Optimising IIoT Control Systems at Demcon: Integrating MQTT,

Sparkplug B, and ISA-88 for Unified Automation

Ana Pintilie

1

, Remco Poelarends

2

and Andrea Capiluppi

1 a

1

Department of Computing Science, University of Groningen, The Netherlands

2

Technology and Innovation Department, Demcon, The Netherlands

Keywords:

Industrial Internet of Things (IIoT), MQTT, Sparkplug B, Unified Namespace, Industry 4.0, .NET

Architecture, TwinCAT, Industrial Automation.

Abstract:

This paper addresses the challenges in optimizing PLC-based industrial control systems at Demcon to meet

IIoT standards. Through a collaboration with the University of Groningen (NL), we redesigned the archi-

tecture using MQTT and Sparkplug B to enable scalable, real-time communication and introduced a Unified

Namespace (UNS) for seamless data exchange. The results demonstrate improved flexibility, scalability, and

latency reduction, validating the approach in an industrial environment and highlighting its broader potential

for IIoT adoption.

1 INTRODUCTION

Industry 4.0 has revolutionized manufacturing by in-

tegrating IIoT and advanced analytics, enabling real-

time data exchange and decision-making. However,

Demcon’s PLC-based control systems face challenges

in scalability, communication, and real-time monitor-

ing, limiting their ability to meet evolving industrial

demands.

This paper presents a case study on redesigning

Demcon’s architecture, leveraging MQTT and Spark-

plug B for scalable communication and introducing a

Unified Namespace (UNS) to standardize data flow.

The redesign aimed to address bottlenecks in real-

time control and enhance operational efficiency, pro-

viding a model for broader IIoT applications.

The remainder of the paper is structured as fol-

lows: Section 2 reviews relevant literature, Sec-

tion 3.2 and 4 outline the case study and the method-

ology, and Section 5 presents the findings. The pa-

per concludes with a discussion of implications (Sec-

tion 6) and future directions (Section 7).

2 RELATED WORKS

Industry 4.0 and IIoT have rapidly transformed var-

ious sectors, improving efficiency, flexibility, and

a

https://orcid.org/0000-0001-9469-6050

communication (Mohammed Saleem et al., 2024).

AI, machine learning and IoT technologies drive this

digital revolution, but challenges such as data man-

agement, security and workforce skills remain sig-

nificant (Z. Jan et al., 2022). Applications extend

beyond manufacturing, impacting healthcare, agri-

culture and education (Bharti Rana and S. Rathore,

2022), and automotive and transportation industries

also benefit from increased customisation and produc-

tivity (Dheeraj Nimawat and B. Gidwani, 2021).

From past research on IIoT, MQTT has often been

favored due to its lightweight nature, making it ideal

for resource-constrained environments (G. Reddy,

2017). Comparative studies have shown its efficiency

in terms of network overhead and latency compared

to CoAP and OPC UA (Iglesias-Urkia et al., 2017).

It has also been demonstrated that integrating MQTT

with Sparkplug B supports efficient data streaming,

with reduced traffic overhead and lower latency (Ko-

prov et al., 2022). However, the choice between

MQTT and other alternatives, such as OPC UA, de-

pends on specific application scenarios, with each of-

fering distinct advantages in industrial communica-

tion (Wang et al., 2022).

IoT communication protocols such as CoAP,

MQTT and OPC UA have been evaluated based on

metrics like latency, scalability and energy efficiency.

CoAP often outperforms other protocols in through-

put, while MQTT excels in resource-constrained en-

vironments (Silva et al., 2021). However, the se-

Pintilie, A., Poelarends, R. and Capiluppi, A.

Optimising IIoT Control Systems at Demcon: Integrating MQTT, Sparkplug B, and ISA-88 for Unified Automation.

DOI: 10.5220/0013142000003928

In Proceedings of the 20th International Conference on Evaluation of Novel Approaches to Software Engineering (ENASE 2025), pages 351-358

ISBN: 978-989-758-742-9; ISSN: 2184-4895

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

351

lection of protocol remains application-dependent, as

OPC UA can perform better in certain industrial sce-

narios (Rocha et al., 2019).

Integrating Operational Technology (OT) with In-

formation Technology (IT) systems in industrial envi-

ronments poses significant challenges due to interop-

erability and security concerns (Watson et al., 2017).

Protocols like MQTT Sparkplug B and OPC UA have

enabled seamless communication and vertical inte-

gration, enhancing flexibility in distributed control

systems (Koprov et al., 2022). Security challenges in

low-power IIoT devices have been mitigated through

the use of integration gateways and improved mod-

els (Mantravadi et al., 2020).

The ISA-88 standard enhances batch process flex-

ibility and standardisation across industries, including

pharmaceuticals and manufacturing (Jim Parshall and

Larry C. Lamb, 1999; De Minicis et al., 2014). In-

tegrating ISA-88 with Industry 4.0 concepts and IIoT

protocols (e.g., MQTT) has improved data flow and

real-time process management (Garcia et al., 2022),

reducing programming efforts and improving process

flexibility (Neugschwandtner et al., 2013).

The Unified Namespace (UNS) standardises data

flow, improving real-time communication and enter-

prise scalability (Abouzied et al., 2024; Li et al.,

2021). MQTT Sparkplug B aids in achieving UNS

by connecting Operational Technology networks to

cloud platforms (Koprov et al., 2022). Emerging

architectures, including Time-Sensitive Networking

(TSN) and hybrid wired-wireless systems, offer fur-

ther advancements in real-time performance and flex-

ibility (Simon Brooks and Ecehan Uludag, 2018).

Edge computing enhances real-time data process-

ing and bandwidth optimisation in IIoT systems (Qiu

et al., 2020). AI and machine learning further

improve predictive maintenance and process opti-

mization by enabling real-time analysis of sensor

data (Walas and Redchuk, 2021). Integrating AI mod-

els with IIoT improves fault detection and decision-

making, thus enhancing industrial efficiency (Gandhi,

2023; Kliestik et al., 2023).

3 KEY DEFINITIONS AND SITE

DESCRIPTION

Section (3) defines the key terms and technologies rel-

evant to the work performed at Demcon. Section 3.2

describes the industrial collaborator’s site and the is-

sues faced in the production site, while section 3.3

highlights the various aspects of intervention in the

architectural redesign.

3.1 Definitions and Technologies Used

• Industrial Internet of Things (IIoT): Connects ma-

chines and sensors in industrial environments for

enhanced efficiency, automation, and real-time

data analysis.

• MQTT: A lightweight messaging protocol ideal

for IIoT, enabling real-time communication be-

tween constrained devices (Stanford-Clark and

Truong, 2013).

• Sparkplug B: An MQTT extension providing

structured data exchange and lifecycle manage-

ment for IIoT devices (Solutions, 2016).

• Unified Namespace (UNS): A centralized reposi-

tory for real-time data and metadata

• PLC: Programmable Logic Controllers used in

automation to control machinery, though less scal-

able in modern IIoT environments.

• TwinCAT: A real-time PLC programming plat-

form used in industries like manufacturing and

pharmaceuticals.

• ISA-88 Standard: Provides guidelines for batch

control, standardizing processes for flexibility and

scalability. It defines three models: Process

Model (production steps), Physical Model (man-

ufacturing environment layers), and Procedural

Model (logical sequence of actions for batch con-

trol).

3.2 Description of the Site

The site selected for this research and implementation

is Demcon Industrial Systems

1

, based in Groningen.

The company was chosen for this project due to its ef-

forts to modernize the control system architecture and

adopt emerging Industrial Internet of Things (IIoT)

technologies, making it an ideal partner for testing in-

novative IIoT solutions.

Demcon operates a sophisticated manufacturing

environment that relies on PLCs to control industrial

processes and its operations are divided into multi-

ple production units, each equipped with specialised

machinery and sensors. These units are connected

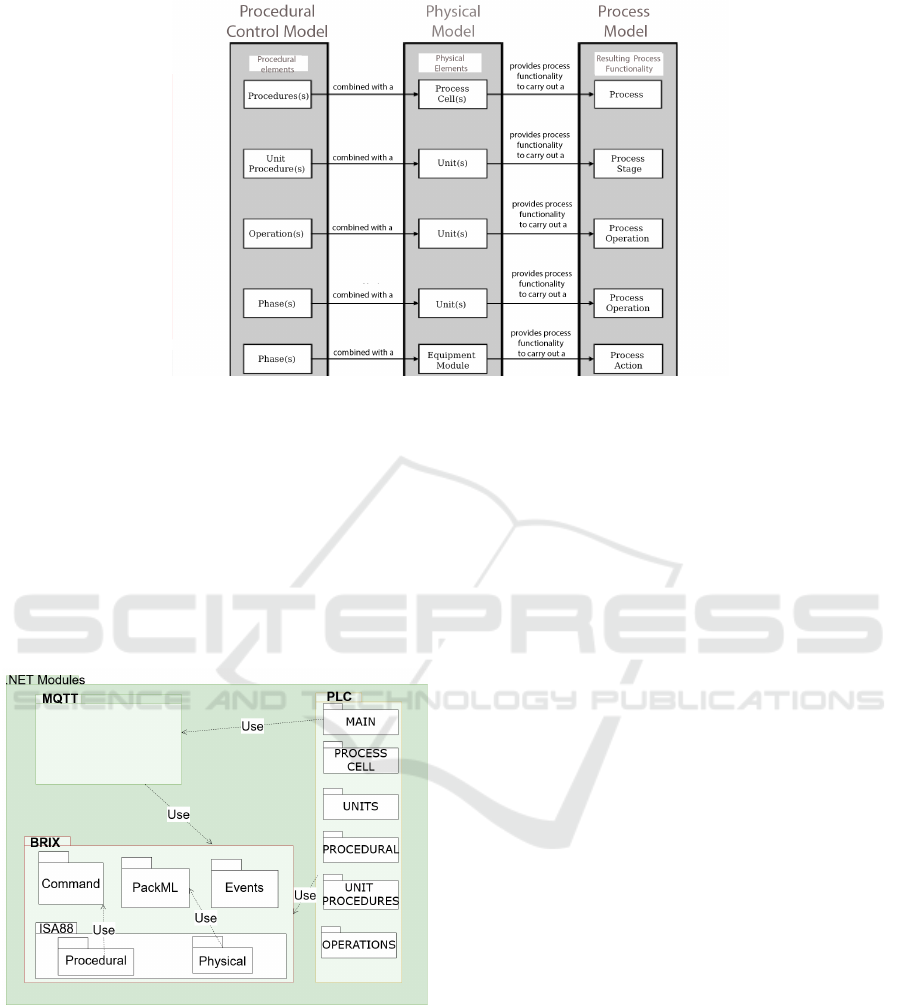

through BRIX (see Figure 1), an internal architecture

based on the traditional industrial pyramid architec-

ture ((Martinez et al., 2021)). While effective for

legacy processes, this architecture poses challenges

in data flow, flexibility and scalability, particularly as

Demcon plans to transition to a smart factory model.

1

https://demcon.com/

ENASE 2025 - 20th International Conference on Evaluation of Novel Approaches to Software Engineering

352

Figure 1: BRIX Architecture currently utilised in Demcon:

the dashed line encloses the extent of the intervention de-

scribed in this work.

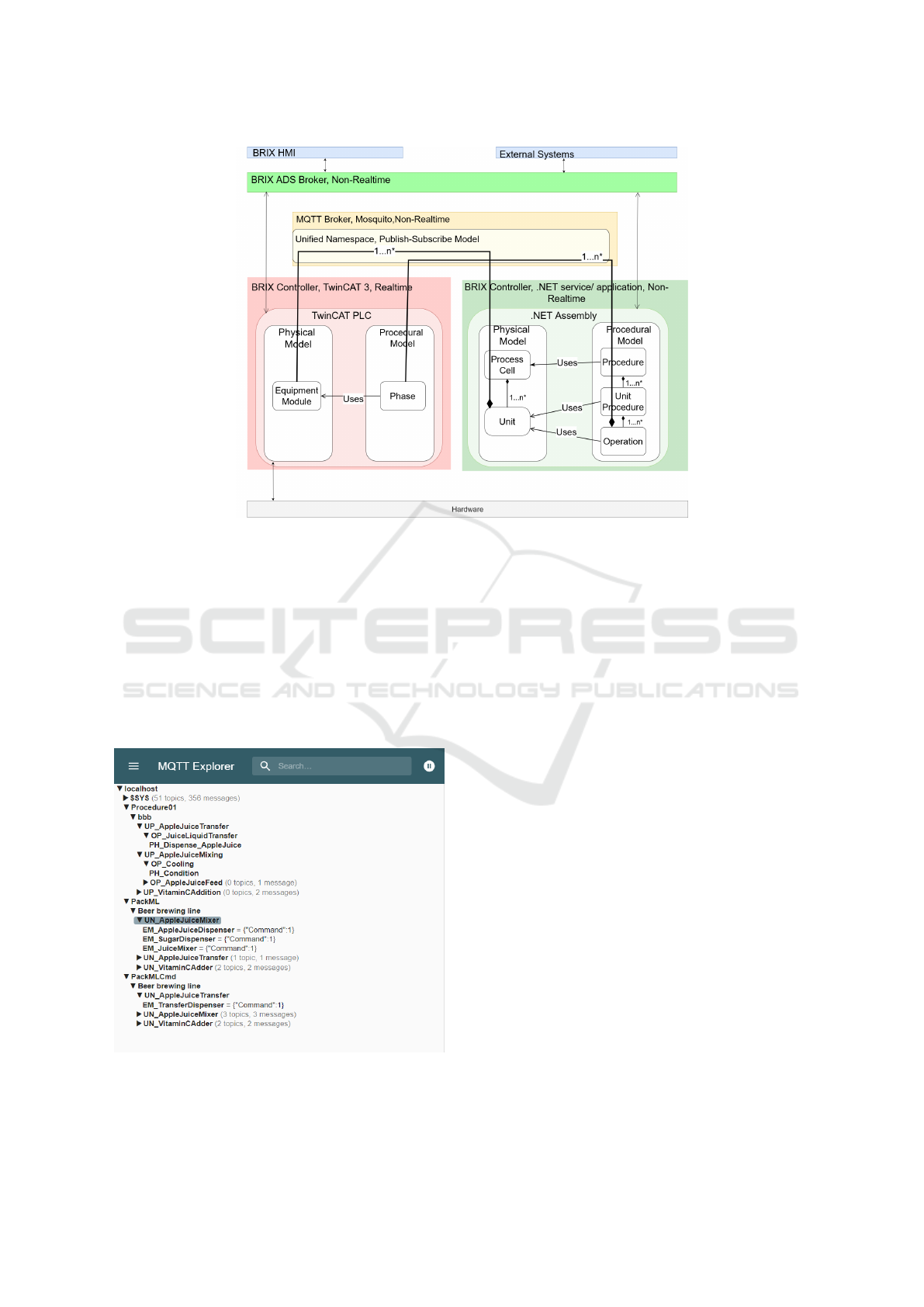

The PLC also contains multiple automated mod-

ules that are abstracted according to the ISA-88 stan-

dard, as shown in Figure 2: redesigning them into a

hybrid architecture was one of the aims of the work

conducted within Demcon.

3.3 Formulation of the Problem

Demcon’s control systems rely on rigid and ineffi-

cient PLCs programmed with TwinCAT, causing bot-

tlenecks in data handling, real-time communication,

and device integration. The hierarchical structure lim-

its real-time data sharing across manufacturing levels,

delaying decision-making and reducing efficiency. As

operational demands grow, a unified communication

protocol is needed to manage the increasing number

of devices and sensors.

A key challenge is the lack of seamless integration

between operational technology (OT) and informa-

tion technology (IT) networks. Data collected at the

PLC level is not efficiently communicated to SCADA,

MES, and ERP systems, leading to delays in analytics

and feedback, which impacts efficiency. Additionally,

Demcon’s reliance on TwinCAT limits system scala-

bility and maintainability due to its rigid structure, not

suited for the dynamic needs of IIoT systems.

Recognizing these limitations, Demcon aims to

design a more flexible, agile system architecture using

IIoT technologies like MQTT and Sparkplug B to en-

hance operational efficiency and scalability. Figure 1

illustrates Demcon’s BRIX architecture, showing the

interaction between control modules and OT.

The proposed intervention, shown in Figure 1 by

a dashed grey rectangle, targets the controllers within

the BRIX architecture. Currently, the ISA-88 based

control modules (see Figure 2) are fully integrated

into the real-time controller. This research proposes

migrating most of these modules to a non-real-time

controller, retaining only essential base modules in

the real-time controller. Communication will occur

through a unified namespace managed by a broker.

The redesign of Demcon’s controlling system archi-

tecture leverages IIoT technologies by focusing on the

control logic within the PLC (the BRIX controllers in

Figure 1), a key element of the traditional automation

pyramid. The current system, limited by the PLC’s

memory and processing, operates in a rigid environ-

ment. A planned migration from a PLC-centred to

a hybrid architecture moves the majority of system

logic to a .NET environment, addressing these con-

straints and enabling more complex control logic and

real-time data processing.

The intervention also implements the MQTT pro-

tocol with Sparkplug B as the backbone for commu-

nication between the migrated .NET modules and the

PLC. MQTT’s publish/subscribe model supports effi-

cient data exchange across production, while Spark-

plug B ensures unified data management and state

control. This enhances scalability, enabling easier de-

vice integration and real-time production monitoring.

Finally, a unified namespace (UNS) standardises

data flows between operational levels, serving as a

”single source of truth” for system data. The UNS

eliminates data exchange bottlenecks, consolidating

communication into a coherent structure. This re-

design improves flexibility and efficiency, allowing

Demcon to adapt to evolving production demands.

4 METHODOLOGY

This section outlines the methodology used to re-

design the industrial control system architecture at

Demcon. The approach involved migrating upper-

level control modules to a .NET environment while

keeping lower-level control within PLCs. Communi-

cation between the two levels was facilitated by an

MQTT broker, with the integration of Sparkplug B

to extend MQTT functionality for real-time data ex-

change.

4.1 System Architecture Redesign

The system follows a hybrid architecture, where most

ISA-88 abstraction layers were migrated from the

real-time PLC system to .NET. Communication be-

tween the real-time and non-real-time components is

facilitated by an MQTT broker (Figure 4). This shift

addresses PLC memory and processing limitations,

enabling more complex control logic and real-time

data processing.

The modular architecture divides the system into

Optimising IIoT Control Systems at Demcon: Integrating MQTT, Sparkplug B, and ISA-88 for Unified Automation

353

Figure 2: Diagram of the BRIX Controller built following the ISA88 standard.

independent components: PLC modules handle real-

time control and lower-level tasks, while .NET mod-

ules manage upper-level logic and dynamic control

flows. The MQTT broker acts as the central mes-

saging hub, enabling publish/subscribe communica-

tion between modules. This modular approach en-

hances scalability, simplifies system updates, ensures

fault isolation, and supports future expansions. Fig-

ure 3 illustrates these components and their interde-

pendencies.

Figure 3: Modular view of .NET modules within the non-

real-time controller (zoom-in representation from Fig 3).

A key part of the intervention was the implemen-

tation of a PLC-level broker (highlighted in yellow

in Figure 4), which serves as a proof of concept

for integration into the broader BRIX broker archi-

tecture. This will provide a more extensive unified

namespace, enhancing flexibility and communication

across the control system.

The system architecture shifted from a cycle-

based PLC approach to an event-driven model in the

.NET modules, where each subprocess triggers the

next immediately. Physical elements change state or

send notifications through the event system, enabling

instant reactions to changes and maintaining contin-

uous operation. This transition replaces fixed cycles

with event-driven behavior, making the system more

dynamic and closer to real-time operation.

4.2 Communication Protocol: MQTT

and Sparkplug B

MQTT, augmented by Sparkplug B, was imple-

mented to enable efficient real-time communication

between the .NET modules, PLCs, and the MQTT

broker. MQTT was chosen for its lightweight pub-

lish/subscribe model, ideal for low-bandwidth en-

vironments. Sparkplug B was used to standardize

data formats, organize data into a hierarchical topic

namespace, and support device lifecycle management

through ”birth” and ”death” messages. These features

helped improve system reliability. However, Spark-

plug B was found to be incompatible with the existing

system due to its rigid structure, limiting its utility in

this specific case.

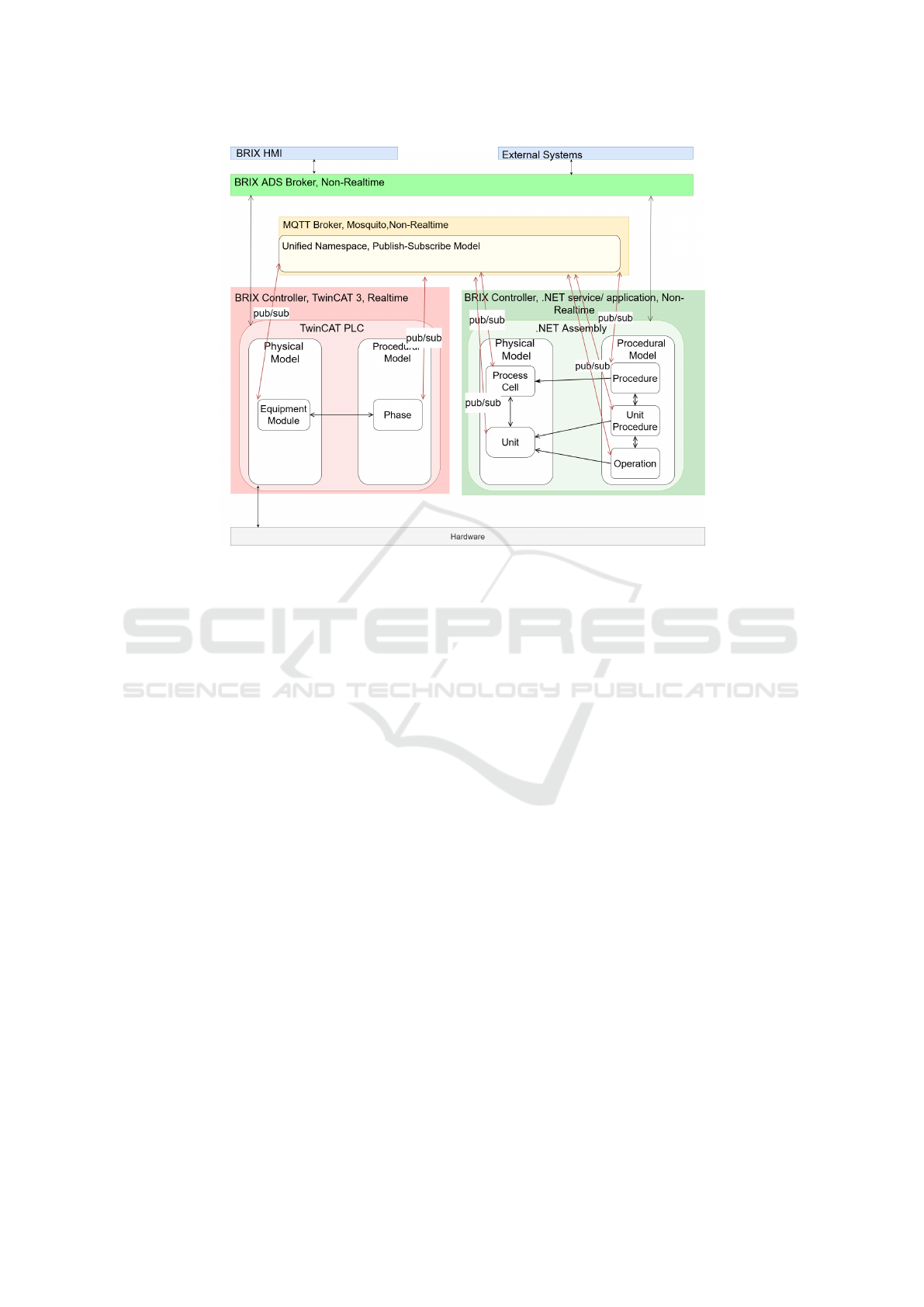

4.3 Data Monitoring and Collection

Real-time data monitoring was implemented using

MQTT Explorer to validate the redesigned archi-

tecture. The tool visualized the data flow between

the .NET modules, PLCs, and the MQTT broker,

ensuring efficient communication through a Unified

Namespace (UNS) based on system constraints and

ENASE 2025 - 20th International Conference on Evaluation of Novel Approaches to Software Engineering

354

Figure 4: BRIX hybrid controller: Composition of ISA-88 abstraction modules, illustrating the division between real-time

and non-real-time components. This zoomed-in view highlights the specific components and interactions within the BRIX

controllers as shown in Figure 1.

inter-module relationships. The data streams included

operational data from sensors, actuators, and PLCs,

system status updates through lifecycle events, and

control commands from .NET modules managing

physical processes. Figure 5 shows the topic hierar-

chy used for monitoring, structured by module loca-

tion and data scope.

Figure 5: Screenshot taken from MQTT Explorer during

system monitoring.

5 RESULTS AND EVALUATION

The project aimed to assess the feasibility of us-

ing MQTT and Sparkplug B for IIoT communication

while designing a scalable control system. These ob-

jectives were successfully met, with MQTT enabling

efficient communication. However, Sparkplug B ex-

hibited limitations due to its rigid structure. The fol-

lowing analysis evaluates system functionality, per-

formance, communication efficiency, and the integra-

tion feasibility of MQTT and Sparkplug B.

5.1 System Functionality and

Performance

Transitioning from a PLC-based to a hybrid architec-

ture combining PLCs and .NET modules enhanced

system flexibility and scalability while retaining es-

sential real-time control for industrial automation.

This aligns with the broader trend of integrating

legacy systems with modern architectures to meet In-

dustry 4.0 and IIoT requirements (Sheetal M. Solanki,

2023; Mohammed Saleem et al., 2024).

The modular design of the .NET-based architec-

ture greatly improved flexibility, allowing for inde-

pendent development of control modules. This facil-

itated easier updates and maintenance while enabling

seamless future expansions without disrupting the

Optimising IIoT Control Systems at Demcon: Integrating MQTT, Sparkplug B, and ISA-88 for Unified Automation

355

system’s existing functionality. In IIoT contexts, such

modularity is critical for scaling and reconfiguring

systems to meet evolving industrial demands (Garcia

et al., 2022). Additionally, the event-driven model

in .NET provided dynamic control, making the sys-

tem more responsive compared to the cyclic execu-

tion inherent in traditional PLCs. This adaptability is

a cornerstone of Industry 4.0, where operational effi-

ciency depends on swift responses to changing condi-

tions (Walas and Redchuk, 2021).

Scalability was also a significant improvement,

supported by MQTT’s publish/subscribe model. This

architecture efficiently managed multiple devices and

data streams, minimising communication overhead.

The lightweight nature of MQTT messaging ensured

that modules only subscribed to relevant topics, re-

ducing unnecessary data exchange and optimising

communication efficiency. This characteristic makes

MQTT particularly suitable for resource-constrained

environments (G. Reddy, 2017).

5.2 Communication Efficiency

The integration of MQTT resulted in noticeable im-

provements in communication efficiency. By utilising

its publish/subscribe model, the system facilitated im-

mediate data transmission between publishers, such

as PLCs and sensors, and subscribers, such as .NET

modules. This mechanism ensured consistently low

latency, with most messages being delivered within

100 milliseconds. Such performance is essential for

industrial applications requiring real-time control and

aligns with findings in other studies that highlight

MQTT’s advantages over alternative protocols such

as CoAP and OPC UA (Rocha et al., 2019).

5.3 Feasibility of MQTT and Sparkplug

B in IIoT Systems

The study examined the feasibility of integrating

MQTT and Sparkplug B within an IIoT framework:

MQTT demonstrated high effectiveness in support-

ing real-time communication, ensuring tight interac-

tion between various system components. Spark-

plug B proved less suitable due to its rigid payload

structure and strict device-oriented namespace rules.

These limitations introduced redundancy and com-

plexity, rather than enhancing scalability or data man-

agement. While the system benefited from MQTT’s

low-latency data exchange, which supported real-time

monitoring and control, Sparkplug B’s inflexible for-

mat hindered its broader applicability (De Minicis

et al., 2014; Neugschwandtner et al., 2013).

5.4 Limitations and Challenges

Despite the successes, the system faced several lim-

itations. One significant challenge was the compati-

bility of Sparkplug B, whose rigid structure and strict

namespace rules were poorly suited to the PLC archi-

tecture. This led to increased redundancy and com-

plexity without providing notable improvements in

data management. Another limitation was the lack of

real-world testing. The system relied on static recipes

and simulated data, restricting its exposure to dy-

namic, real-world industrial conditions. To fully eval-

uate long-term performance, testing in practical envi-

ronments is necessary (Walas and Redchuk, 2021).

Furthermore, this study focused on developing a

proof-of-concept rather than a fully implemented so-

lution, meaning there are no direct performance com-

parisons to traditional PLC systems at this stage. The

results presented here demonstrate the feasibility of

the proposed hybrid architecture and communication

protocols, serving as a foundation for future research.

The integration of MQTT showed clear benefits in

communication efficiency, while the challenges iden-

tified with Sparkplug B suggest areas for further de-

velopment. Future work will focus on completing

the migration of control modules to .NET, optimizing

system performance, and conducting real-world test-

ing to validate the system’s scalability and robustness

in industrial environments.

6 DISCUSSION AND LESSONS

LEARNT

The results of the system redesign highlight the feasi-

bility of integrating MQTT and Sparkplug B into in-

dustrial control architectures. This section explores

the broader implications of the findings, lessons from

the system redesign, and the potential for applying the

architecture to other industrial contexts.

6.1 Key Takeaways

The transition from a traditional PLC-centric system

to a hybrid architecture provided insights into the

challenges and opportunities of IIoT-based industrial

automation. Combining PLCs with .NET-based con-

trol modules proved advantageous, retaining the re-

liability of PLCs for real-time control while lever-

aging the flexibility of .NET for higher-level logic.

This hybrid approach enabled a more adaptive sys-

tem without compromising reliability, aligning with

industry trends towards scalable and adaptable con-

trol systems (Walas and Redchuk, 2021).

ENASE 2025 - 20th International Conference on Evaluation of Novel Approaches to Software Engineering

356

Figure 6: Enhanced communication in BRIX controllers enabled by MQTT and a unified namespace. Red lines represent new

communication channels; black lines depict improved existing connections, derived from legacy architecture.

Standardised communication protocols also

played a vital role, as evidenced by the effectiveness

of MQTT. The adoption of MQTT facilitated seam-

less, scalable communication across diverse devices

and platforms. Literature supports this observation,

noting that protocols like MQTT and Sparkplug

B simplify the management of complex systems

while reducing development and maintenance

efforts (Iglesias-Urkia et al., 2017).

6.2 Applicability to Other Industries

and Future Extensions

This study’s findings are applicable beyond Dem-

con’s systems, offering a versatile model for indus-

tries adopting IIoT technologies, including energy,

healthcare, and logistics. The architectural design,

particularly the use of MQTT and Sparkplug B, aligns

well with requirements in smart factories and dis-

tributed energy systems, where real-time data ex-

change is crucial (Koprov et al., 2022). Addition-

ally, the architecture provides a foundation for inte-

grating advanced technologies, such as AI for predic-

tive maintenance and edge computing for enhanced

real-time processing. As IIoT evolves, these features

position the architecture to address emerging trends

in Industry 4.0 (Waghanna et al., 2024).

7 CONCLUSION

This study presents the successful redesign of a PLC-

based control system into a flexible scalable hybrid

architecture using MQTT and Sparkplug B. The sys-

tem combines PLCs’ real-time control with the dy-

namic, event-driven nature of .NET modules, improv-

ing scalability, communication efficiency, and modu-

larity. MQTT enabled efficient communication, while

Sparkplug B standardized data, allowing seamless in-

tegration across system components and supporting

the evolving demands of industrial automation.

While the architecture was effective in controlled

testing, challenges with Sparkplug B compatibility

and limited real-world testing show areas for further

investigation. The architecture has broader potential

for industries like manufacturing, energy, healthcare,

and logistics, which could benefit from the flexibility

and efficiency of IIoT-based control systems.

In conclusion, this research laid the groundwork

for further development of hybrid architectures at

Demcon, offering a path for integrating modern com-

munication protocols and real-time data processing

into traditional manufacturing environments.

Optimising IIoT Control Systems at Demcon: Integrating MQTT, Sparkplug B, and ISA-88 for Unified Automation

357

REFERENCES

Abouzied, A. A., Kouta, H. K., Elhadek, M. A., and Aly,

S. (2024). Unlocking The Potential of Industry 4.0

Technologies in The Egyptian Industry. Port-Said En-

gineering Research Journal, 0(0):0–0.

Bharti Rana and S. Rathore (2022). Industry 4.0 – Appli-

cations, challenges and opportunities in industries and

academia: A review. Materials Today: Proceedings.

De Minicis, M., Giordano, F., Poli, F., and Schiraldi, M. M.

(2014). Recipe Development Process Re-Design with

ANSI/ISA-88 Batch Control Standard in the Pharma-

ceutical Industry. International Journal of Engineer-

ing Business Management, 6:16.

Dheeraj Nimawat and B. Gidwani (2021). Industry 4.0 in

Various Sectors: Review and Future Scope.

G. Reddy (2017). Message Queuing Telemetry Transport.

Gandhi, A. (2023). Integrating Big Data Analytics and Ma-

chine Learning for Predictive Maintenance within In-

dustrial IoT Frameworks. In 2023 International Con-

ference on Communication, Security and Artificial In-

telligence (ICCSAI), volume 11, pages 1015–1019.

IEEE.

Garcia, A., Oregui, X., Arrieta, U., and Valverde, I. (2022).

Methodology and Tools to Integrate Industry 4.0 CPS

into Process Design and Management: Isa-88 Use

Case. Information, 13(5):226.

Iglesias-Urkia, M., Orive, A., Barcelo, M., Moran, A., Bil-

bao, J., and Urbieta, A. (2017). Towards a lightweight

protocol for Industry 4.0: An implementation based

benchmark. In 2017 IEEE International Workshop of

Electronics, Control, Measurement, Signals and their

Application to Mechatronics (ECMSM). IEEE.

Jim Parshall and Larry C. Lamb (1999). Applying S88:

Batch Control from a User’s Perspective.

Kliestik, T., Nica, E., Durana, P., and Popescu, G. H. (2023).

Artificial intelligence-based predictive maintenance,

time-sensitive networking, and big data-driven algo-

rithmic decision-making in the economics of Indus-

trial Internet of Things. Oeconomia Copernicana,

14(4):1097–1138.

Koprov, P., Ramachandran, A., Lee, Y.-S., Cohen, P., and

Starly, B. (2022). Streaming Machine Generated Data

via the MQTT Sparkplug B Protocol for Smart Fac-

tory Operations. Manufacturing Letters, 33:66–73.

Li, C., Mantravadi, S., Schou, C., Nielsen, H., Madsen, O.,

and Møller, C. (2021). An ISA-95 based Middle Data

Layer for Data Standardization—Enhancing Systems

Interoperability for Factory Automation, pages 187–

194. Springer Berlin Heidelberg.

Mantravadi, S., Schnyder, R., Moller, C., and Brunoe,

T. D. (2020). Securing IT/OT Links for Low Power

IIoT Devices: Design Considerations for Industry 4.0.

IEEE Access, 8:200305–200321.

Martinez, E. M., Ponce, P., Macias, I., and Molina, A.

(2021). Automation pyramid as constructor for a com-

plete digital twin, case study: A didactic manufactur-

ing system. Sensors, 21(14).

Mohammed Saleem, S. Askar, Media Ali Ibrahim, Mina

Othman, and Nihad Abdullah (2024). The Industrial

Internet of Things (IIoT) and its roles in the Fourth

Industrial Revolution: A review. Indonesian Journal

of Computer Science.

Neugschwandtner, G., Reekmans, M., and van der Lin-

den, D. (2013). An open automation architecture for

flexible manufacturing. In 2013 IEEE 18th Confer-

ence on Emerging Technologies &; Factory Automa-

tion (ETFA), pages 1–5. IEEE.

Qiu, T., Chi, J., Zhou, X., Ning, Z., Atiquzzaman, M., and

Wu, D. O. (2020). Edge Computing in Industrial In-

ternet of Things: Architecture, Advances and Chal-

lenges. IEEE Communications Surveys &; Tutorials,

22(4):2462–2488.

Rocha, M. S., Sestito, G. S., Dias, A. L., Turcato, A. C.,

Brand

˜

ao, D., and Ferrari, P. (2019). On the per-

formance of OPC UA and MQTT for data exchange

between industrial plants and cloud servers. ACTA

IMEKO, 8(2):80.

Sheetal M. Solanki (2023). Industry 4.0 and Smart Manu-

facturing: Exploring the integration of advanced tech-

nologies in manufacturing. Revista Review Index

Journal of Multidisciplinary.

Silva, D., Carvalho, L. I., Soares, J., and Sofia, R. C. (2021).

A Performance Analysis of Internet of Things Net-

working Protocols: Evaluating MQTT, CoAP, OPC

UA. Applied Sciences, 11(11):4879.

Simon Brooks and Ecehan Uludag (2018). Time-Sensitive

Networking: From Theor y to Implementation in In-

dustrial Automation.

Solutions, C. L. (2016). Sparkplug B Specification.

Stanford-Clark, A. and Truong, H. L. (2013). Mqtt for sen-

sor networks (mqtt-sn) protocol specification. Inter-

national business machines (IBM) Corporation ver-

sion, 1(2):1–28.

Waghanna, P., Reddy, A., Deshpande, S., Chavan, S.,

Jaiswal, V. R., and Naranje, V. (2024). Effects of

Adopting Industry 4.0 on a Manufacturing Plant. In

2024 11th International Conference on Reliability, In-

focom Technologies and Optimization (Trends and Fu-

ture Directions) (ICRITO), pages 1–6. IEEE.

Walas, F. and Redchuk, A. (2021). Iiot/IoT and Artificial

Intelligence/Machine Learning as a Process Optimiza-

tion driver under industry 4.0 model. Journal of Com-

puter Science and Technology, 21(2):e15.

Wang, X., Mutlu,

˙

I., Rani, F., Drowatzky, L., and Urbas,

L. (2022). A Comparative Study to Evaluate the Per-

formance of Communication Protocols for Process In-

dustry. In 2022 32nd International Telecommunica-

tion Networks and Applications Conference (ITNAC),

volume 26, pages 170–177. IEEE.

Watson, V., Tellabi, A., Sassmannahausen, J., and Lou, X.

(2017). Interoperability and Security Challenges of

Industry 4.0.

Z. Jan, Farhad Ahamed, W. Mayer, Niki Patel, G. Gross-

mann, M. Stumptner, and Anastasia Kuusk (2022).

Artificial intelligence for industry 4.0: Systematic re-

view of applications, challenges, and opportunities.

Expert systems with applications.

ENASE 2025 - 20th International Conference on Evaluation of Novel Approaches to Software Engineering

358