A Discrete Event Simulation Tool for Conducting a Fleet Mix Study

Mikayla Holmes and Lise Arseneau

Defence Research and Development Canada (DRDC), Centre for Operational Research and Development (CORA),

60 Moodie Drive, Ottawa, ON, K1A 0K2, Canada

Keywords: Discrete Event Simulation, Navy, Fleet Mix Study.

Abstract: A fleet mix study is currently being undertaken by the Royal Canadian Navy (RCN) to determine the optimal

composition of its future fleet to meet operational requirements. We introduce a Discrete Event Simulation

(DES) model developed within the Operational Research Integrated Graphical Analysis and Modelling

Environment (ORIGAME), called the ORIGAME Fleet Capacity Evaluation Tool (OFCET) that will be used

to examine how well a proposed future fleet (number and types of naval platforms) meets the desired

operational requirements to fulfill the Navy’s mandate. This paper describes the OFCET in terms of inputs,

outputs and assumptions and presents a case study with notional data to demonstrate how the tool can be used

as part of a fleet mix analysis to answer “what if” type questions. Furthermore, extensions of OFCET and

other problems that can be solved using this model will be provided.

1 INTRODUCTION

The Royal Canadian Navy (RCN) is currently

undergoing the largest recapitalization of its fleet

since the Second World War. To determine the

optimal composition of its fleet to meet future

operational requirements, a fleet mix study is being

undertaken. Fleet mix studies are essentially a

question of supply and demand: how well does a

supply meet an operational demand? For the RCN,

the supply consists of the type and number of

platforms in the proposed fleet and the demand

consists of several tasks and/or scenarios where the

RCN would be expected to provide a response. In

recent years, there have been comprehensive surveys

and literature reviews on modelling and solving fleet

mix-related problems (Wojtaszek and Wesolkowski

2012, Ali 2023). Due to potentially conflicting

objectives, such as performance, deployability,

availability, cost, and risk (Baykasoğlu et al. 2019),

military fleet mix problems can be extremely difficult

to solve.

Defence Research and Development Canada

(DRDC)’s Centre for Operational Research and

Analysis (CORA) has developed a fleet capacity

evaluation tool to conduct the latest fleet mix study

for the RCN. The tool was implemented in the

Operational Research Integrated Graphical Analysis

and Modelling Environment (ORIGAME), a Python-

based open-source discrete event simulation (DES)

interface available on a github repository (DRDC

2023). The model, named the ORIGAME Fleet

Capacity Evaluation Tool (OFCET), builds on

previous work, most notably Tyche (Eisler and Allen

2012) and the Platform Capacity Tool (Fee and Caron

2021). The OFCET is less computationally intensive

than Tyche, where a single simulation run can take

hours to complete (Eisler et al. 2014). Furthermore,

OFCET is based on an open-source programming

language, unlike the Platform Capacity Tool

developed in Arena® software (Rockwell

Automation 2024), and as a result the OFCET is less

expensive and more flexible to modify. The OFCET

has been designed to be flexible and adaptable, where

the supply and demand are modelled as a

deterministic and a stochastic process, respectively.

Following an overview of related work in Section

2, we will describe the OFCET in terms of the main

inputs required to run the simulation, the outputs

produced, as well as the assumptions and limitations

of the tool in Section 3. A case study is provided in

Section 4 using notional data to illustrate the type of

“what if” questions that can be answered as part of the

fleet mix analysis. Concluding comments including

areas of future work are provided in Section 5.

Holmes, M. and Arseneau, L.

A Discrete Event Simulation Tool for Conducting a Fleet Mix Study.

DOI: 10.5220/0013090100003893

In Proceedings of the 14th International Conference on Operations Research and Enterprise Systems (ICORES 2025), pages 207-214

ISBN: 978-989-758-732-0; ISSN: 2184-4372

Copyright © 2025 by Paper copyright by his Majesty the King in Right of Canada as represented by the Minister of National Defence

207

2 RELATED WORK

Fleet mix problems can be categorized as follows:

determining the best fleet for a given interval of time;

scheduling the acquisition and retirement of fleet

platforms; or evaluating a particular fleet on a set of

tasks or scenarios (Wojtaszek and Wesolkowski

2012). The latter problem is representative of the fleet

mix study being undertaken by the RCN, where the

scope involves performing multiple tasks using

multiple types of platforms (increasing the

complexity from a fleet mix study where a single task

and/or a single platform is being assessed).

The determination of operational requirements

(i.e., the demand) can be modeled as being

deterministic or stochastic in nature (Fee and Caron

2021). When the demand is fixed based on wanting

to achieve a certain level of ambition or by examining

specific scenarios, the demand is deterministic. For

example, a planning scenario for a conflict occurring

on the Korean Peninsula was used to determine the

effective mix of the US destroyer fleet (Crary et al.

2002) and a specified number of tasks to assign to

different vehicle types was the demand to determine

an Australian military vehicle fleet (Abbass and

Sarker 2006). While operational requirements

defined using a deterministic approach are concrete,

it fails to consider the inherent uncertainty of

international relations and potential threats (Lane et

al. 2022). Furthermore, the RCN requested that the

fleet mix be assessed against a wide range of tasks,

including combat, patrol, search and rescue, and

surveillance, each requiring the use of a variety of

assets to provide a response.

In this paper, we will use stochastic simulation to

determine demand where RCN operational

requirements are represented by possible future

timelines of vignettes (or scenarios), which can occur

concurrently. The list of hypothetical vignettes

represents the full scale of activities that would

require the use of a naval platform, where each

vignette can be characterized by type (e.g., peacetime

or wartime), frequency, and duration, where all

vignettes are distinct from one another. Several

studies have estimated operational demand using a

stochastic approach. As mentioned earlier, previous

RCN fleet mix structure analyses were conducted

using Tyche, where the demand is constructed

stochastically from scenarios using frequency, start

date, and duration inputs. The scenarios were

randomly generated using a Poisson process or

scheduled at known intervals (Eisler and Allen 2012).

In another study, the RCN requested DRDC CORA

determine the optimal number and types of platform

modules to meet its mandate. A Monte Carlo discrete

event simulation is used to generate the operational

demand from 54 vignettes and a mixed-integer linear

programming (MILP) model is used to determine the

optimal mix of modules (Caron et al. 2019).

Other military applications where demand has

been modeled stochastically include exploring

ammunition stockpiles based on vignettes describing

activities from several types of training and military

missions that require ammunition (Caron et al. 2023),

determining the fleet configuration of types of aircraft

by modeling air mobility requirements from 127

different tasks over a one-year period (Wesolkowski

and Billyard 2008, Wesolkowski and Wojtaszek

2012), and estimating operational demand from a set

of 17 scenarios covering a full range of missions

mandated by Canadian defense policy, with

approximately 80 variants developed specifically to

determine the force mix of personnel (Dobias et al.

2019).

Even though multiple platform types are being

included in the RCN fleet mix study, the number of

platforms in the proposed fleet to assess has been

specified, making the supply deterministic. Each

platform type has an operational cycle (OPCYCLE)

which specifies when the platform is available to

respond to tasks and when the platform requires

maintenance. In order to maximize the number of

platforms of a certain type available and minimize the

number simultaneously in maintenance, the start of

each OPCYCLE from asset-to-asset is offset to

generate a schedule to accomplish these objectives.

However, since the OPCYCLE for the proposed fleet

are not known, the platform availability will be varied

by examining a few different cases of maintenance

profiles for each platform type.

3 OFCET

3.1 Overview

In its simplest terms, OFCET is a supply and demand

model built within the DRDC developed DES

environment named ORIGAME. The OFCET model,

like its predecessor the PCT, attempts to allocate

naval platforms (supply) to a stochastic operational

demand which is generated over a specified timeline

(Fee, 2024). The OFCET is written using an object-

oriented programming (OOP) framework which

gives rise to the model structure wherein objects of

demand (vignettes) interact with objects of supply

(platforms) based on various conditions and

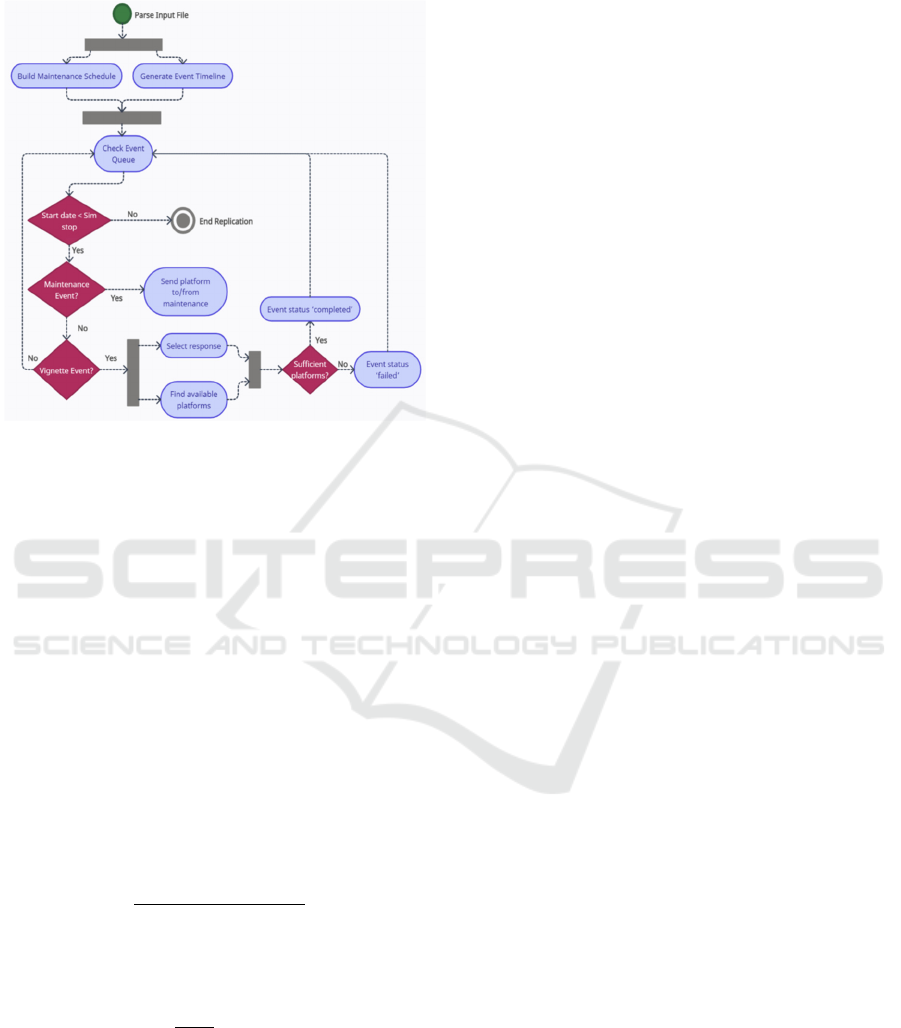

constraints. Figure 1 presents the steps that OFCET

ICORES 2025 - 14th International Conference on Operations Research and Enterprise Systems

208

takes to progress from operational demand generation

to platform assignment.

Figure 1: OFCET activity diagram.

The first step in the OFCET algorithm after the

input data has been imported is to generate

operational demand using vignette characteristics.

The number of times an event occurs over the

simulation timeline as well as its start date(s),

depends on event type (random or scheduled) and

frequency. For random events, a Poisson distribution

is used to determine the number of events of that

vignette type to be scheduled across the simulation

timeline. A uniform distribution is then used to

schedule the start date for each event. By default, this

is set to assume equal probability of an event starting

on each day of the simulation, however, it can be

modified to only include a certain timeframe within

the simulation (Fee, 2024). Equations 1 and 2 display

the distributions and their respective parameters for

random event scheduling.

𝒇

𝒌

𝒆

𝒇𝒓𝒆𝒒∗𝑳

𝒔𝒊𝒎

𝒇𝒓𝒆𝒒 ∗ 𝑳

𝒔𝒊𝒎

𝒌

𝒌!

𝒇

𝒌 probability that k events occur across simulation

𝒇

𝒓𝒆𝒒 historical frequency of vignette per year

𝑳

𝒔𝒊𝒎

length of simulation

(1)

𝒇

𝒍

𝟏

𝒃𝒂

,𝒂𝒃

𝒇

𝒍 probability of start date on day 𝒍

𝒂 first day event can occur Defaultfirst day of simulation

𝒃 last day event can occur Defaultlast day of simulation

(2)

For scheduled event types, the number of events

is determined for each year of the simulation using

historical data. If the event occurs an even number of

times per year it is scheduled accordingly. If, for

example, an event occurs on average 3.2 times per

year the model will schedule the vignette three times

a year, 80% of the time and four times in a year, 20%

of the time (Fee, 2024). Moreover, one can prespecify

an interval of time in which a vignette is scheduled if

the event must occur during timeframes throughout

the simulation. For example, exercises in the Arctic

may only be scheduled during the summer.

Duration and location of events are determined

the same way for both event types. Duration of events

is calculated using a triangular or uniform distribution

depending on whether the minimum, mode

(sometimes unavailable) and maximum parameters

are known (Fee, 2024). The location of an event is

chosen using a prespecified probability matrix that is

based on historical data and subject matter expertise.

Maintenance schedules for each platform are

generated concurrently to operational demand, but

before the assignment process. All platforms have an

OPCYCLE which specifies the timelines and

sequence in which a platform is prepared to do certain

tasks. During high readiness (HR) a platform can

conduct the full spectrum of combat operations, while

during normal readiness (NR) a platform is capable

of employment to operations in permissive

environments. The platform also goes into

maintenance periods called docking or short work

period (DWP or SWP) (Royal Canadian Navy, 2017).

In terms of platform availability, DWPs have the

largest impact, as some platform types are scheduled

to be in maintenance for 18 months within a 6-year

OPCYCLE, therefore the OFCET builds a schedule

specifically for each platform class based on the

DWPs only (but SWPs can be added if desired).

To minimize overlapping of unavailability

amongst platforms of the same class, a staggered

scheduling approach is taken following the

methodology seen in previous fleet mix studies. The

duration for which a DWP is shifted depends on the

length of the OPCYCLE and how many assets the

fleet contains of that class type. The maintenance

module can also incorporate varying numbers of

platforms by coast if desired.

For each replication, the simulation begins its

assignment pipeline after demand and maintenance

generation is complete. Since the OFCET is a DES,

the state of the system is assumed to be constant

between days in which an event appears on the event

queue. Within the OFCET there are two types of

demand which arise on the event queue – vignette

A Discrete Event Simulation Tool for Conducting a Fleet Mix Study

209

events or maintenance events. Vignette events are

prioritized within the event queue according to their

consequence of failure. This measure goes from 1 –

‘very low’ to 5 – ‘high’ and is a prespecified input.

Maintenance events have a priority value of 1000 so

that all platforms go to or return from maintenance on

a given day before a response is assigned to any

operational demand. After each platform’s

availability is fixed for a given day, the OFCET looks

at a variety of conditions to determine whether a

response is possible for each vignette event.

The current version of the model does not

consider platforms for assignment if they are on

another event or in maintenance when a new event

appears in the queue. For each platform available on

day x, the OFCET assesses whether the platform:

i. Can get to the location of the event

within the desired response time.

ii. Can complete the event and get back to

home port before the next DWP.

iii. Has enough days left at HR if the event

requires that level of readiness.

The platforms which satisfy these conditions are

then compared to the vignette’s chosen response

option.

If the list of available platforms does not meet the

requirements of the randomly chosen vignette

response option, the event’s completeness attribute is

set to ‘Failed’ and the simulation proceeds to the next

event. If, however, the available platforms meet or

exceed the required response, they are then ranked

based on the number of days the platform has left at

HR as well as its respective travel time to the vignette

location. If platforms within a certain class have

different values for HR days and travel time, then the

order of priority depends on whether the event

requires HR. If a vignette requires HR, the

platform(s) with the fewest days remaining at HR are

assigned to maximize the utility of the platforms

before they go down to NR. If the HR days are tied in

ranking the platform with the shortest response time

is assigned and vice versa. Lastly, the prioritized

platforms are assigned, and their status becomes

unavailable for the duration of the event plus two

times their specific travel time. This process

continues until an event appears on the queue which

has a duration and response time which extends

beyond the last simulation day, at which time the

model replication is complete.

The four OFCET model output files and input file

details are discussed below in Section 3.2 and 3.3.

3.2 Inputs

As mentioned above, the OFCET relies on several

input parameters to generate the operational demand

and platform maintenance schedules. Simulation

specific parameters and platform attributes are also

contained in the input file. One input file is required

for OFCET which contains 6 mandatory worksheets.

The worksheets are named Vignette Information,

Distance Matrix, Ship Information, OPCYCLE

Parameters, Response List, and Simulation

Parameters. The following list provides a summary

of what information is contained in each worksheet as

well as the primary use of that information during the

modelling process.

1. Vignette Information: contains type, annual

frequency, duration parameters, response

time, consequence of failure (1-5), HR

(boolean) and location for each vignette and

is used to generate operational demand.

2. Distance Matrix: Contains location names

and IDs for all vignettes and the nautical

miles from each location to the west and east

coast RCN home ports – used to calculate

platform travel time.

3. Ship Information: Contains ship class ID,

name, home port, cruising speed and length

of time at HR – used to allocate appropriate

platform and time spent at HR.

4. OPCYCLE Parameters: Contains ship class,

ID and number of assets, length of DWP and

OPCYCLE – used to generate platform

maintenance schedules.

5. Response List: Contains vignette ID and

name, platform classes as columns and all

combinations of allowed response options –

used to assign platforms to vignette events.

6. Simulation Parameters: Contains length of

simulation (years) and event run on length –

used to define model and event lengths.

3.3 Outputs and Post-Analysis

Modifying output specifics to the OFCET is a simple

task due to the user-friendly and flexible nature of

ORIGAME. The current iteration of the OFCET is

built to output four files which provide information

on: the operational demand generated, platform

allocation, response option distribution and a history

log that documents reason for failure of any event.

The structure of the output files depends on which

mode the simulation was run inside ORIGAME.

Since all simulations use the batch mode, it will be

discussed here. When running a batch mode,

ICORES 2025 - 14th International Conference on Operations Research and Enterprise Systems

210

simulation averaged metrics can be obtained, and the

stochastic nature of event generation is exemplified.

As such, ORIGAME builds a SQL database file for

batch runs which has four tables named History,

RespData, eventData and shipData. The database

files must be processed using an integrated

development environment (IDE) to calculate

averaged metrics. Some of these could include event

completion rate by vignette or overall, distribution of

platform demand generated by the random response

options, and the average number of HR events on any

given simulation day. These metrics (among others)

provide useful insight into how well the fleet is

meeting its operational demand.

The following case study aims to provide clarity

on the benefits of these output types and the overall

flexibility of the OFCET as a naval planning tool.

4 CASE STUDY

4.1 Assumptions

Before outlining the case study details and results,

some assumptions and caveats will be presented. It is

important to note that unlike previous fleet capacity

tools, these caveats are not necessarily permanent.

Modifications of the OFCET can be implemented as

required since it is based in an open-source

programming language (Python) and not hindered by

any licensing or software restrictions.

The OFCET caveats which are discussed below:

i. No re-assignment of platforms when

away from home port.

ii. Time at HR for all platforms modelled

optimistically.

iii. No SWPs incorporated into

maintenance schedule.

Re-assignment pertains to the functionality where

a platform can be re-tasked to a higher priority event

while currently assigned to an event. This capability

may represent reality more accurately, however, the

output files which keep track of why events have

failed do not indicate a pressing need to add this into

the current version of the model.

Platform readiness levels for the RCN, both

duration, time frame and type, are defined in each

platform’s OPCYCLE. For this case study, the

platform availability has been modelled

optimistically because we have not included SWPs in

the maintenance profiles. Furthermore, platform

readiness levels have been modelled optimistically as

well. The platform goes to HR for the first time when

an HR event occurs after the platform has finished a

DWP. The platform then remains at HR for a set

number of days (can be different for each platform or

class) regardless of whether it is assigned to HR or

NR events during that time. After those days have

lapsed, the platform must come out of a DWP before

it can go back to HR which accurately represents the

real-life platform readiness cycle.

The last assumption to be discussed relates to the

way response options are decided on. A vignette can

have many acceptable combinations of platforms that

can complete it. Whether an assignment is possible or

not requires comparing the platforms available to

those acceptable response options. The OFCET

currently selects a response option randomly with

equal probability across options since running batch

simulations with many replications allows for all

options to be selected and compared. The following

subsections will outline a fleet mix study conducted

using OFCET with notional data.

4.2 Inputs

The notional fleet mix study presented here

exemplifies the primary use case for the OFCET

model. Specifically, the OFCET was used to assess

how one RCN fleet composition meets three different

cases of demand. For each of these cases (outlined

below), the operational demand is generated, and

platforms are assigned the same way; however, each

scenario has a different (not mutually exclusive) set

of maritime events for which the fleet is assessed

against. It is important to note that the OFCET can

also be generalized to solve workforce supply and

demand problems for army and air force as well as

assist in decision making processes regarding impact

of maintenance period times or demand requirements.

Recall, from Section 3.1, that all operational

demand is generated according to vignette

characteristics. Historical data and discussions with

subject matter experts (SMEs) can also provide

qualitative information which enhances the

modelling approach taken here (Dobias et al, 2019).

The historical data can also provide information about

the realistic concurrency between vignettes.

Concurrency of events is a challenge to consider

within fleet capacity tools. It is imperative to assess

naval capability based on future timelines of

operational demand that are as realistic as possible;

however, this is difficult to emulate when the demand

includes all events the fleet could undertake. For

example, day-to-day operations like a public

engagement event would be quickly halted if a search

A Discrete Event Simulation Tool for Conducting a Fleet Mix Study

211

and rescue or full spectrum operations event occurred

requiring a naval response.

One way to limit the impact of demand

concurrency is to define categories: wartime (WT),

peacetime (PT), discretionary (D) and non-

discretionary (ND) for each vignette based on the

type of operation it involves. Categorization allows

for input files to be scoped down into wartime or

peacetime scenarios and thus minimize unrealistic

concurrency of operational demand. Ideally, this

scoping will also allow the overall fleet capacity

metrics to more accurately express how well the

demand is met.

Three demand cases are explored here using the

OFCET model. They are the full, peacetime (excludes

WT) and wartime (excludes PT and D) scenarios. The

total number of vignettes are 63, 44 and 26,

respectively. Table 2 contains a subset of 4 notional

vignettes with their input format for reference.

Table 2: Subset of 4 notional vignettes and characteristics.

Duration (days)

ID Category Frequency

(annual)

Min Mode Max

2 WT 0.5 30 227 730

5 PT 6 7 NA 50

11 ND 0.07 10 35 60

40 D 1 30 NA 30

The supply for the notional fleet mix study is

predetermined and consists of four classes of

platforms with a different number of assets within

each class. Additionally, each class has a specific

OPCYCLE and predetermined length of time in

maintenance which impacts the overall supply. These

details are presented in Table 3, followed by Section

4.3 which goes over various metrics used to assess

how well our supply met the operational demands for

all three cases.

Table 3: Supply for notional fleet mix study.

Class No. of

Assets

Length of

OPCYCLE

Months in

DWP

A 10 5 yrs. 12

B 5 5

y

rs. 15

C 7 6

y

rs. 18

D 2 6 yrs. 6

4.3 Results

All results are derived from the OFCET model

running over 80 replications with a simulation length

of 13 years. One year burn-in and cool-down periods

are used and therefore all metrics presented come

from data across 11-year timelines. These

adjustments are necessary as platforms are not

prepositioned on events or in maintenance when the

simulation begins and similarly platforms will not be

assigned to an event if the end of that event surpasses

the simulation timeframe. For the case study 80

replications was sufficient and takes less than 15

minutes to complete for the full demand input file.

The wartime demand case with only 26 vignettes,

completes in six minutes, which highlights

improvement on long computation times seen with

the previous fleet capacity tool Tyche.

Typically, with supply and demand models, the

first metric looked at is overall event completion rate.

Within the framework of fleet capacity and any

defense related capacity model there are multiple

factors and interactions at play which must be

considered in addition to overall event completion.

These factors and their impact are emphasized by an

example, discussed below with aiding information in

Table 4.

To illustrate, consider a randomly generated

timeline that contains an instance of vignette 2 which

requires a multi-platform response, all of which must

be at HR for a duration of 6 to 8 months. The

completion of this event can have a large impact on

whether many occurrences of a shorter, less

demanding vignette, for example 5, gets completed

over that same time frame. In this example, an overall

event completion rate which averages out the failure

of many instances of vignette 5 with one completion

of vignette 2 can miss these nuances entirely.

Table 4: Response options and HR requirements for

vignettes discussed in previous example.

Platform Class

ID HR A B C D

2Yes 3 2 0 1

5 No 0 0 0 1

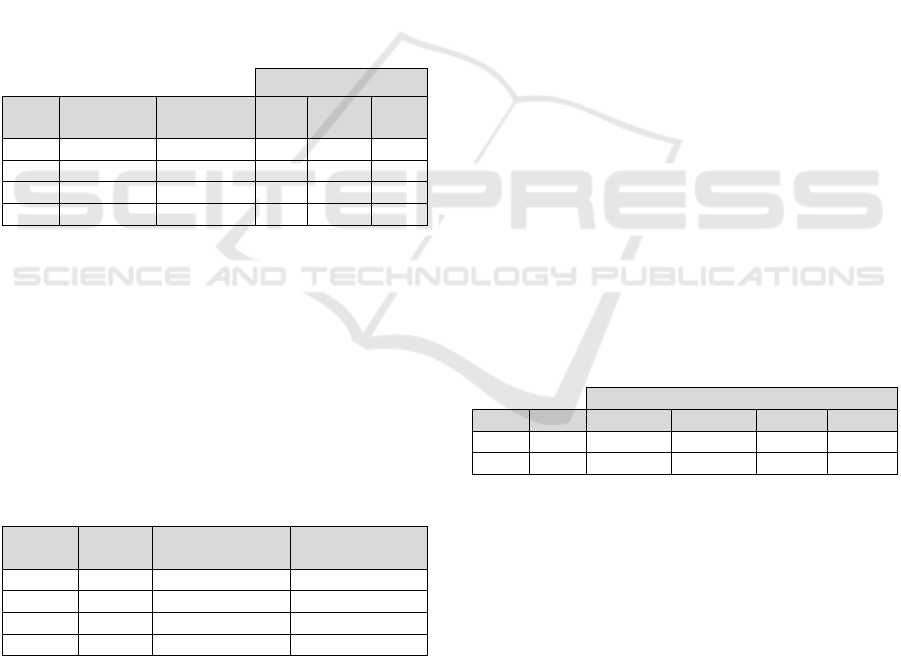

For the case study being discussed here, a variety

of metrics will be shown to demonstrate the type of

results that can be obtained from the OFCET. First,

the overall event completion rate for all three demand

cases is shown in Table 5. To gain further insights

into how well the supply meets some of our wartime

demand, Figure 2 displays the average event

completion rate for 14 of the 26 vignettes. Figure 2

also illustrates how the overall event completion rate

is unable to capture the large variation in event

completion for individual vignettes and the

importance of investigating vignette specific

completion rates.

ICORES 2025 - 14th International Conference on Operations Research and Enterprise Systems

212

Table 5: Overall event completion rate for three demand

cases.

Demand Case

No. of

Vi

g

nettes

Overall Event

Com

p

letion

Full 63 70%

Peacetime 44 73%

Wartime 26 75%

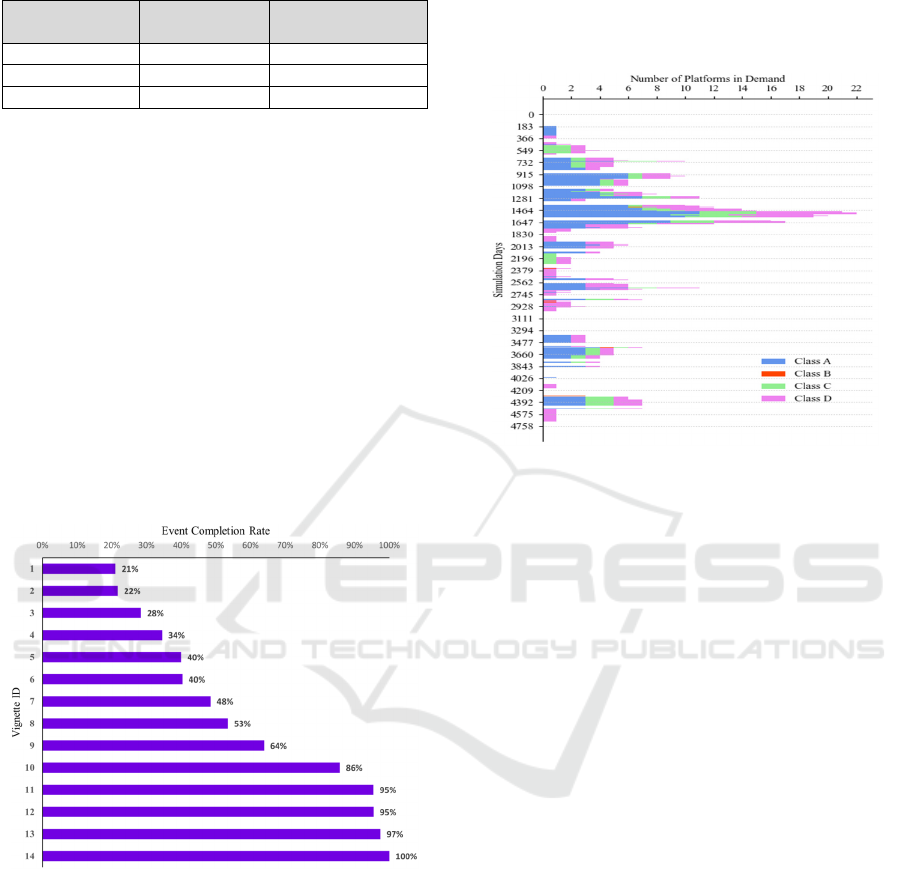

An additional function of the OFCET model is

that for any demand scenario, the user can specify that

they want only the event timeline to be generated,

which means no assignment phase will occur. Figure

3 displays one possible timeline generated using the

26 vignettes within the wartime demand case.

Although these analyses of the OFCET outputs do not

explore how much of the demand is currently met

with a specified fleet, it can be used to inform naval

planners about the potential requirements for certain

platform classes and/or lengths of time needed at HR.

Additionally, looking at the various platform

response options for certain demand cases can assist

in identifying how commissioning or

decommissioning a platform class will impact the

overall fleet’s ability to meet operational

requirements.

Figure 2: Event completion rate of 14 vignettes from the

wartime demand case.

In summary, the results of the notional fleet mix

study presented above demonstrate useful metrics and

information one can acquire through use of the

OFCET. Overall event completion rates across the

three demand cases increased slightly as the number

of included vignettes decreased, however, careful

consideration is required when looking at one

aggregate metric. Average event completion rate for

individual vignettes provides a greater degree of

certainty towards how well the fleet can meet

operational demands. Additional outputs, such as

event failure logs, also aid in providing naval

personnel with explanations regarding specific

vignettes completion rate. These outputs emphasize

areas where the model can be improved to more

accurately represent naval scenarios.

Figure 3: 13-year operational demand of each platform

class for wartime case.

5 EXTENSIONS

One benefit of the OFCET model being based in a

DRDC tailored, open-source platform is the

opportunities for improving and adding new modules

to the model. Some of these potential modules could:

• Re-task platforms.

• Incorporate an optimization algorithm.

• Build commission and decommission

functionality.

• Incorporate platform attrition.

• Add in crewing and/or training component.

In general, it is valuable to incorporate aspects of

the RCN functionality into fleet capacity tools to

provide the most useful results to decision makers.

Re-tasking platforms would mimic the real-life

scenario in which a platform is originally assigned to

an event but gets re-assigned to a new, higher priority

event in a nearby geographical area – i.e. a search and

rescue mission. These demands are often sporadic in

nature and can be investigated by using the current

OFCET version and assessing information within the

event history output files.

Incorporating previous work done by Widmer

(2024) and Fee (2019) would allow for maintenance

schedules to be optimized and can easily be

incorporated into the OFCET due to its Python

A Discrete Event Simulation Tool for Conducting a Fleet Mix Study

213

framework.

The OFCET could also be extended to deal with

platform transitions and their effect on the RCN fleet

capacity. Moreover, army and air force services could

utilize the platform specific approach of the OFCET to

assist in understanding how their resources meet

operational demands. The general workforce

modelling approach within the OFCET can be adapted

for many problems outside of naval fleet procurement.

6 CONCLUSION

This paper presents a new fleet capacity evaluation

tool along with a notional fleet mix study to display

the OFCET’s functionality. The OFCET model is not

computationally taxing and is flexible, which

improves upon the limitations of previous fleet

capacity tools such as PCT and Tyche. It is based in

the DES framework of ORIGAME which improves

its longevity due to having fewer licensing and

software constraints. The OFCET provides various

outputs that can be used to investigate questions

asked by stakeholders, naval planners and other

services alike. This information assists in informing

how certain fleet composition(s) can meet RCN

operational demands. The OFCET is easily adaptable

and can be implemented as required to address

subsequent RCN questions, or more broadly, defence

supply and demand problems.

ACKNOWLEDGEMENTS

The authors would like to acknowledge the work of

Benjamin Baker, previously a student with CORA,

who developed OFCET version one.

REFERENCES

Abbass, H., Sarker, R. (2006). Identifying the fleet mix in a

military setting. In Proceedings of the Second

International Intelligent Logistics Systems Conference

2006. Australian Society for Operations Research.

Baykasoğlu, A., Subulan, K., Taşan, A.S., Dudaklı, N.

(2019). A review of fleet planning problems in

single and multimodal transportation systems.

Transportmetrica A: Transport Science, 15(2):631–697.

Crary, M., Nozick, L.K., Whitaker, L.R. (2002). Sizing the

US destroyer fleet. European Journal of Operational

Research 136: 680-695.

Caron, J.-D., Fong, V., Brion, V. (2019). On the Use of

Simulation and Optimization for Mission Modules

Selection in a Maritime Context. Military Operations

Research Journal 24(1):41–56.

Caron, J.-D., Bryce, R.M., Young, C. (2023). A Simulation

Tool for Exploring Ammunition Stockpile Dynamics.

In Proceedings of the 12th International Conference on

Operations Research and Enterprise Systems

(ICORES), Volume 1:38-49. SCITEPRESS.

Defence Research and Development Canada. (2023).

ORIGAME. https://github.com/DND-DRDC-

RDDC/OS_ORIGAME.

Dobias, P., Hotte, Maj. D., Kampman, J., Laferriere, B.

(2019). Modeling Future Force Demand: Force Mix

Structure Design. In Proceedings from the 36th

International Symposium on Military Operational

Research. ISMOR.

Eisler, C., Allen, D. (2012). A Strategic Simulation Tool for

Capability-Based Joint Force Structure Analysis. In

Proceedings of the 1st International Conference on

Operations Research and Enterprise Systems, pages

21-30. SCITEPRESS.

Eisler, C., Wesolkowski, S., Wojtaszek, D. (2014). The

Tyche and SaFE Models: Comparting Two Military

Force Structure Analysis Simulations. In Proceedings

28th European Conference on Modelling and

Simulation. ECMS.

Fee, M., Caron, J.-D., Fong, V. (2019). Genetic algorithm

for optimization of the replacement schedules for major

surface combatants. In Theory and Practice of Natural

Computing – 8

th

International Conference, pages 161–

172. Springer.

Fee, M., Caron, J.-D. (2021). A simulation model to

evaluate naval force fleet mix. In 2021 Winter

Simulation Conference (WSC), pages 1–12. IEEE.

Fee, M., Baker, B. (2024). ORIGAME Fleet Capacity

Evaluation Tool. Reference Document. DRDC-RDDC-

2024-D019.

Lane, M., Frederick, B., Kavanagh, J., Watts, S., Chandler,

N., Smith, M.L. (2022). Forecasting Demand for U.S.

Ground Forces: Assessing Future Trends in Armed

Conflict and U.S. Military Interventions. RAND

Corporation.

Rockwell Automation. (2024). Arena Simulation Software.

https://www.rockwellautomation.com/en-

ca/products/software/arena-simulation.html.

Royal Canadian Navy, Assistant Chief of the Naval Staff

(2017). CFCD 129 – Royal Canadian Navy Readiness

and Sustaiment, Ottawa.

Wesolkowski, S., Billyard, A. (2008). The Stochastic Fleet

Estimation (SaFE) model. In Proceedings of the 2008

Spring Simulation Multiconference, pages 1-5. Society

for Computer Simulation International.

Wesolkowski, S., Wojtaszek, D. (2012). Multi-objective

optimization of the fleet mix problem using the SaFER

model. In Proceedings of WCCI 2012 IEEE World

Congress on Computational Intelligence, pages 1-8. IEEE.

Widmer, M., Fee, M., Bourque, F.A. (2024). Naval Fleet

Schedule Optimization Using an Integer Linear

Program. In Proceedings of the 13th International

Conference on Operations Research and Enterprise

Systems (ICORES), pages 47-57. SCITEPRESS.

ICORES 2025 - 14th International Conference on Operations Research and Enterprise Systems

214