Data Collection and Preparation: Driving data

should be collected from the advanced CA

systems: Inputs: CA input (yaw rate in our

case), system and environment specification

(vehicle speed, vehicle mass, steering

angle...); Outputs: CA output (longitudinal

and lateral forces in our case).

Model design and training: A neural network

model with appropriate layers and neurons

should be chosen. A great importance should

be given to the type of the NNs used as it

highly depends on the nature of the expert.

Then, the model should be trained using the

dataset, to minimize the error between the

predicted and actual control actions. Multi-

objective optimization can be achieved by

integrating other objectives like energy

optimization in the neural network loss

function.

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

470

Model deployment: The model is then

implemented in the vehicle’s onboard

computer to ensure real-time execution for

predicting control actions based on current

sensor inputs.

For transfer learning (TL), the idea of combining

BC and RL seems relevant. As an example, BC can

be used to mimic the existing CA, and DRL can be

used to achieve a generalization of the behavior of the

cloner through TL to introduce adaptability.

However, a study of the limitations of BC should be

conducted to justify the use of TL as the automotive

field is so restrictive in terms of computational power.

6 CONCLUSIONS

In this paper, three learning approaches to implement

control allocation have been introduced. Control

orchestration needs for chassis systems have been

presented and the limitations of optimization-based

coordination have been discussed. The main results

obtained from the state of the art present a big

motivation to satisfy our needs in terms of

generalization, prediction, and fidelity.

The coming work will concern an in-depth

discussion of the main missing points and doubts that

have to be revisited in our future studies relating to

imitation learning in general, and learning of CA

more specifically. The example taken in this article

will be used to see the reliability of imitation learning

in CA problems.

REFERENCES

Vries, P., & Van Kampen, E.-J. (2019). Reinforcement

learning-based control allocation for the innovative

control effectors aircraft. In Proceedings of the AIAA

Scitech 2019 Forum. https://doi.org/10.2514/6.2019-

0144.

Raghunathan, R. N., Skulstad, R., Li, G., & Zhang, H.

(2023). Design of constraints for a neural network

based thrust allocator for dynamic ship positioning. In

IECON 2023 - 49th Annual Conference of the IEEE

Industrial Electronics Society (pp. 1–6).

https://doi.org/10.1109/IECON51785.2023.10312100.

Khan, H. Z. I., Mobeen, S., Rajput, J., & Riaz, J. (2024).

Nonlinear control allocation: A learning-based

approach. arXiv. https://arxiv.org/abs/2201.06180.

Skulstad, R., Li, G., Fossen, T. I., & Zhang, H. (2023).

Constrained control allocation for dynamic ship

positioning using deep neural network. Ocean

Engineering, 279, 114434. https://doi.org/10.1016/j.

oceaneng.2023.114434.

Wu, K. C., & Litt, J. S. (2023). Reinforcement learning

approach to flight control allocation with distributed

electric propulsion (NASA Technical Memorandum

No. 20230014863). National Aeronautics and Space

Administration, Glenn Research Center.

https://ntrs.nasa.gov/.

Skrickij, V., Kojis, P., Šabanovič, E., Shyrokau, B., &

Ivanov, V. (2024). Review of integrated chassis control

techniques for automated ground vehicles. Sensors,

24(2), 600. https://doi.org/10.3390/s24020600.

Hua, J., Zeng, L., Li, G., & Ju, Z. (2021). Learning for a

robot: Deep reinforcement learning, imitation learning,

transfer learning. Sensors, 21(4), 1278. https://doi.

org/10.3390/s21041278.

Zare, M., Kebria, P. M., Khosravi, A., & Nahavandi, S.

(2023). A survey of imitation learning: Algorithms,

recent developments, and challenges. arXiv.

https://arxiv.org/abs/2309.02473.

Johansen, T. A., & Fossen, T. I. (2013). Control

allocation—A survey. Automatica, 49(5), 1087–1103.

https://doi.org/10.1016/j.automatica.2013.01.035.

Kissai, M. Optimal Coordination of Chassis Systems for

Vehicle Motion Control. Automatic Control

Engineering. Universite´ Paris Saclay (COmUE), 2019.

English. 〈NNT : 2019SACLY004〉.

Norouzi, A., Heidarifar, H., Borhan, H., Shahbakhti, M., &

Koch, C. R. (2023). Integrating machine learning and

model predictive control for automotive applications: A

review and future directions. Engineering Applications

of Artificial Intelligence, 120, 105878. https://doi.

org/10.1016/j.engappai.2023.105878.

Kissai, M., Monsuez, B., Mouton, X., Martinez, D., &

Tapus, A. (2019). Model predictive control allocation

of systems with different dynamics. In 2019 IEEE

Intelligent Transportation Systems Conference (ITSC)

(pp.4170–4177). https://doi.org/10.1109/ITSC.2019.

8917438.

Kissai, M., Monsuez, B., & Tapus, A. (2017, June). Current

and future architectures for integrated vehicle dynamics

control.

Yuan, Y., Chen, L., Wu, H., & Li, L. (2022). Advanced

agricultural disease image recognition technologies: A

review. Information Processing in Agriculture, 9(1),

48–59. https://doi.org/10.1016/j.inpa.2021.01.003.

Latif, S., Cuayáhuitl, H., Pervez, F., Shamshad, F., Ali, H.

S., & Cambria, E. (2021). A survey on deep

reinforcement learning for audio-based applications.

arXiv. https://arxiv.org/abs/2101.00240.

Dey, S., Marzullo, T., Zhang, X., & Henze, G. (2023).

Reinforcement learning building control approach

harnessing imitation learning. Energy and AI, 14,

100255. https://doi.org/10.1016/j.egyai.2023.100255.

Manuel Davila Delgado, J., & Oyedele, L. (2022). Robotics

in construction: A critical review of the reinforcement

learning and imitation learning paradigms. Advanced

Engineering Informatics, 54, 101787. https://doi.

org/10.1016/j.aei.2022.101787.

Using Imitation Learning to Implement Control Orchestration for Smart Chassis

471