Efficient Modelling with Logic-Labelled Finite-State Machines of

IEC 61499 Function Blocks: Simulation, Execution and Verification

Vladimir Estivill-Castro

1 a

, Miguel Carrillo

2 b

and David A. Rosenblueth

2 c

1

Department of Engineering, Pompeu Fabra University, Roc Boronat 138, Barcelona 08018, Spain

2

Instituto de Investigaciones en Matem

´

aaticas Aplicadas y en Sistemas, Universidad Nacional Aut

´

onoma de M

´

exico,

Apdo. 20-126, Ciudad de M

˙

exico 01000, Mexico

Keywords:

Models of Behaviour, Finite-State Machines, Distributed Systems, Formal Verification.

Abstract:

As automation grows, so does the complexity of software systems. Hence, the urgent and pressing need

for software verification, particularly for distributed systems, as they are notoriously difficult to verify. The

widespread of verification techniques, such as model checking, however, have been hindered by requiring a

significant level of expertise. In the realm of industrial automation, on the other hand, the IEC 61499 function

block architecture has gained prominence for modelling intricate distributed automation systems, especially in

demanding scenarios such as process control. However, it suffers from being event-driven, forcing semantic

interpretations and the use of timed events by a central clock, to produce input for model checkers. We argue

that this situation can be remedied by logic-labelled finite-state machines and control-status messages. This is

the first time that these concepts have been used for producing executable and verifiable models of distributed

systems for industrial automation with communication delays as is the current environment of application of

the IEC 61499.

1 INTRODUCTION

“Formal methods are critical to the development of

autonomous systems. Moreover, verification of the be-

haviour of autonomous systems is especially impor-

tant when they are embedded in safety-critical sys-

tems, which are increasingly being introduced into ev-

eryday settings.” (Provan, 2024). For effective appli-

cation (Sinha et al., 2019), formal verification neces-

sitates the development of tools and methods seam-

lessly integrating design models with their simulation,

execution, and formal verification of models without

semantic discrepancies. We introduce logic-labelled

finite-state machines (LLFSMs) for modelling dis-

tributed systems described with the IEC 61499 stan-

dard and show that this enables the simulation, execu-

tion, and formal verification of design. We illustrate

our approach with a three-level elevator.

In the realm of industrial automation, the

IEC 61499 standard’s function block architec-

ture (Vyatkin, 2011) is gaining prominence for mod-

elling intricate distributed automation systems, par-

a

https://orcid.org/0000-0001-7775-0780

b

https://orcid.org/0000-0003-2105-3075

c

https://orcid.org/0000-0001-8933-8267

ticularly in demanding scenarios such as process con-

trol. A factor fuelling this explosion of the IEC 61499

standard is the integration of operational technology

(OT) with information technology (IT), resulting in a

critical shift in the industrial sector (Bencherki et al.,

2024). (Bencherki et al., 2024) believes that Infor-

mation Technology’s rapid advancements have out-

paced those in OT. As a result, the IEC 61499 stan-

dard has been postulated as the most suitable tool for

the integration of IT and OT in industrial automa-

tion (Bencherki et al., 2024).

Like Ptolemy II, IEC 61499 uses event-driven

block diagrams for modelling cyber-physical systems

(CPSs), integrating physical processes with control

and communication mechanisms. While simulation

is the most commonly used validation method, it

has limitations in identifying potential faults. Model

checking provides exhaustive testing but faces risks,

such as combinatorial explosion, particularly with

complex data types and computations.

(Sinha et al., 2019) reviewed the application of

formal methods in the context of industrial automa-

tion. Over the past 15 years of research, some ad-

vancements have been made in formal modelling

within the IEC 61499 framework, though early efforts

Estivill-Castro, V., Carrillo, M. and Rosenblueth, D. A.

Efficient Modelling with Logic-Labelled Finite-State Machines of IEC 61499 Function Blocks: Simulation, Execution and Verification.

DOI: 10.5220/0013095200003896

In Proceedings of the 13th International Conference on Model-Based Software and Systems Engineering (MODELSWARD 2025), pages 141-149

ISBN: 978-989-758-729-0; ISSN: 2184-4348

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

141

were limited by support for only basic data types,

non-timed semantics, and small-scale systems.

One of the most serious limitations was the

definition of a semantics for the IEC 61499. In

2010, (Cengic and Akesson, 2010) highlighted that

“IEC 61499 is based on function blocks for devel-

oping distributed control applications. However, the

standard has no formal semantics, and different in-

terpretations of it have emerged. Since then, many

efforts have been dedicated to providing such seman-

tics (Vyatkin, 2009; Lindgren et al., 2015; Pang et al.,

2014; Dubinin and Vyatkin, 2012).

We use LLFSMs (Carrillo et al., 2020) and

control-status messages (Kopetz, 2011) to demon-

strate that we can efficiently and effectively produce

models for industrial automation analogous to those

of the function blocks of the IEC 61499 architecture.

In Section 2, we review related work. In Section 3,

we show the modelling of a canonical example of the

IEC 61499 architecture. Subsection 3.1 describes the

case study appears repeatedly in the literature (Droz-

dov et al., 2021; Shatrov and Vyatkin, 2021; Droz-

dov et al., 2017) of formal verification of a complex

distributed system of function blocks with communi-

cation delays on messages. Subsection 3.2 presents

the model when there are no delays in the commu-

nication channels. In this case, a simple controller

results in an executable and verifiable model that sat-

isfies safety properties and liveness properties. How-

ever, in Subsection 3.3, we do model the delays in

the communication channel and show that the sim-

ple controller is insufficient. All safety properties and

liveness properties become false. Thus, in Subsec-

tion 3.4 we introduce the corrected controller that ac-

counts for message delays, and all properties become

valid again. Section 3.6 shows that our modelling en-

ables more efficient formal verification than an ear-

lier version available in GitHub (Shatrov, 2021). Sec-

tion 4 provides conclusions.

2 RELATED WORK

A function block is the modelling unit of the

IEC 61499 standard (International Electrotechnical

Commission (IEC), 2012). A function block is an

abstraction of a composable entity that has input and

output communication channels to connect to other

function blocks. Both input and output channels can

be (input/output) variables and (reception/generation

of) events. A function block encapsulates local vari-

ables, the event handling of the input events, and, if

it is a basic block, a behaviour defined by a state ma-

chine. Function blocks are grouped into composite

function blocks.

Formal verification of systems defined by function

blocks uses a particular semantics, where blocks at

the same level of composition receive a turn each and

no two blocks execute concurrently (Drozdov et al.,

2021). A distributed model partitions a set of com-

posite blocks into parts with access to a central clock.

The parts can execute concurrently corresponding to

the placement of composite function blocks on dis-

tributed hardware where connections are either wired

(no delays) or wireless. Wireless links exhibit random

jitter, ranging from no delay to a maximum value.

By adding time stamps to events, time-aware com-

putation (TAC) (Drozdov et al., 2021) provides a for-

mal semantics to a function-block architecture and

translate an IEC 61499 standard (International Elec-

trotechnical Commission (IEC), 2012) models to SMV

for formal verification (Drozdov et al., 2021; Xavier

et al., 2021; Drozdov et al., 2016; Patil et al., 2015;

Drozdov et al., 2017). TAC is an extension of the

use of event-timestamping (Vyatkin et al., 2015; Dai

et al., 2020; Shatrov and Vyatkin, 2020) where all

events across function blocks receive a double-valued

integer timestamp. The first value is the system clock

when the event is generated. The second value is the

system clock at consumption by a function block or

processing at an interface.

Thus, as far as we are aware, formal verification

(of a system represented by function blocks of the

IEC 61499 standard) only exists by translation to SMV,

under TAC, and with a queue of events that consid-

ers a first-in-first-out queue for event handling. In the

case of two events with the same timestamp, a sys-

tem of priorities breaks ties in the scheduler (Drozdov

et al., 2021, Page 174).

(Carrillo et al., 2020) provide a formal sequen-

tial semantics for an arrangement of LLFSMs, where

each machine executes in a round-robin fashion on a

single CPU, implying concurrency but not distribu-

tion. This formal semantics was used to transform

LLFSMs to SMV (NuSMV’s input language), providing

practical semantics as a Kripke structure. Later, (Mc-

Coll et al., 2022) showed that LLFSMs could be par-

titioned into groups with no communication, allow-

ing parallel execution across different processors. Al-

though this suggests potential distribution, our inter-

est here is when the groups are distributed because of

local functionality, and there is communication.

3 LLFSMs FOR THE IEC 61499

In contrast to TAC, LLFSMs are time-triggered, and

in the case of distributed systems, we propose they

MODELSWARD 2025 - 13th International Conference on Model-Based Software and Systems Engineering

142

offer the following advantages.

1. LLFSMs can model (define) a scheduler for sub-

groups of LLFSMs, which can be either round-

robin, non-deterministic or some other predefined

one, allocating the turn of the LLFSMs in the sub-

group. These schedulers enable the modelling of

different concurrency types, progress rates, and

can specify which parts of the system are dis-

tributed.

2. LLFSMs model communication with shared vari-

ables; these variables are called whiteboard vari-

ables.

3. The modelling can utilise the mechanisms of a

“time-triggered communication system and con-

trol/status messages” (Kopetz, 2011) instead of

event channels (also known as an event-triggered

communication system (Kopetz, 2011); which

avoids the use of time-stamping.

We now exhibit visual, graphical, executable and

formal modelling with LLFSMs of distributed sys-

tems with communication delays. For this, we use

a well-studied case of distributed systems within the

IEC 61499 standard (International Electrotechnical

Commission (IEC), 2012). The effectiveness of ar-

rangements of LLFSMs for modelling cyber-physical

distributed systems will be even more representative

because we will show we can model the message de-

lays in communications channels from one section of

the system to another.

The modelling of an elevator has been a clas-

sical case study for model checking (Merz, 2008).

Moreover, the elevator case study appears in the lit-

erature of MDSD and translation for formal verifica-

tion (Meyers et al., 2020). It is the canonical exam-

ple for the IEC 61499 standard (Drozdov et al., 2021;

Shatrov and Vyatkin, 2021; Drozdov et al., 2017).

Moreover, we could retrieve the function-block model

and its translation to SMV (Shatrov and Vyatkin, 2021;

Shatrov, 2021) in the case of delays in communica-

tion between components. We describe now how we

reproduced particularly closely the modelling of this

system, but with an arrangement of LLFSMs.

This case study involves three sub-cases. The first

demonstrates system correctness when distributed

and without message delays or losses. Formal veri-

fication ensures the system meets safety and liveness

properties. A safety property (B

´

erard et al., 2001)

guarantees that an undesirable state never occurs –—

for the elevator example, the doors never open unless

the elevator is correctly stationed at the floor (Absence

Property Pattern (Dwyer et al., 1998)). A liveness

property ensures that certain actions will eventually

happen, such as the elevator reaching a requested floor

(Response Property Pattern (Dwyer et al., 1998)).

Secondly, we demonstrate the failure of the prop-

erties when the same controller is used, but the system

may suffer message delays between sections. Thirdly,

we demonstrate correctness (the properties are valid

again) when the controller is extended to consider

such message delays. We conclude with a demonstra-

tion of the efficiency of our translated models by com-

paring the execution times of verification with pub-

licly available ones.

3.1 The Three-Level Elevator Case

Study

The three-level elevator system involves a controller

(software) and physical components (sensors, but-

tons, elevator, motor) that are distributed and con-

nected through a network with potential delays. Each

level has a sensor to detect when the elevator reaches

that floor, sending a signal to the controller. If the

floor matches the destination, the controller stops the

elevator and opens the door. However, network delays

may cause the elevator to miss the floor, stop beyond

it, and open the door, posing safety risks for users.

In this case, the system implements a correction,

reversing the direction of the elevator for a period

corresponding to the detectable delay in the message

from the sensor. The three-level elevator models must

satisfy the safety property and the liveness property

mentioned before for each level, in total six prop-

erties (Shatrov and Vyatkin, 2021; Drozdov et al.,

2017). Recall that the safety properties are that this

automation cyber-physical distributed system with the

correction never opens a door without the elevator

properly placed at the corresponding door. We write

this property in LTL for level 0, as follows.

G(door_0.At_CLOSED_0 ->

X(G(elevator.At_POSITION_FLOOR_0 | door_0.At_CLOSED_0))

)

Replacing 0 by 1 or 2 results in the other two prop-

erties for this safety property. The other property ver-

ified in the literature (Shatrov and Vyatkin, 2021) is a

liveness property and requires that a request at a floor

be eventually fulfilled by the elevator getting there.

For floor 2, the LTL formulation in SMV is as follows

G(button_floor_2.At_REQUESTED_2

-> F elevator.At_POSITION_FLOOR_2)

while for TLA+ we have

[] (button_floor_2State="REQUESTED_2"

˜> elevatorState="POSITION_FLOOR_2")

The controller must initialise the elevator by com-

manding it to go to level 0. The existing versions of

the SMV model (Shatrov, 2021) assume that when the

Efficient Modelling with Logic-Labelled Finite-State Machines of IEC 61499 Function Blocks: Simulation, Execution and Verification

143

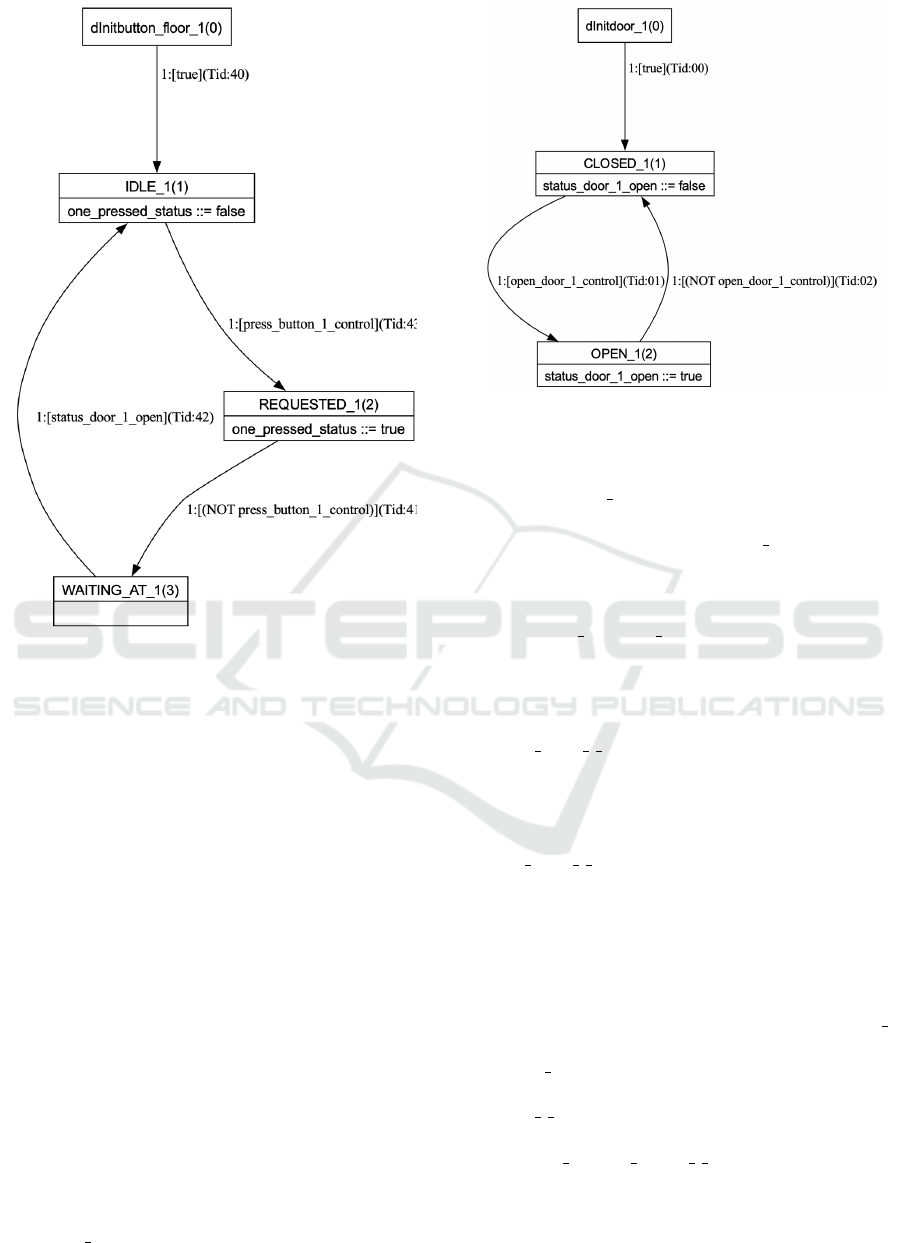

Figure 1: A drawing of the LLFSM for the call button at

level 1.

system starts, all doors are closed. For formal verifi-

cation of the sanity and liveness properties, the litera-

ture (Drozdov et al., 2017; Shatrov, 2021) proposes a

closed-loop model that we also replicate. Thus, once

initialisation is complete, users request the elevator

first in level 1, then in level 2, and finally in level 0.

This proposed test case (Drozdov et al., 2017) does

not stop at level 1 when going to level 2. By contrast,

we do not assume the doors are initially closed. Our

controller not only posts commands for the elevator

to reach level 0, but closes all potentially open doors

during initialisation. This explains our use of the X

operator in the first safety property.

3.2 Messages Without Delays

The first model does not have messaging delays, and

the controller does not consider this; thus, it has no

corrections. Nevertheless, all six properties are valid.

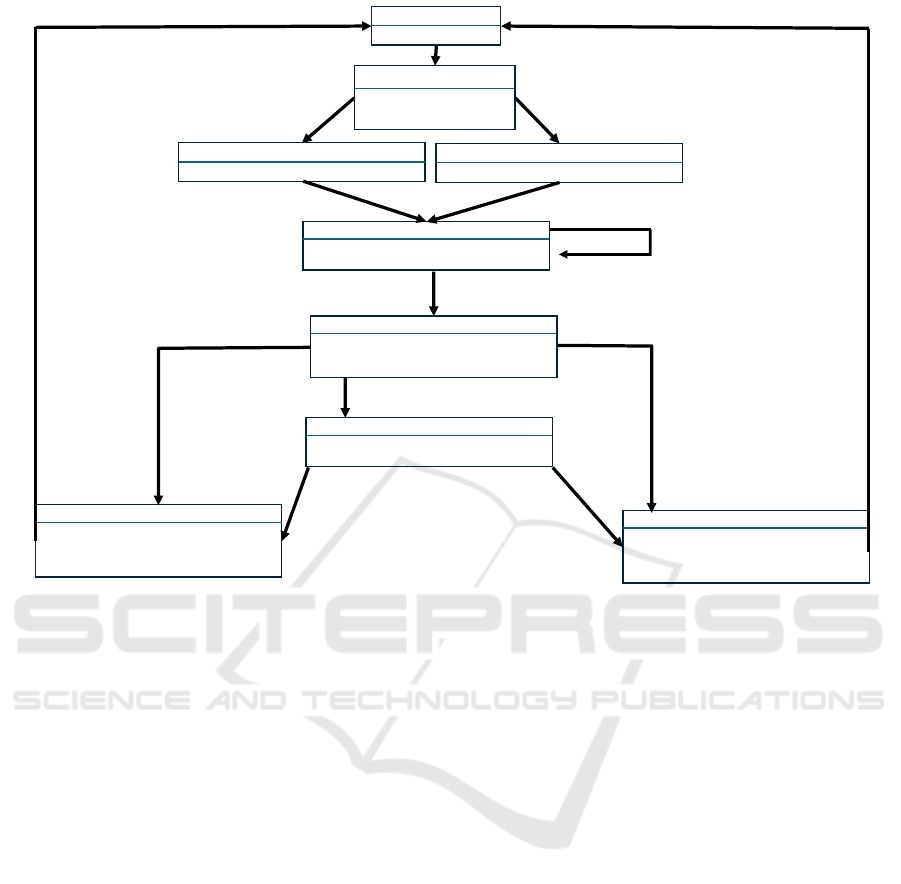

Fig. 1 shows the LLFSM for the call button at

level 1. There will be three analogous LLFSM in the

arrangement corresponding to the call buttons of the

three floors. A call button in floor i is typically in the

state IDLE i unless it receives a control message that a

Figure 2: A drawing of the LLFSM for the door at level 1.

request by a user has been made on that floor. If such

a message is received, this LLFSM will move to the

state REQUESTED i. When the user releases the button

(no longer a control message that it is pressed, this

LLFSM moves to the state WAITING i, until it notices

the status message of the door at level i indicating the

door is open (thus, the request is served). Note that

such call button LLFSM creates a status message, as

the variable i pressed status in the whiteboard.

Fig. 2 shows the LLFSM corresponding to the

door at level 1. A door at level i can either be

CLOSED or OPEN, and this is communicated in a sta-

tus message by updating the whiteboard variable

status door i open (notice that this is the status

that the call button consults). The doors are sub-

ject to the controller that sends them a control mes-

sage to close or open them. For the i-th door, this

is the control message in the whiteboard variable

[open door i control.

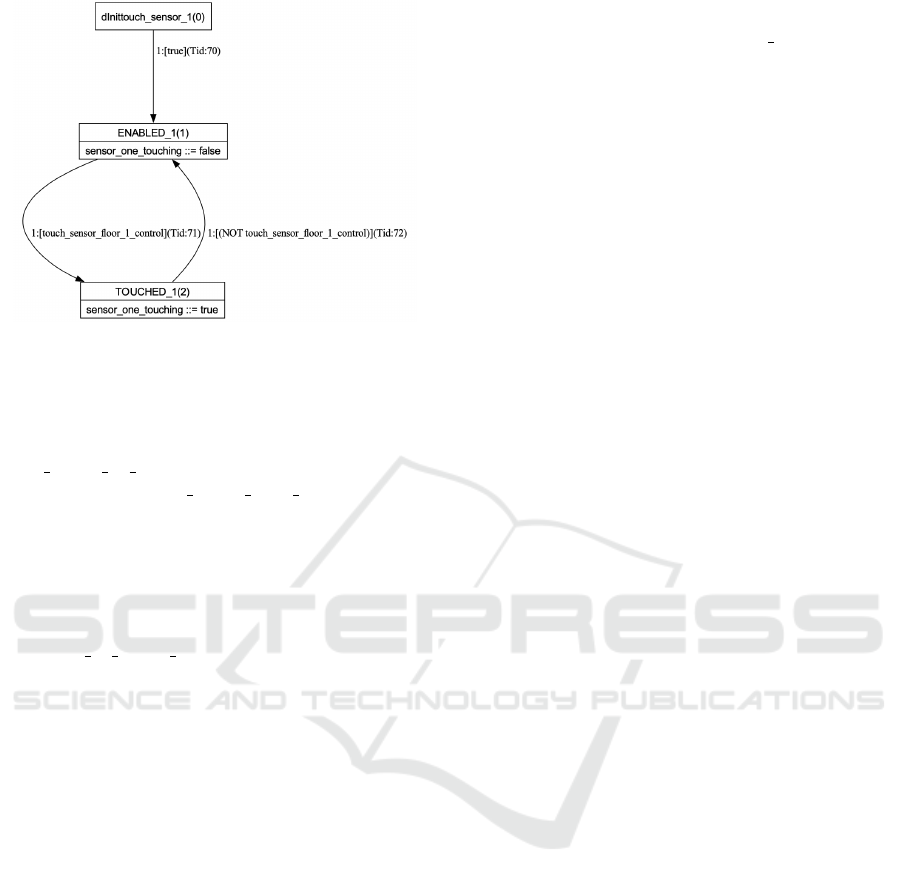

The LLFSMs for the sensors that detect whether

the elevator is on their floor are also machines with

two states. Fig. 3 shows the LLFSM corresponding to

the touch-sensor at level 1. There are three machines

modelling each sensor at each level.

The i-sensor has two states. When it is being

pressed by the elevator, it is in the state TOUCHED i,

and when it is not being pressed, it is in the state

ENABLED i. The touch sensor communicates its state

with a status message in the whiteboard variable

sensor i touching. The elevator controls the state

of the touch sensor with a control message on the vari-

able touch sensor floor i control.

The elevator is a more complicated LLFSM, as

shown by Fig. 4.

As per the descriptions of this case study, the

elevator takes four units of time to travel be-

MODELSWARD 2025 - 13th International Conference on Model-Based Software and Systems Engineering

144

Figure 3: A drawing of the LLFSM for the touch sensor at

level 1.

tween two consecutive floors. It reacts to the

controller’s control messages on its motor. The

elevator moves up when the whiteboard variable

turn motor up control is true, and it moves down

when the variable turn motor down control is true.

The elevator is (a) at one of the three levels, (b) in

between levels lower than the bottom, or (c) higher

than the top level. So as not to use even more

states, three local variables are used to indicate how

far it is when in between levels. For instance,

when between levels one and two, the local variable

distance to floor 1 can have values in {1, 2, 3}.

The simple controller (Fig. 5) does not consider

the possibility of the elevator bypassing a floor since

there are no delays. The elevator’s arrival on a floor

causes sensor detection, and the controller reads the

sensor’s status immediately after.

To complete the arrangement as a closed model,

we have an LLFSM (Fig. 6) that models interaction

with the user and sends the control messages to the

call buttons, waiting for the elevator to arrive before

issuing the following control message.

3.3 Messages with Delays and

Controller Without Corrections

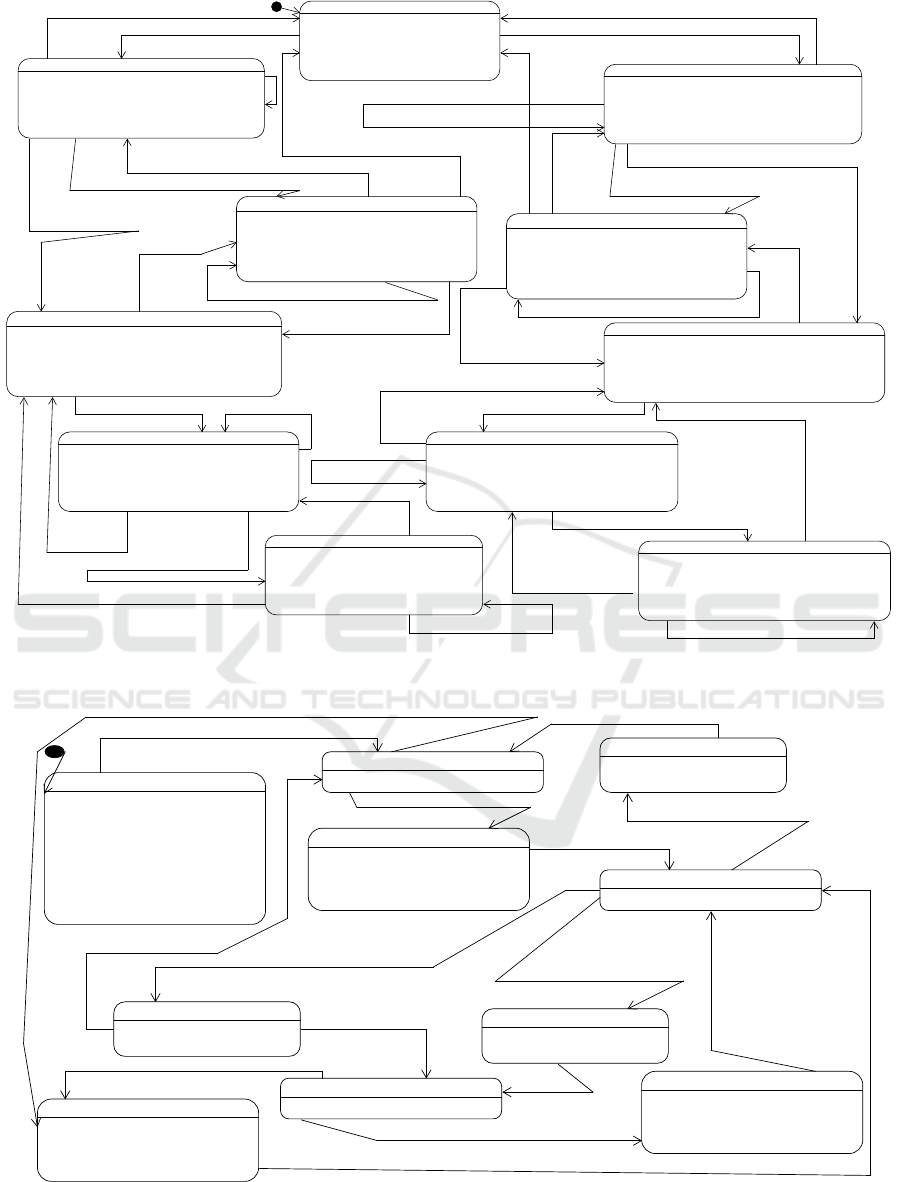

The second model introduces delays parameterised by

a maximum delay of 0, 1, or 2 units (in the litera-

ture (Shatrov and Vyatkin, 2021) the maximum de-

lay is set to 2 units). The delays in the communica-

tion channels are placed as in the literature (Shatrov

and Vyatkin, 2021) between the touch sensors and the

controller. The signal that the elevator is at a particu-

lar floor can be delayed as much as 2 time units. Fig. 7

shows the LLFSM that introduces a delay between the

touch sensor at level 1 and the controller. The sys-

tem now has three of these delaying machines, one

for each touch sensor.

The LLFSM is analogous to a E DELAY function

block presented in Fig. 2 by (Drozdov et al., 2016) or

in Fig. 6 by (Drozdov et al., 2017). The delay is non-

deterministic, meaning it can take any of the values

0, 1, or 2 units and the system shall be correct for all

these possibilities for every message.

Naturally, when the maximum delay is 0, this

model reduces to the earlier model of the previous

section (the delaying LLFSMs participate but have no

effect). But, since the controller assumes no delays,

it is enough for the maximum delay to be 1 for all

properties to be false; thus, with maximum delay 2,

all properties are also false (the trace that makes them

false with maximum delay 1 is a trace for the case

when the maximum delay is 2).

3.4 Messages with Delays and

Controller With Corrections

Our third model incorporates the correction in the

controller into the second model and now, no matter

how we set the maximum delay, all properties are sat-

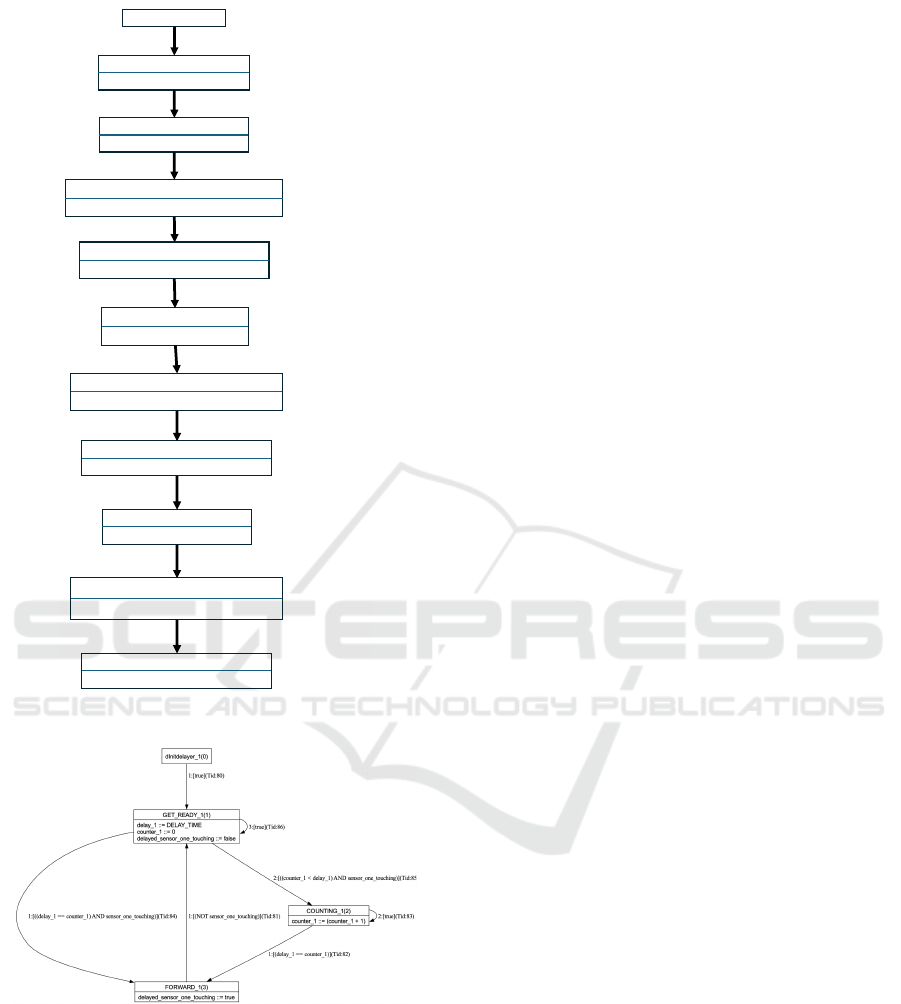

isfied. Fig. 8 shows a fraction of the new controller.

This fraction shows when the elevator departs from

floor 0 to floor 1 or to floor 2. The controller closes

the door at level 0, and then, according to the target

floor, calculates the expected time for the displace-

ment. The status of the calling button gives the tar-

get floor. A signal from a touch sensor at floor 1 or

floor 2 (which may be delayed) is sufficient for the

controller to stop the motor. Analogously to the cor-

rection in the literature, a difference between the ex-

pected travel time and the counting of time defines

how many steps to run the motor in the opposite di-

rection. Once the elevator arrives at a floor, the cor-

responding door is opened, and the elevator becomes

available again. Naturally, the three possible depar-

tures imply a larger controller, that for space reasons

is omitted, but available with our released examples.

3.5 Real-Time Properties

We reproduced the verification of all the safety prop-

erties and liveness properties we found in the liter-

ature. We now show that, with our translation to

SMV, we can verify real-time properties. There are

two types of real-time properties (Lamport, 2002)

(or Bounded Existence (Dwyer et al., 1998)). First,

there are properties that ensure an upper bound on

the length of time for the system to respond. Second,

there are those that ensure a lower bound on the length

of time that an aspect of the state is present. For the

first type of property, we verify that the waiting time

Efficient Modelling with Logic-Labelled Finite-State Machines of IEC 61499 Function Blocks: Simulation, Execution and Verification

145

BELOW_0_WENT_UP

touch_sensor_floor_1_control := false

touch_sensor_floor_2_control := false

touch_sensor_floor_0_control := false

distance_to_floor_1 := (distance_to_floor_1 - 1)

distance_to_floor_2 := (distance_to_floor_2 - 1)

distance_to_floor_0 := (distance_to_floor_0 - 1)

BELOW_0_WENT_DOWN

touch_sensor_floor_1_control := false

touch_sensor_floor_2_control := false

touch_sensor_floor_0_control := false

distance_to_floor_1 := (distance_to_floor_1 + 1)

distance_to_floor_2 := (distance_to_floor_2 + 1)

distance_to_floor_0 := (distance_to_floor_0 + 1)

ABOVE_2_WENT_DOWN

touch_sensor_floor_1_control := false

touch_sensor_floor_2_control := false

touch_sensor_floor_0_control := false

distance_to_floor_1 := (distance_to_floor_1 - 1)

distance_to_floor_2 := (distance_to_floor_2 - 1)

distance_to_floor_0 := (distance_to_floor_0 - 1)

ABOVE_2_WENT_UP

touch_sensor_floor_1_control := false

touch_sensor_floor_2_control := false

touch_sensor_floor_0_control := false

distance_to_floor_1 := (distance_to_floor_1 + 1)

distance_to_floor_2 := (distance_to_floor_2 + 1)

distance_to_floor_0 := (distance_to_floor_0 + 1)

BETWEEN_0_AND_1_WENT_UP

touch_sensor_floor_1_control := false

touch_sensor_floor_2_control := false

touch_sensor_floor_0_control := false

distance_to_floor_1 := (distance_to_floor_1 - 1)

distance_to_floor_2 := (distance_to_floor_2 - 1)

distance_to_floor_0 := (distance_to_floor_0 + 1)

POSITION_FLOOR_0

touch_sensor_floor_0_control := true

touch_sensor_floor_2_control := false

touch_sensor_floor_1_control := false

distance_to_floor_0 := 0

distance_to_floor_1 := TRAVEL_TIME

distance_to_floor_2 := (TRAVEL_TIME + TRAVEL_TIME)

POSITION_FLOOR_2

touch_sensor_floor_2_control := true

touch_sensor_floor_1_control := false

touch_sensor_floor_0_control := false

distance_to_floor_2 := 0

distance_to_floor_1 := TRAVEL_TIME

distance_to_floor_0 := (TRAVEL_TIME + TRAVEL_TIME)

BETWEEN_1_AND_2_WENT_UP

touch_sensor_floor_1_control := false

touch_sensor_floor_2_control := false

touch_sensor_floor_0_control := false

distance_to_floor_1 := (distance_to_floor_1 + 1)

distance_to_floor_2 := (distance_to_floor_2 - 1)

distance_to_floor_0 := (distance_to_floor_0 + 1)

BETWEEN_2_1_WENT_DOWN

touch_sensor_floor_1_control := false

touch_sensor_floor_2_control := false

touch_sensor_floor_0_control := false

distance_to_floor_1 := (distance_to_floor_1 - 1)

distance_to_floor_2 := (distance_to_floor_2 + 1)

distance_to_floor_0 := (distance_to_floor_0 - 1)

BETWEEN_1_AND_0_WENT_DOWN

touch_sensor_floor_1_control := false

touch_sensor_floor_2_control := false

touch_sensor_floor_0_control := false

distance_to_floor_1 := (distance_to_floor_1 + 1)

distance_to_floor_2 := (distance_to_floor_2 + 1)

distance_to_floor_0 := (distance_to_floor_0 - 1)

POSITION_FLOOR_1

touch_sensor_floor_1_control ::= true

touch_sensor_floor_2_control ::= false

touch_sensor_floor_0_control ::= false

distance_to_floor_1 ::= 0

distance_to_floor_2 ::= TRAVEL_TIME

distance_to_floor_0 ::= TRAVEL_TIME

2:(turn_motor_down_control AND (1 < distance_to_floor_2))

2:turn_motor_down_control

2:turn_motor_up_control

1:(turn_motor_up_control AND (1 == distance_to_floor_0))

3:(turn_motor_up_control AND (1 < distance_to_floor_0))

2:turn_motor_down_control

2:(turn_motor_up_control AND (1 < distance_to_floor_0))

1:[(turn_motor_up_control AND (1 == distance_to_floor_0))

3:turn_motor_down_control

2:turn_motor_up_control

1:(turn_motor_down_control AND (1 == distance_to_floor_2))

3:(turn_motor_down_control AND (1 < distance_to_floor_2))

AND (1 == distance_to_floor_2))

1:(turn_motor_down_control

3:turn_motor_up_control

1:turn_motor_up_control

2:turn_motor_down_control

3:(turn_motor_down_control AND (1 == distance_to_floor_0))

2:(turn_motor_up_control AND (1 < distance_to_floor_1))

4:(turn_motor_down_control AND (1 < distance_to_floor_0))

4:(turn_motor_up_control AND (1 < distance_to_floor_1))

4:(turn_motor_down_control AND (1 < distance_to_floor_1))

3:(turn_motor_up_control AND (1 == distance_to_floor_2))

1:(turn_motor_down_control AND (1 == distance_to_floor_0))

3:(turn_motor_down_control AND (1 < distance_to_floor_0))

1:(turn_motor_down_control AND (1 == distance_to_floor_1))

2:(turn_motor_up_control AND (1 == distance_to_floor_1))

1:(turn_motor_up_control AND (1 == distance_to_floor_1))

2:(turn_motor_up_control AND (1 < distance_to_floor_2))

1:(turn_motor_up_control AND (1 == distance_to_floor_2))

2:(turn_motor_down_control AND (1 == distance_to_floor_1))

3:(turn_motor_up_control AND (1 < distance_to_floor_2))

4:(turn_motor_down_control AND (1 < distance_to_floor_1))

1:turn_motor_up_control

2:(turn_motor_down_control)

Figure 4: A drawing of the LLFSM for the elevator.

ARRIVED_AT_TWO

turn_motor_up_control := false

turn_motor_down_control := false

open_door_2_control := true

press_button_2_control := false

ARRIVED_AT_ONE

turn_motor_up_control := false

turn_motor_down_control := false

open_door_1_control := true

press_button_1_control := false

DOOR_CLOSED_MOVING_UP

turn_motor_up_control := true

CLOSING_DOOR_2

open_door_2_control := false

elevator_ready := false

DOOR_1_CLOSING

open_door_1_control := false

elevator_ready := false

DOOR_0_CLOSING

open_door_0_control := false

elevator_ready := false

WAITING_IDLE

elevator_ready := true

ARRIVED_AT_ZERO

turn_motor_down_control := false

turn_motor_up_control := false

open_door_0_control := true

press_button_0_control := false

DOOR_CLOSED_MOVING_DOWN

turn_motor_down_control := true

STARTING

open_door_1_control := false

open_door_2_control := false

open_door_0_control := false

turn_motor_up_control := false

turn_motor_down_control := false

press_button_1_control := false

press_button_2_control := false

press_button_0_control := true

elevator_ready := false

1:((NOT status_door_1_open)

AND zero_pressed_status)

1:(NOT status_door_2_open)

2:((NOT status_door_1_open)

AND two_pressed_status)

(NOT status_door_0_open)

3:(sensor_two_touching

AND (zero_pressed_status OR one_pressed_status))

2:(sensor_zero_touching

AND (one_pressed_status OR two_pressed_status))

1:(sensor_one_touching

AND (zero_pressed_status OR two_pressed_status))

1:sensor_one_touching AND one_pressed_status

2:sensor_two_touching AND two_pressed_status

status_door_2_open

status_door_1_open

status_door_0_open

1:sensor_zero_touching AND zero_pressed_status

2:sensor_one_touching AND one_pressed_status

(NOT status_door_1_open)

AND (NOT status_door_2_open) AND (NOT status_door_0_open)

Figure 5: A drawing of the LLFSM for the controller that does not handle communication delays.

MODELSWARD 2025 - 13th International Conference on Model-Based Software and Systems Engineering

146

dInithmi(0)t

IS_ELEVATOR_READY(1)

PRESS_1(4)

WAITING_FOR_ELEVATOR_AT _1(2)

DOOR_OPENED_AT_ONE(3)

PRESS_2(5)

WAITING_FOR_ELEVATOR_AT_2(6)

DOOR_OPENED_AT_TWO(7)

PRESS_0(8)

WAITING_FOR_ELEVATOR_AT_0(9)

DOOR_OPENED_AT_ZERO(10)

1:[true](Tid:140)

1:[elevator_ready](Tid:142)

1:[one_pressed_status](Tid:143)

1:[status_door_1_open](Tid:141)

1:[true](Tid:144)

1:[two_pressed_status](Tid:145)

1:[status_door_2_open](Tid:146)

1:[true](Tid:149)

1:[zero_pressed_status](Tid:147)

1:[status_door_0_open](Tid:148)

Figure 6: A drawing of the LLFSM for the user interaction.

Figure 7: A drawing of the LLFSM that delays the signal

of the touch sensor at level 1.

once the elevator is called at a floor is bounded by a

constant.

LTLSPEC

G( button_floor_0.At_REQUESTED_0

-> F[0,147] elevator.At_POSITION_FLOOR_0

)

This illustrates that a request for the elevator at

level 0 is serviced by the close model in no more than

147 Kripke states.

For the second type, we verify that once a door is

open, it remains open for at least a certain period.

LTLSPEC

G

( (door_1.At_OPEN_1& X !door_1.At_OPEN_1)

-> H[0,44] door_1.At_OPEN_1

)

This property indicates that door 1 remains open

for at least 44 Kripke states.

3.6 Comparison

Using the Eclipse Modelling Framework, we devel-

oped tools to translate LLFSMs models into SMV and

TLA+ through model-to-text transformations. Our

tools and examples are released as a Docker con-

tainer for ease of installation. The model checker

NuSMV completes the verification of the six proper-

ties for all three models in a matter of minutes. We

replicated this in a machine running Linux with a

CPU i7-10850H,0 and 16GB of RAM and a machine

tuning macOs Sonoma 14.5 with an Apple Arm M1

and 16GB of RAM. In contrast, the SMV model with

time-stamped events in the public domain (Shatrov,

2021) includes a script for verification. Our attempts

to run the verification failed to terminate in machines

with less than 16GB of RAM and required 2 hours

and 20 minutes to verify only one property on both

systems mentioned earlier. Moreover, for this model,

NuSMV raises a warning “Fair states set of the finite

state machine is empty” and the SMV formulation in-

cludes FAIRNESS directives, which raises issues about

the apparent verification of a property because the

property may be true by vacuity.

4 CONCLUSIONS

Whether a language is a domain-specific modelling

language or a general modelling language is in the

eye of the beholder (Wasowski and Berger, 2023).

Although Turing complete, LLFSMs can be consid-

ered a domain specific language tailored to describe

CPSs’ behaviour. LLFSMs are short of describ-

ing data structures or object-oriented mechanisms al-

though there is no reason why LLFSMs can be organ-

ised in inheritance hierarchies and also contain meth-

ods using statements as per the code associated with

states (LLFSMs already contain local variables).

The unambiguous semantics of LLFSMs, com-

bined with control-status messages, improve the reli-

ability of industrial automation and software systems

by eliminating semantic discrepancies. This ensures

Efficient Modelling with Logic-Labelled Finite-State Machines of IEC 61499 Function Blocks: Simulation, Execution and Verification

147

1:[delayed_sensor_zero_touching AND (one_pressed_status OR two_pressed_status](Tid:133)

WAITING_IDLE(2)

elevator ready ::= true

CLOSING_DOOR_0(6)

open_door_0_control ::= false

elevator_ready ::= false

global _clock_counter ::= 0

GOING_FROM_0_TO_2(11)

expected_arrival ::= TRAVEL_TIME+TRAVELTIME

GOING_FROM_0_TO_1(11)

expected_arrival ::= TRAVEL_TIME

DOOR_CLOSED_MOVING_UP(7)

turn_motor_up_control ::= true

global_clock_counter ::= global_clock+1

1:[one_pressed_status AND (NOT status_door_0_open)](Tid:139)

1:[two_pressed_status AND (NOT status_door_0_open)](Tid:1310)

1:[true]Tid:138)

1:[true]Tid:137)

STOP_GOING_UP(7)

turn_motor_up_control ::= false

turn_motor_down_control ::= false

count_back ::= global_clock – expected_arrival

2:[true]Tid:1320)

1:[(one pressed _status AND delayed_sensor_one_touching)

OR

(two_pressed_status AND delayed_sensor_two_touching]Tid:1319)

ARRIVED_AT_TWO(7)

turn_motor_up_control ::= false

turn_motor_down_control ::= false

open_door_2_control ::= true

press_button_2_control ::= false

ARRIVED_AT_ONE(7)

turn_motor_up_control ::= false

turn_motor_down_control ::= false

open_door_1_control ::= true

press_button_1_control ::= false

1:[status_door_1_open]Tid:134)

1:[status_door_2_open]Tid:134)

2:[expected_arrival == global_clock_counter

AND two_pressed_status](Tid:1310)

1:[expected_arrival == global_clock_counter

AND one_pressed_status](Tid:1310)

CORRECT_DOWN(13)

turn_motor_down_control ::= true

count_back ::= count_back -1

3:[expected_arrival < global_clock_counter](Tid:1331)

2:[two_pressed_status

AND (0==count_back](Tid:1331)

1:[one_pressed_status

AND (0==count_back](Tid:1311)

Figure 8: Fraction of the controller LLFSM that detects when the elevator bypasses a target floor and redirects it back.

consistency across different model checkers. Our

tools can translate LLFSM models into multiple pro-

gramming languages, with equivalent traces. While

translations to C and assembly may run at different

speeds, the execution times are proportional, allow-

ing for real-time property verification. Although not

shown here, the action language used in LLFSMs also

supports timed transitions, which allow system calls

to the system clock. Therefore, this introduction of

the LLFSMs approach and its tools for incorporating

them into the IEC 61499 standard is a step towards

even more trustworthy and certifiable distributed sys-

tems.

Software language engineering (SLE) is the ap-

plication of systematic, disciplined, and measurable

approaches to the development, deployment, use,

and maintenance of software (domain-specific) lan-

guages. The technology for this is now heavily reliant

of language workbenches. Language workbenches

are tools for reducing the gap between the design

and implementation of (external) domain-specific lan-

guages. Our tools are currently based on the Eclipse-

Modelling Framework. To modernise them for lan-

guage workbenches, in the future, we plan to shift

them to the GSLP (Metin and Bork, 2023).

REFERENCES

Bencherki, Z., Meyrueis, V., Benfriha, K., Cachot, L., and

Soares, P. (2024). The IEC 61499 standard in industry

4.0. IEEE Int. Conf. Automatic Control and Intelligent

Systems (I2CACIS), p. 24–29.

B

´

erard, B., Bidoit, M., Finkel, A., Laroussinie, F., Petit,

A., Petrucci, L., Schnoebelen, P., and McKenzie, P.

(2001). Systems and Software Verification. Model-

Checking Techniques and Tools. Springer.

Carrillo, M., Estivill-Castro, V., and Rosenblueth, D. A.

(2020b). Verification and simulation of time-domain

properties for models of behaviour. Model-Driven En-

gineering and Software Development Revised Selected

Papers, vol. 1361 CCIS, p. 225–249. Springer.

Cengic, G. and Akesson, K. (2010). On formal analysis

of IEC 61499 applications, part A: Modeling. IEEE

Trans. Industrial Informatics, 6(2):136–144.

Dai, W., Pang, C., Vyatkin, V., Christensen, J. H., and Guan,

X. (2020). Discrete-event-based deterministic execu-

tion semantics with timestamps for industrial cyber-

physical systems. IEEE Trans. Systems, Man, and Cy-

bernetics: Systems, 50(3):851–862.

Drozdov, D., Dubinin, V., Patil, S., and Vyatkin, V. (2021).

A formal model of IEC 61499-based industrial au-

tomation architecture supporting time-aware compu-

tations. IEEE Open J. Industrial Electronics Society,

2:169–183.

MODELSWARD 2025 - 13th International Conference on Model-Based Software and Systems Engineering

148

Drozdov, D., Patil, S., Dubinin, V., and Vyatkin, V. (2016).

Formal verification of cyber-physical automation sys-

tems modelled with timed block diagrams. IEEE 25th

Int. Symposium on Industrial Electronics (ISIE), pages

316–321.

Drozdov, D., Patil, S., Dubinin, V., and Vyatkin, V. (2017a).

Towards formal verification for cyber-physically ag-

nostic software: A case study. IECON 43rd An-

nual Conf. IEEE Industrial Electronics Society, pages

5509–5514.

Dubinin, V. N. and Vyatkin, V. (2012). Semantics-robust

design patterns for IEC 61499. IEEE Trans. Industrial

Informatics, 8(2):279–290.

Dwyer, M. B., Avrunin, G. S., and Corbett, J. C. (1998).

Property specification patterns for finite-state verifica-

tion. Proc. Second Workshop on Formal Methods in

Software Practice, FMSP, p. 7–15, NY, USA. ACM.

International Electrotechnical Commission (IEC) (2012).

IEC 61499-1:2012 Function blocks - Part 1: Archi-

tecture.

Kopetz, H. (2011). Real-Time Systems: Design Principles

for Distributed Embedded Applications. Springer, 2nd

edition.

Lamport, L. (2002). Specifying Systems: The TLA+ Lan-

guage and Tools for Hardware and Software Engi-

neers. Addison-Wesley, USA.

Lindgren, P., Lindner, M., Lindner, A., Vyatkin, V., Pereira,

D., and Pinho, L. M. (2015). A real-time semantics for

the IEC 61499 standard. IEEE 20th Conf. on Emerg-

ing Technologies & Factory Automation (ETFA), p. 1–

6.

McColl, C., Estivill-Castro, V., McColl, M., and Hexel,

R. (2022a). Decomposable and executable models

for verification of real-time systems. 9th Int. Conf.

Revised papers form Model-Driven Engineering and

Software Development MODELSWARD, vol 1708 of

CCIS, p. 135–156. Springer.

Merz, S. (2008). An introduction to model checking. Mod-

eling and Verification of Real-Time Systems: For-

malisms and Software Tools, p. 81–116. Wiley.

Metin, H. and Bork, D. (2023). On developing and operat-

ing GLSP-based web modeling tools: Lessons learned

from BIGUML. 2023 ACM/IEEE 26th Int. Conf.

Model Driven Engineering Languages and Systems

(MODELS), p. 129–139, IEEE Comp. Soc.

Meyers, B., Vangheluwe, H., Denil, J., and Salay, R.

(2020). A framework for temporal verification support

in domain-specific modelling. IEEE Trans. Software

Engineering, 46(4):362–404.

Pang, C., Patil, S., Yang, C.-W., Vyatkin, V., and Shalyto,

A. (2014). A portability study of IEC 61499: Seman-

tics and tools. 2014 12th IEEE Int. Conf. Industrial

Informatics (INDIN), pages 440–445.

Patil, S., Dubinin, V., and Vyatkin, V. (2015). Formal verifi-

cation of IEC61499 function blocks with abstract state

machines and SMV – modelling. 2015 IEEE Trust-

com/BigDataSE/ISPA, vol 3, p. 313–320.

Provan, G. (2024). Formal methods for autonomous vehi-

cles. IT Professional, 26(1):50–56. Reproduced in the

Column on Formal Methods in Industry, IEEE Com-

puting Edge.

Shatrov, V. (2021). INDIN2021 — examples of two IEC

61499 systems for comparison of formal verification

approaches. On github. https://github.com/vi34/

conf/tree/main/INDIN2021.

Shatrov, V. and Vyatkin, V. (2020). Formal verification of

IEC 61499 enhanced with timed events. Technolog-

ical Innovation for Life Improvement, IFIP Advances

in Information and Communication Technology, vol

577, p. 168–178. Springer.

Shatrov, V. and Vyatkin, V. (2021). Promela formal mod-

elling and verification of IEC 61499 systems with

comparison to SMV. IEEE 19th Int. Conf. on Indus-

trial Informatics (INDIN), pages 1–6.

Sinha, R., Patil, S., Gomes, L., and Vyatkin, V. (2019). A

survey of static formal methods for building depend-

able industrial automation systems. IEEE Trans. In-

dustrial Informatics, 15(7):3772–3783.

Vyatkin, V. (2009). The IEC 61499 standard and its seman-

tics. IEEE Industrial Electronics Magazine, 3(4):40–

48.

Vyatkin, V. (2011). IEC 61499 as enabler of distributed and

intelligent automation: State-of-the-art review. IEEE

Trans. Industrial Informatics, 7(4):768–781.

Vyatkin, V., Pang, C., and Tripakis, S. (2015). Towards

cyber-physical agnosticism by enhancing IEC 61499

with PTIDES model of computations. IECON 41st

Annual Conf. IEEE Industrial Electronics Society, p.

001970–001975.

Wasowski, A. and Berger, T. (2023). Domain-Specific Lan-

guages: Effective modeling, automation, and reuse.

Springer.

Xavier, M., Patil, S., and Vyatkin, V. (2021). Cyber-

physical automation systems modelling with

IEC 61499 for their formal verification. IEEE

19th Int. Conf. Industrial Informatics (INDIN), pages

1–6.

Efficient Modelling with Logic-Labelled Finite-State Machines of IEC 61499 Function Blocks: Simulation, Execution and Verification

149