Fuzzy MCDM Framework for Risk Management in Construction

Supply Chain

Abdullah Ali Salamai

a

Management Department, Applied College, Jazan University, Jazan, Saudi Arabia, K.S.A.

Keywords: Risk Management, Construction Supply Chain, Fuzzy Sets, Multi-Criteria Decision Making, Supply Chain

Management, Artificial Intelligence, Blockchain.

Abstract: Risk management in the construction supply chain (CSC) is vital in construction project risks. CSC has

various risks affecting product quality and project timeline, such as operational, social, financial, technical,

design, and safety risks. These risks should be mitigated in project construction. So, this paper proposed a set

of technologies to overcome risks in CSC, like artificial intelligence (AI), blockchain, data analytics, and IoT,

to select the best one. So, the multi-criteria decision-making (MCDM) methodology is used to deal with

various risks. The Multi-Attribute Utility Theory (MAUT) method is used to rank technologies. The weights

of risks are obtained by the average method by using the decision matrix. The MCDM methodology is

integrated with a fuzzy set to overcome uncertainty data. Experts used triangular fuzzy numbers to express

their opinions instead of exact numbers. These allow the model to overcome inconsistent and vague data. The

MCDM methodology was applied to 18 risks and 5 technologies. The results show that social risks have the

highest weight. AI is the best technology for overcoming risks in CSC. AI can integrate with CSC from raw

data to final products to deliver to the usert.

1 INTRODUCTION

Supply chain management (SCM) controls the

production flow of products and services from raw

materials to the final product to deliver goods to

clients. Firms and companies use various suppliers to

deliver projects, from raw materials to final products

and users. The role of SCM is to reduce the time of

the production cycle and reduce cost. The

effectiveness of the SCM maximizes the value of the

supply chain. Various criteria are performed to

increase the effectiveness of SCM, like identifying

potential issues, optimizing price dynamically, and

enhancing inventory allocation (Hmouda et al., 2024;

Oyewole et al., 2024).

SCM was extended with various applications and

case studies in healthcare, medical, retail, suppliers

section(Sa’diyah et al., 2022), service companies, and

food industries. Construction plays a vital role in the

global marketplace. It can aid countries in creating

opportunities for skilled and unskilled labor.

A construction project refers to using energy and

raw materials, products, and hybrid nature. The

a

https://orcid.org/0000-0001-9679-1545

quality of construction projects is increased by the

performance of the project team and customer

satisfaction with products.

Construction supply chain (CSC) refers to the

process of a series of tasks from raw data to final

goods in the construction industry. CSC is the process

of sourcing, purchasing, and delivering materials. It

is a network of suppliers that provide raw data into a

final product to the user. It includes the flow of

produce from suppliers to the construction site. It

plays a vital role in the cost, time of projects, and

quality of projects. CSC has various risks that affect

the quality and performance of the system. These

risks include cultural risks, social risks, financial

risks, technical risks, and design risks. Various

technologies are used with CSC to reduce these risks,

like artificial intelligence (AI), blockchain, IoT, and

data analysis (Chen et al., 2024; Gharaibeh et al.,

2024).

AI is the common solution for addressing and

minimizing risks in CSC. Each part in CSC forms raw

data and the final product is managed by AI. The role

of AI in CSC can optimize productivity and reduce

146

Salamai, A. A.

Fuzzy MCDM Framework for Risk Management in Construction Supply Chain.

DOI: 10.5220/0013135700003956

In Proceedings of the 7th International Conference on Finance, Economics, Management and IT Business (FEMIB 2025), pages 146-153

ISBN: 978-989-758-748-1; ISSN: 2184-5891

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

the effect of labor storage. AI can use the historical

data of products and aid companies in predicting

operational resources. AI can implement proactive

maintenance methods and strategies. AI can analyze

the unstructured data (Pournader et al., 2021; Singh et

al., 2023).

Blockchain aids companies and firms in CSC by

knowing the SC network, where the accumulation

and exchange of value happen through a set of

transactions, services, products, and information.

Every business can add value for good before

reaching the final step. Blockchain is interfaced with

other technologies such as IoT and AI to deliver

sustainable, secured, and safe CSC (Hijazi et al.,

2019; Yoon & Pishdad-Bozorgi, 2022).

In decision-making, the experts and decision-

makers are complex, and it is difficult to express their

opinions in exact numbers in multi-criteria decision-

making (MCDM) systems. So, the fuzzy set was

applied to deal with vague data. The fuzzy set was

used in various decision-making issues. So, the fuzzy

set is a suitable framework for enabling decision-

makers to express their opinions using v, uncertain

data instead of exact numbers. Triangular fuzzy

numbers (TFNs) are fuzzy sets that deal with vague

data(Dong et al., 2021; Dubois et al., 2004). The

MCDM methods are applied in various decision-

making issues like renewable energy sources(Ali &

Muthuswamy, 2023), green fuels evaluation(Elsayed,

2024), wastewater treatment(Saeed et al., 2024), and

energy solar(Alharbi et al., 2024).

The Multi-Attribute Utility Theory (MAUT)

approach is an MCDM methodology. The main

advantage of the MAUT method is its simplicity in

solving various criteria in decision-making problems.

It can offer abundant freedom of action experts to

make outcomes more effective and accurate. This

method is applied in decision-making issues to select

the best option. This method belongs to compensatory

approaches; factors are independent, and qualitative

factors are converted into quantitative ones(de Freitas

et al., 2013; Işık, 2017).

1.1 Risk Management

Construction is quick and is a vital element in the

supply chain. Delivering raw data from suppliers to

sites is essential for a timely project. The main

challenges of construction are sourcing and

procurement of materials. There are various

categories of materials in the supply chain

(Shishehgarkhaneh et al., 2024; Yu & Ma, 2024).

There are steps in risk management to reduce risks in

CSC:

Identify and evaluate the potential risks in SC

materials. It makes the SC more comprehensive in

supply chain management. The project manager can

investigate their vendor network to reduce risks.

Identifying the risks can reduce the time of the project

and deliver products and services on time.

Applying risk mitigation methods and strategies

to reduce complex timelines in construction projects.

The construction projects have risk mitigation

strategies to deliver projects on time.

1.2 Contributions of this Study

The primary contributions of this work are:

• This work presents the risk management for the

construction supply chain. We introduced the

risks of CSC and how to reduce these risks.

• We introduce some trend technologies to

overcome CSC risks. We introduce five trend

technologies to select the best one.

• We used the MCDM concept to manage

multiple risks in CSC and the MCDM method

to select the best technology.

• We used a triangular fuzzy set to deal with

vague data in the selection problem. This study

uses five main technologies and 18 CSC risks.

• We show that AI is the best technology to

reduce CSC risks by analyzing the historical

data and predicting the demand of supply to

overcome risks.

1.3 Organization of this Paper

The rest of this paper is organized as follows: Section

2 shows the previous studies in CSC for risk

management. Section 3 shows the materials and

methods of this study; we introduce the MCDM

methodology with the fuzzy set to deal with vague

data. Section 4 shows the results and discussion of

this study. Section 5 shows the sensitivity analysis.

Section 6 shows the conclusions of this work.

2 LITERATURE REVIEW

Risk management plays an important role in CSC for

effective performance and operation with uncertainty

degrees. Various models and frameworks are used to

reduce risks in CSC, like supply risks and risks of

SCM. Pham et al. (Pham et al., 2023) aimed to reduce

and overcome risks in CSC. They presented a

complete review to show different risks and how to

Fuzzy MCDM Framework for Risk Management in Construction Supply Chain

147

reduce them in CSC. They focused on risk

management for the CSC process and operation.

Shojaei and Haeri (Shojaei & Haeri, 2019)

proposed a framework to reduce risks in CSC. They

used fuzzy cognitive mapping and gray relational

analysis. They applied their model in real cases to

show the performance and effectiveness of their

model. They evaluated various risks by their model.

They applied their model to reduce complexity and

risks in the construction process, avoid time and cost,

and project failure.

Tah and Carr (Tah & Carr, 2001) defined the

limitations in risk management for CSC tools, and

methods. They used the methods for describing risks

for the development stable knowledge-driven method

for risk management. They defined the generic risk

and remedial action in descriptive terms. They

implemented their model in the data management

system. They adopted a prototype system to support

risk management in CSC.

Aloini et al. (Aloini et al., 2012) proposed work to

analyze the CSC with various factors in the

construction industry. They provided a complete

review of risk management in CSC. They provided

case studies and tests to show the limitations results

of CSC.

Hernadewita and Saleh (Hernadewita & Saleh,

2020) enhanced tools and approaches for risk

management and evaluation in CSC. They used the

literature review methodology to find tools and

methods, including AHP, FMEA, SCOR, and

HAZOP. They show the limitations and advantages

of defining and evaluating CSC for risk management.

Abas et al. (Abas et al., 2022) aimed to identify

the risks and factors impacting CSC. They adopted a

methodology for identifying risk and success criteria.

They created questionnaires to collect the opinions of

firms and project managers. They show the highest

risk in CSC financials, followed by storage materials,

cash flow, and bad weather. Their study shows the

enhancement of the construction industry.

Senthil and Muthukannan (Senthil &

Muthukannan, 2022) introduced a complete survey to

focus on quality management and quality assurance

processes in the construction industry. They reviewed

the risk management for CSC and showed that a

neural network depends on a network by weight

training input.

Rudolf and Spinler (Rudolf & Spinler, 2018)

introduced a ranked view on the CSC for risk

management. They provide a contextualized risk for

engineering and construction projects. They showed

the highest risk is inherent risk in large-scale projects

and behavior risks.

Obayi et al. (Obayi & Ebrahimi, 2021) provided a

study to show the role of external pressures in risk

management in CSC. They showed a case study of

regulatory strategies in CSC. They showed that

relational costs have the highest weight, followed by

transportation costs.

Deng et al. (Deng et al., 2019) presented a

framework to analyze the CSC risks. They used the

fuzzy synthetic evaluation to evaluate the risks in

CSC. They presented nine risks with high weight and

discussed the criteria risks in CSC.

3 MATERIAL AND METHODS

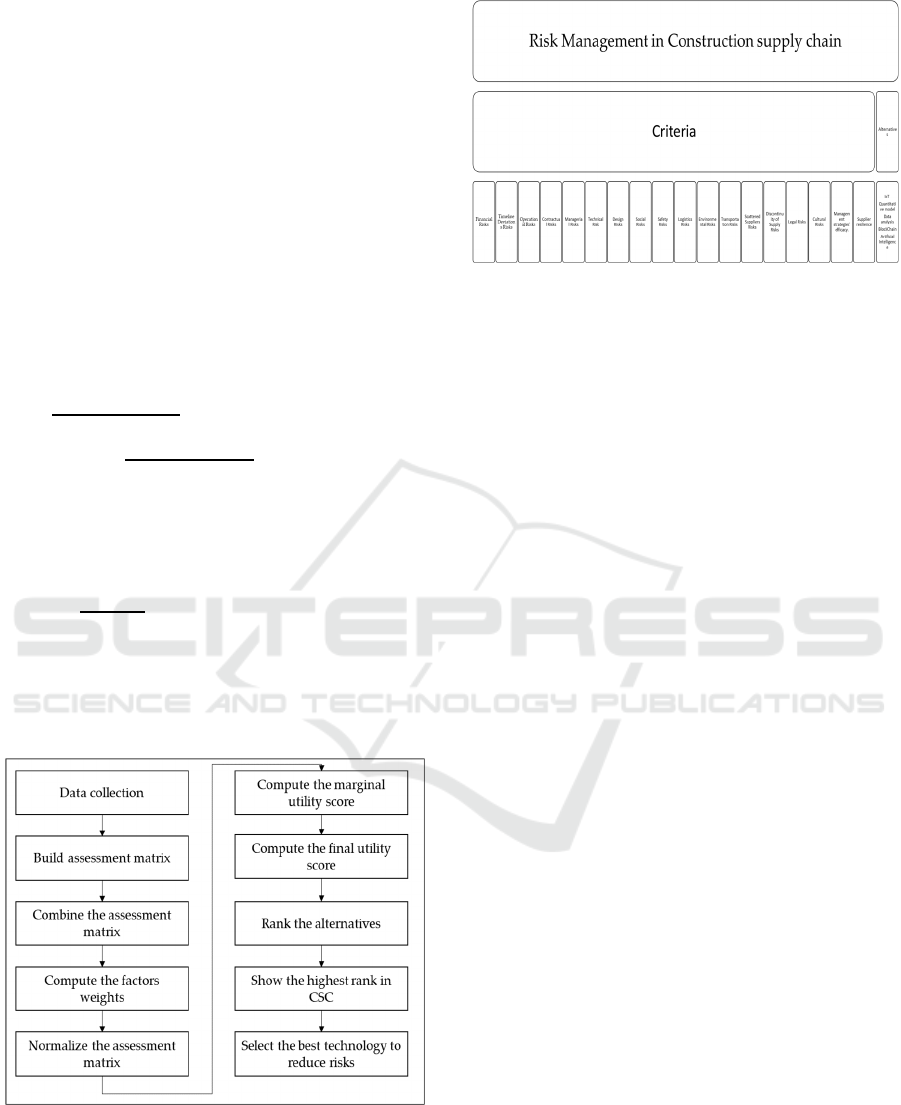

MCDM methods are used in decision-making issues

to make the best decision. This section shows the

steps of the MCDM framework under TFNs to select

the best technology in CSC risk management (Dong

et al., 2021; Işık,, 2017). Figure 1 shows the MCDM

framework. Also, we show some definition of TFNs

as:

Definition 1

We introduce some definition of triangular fuzzy

numbers (TFNs) as:

TFNs defined as: 𝑏=

𝑏

,𝑏

,𝑏

is a fuzzy set

defined on the set R of real numbers whose

membership is:

𝑧

𝑥

=

⎩

⎪

⎨

⎪

⎧

, 𝑖𝑓 𝑏

≤𝑥≤ 𝑏

, 𝑖𝑓 𝑏

≤𝑥≤ 𝑏

0, 𝑖𝑓 𝑥>𝑏

𝑜𝑟 𝑥<𝑏

(1)

Where 𝑏

,𝑏

,𝑏

define as a low, mode, and

upper bound of TFNs.

Definition 2

We can compute the graded mean integration

representation:

𝑅

𝑏

=

𝑏

+4𝑏

+𝑏

(2)

Definition 3

The fuzzy weights vector of TFNs can be defined

as:

∑

𝑤

=1,𝑤

+

∑

𝑤

,

≤1,𝑤

+

∑

𝑤

,

≥1 (3)

Step 1. Data collection

The step invited the experts to evaluate the criteria

and alternatives. This study invited 5 experts with

high experience. These experts have more than 20

years of experience in supply construction chain

management.

FEMIB 2025 - 7th International Conference on Finance, Economics, Management and IT Business

148

Step 2. Build assessment matrix

The assessment matrix is built between factors

and options by using the options of experts. The

experts used the linguistic terms of triangular fuzzy

sets. Then we used the triangular fuzzy numbers to

build the assessment matrix. Then we convert these

numbers into crisp numbers.

Step 3. Combine the assessment matrix.

The assessment matrix is combined by using the

average method to attain one matrix.

Step 4. Compute the factors' weights.

The experts evaluated the factors and options.

Then we used the average method to combine these

factors to attain factor weights.

Step 5. Normalize the assessment matrix.

The assessment matrix is normalized by using the

beneficial and non-beneficial factors such as:

𝑥

=

;𝑖=1,…,𝑚;𝑗=1,…,𝑛 (4)

𝑥

=1+

;𝑖=1,…,𝑚;𝑗=

1,…,𝑛 (5)

Where 𝑞

refers to the value in the assessment

matrix.

Step 6. Compute the marginal utility score

𝑦

=

.

;𝑖=1,…,𝑚;𝑗=1,…,𝑛 (6)

Step 7. Computing the final utility score

𝑅

=

∑

𝑤

𝑦

;𝑖=1,…,𝑚 (7)

Step 8. Rank the alternatives.

The final utility score is ranked descending to

obtain the final rank of options.

Figure 1: The steps of MCDM methodology.

Figure 2: List of factors and technologies.

4 RESULTS AND DISCUSSION

This section shows the results of the MCDM

framework for selecting the best technology to reduce

risks in CSC through risk management. This study

used the MCDM method to rank alternatives. The

fuzzy set is used to overcome vague data through

evaluation steps.

CSC is the process used to control the flow of

sources and materials in the construction area. CSC

has various components and steps, such as project

management, logistic operations, manufacturing

elements, and raw materials procurement. CSC aims

to preserve and maintain strong relations between

manufacturers and suppliers. The best SCM with

cost-effective products delivered on time and project-

building effectiveness. However, several risks the

CSC faces affect its process, performance, and

effectiveness. CSC has various risks and challenges,

such as multiple fragmented processes, long

production times, balancing inventory levels, legal

risks, safety risks, environmental risks, financial

risks, and culture risks.

Risks in CSC can lead to a complex SC process

and bad quality products and performance.

Construction firms must select technology to aid them

in the SC process, complete their projects on time,

and preserve a competitive edge in the construction

industry. AI can overcome and reduce the risks in

CSC. AI aids construction firms in reducing safety

risks, operational risks, and costs. AI can be used

throughout the CSC process, from planning to the

final steps. AI has various models and algorithms that

can analyze large amounts of data from multiple

sources to show predictive results. These models can

solve the risk of prediction delays. AI models can aid

in the preservation of business continuity. AI models

can analyze and train large amounts of data, like

historical project data, customer needs, and market

Fuzzy MCDM Framework for Risk Management in Construction Supply Chain

149

trends, to predict accurate demand predictions.

Construction firms can use the demand prediction

results to predict the upcoming materials and data to

overcome the risks.

AI models and algorithms can aid a firm’s

construction to assess suppliers with some factors like

time of delivery, dependability, and quality of goods.

AI models can evaluate the performance of each

supplier in CSC and select the best one. This can

increase the performance and effectiveness of each

supplier in CSC. AI models and algorithms can

reduce risks in CSC by empowering firms to design

risk mitigation methods and strategies. Firms can use

AI models for early detection of risks to mitigate the

effect of one project's time and cost.

Step 1. Criteria are collected from previous

studies based on CSC risks, and five main

technologies are used to select the best one to reduce

risks in CSC. Figure 2 shows the risks and

technologies for CSC. This study invited five experts

to assess the factors and technologies. These experts

used the linguistic terms of triangular fuzzy sets.

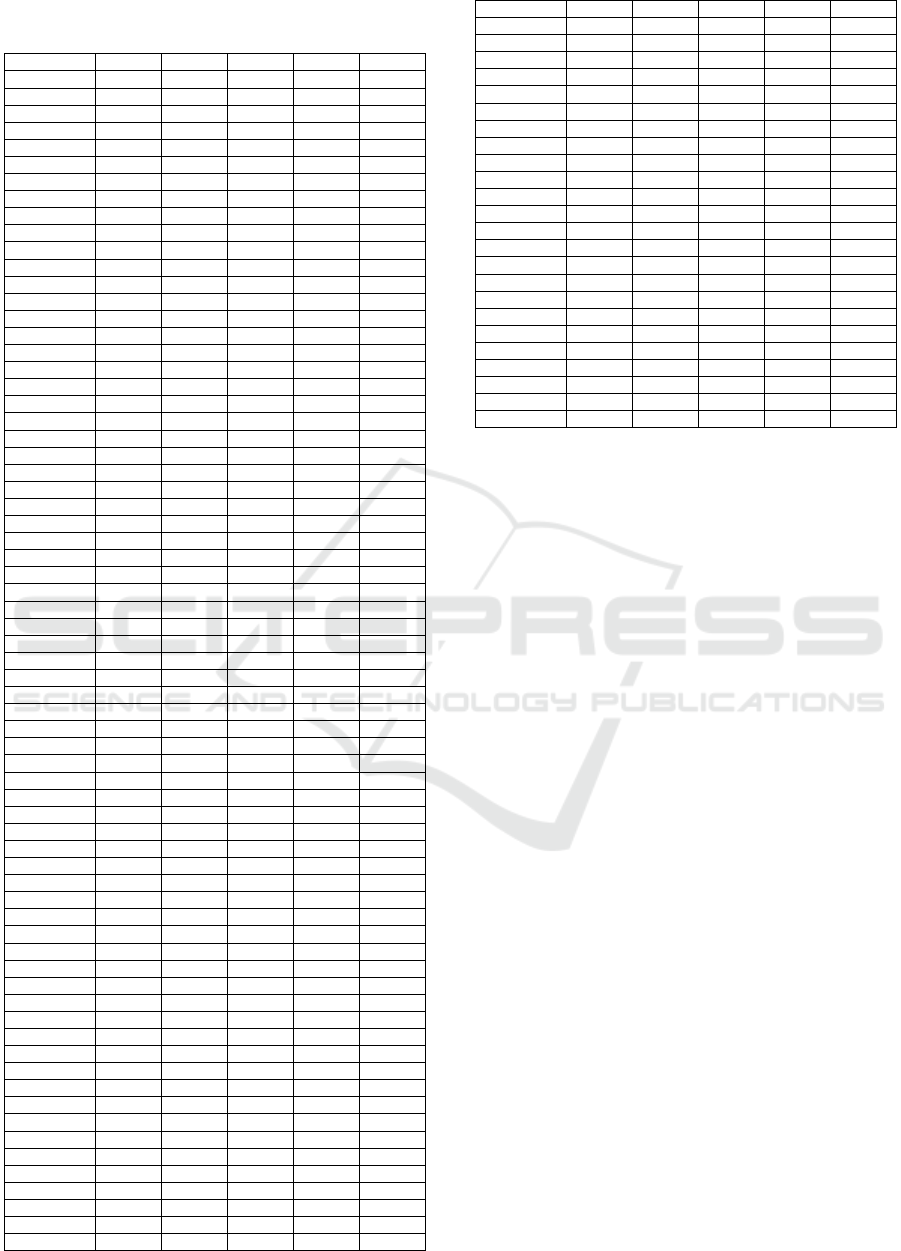

Step 2. The assessment matrix is built between

factors and technologies using the TFNs. Then, these

numbers are converted to crisp numbers as shown in

Table 3.

Step 3. The assessment matrix combines factors

and technologies to obtain a single matrix with TFNs.

Step 4. The factor weights are obtained by using

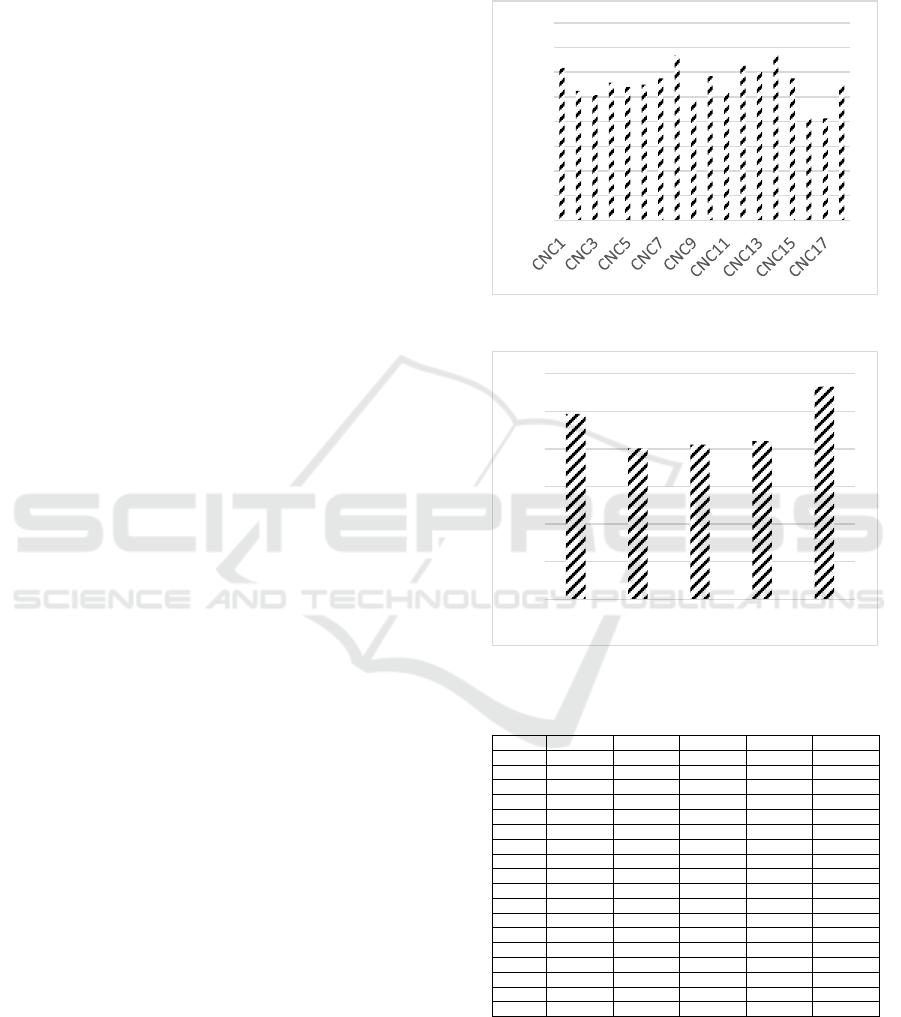

the average method. Figure 3 shows the factor's

weights.

From the weights results, we show that social

risks are the most important, with a weight of

0.066922, followed by discontinuity of supply risks,

with a weight of 0.066922, Transportation Risks, with

a weight of 0.06266; Financial Risks, with a weight

of 0.061807, Scattered Supplier Risks, with a weight

of 0.060102, and Logistics Risks, with a weight of

0.058397.

We show the management strategies' efficacy has

the lowest importance with a weight of 0.041347,

followed by Cultural Risks with a weight of

0.042199, followed by safety risks with a weight of

0.04902, Operational Risks with a weight of

0.050725, and Timeline Deviations Risks with a

weight 0.05243.

Step 5. Eq. (4) is used to normalize the decision

matrix between factors and technologies as shown in

Table 1.

Step 6. Eq. (6) is used to compute the marginal

utility score as shown in Table 2.

Step 7. Eq. (7) is used to compute the final utility

score as shown in Figure 4.

Step 8. Technologies are ranked based on the

highest value in the final utility score. We show that

AI has the highest rank followed by IoT, Blockchain,

data analytics, and quantitative models.

Figure 3: Factors weights.

Figure 4: Final utility score values for each technology.

Table 1: The Normalized Decision Matrix.

CNT

1

CNT

2

CNT

3

CNT

4

CNT

5

CNC

1

0.875 0 1 0.375 0.25

CNC

2

1 0.5 0.083333 0 0.416667

CNC

3

0 0.526316 0.631579 0.315789 1

CNC

4

0.3 0.9 0.6 0 1

CNC

5

0.416667 0.833333 1 0.333333 0

CNC

6

1 0 0.5 0.9 0.3

CNC

7

1 0.5625 0.9375 0.625 0

CNC

8

1 0 0.375 1 0.875

CNC

9

0 1 0.666667 0.75 0.916667

CNC

10

0.181818 1 0.181818 0 1

CNC

11

0 0 0.545455 0.636364 1

CNC

12

0 0.166667 0.833333 0.666667 1

CNC

13

1 0.25 0 1 1

CNC

14

1 0.625 0 0.125 0.875

CNC

15

0.777778 1 0.333333 0 0.666667

CNC

16

1 0 0.636364 0.545455 0.272727

CNC

17

0 1 0.8 1 0.8

CNC

18

0 0.375 0.6875 1 0.875

0

0.01

0.02

0.03

0.04

0.05

0.06

0.07

0.08

0

0.5

1

1.5

2

2.5

3

CNT1 CNT2 CNT3 CNT4 CNT5

FEMIB 2025 - 7th International Conference on Finance, Economics, Management and IT Business

150

Table 2: The marginal utility score.

CNT

1

CNT

2

CNT

3

CNT

4

CNT

5

CNC

1

3.365265 0.584795 4.321085 1.238012 0.964164

CNC

2

4.321085 1.589638 0.690854 0.584795 1.3456

CNC

3

0.584795 1.675545 2.068171 1.099753 4.321085

CNC

4

1.065567 3.537806 1.941589 0.584795 4.321085

CNC

5

1.3456 3.096193 4.321085 1.139026 0.584795

CNC

6

4.321085 0.584795 1.589638 3.537806 1.065567

CNC

7

4.321085 1.801296 3.813345 2.041136 0.584795

CNC

8

4.321085 0.584795 1.238012 4.321085 3.365265

CNC

9

0.584795 4.321085 2.218519 2.620871 3.65772

CNC

10

0.841258 4.321085 0.841258 0.584795 4.321085

CNC

11

0.584795 0.584795 1.740924 2.088057 4.321085

CNC

12

0.584795 0.816148 3.096193 2.218519 4.321085

CNC

13

4.321085 0.964164 0.584795 4.321085 4.321085

CNC

14

4.321085 2.041136 0.584795 0.750892 3.365265

CNC

15

2.770595 4.321085 1.139026 0.584795 2.218519

CNC

16

4.321085 0.584795 2.088057 1.740924 1.009001

CNC

17

0.584795 4.321085 2.89651 4.321085 2.89651

CNC

18

0.584795 1.238012 2.31291 4.321085 3.365265

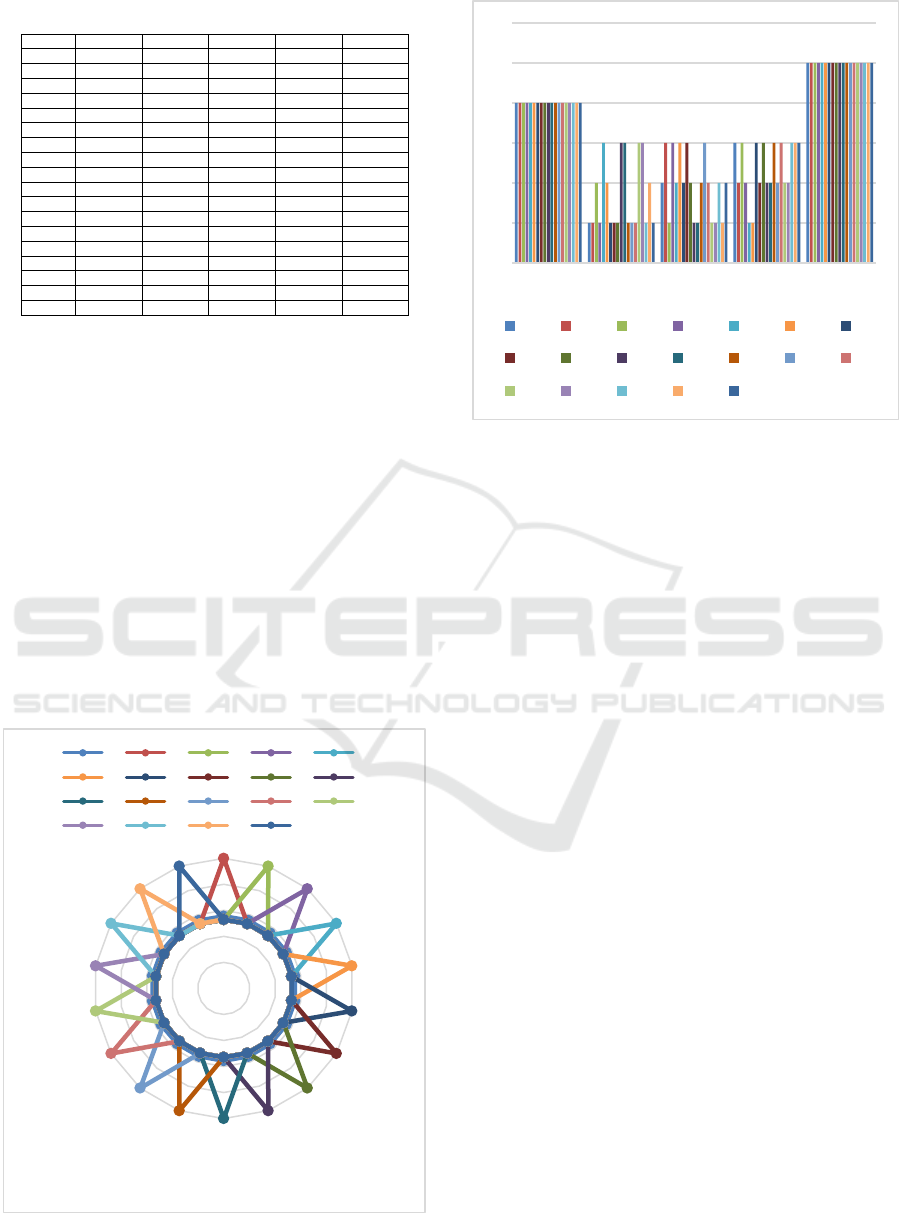

5 SENSITIVITY ANALYSIS

We conducted a sensitivity analysis to ensure the

validity of the proposed model by showing the rank

of alternatives under different situations. We

proposed nineteen situations of criteria weights, as

shown in Figure 5. In the first situation, all criteria

were given equal weight. Then, in the second

situation, the first criterion was given 0.1 weight, and

all criteria had the same weight.

Then, we show the rank of alternatives under

different situations, as shown in Figure 6. We show

that alternative 5 is the best in all situations. So, the

rank of other options is stable under different

situations.

Figure 5. The different situations of criteria weights.

Figure 6: The rank of alternatives under different situations.

6 CONCLUSIONS

This study proposed an MCDM model for reducing

risks in CSC using the risk management framework.

This study used the MCDM method, and MAUT was

used to rank options. The average method using the

decision matrix obtains the factors' weights. Five

experts with experience in CSC and risk management

evaluated the factors and technologies. There are 18

risks, and 5 technologies were used in this study. The

assessment matrix is built between factors and 5

technologies. The triangular fuzzy numbers are used

to evaluate the factors and options. Then, these

numbers are converted to the crisp number. Then, we

combined this matrix into one matrix. The criteria

weights are obtained. The results show that social risk

has the highest weight. The MAUT is applied to rank

the options. The results show that AI has the highest

rank. AI can aid CSC by reducing the risks by

predicting historical data to show the best demand in

the future to deliver products on time.

The limitations of this paper are a few criteria and

alternatives. So, in future work, we will maximize the

number of criteria and alternatives. Another

limitation is the number of experts, in future study,

the number of experts will increase.

Various MCDM methods, such as AHP, BWM,

and DEMATEL, will be used to obtain the factor's

weight in future studies. The 5 technologies can be

extended to include multiple technologies to reduce

risks in CSC.

0.00

0.02

0.04

0.06

0.08

0.10

CNC1

CNC2

CNC3

CNC4

CNC5

CNC6

CNC7

CNC8

CNC9

CNC…

CNC…

CNC…

CNC…

CNC…

CNC…

CNC…

CNC…

CNC…

S1 S2 S3 S4 S5

S6 S7 S8 S9 S10

S11 S12 S13 S14 S15

S16 S17 S18 S19

0

1

2

3

4

5

6

CNT1 CNT2 CNT3 CNT4 CNT5

S1 S2 S3 S4 S5 S6 S7

S8 S9 S10 S11 S12 S13 S14

S15 S16 S17 S18 S19

Fuzzy MCDM Framework for Risk Management in Construction Supply Chain

151

Table 3: The assessment matrix between factors and

technologies.

CNT

1

CNT

2

CNT

3

CNT

4

CNT

5

CNC

1

(

5,7,9

)

(

3,5,7

)

(

7,9,11

)

(

1,3,5

)

(

5,7,9

)

CNC

2

(7,9,11) (1,1,1) (1,3,5) (1,1,1) (3,5,7)

CNC

3

(

1,1,1

)

(

1,3,5

)

(

7,9,11

)

(

1,1,1

)

(

7,9,11

)

CNC

4

(1,3,5) (5,7,9) (7,9,11) (1,3,5) (5,7,9)

CNC

5

(

3,5,7

)

(

7,9,11

)

(

5,7,9

)

(

1,1,1

)

(

1,3,5

)

CNC

6

(5,7,9) (1,1,1) (5,7,9) (7,9,11) (1,3,5)

CNC

7

(

7,9,11

)

(

1,3,5

)

(

7,9,11

)

(

7,9,11

)

(

1,1,1

)

CNC

8

(7,9,11) (3,5,7) (7,9,11) (5,7,9) (5,7,9)

CNC

9

(

1,1,1

)

(

5,7,9

)

(

1,1,1

)

(

1,3,5

)

(

5,7,9

)

CNC

10

(1,3,5) (7,9,11) (1,3,5) (1,3,5) (7,9,11)

CNC

11

(

1,3,5

)

(

1,1,1

)

(

5,7,9

)

(

1,1,1

)

(

7,9,11

)

CNC

12

(

3,5,7

)

(

1,3,5

)

(

7,9,11

)

(

7,9,11

)

(

5,7,9

)

CNC

13

(

5,7,9

)

(

3,5,7

)

(

1,1,1

)

(

5,7,9

)

(

7,9,11

)

CNC

14

(

7,9,11

)

(

5,7,9

)

(

1,3,5

)

(

3,5,7

)

(

5,7,9

)

CNC

15

(

5,7,9

)

(

7,9,11

)

(

1,1,1

)

(

1,3,5

)

(

3,5,7

)

CNC

16

(

5,7,9

)

(

1,1,1

)

(

1,3,5

)

(

1,1,1

)

(

1,3,5

)

CNC

17

(

1,1,1

)

(

1,3,5

)

(

3,5,7

)

(

5,7,9

)

(

1,1,1

)

CNC

19

(

1,1,1

)

(

1,3,5

)

(

5,7,9

)

(

7,9,11

)

(

5,7,9

)

Second ex

p

ert CNT

1

CNT

2

CNT

3

CNT

4

CNT

5

CNC

1

(

5,7,9

)

(

1,3,5

)

(

5,7,9

)

(

7,9,11

)

(

5,7,9

)

CNC

2

(

1,3,5

)

(

5,7,9

)

(

7,9,11

)

(

1,1,1

)

(

3,5,7

)

CNC

3

(

1,1,1

)

(

1,3,5

)

(

5,7,9

)

(

7,9,11

)

(

7,9,11

)

CNC

4

(

1,3,5

)

(

5,7,9

)

(

7,9,11

)

(

1,3,5

)

(

5,7,9

)

CNC

5

(

3,5,7

)

(

1,3,5

)

(

5,7,9

)

(

7,9,11

)

(

1,3,5

)

CNC

6

(

5,7,9

)

(

1,1,1

)

(

1,3,5

)

(

5,7,9

)

(

7,9,11

)

CNC

7

(

1,3,5

)

(

5,7,9

)

(

7,9,11

)

(

7,9,11

)

(

1,1,1

)

CNC

8

(

7,9,11

)

(

1,3,5

)

(

5,7,9

)

(

7,9,11

)

(

5,7,9

)

CNC

9

(

1,3,5

)

(

5,7,9

)

(

7,9,11

)

(

1,3,5

)

(

5,7,9

)

CNC

10

(

1,3,5

)

(

7,9,11

)

(

1,3,5

)

(

5,7,9

)

(

7,9,11

)

CNC

11

(

1,3,5

)

(

1,3,5

)

(

5,7,9

)

(

7,9,11

)

(

7,9,11

)

CNC

12

(

3,5,7

)

(

1,3,5

)

(

5,7,9

)

(

7,9,11

)

(

5,7,9

)

CNC

13

(

1,3,5

)

(

5,7,9

)

(

1,3,5

)

(

5,7,9

)

(

7,9,11

)

CNC

14

(

7,9,11

)

(

5,7,9

)

(

1,3,5

)

(

5,7,9

)

(

7,9,11

)

CNC

15

(

1,3,5

)

(

5,7,9

)

(

7,9,11

)

(

1,3,5

)

(

3,5,7

)

CNC

16

(

5,7,9

)

(

1,3,5

)

(

5,7,9

)

(

7,9,11

)

(

1,3,5

)

CNC

17

(

1,1,1

)

(

1,3,5

)

(

1,3,5

)

(

5,7,9

)

(

7,9,11

)

CNC

18

(

1,1,1

)

(

1,3,5

)

(

5,7,9

)

(

7,9,11

)

(

5,7,9

)

Third Ex

p

ert CNT

1

CNT

2

CNT

3

CNT

4

CNT

5

CNC

1

(

5,7,9

)

(

3,5,7

)

(

7,9,11

)

(

1,1,1

)

(

1,3,5

)

CNC

2

(

7,9,11

)

(

7,9,11

)

(

1,1,1

)

(

1,3,5

)

(

3,5,7

)

CNC

3

(

1,1,1

)

(

7,9,11

)

(

7,9,11

)

(

1,1,1

)

(

7,9,11

)

CNC

4

(

7,9,11

)

(

7,9,11

)

(

1,1,1

)

(

1,3,5

)

(

5,7,9

)

CNC

5

(3,5,7) (7,9,11) (7,9,11) (7,9,11) (1,1,1)

CNC

6

(

5,7,9

)

(

7,9,11

)

(

7,9,11

)

(

1,1,1

)

(

1,3,5

)

CNC

7

(7,9,11) (7,9,11) (7,9,11) (1,1,1) (1,1,1)

CNC

8

(

7,9,11

)

(

7,9,11

)

(

1,1,1

)

(

5,7,9

)

(

5,7,9

)

CNC

9

(1,1,1) (5,7,9) (7,9,11) (7,9,11) (1,1,1)

CNC

10

(

7,9,11

)

(

7,9,11

)

(

1,1,1

)

(

1,3,5

)

(

7,9,11

)

CNC

11

(1,3,5) (1,1,1) (7,9,11) (7,9,11) (1,1,1)

CNC

12

(

3,5,7

)

(

7,9,11

)

(

7,9,11

)

(

1,1,1

)

(

5,7,9

)

CNC

13

(5,7,9) (3,5,7) (7,9,11) (7,9,11) (1,1,1)

CNC

14

(

7,9,11

)

(

7,9,11

)

(

7,9,11

)

(

1,1,1

)

(

5,7,9

)

CNC

15

(5,7,9) (7,9,11) (7,9,11) (1,1,1) (3,5,7)

CNC

16

(

5,7,9

)

(

1,1,1

)

(

1,3,5

)

(

1,1,1

)

(

1,3,5

)

CNC

17

(1,1,1) (7,9,11) (7,9,11) (1,1,1) (1,1,1)

CNC

18

(

1,1,1

)

(

1,3,5

)

(

5,7,9

)

(

7,9,11

)

(

5,7,9

)

Fourth ex

p

ert CNT

1

CNT

2

CNT

3

CNT

4

CNT

5

CNC

1

(

5,7,9

)

(

3,5,7

)

(

7,9,11

)

(

5,7,9

)

(

1,1,1

)

CNC

2

(

7,9,11

)

(

5,7,9

)

(

1,1,1

)

(

1,3,5

)

(

3,5,7

)

CNC

3

(

1,1,1

)

(

5,7,9

)

(

1,1,1

)

(

1,3,5

)

(

7,9,11

)

CNC

4

(

1,3,5

)

(

5,7,9

)

(

1,1,1

)

(

1,3,5

)

(

5,7,9

)

CNC

5

(

3,5,7

)

(

7,9,11

)

(

5,7,9

)

(

1,1,1

)

(

1,3,5

)

CNC

6

(

5,7,9

)

(

1,1,1

)

(

1,3,5

)

(

7,9,11

)

(

1,3,5

)

CNC

7

(

7,9,11

)

(

1,3,5

)

(

5,7,9

)

(

1,1,1

)

(

1,3,5

)

CNC

8

(

5,7,9

)

(

1,1,1

)

(

1,3,5

)

(

5,7,9

)

(

5,7,9

)

CNC

9

(

1,1,1

)

(

5,7,9

)

(

1,1,1

)

(

1,3,5

)

(

5,7,9

)

CNC

10

(

1,3,5

)

(

7,9,11

)

(

5,7,9

)

(

1,1,1

)

(

1,3,5

)

CNC

11

(

1,3,5

)

(

5,7,9

)

(

1,1,1

)

(

1,3,5

)

(

7,9,11

)

CNC

12

(

3,5,7

)

(

5,7,9

)

(

1,1,1

)

(

1,3,5

)

(

5,7,9

)

CNC

13

(

5,7,9

)

(

3,5,7

)

(

5,7,9

)

(

1,1,1

)

(

1,3,5

)

CNC

14

(

7,9,11

)

(

5,7,9

)

(

1,1,1

)

(

1,3,5

)

(

5,7,9

)

CNC

15

(5,7,9) (5,7,9) (1,1,1) (1,3,5) (3,5,7)

CNC

16

(

5,7,9

)

(

1,1,1

)

(

1,3,5

)

(

1,1,1

)

(

1,3,5

)

CNC

17

(1,1,1) (5,7,9) (1,1,1) (1,3,5) (1,1,1)

CNC

18

(

1,1,1

)

(

5,7,9

)

(

1,1,1

)

(

1,3,5

)

(

5,7,9

)

Fifth expert CNT

1

CNT

2

CNT

3

CNT

4

CNT

5

CNC

1

(

5,7,9

)

(

1,3,5

)

(

1,3,5

)

(

5,7,9

)

(

5,7,9

)

CNC

2

(7,9,11) (1,3,5) (1,3,5) (5,7,9) (3,5,7)

CNC

3

(

1,1,1

)

(

1,3,5

)

(

1,3,5

)

(

1,3,5

)

(

5,7,9

)

CNC

4

(1,3,5) (1,3,5) (5,7,9) (1,3,5) (5,7,9)

CNC

5

(

1,3,5

)

(

1,3,5

)

(

5,7,9

)

(

1,1,1

)

(

1,3,5

)

CNC

6

(5,7,9) (1,3,5) (1,3,5) (5,7,9) (1,3,5)

CNC

7

(

7,9,11

)

(

1,3,5

)

(

1,3,5

)

(

5,7,9

)

(

1,1,1

)

CNC

8

(

1,3,5

)

(

1,3,5

)

(

5,7,9

)

(

5,7,9

)

(

5,7,9

)

CNC

9

(

1,1,1

)

(

1,3,5

)

(

1,3,5

)

(

5,7,9

)

(

5,7,9

)

CNC

10

(

1,3,5

)

(

1,3,5

)

(

5,7,9

)

(

1,3,5

)

(

7,9,11

)

CNC

11

(

1,3,5

)

(

1,3,5

)

(

1,3,5

)

(

5,7,9

)

(

7,9,11

)

CNC

12

(

1,3,5

)

(

1,3,5

)

(

5,7,9

)

(

7,9,11

)

(

5,7,9

)

CNC

13

(

5,7,9

)

(

1,3,5

)

(

1,3,5

)

(

5,7,9

)

(

7,9,11

)

CNC

14

(

1,3,5

)

(

1,3,5

)

(

5,7,9

)

(

7,9,11

)

(

5,7,9

)

CNC

15

(

5,7,9

)

(

1,3,5

)

(

1,3,5

)

(

5,7,9

)

(

7,9,11

)

CNC

16

(

1,3,5

)

(

1,3,5

)

(

5,7,9

)

(

7,9,11

)

(

1,3,5

)

CNC

17

(

1,1,1

)

(

1,3,5

)

(

1,3,5

)

(

5,7,9

)

(

7,9,11

)

CNC

18

(

1,3,5

)

(

1,3,5

)

(

5,7,9

)

(

7,9,11

)

(

5,7,9

)

REFERENCES

Abas, M., Khattak, S. B., Habib, T., & Nadir, U. (2022).

Assessment of critical risk and success factors in

construction supply chain: a case of Pakistan.

International Journal of Construction Management,

22(12), 2258–2266.

Alharbi, A. H., Jabali, H. M., Rajan, P., & Salamai, A. A.

(2024). Evaluation Challenges of Leadership

Management in the Energy Sector using Multi-Criteria

Decision Making Approach. Multicriteria Algorithms

with Applications, 4, 16–27.

Ali, A. M., & Muthuswamy, M. (2023). Neutrosophic

Multi-Criteria Decision-Making Framework for

Sustainable Evaluation of Power Production Systems in

Renewable Energy Sources. Sustainable Machine

Intelligence Journal, 4, 1–3.

Aloini, D., Dulmin, R., Mininno, V., & Ponticelli, S.

(2012). Supply chain management: a review of

implementation risks in the construction industry.

Business Process Management Journal, 18(5), 735–

761.

Chen, Z., Hammad, A. W. A., & Alyami, M. (2024).

Building construction supply chain resilience under

supply and demand uncertainties. Automation in

Construction, 158, 105190.

de Freitas, L. V., de Freitas, A., Veraszto, E. V., Marins, F.

A. S., & Silva, M. B. (2013). Decision-making with

multiple criteria using AHP and MAUT: An industrial

application. Eur. Int. J. Sci. Technol, 2(9), 93–100.

Deng, X., Yang, X., Zhang, Y., Li, Y., & Lu, Z. (2019).

Risk propagation mechanisms and risk management

strategies for a sustainable perishable products supply

chain. Computers & Industrial Engineering, 135,

1175–1187.

Dong, J., Wan, S., & Chen, S.-M. (2021). Fuzzy best-worst

method based on triangular fuzzy numbers for multi-

FEMIB 2025 - 7th International Conference on Finance, Economics, Management and IT Business

152

criteria decision-making. Information Sciences, 547,

1080–1104.

Dubois, D., Foulloy, L., Mauris, G., & Prade, H. (2004).

Probability-possibility transformations, triangular

fuzzy sets, and probabilistic inequalities. Reliable

Computing, 10(4), 273–297.

Elsayed, A. (2024). Multi-Criteria Decision-Making

Framework for Evaluating Green Fuels Alternatives: A

Hybrid MEREC-TODIM Approach. Neutrosophic

Optimization and Intelligent Systems, 3, 41–56.

Gharaibeh, L., Eriksson, K. M., Lantz, B., Matarneh, S., &

Elghaish, F. (2024). Toward digital construction supply

chain-based Industry 4.0 solutions: scientometric-

thematic analysis. Smart and Sustainable Built

Environment, 13(1), 42–62.

Hernadewita, H., & Saleh, B. I. (2020). Identifying tools

and methods for risk identification and assessment in

construction supply chain. International Journal of

Engineering, 33(7), 1311–1320.

Hijazi, A. A., Perera, S., Alashwal, A., & Calheiros, R. N.

(2019). Blockchain adoption in construction supply

chain: A review of studies across multiple sectors. CIB

World Building Congress, Hong Kong, 2021.

Hmouda, A. M. O., Orzes, G., & Sauer, P. C. (2024).

Sustainable supply chain management in energy

production: A literature review. Renewable and

Sustainable Energy Reviews, 191, 114085.

Işık, A.T. (2017). Critic and Maut Methods for the Contract

Manufacturer Selection Problem. European Journal of

Multidisciplinary Studies Articles, 2.

Obayi, R., & Ebrahimi, S. N. (2021). A neo-institutional

view of the transaction cost drivers of construction

supply chain risk management. Supply Chain

Management: An International Journal, 26(5), 592–

609.

Oyewole, A. T., Okoye, C. C., Ofodile, O. C., & Ejairu, E.

(2024). Reviewing predictive analytics in supply chain

management: Applications and benefits. World Journal

of Advanced Research and Reviews, 21(3), 568–574.

Pham, H. T., Pham, T., Truong Quang, H., & Dang, C. N.

(2023). Supply chain risk management research in

construction: a systematic review. International

Journal of Construction Management, 23(11), 1945–

1955.

Pournader, M., Ghaderi, H., Hassanzadegan, A., &

Fahimnia, B. (2021). Artificial intelligence applications

in supply chain management. International Journal of

Production Economics, 241, 108250.

Rudolf, C. A., & Spinler, S. (2018). Key risks in the supply

chain of large scale engineering and construction

projects. Supply Chain Management: An International

Journal, 23(4), 336–350.

Sa’diyah, N. K., Enggarsasi, U., & Prameswari, S. (2022).

Automatic Transportation System and Human

Resources Development on Society Era 5.0 in

Indonesia. ICoSTE 2020, 111–116.

https://doi.org/10.5220/0010797000003317

Saeed, M., Kareem, K., Razzaq, F., & Saqlain, M. (2024).

Unveiling Efficiency: Investigating Distance Measures

in Wastewater Treatment Using Interval-Valued

Neutrosophic Fuzzy Soft Set. Neutrosophic Systems

with Applications, 15, 1–15.

Senthil, J., & Muthukannan, M. (2022). Development of

lean construction supply chain risk management based

on enhanced neural network. Materials Today:

Proceedings, 56, 1752–1757.

Shishehgarkhaneh, M. B., Moehler, R. C., Fang, Y., Hijazi,

A. A., & Aboutorab, H. (2024). Transformer-Based

Named Entity Recognition in Construction Supply

Chain Risk Management in Australia. IEEE Access, 12,

41829–41851.

Shojaei, P., & Haeri, S. A. S. (2019). Development of

supply chain risk management approaches for

construction projects: A grounded theory approach.

Computers & Industrial Engineering, 128, 837–850.

Singh, A., Dwivedi, A., Agrawal, D., & Singh, D. (2023).

Identifying issues in adoption of AI practices in

construction supply chains: towards managing

sustainability. Operations Management Research,

16(4), 1667–1683.

Tah, J. H. M., & Carr, V. (2001). Towards a framework for

project risk knowledge management in the construction

supply chain. Advances in Engineering Software,

32(10–11), 835–846.

Yoon, J. H., & Pishdad-Bozorgi, P. (2022). State-of-the-art

review of blockchain-enabled construction supply

chain. Journal of Construction Engineering and

Management, 148(2), 3121008.

Yu, R., & Ma, L. (2024). Risk evaluation of mega

infrastructure construction supply chain in engineering-

procurement-construction projects: an integrated fuzzy

AHP and fuzzy DEMATEL approach. Engineering,

Construction and Architectural Management.

Fuzzy MCDM Framework for Risk Management in Construction Supply Chain

153