Exploration of a Generalized Benders Decomposition Method for Solving

Project Scheduling Problems with Resource Constraints

Alfredo S. Ramos

1 a

, Pablo A. Miranda-Gonzalez

2 b

and Elias Olivares-Benitez

1 c

1

Facultad de Ingenier

´

ıa, Universidad Panamericana,

´

Alvaro del Portillo 49, Zapopan, Jalisco, Mexico

2

Departamento de Ingenier

´

ıa Industrial, Universidad Cat

´

olica del Norte, Av. Angamos 0610, Antofagasta, Chile

Keywords:

Generalized Benders Decomposition, Project Scheduling, Mathematical Programming.

Abstract:

This research introduces a new Generalized Benders Decomposition-based Algorithm (GBDA) to solve the

Multi-Mode Resource-Constrained Project Scheduling Problem (MRCPSP). The MRCPSP is a scheduling

problem that besides precedence constraints, includes renewable and non-renewable resource constraints, as

well as the selection of execution modes for the project activities. This mode selection determines the resource

usage and duration of each activity. The GBDA splits the problem into a Master Problem (MP) and a Sub-

Problem (SP) with a relaxation. Both problems are solved alternately, each one incorporating information

from the other at each iteration, until a stopping criterion is met. Additionally, at each iteration, a non-relaxed

SP is solved to obtain a solution for the original problem, and the best solution from all iterations is reported.

The GBDA was tested, with three different stopping criteria, on benchmark instances from a public library

and compared against solving the traditional formulation of the problem with an exact Mixed Integer Linear

Programming (MILP) method. The GBDA found solutions of good quality in less than half the computing

time than the exact method, with one of the stopping criteria. The analysis of the results provides valuable

insights for future research.

1 INTRODUCTION AND

LITERATURE REVIEW

The project scheduling branch of operations research

deals with several types of optimization problems

that require project activities to be sequenced sub-

ject to precedence constraints (i.e., some activities

must be finished for other activities to start), usually

with the objective or minimizing the duration of the

project. One version of such project scheduling prob-

lems is the Resource-Constrained Project Scheduling

Problem (RCPSP), which besides the usual prece-

dence constraints, includes also resource constraints

(i.e., activities require a certain amount of resources

to be performed, and there is a maximum availabil-

ity of those resources). This problem was intro-

duced by (Dike, 1964), and since then, several authors

have proposed variants extending or generalizing the

RCPSP (Ding et al., 2023).

One well-known generalization of the RCPSP,

a

https://orcid.org/0000-0002-2155-9925

b

https://orcid.org/0000-0003-4885-4200

c

https://orcid.org/0000-0001-7943-3869

proposed by (Elmaghraby, 1977), is the Multi-Mode

Resource-Constrained Project Scheduling Problem

(MRCPSP), which considers that project activities

can be performed according to different execution

modes, and that the resource consumption and dura-

tion of each activity depend on its selected execution

mode, with a trade-off among them. If an activity is

performed under an execution mode with a shorter

duration, it will consume more resources, and vice-

versa. Those resources can be renewable (i.e. their

availability renews every time period), like workers

or machinery; or non-renewable (i.e. they have a lim-

ited availability for the complete project), like mone-

tary resources. The solution of the problem involves

two decisions: the selection of an execution mode for

each activity and the scheduling (i.e. selection of a

start and finish time) of all activities.

There are several real-life applications of the MR-

CPSP, mostly in industrial and business contexts.

Considering a manufacturing project as an example,

an operation (project activity) can be performed faster

(shorter activity duration) if more workers are as-

signed to it (greater renewable resource consump-

tion). Or, if there is an operation that requires some

Ramos, A. S., Miranda-Gonzalez, P. A. and Olivares-Benitez, E.

Exploration of a Generalized Benders Decomposition Method for Solving Project Scheduling Problems with Resource Constraints.

DOI: 10.5220/0013116300003893

In Proceedings of the 14th International Conference on Operations Research and Enterprise Systems (ICORES 2025), pages 57-66

ISBN: 978-989-758-732-0; ISSN: 2184-4372

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

57

material to be dried, for example, there could be two

options (execution modes): to let it dry on its own

(longer duration) or to use a drier machine (shorter

duration) which costs more (greater non-renewable

resource consumption). Besides manufacturing, soft-

ware development and construction projects, among

others, can also be modeled as MRCPSP.

The complexity of the MRCPSP was classified

as NP-Hard by (Blazewicz et al., 1983). Several

solution methods have been proposed to solve it,

including exact mixed-integer linear programming

(MILP) methods (Sprecher et al., 1997; Kyriakidis

et al., 2012). However, due to the difficulty of solv-

ing large instances of the problem within computa-

tional times short enough to be practical using tra-

ditional exact methods (Sprecher and Drexl, 1998),

some authors have proposed heuristic and metaheuris-

tic methods to solve them. (Van Peteghem and Van-

houcke, 2014) provide a review of the most rele-

vant metaheuristic methods proposed to solve the

MRCPSP until 2012. Since then, more metaheuris-

tic methods have been studied including: path re-

linking (Muritiba et al., 2018), variable neighbour-

hood search (Chakrabortty et al., 2019), simulated

annealing (Shokoohyar and Amiri, 2021), memetic

algorithms (Machado-Dom

´

ınguez et al., 2021), ge-

netic algorithms (Sebt et al., 2015; Zamani, 2019;

Shokoohyar and Amiri, 2021; Afshar et al., 2022),

multi-start iterated local search (Ramos et al., 2022),

and ant colony optimization (Li and Zhang, 2013;

de la Pisa et al., 2024). While there has been a sub-

stantial amount of research regarding metaheuristic

methods for solving the MRCPSP, there have been

considerably fewer attempts at using mathematical

programming strategies to solve it efficiently.

A mathematical programming-based method used

for solving MILP problems, known as Benders De-

composition (BD) and proposed originally by (Ben-

ders, 1962), is a technique that separates the decision

variables of the problem in two sets, one of them han-

dled by a Master Problem (MP), and the other one

by a Sub-problem (SP). The values of the decision

variables obtained by solving the MP become fixed

parameters in the SP, and the solution of the SP pro-

vides optimality and feasibility cuts that are added to

the MP, which is solved again, providing new values

for the SP. This process iterates until a convergence

criterion is reached. This method has been used to

solve the p-median problem (Duran-Mateluna et al.,

2023), assembly line balancing problems (Sikora and

Weckenborg, 2023), location problems (Bayram and

Yaman, 2018), vehicle routing problems (Fachini and

Armentano, 2020), and multi-trip traveling repairman

problems (Bruni et al., 2022), among others.

An extension of BD, capable of dealing with non-

linear formulations by relying on the dual-Lagrangian

formulation of the SP for generating the feasibility

and optimality cuts, is known as Generalized Benders

Decomposition (GBD) and was proposed by (Geof-

frion, 1972). This approach has been used to solve

pricing problems (Shams-Shoaaee and Hassini, 2020;

Yaghin and Goh, 2021), inventory location problems

(Tapia-Ubeda et al., 2018; Tapia-Ubeda et al., 2024),

resource allocation problems (Li et al., 2019), and

others.

There are some studies involving the utilization of

BD or GBD for solving some versions of the MR-

CPSP or related problems, including: a matheuris-

tic approach to solve the MRCPSP by (Ramos

et al., 2024) combining GBD and heuristic schedul-

ing strategies; the work by (Balouka and Cohen,

2021) and (Bold and Goerigk, 2022), who developed

methods based on BD to solve stochastic versions of

the MRCPSP; a BD approach to solve the single-

mode RCPSP by (Bruni et al., 2017); the proposal

by (Sadeghloo et al., 2023) of a goal programming

method in combination with BD for the Multi-Project

MRCPSP; and finally, the research by (Maniezzo and

Mingozzi, 1999) regarding using BD only with the

purpose of finding lower bounds for instances of the

MRCPSP. It is worth noting that most of these stud-

ies use BD, not GBD, and solve a variety of problems

similar to the MRCPSP. To the best of our knowledge,

there are currently no published research articles that

employ the same GBD-based solution method as the

one proposed in this research, for solving the deter-

ministic MRCPSP.

In order to address this gap in the scientific lit-

erature, the purpose of this research, is to propose

a Generalized Benders Decomposition-based Algo-

rithm (GBDA) to solve the MRCPSP, capable of find-

ing good-quality solutions in short computing times.

The proposed GBDA works by applying a partial re-

laxation to the problem; solving it with the GBD

method; solving the original problem (without the re-

laxation) with an exact method at each iteration; and

finding the best solution of all iterations.

The proposed GBDA was tested, with three dif-

ferent stopping criteria, on benchmark instances with

30 activities per project, obtained from the PSPLIB

library published by (Kolisch and Sprecher, 1997).

The results of the computational tests show a trade-

off between computing time and solution quality in

the three cases. With one of the tested stopping cri-

teria, the GBDA was able to provide good quality so-

lutions in less than half the time taken by a Baseline

method, which solves the traditional formulation of

the problem with an exact MILP method.

ICORES 2025 - 14th International Conference on Operations Research and Enterprise Systems

58

The development of the proposed GBDA, as a new

method to solve the MRCPSP, as well as the insights

from the analysis of the results of its implementation,

provide valuable contributions to the research field,

mainly as a starting point for future research along

this scarcely explored, but promising path.

2 PROBLEM FORMULATION

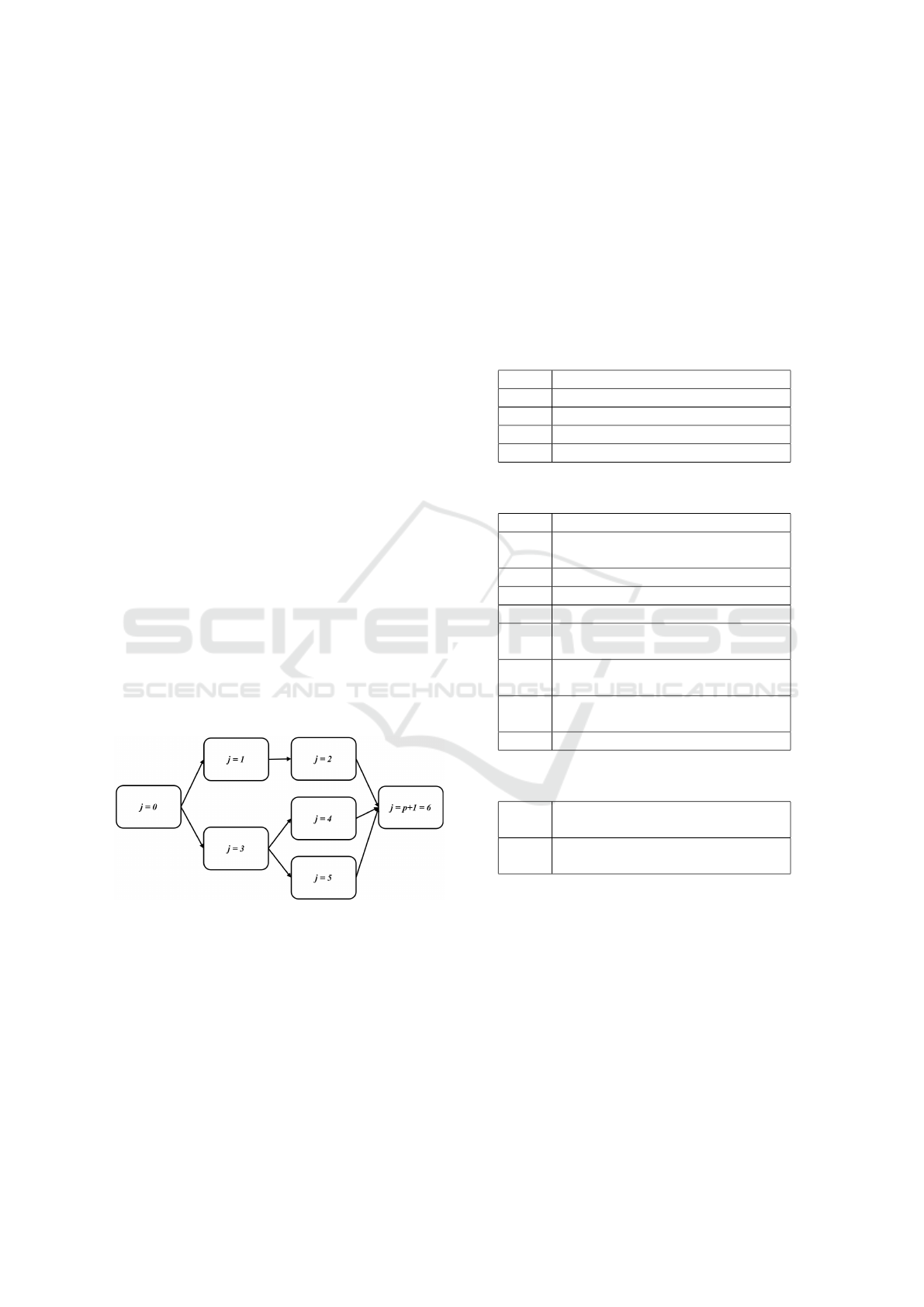

The MRCPSP contains a set of project activities j

or k ∈ J, which are numbered from 1 to p, plus

two dummy activities: a ”start” activity number 0

and a ”finish” activity number p + 1. These ac-

tivities require to be sequenced considering a set

of relationships of precedence among pairs of them

( j, k) ∈ PR, and without exceeding resource avail-

abilities. Dummy activities have a duration of 0

time units and no resource usage. There is a set of

non-renewable resources n ∈ NR with a maximum

availability of QN

n

. There is also a set of renew-

able resources r ∈ RR with a maximum availabil-

ity of QR

r

, which renews itself each time period t.

Activities can be performed according to different

modes m ∈ M, which determine their duration d

jm

and their consumption of non-renewable qn

jmn

and

renewable qr

jmr

resources. Figure 1 shows a net-

work diagram as a representation of a MRCPSP in-

stance, consisting of 5 project activities, plus the two

dummies, where activities are represented by nodes

and relationships of precedence by arrows, and PR =

{(0, 1), (0, 3), (1, 2), (2, 6), (3, 4), (3, 5), (4, 6), (5, 6)}.

Figure 1: Network diagram or a MRCPSP instance.

A lower bound EF

j

(earliest finish) and an upper

bound LF

j

(latest finish) for the finish time of each ac-

tivity, as well as an upper bound T for the makespan

of the project can be computed prior to solving the

problem with the procedure described by (Lova et al.,

2009). The solution of the problem includes two de-

cisions. The first decision is the selection of an ex-

ecution mode m for each activity j, modeled by the

binary decision variable x

jm

, which takes the value of

1 if activity j is executed in mode m and a value of

0 otherwise. The second decision is the assignment

of a finish time t to each activity j, modeled by the

binary decision variable y

jt

, which takes the value of

1 if activity j finishes at time t and a value of 0 oth-

erwise. The objective is to minimize the makespan of

the project, which is equivalent to the finish time of

the activity p + 1.

Tables 1, 2 and 3 show a summary of the sets, pa-

rameters and variables of the mathematical model, re-

spectively,

Table 1: MRCPSP mathematical model sets.

J Project activities j or k

PR Relationships of precedence ( j, k)

M Execution modes m

NR Non-renewable resources n

RR Renewable resources r

Table 2: MRCPSP mathematical model parameters.

p Number of project activities

T Upper bound for the project

makespan

EF

j

Earliest finish time of activity j

LF

j

Latest finish time of activity j

d

jm

Duration of activity j in mode m

qn

jmn

Usage of non-renewable resource n

by activity j in mode m

qr

jmr

Usage of renewable resource r by

activity j in mode m

QN

n

Availability of non-renewable re-

source n

QR

r

Availability of renewable resource r

Table 3: MRCPSP mathematical model variables.

x

jm

Binary variable with a value of 1 if

activity j is performed in mode m

y

jt

Binary variable with a value of 1 if

activity j finishes at time period t.

Mathematical formulation:

Minimize:

LF

p+1

∑

t=EF

p+1

t y

p+1,t

, (1)

subject to:

∑

m∈M

x

jm

= 1 ∀ j ∈ J, (2)

LF

j

∑

t=EF

j

y

jt

= 1 ∀ j ∈ J, (3)

Exploration of a Generalized Benders Decomposition Method for Solving Project Scheduling Problems with Resource Constraints

59

LF

j

∑

t=EF

j

t y

jt

≤

LF

k

∑

t=EF

k

t y

kt

−

∑

m∈M

d

km

x

km

∀( j, k) ∈ PR, (4)

∑

j∈J

∑

m∈M

qn

jmn

x

jm

≤ QNn ∀n ∈ NR, (5)

∑

j∈J

∑

m∈M

t+d

jm

−1

∑

q=t

qr

jmr

x

jm

y

jq

≤ QR

r

∀r ∈ RR, ∀t ∈ {0, ..., T }, (6)

x

jm

∈ {0, 1}, y

jt

∈ {0, 1} ∀ j ∈ J

∀m ∈ M ∀t ∈ {0, . . . , T }. (7)

Equation (1), the objective function to be mini-

mized, represents the finish time of the last project

activity. Constraints (2) and (3) ensure that one and

only one execution mode and finish time is assigned

to each activity. Equation (4) guarantees that all the

predecessors of an activity are finished before it starts.

Constraint sets (5) and (6) specify that resource avail-

abilities cannot be exceeded, for non-renewable and

for renewable resources, respectively. Equations (7)

state the domain of the decision variables.

3 METHODOLOGY

The mathematical formulation of the MRCPSP de-

scribed in section 2 defines two decision variables:

x

jm

to assign an execution mode to each activity and

y

jt

to assign a finish time to each activity. This nonlin-

ear formulation, as proposed by (Ramos et al., 2024),

allows the problem to be addressed with a decom-

position approach. The traditional linear formulation

of the MRCPSP, proposed by (Talbot, 1982) includes

only one decision variable, and thus, cannot be solved

using a decomposition method.

Since the formulation to be addressed is nonlin-

ear due to the quadratic formulation of equation (6),

GBD is employed. Under this approach, the problem

is decomposed into a MP that deals with the mode se-

lection (variables x

jm

) and a SP that deals with the ac-

tivity scheduling (variables y

jt

). This decomposition

of the problem is employed as part of the proposed

GBDA described in this section.

A requirement for GBD to ensure optimality

is that the variables in the SP are continuous. For

this reason, a partial relaxation is necessary in the

formulation of the SP, by changing the domain of the

y

jt

variables from binary to continuous, otherwise the

proposed method could not be employed. Once this

partial relaxation is considered, the SP to be solved at

each iteration of the GBDA is formulated as follows:

Minimize:

LF

p+1

∑

t=EF

p+1

t y

p+1,t

(8)

subject to:

LF

j

∑

t=EF

j

y

jt

= 1 ∀ j ∈ J, (9)

LF

j

∑

t=EF

j

t y

jt

≤

LF

k

∑

t=EF

k

t y

kt

−

∑

m∈M

d

km

x

i

km

∀( j, k) ∈ PR, (10)

∑

j∈J

∑

m∈M

t+d

jm

−1

∑

q=t

qr

jmr

x

i

jm

y

jq

≤ QR

r

∀r ∈ RR,

∀t ∈ {0, ..., T }, (11)

0 ≤ y

jt

≤ 1 ∀ j ∈ J ∀t ∈ {0, . . . , T }. (12)

Where equations (8), (9), (10) and (11) are the

equivalent for the SP of equations (1), (3), (4) and

(6), respectively; equation (12) states the domain of

the decision variables; and x

i

jm

are the fixed values of

the variables x

jm

(mode selection) obtained by the so-

lution of the MP at each iteration i of the GBDA. It

is important to note that the solutions of the SP (vari-

ables y

jt

) are only valid for the relaxed (continuous)

formulation, and not for the original (binary) problem.

Subsequently, the formulation of the correspond-

ing MP to be solved at each iteration of the GBDA is

the following:

Minimize:

γ (13)

subject to:

∑

m∈M

x

jm

= 1 ∀ j ∈ J, (14)

∑

j∈J

∑

m∈M

qn

jmn

x

jm

≤ QNn ∀n ∈ NR, (15)

ICORES 2025 - 14th International Conference on Operations Research and Enterprise Systems

60

γ ≥

LF

p+1

∑

t=EF

p+1

t y

h

p+1,t

−

∑

j|( j,k)∈PR

∑

k|( j,k)∈PR

λ

h

jk

∑

m∈M

d

km

x

km

−

LF

k

∑

t=EF

k

t y

h

kt

+

LF

j

∑

t=EF

j

t y

h

jt

−

∑

r∈RR

T

∑

t=0

µ

h

rt

∑

j∈J

∑

m∈M

t+d

jm

−1

∑

q=t

qr

jmr

x

jm

y

h

jq

−QR

r

∀h = 1, ..., i

(16)

x

jm

∈ {0, 1} ∀ j ∈ J ∀m ∈ M. (17)

Where equation (13) is the objective function;

equations (14) and (15) are the equivalent in the MP

of equations (2) and (5); equation (16) represents

the optimality cuts added at each iteration i of the

GBDA derived from the dual Lagrangian equivalence

obtained by solving the SP; y

i

jt

are the values of the

decision variables y

jt

from the solution of the SP at it-

eration i; and λ

i

jk

and µ

i

rt

are the Lagrangian multipli-

ers given by the dual values for constraints (10) and

(11), respectively, obtained from the solution of the

SP at each iteration i. Feasibility cuts are not needed

because the MP guarantees feasibility regarding non-

renewable resources when selecting execution modes

(variables x

jm

), which become fixed values in the SP

which only deals with activity scheduling (variables

y

jt

).

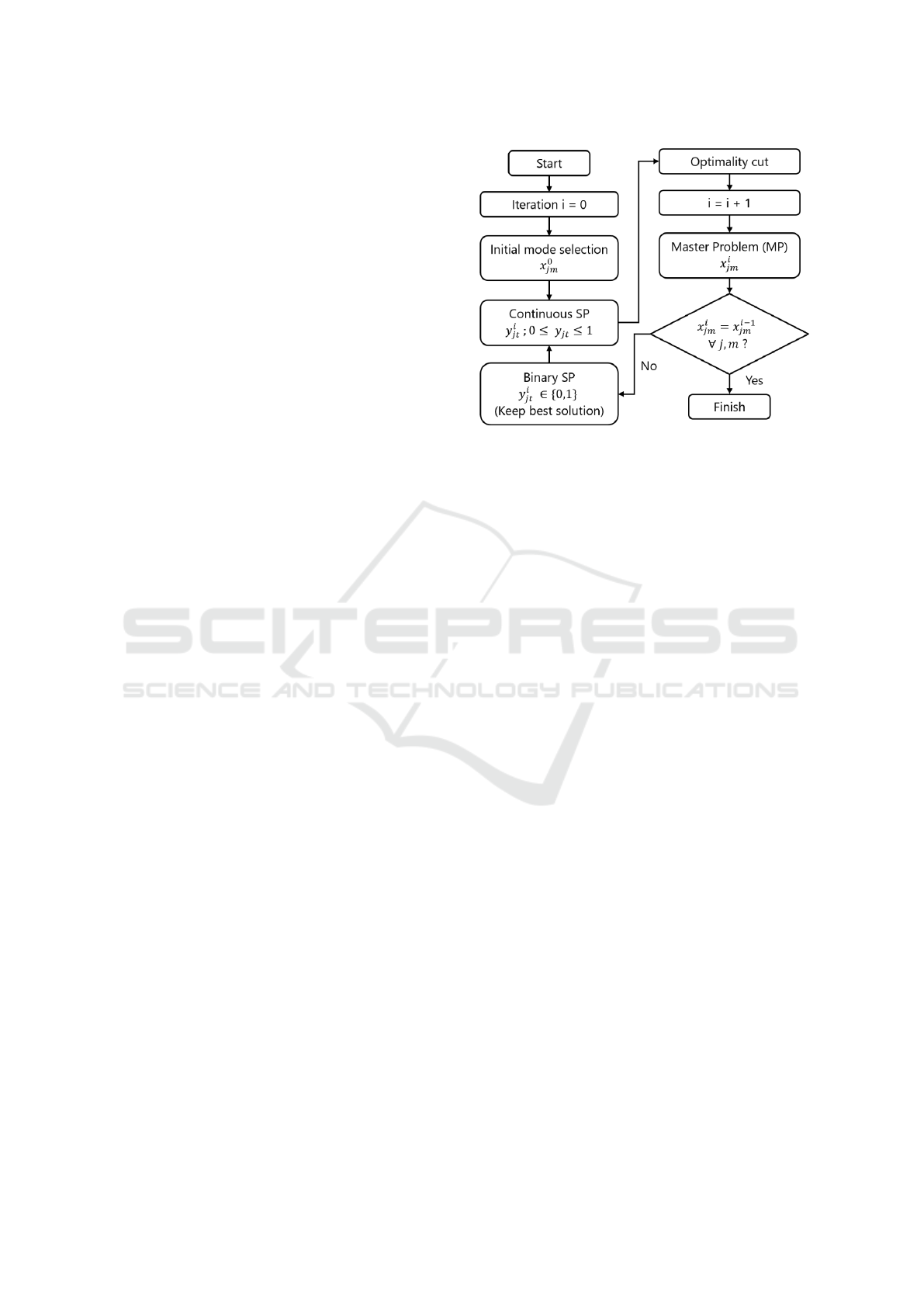

Since the solution of the relaxed SP formulated by

equations (8) to (12) provides continuous values for

variables y

jt

, which in the original problem are bi-

nary variables, to be able to obtain solutions for the

original problem, a binary SP is also formulated con-

taining equations (8) to (11) and equation (18), which

replaces equation (12).

y

jm

∈ {0, 1}, ∀ j ∈ J. (18)

The solution of the MP (mode selection), along

with the solution of its corresponding binary SP (ac-

tivity scheduling), constitute a complete solution for

the original problem. Consequently, at each iteration

of the GBDA, after solving the MP and obtaining the

values of the x

jm

variables, the two versions of the SP

are solved: the continuous SP is solved in order to ob-

tain the values of the continuous y

jt

variables and the

optimality cut required by the MP for the next itera-

tion; and the binary SP is solved to obtain a solution

for the original problem including the binary values

for the y

jt

variables. The algorithm stops when the

solution of the MP at two consecutive iterations is the

same. Figure 2 shows a flowchart of the proposed

GBDA.

Figure 2: Flowchart of the GBDA.

4 EXPERIMENTATION

In order to assess the performance of the GBDA

for solving the MRCPSP, several computational tests

were performed on a personal computer with an 11th

generation Intel i7 processor, a 2.8 GHz CPU and 32

GB of RAM. The AMPL software with the Gurobi

optimization engine were employed. 50 Benchmark

instances with 30 activities per project, 3 execution

modes per activity, 2 types of renewable resources and

2 types of non-renewable resources, were used. They

were obtained from the PSPLIB library published by

(Kolisch and Sprecher, 1997).

Four different computational tests were carried

out:

• Baseline: Solving the instances with the tradi-

tional linear formulation, using an exact MILP

method directly with Gurobi, establishing a time

limit of 100 minutes. The parameters for the opti-

mization engine to establish the stopping criterion

were set as follows:

option gurobi_options "timelim=6000"

• GBDA-A: Solving the instances with the GBDA

described in section 3, considering a time limit of

100 seconds for each time the binary SP is solved.

The parameters for the optimization engine to es-

tablish the stopping criterion were set as follows:

option gurobi_options "timelim=100"

• GBDA-B: Solving the instances with the GBDA,

considering a time limit of 50 seconds for each

time the binary SP is solved, and adjusting the

Gurobi parameters to report optimality at a rela-

tive gap of 10%. The parameters for the optimiza-

Exploration of a Generalized Benders Decomposition Method for Solving Project Scheduling Problems with Resource Constraints

61

tion engine to establish the stopping criterion were

set as follows:

option gurobi_options "timelim=50

mipgap=0.1"

• GBDA-C: Solving the instances with the GBDA,

considering a time limit of 30 seconds for each

time the binary SP is solved, and adjusting the

Gurobi parameters to report optimality at a rela-

tive gap of 20%. The parameters for the optimiza-

tion engine to establish the stopping criterion were

set as follows:

option gurobi_options "timelim=30

mipgap=0.2"

The purpose of the Baseline method is to establish

a benchmark against which to compare the GBDA.

Since the GBDA solves the problem at each iteration,

as opposed to the baseline method that solves it only

once, a much shorter time limit per solution was de-

fined, in order to obtain reasonable computing times

for the GBDA. A time limit of 100 seconds per solu-

tion was set for test A of the GBDA. Considering the

possibility that the solver could have already reached

an optimal solution without being certain of it and still

spend a considerable amount of time until optimality

is proven, two other test of the GBDA were imple-

mented: test B with a time limit of 50 seconds per

solution and an relative MIP gap of 10%; and test C

with a time limit of 30 seconds per solution and an rel-

ative MIP gap of 20%. The purpose of these different

stopping criteria is to obtain solutions that could be

optimal or sub-optimal with good quality, in a shorter

amount of time.

5 RESULTS AND DISCUSSION

The results of the experiments were measured with

the following variables: OPT SOL, defined as the

percentage of instances for which the optimal solu-

tion was found within the established time limits, in

other words, the ”success rate”; OF DIF, defined as

the average difference between the value of the ob-

jective function from the best solution found by the

GBDA and the one from the best solution found by

the Baseline method, expressed as a percentage; and

TIME DIF, defined as the average difference between

the elapsed computing time needed by the GBDA and

the one needed by the Baseline method to solve each

instance, expressed as a percentage.

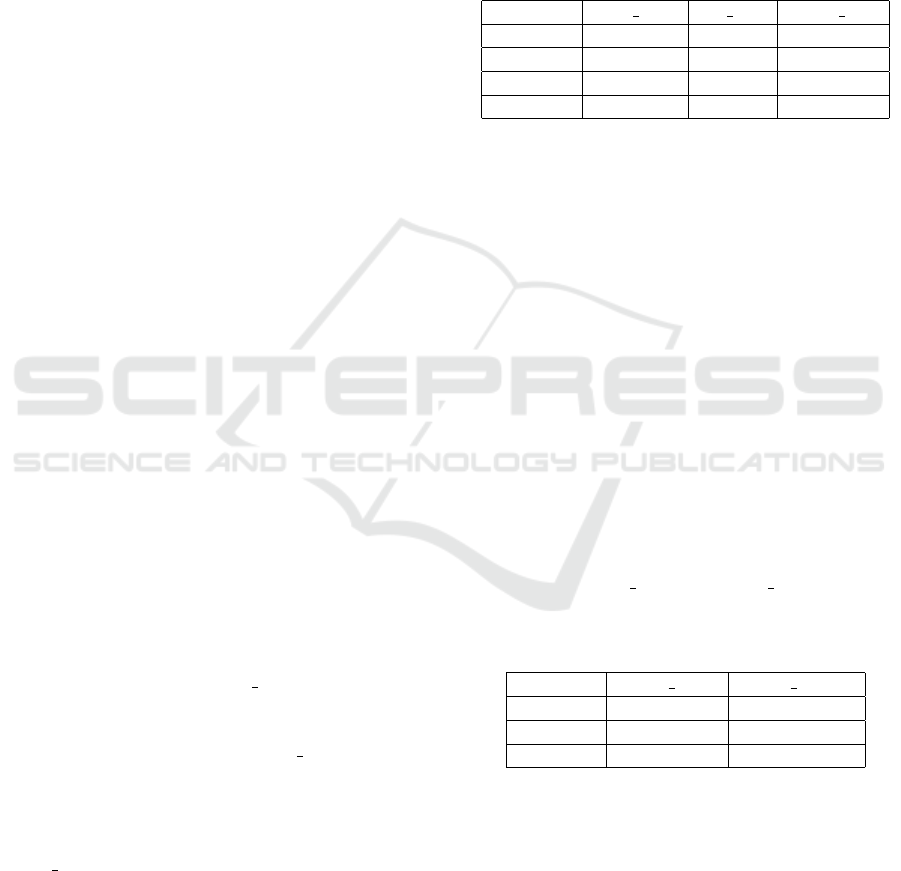

The results showing the performance of each of

the methods are summarized in Table 4, while the

complete results are presented in the appendix. A

clear trade-off was found between the quality of the

solutions found and the computational time taken by

the GBDA in each of the tests. The values of the ob-

jective functions obtained with the GBDA range from

4.96% higher than the Baseline method to 8.96%

higher, while the computational time taken ranges

from 58.74% longer than the Baseline method to

49.22% shorter.

Table 4: Performance of the GBDA.

Method OPT SOL OF DIF TIME DIF

Baseline 94%

GBDA-A 58% 4.96% 58.74%

GBDA-B 58% 5.69% -5.95%

GBDA-C 58% 8.22% -49.22%

The knowledge of this trade-off is valuable for

decision-making. If a good-quality sub-optimal so-

lution is acceptable, and time is limited, the GBDA-

C method could be employed. On the other hand, if

computing time is not a pressing issue and the opti-

mal solution is highly preferred, the Baseline method

is the best option. Table 4 also shows that reducing

the time limit in combination with incrementing the

relative MIP gap has a greater impact on the comput-

ing time (which is reduced considerably) than in the

quality of the solution (which increases only a rela-

tively small amount).

Additionally, to better understand the perfor-

mance of the GBDA, the proportion of the total com-

putational time devoted to the GBD method (i.e. solv-

ing the MP and the continuous SP), and the proportion

of time devoted to solving the binary SP to obtain the

solution of the original problem, were recorded sep-

arately. Their averages were calculated and assigned

the variables TIME GBD and TIME BINSP. The re-

sulting values are shown in Table 5.

Table 5: Proportion of time taken.

Method TIME GBD TIME BINSP

GBDA-A 8.74% 91.26%

GBDA-B 9.11% 90.89%

GBDA-C 18.07% 81.93%

It is clear that solving the binary SP employs most

of the computing time taken by the GBDA, more than

90% in the case of GBDA-A and GBDA-B, and more

than 80% in the case of GBDA-C, on average. While

the GBD portion of the algorithm that deals with the

MP and the continuous (relaxed) SP, is quite fast, once

the relaxation is removed and the y

jt

variables are

considered binary as in the original problem, the SP

requires considerably more computational time to be

solved.

ICORES 2025 - 14th International Conference on Operations Research and Enterprise Systems

62

6 CONCLUSIONS

This research proposed a Generalized Benders

Decomposition-based Algorithm (GBDA) to solve

the Multi-Mode Resource-Constrained Project

Scheduling Problem (MRCPSP). The algorithm

divides the problem into a Master Problem (MP)

and a relaxed (continuous) Sub-problem (SP) which

are alternately solved, with the SP taking values

from the solution of the MP, and with optimality

cuts derived from the solution of the continuous SP

being incorporated to the MP. This process iterates

until convergence is met, resulting in an optimal

solution for the relaxed problem. Additionally, at

each iteration, a non-relaxed (binary) SP is solved to

arrive at a solution of the original problem, finally

reporting the best one across all iterations.

The GBDA, with three different stopping criteria,

was tested and compared against a Baseline method,

which solves the traditional MILP formulation with

the Gurobi optimization engine. The results showed a

trade-off between computing time and solution qual-

ity. With one of the tested stopping criteria, the

GBDA took on average a little less than half the

time taken by the baseline method, and provided so-

lutions with an objective function value on average

8.22% above the one obtained by the baseline method.

This is useful in the cases when arriving to a solution

sooner has a higher priority than finding the optimal

solution.

The main contributions of this research rely on the

formulation of the GBDA as a new method to solve

the MRCPSP. Besides being able to provide good-

quality solutions in considerably less time than the

traditional exact method, which is itself a useful con-

tribution, the analysis of the proposed algorithm and

its results provide important insights, valuable spe-

cially for future exploration. One of these insights is

that most of the time taken by the algorithm is spent

on solving the Binary SP. Future research could, thus,

focus on exploring other decomposition variants or

hybrid methods to improve the efficiency of solving

the binary SP; or on using the relaxed GBD part of

the algorithm, which proved to be very fast, as part of

another algorithm or as some sort of pre-processing

technique.

Another important finding is that increasing the

optimality gap in Gurobi, had a much greater effect

on the computational time than on the solution qual-

ity, which presents as well interesting opportunities

for future exploration, for example by testing differ-

ent combinations of time limits and MIP optimality

gaps. The proposed algorithm could also be extended

or modified to be used for similar problems or its

variants, for example stochastic versions of the MR-

CPSP, multi-project scheduling, or other variants of

the RCPSP.

ACKNOWLEDGEMENTS

This research was funded by Universidad Panameri-

cana. Grant number UP-CI-2024-GDL-08-ING.

REFERENCES

Afshar, M. R., Shahhosseini, V., and Sebt, M. H. (2022). A

genetic algorithm with a new local search method for

solving the multimode resource-constrained project

scheduling problem. International Journal of Con-

struction Management, 22:357–365.

Balouka, N. and Cohen, I. (2021). A robust optimization

approach for the multi-mode resource-constrained

project scheduling problem. European Journal of Op-

erational Research, 291:457–470.

Bayram, V. and Yaman, H. (2018). Shelter location and

evacuation route assignment under uncertainty: A

benders decomposition approach. Transportation sci-

ence, 52:416–436.

Benders, J. F. (1962). Partitioning procedures for solving

mixed-variables programming problems. Numerische

mathematik, 4(1):238–252.

Blazewicz, J., Lenstra, J. K., and Kan, A. H. (1983).

Scheduling subject to resource constraints: classifica-

tion and complexity. Discrete Applied Mathematics,

5(1):11–24.

Bold, M. and Goerigk, M. (2022). A faster exact method for

solving the robust multi-mode resource-constrained

project scheduling problem. Operations Research

Letters, 50:581–587.

Bruni, M., Khodaparasti, S., and Moshref-Javadi, M.

(2022). A logic-based benders decomposition

method for the multi-trip traveling repairman prob-

lem with drones. Computers & Operations Research,

145:105845.

Bruni, M. E., Pugliese, L. D. P., Beraldi, P., and Guerriero,

F. (2017). An adjustable robust optimization model

for the resource-constrained project scheduling prob-

lem with uncertain activity durations. Omega (United

Kingdom), 71:66–84.

Chakrabortty, R. K., Abbasi, A., and Ryan, M. J. (2019).

Multi-mode resource-constrained project scheduling

using modified variable neighborhood search heuris-

tic. International Transactions in Operational Re-

search, 0:1–30.

de la Pisa, M. P., Molina, J. C., and Egu

´

ıa, I. (2024).

Ant colony algorithms for minimizing costs in multi-

mode resource constrained project scheduling prob-

lems with spatial constraints. International Journal

of Industrial Engineering Computations, 15:667–684.

Exploration of a Generalized Benders Decomposition Method for Solving Project Scheduling Problems with Resource Constraints

63

Dike, S. H. (1964). Project scheduling with resource con-

straints. IEEE Transactions on Engineering Manage-

ment, EM-11(4):155–157.

Ding, H., Zhuang, C., and Liu, J. (2023). Extensions of

the resource-constrained project scheduling problem.

Automation in Construction, 153.

Duran-Mateluna, C., Ales, Z., and Elloumi, S. (2023).

An efficient benders decomposition for the p-median

problem. European journal of operational research,

308:84–96.

Elmaghraby, S. E. (1977). Activity networks: Project plan-

ning and control by network models. John Wiley &

Sons.

Fachini, R. F. and Armentano, V. A. (2020). Logic-based

benders decomposition for the heterogeneous fixed

fleet vehicle routing problem with time windows.

Computers & Industrial Engineering, 148:106641.

Geoffrion, A. M. (1972). Generalized benders decomposi-

tion. Journal of optimization theory and applications,

10:237–260.

Kolisch, R. and Sprecher, A. (1997). PSPLIB - A project

scheduling problem library. European Journal of Op-

erational Research, 96(1):205–216.

Kyriakidis, T. S., Kopanos, G. M., and Georgiadis, M. C.

(2012). MILP formulations for single- and multi-

mode resource-constrained project scheduling prob-

lems. Computers and Chemical Engineering,

36(1):369–385.

Li, H. and Zhang, H. (2013). Ant colony optimization-based

multi-mode scheduling under renewable and nonre-

newable resource constraints. Automation in Con-

struction, 35:431–438.

Li, R., Wang, L., Tao, X., Song, M., and Han, Z. (2019).

Generalized benders decomposition to secure energy-

efficient resource allocation for multiuser full-duplex

relay cooperative networks. IEEE transactions on ve-

hicular technology, 68:10728–10741.

Lova, A., Tormos, P., Cervantes, M., and Barber, F. (2009).

An efficient hybrid genetic algorithm for scheduling

projects with resource constraints and multiple exe-

cution modes. International Journal of Production

Economics, 117(2):302–316.

Machado-Dom

´

ınguez, L. F., Paternina-Arboleda, C. D.,

V

´

elez, J. I., and Barrios-Sarmiento, A. (2021).

A memetic algorithm to address the multi-node

resource-constrained project scheduling problem.

Journal of Scheduling, 24:413–429.

Maniezzo, V. and Mingozzi, A. (1999). A Heuristic Proce-

dure for The Multi-Mode Project Scheduling Problem

Based On Benders’ Decomposition, pages 179–196.

Springer Science+Business Media.

Muritiba, A. E. F., Rodrigues, C. D., and da Costa, F. A.

(2018). A Path-Relinking algorithm for the multi-

mode resource-constrained project scheduling prob-

lem. Computers & Operations Research, 92:145–

154.

Ramos, A. S., Miranda-Gonzalez, P. A., Olivares-Benitez,

E., and Mendoza, A. (2024). Generalized ben-

ders decomposition-based matheuristics for the multi-

mode resource-constrained project scheduling prob-

lem [manuscript submitted for publication]. Opti-

mization and Engineering.

Ramos, A. S., Olivares-Benitez, E., and Miranda-Gonzalez,

P. A. (2022). Multi-start iterated local search meta-

heuristic for the multi-mode resource-constrained

project scheduling problem. Expert Systems, 39:1–

23.

Sadeghloo, M., Emami, S., and Divsalar, A. (2023). A

benders decomposition algorithm for the multi-mode

resource-constrained multi-project scheduling prob-

lem with uncertainty. Annals of Operations Research.

Sebt, M. H., Afshar, M. R., and Alipouri, Y. (2015).

An efficient genetic algorithm for solving the multi-

mode resource-constrained project scheduling prob-

lem based on random key representation. Inter-

national Journal of Supply and Operations Manage-

ment.

Shams-Shoaaee, S. S. and Hassini, E. (2020). Price opti-

mization with reference price effects: A generalized

benders’ decomposition method and a myopic heuris-

tic approach. European journal of operational re-

search, 280:555–567.

Shokoohyar, S. and Amiri, J. (2021). Developing a multi-

mode doubly resource constrained project scheduling

problem using meta-heuristic approaches. Interna-

tional Journal of Project Organisation and Manage-

ment, 13(1):31 – 59.

Sikora, C. G. S. and Weckenborg, C. (2023). Balancing

of assembly lines with collaborative robots: compar-

ing approaches of the benders’ decomposition algo-

rithm. International journal of production research,

61:5117–5133.

Sprecher, A. and Drexl, A. (1998). Multi-mode resource-

constrained project scheduling by a simple, general

and powerful sequencing algorithm. European Jour-

nal of Operational Research, 107(2):431–450.

Sprecher, A., Hartmann, S., and Drexl, A. (1997). An exact

algorithm for project scheduling with multiple modes.

Operations-Research-Spektrum, 19(3):195–203.

Talbot, F. B. (1982). Resource-Constrained Project

Scheduling with Time-Resource Tradeoffs: The

Nonpreemptive Case. Management Science,

28(10):1197–1210.

Tapia-Ubeda, F. J., Miranda, P. A., and Macchi, M. (2018).

A generalized benders decomposition based algorithm

for an inventory location problem with stochastic in-

ventory capacity constraints. European Journal of

Operational Research, 267(3):806–817.

Tapia-Ubeda, F. J., Miranda-Gonzalez, P. A., and Guti

´

errez-

Jarpa, G. (2024). Integrating supplier selection deci-

sions into an inventory location problem for designing

the supply chain network. Journal of Combinatorial

Optimization, 47(2):2.

Van Peteghem, V. and Vanhoucke, M. (2014). An experi-

mental investigation of metaheuristics for the multi-

mode resource-constrained project scheduling prob-

lem on new dataset instances. European Journal of

Operational Research, 235(1):62–72.

Yaghin, R. G. and Goh, M. (2021). Procurement, produc-

tion, and price planning under visibility and risk: a

ICORES 2025 - 14th International Conference on Operations Research and Enterprise Systems

64

generalised benders decomposition method. Interna-

tional journal of production research, 59:5626–5646.

Zamani, R. (2019). An effective mirror-based genetic

algorithm for scheduling multi-mode resource con-

strained projects. Computers & Industrial Engineer-

ing, 127:914–924.

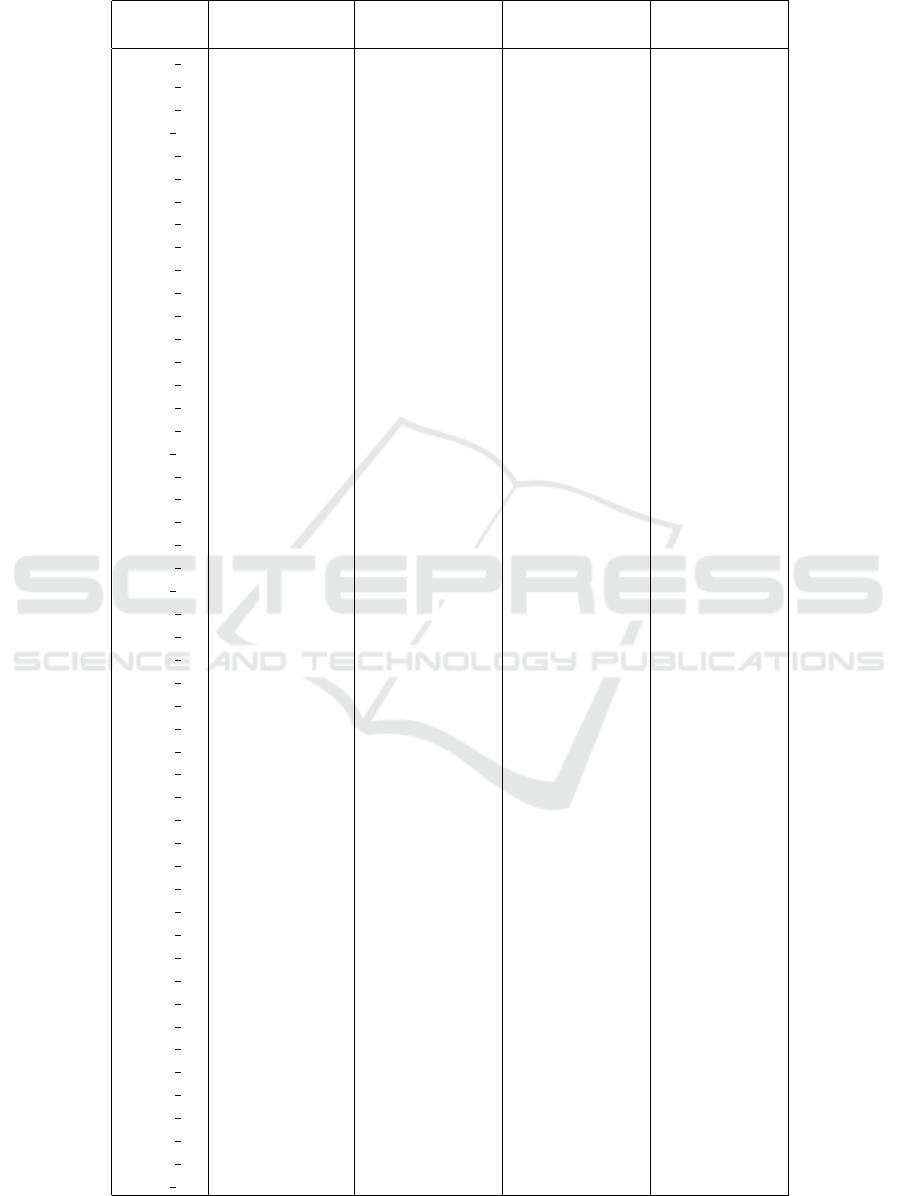

APPENDIX

Table 6 shows the complete results of the computa-

tional implementation for the 50 benchmark instances

with the 4 methods.

The benchmark instances used for this re-

search are publicly available at https://www.om-

db.wi.tum.de/psplib/data.html.

Exploration of a Generalized Benders Decomposition Method for Solving Project Scheduling Problems with Resource Constraints

65

Table 6: Results. a: Objective Function Value; b: Computational time (seconds).

Baseline GBDA-A GBDA-B GBDA-C

Instance OF

a

Time

b

OF TIME OF TIME OF TIME

j3010 3 24 6.047 25 7.234 25 6.797 25 2.859

j3012 7 27 6.469 27 1.719 27 1.75 27 0.766

j3012 9 22 5.484 22 2.203 22 2.203 22 1.359

j3013 10 43 6000 49 4546.453 49 652.733 51 146.109

j3015 5 24 18.547 27 53.765 28 19.547 31 8.984

j3016 1 27 9.297 27 2.506 27 2.578 27 1.219

j3016 2 41 7.891 41 4.578 41 4.531 41 2.031

j3016 5 30 7.922 31 9.89 32 9.234 32 1.906

j3016 9 24 7.797 24 5.703 24 5.797 24 2.875

j3018 6 25 2.125 25 2.75 25 2.906 25 1.57

j3019 1 35 5.406 35 4.578 35 4.374 35 1.781

j3020 4 35 2.125 35 1.672 35 1.812 35 0.89

j3020 7 30 2.562 30 4 30 4.156 30 1.969

j3021 4 37 879.781 43 4025.594 44 224.297 45 44.937

j3021 5 37 6000 44 4443.797 44 1268.557 45 270.484

j3022 5 30 153.094 34 2339.563 36 45.86 39 35.844

j3022 9 34 11.484 34 13.203 34 10.859 34 5.344

j3023 10 21 7.703 21 8.578 21 7.312 21 3.968

j3025 1 34 5.547 38 14.016 38 11.031 39 1.028

j3025 8 33 5.875 39 23.969 39 17.688 43 7.284

j3026 2 22 2.328 27 8.375 27 7.828 29 3.297

j3026 5 22 4 22 3.078 22 2.75 22 1.453

j3027 3 28 1.75 28 1.749 28 1.546 28 0.843

j3027 10 29 1.625 29 1.735 29 1.781 29 1.062

j3028 1 37 3.688 37 1.641 37 1.547 37 0.875

j3028 5 23 3.609 23 1.031 23 1.172 23 0.609

j3031 1 25 4.125 28 10.359 29 7.312 30 5.14

j3031 2 43 5.828 43 4.03 43 3.687 43 2.109

j3032 8 29 2.578 29 3.125 29 3.172 29 1.375

j3039 2 42 81.656 43 14.734 43 11.328 43 5.422

j3039 4 49 58.469 51 7.64 51 6.296 62 3.202

j3040 9 43 14.688 43 4.406 43 4.25 43 2

j3041 7 39 203.312 43 50.437 46 31.938 43 21.234

j3043 7 33 4.078 33 3.922 33 3.703 33 2

j3044 3 34 11 34 2.875 34 2.672 34 1.5

j3045 6 47 6000 51 5579.797 50 1148.015 53 176.562

j3047 4 38 28.9 41 17.484 41 14.265 45 6.593

j3047 5 26 21.781 28 10.046 29 9.499 29 4.499

j3048 1 28 10.188 28 8.906 28 8.843 28 4.093

j3049 4 37 14.5 44 30.625 45 19.953 48 9.265

j3050 8 27 8.328 29 12.125 29 10.765 29 5.609

j3051 3 27 5.469 27 3.344 27 3.609 27 1.891

j3051 4 51 5.656 51 1.624 51 1.672 51 0.812

j3055 7 44 8.125 44 3.203 44 3.109 44 2.531

j3056 9 33 6.813 33 11.016 33 9.781 33 3.328

j3057 7 27 4.578 33 39.375 34 21.625 41 13.031

j3057 9 26 11.203 29 30.187 29 21.109 29 7.03

j3060 1 22 1.797 22 1.843 22 1.765 22 6.968

j3063 2 30 3.844 30 3.718 30 3.604 30 1.812

j3064 10 36 4.89 36 3.734 36 3.828 36 1.515

ICORES 2025 - 14th International Conference on Operations Research and Enterprise Systems

66