Vision-Language In-Context Learning Driven Few-Shot Visual

Inspection Model

Shiryu Ueno

1 a

, Yoshikazu Hayashi

1

and Shunsuke Nakatsuka

1

, Yusei Yamada

1

,

Hiroaki Aizawa

2 b

and Kunihito Kato

1

1

Faculty of Engineering, Gifu University, 1-1 Yanagido, Gifu, Japan

2

Graduate School of Advanced Science and Engineering, Hiroshima University,

Higashihiroshima, Hiroshima 739-8527, Japan

{ueno, hayashi, nakatsuka, yyamada}@cv.info.gifu-u.ac.jp, hiroaki-aizawa@hiroshima-u.ac.jp

Keywords:

Visual Inspection, Vision-Language Model, In-Context Learning.

Abstract:

We propose general visual inspection model using Vision-Language Model (VLM) with few-shot images of

non-defective or defective products, along with explanatory texts that serve as inspection criteria. Although ex-

isting VLM exhibit high performance across various tasks, they are not trained on specific tasks such as visual

inspection. Thus, we construct a dataset consisting of diverse images of non-defective and defective products

collected from the web, along with unified formatted output text, and fine-tune VLM. For new products, our

method employs In-Context Learning, which allows the model to perform inspections with an example of

non-defective or defective image and the corresponding explanatory texts with visual prompts. This approach

eliminates the need to collect a large number of training samples and re-train the model for each product. The

experimental results show that our method achieves high performance, with MCC of 0.804 and F1-score of

0.950 on MVTec AD in a one-shot manner. Our code is available at https://github.com/ia-gu/Vision-Language-

In-Context-Learning-Driven-Few-Shot-Visual-Inspection-Model.

1 INTRODUCTION

In this study, we propose a method that can de-

tect defective locations in new product images by

using Vision-Language Model (VLM) (Yin et al.,

2024) (Liu et al., 2024b) and In-Context Learn-

ing (ICL) (Dong et al., 2023) (Zong et al., 2024).

With the advancements in deep learning technol-

ogy, the automation of visual inspection has become

increasingly common in recent years. However, cur-

rent visual inspection models inspect specific prod-

ucts by collecting a large number of images of the tar-

get product and training the model. Thus, these mod-

els are only applicable to the target products on which

they have been trained, and re-training is necessary

for new products. Although some methods can in-

spect multiple products with a single model, they still

require hyperparameter tuning or additional training

for each product. In this study, we propose a general

visual inspection model that leverages VLM and ICL

allowing the inspection of new products without any

a

https://orcid.org/0009-0006-0842-1362

b

https://orcid.org/0000-0002-6241-3973

hyperparameter tuning or model training.

Many of the current VLMs (Liu et al.,

2024a) (Chen et al., 2023) leverage Large Lan-

guage Model (LLM) to align visual and language

features, demonstrating excellent performance in a

wide range of tasks. These tasks range from basic

image recognition tasks, such as classification, to

advanced vision-language tasks, such as Visual Ques-

tion Answering (VQA). However, these VLMs are

not trained on specific tasks such as visual inspection.

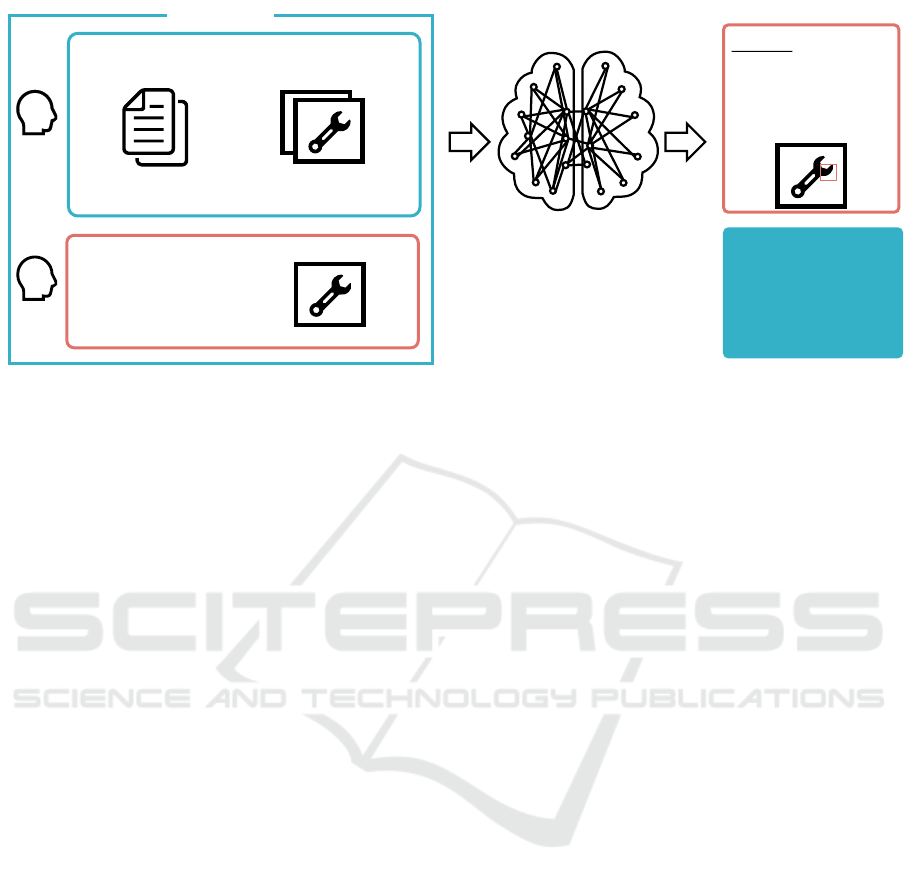

In this study, we propose a general visual in-

spection model that can detect defective locations in

new products without any hyperparameter tuning or

model re-training, using VLM and ICL. The frame-

work of our proposed method is shown in Fig. 1.

First, we fine-tune the VLM for general visual inspec-

tion with a dataset constructed from a diverse set of

non-defective and defective product images collected

from the web. In this study, we use ViP-LLaVA (Cai

et al., 2024), which has been trained on visual prompt

recognition, as the foundation of our VLM, and fine-

tune it with our dataset. In addition, in typical vi-

sual inspection processes by humans, inspectors use

inspection standards for the target products. To em-

Ueno, S., Hayashi, Y., Nakatsuka, S., Yamada, Y., Aizawa, H. and Kato, K.

Vision-Language In-Context Learning Driven Few-Shot Visual Inspection Model.

DOI: 10.5220/0013088100003912

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 20th International Joint Conference on Computer Vision, Imaging and Computer Graphics Theory and Applications (VISIGRAPP 2025) - Volume 2: VISAPP, pages

253-260

ISBN: 978-989-758-728-3; ISSN: 2184-4321

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

253

Large Vision-Language Model

Understanding the general

knowledge needed for visual

inspection via fine-tuning.

Understanding the product-

specific decision criteria via

In-Context Learning.

Explainable

Few-Shot Visual

Inspection Model

◼ Defective example

◼ Non-defective example

◼ Standards Document

◼ Inspection Items

In-Context Learning

Text

Image

Prompt

User

User

Is this product defective?

Answer:

There is a dent on

(x

1

, x

2

, y

1

, y

2

),

indicating this product

is defective.

Figure 1: Framework of our proposed method. We utilize ICL for multiple image inputs to give VLM the inspection criteria

of new products. Our framework gives the coordinates of the defective location, which helps the user understand the model’s

decision. In addition, it is easy to address by replacing the foundational model when a better VLM is proposed.

ulate this inspection process by human, we use ICL

during the evaluation to provide an example of non-

defective or defective product image along with ex-

planatory texts that serve as inspection criteria. ICL is

a method the model learns from few-shot input-output

examples as prompts, without parameter update. Us-

ing ICL during the inference of new products, we pro-

vide VLM with inspection criteria, enabling specific

inspection of target products. Since ICL performance

varies significantly based on the provided examples,

we propose an algorithm that can select high-quality

example based on the distance in Euclidean space.

Consequently, our proposed method does not need

to collect a large number of images or to re-train the

model for each target product.

In summary, our main contributions are:

• We propose a general visual inspection model ca-

pable of inspections and detecting defective loca-

tions for new products using VLM and ICL with

only an example. In our proposed method, fine-

tune VLM on visual inspection and utilize ICL

enabling the inspection of specific products.

• We construct a new dataset consisting of diverse

non-defective and defective products collected

from the web, along with unified formatted out-

put, for fine-tuning. Also, our dataset includes co-

ordinates of defective locations for defective prod-

ucts, ensuring the explainability of the model.

• To empirically verify the proposed methodology,

we evaluate on MVTec AD (Bergmann et al.,

2019) and VisA (Zou et al., 2022). Our method

achieves MCC (Chicco Davide and Jurman

Giuseppe, 2020) of 0.804 and F1-score (Sokolova

et al., 2006) of 0.950 on the MVTec AD dataset in

a one-shot manner.

2 RELATED WORK

2.1 Visual Inspection

Many visual inspection methods based on deep learn-

ing are trained only on non-defective images (Yi and

Yoon, 2020) (Defard et al., 2021). Thus, such meth-

ods require the collection of training samples and the

re-training of the model for each target product. Con-

sequently, it is challenging to apply the same model

to different products without re-training.

Recently, visual inspection methods combining

vision and language have been proposed. Anoma-

lyGPT (Gu et al., 2024) can detect defective locations

by learning an image decoder from non-defective and

pseudo-defective images. However, AnomalyGPT

utilizes PaDiM or PatchCore (Roth et al., 2022) for

anomaly maps, and these methods need re-training for

each products. WinCLIP (Jeong et al., 2023) calcu-

lates the similarity between images and texts of non-

defective and defective images using CLIP (Radford

et al., 2021) and can detect defective locations by us-

ing relative anomaly scores. However, WinCLIP only

assigns anomaly scores to test samples during infer-

ence. To inspect correctly, it is necessary to experi-

mentally determine the optimal threshold on test sam-

ples. Thus, these existing approaches cannot be con-

sidered general visual inspection models.

VISAPP 2025 - 20th International Conference on Computer Vision Theory and Applications

254

This is an Image of cup.

Is this cup defective?

User

CLIP ViT

Tokenizer

LN, MLP

Large

Language

Model

(LLaMA2)

Answer:

[124, 144, 33, 49]

:Finetuning

:Frozen

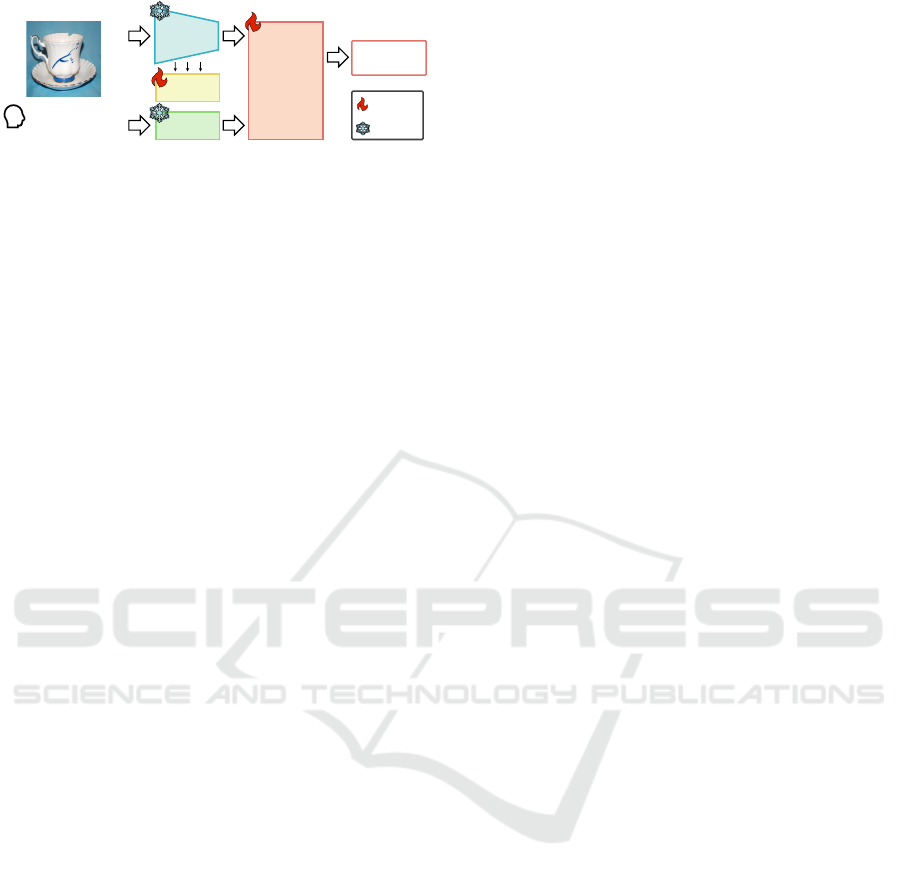

Figure 2: Architecture of ViP-LLaVA. After providing an

image and the corresponding text, the image is tokenized

by CLIP ViT, LayerNorm, and MLP layers, while the text

is tokenized by tokenizer. Then the visual tokens and the

text tokens are given to the LLM to generate the answer.

2.2 Vision-Language Model

VLMs leverage LLM to align visual and language

features, demonstrating excellent performance across

a wide range of tasks, from basic image recog-

nition tasks such as classification, to advanced

vision-language tasks, such as VQA. For example,

LLaVA (Liu et al., 2023) inputs the vision embed-

ding vectors and language embedding vectors into the

LLM decoder to learn the alignment between vision

and language. LLaVA has spawned many derivative

methods, among which ViP-LLaVA focuses on visual

prompt recognition by utilizing a dataset where ar-

rows or visual cues are directly embedded in the in-

put images, thereby strengthening the alignment be-

tween low-level image details and language. How-

ever, these VLMs have not been trained on visual in-

spection tasks and thus lack the general knowledge

for visual inspection (Liu et al., 2024b).

2.3 In-Context Learning

ICL is a method that the model learns from few-shot

input-output examples as prompts, without updating

model parameters. For instance, given the input “Ex-

ample input: (4, 2), Example output: 6, Question: (5,

6),” the model infers from the provided example that

the task is addition and can answer “11.” In multi-

modal ICL, the model makes inferences based on im-

ages, prompts, and their examples. Many VLMs are

trained on diverse image-text pairs, enabling them to

acquire ICL capabilities (Chen et al., 2024).

Some VLMs are explicitly built to enhance ICL

capabilities. Otter (Li et al., 2023b) enhances ICL

capabilities by fine-tuning Open Flamingo (Awadalla

et al., 2023) on MIMIC-IT (Li et al., 2023a), which is

in an ICL and Instruction Tuning format. At the same

time, not to forget the knowledge of Open Flamingo,

Otter only update parameters of Perceiver Resampler

and Cross Attention Layer in language model. Simi-

larly, LCL (Tai et al., 2023) proposes a new evaluation

dataset, ISEKAI, which includes new concepts in the

examples, making it challenging without seeing the

examples. To address ISEKAI, LCL enhances its ICL

capability by fully fine-tuning Shikra (Chen et al.,

2023) on a custom dataset based on ImageNet (Deng

et al., 2009). However, in practice, these VLM ex-

plicitly designed to enhance ICL capabilities do not

necessarily outperform regular VLM (Chen et al.,

2024) (Zong et al., 2024).

3 PROPOSED METHOD

3.1 Overview

In this study, we propose a general visual inspection

model that combines VLM and ICL, enabling the spe-

cific inspection of new products without parameter

optimization. In addition, by constructing unified out-

put format dataset for fine-tuning, we enable quantita-

tive evaluation of visual inspections using VLM. An

overview of the proposed method is shown in Fig. 1.

3.2 Model

In this study, we use ViP-LLaVA (Cai et al., 2024)

as the foundational VLM. ViP-LLaVA is a model that

improves recognition capabilities for visual prompts

by fine-tuning LLaVA 1.5 (Liu et al., 2024a) on a

dataset where red circles or arrows are overlaid on the

original images. In addition to this, ViP-LLaVA uti-

lizes the multi-level visual features to address the ten-

dency of CLIP’s deeper features to overlook low-level

details. These methodologies improves the recogni-

tion capability for low-level details, which is espe-

cially needed for visual inspection. ViP-LLaVA has

not been trained on visual inspection tasks.

The model architecture of ViP-LLaVA is shown

in Fig. 2. ViP-LLaVA consists of a vision encoder to

extract visual features, LayerNorm (Ba et al., 2016)

and an MLP to tokenize visual features, a tokenizer

to tokenize the language, and an LLM to gener-

ate text from these tokens. The vision encoder is

CLIP-ViT-L/14(Radford et al., 2021), and the LLM is

LLaMA2 (Meta, 2023) During fine-tuning, we update

the parameters of the LayerNorm, MLP, and LLM in

accordance with the ViP-LLaVA procedure.

3.3 Dataset for Fine-Tune

To enhance the general knowledge of existing VLM

for visual inspection, we collect images of non-

defective and defective products from the web. The

image collection process consists of five main steps:

Vision-Language In-Context Learning Driven Few-Shot Visual Inspection Model

255

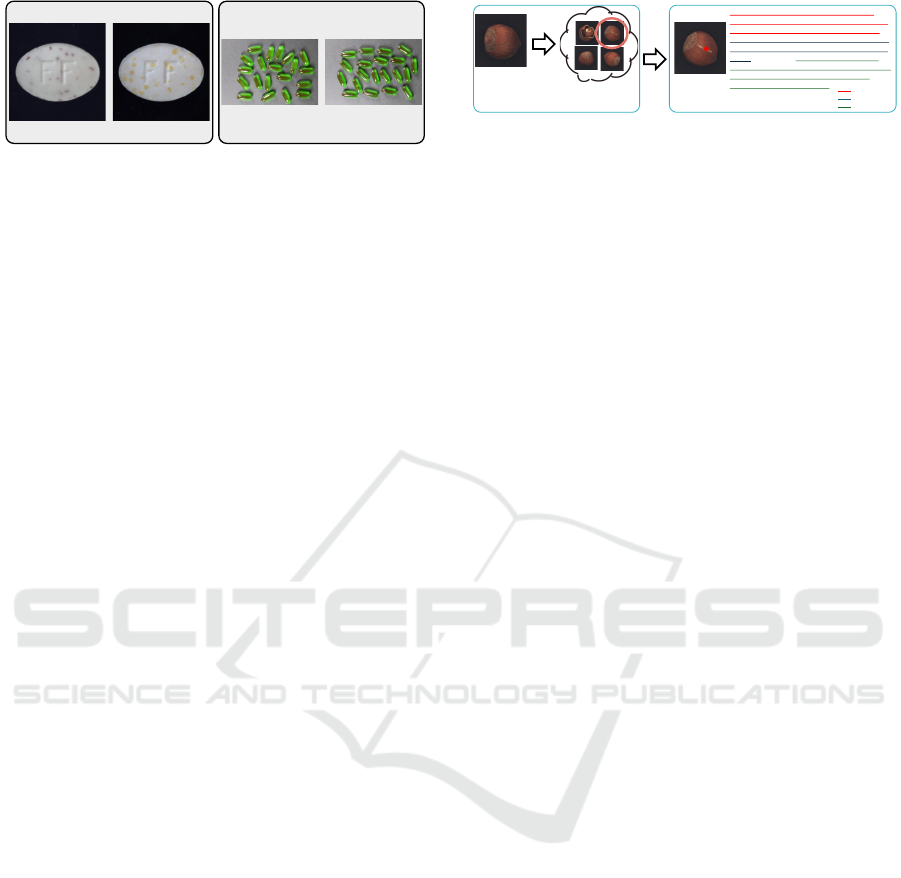

non-defective defective

MVTec-AD Pill

non-defective defective

VisA Capsules

Figure 3: Examples of non-defective and defective images

of “Pill” in MVTec AD and “Capsules” in VisA. For “Pill”,

the non-defective image also contains red spots, making

it difficult to inspect Similarly, for “Capsules”, the non-

defective image also contains brown stains.

1. Generate product names and inspection-related

keywords (e.g., “disk”, “broken disk”, “discol-

ored disk”) by GPT-4 (OpenAI, 2023).

2. Expand the keywords into eight languages: En-

glish, Chinese, Spanish, French, Portuguese, Ger-

man, Italian, and Japanese.

3. Perform image searches using the expanded key-

words and collect images with selenium.

4. Remove duplicate or unclear images.

5. Annotate the defective location coordinates for

the defective images in the remaining set.

Through this procedure, we collect images of var-

ious products. Each product category includes images

of non-defective and defective products with up to five

types of defects. Finally, we obtained a final set of 941

images of 84 categories.

After collecting the images, we construct a dataset

for fine-tuning. The format of the dataset is based on

VQA (i.e., a pair of question and answer for each im-

ages). Question is “This is an image of {product}.

Does this {product} in the image have any defects? If

yes, please provide the anomaly mode and the bound-

ing box coordinate of the region where the defect is

located. If no, please say None.”, answer is coordi-

nates of the defective location for defective image,

“None” for non-defective image.

3.4 In-Context Learning Driven Visual

Inspection

It is challenging to inspect new products from a single

image. An example is shown in Fig. 3. As shown in

Fig. 3, some products need their specific inspection

criteria for accurate visual inspection. Thus, in this

study, we utilize ICL to provide an example of non-

defective or defective image along with explanatory

texts that serve as inspection criteria. Based on the

example, model precisely inspects new products.

In addition, in multi-modal ICL, example images

significantly influence the output of VLM (Baldassini

test image q

This is an image of shell of hazelnut used for

visual inspection. Shells or ridges like the ones in

the image are not considered defects this time.

Based on this, the first image is defective because

the area marked with a red circle is considered a

defect.¥n<image>¥nThen, is the second image

defective? If yes, please provide the bounding box

coordinate of the region where the defect is

located. If no, please say None.

ICL Prompt

Explanation

Visual Prompt

Question

support set

Example Selection

Figure 4: Framework of evaluation. First, select the exam-

ple based on Eq. (1), then infer the test image with ICL.

et al., 2024). RICES (Yang et al., 2022) is an existing

algorithm for selecting examples in ICL, it uses co-

sine similarity of features. However, cosine similarity

can yield high values when the scales of features dif-

fer or when the feature dimensions are large, failing

to accurately evaluate similarity (Steck et al., 2024).

Thus, in this study, we propose a new selection algo-

rithm. Our proposed method is shown in Eq. (1).

argmin

min

f (x

i

) − f (x

q

)

2

(1)

Where x denotes the image, f denotes the vision

encoder (pre-trained ResNet50 (He et al., 2015)), and

q denotes the index of the test image for inference, i

denotes the index of the image except for q. Eq. (1)

is an algorithm that selects neighboring image of the

test image as example based on Euclidean distance.

By this, Eq. (1) takes into account the scale and di-

mensions of the features, and expected to select better

example compared to RICES.

4 EXPERIMENT

4.1 Settings

The dataset used for fine-tuning was collected and

created as described in Sec. 3.3. We perform one-

stage fine-tuning for 300 epochs using ZeRO2 with

XTuner (XTuner Contributors, 2023) on 8 NVIDIA

6000Ada-48GB GPUs. The batch size is set to 4,

thus the global batch size is set to 32. We utilized

the AdamW (Loshchilov and Hutter, 2019) optimizer

and 1e-4 learning rate, with the warm-up ratio set to

0.03. We also apply cosine decay to the learning rate.

To evaluate the performance, we used MVTec AD

and VisA. These datasets were not used at all during

training. During the evaluation, one example image

is given by using ICL (i.e., one-shot manner). The

method for selecting the example image follows the

procedure described in Eq. (1). Also, to evaluate

the effectiveness of the proposed example image se-

lection algorithm, we compare its performance with-

out example image and with that of RICES. Finally,

framework of the evaluation is shown in Fig. 4.

We use F1-score (Sokolova et al., 2006) and

Matthews Correlation Coefficient (MCC) (Chicco

VISAPP 2025 - 20th International Conference on Computer Vision Theory and Applications

256

Table 1: Result of MVTec-AD. ’N/A’ means that zero division occurred. Bold means the highest performance.

Settings Vanilla w/o ICL ICL (RICES) ICL (Ours)

Product Name F1-score MCC F1-score MCC F1-score MCC F1-score MCC

Bottle N/A N/A 0.863 N/A 0.892 0.510 0.917 0.610

Cable N/A N/A 0.400 0.338 0.795 0.564 0.899 0.754

Capsule N/A N/A 0.750 0.426 0.912 0.384 0.946 0.658

Carpet 0.044 0.074 1.000 1.000 0.983 0.929 1.000 1.000

Grid N/A N/A 0.973 0.910 0.884 0.476 0.982 0.935

Hazelnut 0.228 0.226 0.780 N/A 0.795 0.257 0.800 0.289

Leather 0.043 0.076 1.000 1.000 1.000 1.000 1.000 1.000

Metal Nut N/A N/A 0.832 0.540 0.912 0.468 0.989 0.947

Pill N/A N/A 0.838 0.402 0.922 0.368 0.968 0.814

Screw 0.209 0.140 0.851 0.244 0.903 0.506 0.925 0.673

Tile N/A N/A 0.957 0.870 0.977 0.916 0.977 0.916

Toothbrush N/A N/A 0.906 0.633 0.866 0.418 0.921 0.697

Transistor N/A N/A 0.762 0.592 0.871 0.780 0.894 0.821

Wood N/A N/A 0.976 0.752 0.992 0.965 0.992 0.965

Zipper N/A N/A 0.741 0.541 0.975 0.879 0.987 0.941

All category 0.042 0.068 0.860 0.519 0.917 0.665 0.950 0.804

Davide and Jurman Giuseppe, 2020) for the evalua-

tion. F1-score, as shown in Eq. (2) , is a common

metric for binary classification.

F1-score =

2 × TP

2 × TP + FP + FN

(2)

As shown in Eq. (2), F1-score does not use pre-

diction of true negative. Thus, when there is a large

number of positive samples during inference, the per-

formance can be significantly inflated by predicting

all samples as positive. For instance, in MVTec AD,

with 1,258 positive samples and 467 negative sam-

ples in the test data, F1-score shows a high value of

0.844. This shows F1-score is suspicious when there

is a bias in the test data. Thus, we use not only F1-

score but also MCC as evaluation metrics. MCC is re-

ported to be adequate for binary classification, partic-

ularly for better consistency and less variance (Gran-

dini et al., 2020) (G

¨

osgens et al., 2022). MCC is

shown in Eq. (3).

MCC =

TP × TN − FP × FN

p

(TP + FP)(TP + FN)(TN +FP)(TN + FN)

(3)

MCC ranges from -1 to 1, where 1 indicates per-

fect prediction of all samples, -1 indicates incorrect

prediction of all samples, and 0 indicates random pre-

diction. In the previously mentioned example, MCC

cannot be calculated because the denominator be-

comes zero. Thus, in this study, we use both F1-

score and MCC for evaluation. The evaluation meth-

ods include assessing the performance for each prod-

uct within each dataset, as well as the overall perfor-

mance across the entire dataset.

4.2 Evaluation of Results

4.2.1 Result of MVTec AD

The results for MVTec AD are shown in Tab. 1. The

settings are as follows: “Vanilla” for ViP-LLaVA be-

fore fine-tune, “w/o ICL” for ViP-LLaVA after fine-

tune without using an example during inference, “ICL

(RICES)” for using a selected example image with the

RICES algorithm during inference, and “ICL (Ours)”

for using a selected example image with Eq. (1) dur-

ing inference. In each settings, results of F1-score

and MCC are in a row. From the table, we confirm

that providing an example significantly improves per-

formance. This demonstrates the effectiveness of our

framework. Additionally, compared to RICES, our

selection algorithm achieves improvement in perfor-

mance with an increase in MCC, demonstrating the

effectiveness of our algorithm.

Next, for qualitative evaluation, the visualization

of the model prediction is shown in Fig. 5. As shown

in the figure, our approach can roughly detect defec-

tive locations, which means the model recognizes the

defects in the image. However, the model cannot de-

tect multiple defects or logical defects, such as those

in “Cable”. This is due to the lack of variety in the

training dataset. Thus, further image collection and

an enlarged training dataset are required for perfor-

mance improvement.

Also, for some products like “Hazelnut”, while

our approach improved the performance, it is still in-

sufficient for real-world conditions. For “Hazelnut”,

the model detected thin parts as defective, indicat-

Vision-Language In-Context Learning Driven Few-Shot Visual Inspection Model

257

Figure 5: Visualize the model prediction for MVTec AD.

ing that the model does not fully leverage ICL. Thus,

providing detailed inspection criteria is necessary. It

has been reported that increasing the number of ex-

amples improves ICL performance (Agarwal et al.,

2024) (Bertsch et al., 2024). Alternatively, further

performance improvement is expected by proposing

an optimal selection algorithm that selects multiple

example images (based on the query strategies, in-

cluding those from Deep Active Learning (Pengzhen

Ren et al., 2021) (Ueno et al., 2023)).

Additionally, for all products, although coordi-

nates are output, their positions deviate from the ac-

tual defective locations. Indeed, pixel-level AUROC

was 0.730, which is very low compared to the existing

methods. This is because the CrossEntropyLoss used

for training uniformly calculates the loss for differ-

ences in token values. For example, when the ground

truth of the starting x-coordinate is 100, the loss is

the same when the model outputs 101 and 900 (as-

suming the prediction probabilities are equal). Thus,

CrossEntropyLoss is not optimal for tasks requiring

specific numerical outputs like coordinates. How-

ever, existing VLMs are trained with CrossEntropy-

Loss, meaning their outputs are text-based cannot be

safely converted to floats (with gradient flow intact),

thus performance improvement is expected by con-

structing a multi-head VLM for defect detection and

modifying the loss function to alternatives like Mean

Squared Error or GIoU Loss.

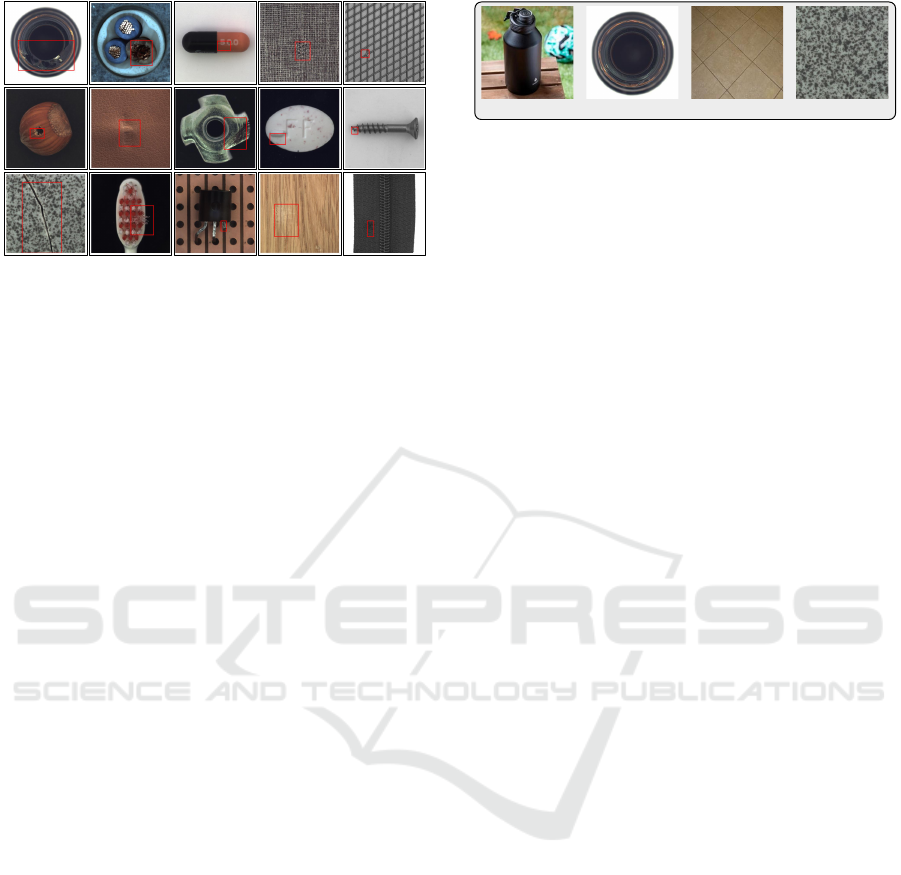

While “Bottle” has the same product in the train-

ing dataset, their performance is lower compared to

“Wood”, which also has the same product in the train-

ing dataset. This is likely due to the significant dif-

ferences in appearance between the images in the

training data and those in MVTec AD, as shown in

Fig. 6. However, despite the differences in appear-

ance, “Tile” shows high performance, confirming the

generalization capability for some products. Also,

to prevent the forgetting of knowledge acquired dur-

ing pre-training when fine-tuning, it is necessary to

use Parameter Efficient Fine-Tuning methods, such as

Bottle Tile

Figure 6: Examples of the images of “Bottle”, and “Tile”

from the collected images and MVTec AD.

Low-Rank Adaptation (Hu et al., 2021), which forget

less than fine-tuning (Biderman et al., 2024).

4.2.2 Result of VisA

The results for VisA are shown in Tab. 2. The table

follows the same format as Tab. 1. From the table,

it can be confirmed that the performance improves

by using ICL in VisA as well, demonstrating the ef-

fectiveness of the proposed framework. However,

compared to RICES, our selection algorithm does

not show significant improvement. This is because

both RICES and our selection algorithm are based

on similarity, which depends on the data distribu-

tion. Most of the products in VisA are too widely dis-

tributed (e.g., “Macaroni”, “PCB”). Thus, proposing

a more distribution-robust selection algorithm could

potentially improve performance. Also, it can be

seen that the performance does not improve regard-

less of the presence of ICL when there are two or

more products in the image, especially if those prod-

ucts are not aligned. In fact, “Macaroni1”, which is

neatly aligned, shows higher qualitative and quanti-

tative performance compared to “Macaroni2”, which

is randomly arranged. This is likely due to the lack

of training dataset that considers differences in prod-

uct positions and orientations. Thus, performance im-

provement is expected by collecting fine-tuning data

and performing data augmentation, such as rotation

and flipping. Simultaneously, it should be noted that

for some products, positional shifts or orientation dif-

ferences may be defined as defects.

For qualitative evaluation, the visualization of the

model prediction is shown in Fig. 7. As shown in

Fig. 7, for products that have multiple objects like

“Candle” or “Capsules”, the model prediction gets

worse. As mentioned, our dataset is still insufficient

for generalization because there are limited products

and they are mostly single object. In addition, images

with multiple objects are highly distributed compared

to the images with single object, which influences the

performance of ICL because the selection algorithms

depend on the distribution.

VISAPP 2025 - 20th International Conference on Computer Vision Theory and Applications

258

Table 2: Result of VisA.

Settings Vanilla w/o ICL ICL (RICES) ICL (Ours)

Product Name F1-score MCC F1-score MCC F1-score MCC F1-score MCC

Candle N/A N/A 0.635 0.539 0.692 0.241 0.694 0.253

Capsules N/A N/A 0.599 0.415 0.841 0.513 0.809 0.389

Cashew N/A N/A 0.814 0.623 0.890 0.670 0.889 0.674

Chewinggum N/A N/A 0.921 0.758 0.921 0.758 0.935 0.804

Fryum N/A N/A 0.867 0.699 0.917 0.741 0.888 0.648

Macaroni1 N/A N/A 0.760 0.502 0.685 0.204 0.683 0.190

Macaroni2 N/A N/A 0.669 0.071 0.667 N/A 0.667 N/A

PCB1 N/A N/A 0.131 0.190 0.891 0.792 0.875 0.762

PCB2 N/A N/A 0.347 0.343 0.772 0.493 0.763 0.471

PCB3 N/A N/A 0.243 0.248 0.747 0.503 0.751 0.513

PCB4 N/A N/A 0.622 0.516 0.801 0.594 0.817 0.610

Pipe Fryum N/A N/A 0.870 0.726 0.920 0.744 0.929 0.774

All category N/A N/A 0.671 0.429 0.800 0.492 0.795 0.479

Figure 7: Visualize the model prediction for VisA.

5 CONCLUSION

In this study, we propose a general visual inspection

model based on a few images of non-defective or de-

fective products along with explanatory texts serv-

ing as inspection criteria. For future work, further

performance improvement is expected by collecting

more images for fine-tuning. In this study, we en-

abled visual inspection using VLM by training on a

dataset consisting of only 941 images, which is very

small compared to the pre-training dataset of VLM.

Another consideration is to construct the multi-head

VLM and change of the loss function. Furthermore,

introducing the example image selection algorithm is

another way for improvement. Specifically, existing

algorithms are for selecting one example image for

the inspection, so proposing an optimal selection al-

gorithm for many example images improves model

performance. Finally, the proposed method is based

on VLM, so by adding the rationale statements for

the decision in the response, model explainability is

expected to improve, and performance could be en-

hanced through multitasking.

REFERENCES

Agarwal, R., Singh, A., Zhang, L. M., Bohnet, B., Rosias,

L., Chan, S., Zhang, B., Anand, A., Abbas, Z., Nova,

A., Co-Reyes, J. D., Chu, E., Behbahani, F., Faust,

A., and Larochelle, H. (2024). Many-Shot In-Context

Learning.

Awadalla, A., Gao, I., Gardner, J., Hessel, J., Hanafy, Y.,

Zhu, W., Marathe, K., Bitton, Y., Gadre, S., Sagawa,

S., Jitsev, J., Kornblith, S., Koh, P. W., Ilharco,

G., Wortsman, M., and Schmidt, L. (2023). Open-

Flamingo: An Open-Source Framework for Training

Large Autoregressive Vision-Language Models.

Ba, J. L., Kiros, J. R., and Hinton, G. E. (2016). Layer

Normalization.

Baldassini, F. B., Shukor, M., Cord, M., Soulier, L., and

Piwowarski, B. (2024). What Makes Multimodal In-

Context Learning Work?

Bergmann, P., Fauser, M., Sattlegger, D., and Steger, C.

(2019). MVTec AD — A Comprehensive Real-World

Dataset for Unsupervised Anomaly Detection. In

IEEE/CVF Conference on Computer Vision and Pat-

tern Recognition (CVPR), pages 9584–9592. IEEE.

Bertsch, A., Ivgi, M., Alon, U., Berant, J., Gormley, M. R.,

and Neubig, G. (2024). In-Context Learning with

Long-Context Models: An In-Depth Exploration.

Biderman, D., Ortiz, J. G., Portes, J., Paul, M., Green-

gard, P., Jennings, C., King, D., Havens, S., Chiley,

V., Frankle, J., Blakeney, C., and Cunningham, J. P.

(2024). LoRA Learns Less and Forgets Less.

Cai, M., Liu, H., Park, D., Mustikovela, S. K., Meyer, G. P.,

Chai, Y., and Lee, Y. J. (2024). ViP-LLaVA: Mak-

ing Large Multimodal Models Understand Arbitrary

Visual Prompts.

Chen, K., Zhang, Z., Zeng, W., Zhang, R., Zhu, F., and

Zhao, R. (2023). Shikra: Unleashing Multimodal

LLM’s Referential Dialogue Magic.

Vision-Language In-Context Learning Driven Few-Shot Visual Inspection Model

259

Chen, S., Han, Z., He, B., Buckley, M., Torr, P., Tresp, V.,

and Gu, J. (2024). Understanding and Improving In-

Context Learning on Vision-language Models. arXiv.

Chicco Davide and Jurman Giuseppe (2020). The advan-

tages of the Matthews correlation coefficient (MCC)

over F1 score and accuracy in binary classification

evaluation. BMC genomics, 21:1–13.

Defard, T., Setkov, A., Loesch, A., and Audigier, R. (2021).

Padim: A patch distribution modeling framework for

anomaly detection and localization. In International

Conference on Pattern Recognition, pages 475–489.

Springer.

Deng, J., Dong, W., Socher, R., Li, L.-J., Li, K., and Fei-

Fei, L. (2009). Imagenet: A large-scale hierarchical

image database. In IEEE/CVF Conference on Com-

puter Vision and Pattern Recognition, pages 248–255.

Dong, Q., Li, L., Dai, D., Zheng, C., Wu, Z., Chang, B.,

Sun, X., Xu, J., Li, L., and Sui, Z. (2023). A Survey

on In-context Learning.

G

¨

osgens, M., Zhiyanov, A., Tikhonov, A., and

Prokhorenkova, L. (2022). Good Classification

Measures and How to Find Them. neural information

processing systems, 34(17136-17147).

Grandini, M., Bagli, E., and Visani, G. (2020). Metrics for

Multi-Class Classification: An Overview.

Gu, Z., Zhu, B., Zhu, G., Chen, Y., Tang, M., and

Wang, J. (2024). AnomalyGPT: Detecting Indus-

trial Anomalies Using Large Vision-Language Mod-

els. In AAAI Conference on Artificial Intelligence, vol-

ume 38, pages 1932–1940. arXiv.

He, K., Zhang, X., Ren, S., and Sun, J. (2015). Deep Resid-

ual Learning for Image Recognition. In IEEE/CVF

Conference on Computer Vision and Pattern Recogni-

tion, pages 770–778.

Hu, E. J., Shen, Y., Wallis, P., Allen-Zhu, Z., Li, Y., Wang,

S., Wang, L., and Chen, W. (2021). LoRA: Low-Rank

Adaptation of Large Language Models.

Jeong, J., Zou, Y., Kim, T., Zhang, D., Ravichandran,

A., and Dabeer, O. (2023). WinCLIP: Zero-/Few-

Shot Anomaly Classification and Segmentation. In

IEEE/CVF Conference on Computer Vision and Pat-

tern Recognition, pages 19606–19616. arXiv.

Li, B., Zhang, Y., Chen, L., Wang, J., Pu, F., Yang, J., Li,

C., and Liu, Z. (2023a). MIMIC-IT: Multi-Modal In-

Context Instruction Tuning.

Li, B., Zhang, Y., Chen, L., Wang, J., Yang, J., and Liu,

Z. (2023b). Otter: A Multi-Modal Model with In-

Context Instruction Tuning.

Liu, H., Li, C., Li, Y., and Lee, Y. J. (2024a). Improved

Baselines with Visual Instruction Tuning.

Liu, H., Li, C., Wu, Q., and Lee, Y. J. (2023). Visual In-

struction Tuning. In Advances in Neural Information

Processing Systems, volume 36. arXiv.

Liu, Y., Duan, H., Zhang, Y., Li, B., Zhang, S., Zhao, W.,

Yuan, Y., Wang, J., He, C., Liu, Z., Chen, K., and Lin,

D. (2024b). MMBench: Is Your Multi-modal Model

an All-around Player?

Loshchilov, I. and Hutter, F. (2019). Decoupled Weight De-

cay Regularization.

Meta (2023). Llama 2: Open Foundation and Fine-Tuned

Chat Models.

OpenAI (2023). GPT-4 Technical Report.

Pengzhen Ren, Xiao, Y., Chang, X., Huang, P.-Y., Li, Z.,

Gupta, B. B., Chen, X., and Wang, X. (2021). A Sur-

vey of Deep Active Learning. ACM computing surveys

(CSUR), 54(9):1–40.

Radford, A., Kim, J. W., Hallacy, C., Ramesh, A., Goh, G.,

Agarwal, S., Sastry, G., Askell, A., Mishkin, P., Clark,

J., Krueger, G., and Sutskever, I. (2021). Learning

Transferable Visual Models From Natural Language

Supervision. In International Conference on Machine

Learning, pages 8748–8763.

Roth, K., Pemula, L., Zepeda, J., Sch

¨

olkopf, B., Brox,

T., and Gehler, P. (2022). Towards total recall in

industrial anomaly detection. In Proceedings of the

IEEE/CVF Conference on Computer Vision and Pat-

tern Recognition, pages 14318–14328.

Sokolova, M., Japkowicz, N., and Szpakowicz, S. (2006).

Beyond Accuracy, F-Score and ROC: A Family of

Discriminant Measures for Performance Evaluation.

In AI 2006: Advances in Artificial Intelligence, Lec-

ture Notes in Computer Science, volume 4304, pages

1015–1021.

Steck, H., Ekanadham, C., and Kallus, N. (2024). Is Cosine-

Similarity of Embeddings Really About Similarity?

In Companion Proceedings of the ACM on Web Con-

ference 2024, pages 887–890.

Tai, Y., Fan, W., Zhang, Z., Zhu, F., Zhao, R., and Liu,

Z. (2023). Link-Context Learning for Multimodal

LLMs.

Ueno, S., Yamada, Y., Nakatsuka, S., and Kato, K. (2023).

Benchmarking of Query Strategies: Towards Future

Deep Active Learning.

XTuner Contributors (2023). XTuner: A Toolkit for Effi-

ciently Fine-tuning LLM.

Yang, Z., Gan, Z., Wang, J., Hu, X., Lu, Y., Liu, Z., and

Wang, L. (2022). An Empirical Study of GPT-3 for

Few-Shot Knowledge-Based VQA. In AAAI Confer-

ence on Artificial Intelligence, volume 36 of 3, pages

3081–3089. arXiv.

Yi, J. and Yoon, S. (2020). Patch SVDD: Patch-level SVDD

for Anomaly Detection and Segmentation. In Asian

Conference on Computer Vision (ACCV). arXiv.

Yin, S., Fu, C., Zhao, S., Li, K., Sun, X., Xu, T., and Chen,

E. (2024). A Survey on Multimodal Large Language

Models.

Zong, Y., Bohdal, O., and Hospedales, T. (2024). VL-

ICL Bench: The Devil in the Details of Benchmarking

Multimodal In-Context Learning.

Zou, Y., Jeong, J., Pemula, L., Zhang, D., and Dabeer,

O. (2022). SPot-the-Difference Self-Supervised Pre-

training for Anomaly Detection and Segmentation.

In European Conference on Computer Vision, pages

392–408. arXiv.

VISAPP 2025 - 20th International Conference on Computer Vision Theory and Applications

260