Towards Synthesis-Based Engineering for Cyber-Physical Production

Systems

Wytse Oortwijn

1

, Yuri Blankenstein

1,2

, Jos Hegge

1

, Dennis Hendriks

1,3

, Pi

¨

erre van de Laar

1

,

Bram van der Sanden

1

, Laura van Veen

1

and Nan Yang

1

1

TNO-ESI, The Netherlands

2

Capgemini Engineering, The Netherlands

3

Radboud University, The Netherlands

Keywords:

Supervisory Control, Systems Engineering, Synthesis Based Engineering, Model Based Design, Industrial

Adoption.

Abstract:

Supervisory control is a key part of Cyber-Physical Production Systems (CPPSs), to orchestrate all system

resources to work together in a safe, correct, and optimal way. Engineering reliable supervisors for industrial

CPPSs is highly challenging due to their complex nature. Synthesis-Based Engineering (SBE) is an engi-

neering approach centered around supervisory controller synthesis, a technique for automatically computing

correct-by-construction supervisors out of formal system requirements and plant models that describe unre-

stricted system behavior. Even though SBE may lead to higher degrees of automation and faster feedback

cycles, SBE may be difficult to integrate into existing ways of working since it is different from traditional

engineering. This article contributes a three-step approach to gradually introduce SBE in industrial settings.

We are instantiating this approach in a research case together with ASML and VDL-ETG, by developing a

proof-of-principle workflow. In this workflow, control is specified as UML activities, for which we contribute

a formal execution semantics since that is missing in current practice. Moreover, we discuss design assistance

provided in the workflow as well as its evaluation with domain experts. The domain experts see the value of

automated design assistance and are willing to take further steps towards the adoption of SBE.

1 INTRODUCTION

Supervisory control is a key part of Cyber-Physical

Production Systems (CPPSs), which are systems con-

sisting of mechatronic components that comprise the

physical part of a system, and which are coordinated

by control software that comprise the cyber part.

CPPSs evolve over time and are typically not indi-

vidual products, but product lines with many configu-

rations and variations (Linden et al., 2007). Their su-

pervisory controllers should orchestrate all resources

to work together in the right way to ensure safe, cor-

rect, and optimal system behavior.

Engineering reliable supervisory controllers for

industrial CPPSs is challenging due to their complex

nature (Fokkink et al., 2023a). For example, such

systems are typically worked on by multiple engi-

neering teams of various disciplines that must coop-

erate. These teams must engineer supervisory con-

trollers that adhere to many safety and functional re-

quirements, which may be incomplete, could be hard

to realize, and might change over time. The con-

trollers must let the system operate safely, correctly,

and optimally, also in exceptional situations, thereby

considering all configurations and variations for prod-

uct lines as well as potentially high degrees of con-

currency that CPPSs may have. The combination of

all these complexity factors, which moreover tend to

increase further over time due to system evolution,

might make manual engineering infeasible.

One strategy for managing this complexity is em-

ploying Synthesis-Based Engineering (SBE) (Baeten

et al., 2016), which is an engineering approach that

combines model-based engineering with computer-

aided design. SBE is centered around supervisory

controller synthesis (Ramadge and Wonham, 1987;

Wonham et al., 2018), a technique for computing

correct-by-construction controllers from formal plant

models that describe unrestricted system behavior,

and formal system requirements. These formal mod-

158

Oortwijn, W., Blankenstein, Y., Hegge, J., Hendriks, D., Laar, P., van der Sanden, B., Veen, L. and Yang, N.

Towards Synthesis-Based Engineering for Cyber-Physical Production Systems.

DOI: 10.5220/0013103300003896

In Proceedings of the 13th International Conference on Model-Based Software and Systems Engineer ing (MODELSWARD 2025), pages 158-168

ISBN: 978-989-758-729-0; ISSN: 2184-4348

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

els help to manage complexity by their focus on spec-

ifying requirements, i.e., what the system should do

rather than how the controllers should realize them in

every relevant situation. Specifying the how, i.e., the

design, is often significantly more complex than spec-

ifying the what, i.e., requirements

1

. SBE largely auto-

mates the realization of supervisory controllers: they

can automatically be (re)synthesized from the for-

mal specifications in a correct-by-construction fash-

ion. This may lead to higher degrees of automation

and faster feedback cycles in the development pro-

cess (Fokkink et al., 2022; Fokkink et al., 2023b).

Despite these potential benefits, integrating SBE

into existing ways of working is difficult since it dif-

fers from traditional engineering, e.g., by putting a

stronger focus on handling requirements. This article

contributes a three-step approach for gradually intro-

ducing SBE in industrial settings. The first step of this

approach is formalizing the (current) control specifi-

cations, as an enabler for design assistance. A key

aspect of the specification formalism is composition-

ality, the ability to compose larger specifications out

of smaller ones. The second step is introducing design

assistance for validating and verifying specifications,

e.g., by means of simulation and property checking.

This may already lead to less defects and reduced

cost, and puts validation support in place, which is es-

sential in SBE for determining whether the specified

requirements are the right ones. The third step is sup-

porting automated synthesis of these formal control

specifications out of system requirements and plant

models of unrestricted system behavior. The compo-

sitional nature of the formal control specifications al-

lows engineers to synthesize parts of the specification

while still being able to manually specify other parts,

and gradually scale up synthesis as needed. The non-

synthesized parts can then still be verified, to check

their adherence to the specified system requirements.

We are instantiating our three-step approach by

developing a tool-supported workflow, with the aim to

introduce SBE in industrial settings. As a carrier case

for the research, we consider the development pro-

cess of the wafer handler for ASML’s lithography ma-

chines, jointly developed by ASML

2

and VDL-ETG

3

.

The wafer handler is a complex subsystem respon-

sible for transporting wafers between the track and

wafer stage at a specified throughput rate. Eventually,

once this workflow is in place, we aim to investigate

1

A FIFO requirement is an example of an easy-to-

specify yet hard-to-realize requirement, as is showcased

here (Accessed 2024-12-18): https://eclipse.dev/escet/cif/

synthesis-based-engineering/example.html.

2

https://www.asml.com (Accessed 2024-12-18).

3

https://www.vdletg.com (Accessed 2024-12-18).

to what extent SBE can help engineers and architects

that are non-experts in formal methods to manage the

increasing complexity of specifying wafer flow.

Wafer flow is specified in terms of UML activities,

but in an informal way, i.e., in the absence of a formal

definition of what their execution means. Therefore,

addressing step one of the approach, we contribute a

formal execution semantics for these activities, cov-

ering relevant specification concepts that are being

used, in particular atomicity, conditional waiting, and

guards and effects for data handling. To the best of

our knowledge, such concepts are not native in exist-

ing standard definitions of activities like fUML (Ob-

ject Management Group, 2021). That is, these con-

cepts can be expressed in terms of other fUML con-

cepts, but that is cumbersome to specify and not as

intuitive for users.

A first proof-of-principle workflow has been de-

veloped that is centered around these formalized

UML activities. This workflow includes initial design

assistance—step two of the approach—in the form

of modelling, simulation and verification support, by

means of (translations to) off-the-shelf tooling. Sup-

port for synthesis—step three of the approach—is not

yet included. However, the feasibility of synthesizing

UML activities has been demonstrated (Laar, 2023).

We have evaluated our first workflow with engi-

neers and architects from ASML and VDL-ETG, with

positive outcome. They expressed interest in formal-

izing their wafer flow specifications to enable design

assistance and later synthesis, to shorten feedback cy-

cles and help manage the increasing complexity.

To summarize our contributions:

1. We contribute an approach to (gradually) intro-

duce SBE in industrial settings where formal

modelling is not yet common practice.

2. We contribute an execution semantics of UML ac-

tivities. Such a formal semantics is needed as pre-

requisite for applying our approach at ASML and

VDL-ETG.

3. We present first experiences and results with exe-

cuting this approach at ASML and VDL-ETG.

The rest of the article is organized as follows. Sec-

tion 2 gives necessary background on SBE. Section 3

explains the approach towards adopting SBE in in-

dustrial settings. Section 4 discusses the proof-of-

principle workflow that implements our approach.

In particular, we define activities and their execu-

tion semantics as the main specification formalism

(Sec. 4.1), discuss design assistance for these activ-

ities (Sec. 4.2), discuss the evaluation of the work-

flow with architects and engineers from ASML and

VDL-ETG (Sec. 4.3), and outline the high-level strat-

Towards Synthesis-Based Engineering for Cyber-Physical Production Systems

159

egy for extending the workflow with synthesis support

(Sec. 4.4). Finally, Section 5 discusses related work

and Section 6 concludes.

2 SYNTHESIS-BASED

ENGINEERING

Our aim is to gradually introduce SBE of supervisory

control into industrial practices. The supervisory con-

trollers are responsible for orchestrating the individ-

ual system components to work together correctly and

optimally (Sheridan and Johannsen, 1976). We con-

sider supervisors of discrete event systems. That is,

movements of mechanical components are initiated

by discrete outputs from the supervisory controller

(e.g., ‘start’ and ‘stop’) based on discrete inputs from

the system (e.g., sensor observations) although these

movements may themselves be continuous in time.

The SBE approach is centered around supervi-

sory controller synthesis, a technique for automati-

cally computing correct-by-construction supervisory

controllers based on formal specifications of system

requirements and the unrestricted behavior of the

mechanical components. Code generation, e.g., for

PLCs, can then be employed on synthesized con-

trollers (Reijnen, 2020; Reijnen et al., 2022). The

input component specifications for controller synthe-

sis are called plants, and describe all possible unre-

stricted component behavior in terms of events and

indicate which of these are controllable. Supervisors

can only influence controllable events, by disabling

them whenever they would (in)directly cause viola-

tions of requirements. Moreover, synthesized super-

visors are guaranteed to be minimally restrictive: they

do not restrict controllable events more than needed.

Since SBE largely automates the design, realiza-

tion and verification of supervisors, engineers can fo-

cus primarily on specifying and validating the sys-

tem requirements. At the same time this makes SBE

different from traditional engineering, and therefore

non-trivial to integrate into industrial practices. In

traditional engineering, requirements and designs are

typically specified in informal documents, which are

input for software engineers to write code, which in

turn is verified and validated by means of testing.

With Model-Based Engineering (MBE), the design

specifications are formalized as models, from which

code implementations can automatically be gener-

ated. One could additionally formalize the require-

ments, to be able to automatically check them on

the models, leading to the approach of Verification-

Based Engineering (VBE). SBE extends MBE and

takes VBE one step further, by synthesizing the de-

signs from the formal requirements in a correct-by-

construction manner.

3 INCREMENTAL MIGRATION

TO SBE

We contribute a high-level approach for gradually in-

tegrating SBE in industrial ways of working where

(means for) SBE are not yet in place. This approach

is centered around the observation that, in order to

adopt SBE, first MBE and VBE should progressively

be adopted to some extent. This not only enables

SBE, but also gradually scales up the degree of de-

sign automation, thereby allowing users to gradually

get used to formal specifications and think in terms of

requirements (the what) rather than the detailed de-

sign (the how).

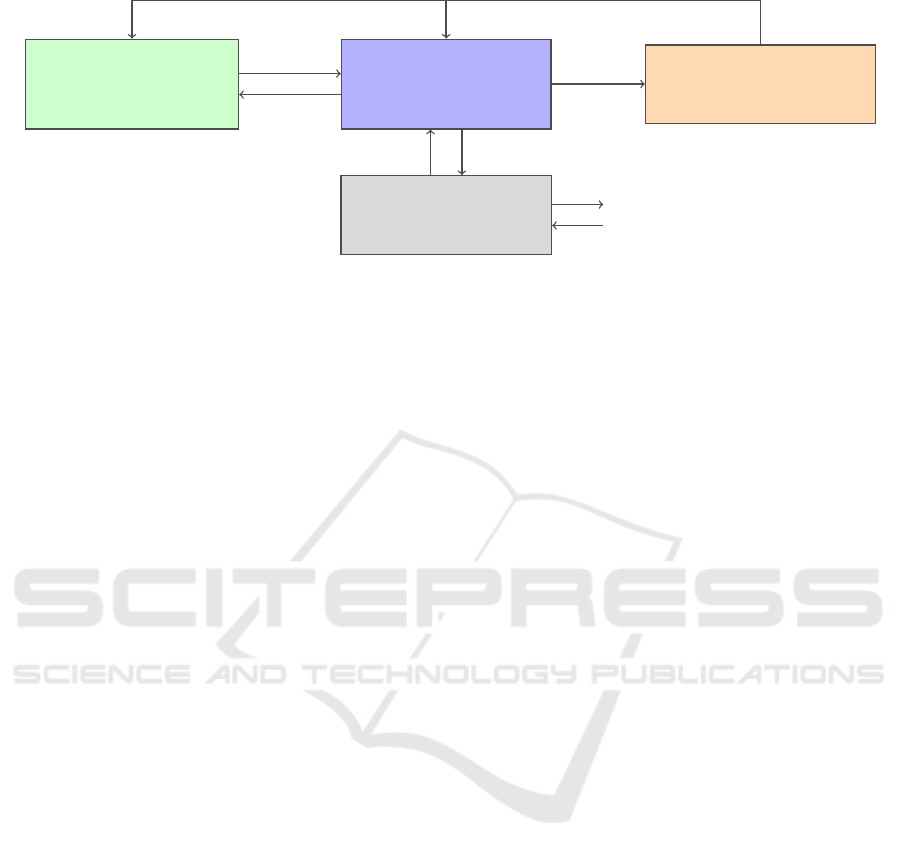

Figure 1 shows the approach (Hegge et al., 2023),

consisting of three steps: (1) formalizing the cur-

rent specifications; (2) providing design assistance for

these formal specifications; and (3) providing support

for synthesizing these specifications.

Step (1). From the starting point of traditional en-

gineering, step (1) is formalizing the current design

specifications into formal models that have a well-

defined unambiguous semantics. Apart from being

essential in enabling design assistance and synthesis,

this step may already provide practical value on itself,

e.g., by requiring engineers to think more critically

about (the meaning of) their specifications. Moreover,

this step enables automatic generation of relevant ar-

tifacts from the models, like code, documentation,

and tests. Generating such artifacts not only reduces

implementation effort, but also ensures that develop-

ments artifacts are consistent with one another. Ar-

tifact generation should however ensure traceability:

whenever an issue occurs during system execution, it

should be possible to link the observed behavior back

to formally specified behavior, to support diagnostics.

To start with step (1), a specification formalism

needs to be defined or chosen. A key property of the

chosen formalism is compositionality: the ability to

compose larger specifications out of smaller ones, for

example by means of hierarchy. Compositional spec-

ifications allow multiple development teams to work

independently on different parts of the overall specifi-

cation. They also simplify the gradual introduction of

SBE, by allowing synthesized control specifications

to be composed with ones that are manually made.

A practical consideration for implementing

step (1), is to stay close to currently-used specifi-

cation languages, even when these are not optimal

MODELSWARD 2025 - 13th International Conference on Model-Based Software and Systems Engineering

160

Formal synthesis

specifications

(e.g., plants, requirements)

Step (3)

Formal control

specifications

(e.g., UML activities)

Step (1)

Design assistance

(e.g., simulation, verification)

Step (2)

Generated artifacts

(e.g., code, documentation)

Synthesize

Link

Analyze

Link

Generate

Execute

Observe

Incorporate feedback

Figure 1: A three-step approach for gradual adoption of SBE. Step (1), formalizing control specifications, is shown in blue.

Step (2), establishing design assistance for formal control specifications, in orange. Step (3), synthesizing control specifica-

tions from synthesis specifications, in green.

for automated analysis and synthesis. Especially in

brownfield situations, switching to a new specifica-

tion formalism would not only require formalizing

the existing specifications, but also converting them

to suit the new formalism, training engineers and

architects to work with this new formalism, adapting

the overall development process accordingly, etc.

Another consideration is to connect to existing in-

dustry standards for modeling, like UML or SysML,

whenever possible. Such industry standards are

accessible for engineers, e.g., due to their widely

available documentation and (community) support

including commercial tooling, while preventing

companies from having to maintain (expertise of)

their own standards and associated tooling.

Step (2). Once formal specifications are in place,

suitable design assistance can be developed for them.

The execution semantics of the formal specifications

enables simulation, and checking of standard prop-

erties like absence of deadlocks. Moreover, a for-

mal semantics allows different validation and verifi-

cation techniques to be consistent with one another,

e.g., any property violation found by a model checker

can be visualized by simulating the counterexample.

Such design assistance helps to find potential prob-

lems early, leading to fewer defects and reduced cost.

It also shortens feedback cycles: architects are able to

validate ideas at design-time, without having to wait

for a concrete code implementation.

One practical consideration for adopting design

assistance is leveraging existing tooling when pos-

sible, to prevent companies from having to de-

velop/maintain in-house technology. For example,

many verifiers come with their own front-end specifi-

cation language, to which the specifications of step (1)

may be translated in a behavior-preserving manner.

Step (3). The next step towards migrating to SBE

is introducing support for synthesizing formal control

specifications. Synthesis requires a separate specifi-

cation formalism that is higher-level than the one in-

troduced for step (1) in the sense that synthesis speci-

fications specify what the system should do, whereas

control specifications specify how to do it. Therefore,

synthesis specifications require (at least) two compo-

nents: a formal specification of the plants, i.e., the

unrestricted system behavior, and a formal specifica-

tion of requirements expressed over this system be-

havior. From a formal synthesis specification, a for-

mal control specification is thus automatically synthe-

sized, rather than manually crafted.

Formalizing system requirements may already

provide value even without support for synthesis, for

various reasons. Firstly, doing so would make re-

quirements precise as well as explicit, as opposed to

being informally written in design documents or hid-

den in (legacy) test suites. Secondly, design assistance

can be devised to model check formalized require-

ments on control specifications. Therefore, synthesis

specifications can themselves also gradually be intro-

duced, by starting with formalizing the requirements.

Once a contextual formal model of (unrestricted)

system behavior is in place as well, e.g., in the form

of a modular library of component models, engineers

can start to synthesize parts of the control specifica-

tions. This can be done incrementally due to the com-

positional nature of the control specifications. For ex-

ample, at first, engineers could synthesize currently

handwritten specifications and compare them for sub-

optimality, in order to gain trust. After that, engi-

neers may start replacing handwritten specifications

by synthesized ones, thereby gradually lifting the

abstraction level by increasingly relying on require-

ments. These synthesized control specifications have

the benefit of being correct-by-construction with re-

Towards Synthesis-Based Engineering for Cyber-Physical Production Systems

161

spect to the requirements, as well as being automati-

cally resynthesizable in case the requirements change.

The degree to which controller synthesis is applied

can be scaled as needed, up to the potential point

where the entire control specification is synthesized.

The gradual introduction of SBE leads to an in-

creasing degree of design automation and therewith

an increasing focus on specifying requirements, since

specifying and verifying the control design requires

less attention. This makes the role of validation

increasingly prominent for determining whether the

specified requirements are the right ones. However,

due to synthesis producing a formal control specifi-

cation as defined for step (1), the necessary means

for validating synthesis specifications, e.g., simulat-

ing synthesized results, are then already established

as part of step (2). This design assistance also en-

ables short feedback cycles for working with synthe-

sis specifications.

4 APPLICATION

We are currently instantiating our three-step approach

in a research case together with ASML and VDL-

ETG, aimed to introduce SBE to help manage the

increasing complexity of the development process of

the wafer handler. The wafer handler is a complex

subsystem of ASML’s lithography machines (Sanden

et al., 2015) that is jointly developed by ASML and

VDL-ETG, and is responsible for transporting wafers

between the input track and wafer stage at a specified

throughput rate. This transportation is done by vari-

ous robots and stations that operate concurrently, i.e.,

multiple wafers are handled simultaneously in order

to meet the required throughput. Concurrency conse-

quently increases the system complexity. The com-

plexity is further increased by expensive cleanroom

space and limited hardware that necessitates resource

sharing, as well as various configurations and varia-

tion points that wafer handlers may have, that can sig-

nificantly influence routing paths of wafers through

the system. Nevertheless, wafer handling should be

done correctly, e.g., according to system-level re-

quirements and without deadlocking.

The aim of our research case is investigating to

what extent SBE can help to manage the increasing

complexity in large industrial settings, in this case to

achieve correct and optimal wafer handling. How-

ever, this requires SBE to be integrated first, for which

we follow our approach as explained in Section 3.

Concretely, we are instantiating our approach by

developing a tool-supported workflow, aimed to in-

troduce SBE at the wafer handler development team.

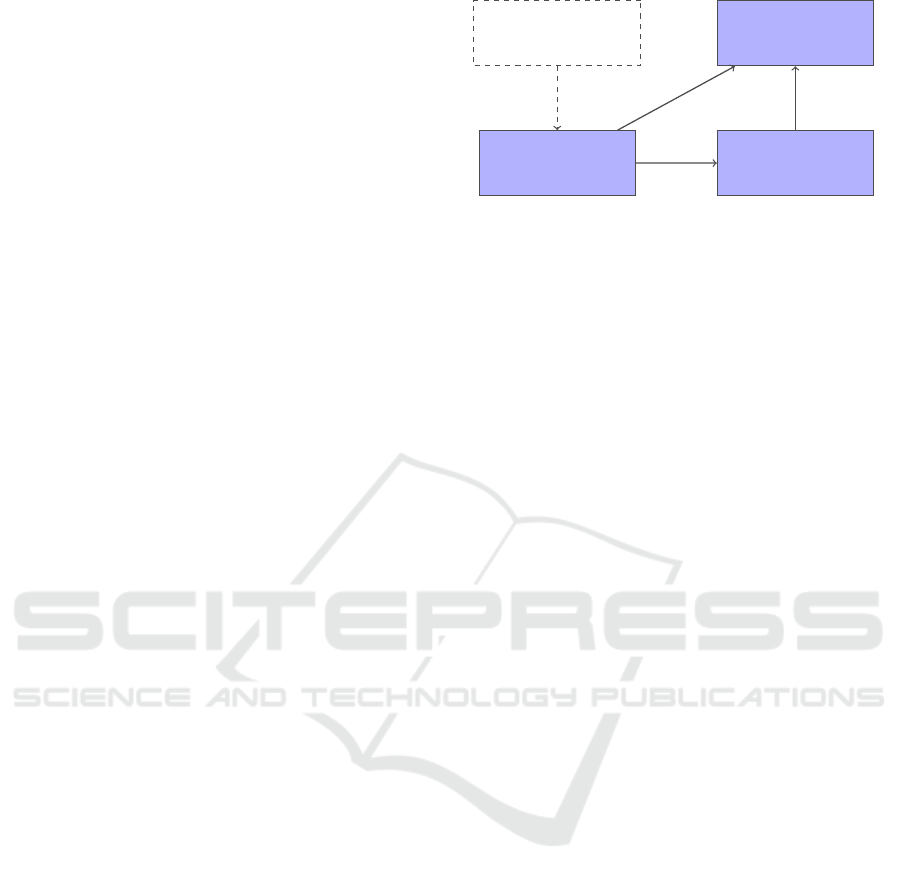

Formal synthesis

specifications

Plants and requirements

Formal control

specifications

UML activities

Simulation model

(e.g., for activity

simulation)

Verification model

(e.g., for deadlock

checking)

Synthesize

Transform

Transform

Export/replay

counterexample

Figure 2: The workflow used to gradually introduce SBE.

Figure 2 illustrates this workflow, which currently

covers steps (1) and (2) of the approach, i.e., formal

modelling and design assistance.

Wafer flow is specified by ASML and VDL-ETG

in terms of UML activities, but in the absence of a

formal semantics of their execution. Therefore, as a

first step in setting up the workflow, we defined an

execution semantics for their activities. This execu-

tion semantics is different from existing semantics in

the literature, on two main aspects. Firstly, the ac-

tivities use specification concepts like action atomic-

ity and conditional waiting, which to the best of our

knowledge are not native in any existing off-the-shelf

execution semantics for activities; see Section 5 for a

more in-depth discussion. Secondly, these specifica-

tion concepts are needed to be able to connect to the

current ways of working. Section 4.1 formally defines

our execution semantics for UML activities.

These formalized activities enable integrating sup-

port for validation and verification into the workflow,

in the form of activity simulation and deadlock prop-

erty checking. This is done by leveraging existing

off-the-shelf tooling, particularly the Cameo Simula-

tion Toolkit (No Magic, nd) and ITS-tools (Thierry-

Mieg, 2015), by translating the formalized activities

to their input formalisms. Section 4.2 briefly explains

the translations, after which Section 4.3 discusses the

evaluation of the workflow with domain experts.

The next (work-in-progress) step, is to support au-

tomatic synthesis of UML activities. Support for ac-

tivity synthesis is not yet implemented in our work-

flow, since formalized models and design assistance

must be in place first. Nevertheless, we have shown

that activity synthesis is technically feasible; Sec-

tion 4.4 outlines the synthesis strategy. Integrating

this strategy into the workflow is thus future work.

4.1 Activities

Our workflow is built around formalized activities, for

which this section defines an execution semantics.

Activities are defined in the presence of state, for

example a set of variables and their current valuation.

MODELSWARD 2025 - 13th International Conference on Model-Based Software and Systems Engineering

162

We keep the notion of state more abstract for the pur-

pose of defining the semantics, and let State be the

set of all states. Users of this semantics could later

instantiate State as desired, e.g., as variable valuation

mappings. Let σ ∈ State be a typical state.

The main building blocks of activities are the ac-

tion nodes, which are nodes that carry out a cer-

tain action. An action α = (a, g,u) ∈ Action is a

triple consisting of an action label, a ∈ Label, a

guard, g ∈ Guard, and an effect, u ∈ Effect. Let

Action = Label × Guard × Effect be the universe set

of all actions, with Guard = State → B the set of

all guards, which are state predicates, and Effect =

State → 2

State

the set of all effects, which are state

transformers. The guard of any action must hold in

order for the action to be executed, and its effect de-

termines possible successor states after having per-

formed the action. For any action α = (a, g,u), let

guard(α) = g and effect(α) = u be projection func-

tions for obtaining the guard and effect of α, respec-

tively.

Activities A = (N,E) are defined as directed

graphs with N ⊆ Node a set of nodes and

E ⊆ N × Guard × N a set of guarded edges, with

Node = ID × Type. Activity nodes, n = (ℓ,t) ∈ Node,

consist of a node identifier ℓ used to give identity to

nodes (e.g., to allow activities to have multiple forks

and joins), and a node type t taken from the following

subset of standard UML activity node types:

Type ::= init | final | fork | join | decision | merge | act(α)

Action-typed nodes act(α) closely relate to

opaque actions in UML in the sense that their execu-

tion updates the current state according to α (possibly

non-deterministically so in case α’s effect has multi-

ple successor states to choose from). The other node

types are standard in UML. However, in UML, ac-

tivity nodes are typically subject to well-formedness

conditions in order for their execution to have mean-

ing. For example, initial nodes are not allowed to have

incoming edges. In contrast, our semantics does not

rely on any such well-formedness constraints.

We define a token-passing execution semantics for

activities. We thereby follow the style of (Daw and

Cleaveland, 2015), which divides Type into two be-

havioral categories: and-nodes requiring a token from

all incoming edges, such as fork and join; and or-

nodes requiring a token from a single incoming edge,

such as decision and merge. This classification allows

the execution semantics of activities to be defined in

terms of just two reduction rules: one for and-nodes

and one for or-nodes. To be able to define these two

reduction rules, we first define a notion of abstract ac-

tivities in which and and or are explicitly represented.

Then we define the two reduction rules in terms of

these abstract activities. Finally, we define the seman-

tics of activities as a translation to abstract activities.

Like (concrete) activities, abstract activities

A = (N ,E) are defined as directed graphs con-

sisting of (abstract) nodes N ⊆ AbstrNode and

guarded edges E ⊆ N × Guard × N . Abstract nodes

η ∈ AbstrNode with AbstrNode = ID × AbstrType, in

turn, are pairs consisting of a node identifier and an

abstract node type from AbstrType ::= and⟨α⟩ | or⟨α⟩

containing an action α and its execution strategy.

Later, when translating concrete activities to abstract

ones, we translate control-typed nodes like fork and

merge as special actions whose guards are always true

and whose effects do not change the state.

Let us introduce some convenient shorthand no-

tation. We define in(η) = {(η

s

,g,η

t

) ∈ E | η

t

= η}

to be the set of all incoming edges of η ∈ N in the

context of some abstract activity A = (N , E), and

in(η,σ) = {ε ∈ in(η)|guard(ε)(σ)} to be all incom-

ing edges of η whose guard holds with respect to state

σ ∈ State. Let out(η) and out(η, σ) be similarly de-

fined to instead capture the outgoing edges of η.

The two execution rules for abstract activities are

defined as a reduction relation between configura-

tions, in the sense that an execution step in an ab-

stract activity gets you from one configuration to an-

other configuration. A configuration c ∈ Config with

Config = 2

E

× State is defined to be a pair c = (Σ, σ)

with Σ ⊆ E a set of edges—the ones currently holding

a token—and σ a (current) state. Any edge ε is said to

be enabled in c if it has a token in c, i.e., if ε ∈ Σ. Note

that the edge guards do not influence whether an edge

is enabled or not. Instead, edge guards restrict when

an edge can receive a token (as opposed to whether

they can hold a token).

The execution semantics of abstract activities

A = (N ,E) is defined in terms of the single-step

labeled reduction relation

.

−→⊆ Config × N × Config.

Figure 3 shows the two reduction rules of

.

−→. The

AND rule defines the execution of nodes η of type

and⟨α⟩. It requires: (1) all incoming edges into η to

have a token; (2) none of the outgoing edges of η ex-

cept self-loops to have a token; (3) the guard of α to

hold with respect to the current state σ; (4) a succes-

sor state σ

′

to be available from α’s effect; and (5) the

guards of all outgoing edges to hold with respect to

σ

′

. If these requirements are all met, AND removes all

tokens from in(η) and puts tokens on out(η), making

(Σ \ in(η)) ∪ out(η) the new arrangement of tokens.

The OR rule defines the execution of nodes η of

type or⟨α⟩. It requires: (1) the existence of an incom-

ing edge ε of η that is enabled; (2) the existence of

an outgoing edge ε

′

of η that is not enabled unless it

Towards Synthesis-Based Engineering for Cyber-Physical Production Systems

163

AND

η = (ℓ, and⟨α⟩)

in(η) ⊆ Σ (out(η) \in(η))∩ Σ =

/

0 guard(α)(σ) σ

′

∈ effect(α)(σ) out(η) = out(η, σ

′

)

(Σ,σ)

η

−→ ((Σ \ in(η)) ∪ out(η), σ

′

)

OR

η = (ℓ, or⟨α⟩) ε ∈ in(η) ∩ Σ ε

′

∈ out(η,σ

′

)\(Σ\{ε}) guard(α)(σ) σ

′

∈ effect(α)(σ)

(Σ,σ)

η

−→ ((Σ \ {ε}) ∪ {ε

′

},σ

′

)

Figure 3: The execution semantics of abstract activities, where c

η

−→ c

′

is shorthand notation for (c,η, c

′

) ∈

.

−→.

[[(ℓ, init)]]

n

= (ℓ,or⟨(init,λσ.true, λσ.σ)⟩)

[[(ℓ, final)]]

n

= (ℓ,or⟨(final,λσ.true, λσ.σ)⟩)

[[(ℓ, fork)]]

n

= (ℓ,and⟨(fork, λσ.true, λσ.σ)⟩)

[[(ℓ, join)]]

n

= (ℓ,and⟨(join,λσ.true, λσ.σ)⟩)

[[(ℓ, decision)]]

n

= (ℓ,or⟨(decision,λσ.true, λσ.σ)⟩)

[[(ℓ, merge)]]

n

= (ℓ,or⟨(merge,λσ.true, λσ.σ)⟩)

[[(ℓ, act(α))]]

n

= (ℓ,and⟨α⟩)

Figure 4: The translation from concrete activity nodes to

abstract activity nodes.

equals ε, and whose guard holds with respect to σ

′

;

(3) the guard of α to hold with respect to the current

state σ; and (4) a successor state σ

′

to be available

from α’s effect. The OR rule allows multiple input

edges to be enabled, but only one of them will par-

ticipate per application of the OR rule. Similarly, if

multiple outgoing edges could potentially participate,

one of them actually participates. If these require-

ments are met, OR removes the token from ε and puts

it on ε

′

, making (Σ \ {ε}) ∪ {ε

′

} the new arrangement

of tokens.

This reduction relation

.

−→ defines an atomic ex-

ecution semantics in the sense that actions are exe-

cuted atomically: in a single execution step, the action

guard is evaluated and a successor state is determined

from the action effect.

The last step is defining the semantics of con-

crete activities, which we do by translating them

to abstract activities to allow AND and OR to give

meaning to concrete node types. The translation

of activity nodes is defined as a translation function

[[ · ]]

n

: Node → AbstrNode, under the assumption that

the set Label of action labels is chosen in such a way

to contain ‘reserved labels’ for all control node types,

i.e., all node types except act. Figure 4 shows the def-

inition of [[ · ]]

n

. In this definition, λσ.true is the con-

stant guard that is always true, and λσ.σ the identity

effect that leaves any state unchanged. Fork and join

nodes are both translated to and-type nodes, allowing

fork nodes to produce multiple tokens in order to ini-

tiate concurrency, and join nodes to consume multiple

tokens in order to behave like a barrier. Action nodes

act are also translated to abstract and nodes, since this

is consistent with fUML semantics, which describes

action nodes to behave like an “implicit fork” (Object

Management Group, 2021). All other node types are

translated to or-type nodes as their execution produces

and consumes tokens on single edges.

The translation of edges is straightforward, since

it simply amounts to translating the source and tar-

get node of the edge using [[ · ]]

n

. The translation of

edges is defined as a function [[ · ]]

e

: Node × Guard ×

Node → AbstrNode × Guard × AbstrNode such that

[[(n, g, n

′

)]]

e

= ([[n]]

n

,g,[[n

′

]]

n

).

Let the translation of any (concrete) activ-

ity A = (N, E) be defined as [[A]] = ({[[n]]

n

|n ∈

N},{[[e]]

e

|e ∈ E}). Then the semantics of A is de-

fined to be the semantics of [[A]].

This finishes the definition of the execution se-

mantics of activities, except for the starting points for

their execution. The starting point of executing con-

crete activities are their init nodes. Since initial nodes

are translated to or-type nodes, the execution of an ac-

tivity is started along exactly one outgoing edge of a

(single) init node. In case an activity has multiple ini-

tial nodes, and/or in case there are initial nodes with

multiple outgoing edges, the activity has multiple po-

tential initial configurations. Given any (concrete) ac-

tivity A = (N,E), the configuration ({ε}, σ

I

) ∈ Config

is defined to be an initial configuration of A for any

choice of initial state σ

I

∈ State, if there exists an ini-

tial node (ℓ, init) ∈ N such that ε ∈ out([[(ℓ, init)]]

n

,σ

I

).

That is, any outgoing edge of any initial node can

form an initial configuration together with some ini-

tial state σ

I

, given that this edge is allowed by its

guard to receive a token in the initial state σ

I

.

Finally, with respect to compositionality, activities

are being used in a hierarchical manner: activities can

call other activities by means of call actions. That

is, concrete activities come with an additional type

Type ::= · ·· | call(ı) and are executed in a context of

a number of activities A

0

,. . . , A

n

, where ı ∈ {0, ..., n}

is a reference to one of those activities. We disallow

(in)direct recursion, so that hierarchy is maintained.

MODELSWARD 2025 - 13th International Conference on Model-Based Software and Systems Engineering

164

By doing so, such extended activities can be flattened

into single activities without any call actions, by in-

lining any activity being called, thereby replacing the

call action. Therefore, the semantics of these extended

activities is defined to be the semantics of the flattened

single activity.

4.2 Workflow

This activity formalism constitutes the basis of the

workflow since its execution semantics enables sup-

port for design assistance and synthesis. Design as-

sistance is provided by leveraging existing tooling for

simulation and deadlock property checking, by trans-

lating activities to their input formalisms.

For (formal) modeling UML Designer (Obeo, nd)

is used, which is a graphical tool for construct-

ing UML diagrams, including activities. The work-

flow thereby uses UML activities, but annotated with

data properties (constituting state), and (action/edge)

guards and effects that are expressed (for now) in

the CIF language (van Beek et al., 2014). We then

consider these activities under the execution seman-

tics defined earlier. The use of an existing UML tool

makes formalizing activities accessible.

For simulation the Cameo Simulation Toolkit (No

Magic, nd) is used, which provides extensive sim-

ulation support for activities under the semantics of

fUML. Although fUML handles action execution dif-

ferently than the execution semantics as defined in

Section 4.1 (which is further detailed in Section 5),

our execution semantics can be encoded in terms of

fUML constructs, e.g., by using different UML con-

cepts like events and signals to encode the notion of

action atomicity. Therefore, for simulation we have

devised an automated UML-to-fUML transformation

that translates action guards/effects, and their atomic

execution semantics, into fUML specifications that

can be simulated using the Cameo Simulation Toolkit.

For verification the model checker ITS-

tools (Thierry-Mieg, 2015) is used, which supports

checking reachability, LTL, and CTL properties, us-

ing a symbolic back-end. The use of symbolic model

checking techniques helps to analyze industry-scale

specifications. The input formalism of ITS-tools

is a compositional model called ITS (Instantiable

Transition Systems) (Thierry-Mieg et al., 2009)

expressed in a DSL called GAL—the Guarded

Action Language. ITS and GAL are well-suited

for translating activities to, since they come with a

Petri net style concurrent semantics that lies close to

our execution semantics. We have implemented an

proof-of-principle automated UML-to-GAL transfor-

mation for activities, to enable verification. Deadlock

properties for activities are then expressed as CTL

properties that are roughly of the form: ‘it globally

holds that, unless there are no more products/wafers

to process, there must always exist an activity node

that can be executed’. Any violation of this property

leads to a counterexample, i.e., a trace from an initial

configuration to a configuration where no further

progress is possible, which may then be simulated.

4.3 Evaluation

We have empirically evaluated our first workflow with

architects and engineers from ASML and VDL-ETG

by means of two validation phases. In the first phase

we investigated whether the workflow can add value

to the wafer handler development process by finding

potential problems early. In the second phase we in-

vestigated whether formal modeling and design assis-

tance would suit the current way of working.

For the first validation phase, we formalized a par-

ticularly complex part of the wafer handler specifi-

cation that comprises over 90 activities in total, to

be able to simulate and verify it, thereby following

the proposed workflow. As a result, we automati-

cally found multiple potential deadlock situations re-

sulting from subtle interleavings of concurrently exe-

cuting activities, that we could present to the domain

experts—the architects and engineers. Such deadlock

situations are difficult to find without design assis-

tance due to the high complexity. The domain experts

indicated that, although we might miss some contex-

tual restrictions due to having formalized only part of

the overall specification, some of the found situations

might be actual deadlock behaviors, though possibly

non-production mode ones. They recognize the value

of design-time validation and verification, and later

synthesis for automatically computing solutions for

such situations, and expressed interest in exploring

the integration of these techniques into their current

way of working.

Therefore, for the second validation phase, we for-

malized another part of the specification in a session

together with domain experts, aimed to get feedback

on the workflow and identify follow-up steps towards

its adoption. The outcome was positive: the domain

experts indicated to be willing to put effort in for-

malizing their specifications, but that first some fur-

ther engineering is needed to make the workflow suf-

ficiently user friendly, e.g., by adding type checking

support of guard expressions, and convenient UI sup-

port for specifying guards and effects. We are cur-

rently working on further maturing the workflow ac-

cording to this feedback.

Towards Synthesis-Based Engineering for Cyber-Physical Production Systems

165

4.4 Activity Synthesis

The next step after formalizing the activities and pro-

viding design assistance, is providing support for syn-

thesis. Although our workflow currently does not sup-

port activity synthesis, we have preliminary results

showing that such synthesis is technically feasible,

and can be automated (Laar, 2023).

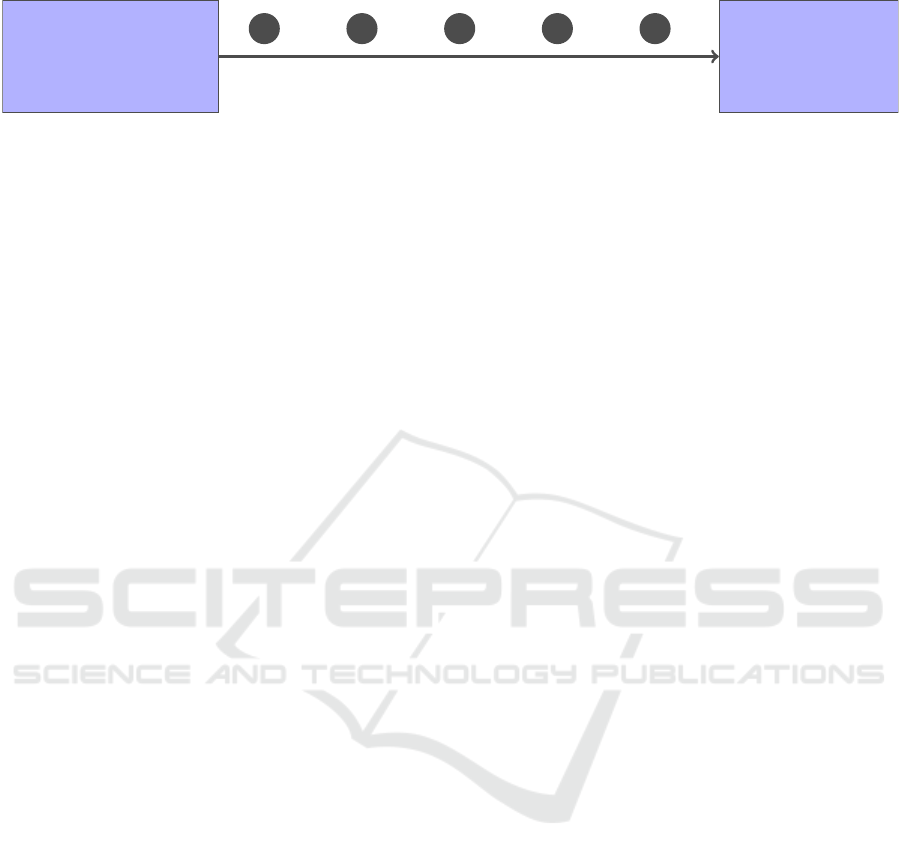

Figure 5 shows the strategy for automatically syn-

thesizing UML activities, as was used in our feasi-

bility study. Firstly, a supervisory controller is syn-

thesized from a specification of plants, requirements,

and pre- and postconditions for the to-be-synthesized

activity. Secondly, the state space of all safe behavior

as allowed by the synthesized supervisor is generated.

Thirdly, a minimal Petri net is synthesized from this

safe state space using the theory of regions (Badouel

and Darondeau, 1998). Minimality of these Petri nets

means that concurrent interleavings (diamond shapes)

in state spaces are reduced to fork-join patterns where

possible. Finally, the Petri net is translated to a UML

activity.

For demonstrating feasibility, we resynthesized

part of the wafer handler control specifications us-

ing this strategy. The synthesis specification was ex-

pressed in CIF for the purpose of showing feasibility,

and the controller synthesis is performed with Eclipse

ESCET™ (Fokkink et al., 2023a)

4

. Moreover, we

used Petrify (Cortadella et al., 1997) for synthesiz-

ing a minimal Petri Net. Overall, the main technical

challenge of synthesizing activities is synthesizing the

guards of edges out of decision nodes, since existing

techniques for Petri net synthesis do not handle data.

5 RELATED WORK

Numerous individual case studies of formal methods

being applied in industry have been reported (Bicar-

regui et al., 2009), e.g., by academic communities like

iFM

5

and FMICS

6

. Moreover, various conceptual so-

lutions, guidelines and experiences are reported on

integrating formal methods into industrial practice in

a broad sense (Nyberg et al., 2018; Huisman et al.,

2022; Gleirscher et al., 2023). However, to the best of

our knowledge, a structured approach for integrating

4

See https://eclipse.dev/escet (Accessed 2024-12-18).

‘Eclipse’, ‘Eclipse ESCET’ and ‘ESCET’ are trademarks

of Eclipse Foundation, Inc.

5

Integrated Formal Methods; http://www.

ifmconference.org (Accessed 2024-12-18).

6

The ERCIM Working Group on Formal Methods for

Industrial Critical Systems; https://fmics.inria.fr (Accessed

2024-12-18).

SBE into industrial practices has not been proposed

earlier.

General recommendations for industrial integra-

tion of formal methods are given in (Huisman et al.,

2022), which are in line with our approach and work-

flow, e.g., investigating existing practices and tool-

ing, keeping end-users in mind, and gradually inte-

grating formal methods by starting lightweight. Ex-

periences on gradually introducing ASD

7

—a formal

approach for modeling, checking of standard prop-

erties and code generation—into an industrial work-

flow at Philips Healthcare are reported in (Osaiweran

et al., 2013) and shown to lead to a reduced defect

rate. In (Nyberg et al., 2018), enablers and obsta-

cles are discussed for introducing formal verification

at Scania. One highlighted obstacle is that formally

modelling code implementations for automated anal-

ysis, e.g., deductive verification or model checking,

is challenging. Our strategy is to apply formal meth-

ods at design time while staying close to current prac-

tices. Integrating formal methods by strongly con-

necting to current practices is also a key principle as

proposed in a recent manifesto on applicable formal

methods (Gleirscher et al., 2023).

With respect to existing semantics for activities;

the current standard semantics for (a subset of) UML

activities is Foundational UML (fUML). However,

fUML’s execution semantics is not formally defined

but rather given the form of pseudo-Java (Laurent

et al., 2014), making it difficult to use for verifica-

tion and synthesis. As a consequence, various alter-

native semantics have been proposed, like (Laurent

et al., 2014; Abdelhalim et al., 2010; Lima et al.,

2013) which define the semantics in terms of math-

ematical languages like CSP or relational calculi, or

do not handle action guards and effects.

Moreover, fUML’s execution semantics does not

natively handle action atomicity nor conditional wait-

ing (i.e. handling of edge guards), which are concepts

needed not only to properly connect to current ways

of working, but also to ease integration with verifi-

cation and synthesis tooling. In fUML there is no

native concept of waiting for an action/edge guard

to become true before execution should resume. In-

stead, if no immediate progress can be made (e.g.,

none of the outgoing edges of a decision node can

currently be taken) then activity execution will di-

rectly terminate. Likewise, for concurrently-enabled

actions, fUML does not guarantee that they execute

atomically, only that they are executed after forking

and before joining. Nevertheless, action atomicity

and conditional waiting can be encoded by means of

7

Analytical Software Design; https://www.verum.com/

asd (Accessed 2024-12-18).

MODELSWARD 2025 - 13th International Conference on Model-Based Software and Systems Engineering

166

Formal synthesis

specifications

(Plants and requirements)

Formal control

specifications

(UML activities)

1 2 3 4 5

Automatic synthesis

Transform

to state

machines

Synthesize

supervisory

controller

Compute

state space

of all safe

behavior

Synthesize

minimal

Petri net

Translate

to activity

Figure 5: The high-level strategy for synthesizing UML activities.

native fUML constructs, e.g., by using UML events

and signals to implement a global locking mechanism

to achieve atomicity. We perform such encodings in

our UML-to-fUML translation for simulation. Fur-

thermore, atomic actions with guards and effects can

straightforwardly be translated to formalisms for ver-

ification and synthesis in a consistent manner, e.g.,

to transition guards/bodies in case of GAL, and edge

guards/updates in case of CIF.

Our semantics of activities closely corresponds to

(colored) Petri Nets, since UML 2.x uses a Petri Net

based model (Daw and Cleaveland, 2015). The ex-

ecution of and-nodes corresponds to transition firing

in Petri Nets. The execution of or-nodes is slightly

different since it only distributes a single token.

Other notable related formalisms are BPMN (Di-

jkman et al., 2008), used to model business processes,

and SysML v2, for which an execution semantics for

activities is not defined (Jansen et al., 2022).

6 CONCLUSION

This article presents a three-step approach to intro-

duce SBE in industrial settings. Since SBE is differ-

ent from traditional engineering approaches, it should

be integrated gradually to help in its acceptance.

Moreover, every (next) migration step should add (ad-

ditional) value to the development process, e.g., by in-

creasingly automating control design. We took initial

steps towards such integration, by instantiating our

approach in a research case together with ASML and

VDL-ETG in the form of a formal modeling work-

flow supported by automated design assistance. The

specification formalism used in the workflow is based

on UML activities, for which this article contributes a

formal execution semantics, which is otherwise miss-

ing. We evaluated this workflow with domain experts,

who considered the workflow conceptually valuable,

and, when made sufficiently user-friendly, would like

to use it to formalize their specifications and thereby

enable design assistance and eventually synthesis.

As future work, we are developing the automated

activity synthesis strategy as sketched in Section 4.4.

This enables step three in our approach: automati-

cally synthesizing wafer control specifications based

on formal requirements that are specified by engineers

and architects themselves. Moreover, we will further

integrate and evaluate steps one and two of our ap-

proach at ASML and VDL-ETG—formal modelling

of UML activities and their design assistance.

ACKNOWLEDGEMENTS

The authors thank ASML and VDL-ETG for the col-

laboration on this project, and especially Abdullah

Alabsawi (VDL-ETG), Falco Creemers (VDL-ETG),

Jip Reinders (VDL-ETG), Joost van Leeuwen (VDL-

ETG), Prabhat Kumar Sharma (VDL-ETG), Rainer

Wolf (ASML), and Saurab Rajkarnikar (VDL-ETG)

for their help and efforts in validating the workflow.

This research is partly carried out at part of the

Poka Yoke program under the responsibility of TNO-

ESI in cooperation with ASML and VDL-ETG. Poka

Yoke is funded by Holland High Tech — TKI HSTM

via the PPP Innovation Scheme (PPP-I) for public-

private partnerships.

REFERENCES

Abdelhalim, I., Sharp, J., Schneider, S., and Treharne, H.

(2010). Formal Verification of Tokeneer Behaviours

Modelled in fUML Using CSP. In Dong, J. and Zhu,

H., editors, ICFEM, pages 371–387. Springer Berlin

Heidelberg.

Badouel, E. and Darondeau, P. (1998). Theory of regions,

pages 529–586. Springer Berlin Heidelberg.

Baeten, J., Mortel-Fronczak, J. v. d., and Rooda, J.

(2016). Integration of Supervisory Control Synthesis

in Model-Based Systems Engineering, pages 39–58.

Springer International Publishing.

Bicarregui, J., Fitzgerald, J., Larsen, P., and Woodcock, J.

(2009). Industrial Practice in Formal Methods: A Re-

view. In Cavalcanti, A. and Dams, D., editors, FM,

pages 810–813. Springer Berlin Heidelberg.

Cortadella, J., Kishinevsky, M., Kondratyev, A., Lavagno,

L., and Yakovlev, A. (1997). Petrify: a tool for ma-

nipulating concurrent specifications and synthesis of

Towards Synthesis-Based Engineering for Cyber-Physical Production Systems

167

asynchronous controllers. EICE Transactions on In-

formation and Systems, E80-D(3):315–325.

Daw, Z. and Cleaveland, R. (2015). Comparing model

checkers for timed UML activity diagrams. Science

of Computer Programming, 111:277–299.

Dijkman, R., Dumas, M., and Ouyang, C. (2008). Se-

mantics and analysis of business process models

in BPMN. Information and Software Technology,

50(12):1281–1294.

Fokkink, W., Goorden, M., Hendriks, D., Beek, D. v.,

Hofkamp, A., Reijnen, F., Etman, L., Moormann,

L., Mortel-Fronczak, J. v. d., Reniers, M., Rooda, J.,

Sanden, B. v. d., Schiffelers, R., Thuijsman, S., Ver-

bakel, J., and Vogel, J. (2023a). Eclipse ESCET™:

The Eclipse Supervisory Control Engineering Toolkit.

In Sankaranarayanan, S. and Sharygina, N., editors,

TACAS, pages 44–52. Springer Nature Switzerland.

Fokkink, W., Goorden, M., Hendriks, D., Mortel-Fronczak,

J. v. d., Oortwijn, W., and Rooda, J. (2023b).

Synthesis-Based Engineering of Supervisory Con-

trollers. Mikroniek, 6:22–26.

Fokkink, W., Goorden, M., Mortel-Fronczak, J. v. d., Rei-

jnen, F., and Rooda, J. (2022). Supervisor Synthesis:

Bridging Theory and Practice. Computer, 55(10):48–

54.

Gleirscher, M., Pol, J. v. d., and Woodcock, J. (2023). A

manifesto for applicable formal methods. Software

and Systems Modeling, 22:1737–1749.

Hegge, J., Hendriks, D., Laar, P. v. d., Sanden, B.

v. d., Oortwijn, W., and Yang, N. (2023). State-

of-the-art study on formalisms and methods to

specify and analyze flows in logistic processes.

TNO Report 2023-R12176, https://repository.tno.nl/

SingleDoc?docId=57891 (Accessed 2024-12-18).

Huisman, M., Gurov, D., and Malkis, A. (2022). Formal

Methods: From Academia to Industrial Practice. A

Travel Guide.

Jansen, N., Pfeiffe, J., Rumpe, B., Schmalzing, D., and

Wortmann, A. (2022). The Language of SysML v2

under the Magnifying Glass. The Journal of Object

Technology, 21.

Laar, P. v. d. (2023). Synthesis-Based Engineer-

ing of Activity Diagrams. Presentation at

the 2nd Eclipse ESCET community meeting.

https://gitlab.eclipse.org/eclipse/escet/escet/uploads/

44f7235a5f3a4304bbe78355c718d5d9/3 - Eclipse

ESCET community meeting 2 - Synthesis-Based

Engineering of activity diagrams.pdf (Accessed

2024-12-18).

Laurent, Y., Bendraou, R., Baarir, S., and Gervais, M.

(2014). Formalization of fUML: An Application to

Process Verification. In Jarke et al., M., editor, CAiSE,

pages 347–363. Springer International Publishing.

Lima, L., Didier, A., and Corn

´

elio, M. (2013). A Formal

Semantics for SysML Activity Diagrams. In Iyoda,

J. and Moura, L. d., editors, SBMF, pages 179–194.

Springer Berlin Heidelberg.

Linden, F. v. d., Schmid, K., and Rommes, E. (2007). Soft-

ware Product Lines in Action: The Best Industrial

Practice in Product Line Engineering. Springer Sci-

ence & Business Media.

No Magic (n.d.). Cameo Simulation Toolkit.

https://www.3ds.com/products/catia/no-magic/

cameo-simulation-toolkit (Accessed 2024-12-18).

Nyberg, M., Gurov, D., Lidstr

¨

om, C., Rasmusson, A., and

Westman, J. (2018). Formal Verification in Automo-

tive Industry: Enablers and Obstacles. In Margaria,

T. and Steffen, B., editors, ISoLA, pages 139–158.

Springer International Publishing.

Obeo (n.d.). UML Designer. https://www.umldesigner.org

(Accessed 2024-12-18).

Object Management Group (2021). Semantics of a

Foundational Subset for Executable UML Models

(fUML), v1.5. https://www.omg.org/spec/FUML/1.5

(Accessed 2024-12-18).

Osaiweran, A., Schuts, M., Hooman, J., and Wesselius, J.

(2013). Incorporating formal techniques into indus-

trial practice: an experience report. In FESCA, pages

49–63.

Ramadge, P. and Wonham, W. (1987). Supervisory Control

of a Class of Discrete Event Processes. SIAM Journal

on Control and Optimization, 25(1):206–230.

Reijnen, F. (2020). Putting supervisor synthesis to work:

controller software generation for infrastructural sys-

tems. PhD thesis.

Reijnen, F., Erens, T., Mortel-Fronczak, J. v. d., and Rooda,

J. (2022). Supervisory controller synthesis and imple-

mentation for safety PLCs. Discrete Event Dynamic

Systems, 32:115–141.

Sanden, B. v. d., Reniers, M., Geilen, M., Basten, T., Ja-

cobs, J., Voeten, J., and Schiffelers, R. (2015). Mod-

ular model-based supervisory controller design for

wafer logistics in lithography machines. In MODELS,

pages 416–425.

Sheridan, T. and Johannsen, G. (1976). Monitoring Behav-

ior and Supervisory Control. Springer New York.

Thierry-Mieg, Y. (2015). Symbolic Model-Checking Us-

ing ITS-Tools. In Baier, C. and Tinelli, C., editors,

TACAS, pages 231–237. Springer Berlin Heidelberg.

Thierry-Mieg, Y., Poitrenaud, D., Hamez, A., and Kordon,

F. (2009). Hierarchical Set Decision Diagrams and

Regular Models. In Kowalewski, S. and Philippou,

A., editors, TACAS, pages 1–15. Springer Berlin Hei-

delberg.

van Beek, D., Fokkink, W., Hendriks, D., Hofkamp, A.,

Markovski, J., Mortel-Fronczak, J. v. d., and Reniers,

M. (2014). CIF 3: Model-Based Engineering of Su-

pervisory Controllers. In

´

Abrah

´

am, E. and Havelund,

K., editors, TACAS, pages 575–580. Springer Berlin

Heidelberg.

Wonham, W., Cai, K., and Rudie, K. (2018). Supervisory

control of discrete-event systems: A brief history. An-

nual Reviews in Control, 45:250–256.

MODELSWARD 2025 - 13th International Conference on Model-Based Software and Systems Engineering

168