Long-Term Planning of Preventive Maintenance Using Constraint

Programming: A Naval Case Study

Rapha

¨

el Boudreault

1 a

and Vanessa Simard

2 b

1

Thales, Qu

´

ebec, Canada

2

Independent Researcher, Canada

Keywords:

Preventive Maintenance, Planning, Constraint Programming, Optimization, Ship, Naval, In-Service Support.

Abstract:

Maintenance planning is an essential element in the life-cycle management of an asset. Unplanned main-

tenance work can cause significant productivity and financial loss, while manually assessing compliance is

complex and prone to errors. In the naval domain, ensuring mission readiness and operational availability is

critical. Thus, periodic preventive maintenance tasks must be carefully allocated over a long-term horizon con-

sidering the ship availability, business rules, and workload limitations. This distribution over fixed short work

periods can result in tasks being excessively advanced or deferred instead of executed when due. We propose a

Constraint Programming approach to produce feasible tactical plans of preventive maintenance for ships mini-

mizing advancements and deferrals of tasks. We validate our methodology on an industrial naval use case and

demonstrate its relevance compared to a currently used planning method, greatly reducing over-maintenance

with occurrences decreased by up to 25% and advancements by up to 93%. The method is integrated into

Maintenance Optimizer™, an interactive planning solution that supports decision-making in this context.

1 INTRODUCTION

Maintenance planning is a critical component in en-

suring the efficient life-cycle management of assets

across various industries. Unplanned maintenance

work can cause important disruptions in operational

continuity, while incurring substantial productivity

and financial losses. One common strategy to iden-

tify and schedule maintenance activities is to follow

a preventive approach, where tasks are conducted to

prevent system failures from happening. These ac-

tivities may notably be planned according to fixed

periodic recommendations prescribed by the Origi-

nal Equipment Manufacturer (OEM). In the naval do-

main, this approach is widely used to ensure ship

mission readiness and operational availability (Cul-

lum et al., 2018). Given the highly constrained nature

of ship availability, periodic maintenance tasks must

be carefully allocated in short work periods over ex-

tended time frames. For maintenance program plan-

ners, this presents important challenges, as decisions

made over fixed periods may result in excessive ad-

vancement or deferral of task executions, thereby in-

a

https://orcid.org/0000-0002-5602-7515

b

https://orcid.org/0000-0001-8861-8902

troducing additional costs and risks. Moreover, the

manual process of generating viable plans, which in-

cludes assessing maintenance compliance based on

domain-specific business, certification, and workload

limitation rules, is highly complex and susceptible to

errors.

An important part of planning challenges can be

lifted through the use of Computerized Maintenance

Management Systems (CMMS), such as those pro-

vided by Oracle, SAP, and IBM Maximo. These

tools enable real-time monitoring of enterprise assets

and automate the generation of work orders based on

pre-established maintenance frequency rules. How-

ever, their suitability for optimizing preventive main-

tenance planning in the naval domain, with its unique

specificities, is known to be rather limited. Echoing

the insights of (Van Horenbeek et al., 2010), who ad-

vocate for tailoring maintenance optimization models

to specific applications, Thales Canada has set out to

create Maintenance Optimizer™ as an integral com-

ponent of its planning suite (Boudreault et al., 2022;

Lafond et al., 2021). This interactive maintenance

planning solution is expressly designed to enhance

decision-making in this specialized context. The key

motivation for this work comes from identified chal-

lenges and innovation opportunities within the con-

32

Boudreault, R. and Simard, V.

Long-Term Planning of Preventive Maintenance Using Constraint Programming: A Naval Case Study.

DOI: 10.5220/0013106400003893

In Proceedings of the 14th International Conference on Operations Research and Enterprise Systems (ICORES 2025), pages 32-44

ISBN: 978-989-758-732-0; ISSN: 2184-4372

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

text of naval platforms in-service support programs.

The solution is currently operational and deployed on

a secure cloud platform, featuring various capabilities

for comparing or modifying optimization decisions.

This paper presents a Constraint Programming

(CP) approach, currently integrated into Maintenance

Optimizer™, that optimizes the long-term planning

of preventive maintenance for naval assets. CP is a

powerful programming paradigm to solve combinato-

rial problems, notably to optimally solve many large-

scale optimization problems under constraints (Rossi

et al., 2006). The optimization problem under consid-

eration in this work is described in Section 2, while

Section 3 relates it within existing literature to sim-

ilar problems and approaches. In Section 4, we in-

troduce the CP model, along with user options and

optional constraints available in the solution which

may change its definition. Our approach is evaluated

in Section 5 across multiple option configurations us-

ing a benchmark of five instances derived from a real

maintenance program dataset. Finally, Section 6 de-

liberates on the applicability of the solution in our in-

dustrial setting, followed by a conclusion suggesting

directions for future research.

2 PROBLEM DESCRIPTION

The problem addressed herein mirrors the challenges

faced by ship maintenance program planners in im-

plementing a preventive maintenance strategy within

our specific use case. To minimize disruptive fail-

ures and costly corrective maintenance work, and thus

ensure ship mission readiness and operational avail-

ability, preventive maintenance tasks are periodically

planned based on recommendations from the equip-

ment manufacturers. However, the windows for per-

forming maintenance tasks are constrained by a pre-

determined schedule of ship availability, which is de-

fined by the ship deployment periods. The planning

horizon, which may span from one to five years, com-

prises non-overlapping work periods during which the

ship is docked for maintenance purposes, typically

occurring two to four times per year. The most com-

mon type of work period is relatively short, lasting

between two to five weeks, although specific work

periods with longer duration (e.g., dry-dock periods,

where the ship is taken out of the water for extensive

maintenance and repair), lasting up to four months,

may also be scheduled. From a tactical planning per-

spective, each work period is limited in capacity by

an estimated total available labor time, as well as a

maximal task duration. Thus, from this perspective,

labor time, duration, and costs are assumed to be ap-

proximate estimates of reality, yet are sufficient for

long-term allocation of preventive work.

Typical ship maintenance programs contain

around 700 distinct preventive maintenance tasks,

each with estimated labor time and duration. A task

consists of a set of sub-tasks designated for a spe-

cific system and location within the ship. The OEM-

recommended periodicity, ranging from 1 to 180

months, describes how frequently each task should be

performed. This periodicity, calculated from a base-

line date known as clock date, establishes the due

date, i.e. the date at which the maintenance is con-

sidered to be due. For instance, a 12-monthly task

would usually be due around the same date each year.

However, the ship’s schedule may not always align

precisely with these due dates. Hence, a flexibility

rule is applied for most tasks, allowing for a safety

range around the due date. This range usually cor-

responds to 20% of the periodicity, with a maximum

of 90 days. For example, a 12-monthly task could

be planned up to 72 days before or after the due date

without requiring a risk assessment, since 12 months

times 30 days times 20% gives 72 days. Tasks per-

formed excessively early are called advancements,

potentially leading to over-maintenance and increased

costs, while those performed excessively late are

termed deferrals, potentially increasing risks due to

under-maintenance. Throughout the plan, the clock

date of a maintenance task may require to be updated

based on its planned execution. These concepts are

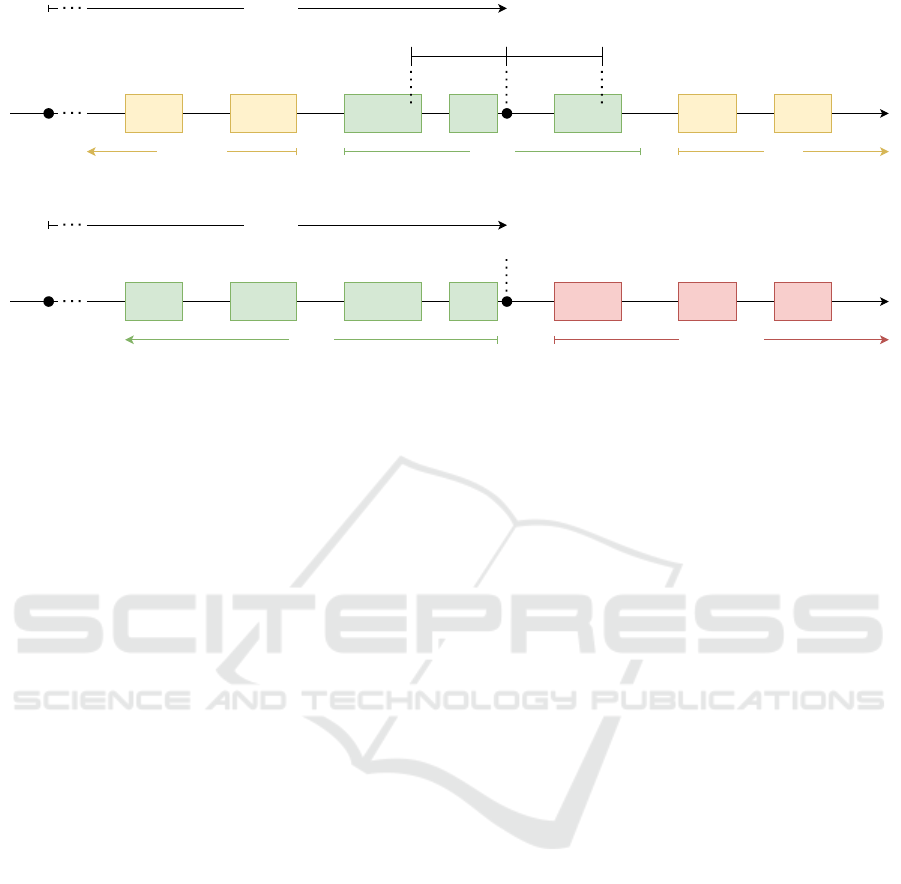

summarized in the example of Figure 1.

Among the tasks included in the program, around

50 preventive maintenance tasks are usually identified

as being bound to certification requirements. These

tasks typically relate to systems critical for the opera-

tion of the ship and the safety of the crew at sea. Thus,

unlike tasks subject to flexibility rules, certified sys-

tems are constrained to always be up to date during

deployment periods, as illustrated in Figure 2.

Maintenance program planners may consider ad-

ditional requirements in certain situations to formu-

late a feasible plan. Maintenance tasks related to the

same ship system and with coinciding periodicity may

need to be considered nested. For instance, the 12-

monthly task for a ship’s cooling system can include

the 3-monthly fluid level check and the 6-monthly

filter replacement, ensuring synchronized execution.

This approach optimizes resource allocation by con-

solidating maintenance efforts. Furthermore, ship de-

ployment readiness may be taken into account for

each work period. This would typically involve ensur-

ing a set of maintenance tasks are up to date before a

specific deployment period according to a given level

(e.g., Minimal, Intermediate, Critical).

Long-Term Planning of Preventive Maintenance Using Constraint Programming: A Naval Case Study

33

Clock date

21 5 63 4

Due date- flexibility + flexibility

7

DeferralAdvancement Potential

Periodicity

Figure 1: Example of planning a periodic preventive maintenance task with the flexibility rule.

Clock date

21 5 63 4 7

Late certificationPotential

Periodicity

Due date

Figure 2: Example of planning a periodic preventive maintenance task with a certification requirement.

3 RELATED WORK

There has been a lot of research on maintenance opti-

mization and planning (Van Horenbeek et al., 2010).

According to (Bousdekis et al., 2019), the objective

of most optimization algorithms is to reduce costs re-

lated to maintenance, risks of failure or the impact of

maintenance on production and supply chain. In ad-

dition, decision-making should ideally be predictive,

i.e. triggered by sensor-driven predictions to gener-

ate proactive maintenance plans. However, this vision

of maintenance planning can hardly be applied to the

ship repair and in-service support industries, where

maintenance scheduling is highly constrained by de-

fined work periods. Notably, (Ahluwalia and Pinha,

2014) point out other particularities of the ship repair

industry such as large distances between ship location

and ship repair facilities, high capital investment in

specialized equipment, such as cranes and dry docks,

and relatively short lead times. This further com-

plicates maintenance planning and renders traditional

time-driven approaches unfit for the use case consid-

ered herein. In this context, (Cullum et al., 2018)

study a risk-based maintenance scheduling frame-

work as a promising way to improve on traditional

management of periodic preventive maintenance, but

also note that its application is mainly limited by or-

ganizational resources. (Boudreault et al., 2022) pro-

pose a CP approach for ship refit project schedul-

ing that produces optimized operational schedules

under various time, precedence, and resource con-

straints. In the present work, the preventive mainte-

nance tasks are instead scheduled at a tactical deci-

sion level. Indeed, tasks must be allocated to individ-

ual work periods without being “exactly” scheduled,

thus each work period corresponds to an independent

project remaining to be scheduled. At both the tactical

and operational levels, (Deris et al., 1999) propose a

constraint-based approach and a genetic algorithm to

solve a Navy maintenance scheduling problem, which

aims to maximize fleet availability under temporal

and dockyard availability constraints. In their work,

the maintenance work periods are to be determined

by the results of the optimization.

Similar challenges are faced in other domains for

establishing a long-term maintenance planning strat-

egy. As stated by (Diallo et al., 2019), most military

systems are designed to operate given alternating se-

quences of missions and scheduled breaks. The au-

thors focused their research on the Selective Mainte-

nance Problem (SMP), where the decision is to se-

lect which task should be performed during a cer-

tain work period to maximize the reliability of the

system. They propose an integer programming ap-

proach to generate maintenance plans, offering an in-

teresting cost and reliability trade-off. The same way

military systems have to take breaks for maintenance,

trains and other transportation equipment have to be

removed from service to perform the most important

preventive work. These tasks usually have long and

uncertain periodic duration. (Gu et al., 2019) pro-

pose a genetic algorithm for deciding the trains’ ar-

rival dates at the maintenance center, tackling a prob-

lem closely related to the Single Machine Schedul-

ing Problem (SMSP). In comparison to our use case,

the imposed ship schedule prevents from choosing

the arrival dates, thus we may only decide the se-

quence of operations. In the drilling domain, (Javan-

mard and al Wahhab Koraeizadeh, 2016) propose a

genetic optimization approach for preventive mainte-

nance scheduling based on reliability and cost estima-

tion models for each of the asset components. Their

ICORES 2025 - 14th International Conference on Operations Research and Enterprise Systems

34

approach allows to decide a maintenance periodicity

minimizing costs with better overall reliability.

In light of the particularities and challenges high-

lighted by previous studies in preventive maintenance,

see e.g. (Basri et al., 2017; Wu, 2011), we aim herein

to reduce the risk of under-maintenance and the un-

derlying cost of over-maintenance by proposing an

optimization-based planning strategy. To the best of

our knowledge, developing this strategy for our spe-

cific use case requires an original approach.

4 METHODOLOGY

The following outlines our proposed CP approach to

solve the problem described in Section 2.

4.1 Model

Input Parameters. First of all, horizon h ∈ Z

>0

determines the planning timeline as the set T

:

=

{0,1,...,h} of time points. Now, let W

:

=

{1,2,...,n} be the set of work periods to include in

the plan. Given that each work period w ∈ W has an

(inclusive) start time s

w

∈ T and an (inclusive) end

time e

w

∈ T , we suppose e

w

< s

w+1

for w ∈ W \ {n},

i.e. the work periods are chronologically ordered

and non-overlapping, with s

1

= 0. Each work period

w ∈ W is also associated with its maximal mainte-

nance task duration d

max

w

∈ Z

>0

and its capacity of

maintenance labor time, c

w

∈ Z

>0

. In order to cor-

rectly plan maintenance tasks at the end of the time-

line and ensure continuity with future work periods,

we consider a virtual work period w

′

:

= n +1. Indeed,

it would be undesirable to plan tasks in the last work

period simply because the model is not aware of an

upcoming work period. Thus, we suppose this work

period starts (and virtually ends) on time point h + 1

and has an unlimited capacity, i.e. s

w

′

,e

w

′

:

= h + 1

and d

max

w

′

,c

w

′

:

= ∞. We use T

′

:

= T ∪ {h + 1} and

W

′

:

= W ∪ {w

′

} in the following.

Let M be the set of preventive maintenance tasks

to plan. Each task m ∈ M has an initial due date

t

init

m

∈ T , which defines the first time in the plan-

ning timeline where the task needs to be executed,

while next due dates are computed using its periodic-

ity, p

m

∈ Z

>0

. Tasks that are bound to a certification,

i.e. required to always be up to date, are contained in

the set M

∗

⊆ M . For all other tasks m ∈ M \ M

∗

,

the acceptable execution range around the due dates

is encoded with its flexibility f

m

∈ Z

≥0

. Finally, each

maintenance task m ∈ M has a duration d

m

∈ Z

>0

that

is assumed to be equal to its required labor time.

The main decisions of the model relate to where

each occurrence of a maintenance task is executed in

the planning timeline. The model supposes a main-

tenance occurrence can be skipped, i.e. that a main-

tenance task can be assigned more than once to the

same work period. However, since the task will only

be executed once during that period, at least one of its

periodic occurrences will appear to be “ignored”. For

this reason, we limit the model decisions to k

max

∈

Z

>0

occurrences for each maintenance task and de-

fine K

:

= {1, 2,. .. ,k

max

} as the set of occurrences.

Variables. The main decision variables of the

model are defined as E

k

m

∈ W

′

for the work period

where occurrence k ∈ K of maintenance task m ∈ M

is planned to be executed. Intermediate variables used

by the model objective and constraints are defined as

follows:

• T

k

m

∈ Z

≥0

, the computed due date for occurrence

k ∈ K of maintenance task m ∈ M , as a time point

in T or later than horizon;

• A

k

m

,D

k

m

,LC

k

m

∈ {0,1}, which are 1 if and only if

occurrence k ∈ K of maintenance task m ∈ M is

respectively by definition an advancement, a de-

ferral, or an unsatisfied (late) certification require-

ment;

• B

w

m

∈ {0,1}, which is 1 if and only if maintenance

task m ∈ M is planned at least once in work pe-

riod w ∈ W

′

.

Objective. The global objective of the model is

to minimize advancements and deferrals of main-

tenance occurrences at the tactical planning level,

while satisfying as much as possible the certifica-

tion requirements. To encode this objective, we de-

fine target(m,k) as the preferred work period in W

′

for planning occurrence k ∈ K of maintenance task

m ∈ M . This preference is to be set as a user option

(see Section 4.2.1). The target is then used to compute

its absolute “difference” from the chosen execution

E

k

m

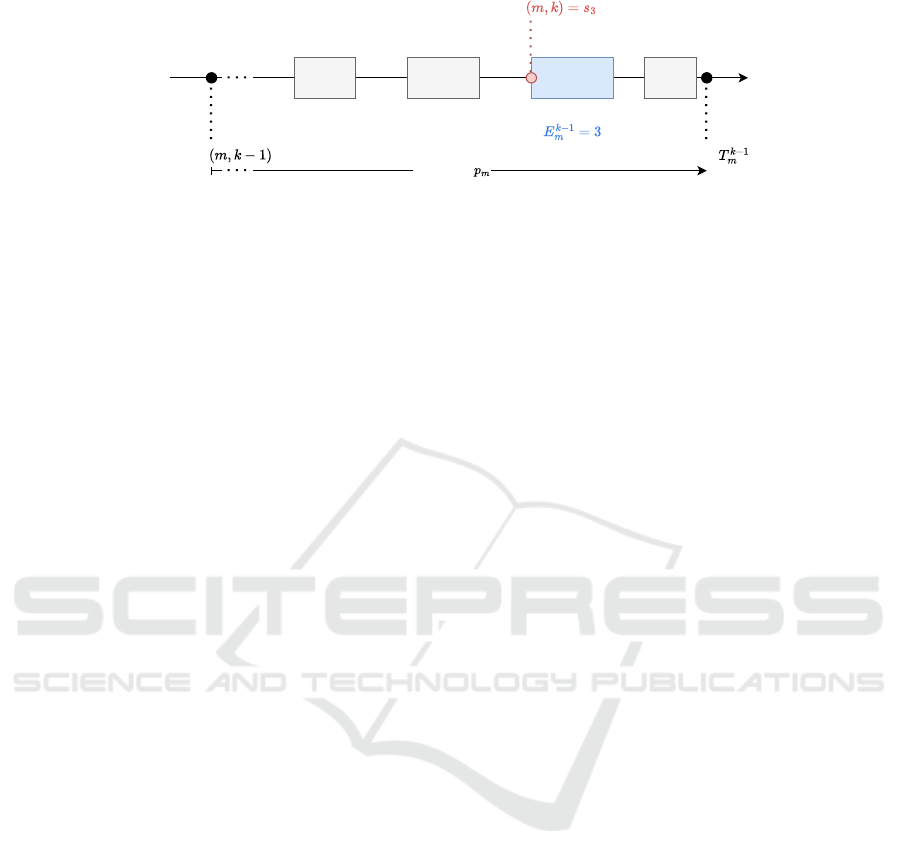

, as a number of work periods (see Figure 3). The

difference (increased by one) is multiplied by penalty

weights, w

A

,w

D

,w

LC

∈ Z

>0

if occurrence k ∈ K of

maintenance task m ∈ M is respectively an advance-

ment, a deferral, or a late certification requirement.

Here, the “+1” ensures the penalties are applied even

in the case where the chosen work period is right on

target. This is relevant when the target is actually

an advancement or a deferral due to the task’s lim-

ited flexibility, as the best choice can be to increase

the difference in order to avoid the greatest penalty.

Summing over all the maintenance occurrences, the

Long-Term Planning of Preventive Maintenance Using Constraint Programming: A Naval Case Study

35

21 5 63 4 7

Difference

from target

Target

3 2 1 0 1 2 3

Figure 3: Illustration of how the target is used in the objective function.

objective is thus

min

∑

m∈M

∑

k∈K

w

k

m

target(m,k) − E

k

m

+ 1

, (1)

where w

k

m

:

=

w

A

if A

k

m

= 1;

w

D

if D

k

m

= 1;

w

LC

if LC

k

m

= 1;

1 else.

Constraints. The constraints of the model are pre-

sented below. Constraints (2) enforce that the initial

due date of each maintenance task is as given by its

parameter.

T

1

m

= t

init

m

, ∀m ∈ M (2)

Then, constraints (3) define the subsequent due dates

by using the periodicity. Following the description

of Section 2, we define clockDate(m, k) as the time

point in T

′

from which to deduce the due date for

occurrence k ∈ K of maintenance task m ∈ M . The

computation rule is to be set as user options (see Sec-

tion 4.2.2).

T

k

m

= clockDate(m, k) + p

m

,

∀m ∈ M , ∀k ∈ K \ {1}

(3)

Constraints (4) make sure the clockDate setting cre-

ates an increasing sequence of due dates for each

maintenance task, thus avoiding the decisions to be

“blocked” in time, except when the current execution

is at the virtual work period. Similarly, constraints (5)

make sure the occurrences of each maintenance task

are assigned in a chronological order of work periods.

Here, the equal case would correspond to a skipped

execution.

E

k

m

< w

′

=⇒ T

k

m

< T

k+1

m

,

∀m ∈ M , ∀k ∈ K \ {k

max

}

(4)

E

k

m

≤ E

k+1

m

, ∀m ∈ M , ∀k ∈ K \ {k

max

} (5)

For maintenance tasks that are not related to a certifi-

cation (m ∈ M \M

∗

), constraints (6) encode when the

occurrence of a task is an advancement, i.e. when the

chosen work period (E

k

m

) is neither virtual nor ending

earlier than its acceptable flexibility before the due

date. Similarly, constraints (7) encode deferrals, i.e.

when the chosen work period starts later than the ac-

ceptable flexibility after the due date. In the case of

certifications, constraints (8) simply set the associated

variables to 0.

A

k

m

= 1 ⇐⇒ E

k

m

< w

′

∧ e

E

k

m

< T

k

m

− f

m

,

∀m ∈ M \ M

∗

,∀k ∈ K

(6)

D

k

m

= 1 ⇐⇒ s

E

k

m

> T

k

m

+ f

m

,

∀m ∈ M \ M

∗

,∀k ∈ K

(7)

A

k

m

= 0 ∧ D

k

m

= 0, ∀m ∈ M

∗

,∀k ∈ K (8)

Constraints (9) and (10) encode when occurrences do

not satisfy certification requirements. This happens

when a maintenance task bound to a certification (m ∈

M

∗

) is planned in a work period where its start time

exceeds the current due date.

LC

k

m

= 1 ⇐⇒ s

E

k

m

> T

k

m

,

∀m ∈ M

∗

,∀k ∈ K

(9)

LC

k

m

= 0, ∀m ∈ M \ M

∗

,∀k ∈ K (10)

Constraints (11) ensure each maintenance task fits ac-

cording to duration in the work periods where it is

planned to be executed.

d

m

≤ d

max

E

k

m

, ∀m ∈ M , ∀k ∈ K (11)

Variables B

w

m

are defined by constraints (12) using the

COUNT global constraint. The latter simply counts

how many times the boolean statement is revealed

to be true, here how many times maintenance task

m ∈ M is planned in work period w ∈ W among the

occurrences K . Finally, these variables are used by

constraints (13) to force each work period in having

a total labor time (as the sum of d

m

where B

w

m

is 1,

m ∈ M ) respecting its capacity.

B

w

m

= 1 ⇐⇒ COUNT(k ∈ K ,E

k

m

= w) ≥ 1

∀m ∈ M , ∀w ∈ W

′

(12)

∑

m∈M

d

m

B

w

m

≤ c

w

, ∀w ∈ W

′

(13)

4.2 User Options

The model of Section 4.1 involves many user options

that affect its definition and thus its behavior. These

options have been considered in order to keep a cer-

tain flexibility in the developed approach. This al-

lowed initial users to maintain their current planning

habits, while providing them with new (and poten-

tially better) possibilities.

ICORES 2025 - 14th International Conference on Operations Research and Enterprise Systems

36

Table 1: Available user options to define target(m,k).

Option

Definition

Closest

Closest work period before or after the due

date T

k

m

.

Latest

Latest work period in the acceptable execu-

tion range, i.e. closest before T

k

m

+ f

m

.

4.2.1 Target Options

First, for certification tasks m ∈ M

∗

and occurrences

k ∈ K , target(m,k) is always defined as the closest

work period before the due date T

k

m

. In Figure 2, this

would correspond to work period 4.

Then, for maintenance tasks m ∈ M \ M

∗

,

target(m,k) must be defined by one of the choices

described in Table 1. Option Closest focuses on fol-

lowing periodicity recommendations as much as pos-

sible. In Figure 1, this would correspond to work pe-

riod 4. Option Latest focuses instead on finding op-

portunities in safety recommendations to overall re-

duce the number of occurrences. In Figure 1, this

would correspond to work period 5. In our imple-

mentation, we use a pre-computed function that maps

each time point in T

′

to its closest (before/after) work

period in W

′

.

4.2.2 Clock Date Options

For maintenance tasks m ∈ M and occurrences k ∈

K \ {1}, clockDate(m, k) is defined by selecting one

option from each of the two sets of options described

below. As a basis, the clock date usually corre-

sponds to the due date of the last occurrence, T

k−1

m

,

so that occurrence k is due on T

k−1

m

+ p

m

based on

constraints (3). However, in the usual case where a

planned occurrence does not exactly match its due

date, this considered clock date is at high risk of caus-

ing non-compliant periodicity intervals. Thus, there is

a need to update it to the planned execution date. This

is particularly true for tasks that are bound to a certi-

fication, m ∈ M

∗

, which always have their clock date

updated. For other tasks m ∈ M \M

∗

, the update con-

dition must be selected from the choices described in

Table 2: Available user options to define the update condi-

tion of clockDate(m,k).

Option

Definition

Never Clock date never updated.

A/D

Clock date only updated when last occur-

rence is an advancement or a deferral.

Always

Clock date always updated at each occur-

rence.

Table 3: Available user options to define the updated date

of clockDate(m,k).

Option

Definition

Start Work period start date, s

E

k−1

m

.

Mid

Work period midpoint date, ⌊

1

/2(s

E

k−1

m

+

e

E

k−1

m

)⌋.

End Work period end date, e

E

k−1

m

.

Table 2. Option Never simply follows the given initial

due date, regardless of the model decisions. Alterna-

tively, option A/D updates the clock date when the last

occurrence is planned outside its flexibility, i.e. when

A

k−1

m

= 1 or D

k−1

m

= 1. Finally, option Always sys-

tematically updates the clock date at each occurrence,

which is in theory the best way to follow periodicity

recommendations and avoid constant replanning ef-

forts.

Since the produced maintenance plan is at the tac-

tical level, execution dates of tasks are not known

within each work period. Thus, when updating the

clock date, the chosen new date must be selected ac-

cording to the choices described in Table 3. Option

Start is the most conservative option, since it as-

sumes the whole work period duration should be in-

cluded in the next due date computation. Alterna-

tively, option Mid will on average be closer to the true

execution. In our implementation, the midpoint dates

are simply pre-computed. Finally, option End is the

most opportunist option, since it assumes the clock is

only updated at the next ship deployment. An exam-

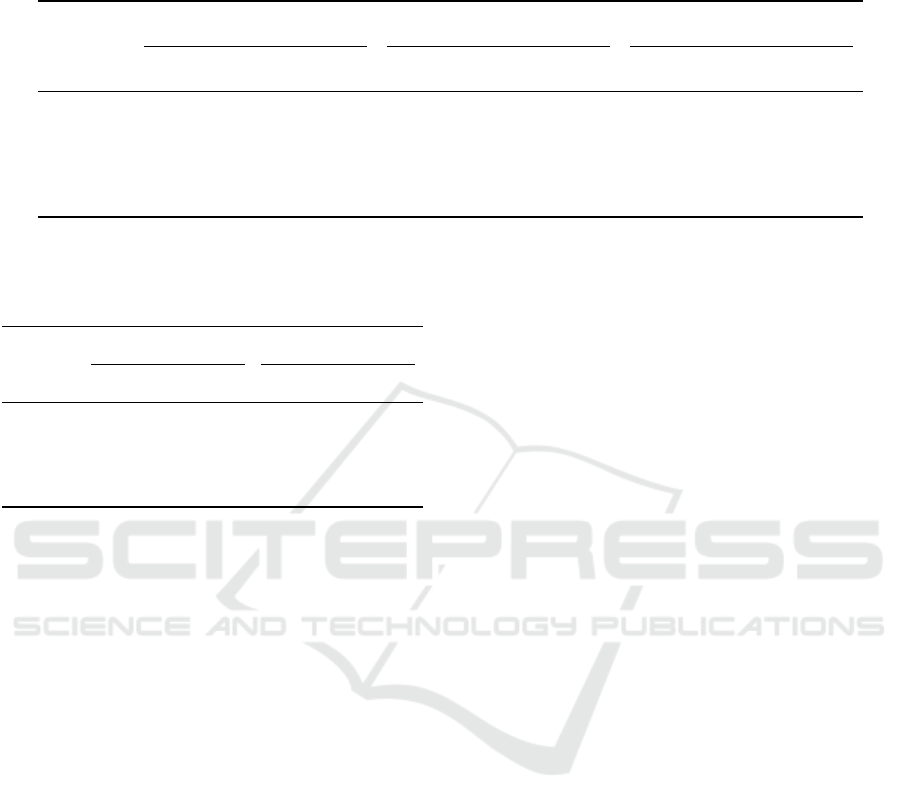

ple of clock date update using option Start is illus-

trated in Figure 4.

4.3 Optional Constraints

The model presented in Section 4.1 has been extended

with optional constraints to better suit the mainte-

nance program planning reality described in Sec-

tion 2. First, users may specify if maintenance tasks

are to be considered nested (in the following, option

Nested). If so, these constraints are included in the

model by encoding an implication on nested main-

tenance task executions, using variables B

w

m

. Then,

constraints on the ship deployment readiness can be

added. As further input parameters, we consider a

set of readiness levels, while each maintenance task

can be associated with a subset of these levels. These

constraints are included in the model by restricting

the values of E

k

m

. Finally, in the user interface of the

solution, users are able to override the optimizer de-

cisions by forcing occurrences to be planned (or not

be planned) in some work periods. Thus, when re-

optimizing, the model must consider these additional

Long-Term Planning of Preventive Maintenance Using Constraint Programming: A Naval Case Study

37

21 3 4

Periodicity

Due date

clockDate

Updated

clockDate

Planned period

Figure 4: Example of updating the clock date for occurrence k of maintenance task m using user option Start. Here, the

planned work period for occurrence k − 1 was 3, thus the clock date for occurrence k will be set to s

3

.

constraints, which are encoded by forcing the values

of B

w

m

.

4.4 Search Heuristic

In our approach, we consider the following search

heuristic for the CP model of Section 4.1. Each

pair of maintenance task m ∈ M and occurrence

k ∈ K is selected in input order, i.e. (m,k) ∈

((1,1), (1,2), .. ., (1,k

max

),(2, 1),. .. ,(2, k

max

),. .. ,

(|M |,k

max

)). Then, it assigns, in order, D

k

m

to its

smallest possible value and the difference to the

target from objective (1),

target(m,k) − E

k

m

, to its

smallest possible value, both prioritizing an assign-

ment to 0 first. In other words, this heuristic focuses

on executing the tasks in their targeted work period

or around it, which directly relates to the objective

function, and prefers initially avoiding deferrals.

The latter preference comes into play in cases where

work periods around the target may involve either

an advancement or a deferral, thus will explore

advancement executions beforehand, assuming its

associated penalty weight w

A

is smaller than the one

associated to deferrals, w

D

. The resulting heuristic

can be formulated with the priority search annotation

from the MiniZinc modeling language (Feydy et al.,

2017; Nethercote et al., 2007), and is supported by

the Chuffed solver (Chu, 2011).

5 EXPERIMENTS

The main objective of the experiments is to evaluate

the performance of our CP approach from Section 4

on a real naval use case, including all of our consid-

ered options, while comparing it to a currently used

planning method performed in Excel. This method,

which we call Heuristic in the following, system-

atically assigns the maintenance task occurrences to

their closest work period before their due date. For

clock updates, it replicates options Never and Start

from Section 4.2.2. Thus, Heuristic is prone to gen-

erate unnecessary advancements, requiring constant

replanning effort, while ignoring over-maintenance

reduction opportunities. Furthermore, it ignores any

constraint related to work period capacities, i.e. con-

straints (11) and (13), and all optional constraints

from section 4.3 due to a current partial planning ap-

proach. Although this might allow Heuristic to pro-

duce unfeasible solutions, in contrast to the CP ap-

proach, it serves as a valuable experimental compari-

son point as we demonstrate in the following.

5.1 Benchmark

Our benchmark consists of five instances created from

a real maintenance program dataset for one ship. This

dataset contains the complete description of 707 pre-

ventive maintenance tasks for different systems over

various functional locations of the ship. Among these

tasks, around 50 are related to certified systems (in

M

∗

). The periodicity of tasks p

m

ranges from 1 to

180 months (avg. 26), while they have a duration d

m

between 0.25 and 240 hours (avg. 10). Their flexi-

bility f

m

is fixed to 20% of the periodicity, in days,

with a maximum of 90 days, which leads to values

between 6 and 90 days (avg. 69). Each maintenance

task is given its initial due date t

init

m

based on past exe-

cution dates, which may fall in the planning timeline

depending on the chosen horizon. The dataset also

describes the ship schedule over five years, including

14 Short Work Periods (SWPs) of between 14 and 39

days (avg. 24), as well as three Dry-Dock Work Pe-

riods, DDWP-1, DDWP-2, and DDWP-3 of respec-

tively 68, 86 days, and 123 days. To allow compar-

ison between short-term and long-term planning, we

generated instances with a varied number of work pe-

riods. For each instance, the horizon h is fixed to the

start date of the following not included work period

(if possible, else 30 days after the last work period).

Thus, we considered:

• 1-year, including DDWP-1 and 3 SWPs, leading

to 493 tasks in the planning timeline;

• 2-years, including 1-year’s work periods and

ICORES 2025 - 14th International Conference on Operations Research and Enterprise Systems

38

four additional SWPs, leading to 497 tasks in the

planning timeline;

• 3-years, including 2-years’ work periods, two

additional SWPs, and DDWP-2, leading to 605

tasks in the planning timeline;

• 4-years, including 3-years’ work periods, two

additional SWPs and DDWP-3, leading to 669

tasks in the planning timeline;

• 5-years, including 4-years’ work periods and

two additional SWPs, leading to 684 tasks in the

planning timeline.

Note that the dataset allows to deduce nested main-

tenance tasks. On our instances, this may involve

up to 598 implied execution constraints using option

Nested (see Section 4.3).

Since some inputs are missing from the dataset,

we make the following additional assumptions based

on current planning habits:

• Each work period has a maximal task duration

d

max

w

based on 8 hours per working day (exclud-

ing weekends), thus ranging from 88 to 712 hours

(avg. 227);

• Each work period has a labor-time capacity c

w

of

320 hours per working day (excluding weekends),

leading to values between 3200 and 28400 hours

(avg. 9000);

• No optional ship deployment readiness con-

straints are considered;

• No optional planning override constraints are con-

sidered.

5.2 Experimental Setup

We implemented the CP approach from Section 4 in

the MiniZinc 2.8.3 language (Nethercote et al., 2007)

and used Chuffed 0.13.1 as solver (Chu, 2011). User

options of Section 4.2 were implemented using “if-

then-else” expressions and intermediate variables rep-

resenting the different cases. Furthermore, we im-

plemented the above-described Heuristic scheme in

Python 3.11. The experiments were performed on a

MSI GP63 Leopard 8RE machine with an Intel i7-

8750H CPU at 2.2 GHz, 6 cores and 32 GB of RAM

in a WSL environment. Each optimization execution

was given a timeout of 30 minutes, while the number

of occurrences to plan was limited to the number of

work periods, i.e. k

max

:

= n. We also fixed the ob-

jective penalty weights as (w

A

,w

D

,w

LC

)

:

= (2,5, 100).

These weights were empirically determined using it-

erative feedback from planners.

For our experiments, each instance was solved by

the CP approach for each combination of user op-

tions from Section 4.2, i.e. (Closest or Latest) and

(Never or A/D or Always) and (Start or Mid or End).

Additionally, each of these configurations was tested

using (or not) option Nested from Section 4.3. In

the following, we denote Not-Nested for the case

where option Nested is not used. Each instance was

also solved using Heuristic, where the generated so-

lution was evaluated according to the Closest and

Latest options.

5.3 Results

Detailed results including each instance and each op-

tion configuration are available in Appendix. Ta-

ble 4 summarizes these results for each instance using

Heuristic and the CP approach for the Not-Nested

and Nested cases, averaged over all option con-

figurations. As stated before, the objective of the

model is to minimize advancements and deferrals,

while satisfying the certification requirements, ac-

cording to a user-defined target preference. Results

show that using Heuristic creates solutions with

at least 21% of occurrences being strictly advance-

ments, while the CP approach always finds solutions

with less than 17% being advancements and deferrals.

The total reduction is on average 67% and can go

up to 93% on 4-years with Closest-Always-End-

Not-Nested. We also observe that the number of late

certifications is always no more than one, while late

occurrences are only generated by the CP approach

on the 5-years instance.

Results on Not-Nested configurations show that

using the CP approach instead of Heuristic always

reduces the objective value, with an average reduction

of 17% and 21% with Closest and Latest, respec-

tively. The most noticeable improvement is with the

1-year instance and the Latest option, where the

objective function is reduced by up to 31%. However,

on 4-years and 5-years instances, using Always

and Start reduces the objective value simply by up

to 2%. Overall, the best configuration varies de-

pending on the size of the instance. For larger in-

stances (3-years and more), the smallest objective

value is obtained using Closest-Always-End. For the

1-year instance, it is rather obtained using Mid, while

for the 2-years instance, it is obtained using Latest

and Start instead. In both cases, the difference be-

tween the best solution and the solution obtained us-

ing Closest-Always-End is less than 1%.

Considering the Nested option, the objec-

tive value increases by up to 5% compared to

Not-Nested. For all instances, the Closest and

Long-Term Planning of Preventive Maintenance Using Constraint Programming: A Naval Case Study

39

Table 4: Summarized results obtained on the benchmark instances using Heuristic and the CP approach, on average, with

Not-Nested or Nested options. Objective value of the best solution found (Obj.), its number of occurrences in T (#O),

advancements (#A), and deferrals (#D).

Instance

Heuristic Not-Nested Nested

Obj. #O #A #D Obj. #O #A #D Obj. #O #A #D

1-year 2878 849 215 0 2008 679 12 1 2145 707 47 2

2-years 2587 755 162 0 2073 632 48 1 2159 650 67 2

3-years 8565 2340 488 0 6924 2236 84 12 7458 2294 183 30

4-years 12 201 3165 697 0 10 186 3124 167 20 10 919 3205 313 46

5-years 14 155 3570 752 0 11 850 3522 173 50 12 805 3643 337 82

Table 5: Average computation time, in seconds, to find an

initial solution using option Always.

Instance

Nested Not-Nested

Start Mid End Start Mid End

1-year 9 6 5 5 7 5

2-years 6 5 5 5 5 5

3-years 191 88 80 57 39 36

4-years 633 269 247 114 66 66

5-years 1088 461 399 166 80 75

Always options similarly lead to a smaller objective

value. In contrast to the Not-Nested configurations,

there is no tendency on the way the clock date should

be chosen (Start, Mid, or End). Due to the addi-

tional constraints, we also observe that using Always-

Start for the 4-years and 5-years instances leads

to a greater objective value than using Heuristic.

Considering the time performance of our ap-

proach, we observe that at least one solution is found

for all instances and configurations. Around 60% of

the CP executions ended with exactly one solution,

while for the others, five intermediate solutions are

found on average. Intermediate solutions never re-

duce the objective value more than 1.4% before the

timeout is reached. Furthermore, 39 CP executions

over 180 (22%) ended with an optimality proof, but

only for 1-year and 2-years instances.

Table 5 reports the average computation time re-

quired to find an initial solution using option Always,

in seconds. We omit A/D and Never here, since they

produce similar results. We observe that the time

varies from 5 seconds to 18 minutes depending on the

instance size and selected options. While for smaller

instances (1-year, 2-years) the difference is negli-

gible, instances 3-years and more show a noticeable

increase in the time required, with the longest sce-

nario being the 5-years instance solved with Start-

Always-Nested.

6 DISCUSSION

The main goal of this research was to create Mainte-

nance Optimizer™, a solution developed to increase

operational availability of ships while decreasing in-

service support costs. Building a feasible preventive

maintenance plan over a long-term horizon satisfy-

ing every constraint is known to be a complex and

time-consuming task. Usability assessments with do-

main experts allowed us to estimate that creating a

one-year plan takes a minimum of 4 hours (scattered

over 2 weeks to minimize cognitive overload) with-

out any compliance verification. Thus, our experi-

ments demonstrated that we can significantly reduce

this process, while guaranteeing rules compliance.

In addition to the number of advancements and

deferrals, we were also interested in reducing over-

maintenance by looking at the proposed number of

occurrences. Unsurprisingly, selecting the latest pos-

sible work period to perform the maintenance tasks

using Latest leads to fewer occurrences. Figure 5

highlights this behavior, by comparing the distribu-

tion of maintenance executions in relation to their due

date. We observe that around 75% of occurrences are

planned on or after their due date using Latest, com-

pared to 65% with Closest, and less than 40% with

Heuristic. The fact that this is not reflected in the

result, since the Closest option offers the smallest

objective value in almost all cases, suggests the need

for further sensitivity analyses. When looking more in

depth at the difference between Closest and Latest,

it is apparent that the plans made by selecting the

latest acceptable work period requires more advance-

ments than the plan made by selecting the one closest

to the due date. However, in the majority of cases,

using Latest creates a similar number of deferrals

or less. Overall, compared to Heuristic, using the

CP approach reduces the number of occurrences by

up to 25%. This potential reduction yet remains to be

ICORES 2025 - 14th International Conference on Operations Research and Enterprise Systems

40

Figure 5: Average distribution of occurrences in relation to

their due date, in percentage, for Heuristic, Closest, and

Latest.

evaluated in terms of monetary savings for in-service

support.

An important observation is that our CP approach

introduces deferrals where the heuristic does not.

Even if deferrals are never more than 8% of all oc-

currences, this is an aspect where the model could

be improved and that should be validated with users.

Indeed, these deferrals may be avoided by poten-

tially creating more advancements. Thus, the penalty

weights in the objective function may have to be

adjusted to offer solutions with even fewer defer-

rals. Furthermore, the Never option seems to of-

fer solutions with fewer deferrals than the A/D and

Always options. Indeed, the results show that ev-

ery Not-Nested and Never cases have not a single

deferral in their solution. This is however expected,

since Never is allowed to cause non-compliant peri-

odicity intervals due to its clock date (and target) defi-

nition. Deferrals with the A/D and Always options can

be explained by maintenance tasks with smaller peri-

odicity, where it is sometimes impossible to execute

them on time when the clock date is updated since the

work periods are so far apart. The number of deferrals

is even higher starting from instance 3-years where

there are only two to three work periods per year.

During our experiments, we observed the cur-

rent computation limitations of our approach. Even

though we always found an initial solution using our

search heuristic, 16 CP executions over 180 (8.9%)

terminated with an “ERROR” status before the time-

out due to the solver reaching its maximal allocated

memory (RAM) during the solving phase, i.e. more

than 30 GB. These cases were encountered on a sub-

set of 4-years and 5-years configurations. This

increase in memory requirements is notably due to

the number of variables and constraints contained

in the generated FlatZinc file given to the solver.

On the 5-years instance, it contained on average

433K variables and 480K constraints, while requir-

ing a compilation time between 13 and 25 seconds.

In comparison, on the 1-year instance, it contained

53K variables and 61K constraints with a compila-

tion time of 1 or 2 seconds. Thus, it may be worth-

while to test the approach on a different setup or

with a different solver. Note that we did try the

OR-Tools CP-SAT solver (Perron and Furnon, 2024)

via its FlatZinc implementation, but preliminary re-

sults showed a greater computation time for simi-

lar or worse solutions. Furthermore, only Chuffed

could directly support the priority search MiniZinc

annotation we used to construct our search heuristic.

Other search heuristics we considered before using

this one include a similar one that did not assigned

variables D

k

m

, as well as a simple sequential search

on distance

target(m,k) − E

k

m

exploring work peri-

ods with E

k

m

≤ target(m,k) first (towards “left”). Fol-

lowing the approach of (Boudreault et al., 2022), we

also tried the free search of Chuffed, as well as the

Solution-Based Phase Saving (SBPS) value-selection

heuristic (Demirovi

´

c et al., 2018), but observed again

greater computation times for similar or worse solu-

tions.

7 CONCLUSION

In this paper, we introduced a CP approach for a pre-

ventive maintenance planning problem in the naval

domain. Our solution was validated on a bench-

mark of instances with varying planning horizons cre-

ated from a real ship maintenance program dataset.

Each instance was solved according to a combina-

tion of user options that changes the behavior of the

CP model, and compared to a currently used planning

method. Our approach clearly demonstrated its worth

in long-term maintenance planning, cutting the con-

sidered objective value by up to 31%, resulting in a

significant decrease of 93% in advancements and de-

ferrals. In addition, we have shown that the CP ap-

proach can greatly reduce over-maintenance, and thus

in-service support costs, with plans having up to 25%

less maintenance occurrences.

Directions for future work include tackling the

current observed limitations of the CP model, such

as time and memory scaling issues as well as objec-

tive function unwanted behavior (e.g., the fact that

deferrals are introduced), notably through a rolling

horizon approach. We also aim at comparing this ap-

proach to an optimization algorithm based on mixed-

integer programming, as well as going towards multi-

objective optimization by integrating an objective of

resource leveling. Finally, we plan to evaluate our re-

sults in terms of in-service support cost savings and

address an extended use case which proposes modifi-

cations to the given ship schedule.

Long-Term Planning of Preventive Maintenance Using Constraint Programming: A Naval Case Study

41

ACKNOWLEDGEMENTS

Thanks are due to the many members of the Thales

project team, as well as our collaborators from Uni-

versit

´

e Laval, Polytechnique Montr

´

eal, and Dalhousie

University, for their invaluable feedback on the prob-

lem definition and for the solution implementation.

REFERENCES

Ahluwalia, R. and Pinha, D. (2014). Decision support sys-

tem for production planning in the ship repair industry.

Industrial and Systems Engineering Review, 2(1):52–

61.

Basri, E. I., Abdul Razak, I. H., Ab-Samat, H., and Ka-

maruddin, S. (2017). Preventive maintenance (PM)

planning: A review. Journal of Quality in Mainte-

nance Engineering, 23(2):114–143.

Boudreault, R., Simard, V., Lafond, D., and Quimper, C.-

G. (2022). A constraint programming approach to

ship refit project scheduling. In Solnon, C., edi-

tor, 28th International Conference on Principles and

Practice of Constraint Programming (CP 2022), vol-

ume 235 of Leibniz International Proceedings in In-

formatics (LIPIcs), pages 10:1–10:16, Dagstuhl, Ger-

many. Schloss Dagstuhl – Leibniz-Zentrum f

¨

ur Infor-

matik.

Bousdekis, A., Lepenioti, K., Apostolou, D., and Mentzas,

G. (2019). Decision making in predictive mainte-

nance: Literature review and research agenda for in-

dustry 4.0. IFAC-PapersOnLine, 52(13):607–612.

Chu, G. G. (2011). Improving Combinatorial Optimization.

PhD thesis, The University of Melbourne. GitHub:

https://github.com/chuffed/chuffed.

Cullum, J., Binns, J., Lonsdale, M., Abbassi, R., and

Garaniya, V. (2018). Risk-based maintenance

scheduling with application to naval vessels and ships.

Ocean Engineering, 148:476–485.

Demirovi

´

c, E., Chu, G., and Stuckey, P. J. (2018). Solution-

based phase saving for CP: A value-selection heuristic

to simulate local search behavior in complete solvers.

In Hooker, J., editor, Principles and Practice of Con-

straint Programming, Lecture Notes in Computer Sci-

ence, pages 99–108, Cham. Springer International

Publishing.

Deris, S., Omatu, S., Ohta, H., Shaharudin Kutar, L. C.,

and Abd Samat, P. (1999). Ship maintenance schedul-

ing by genetic algorithm and constraint-based rea-

soning. European Journal of Operational Research,

112(3):489–502.

Diallo, C., Khatab, A., and Venkatadri, U. (2019). Develop-

ing a bi-objective imperfect selective maintenance op-

timization model for multicomponent systems. IFAC-

PapersOnLine, 52(13):1079–1084.

Feydy, T., Goldwaser, A., Schutt, A., Stuckey, P. J., and

Young, K. D. (2017). Priority Search with MiniZinc.

In ModRef 2017: The Sixteenth International Work-

shop on Constraint Modelling and Reformulation.

Gu, H., Joyce, M., Lam, H. C., Woods, M., and Zinder, Y.

(2019). A genetic algorithm for assigning train arrival

dates at a maintenance centre. IFAC-PapersOnLine,

52(13):957–962.

Javanmard, H. and al Wahhab Koraeizadeh, A. (2016). Op-

timizing the preventive maintenance scheduling by

genetic algorithm based on cost and reliability in Na-

tional Iranian Drilling Company. Journal of Industrial

Engineering International, 12(4):509–516.

Lafond, D., Couture, D., Delaney, J., Cahill, J., Corbett, C.,

and Lamontagne, G. (2021). Multi-objective schedule

optimization for ship refit projects: Toward geospa-

tial constraints management. In Ahram, T., Taiar, R.,

and Groff, F., editors, Human Interaction, Emerging

Technologies and Future Applications IV, Advances in

Intelligent Systems and Computing, pages 662–669,

Cham. Springer International Publishing.

Nethercote, N., Stuckey, P. J., Becket, R., Brand, S., Duck,

G. J., and Tack, G. (2007). MiniZinc: Towards a stan-

dard CP modelling language. In Bessi

`

ere, C., edi-

tor, Principles and Practice of Constraint Program-

ming – CP 2007, Lecture Notes in Computer Science,

pages 529–543, Berlin, Heidelberg. Springer. Web-

site: https://www.minizinc.org/.

Perron, L. and Furnon, V. (2024). OR-Tools. Google. Web-

site: https://developers.google.com/optimization/.

Rossi, F., van Beek, P., and Walsh, T., editors (2006). Hand-

book of Constraint Programming, volume 2 of Foun-

dations of Artificial Intelligence. Elsevier.

Van Horenbeek, A., Pintelon, L., and Muchiri, P. (2010).

Maintenance optimization models and criteria. In-

ternational Journal of System Assurance Engineering

and Management, 1(3):189–200.

Wu, S. (2011). Preventive maintenance models: A review.

In Tadj, L., Ouali, M.-S., Yacout, S., and Ait-Kadi,

D., editors, Replacement Models with Minimal Re-

pair, pages 129–140. Springer, London.

APPENDIX

Detailed results of the experiments from Section 5 are

presented in Table 6. For each instance and each op-

tion configuration, we report the objective value of

the best solution found (Obj.), as well as its number

of occurrences in the timeline T (#O), advancements

(#A), deferrals (#D), and late certifications (#LC).

We also report the number of intermediate solutions

found (#S), along with the solving time (Time) to find

the best solution, in seconds. A “*” next to a solving

time value indicates that the instance was optimally

solved before the timeout was reached. For each

instance, Closest/Latest, and Not-Nested/Nested

configuration, we highlight in bold the smallest objec-

tive value and number of occurrences obtained with

the different clock date user options.

ICORES 2025 - 14th International Conference on Operations Research and Enterprise Systems

42

Table 6: Results obtained on the benchmark instances using Heuristic and the CP approach.

Instance and

User Options

Not-Nested Nested

Obj. #O #A #D #LC #S Time Obj. #O #A #D #LC #S Time

1-year

Closest

Heuristic 2723 849 215 0 0 1 - - - - - - - -

Never

Start 1995 688 13 0 0 1 *5 2003 689 14 0 0 7 *7

Mid 1995 687 13 0 0 1 *3 2003 688 14 0 0 7 *8

End 1995 683 13 0 0 1 *4 2004 685 14 0 0 7 *8

A/D

Start 2008 693 18 1 0 1 *8 2022 692 18 2 0 7 *525

Mid 2013 691 18 0 0 2 *9 2032 693 21 1 0 4 618

End 2014 683 8 1 0 6 *264 2035 687 13 2 0 10 834

Always

Start 2085 780 0 11 0 2 *14 2300 845 68 12 0 2 10

Mid 1986 682 0 0 0 2 *5 2002 679 0 1 0 13 *17

End 2007 666 21 0 0 2 *6 2030 667 24 1 0 10 1487

Latest

Heuristic 2878 849 215 0 0 1 - - - - - - - -

Never

Start 1988 665 13 0 0 1 *5 2220 691 75 0 0 1 5

Mid 1988 664 13 0 0 1 *5 2220 690 75 0 0 1 5

End 1988 660 13 0 0 1 *6 2221 687 75 0 0 1 5

A/D

Start 2001 670 18 1 0 1 *8 2237 729 79 2 0 1 9

Mid 2006 668 18 0 0 2 *10 2242 726 79 1 0 2 10

End 2002 665 18 1 0 1 *8 2239 724 79 2 0 1 8

Always

Start 2086 663 0 11 0 2 *33 2316 721 59 12 0 2 12

Mid 1987 661 0 0 0 2 *9 2219 718 59 1 0 2 8

End 2008 647 21 0 0 2 *9 2256 710 85 1 0 2 8

2-years

Closest

Heuristic 2505 755 162 0 0 1 - - - - - - - -

Never

Start 2138 658 70 0 0 1 *6 2157 662 69 4 0 10 *110

Mid 2138 658 70 0 0 1 *3 2157 662 69 4 0 10 *111

End 2138 655 70 0 0 1 *3 2157 659 69 4 0 10 *81

A/D

Start 2093 663 49 2 0 1 8 2108 669 52 2 0 1 6

Mid 2099 663 54 2 0 1 6 2114 669 57 2 0 1 7

End 2094 660 54 2 0 1 6 2109 666 57 2 0 1 6

Always

Start 2038 666 10 0 0 2 *7 2050 677 10 3 0 6 *59

Mid 2058 666 30 0 0 2 *15 2075 678 32 3 0 3 1588

End 2048 656 22 3 0 1 *4 2061 665 23 3 0 6 1614

Latest

Heuristic 2587 755 162 0 0 1 - - - - - - - -

Never

Start 2065 609 70 0 0 1 *5 2226 628 109 0 0 8 1694

Mid 2065 609 70 0 0 1 *5 2228 629 111 0 0 7 1264

End 2065 606 70 0 0 1 *4 2228 626 111 0 0 7 1276

A/D

Start 2056 614 49 2 0 1 8 2210 646 87 2 0 1 7

Mid 2062 614 54 2 0 1 7 2220 646 96 2 0 1 8

End 2062 611 54 2 0 1 8 2220 643 96 2 0 1 8

Always

Start 2023 595 10 0 0 2 *9 2148 629 34 3 0 4 63

Mid 2043 595 30 0 0 2 *17 2190 629 65 3 0 2 34

End 2035 582 22 0 0 2 *13 2202 621 67 3 0 2 30

3-years

Closest

Heuristic 8318 2340 488 0 0 1 - - - - - - - -

Never

Start 6929 2280 118 0 0 1 14 7239 2295 120 33 0 9 1002

Mid 6929 2279 118 0 0 1 21 7239 2294 120 33 0 9 975

End 6929 2276 118 0 0 1 21 7248 2290 121 33 0 9 1068

A/D

Start 7255 2312 156 16 0 1 37 7608 2350 187 55 0 6 1688

Mid 6958 2282 84 8 0 1 40 7235 2310 115 33 0 8 661

End 6951 2283 76 9 0 3 195 7144 2308 100 25 0 4 211

Always

Start 7155 2377 24 52 0 2 106 7979 2517 232 50 0 5 458

Mid 6812 2253 21 20 0 1 42 7007 2295 66 18 0 4 182

End 6768 2047 34 7 0 2 1524 7018 2105 99 6 0 4 175

Long-Term Planning of Preventive Maintenance Using Constraint Programming: A Naval Case Study

43

Instance and

User Options

Not-Nested Nested

Obj. #O #A #D #LC #S Time Obj. #O #A #D #LC #S Time

3-years

Latest

Heuristic 8565 2340 488 0 0 1 - - - - - - - -

Never

Start 6806 2235 118 0 0 1 30 7639 2263 265 23 0 1 32

Mid 6806 2234 118 0 0 1 38 7639 2262 265 23 0 1 38

End 6806 2231 118 0 0 1 36 7648 2258 266 23 0 1 38

A/D

Start 6995 2267 156 16 0 1 39 7977 2390 329 52 0 5 877

Mid 6853 2237 84 8 0 1 34 7830 2362 294 30 0 10 1604

End 6844 2238 78 8 0 1 31 7758 2357 301 23 0 5 893

Always

Start 7182 2219 29 51 0 3 177 7560 2305 145 49 0 6 514

Mid 6877 2187 22 20 0 1 36 7238 2237 110 18 0 4 231

End 6782 2006 35 8 0 1 34 7241 2085 158 5 0 5 298

4-years

Closest

Heuristic 12 035 3165 697 0 0 1 - - - - - - - -

Never

Start 10 052 3097 155 0 0 1 24 10 582 3131 210 40 0 4 1384

Mid 10 052 3096 155 0 0 1 23 10 779 3124 207 41 0 5 1491

End 9853 3081 155 0 0 1 22 10 587 3112 208 41 0 5 1791

A/D

Start 10 515 3203 235 29 0 1 53 10 784 3270 285 87 0 1 69

Mid 10 190 3145 161 11 0 1 65 10 655 3201 237 47 0 1 56

End 9816 3086 92 11 0 1 49 10 162 3132 149 38 0 3 223

Always

Start 11 816 3327 181 92 0 1 117 12 501 3482 397 88 0 6 848

Mid 10 701 3281 335 23 0 1 64 11 015 3317 407 24 0 1 278

End 9514 2929 34 11 0 1 63 9925 3009 150 8 0 5 640

Latest

Heuristic 12 201 3165 697 0 0 1 - - - - - - - -

Never

Start 9815 3088 155 0 0 1 61 10 960 3134 373 37 0 1 58

Mid 9815 3087 155 0 0 1 58 11 159 3128 373 37 0 1 57

End 9616 3072 155 0 0 1 54 10 967 3116 374 37 0 1 57

A/D

Start 10 321 3194 235 29 0 1 58 11 344 3368 432 88 0 1 76

Mid 9924 3136 161 11 0 1 65 11 174 3319 468 49 0 1 76

End 9662 3077 92 11 0 1 62 10 800 3234 355 37 0 1 75

Always

Start 12 021 3248 186 92 0 1 110 12 271 3335 322 85 0 9 865

Mid 10 137 3216 336 23 0 1 69 10 620 3274 453 24 0 1 259

End 9529 2866 35 11 0 1 69 10 259 3005 236 12 0 1 252

5-years

Closest

Heuristic 13 840 3570 752 0 0 1 - - - - - - - -

Never

Start 11 675 3592 166 0 1 1 30 12 651 3637 225 56 1 5 1467

Mid 11 675 3590 166 0 1 1 45 12 644 3633 223 56 1 5 1575

End 11 476 3574 166 0 0 1 31 12 454 3618 227 55 0 4 1570

A/D

Start 12 123 3667 235 57 1 1 66 12 857 3786 325 128 1 1 74

Mid 11 805 3602 161 11 1 1 66 12 466 3726 243 71 1 1 74

End 11 511 3569 111 13 0 1 60 12 124 3658 229 55 0 1 70

Always

Start 13 650 3836 181 285 1 1 164 14 678 4077 419 280 1 7 1282

Mid 12 530 3649 335 59 1 1 70 13 059 3761 459 60 1 1 471

End 11 145 3260 34 25 0 1 66 11 681 3382 182 26 0 1 397

Latest

Heuristic 14 155 3570 752 0 0 1 - - - - - - - -

Never

Start 11 415 3433 166 0 1 1 77 12 825 3483 395 36 1 1 78

Mid 11 415 3431 166 0 1 1 76 12 819 3480 393 36 1 1 72

End 11 216 3415 166 0 0 1 79 12 627 3464 394 36 0 1 75

A/D

Start 11 953 3538 235 57 1 1 74 13 223 3721 438 112 1 1 90

Mid 11 514 3473 161 11 1 1 75 12 831 3671 468 57 1 1 91

End 11 294 3440 111 13 0 1 79 12 528 3628 394 45 0 1 82

Always

Start 13 914 3714 186 285 1 1 169 14 436 3861 329 276 1 11 1342

Mid 12 030 3565 336 59 1 1 90 12 570 3632 466 60 1 1 451

End 11 215 3214 35 25 0 1 85 12 014 3359 255 26 0 1 402

ICORES 2025 - 14th International Conference on Operations Research and Enterprise Systems

44