Heat Transfer in Laparoscopic Trocar System: Analytical and

Numerical Study

Mohammad Al Amin Al Tahhan

1

, Wassim Salameh

2

, Ali Shaito

1

, Ali Cherry

3

, Soumaya Berro

4

and Mohamad Hajj-Hassan

4

1

Department of Mechanical Engineering, Lebanese International University, Bekaa, Lebanon

2

Department of Mechanical Engineering, The International University of Beirut, Beirut, Lebanon

3

Department of Biomedical Engineering, The International University of Beirut, Beirut, Lebanon

4

Department of Biomedical Engineering, Lebanese International University, Bekaa, Lebanon

Keywords: Laparoscopy, Trocar, Fluid Flow, Heat Transfer.

Abstract: In laparoscopic surgeries, CO

2

insufflation through a trocar system is required to fill the abdominal or pelvic

cavity and provide a working space for the surgeon. The problem arises from the heat loss from the CO

2

gas

to the surroundings of the trocar since it results in a temperature difference between the entering CO

2

and the

temperature of the patient’s body, which results in fog formation on the camera lens, blocking the surgeon’s

vision. This heat loss occurs by convection between the flowing fluid inside and outside the trocar and by

conduction through the trocar’s cannula. The primary objective of this research is to investigate the heat loss

of CO

2

through the trocar cannula for different materials. These materials should meet specific requirements

in order to be used in such surgery. The requirements are biocompatibility, transparency, eco-friendliness,

and solid state. The selected materials are PET, PVDF, PEI, PEEK, and PC. Heat transfer and finite element

analysis case studies were investigated to observe internal fluid flow behavior for velocity profile and

temperature distribution. Then, a model was created and simulated on ANSYS workbench using proper

boundary conditions that match real-life conditions. Comparative studies were done using ANSYS for the

velocity profile, mean temperature distribution, axial temperature distribution, and radial temperature

distribution of CO

2

. The simulated results showed that PVDF was the best material to be used in the

composition of the trocar’s cannula since it resisted the most heat transfer, followed by PC, PET, PEEK, and

PEI, respectively.

1 INTRODUCTION

Laparoscopic surgery, known as keyhole surgery, is

an exploratory surgery that allows the surgeon to

explore and examine the abdominal and/or pelvic

cavities through a simple mechanism performed by

creating a small incision near the belly button or

pelvic bone and inserting a narrow surgical tube

called a trocar through this incision. A trocar is a

specialized medical equipment that acts as a port for

different uses, such as the insertion of surgical

instruments and carbon dioxide (CO

2

) insufflation.

The carbon dioxide insufflation is done by inserting a

gas tube into the trocar to fill the patient’s abdominal

or pelvic cavity with CO

2

gas in order to separate the

abdominal wall from other organs for clearance and

more visibility of the examined area on the video

monitor (Cleveland, 2024).

During CO

2

insufflation operation, heat loss

occurs from the CO

2

passing through the trocar into

the patient’s body by conduction and convection due

to the temperature difference between the CO

2

flowing in the trocar, which has the same temperature

as the abdominal cavity initially, and the operation

room’s low temperature. This heat loss creates a

difference in temperature between the CO

2

entering

the body and the body’s temperature, which leads to

condensation on the camera lens that separates them.

The condensation will result in water vapor formation

on the camera lens, which will fog the surgeon’s view

during the surgery.

Here, the trocar is modeled as a pipe with an

internal fluid flow. This assumption was made for

comparison with a numerical and experimental heat

transfer study conducted on an internal laminar fluid

flow to observe the velocity magnitude with respect

132

Al Tahhan, M. A., Salameh, W., Shaito, A., Cherry, A., Berro, S. and Hajj-Hassan, M.

Heat Transfer in Laparoscopic Trocar System: Analytical and Numerical Study.

DOI: 10.5220/0013132900003911

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 18th International Joint Conference on Biomedical Engineer ing Systems and Technologies (BIOSTEC 2025) - Volume 1, pages 132-138

ISBN: 978-989-758-731-3; ISSN: 2184-4305

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

to the tube diameter (Al‐Obaidi, 2021). It was

observed that the velocity profile resulted in a

parabolic shape. A study was done on a pipe with

internal turbulent water flow exposed to a constant

wall temperature of 500 K, 750 K, and 1000 K (Al-

Zaharnah, 2004). It was observed that the

dimensionless temperature increases when the

studied point is farther away from the center, closer

to the inner radius, and toward the end of the pipe.

This increase in the dimensionless temperature means

that the fluid’s temperature is increasing. Another

study on ANSYS and MATLAB shed light on the

heat loss in a pipeline with multiple insulation layers

with an internal turbulent fluid flow (Patil, 2016). The

pipe layers consisted of glass wool, aluminium foil,

and steel with different thicknesses. It was observed

that the initial temperature of the steam flowing inside

the pipe, at 0 m in length, was 503 K. Then, it

decreased gradually throughout the pipe’s length to

reach a temperature of 423 K. A study on a vertical

hollow cylinder having specific dimensions was done

on ANSYS (Chandrakar, 2021). The cylinder having

an internal fluid flow and exposed to high and low

temperatures was studied. At lower temperatures, 350

K and 400 K, the convection and radiation heat

transfer rates increased similarly. At higher

temperatures, 450 K to 550 K, the increase in heat

transfer rate by radiation was higher than that by

convection. A heat transfer study using the

orthogonal collocation method was done on a circular

tube with laminar and fully developed internal fluid

flow, exposed to a constant wall temperature

(Belhocine, 2016). The dimensionless temperature

decreases exponentially when the fluid moves

towards the end of the tube, which means that the

temperature of the fluid is getting higher and is thus

getting closer to the high wall temperature.

The material of the trocar’s cannula must be

precisely selected to meet the proper material

requirements which are: biocompatibility,

transparency, eco-friendliness, and solid state. The

material should also be able to have minimal heat

transfer; it should act as an insulation material.

Multiple materials will be selected while adhering to

these requirements in order to reduce heat loss in the

trocar's cannula during the CO

2

insufflation

operation, which will reduce the condensation

occurring on the camera lens. A simulation on

ANSYS workbench will be conducted to compare the

heat loss through the trocar using different materials

in the cannula composition under real-life conditions.

The trocar is modeled as a tube with an inner and

outer diameter. The CO

2

fluid will flow through the

inner diameter, and the tube will be exposed to

ambient air flow with a low temperature at the outer

diameter. The outcome of the numerical study will

determine the temperature distribution that will be

observed along the trocar.

An ANSYS simulation for the velocity profile

will take place, and then it will be validated using

theoretical equations and a previous published case

study. After that, the mean, axial, and radial

temperature distributions will be simulated in order to

find the best trocar material to resist heat transfer.

2 METHODOLOGY

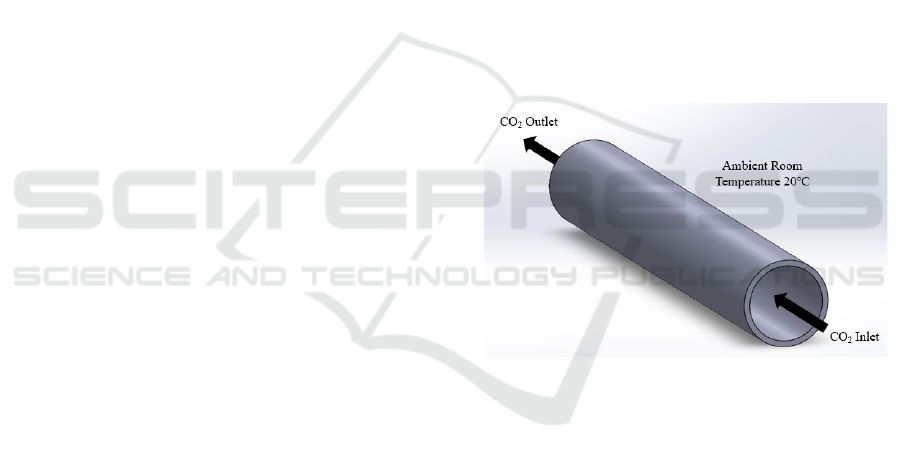

The trocar is modeled based on the characteristics of

the commercial trocar system from XNY Medical, a

manufacturer and distributor of minimal invasive

surgery (MIS) medical devices, China. The trocar is

considered to be a hollow tube with an internal CO

2

fluid flow and a surrounding ambient operating room

temperature of 20

o

C causing natural convection, as

shown in Figure 1.

Figure 1: Trocar Model.

2.1 Material Selection

In the medical field, it is important to abide by the

specific material requirements, which are, in this

case, biocompatibility, transparency, eco-

friendliness, and solid state. By definition,

biocompatible materials are polymers, metals, and

ceramics that don’t produce an immune or toxic

response within the human body. It is vital for the

trocar to use a biocompatible material since it protects

the patient from adverse reactions such as infection,

toxicity, or an allergic response when it’s inserted into

the body. Another material requirement to take into

consideration is the trocar’s optical transparency,

since it helps the surgeon visualize the tissue layers

before the trocar’s insertion in order to prevent organ

injury (Tanaka, 2019). Finally, it’s important for

Heat Transfer in Laparoscopic Trocar System: Analytical and Numerical Study

133

trocars to have a solid state and to be composed of

eco-friendly material.

The common trocar’s materials that meet these

requirements are PolyEthylene Terephthalate (PET),

PolyVinyliDene Fluoride (PVDF), PolyCarbonate

(PC), Poly-EtherImide (PEI), and Polyether Ether

Ketone (PEEK).

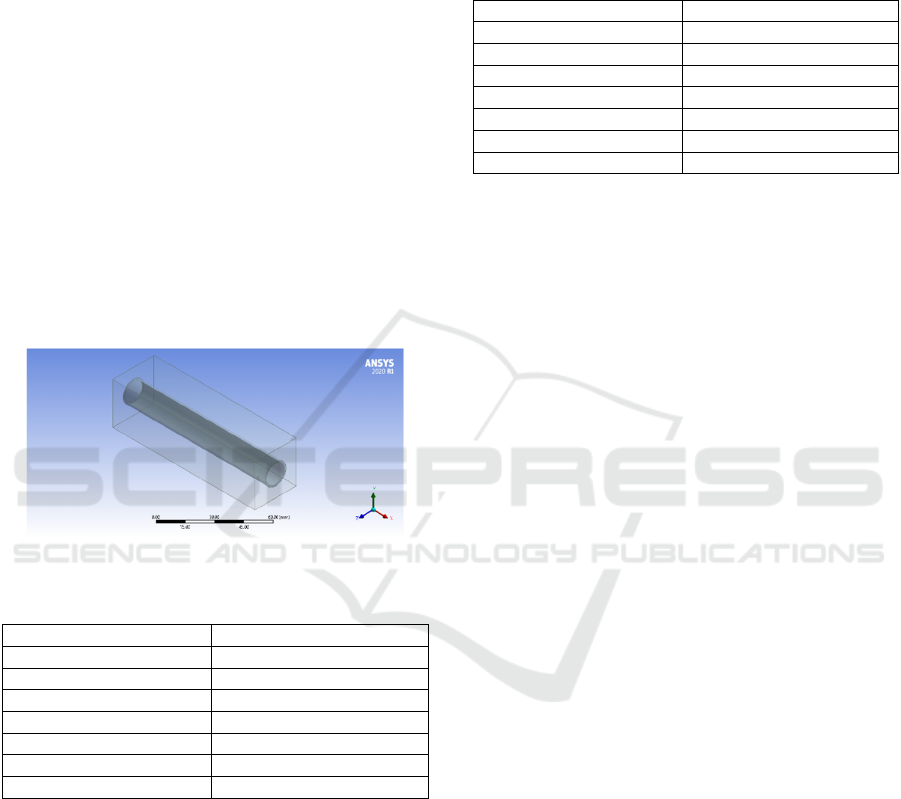

2.2 Numerical Model

The trocar is modeled as a hollow tube, as shown in

Figure 2, that has the geometry shown in Table 1. This

tube has a solid state and its properties were set

according to the materials tested. The CO

2

fluid

passing through the trocar was modeled as a cylinder.

This cylinder has a fluid state to represent the CO

2

and the suitable properties of CO

2

were inserted.

When it comes to the ambient air surrounding the

trocar, a rectangular box was modeled as fluid to

represent the air flowing in the room, causing natural

convection.

Figure 2: Trocar Model in ANSYS.

Table 1: Dimensions of the model components.

Parameter Value

Tube Length 103 mm

Inlet Diamete

r

13 mm

Outlet Diamete

r

15 mm

Tube Thickness 1 mm

Box Length 30 mm

Box Width 103 mm

Box Height 30 mm

In the trocar model simulation, the boundary

conditions are set to match the operating room

conditions, where the CO

2

insufflation operation

takes place. The CO

2

entering the trocar has an initial

temperature and a volumetric flow rate which are

shown in Table 2. On the other hand, the ambient air

surrounding the trocar has a temperature and a

velocity magnitude, which create a constant heat flux

on the surface of the trocar. A box was created to

represent the ambient air surrounding the trocar. The

constant heat transfer coefficient of the CO

2

is

calculated and set on the surface of the inner diameter

of the trocar. In addition, the heat transfer coefficient

of air is assumed, according to the range of typical

values of free convection gases, and set on the surface

of the outer diameter of the tube (Incropera, 1996).

Table 2: Simulation conditions.

Parameter Value

Tube Length 103 mm

Inlet Diamete

r

13 mm

Outlet Diamete

r

15 mm

Tube Thickness 1 mm

Box Len

g

th 30 mm

Box Width 103 mm

Box Height 30 mm

2.3 Velocity Profile

The internal volumetric flow rate of CO

2

in this study

during the CO

2

insufflation operation is assumed to

be in the range of 0.1 to 3 L/min. First, the mesh

sensitivity will be studied. Second, the velocity

profile will be simulated on ANSYS, and then the

theoretical equations will be gathered. After that, a

comparative study will take place between the results

of the simulation, theoretical, and a previous case

study in order to validate the ANSYS model.

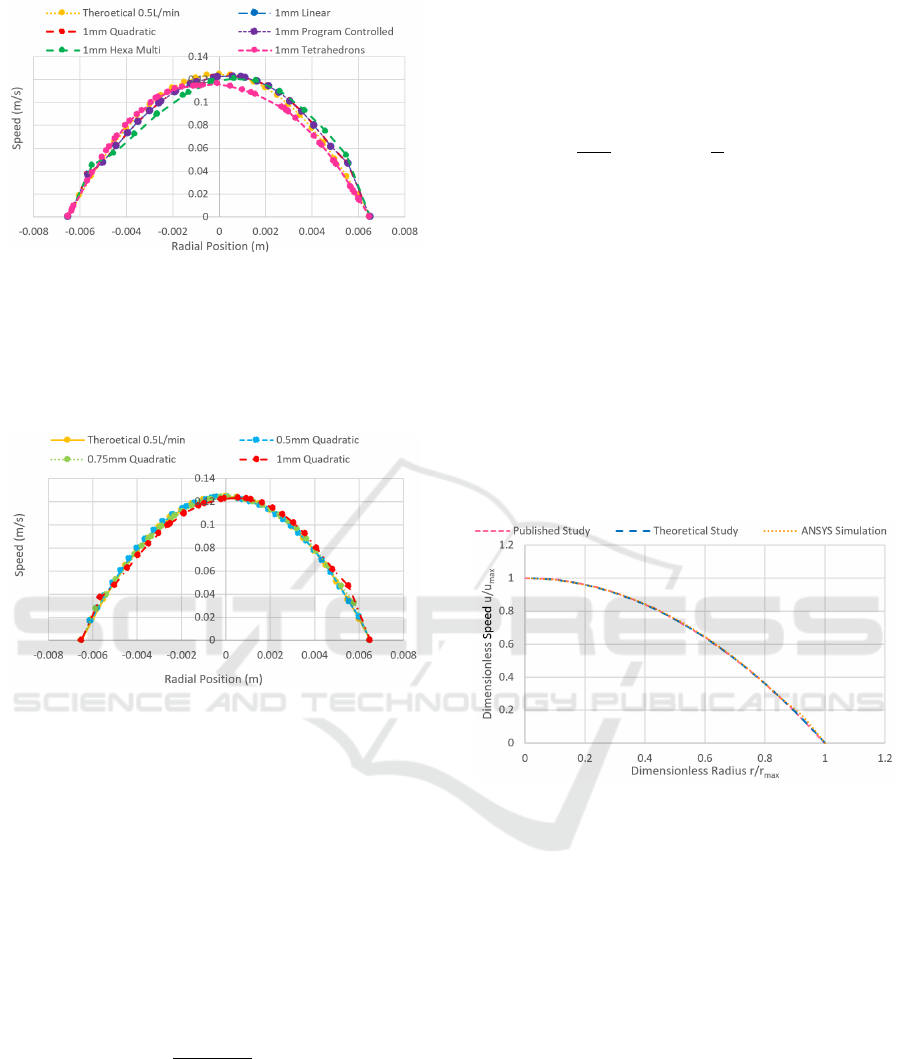

2.3.1 Model Mesh Sensitivity

Meshing has an important role in modeling and

simulation since it is a method of breaking down the

model into elements by generating grids. Meshing is

used to discretize and analyze the simulation. The

mesh types that are used in the ANSYS simulation are

the linear, quadratic, program-controlled, tetrahedral,

and hexa core types. A comparative study of the

velocity profile between the theoretical and the

simulation at 0.5 L/min internal flow using different

types of mesh at 1 mm mesh size will indicate the

most accurate mesh type. Figure 3 represents the

variation of speed with respect to the radial position.

The velocity profile for the internal CO

2

fluid flow

is shown to have a parabolic shape. It was observed

from the results above that the quadratic and the

program-controlled mesh types had the closest peak

speeds and parabolic shapes to the theoretical results,

which makes them the most accurate types of mesh.

The mesh element size indicates the accuracy of

the results and the number of meshes required for the

model to be divided into, which means that a smaller

element size will give more accurate results (Dutt,

2015). A comparative study of the velocity profile

between the theoretical and the simulation at 0.5

L/min internal flow using quadratic mesh having

BIODEVICES 2025 - 18th International Conference on Biomedical Electronics and Devices

134

Figure 3: Variation of the speed for different mesh types

with respect to the radial position.

different element sizes of 0.5, 0.75, and 1 mm, will

indicate the most accurate element size. Figure 4

represents the variation of speed with respect to the

radial position.

Figure 4: Variation of the speed for different mesh element

sizes with respect to the radial position.

According to the results above, the 0.5 mm

element size was the most accurate since it was the

closest to the theoretical peak speed and the nearest

to the theoretical parabolic shape. Therefore, the 0.5

mm quadratic mesh will be used for further

simulations since it has the highest mesh sensitivity.

2.3.2 Analytical Model

To indicate the type of internal flow, Reynolds

number will be studied at different volumetric flow

rates. The Reynolds number is expressed as:

𝑅𝑒 =

𝜌×𝑢×𝑑

𝜇

(1)

Where Re is Reynolds number (unitless), ρ is the

fluid's density (kg/m

3

), u is the fluid's speed with

respect to the cylinder (m/s), d

i

is the cylinder's inner

diameter (m), and μ is the fluid's dynamic viscosity

(kg/m.s) (Incropera, 1996).

Using Equation 1, Reynolds number has a range

of 18.879 to 566.38 over the volumetric flow rate

range, which means that the internal CO

2

fluid flow

is laminar since Reynolds number is less than 2300

(Incropera, 1996).

The equation of the dimensionless velocity profile

of a laminar flow in a cylinder is represented by:

𝑢(𝑟)

𝑢

=2×1−(

𝑟

𝑟

)

(2)

Where u

m

is the mean speed of the fluid (m/s), r is

the radius of the studied location (m), and r

i

is the

inner radius of the cylinder (m).

To validate the ANSYS model, a comparative

study will take place between the simulated results,

theoretical results, and a previous published case

study for the velocity profile. A previous published

paper studied internal water flow in a pipe having a

0.5 m inner radius, a 1 m pipe length, and a maximum

speed of 0.7 m/s (Najmi, 2017). After plotting the

dimensionless speed with respect to the

dimensionless radius for each one, as shown in Figure

5, it was observed that they had similar curves, which

validates the ANSYS model.

Figure 5: Dimensionless speed with respect to

dimensionless radius for different studies.

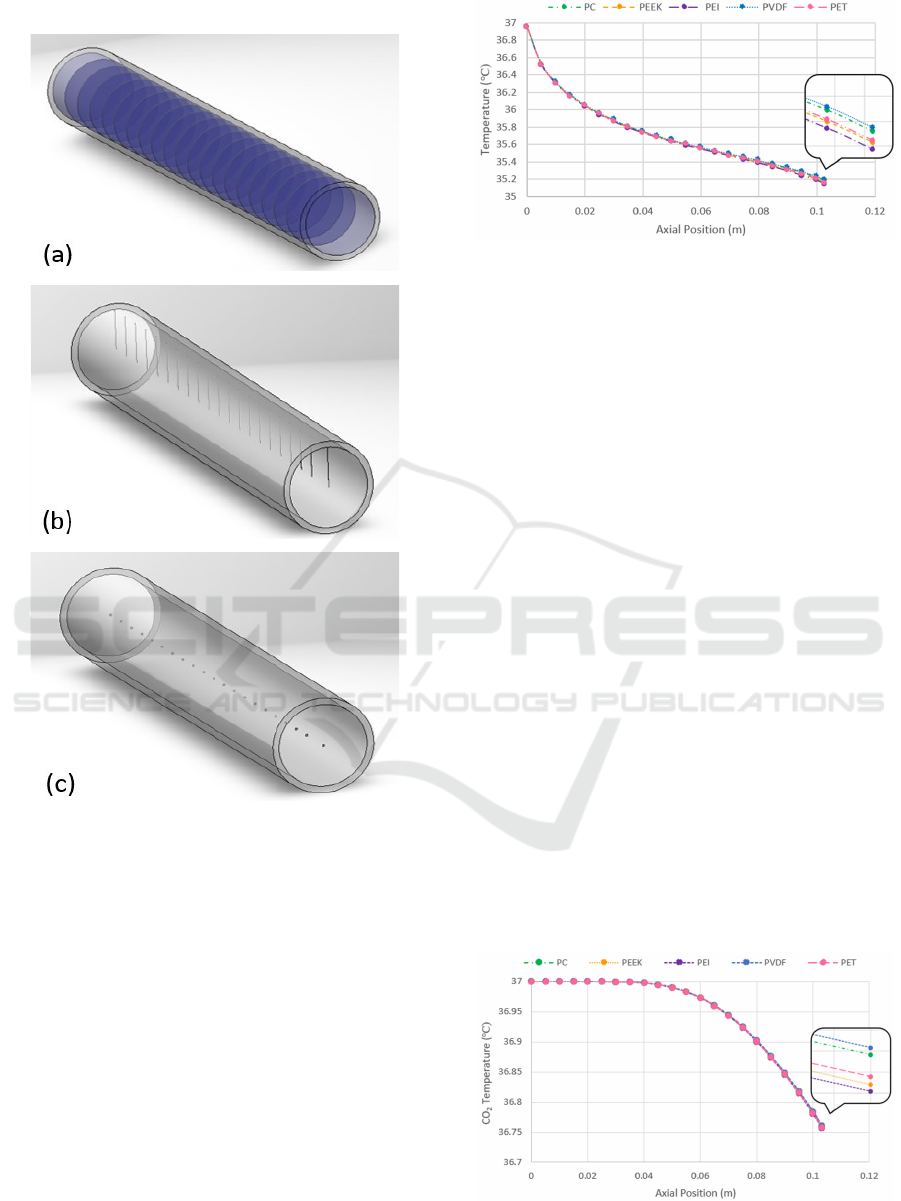

2.4 Heat Transfer

During CO

2

insufflation operation, heat transfer in the

trocar takes place by convection (both externally and

internally) and conduction. The external convention

occurs between the trocar surface and the air inside

the room, while the internal convection occurs

between the moving CO

2

gas inside the trocar and its

walls. The conduction occurs through the thickness of

the trocar’s cannula. To compare the materials used

in the trocar’s composition, a thermal comparative

study will be done on ANSYS using different trocar

materials. The boundary conditions were properly set

in ANSYS Fluent, as previously stated. The material

of the tube was assigned separately to be PET, PVDF,

PC, PEI, and PEEK, along with their properties. The

mean, axial, and radial CO

2

temperature distributions

Heat Transfer in Laparoscopic Trocar System: Analytical and Numerical Study

135

were simulated on ANSYS as shown in Figure 6.

Figure 6: (a) Mean Temperature Distribution Simulation,

(b) Axial Temperature Distribution Simulation, (c) Radial

Temperature Distribution Simulation.

3 RESULTS

3.1 Mean Temperature Distribution

After simulating the ANSYS model, the results of the

mean temperature were obtained along the axial

position with an increment of 5 mm, as shown in

Figure 7.

To analyze Figure 7, all the mean temperature

curves using different materials started at 37 ℃ at the

inlet of the tube. Then, they reached different values

at the end of the tube, at 0.103 m, using different

materials. It was observed from the results that the

material that most resisted heat transfer was PVDF,

Figure 7: The mean temperature distribution of CO

2

at the

axial position using different materials.

which has the lowest thermal conductivity of 0.185

W/m.K. PVDF showed the highest CO

2

mean

temperature of 35.188 ℃, which is the closest to the

CO

2

initial inlet temperature, 37 ℃. PC showed a

lower mean temperature of CO

2

than PVDF followed

by PET and PEEK, respectively. Finally, the least

material that resisted heat transfer was PEI, which has

the highest thermal conductivity of 0.328 W/m.K.

PEI had the lowest mean temperature of 35.143 ℃,

which is the farthest away from the CO

2

initial inlet

temperature.

3.2 Axial Temperature Distribution

After simulating the ANSYS model, the results of the

axial temperature were obtained along the axial

position, as shown in Figure 8. The temperature of the

internal CO

2

fluid started at 37 ℃ and then started to

decrease along the trocar’s length to reach different

values at the end of the trocar using different trocar

materials. It was observed that the trocar material that

resisted CO

2

heat loss the most along the length of the

trocar was PVDF. This is because it has the lowest

thermal conductivity of 0.185 W/m.K and the CO

2

temperature decreased the least from 37 ℃ at the

beginning of the trocar to 36.76132 ℃ at the end of

the trocar. PC resulted in a lower axial temperature of

Figure 8: Distribution of CO

2

along the axial position using

different materials.

BIODEVICES 2025 - 18th International Conference on Biomedical Electronics and Devices

136

CO

2

followed by PET and PEEK, respectively.

Finally, the least material that resisted heat transfer

was PEI, which has the highest thermal conductivity

of 0.328 W/m.K and resulted in the lowest axial

temperature, which is the farthest from the CO

2

initial

inlet temperature.

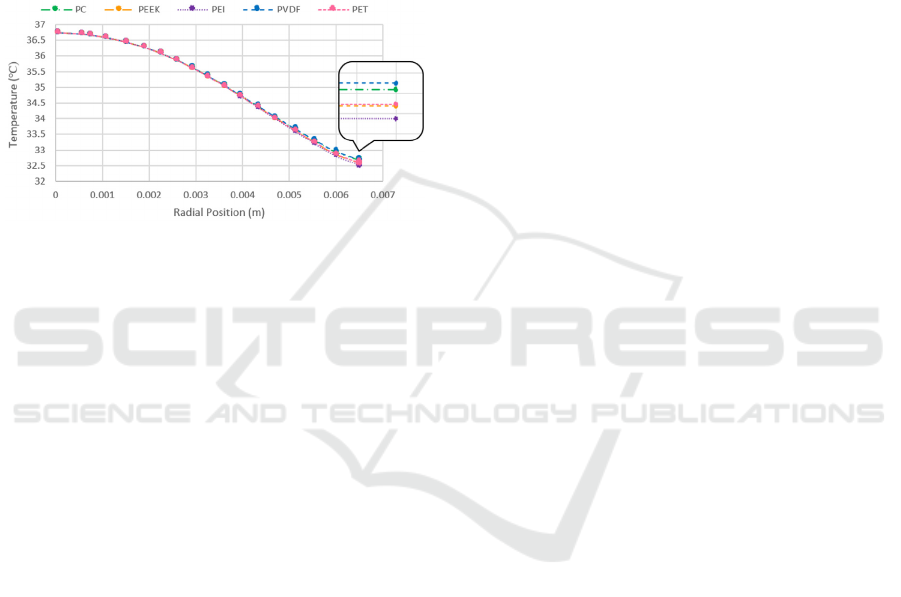

3.3 Radial Temperature Distribution

After simulating the ANSYS model, the results of the

radial temperature were obtained along the radial

position, as shown in Figure 9.

Figure 9: Temperature distribution of CO

2

with respect to

the radial position using different trocar materials.

Figure 9 shows the temperature distribution of

CO

2

along the radial position. For all materials, the

curves start at a specific peak value at the center of

the trocar and then decrease as they get closer to the

inner wall of the trocar. It was observed that the CO

2

temperature at the inner wall of the trocar was the

highest, with a value of 32.699 ℃, when the trocar

material was PVDF. The temperature difference was

the lowest, 3.569 ℃, which means that PVDF

exhibited the highest resistance to heat transfer.

Following that is PC, which showed a lower CO

2

temperature at the inner wall of the trocar and a

greater temperature difference; next is PET, followed

by PEEK. The material that resisted heat transfer the

least was PEI, which had the lowest CO

2

temperature

at the inner wall, with a value of 32.524 ℃, and the

highest temperature difference of 3.734 ℃.

4 CONCLUSIONS

In laparoscopic surgeries, during CO

2

insufflation, the

CO

2

entering a patient’s body at 37 ℃ through the

trocar loses heat due to its surroundings. This

temperature difference causes fog to form on the

camera lens inside the body. In order to mitigate this

heat transfer, multiple materials that can be used in the

composition of the trocar were compared to determine

which material results in the least temperature

difference between the inlet and outlet of the trocar,

thereby reducing condensation. The selected materials

are PET, PVDF, PEI, PEEK, and PC.

The trocar was modeled using ANSYS Fluent

Fluid Flow, where proper boundary conditions and

geometry were applied to match the trocar and the

operating room conditions. The ANSYS simulation

was validated by a comparative study with the

theoretical equation and a previous case study.

The mean, axial, and radial temperature

distributions using each of the five materials in the

composition of the trocar were plotted using ANSYS.

Results showed that PVDF, having the lowest

thermal conductivity, had the highest resistance to

heat transfer with a CO

2

mean temperature of

35.18817 ℃ and an axial temperature of 36.76132 ℃

at the end of the trocar’s length. It was followed by

PC, PET, PEEK, and PEI. Moreover, the CO

2

radial

temperature distribution indicated that PVDF also

had the highest resistance to heat loss radially with a

CO

2

temperature difference of 3.569 ℃ from the

center to the trocar inner surface at the end of the

trocar, followed by PC, PET, PEEK, and PEI.

In summary, the best material that can be used in

the composition of the trocar is PVDF since it has the

greatest CO

2

heat loss resistance throughout the

length of the trocar, which will result in the least fog

formation on the camera lens.

As a future plan, an experimental study will be

performed using different trocar materials in order to

study the actual CO

2

temperature distribution along

the trocar. Validating the numerical and

computational methods using an experimental study

will lead to refining the model and confirming the

optimal material to be used in the trocar composition,

which will result in minimal CO

2

heat loss to prevent

fog formation.

REFERENCES

Treatments. Cleveland Clinic. (n.d.). https://my.

clevelandclinic.org/health/treatments, (accessed

2024/7/21).

Al‐Obaidi, A. R. (2021). Investigation of the flow, pressure

drop characteristics, and augmentation of heat

performance in a 3D flow pipe based on different

inserts of twisted tape configurations. Heat Transfer,

50(5), 5049–5079. https://doi.org/10.1002/htj.22115.

Al-Zaharnah, I., & Yilbas, B. (2004). Thermal analysis in

pipe flow: Influence of variable viscosity on entropy

generation. Entropy, 6(3), 344–363. https://doi.

org/10.3390/e6030344.

Heat Transfer in Laparoscopic Trocar System: Analytical and Numerical Study

137

Patil, M. M., Nadar, M. D., & Uthale, S. A. (2016). To

investigate Heat Loss of a Fluid flowing through a

Pipeline for Turbulent Flow. International Journal of

Advanced Engineering Research and Applications

(IJAERA).

Chandrakar, V., Senapati, J. R., & Mohanty, A. (2021).

Conjugate heat transfer due to conduction, natural

convection, and radiation from a vertical hollow

cylinder with finite thickness. Numerical Heat Transfer,

Part A: Applications, 79(6), 463-487.

Belhocine, A. (2016). Numerical study of heat transfer in

fully developed laminar flow inside a circular tube. The

International Journal of Advanced Manufacturing

Technology, 85, 2681-2692.

Tanaka, C., Fujiwara, M., Kanda, M., Murotani, K., Iwata,

N., Hayashi, M., ... & Kodera, Y. (2019). Optical trocar

access for initial trocar placement in laparoscopic

gastrointestinal surgery: A propensity score‐matching

analysis. Asian Journal of Endoscopic Surgery, 12(1),

37-42.

Incropera, F. P., DeWitt, D. P., Bergman, T. L., & Lavine,

A. S. (1996). Fundamentals of heat and mass transfer

(Vol. 6, p. 116). New York: Wiley.

Dutt, A. (2015). Effect of mesh size on finite element

analysis of beam. International Journal of Mechanical

Engineering, 2(12), 8-10.

Najmi, J., & Ali Shah, S. I. (2017). Analysis of Velocity

Profile for Laminar Flow in a Round Pipe. Fifth

International Conference on Aerospace Science &

Engineering (ICASE), Institute of Space Technology,

Islamabad, Pakistan (2017).

BIODEVICES 2025 - 18th International Conference on Biomedical Electronics and Devices

138