Modeling of an Electric-Based Defogging System for Laparoscopy

Ali Al Hadi Orabi Al Haddad

1

, Nour Mansour

1

, Wassim Salameh

2

, Ali Cherry

3

, Bassam Hussein

4

,

Houssein Hajj Hassan

5

and Mohamad Hajj-Hassan

1

1

Department of Biomedical Engineering, Lebanese International University, Bekaa, Lebanon

2

Department of Mechanical Engineering, The International University of Beirut, Beirut, Lebanon

3

Department of Biomedical Engineering, The International University of Beirut, Beirut, Lebanon

4

Department of Industrial Engineering, The International University of Beirut, Beirut, Lebanon

5

Faculty of Health Sciences, Al Maaref University, Beirut, Lebanon

Keywords: Laparoscopy, Defogging, Modeling.

Abstract: This paper addresses the common issue of laparoscopic lens fogging (LLF), which hampers the surgeon's

visibility and prolongs procedures. The proposed solution involves an advanced electrical defogging system

utilizing a thin, conductive transparent material in different configurations such as circular disk and concentric

spiral models. These configurations generate consistent heat on the lens surface, minimizing the temperature

difference between the lens and the inside of the body. The ideal results were achieved with a 14-circle ITO

model, maintaining a constant 310 K (37°C) on the lens surface. Through detailed simulations and modeling,

this research demonstrates the effectiveness of the proposed system in maintaining a fog-free lens, ultimately

reducing operational delays and enhancing both surgical efficiency and patient safety in laparoscopic

procedures.

1 INTRODUCTION

Laparoscopy is a minimally invasive surgical

technique that relies heavily on the clarity of the

laparoscopic lens to provide surgeons with a clear

view of the operative field. It is conducted in response

to view internal organs of the body clearly such as

checking for polyps in stomach, bleeding, infections,

and blockages. The main advantages of this surgery

are faster recovery times and less bleeding compared

to exploratory laparotomy leading to shorter stay at

the hospital. Fogging of the laparoscope lens is a

prevalent issue in laparoscopic surgery. It arises from

the temperature disparity between the human body

and the laparoscope lens, leading to the condensation

of water vapor on the cold lens leading to obstructing

the view. Multiple methods exist that solve this issue

but none has the efficiency to provide both a totally

clear image and full safety of the patients with zero

side effects. Several anti-fogging approaches have

been established and are used in the laparoscopic

surgical field. Physical methods include preheating

the endoscope camera with 60-80℃ sterile normal

saline for 5-10 minutes before insertion. Chemical

methods involve applying substances like iodine,

anti-fog oil, and alcohol to the lens. Ventilation

systems work by maintaining airflow to prevent

fogging using CO2 (Calhoun & Redan, 2014). Each

method has its advantages and drawbacks. Physical

methods can be time-consuming and lack

effectiveness but are the cheapest among all methods

(Yasui & Kubo, 2022), while chemical methods may

leave residues that harm the lens or cause irritation to

the patient but can have a very clear image (World

Laparoscopy Hospital, 2013). Ventilation systems

can cause heart and other health issues to the patient

but also provides a clear image (Jiang & Sun, 2019).

The aim of this research is to investigate defogging

using heating to provide a clearer and more visible

image during laparoscopic surgeries with minimal

side-effects.

2 METHODOLOGY

The proposed defogging system employs a thin

conductive Indium Tin Oxide (ITO) layer to generate

heat over the laparoscopic lens, maintaining a

constant temperature of 310 K (37°C), which is safe

for both human cells and the laparoscopic lens. This

Al Haddad, A. H. O., Mansour, N., Salameh, W., Cherry, A., Hussein, B., Hassan, H. H. and Hajj-Hassan, M.

Modeling of an Electric-Based Defogging System for Laparoscopy.

DOI: 10.5220/0013133200003911

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 18th International Joint Conference on Biomedical Engineering Systems and Technologies (BIOSTEC 2025) - Volume 1, pages 139-142

ISBN: 978-989-758-731-3; ISSN: 2184-4305

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

139

system prevents fogging by reducing the temperature

difference between the body and the lens to near zero,

effectively eliminating condensation. The research

approach includes defining boundary conditions,

implementing electrical and heat transfer models, and

conducting simulations to optimize the ITO

configuration. COMSOL Multiphysics software is

used for modeling the electric-based defogging

system. Detailed simulations are conducted to model

the temperature distribution and effectiveness of the

system, considering various parameters such as film

thickness, electrical properties, and heating

efficiency. The modeling starts with sketching a 10

mm diameter circle extruded by 1mm as thickness

which will represent the lens. Followed by sketching

another circle over the lens with approximately 10

mm diameter and later replaced by concentric spiral

circles with 10 μm thickness for both which will be

the ITO layer. The lens is made of silica glass which

withstands up to 1100°C and has many other

characteristics that make it suitable for this project.

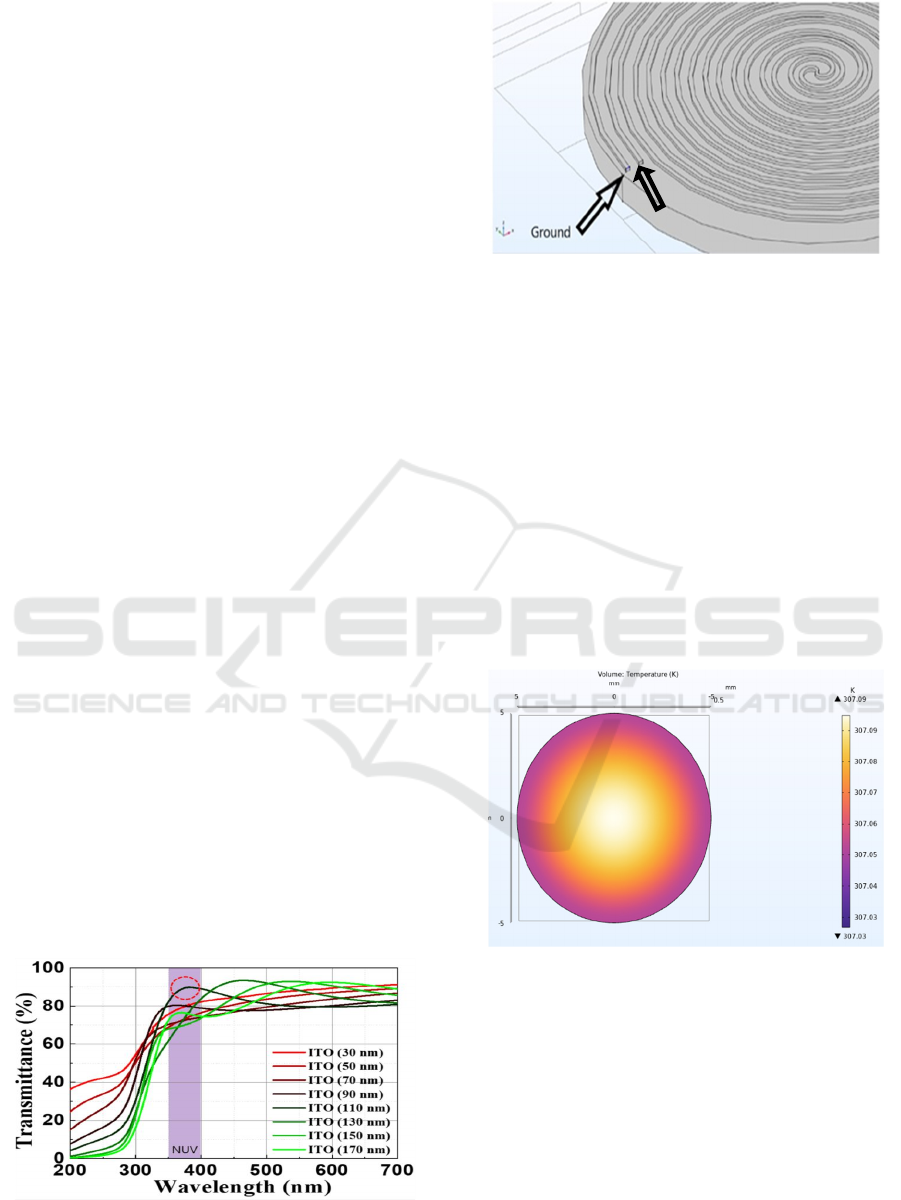

And as for the ITO it was chosen in this project due

to its high transparency which peaks around 93% and

always above 80% throughout all the visible spectrum

as shown in figure 1. while having high electrical and

thermal conductivity to be able to generate heat using

current by utilizing joule’s effect. After everything is

in place we begin to assign the electrical properties

initializing with having an electric potential of 5V as

a constant input which is used in laparoscopy

machines and assigning a ground. Each is assigned

over 1 of the edges of the ITO circuit as shown in

Figure 2 note that both edges indicated by the arrows

should be connected to external pads using a wire

bonding machine. Additionally, for the circular disk

model, two pads should be placed directly on the

opposite edges of the disk for voltage and ground

interfacing and connections. DC current is used in this

simulation which generates more heat than AC

current. Heat transfer in solids is used to simulate the

heat transfer between the ITO and the lens to finally

Figure 1: Transmission spectra of a typical ITO thin film

(Kim, 2023).

Figure 2: Assignment of electric potential and ground on

ITO spiral.

get the results. Design optimization is applied to the

concentric circles by increasing the number of circles

placed on the lens to get the ideal result which is full

distribution of 310K over all the lens which is the

human body temperature.

3 RESULTS AND DISCUSSION

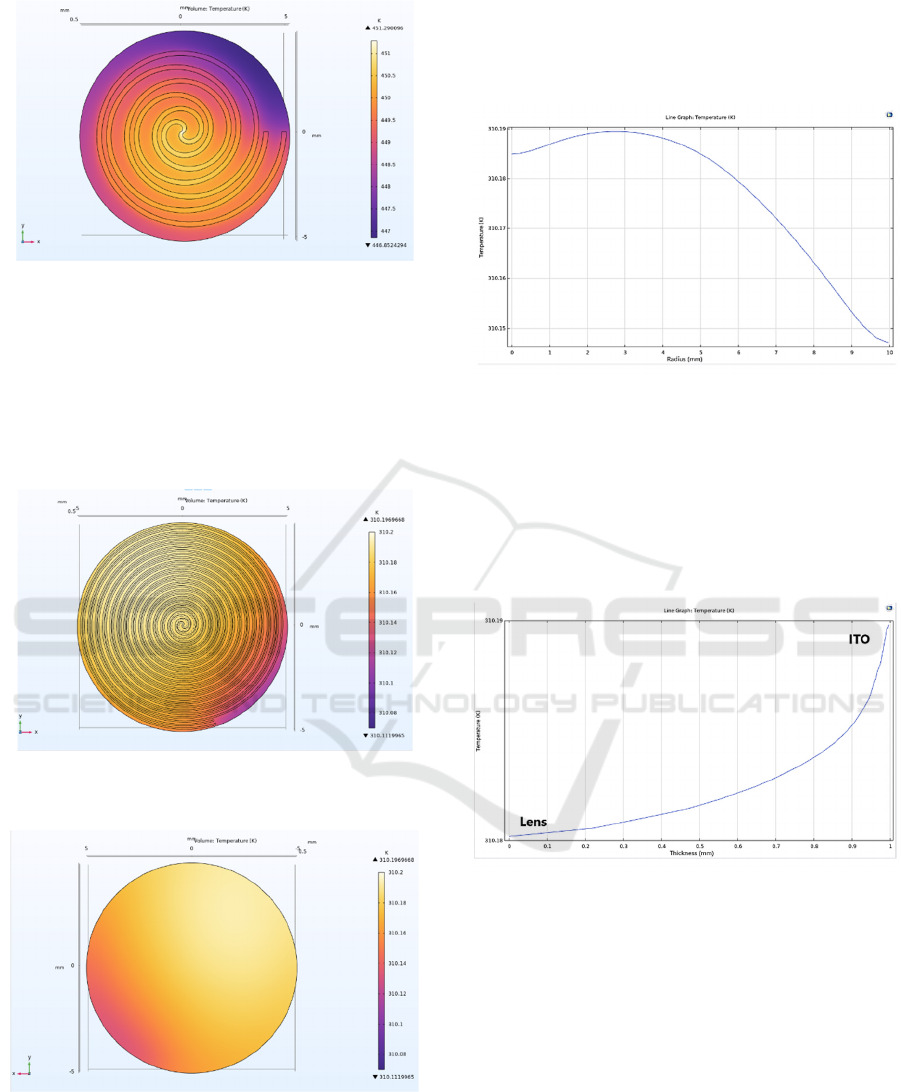

The simulations of the first circular configuration will

be observed, then using the second spiral

configuration numerous results have been derived

while optimizing the size of ITO in order to detect

variable results reaching the ideal outcome.

Figure

3

: Temperature distribution on the ITO circular full

disc.

After observing the above simulation in Figure 3, it is

noticeable that the temperature is disturbed in a very

inadequate and inefficient manner reaching a max

temperature of 307 K only on the center of the lens.

Thus, circular disc configuration that is used is no

longer applicable to reach the most ideal and desired

results needed for this research.

DC Voltage

BIODEVICES 2025 - 18th International Conference on Biomedical Electronics and Devices

140

Figure

4

: Temperature distribution on the 3 circles ITO

spiral.

Figure 4 shows the temperature distribution on the

three circle ITO spiral and on the laparoscopic lens

respectively. It can be noticed that a high temperature

of 451 K is reached only on the middle of the lens and

gradually decreasing reaching a minimal value of 447

K on the edges.

Figure

5

: Temperature distribution on the 14 circles ITO

spiral.

Figure

6

: Temperature distribution on the lens of 14 circles

ITO model.

Figures 5 and 6 show the ideal temperature

distribution on the 14 circles ITO spiral and on the

laparoscopic lens respectively. Observing that a

desired maximal temperature of 310.2 K is distributed

on the whole lens, bear in mind that there is a

negligible difference of 0.08 K on the lower edge

reaching a value of 310.14 K.

Figure

7

: Line graph representing temperature distribution

with respect to the radius of the lens.

Figure 7 shows the temperature distribution on the

laparoscopic lens in Kelvin while using 14 circles

ITO model with respect to the radius of the lens in

mm. Noting that it reaches a peak of 310.19 K at a 3

mm radius near to the center of the lens.

Figure

8

: Line graph representing temperature distribution

with respect to the thickness of the lens.

Figure 8 shows the temperature distribution on the

laparoscopic lens in Kelvin while using 14 circles

ITO model with respect to the thickness of the lens in

mm. It demonstrates that the temperature is higher on

the ITO side, as the heat generated by the ITO, which

is embedded within the laparoscope, gradually

transfers to the lens.

The first simulation with a circular ITO disc

resulted a deficient and inadequate temperature

distribution on the lens with a temperature of 307 K.

The second configuration that have a spiral form,

multiple simulations have been resulted initializing

with 3 circles ITO then increasing the number of

Modeling of an Electric-Based Defogging System for Laparoscopy

141

circles to attempt 5, 8, 10 and ending with 14 circles

of ITO. At first, 3 circles ITO have shown an

insufficient temperature distribution with an

extremely high temperature of 451 K. As the number

of circles increases, the temperature distribution

becomes better and more intensified because less

distance is found between turns. In addition, the

temperature value is decreasing due to increasing the

length of the wire. This can be noticed by comparing

the 3-circle configuration with the 14 circles, where

the distribution being uniform all over the surface and

the temperature dropped from around 450K to 310K.

The 14 circles ITO configuration has the ideal

temperature reached with a value of 310.2 K

representing body temperature that is perfectly and

equally distributed on the whole lens where such

result is emitted by applying an input voltage of 5 V

only. Thus, the 14 circles configuration was the

optimized result. In addition, it is important to

mention that as the thickness of the laparoscopic lens

increases moving toward the ITO, the temperature

distribution increases as shown in figure 8 and vice

versa moving away from the ITO spiral thus the

temperature distribution will keep decreasing till

reaching the lens. Finally, after the above analysis and

interpretation of the whole results and after reaching

our optimal distribution. It is essential to highlight on

the main points that specializes our research from any

other available techniques that improve vision during

laparoscopic surgeries. This research will initially add

a special advantage of keeping a clear and vivid

image during the whole laparoscopic surgical

procedure. Adding, it will maintain a safe and secured

heating technique on the lens since it is found on the

inside of the laparoscope keeping the patient well and

protected without any side effects compared to any

other technique.

4 CONCLUSIONS

The development of an electric-based defogging

system for laparoscopy represents a significant

advancement in surgical technology. This research

demonstrates that the proposed system can effectively

maintain a clear lens surface, addressing a common

issue that hinders laparoscopic surgeries while not

harming the patient with any side effects. Future work

should focus on the testing of the system under real-

life conditions to validate its performance and

reliability. Further optimization and experimental

validation are necessary to enhance system

performance and ensure practical applicability.

ACKNOWLEDGEMENTS

We would like to acknowledge the financial support

from the XNY Medical, a manufacturer and

distributor of minimal invasive surgery (MIS)

medical devices, China.

REFERENCES

Calhoun, J., and Redan, J. (2014, January). Elimination of

Laparoscopic Lens Fogging Using Directional Flow of

CO2. Journal of the society of laparoscopic and

Robotic Surgeons, 18. Retrieved from https://www.

ncbi.nlm.nih.gov/pmc/articles/PMC3939343/

Yasui, T., and Kubo, Y. (2022). Mechanism underlying lens

fogging and its countermeasure in laparoscopic surgery.

Minimally Invasive Therapy and Allied Technologies,

32(2), 56-61.

World Laparoscopy Hospital. (2013, February 3).

Retrieved from https://www.laparoscopyhospital.com/

news/preview.php?id=93#:~:text=Ventilation%20Syst

ems%20-%20Ventilation%20systems%20are,the%20l

ens%20and%20creating%20fog

Jiang, R., and Sun, Y. (2019). Effect of different carbon

dioxide (CO2) insufflation for laparoscopic colorectal

surgery in elderly patients. National Library Of

Medicine, 98(41).

Kim, M.-J. (2023). A Study on Optimal Indium Tin Oxide

Thickness as Transparent Conductive Electrodes for

Near-Ultraviolet Light-Emitting Diodes. MDPI,

16(13), 4718.

BIODEVICES 2025 - 18th International Conference on Biomedical Electronics and Devices

142