Repurposing Alternators as Motors: Promoting Sustainability and

Circular Economy in Low-Cost Mobility Systems

Maximilian Dillitzer

1,∗

, Patrick Issle

1,∗

, Julian Schwarz

1,∗

, Tin Stribor Sohn

2,∗

,

Michael Auerbach

1

and Wolfgang Gruel

1

1

Hochschule Esslingen, Esslingen, Germany

2

Porsche AG, Weissach, Germany

{madifz04, paisfz00, juscfz05, michael.auerbach, wolfang.gruel}@hs-esslingen.de, tin stribor.sohn@porsche.de

Keywords:

Sustainable Mobility System, Reusability, Circular Economy, User Centered Design, Alternators.

Abstract:

The automotive industry is undergoing a transformation driven by electric mobility, automated driving, and

value creation. However, this shift often overlooks developing regions, where unique challenges restrict ac-

cess to affordable, low-emission transportation. This paper explores how repurposing parts from end-of-life

vehicles can promote sustainable mobility solutions in developing regions, where access to transportation is

limited. We focus on converting alternators from internal combustion engines into electric motors, benefiting

both the environment and resource-constrained populations. Our approach follows seven requirements for a

sustainable mobility system, emphasizing affordability, sustainability, and circular economy principles over

high-performance, costly solutions. By applying circular economy principles, we highlight the reuse of avail-

able alternators from scrap vehicles, providing a cost-effective and eco-friendly solution suited to the needs

of developing regions. This approach addresses several Sustainable Development Goals, enhancing access to

clean energy, economic growth, and responsible consumption. Engaging with local communities provided in-

sights into specific needs and ensured practical applicability. To validate our approach, we conducted rig tests

and field studies in Africa and Germany to assess the performance and viability of the repurposed alternators

in real-world conditions. Successful testing in both regions demonstrates that this mobility system offers a

practical solution to real-world challenges.

1 INTRODUCTION

Mobility in Africa faces significant challenges, as in-

adequate transportation infrastructure and high costs

hinder development and limit access to essential ser-

vices. These issues not only contribute to social in-

equality but also impede economic growth in many

regions. Many communities are left with little choice

but to rely on expensive transportation options, which

are often not sustainable nor accessible for lower-

income populations. Moreover, there is a consider-

able amount of scrap material, including vehicle alter-

nators, that could be repurposed for alternative uses,

alongside solar energy resources that remain under-

utilized.

This research addresses the conversion of vehi-

cle alternators into electric motors as a low-cost so-

lution to mobility challenges in resource-limited en-

vironments. By repurposing alternators, originally

∗

Equal contribution

designed to convert mechanical energy into electri-

cal energy for battery charging, this approach offers

a sustainable alternative to conventional electric mo-

tors, especially when vehicles are no longer opera-

tional.

Grounded in circular economy principles, this

conversion minimizes environmental impact by ex-

tending the life cycle of existing components, reduc-

ing the need for new motor production. Further-

more, it addresses the economic limitations of devel-

oping regions and supports the achievement of Sus-

tainable Development Goals (SDGs) related to acces-

sibility and sustainability, particularly in African con-

texts where financial resources are limited.

The goal of this research is not to improve the

electrical performance of the alternator in its new ap-

plication, but rather to maximize its applicability as an

electric motor within the constraints of affordability,

technical limitations of the given alternator, and sus-

tainability. This includes addressing challenges such

as the performance of the alternator in low speed sce-

Dillitzer, M., Issle, P., Schwarz, J., Sohn, T. S., Auerbach, M. and Gruel, W.

Repurposing Alternators as Motors: Promoting Sustainability and Circular Economy in Low-Cost Mobility Systems.

DOI: 10.5220/0013145300003953

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 14th International Conference on Smart Cities and Green ICT Systems (SMARTGREENS 2025), pages 77-86

ISBN: 978-989-758-751-1; ISSN: 2184-4968

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

77

narios and identifying cost-effective modifications,

such as the integration of Hall sensors, to improve its

usability. These modifications is evaluated both un-

der field conditions in The Gambia and through con-

trolled testing in Germany to assess their practical im-

pact on vehicle performance.

This paper contributes to the state of the art by:

• Showcasing a practical implementation of circu-

lar economy principles in the automotive sector

through the reuse of vehicle alternators for mobil-

ity solutions.

• Presenting a structured approach for optimizing

the performance of repurposed alternators as elec-

tric motors, focusing on cost-effective modifica-

tions.

• Linking circular economy, reuse, engineering op-

timization, and sustainability to address real-

world mobility challenges.

• Conducting a field study to demonstrate the feasi-

bility of a low-cost solution for providing afford-

able and sustainable transportation in resource-

limited regions.

• Addressing a gap in the literature by focusing on

the transportation needs of developing countries

through reused, low-cost components.

2 MOBILITY IN AFRICA

The mobility situation in many African countries, es-

pecially in rural areas, faces distinct challenges. Eco-

nomic constraints and poor infrastructure are major

factors affecting transportation. In Malawi, Tanza-

nia, and Uganda, households spend 62% of their in-

come on food and 15% on utilities, leaving little

for transportation (De Magalh

˜

aes and Santaeul

`

alia-

Llopis, 2018). With an average monthly GDP per

capita of $156.29, many cannot afford regular ve-

hicle ownership (Statista, 2024d). In addition, fuel

prices, with octane-95 gasoline averaging $1.478 per

liter across seven African countries, further compli-

cate affordability for many (Statista, 2024c).

Rural transportation costs are also disproportion-

ately high. In Zimbabwe, the availability of motor-

ized vehicles is limited, with an average of only one

vehicle per 300 people. In addition, the cost of trans-

portation for a 30 km trip is 2.5 times higher than

in comparable Asian regions. Poor road conditions,

unreliable transport services, and high travel costs

make it difficult for rural residents to access essential

services such as markets, health care, and education

(Porter, 2002). Non-motorized and animal-powered

transportation, including bicycles and ox carts, re-

main common due to economic and infrastructure

constraints, while motorized transportation is scarce

in many regions (Porter, 2016).

In urban areas, the growing use of cheap imported

cars, coupled with underdeveloped public transport,

has led to congestion and pollution. In Freetown,

Sierra Leone, car ownership remains below 20%,

leading many residents to rely on walking or public

transportation. While these options may provide envi-

ronmental benefits, it is crucial that they facilitate uni-

versal access and provide pathways for other oppor-

tunities to align with the SDGs on inclusion and eco-

nomic growth. This highlights the need for more sus-

tainable and accessible mobility solutions (Teoh et al.,

2020; Cavoli, 2021; Pojani and Stead, 2017; Koroma

et al., 2021; Oviedo et al., 2024). Additionally, out-

dated vehicles contribute to environmental and health

risks that cause one in eight premature deaths world-

wide each year (World Health Organization, 2016).

In many African countries, vehicle regulations are

often loosely defined or inconsistently enforced, par-

ticularly in rural areas (DW, 2018). This lack of strict

regulation presents an opportunity for more self-built

solutions, as they can be deployed without the rigid

compliance requirements typical of more regulated

markets. In addition, low income levels, as indicated

by average GDP per capita, necessitate reliance on

small and community-based ventures, such as vehi-

cle maintenance and modification (Moos and Sambo,

2018; Izogo, 2015). The limited financial resources,

coupled with restricted access to formal automotive

services and new vehicles, drive local communities to

depend on these smaller enterprises.

In terms of energy, Gabon achieved the high-

est Environmental Performance Index (EPI) score in

Africa in 2024, with 53.1 out of 100, compared to

Estonia’s highest European score of 75.3 (Statista,

2024b; Statista, 2024e). This highlights the environ-

mental challenges faced by the continent, as the con-

tinent’s best score of 53.1 indicates that overall per-

formance in other regions is considerably lower. In

response, many African countries have implemented

regulatory measures, including restrictions on the im-

port of older, more polluting vehicles, to reduce

harmful emissions. In 2020, all 15 member states

of the Economic Community of West African States

(ECOWAS) agreed on provisional regulations to pro-

mote cleaner fuels and vehicles in the region (Ayetor

et al., 2021). This aligns with Africa’s increasing re-

newable energy generation, reaching 218.3 TWh in

2023, up from 140 TWh in 2015, underscoring the

continent’s commitment to sustainable energy sources

and their long-term availability (Statista, 2024a).

SMARTGREENS 2025 - 14th International Conference on Smart Cities and Green ICT Systems

78

2.1 Requirements for Low-Cost

Mobility Systems

Based on the analysis of the mobility situation in

Africa, requirements (R) are derived for a mobility

system applicable in this domain:

R1: The mobility system must be affordable,

taking into account the financial constraints of the

general population to ensure widespread adoption.

R2: The production process of the mobility sys-

tem must be sustainable, incorporating the use of

recycled materials and environmentally friendly prac-

tices to minimize ecological impact.

R3: The operation of the mobility system must

be sustainable, prioritizing renewable energy sources

and minimizing dependence on fossil fuels to ensure

environmental compatibility, economic viability, and

social equity over the long term.

R4: The energy source for the mobility system

must be accessible and affordable to the majority of

the general African population.

R5: The mobility system must be integrated

into existing value chains, using existing resources

to facilitate rapid deployment without the need for

new supply chains.

R6: The mobility system must comply with lo-

cal regulations, ensuring compliance with existing

laws on vehicles and mobility systems.

R7: The mobility system shall promote lo-

cal business opportunities, supporting community-

driven enterprises in the sale, customization, mainte-

nance and modification of the system, thereby foster-

ing local economic growth and innovation.

3 RELATED WORK

In recent years, several mobility solutions have been

developed with the goal of providing sustainable,

low-cost transportation suitable for use in Africa.

3.1 The aCar

The aCar, developed by Evum Motors, is a multi-

purpose electric vehicle designed for agricultural

transport and small public transport (

ˇ

Solt

´

es et al.,

2018; Minnerup et al., 2018). Equipped with two 8

kW motors, the aCar has a range of 80 km, a top

speed of 50-60 km/h and a payload capacity of up

to 800 kg. Although promoted as a low-cost solu-

tion for the African market, the aCar is manufactured

exclusively in Germany, with sales today limited to

European markets and acquisition costs unspecified.

This production model increases costs and limits ac-

cessibility for African users. The aCar’s design relies

on purpose-built electric motors and a large battery,

relying on components that are not widely available

in Africa. This reliance disrupts local value chains

and reduces the potential for community involvement

in assembly. While complying with European reg-

ulations, the aCar’s distribution model excludes lo-

cal businesses, limiting opportunities for community-

driven economic development.

3.2 The B-Van and Bee Models

Bako Motors’ B-Van and Bee vehicles are solar-

assisted electric vehicles designed for urban trans-

portation and last-mile delivery in African cities

(Bako Motors, 2024). The B-Van, priced between

$7,345 and $12,915 (excluding import tax), has a 7.5

kW motor, a range of 100-300 km, a payload ca-

pacity of 400 kg, and a top speed of 70 km/h. The

Bee, priced from $5,271 to $8,049 (excluding import

tax), has a 2 kW motor, a range of 50-120 km, and

a top speed of 45 km/h. While solar charging ex-

tends battery life, these prices limit affordability for

many African users. Both models rely on custom-

made components, creating a dependency on exter-

nal supply chains and imported parts, which increases

costs and hinders local integration. With assembly in

Tunisia, the vehicles are primarily available in that re-

gion, limiting the accessibility and participation of lo-

cal businesses in broader African markets.

3.3 The Jidi Electric Motorcycle

In collaboration with a Chinese company, Kofa devel-

oped the Jidi electric motorcycle as part of a battery-

swapping network in Accra, Ghana (Kofa, 2024). The

Jidi has a top speed of 85 km/h, a payload capacity

of 223 kg, and a range of 100 km per charge. The

battery swapping stations provide a convenient option

for users, reducing downtime associated with charg-

ing. Although positioned as an affordable alternative

to internal combustion motorcycles, the exact cost of

the Jidi is not specified. Its reliance on a centralized

battery swapping network limits scalability outside of

supported regions. Without local manufacturing or

assembly, reliance on imported components limits in-

tegration into local economies, reducing opportunities

for local job creation and entrepreneurship in African

communities.

Repurposing Alternators as Motors: Promoting Sustainability and Circular Economy in Low-Cost Mobility Systems

79

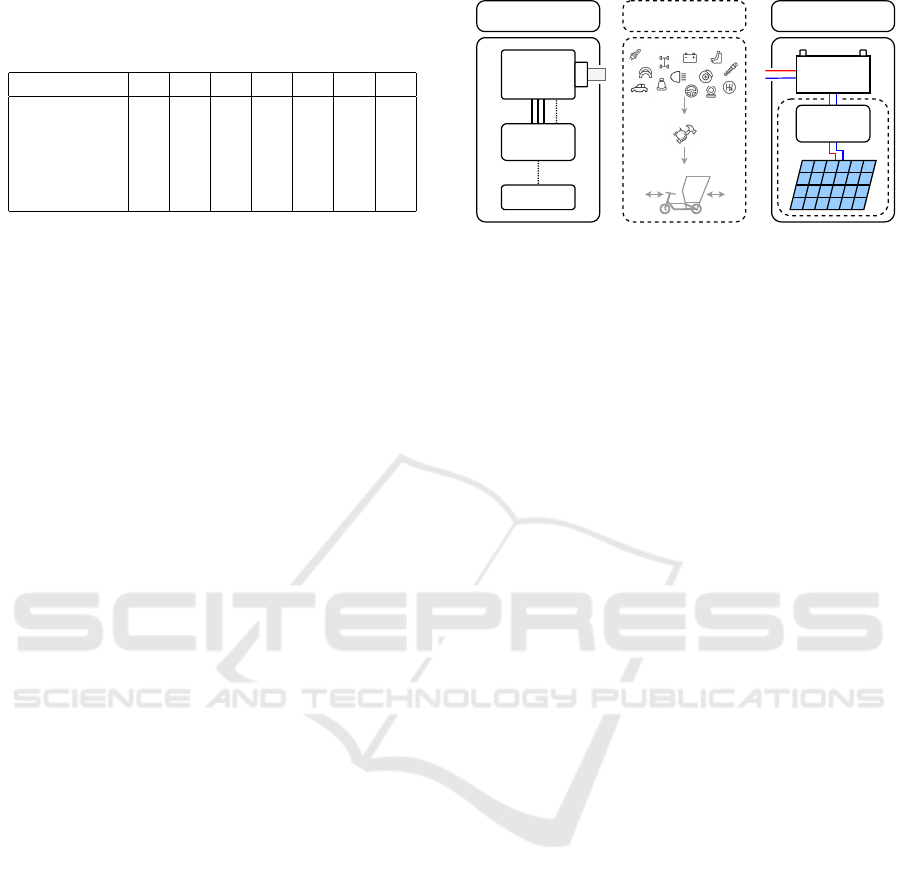

Table 1: Mapping of mobility solutions of the related work

to the requirements (R) of a low-cost mobility system for

Africa.

R1 R2 R3 R4 R5 R6 R7

(

ˇ

Solt

´

es et al., 2018) - - ✓ ✓ - ✓ -

(Bako Motors, 2024) - - ✓ ✓ - ✓ -

(Kofa, 2024) - - ✓ ✓ - ✓ -

(ITQ, 2024) - ✓ ✓ ✓ ✓ ✓ ✓

(Dayang Naki, 2024) - - - - - ✓ -

3.4 The Bamboo Solar Car

The Bamboo Solar Car, developed by ITQ GmbH,

is a prototype for low-cost, sustainable mobility us-

ing bamboo and recycled materials, designed for re-

gions with limited infrastructure (ITQ, 2024). Pow-

ered by a solar panel with an energy output of up to

4 kWh, it has a range of 30 km and a top speed of

40 km/h. Despite the use of recycled materials, the

core of the system relies on a purpose-built electric

motor, adding to the overall cost. According to an in-

terview with the developer, the prototype cost approx-

imately $3,000, highlighting the limitations of afford-

ability despite the project’s focus on sustainability and

accessibility.

3.5 The DY-H6 Tricycle

The DY-H6 tricycle, produced by Chongqing Beiyi

Vehicle Co., Ltd. in China, is designed for cargo

transport in Africa, featuring a 250cc water-cooled

petrol engine and a maximum speed of 60 km/h

(Dayang Naki, 2024). With a payload capacity of up

to 1,500 kg and a price of approximately $1,313 (ex-

cluding import duty), it offers utility for heavy loads.

However, the DY-H6’s fossil fuel engine aggravates

greenhouse gas emissions and does not meet long-

term sustainability goals in Africa, demanding envi-

ronmentally friendly transport. Furthermore, its con-

struction lacks integration with local renewable re-

sources, limiting potential economic benefits for com-

munities.

Despite the interest in sustainable solutions,

achieving affordability, accessibility, and integration

with local resources remains a challenge. These

mobility solutions, while innovative in addressing

Africa’s mobility challenges, are constrained by re-

liance on imported components and varying degrees

of sustainability, which impact their overall effective-

ness and accessibility.

Inverter

(Motor)

Alternator

Repurposed

Controller

Solar Charge

48V

Battery

Propulsion System

Motor Controller

Exchangeable Chassis

(Self-built)

Energy Source

(optional Solar Infrastructure)

Vehicle Scrap Parts

Self-build Process

Exchangeable self-built Chassis

. . .. . .

Figure 1: Adaptable architecture of the proposed mobility

system that promotes sustainability and circular economy to

meet R1-7.

4 METHOD

The analysis of current mobility systems reveals that

no existing concept is fully suitable as a low-cost and

sustainable solution for the African market, as none

of the available technologies meets all of the outlined

requirements (Tab. 1). While existing concepts may

not fully address these needs, the topic of repurpos-

ing components has not yet been explored and holds

significant potential in this context. To address this

gap, a novel method is proposed, targeting the specific

constraints and opportunities of the African market.

The core structure of the proposed mobility sys-

tem is designed to be cost-effective, sustainable, and

easy to implement by utilizing repurposed compo-

nents to meet the requirements R1-7. It promotes

the principles of a circular economy, emphasizing

reuse, resource efficiency, and local economic em-

powerment. To achieve this, the mobility system is

divided into three primary subsystems derived from

the fundamental systems of any vehicle: the propul-

sion system, the chassis, and the energy source. The

proposed mobility system includes a repurposed alter-

nator that functions as a motor, an exchangeable self-

built chassis that allows for flexibility, and a battery

for energy storage with the potential for solar energy

integration (Fig. 1). Each subsystem needs to be con-

sidered on its own to provide an affordable and sus-

tainable solution suitable for potentially widespread

adoption in the African market.

4.1 The Propulsion System

The propulsion system consists of a motor and a con-

troller. To reduce costs, a repurposed vehicle alter-

nator, in this case a $164 truck alternator, is repur-

posed to function as an electric motor. This compo-

nent is readily available within existing value chains,

facilitating easy access and implementation. Typi-

cally used in conventional vehicles to generate elec-

SMARTGREENS 2025 - 14th International Conference on Smart Cities and Green ICT Systems

80

tricity, this alternator has been retrofitted with a motor

controller to enable its use as an electric motor. This

modification brings the alternator closer to the perfor-

mance level of a purpose-built electric motor, which

would cost between $262 and $313 (Zhyt, 2024; QS

Motors, 2024).

To ensure safety, especially in the absence of com-

prehensive regulatory requirements, the system volt-

age is limited to 48V, providing a balance between

safety and performance. Since the alternator is a

key component of the propulsion system, it remains

a standardized, non-interchangeable element, ensur-

ing that all requirements R1-7 are met. Since vehi-

cle alternators are primarily optimized for generating

electrical energy from mechanical energy, they do not

provide sufficient power when repurposed for use as

electric motors, especially given their sensorless de-

sign. Therefore, an optimization process is imple-

mented to enhance their performance and reliability,

ensuring long-term functionality in the target domain.

4.2 The Chassis

Given the propulsion system and in accordance with

circular economy principles, the chassis can be as-

sembled from any modular components, allowing

end-users to build their own vehicles using locally

available materials. This approach supports local

entrepreneurship and innovation, as users can use

scrapped vehicles, bicycles, tricycles, motorcycles,

or fabricate new chassis using scrap metal and other

reused materials. This flexibility enables individuals

to create a wide range of mobility solutions tailored to

specific needs, while keeping costs low and encourag-

ing local economic participation.

4.3 The Energy Source

The choice of energy source is driven by accessibil-

ity, affordability, and sustainability. Fossil fuels, as

outlined in the analysis in Chapter 2, are economi-

cally prohibitive, consuming a significant percentage

(0.95%) of monthly income per liter. Instead, elec-

tric energy is identified as the most viable and sus-

tainable option, as reusing old 12 V vehicle batter-

ies for energy storage supports both renewable energy

and circular economy goals. In addition, accessibility

can be improved by using existing solar infrastruc-

ture, as Africa receives up to 9.5 hours of sunlight per

day (Luxman Light, 2019) with solar panels produc-

ing 263 W/m² (European Union, 2022). This solar

resource makes electric power the most suitable low-

cost energy source for the proposed mobility system.

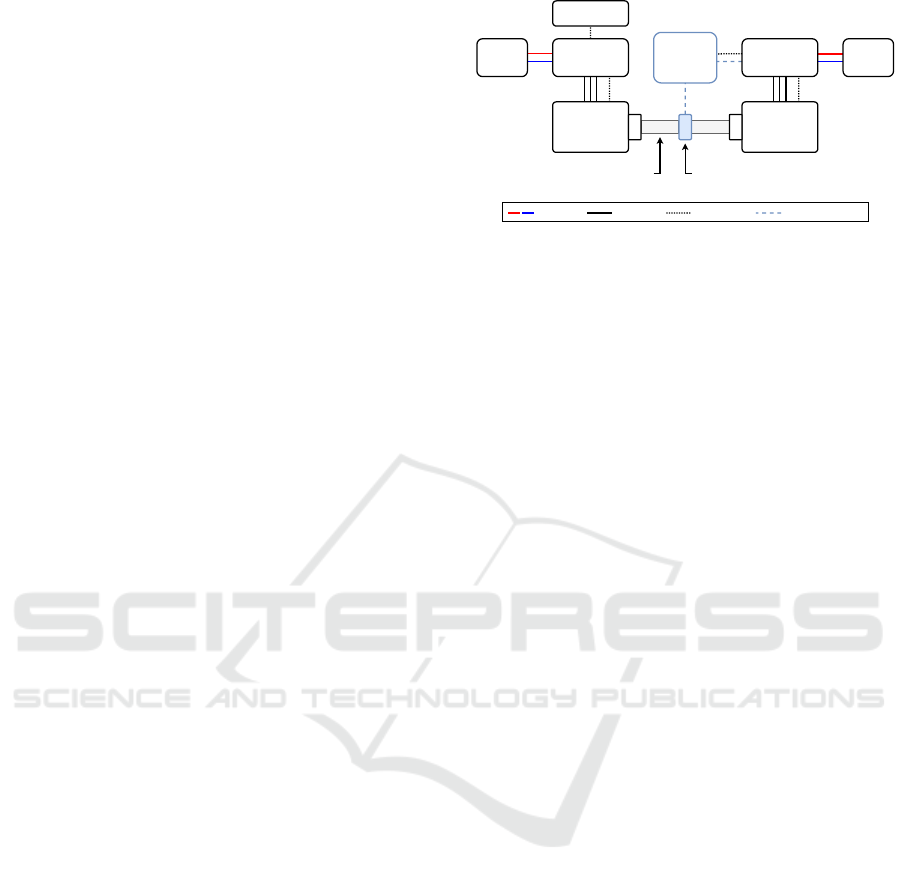

Legend

DC Line AC Line Signal Line Measurement Line

Repurposed

Alternator

Torque Measurement BoxConnecting Shaft

Electric Brake

48V

Battery

48V

Battery

Testing

Unit

Inverter

(Brake)

Motor Controller

Inverter

(Motor)

Figure 2: Measurement setup for rig testing in Germany.

4.4 Evaluation of the Propulsion System

As core component of the mobility system, the

propulsion system is evaluated in two key ways:

1. Rig testing is conducted to evaluate the techni-

cal feasibility and performance of the alternator-

based propulsion system. This testing focuses on

ensuring that the repurposed alternator will func-

tion effectively under realistic operating condi-

tions.

2. A field study analysis in Africa and Germany is

used to test the applicability of the system within

the target domain, evaluating how well the solu-

tion fits with local needs, infrastructure and user

capabilities.

By integrating low-cost, reusable components and

focusing on circular economy principles, the pro-

posed approach provides a sustainable, affordable and

scalable solution for mobility in Africa that meets the

requirements outlined in R1-7.

5 EXPERIMENTS

5.1 Measurement Setup

The measurement setup is designed to evaluate the

electrical performance in terms of power output of

the repurposed alternator acting as a motor (Fig. 2).

The test rig includes a dedicated electric motor that

acts as an electric brake. This brake motor is me-

chanically coupled to the motor under test via a joint

shaft, allowing the motor under test to operate against

a variable resistance. This setup allows characteri-

zation of the motor performance under different load

conditions.

A torque sensor is mounted on the shaft to mea-

sure the torque output of the motor under test. In ad-

dition, the speed (in rpm) is monitored at the elec-

tric brake, which remains synchronized with the mo-

tor under test due to the direct mechanical coupling.

Repurposing Alternators as Motors: Promoting Sustainability and Circular Economy in Low-Cost Mobility Systems

81

0 10 20 30

0

5

10

15

Time t [s]

Torque τ [Nm]

τ

0

500

1,000

Motor Speed n [rpm]

n

Figure 3: Exemplary measurement of the performance at

the operating point of the motor under test at 1000 rpm.

To generate a performance map, the motor under

test, in this case the repurposed alternator, is evaluated

over a range of operating points. The motor controller

of the motor under test is configured to maintain a

constant, predefined speed. Meanwhile, the electric

brake incrementally increases the resisting torque in

a linear pattern. When the speed of the motor under

test drops more than 50 rpm from the set point, the

corresponding torque value is recorded (Fig. 3). This

procedure is repeated at various speeds to produce a

complete torque-speed map of the motor under test.

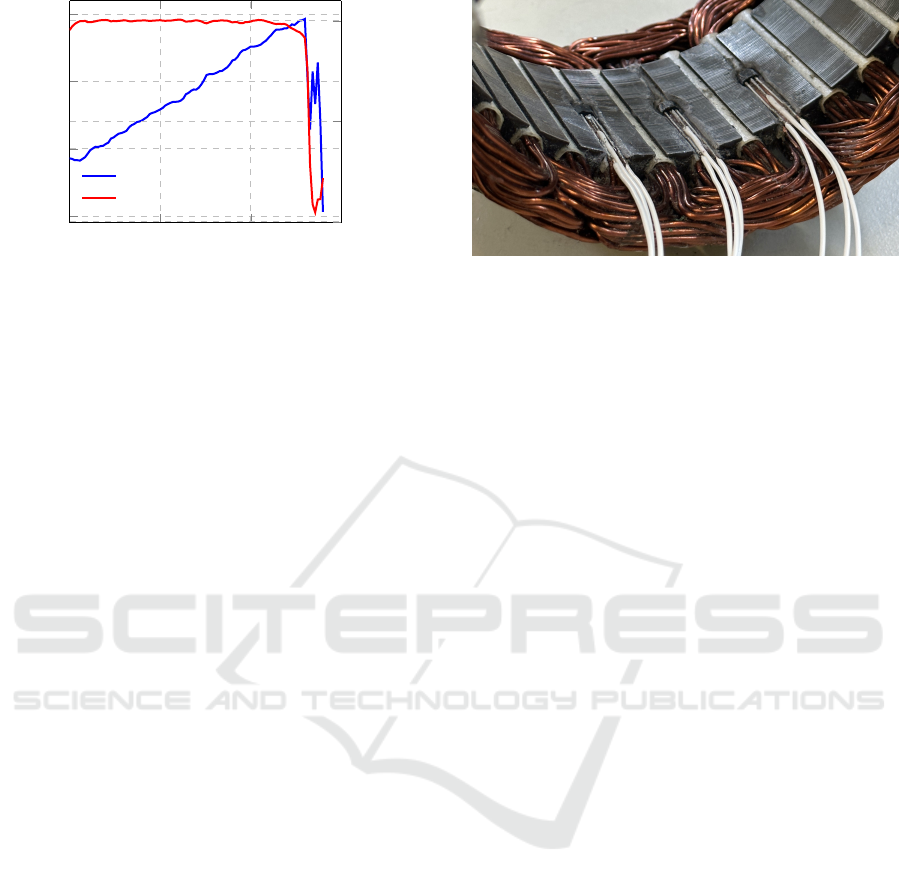

5.2 Low-Cost Optimization Process

The direct use of a repurposed alternator as an elec-

tric motor results in performance limitations, espe-

cially at low speeds, which reduces the overall usabil-

ity of the propulsion system for the intended applica-

tion. These performance limitations were particularly

evident during acceleration, where very fine throttle

control was required, causing the vehicle to start in a

jerky rather than smooth manner. This is due to the

lack of rotor position sensors which support accurate

motor control. To address this issue, a low-cost opti-

mization is introduced by integrating three Hall sen-

sors to measure the rotor position. This optimization

adds only $3.17 (Reichelt Elektronik, 2024) to the to-

tal system cost (excluding labor), making it a cost-

effective solution for improving performance.

To ensure accurate sensor placement, the Hall sen-

sors are embedded directly into the stator by milling

recesses in its winding slots at 120° electrical inter-

vals (Fig. 4). This arrangement ensures precise phase

alignment and improves the overall control of the mo-

tor during operation. Rotor position data is a crucial

parameter for the motor controller as it allows pre-

cise phase switching during operation. Without this

data, the controller must estimate the optimal timing

for phase activation, resulting in inefficiencies and re-

Figure 4: Low-cost integration of three Hall sensors into the

stator of a repurposed alternator.

duced performance. By integrating Hall sensors, the

motor controller receives direct feedback on the ro-

tor position, allowing more accurate control of each

phase. This improves motor performance in both

start-up scenarios and continuous operation.

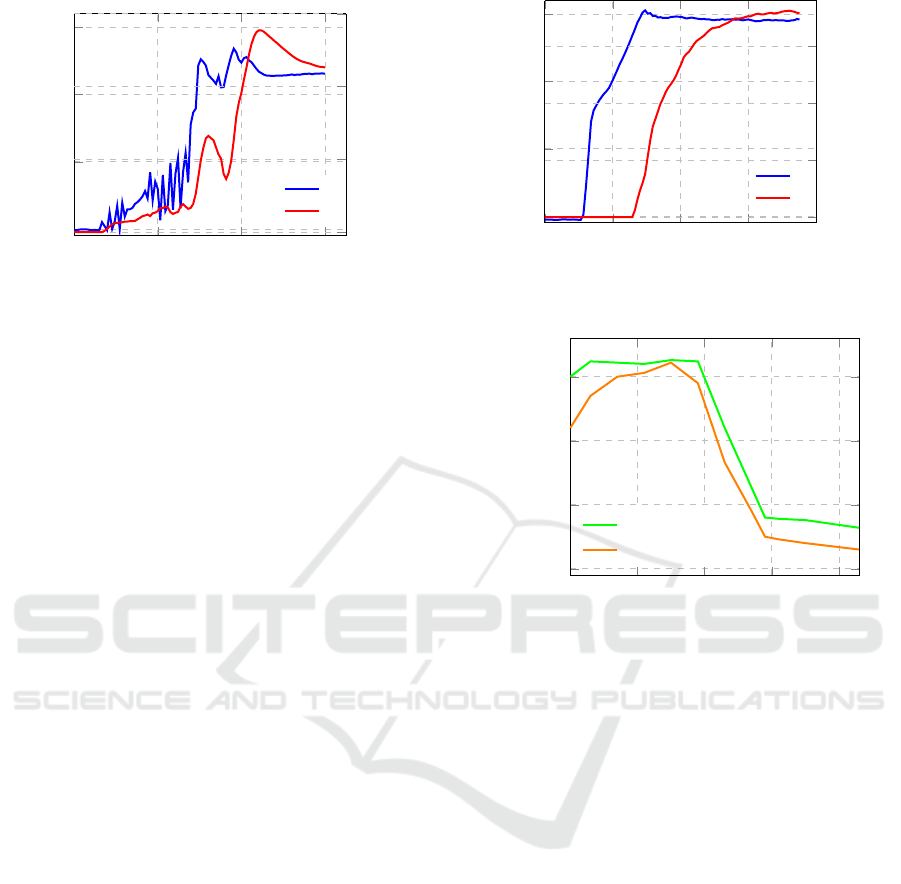

5.3 Optimization Results

In scenarios where the motor operates without Hall

sensor optimization, start-up oscillations occur, last-

ing about 3.79 seconds with an amplitude of 2.43 Nm

and 60 rpm. These oscillations cause instability in

both torque output and rotational speed (Fig. 5), de-

laying the motor’s ability to reach a stable state and

reducing its suitability for real-world driving due to

compromised driving behavior.

After the optimization of integrating three Hall

sensors, the motor’s performance in start-up scenar-

ios is significantly improved. The motor reaches a

stable operating state almost immediately, with no ob-

servable oscillations. Additionally, the torque dur-

ing the start-up phase is increased by 3.7 Nm, en-

suring smoother acceleration and better handling in

low-speed conditions (Fig. 6). This improvement en-

hances the overall driving experience, particularly in

scenarios requiring frequent stops and starts, such as

urban driving or off-road mobility, and enables higher

payloads or steeper inclines in practical applications.

Experimental testing of the motor at various op-

erating points indicates a significant improvement in

driving performance after optimization. The mo-

tor’s torque-speed characteristic shows a consistently

higher torque output at equivalent rpm levels. The

optimized motor setup with Hall sensors shows an

18.74% increase in the area under the torque-speed

curve, corresponding to an increase in performance

over the entire operating range (Fig. 7). This perfor-

mance gain allows the motor to handle a wider range

of driving conditions while maintaining the low-cost

goals of the concept.

SMARTGREENS 2025 - 14th International Conference on Smart Cities and Green ICT Systems

82

0 2 4

6

0

5

10

15

Time t [s]

Torque τ [Nm]

τ

0

100

200

300

Motor Speed n [rpm]

n

Figure 5: Start-up scenario without optimization.

6 FIELD STUDY

Since technical feasibility is not sufficient to prove the

applicability of the mobility system with the repur-

posed alternator as the propulsion unit in the given

domain, a field study was conducted in Africa. In

this field study, a participant from The Gambia has

constructed a self-built vehicle by following a multi-

step process. These tasks involved both mechani-

cal and electrical work to repurpose an alternator and

self-build a chassis, with the goal of creating a func-

tional vehicle capable of daily use in the local envi-

ronment. The results of this field study in The Gam-

bia is complemented by controlled performance eval-

uations conducted in Germany.

6.1 Field Study in the Gambia

A 37-year-old car mechanic from The Gambia was

selected for the study. Using scrap parts from two

motorcycles, he constructed a self-built steel chassis

(Fig. 8(a), 8(b)). While the participant had sufficient

mechanical knowledge to build the chassis, his elec-

trical knowledge was limited. However, with the help

of a detailed manual for the conversion process, he

was able to repurpose a $35 used car alternator and

complete the electrical integration of the motor and

controller into the vehicle. To improve energy effi-

ciency and reduce dependence on external charging

infrastructure, the participant was also tasked with

installing a solar panel on the roof of the vehicle

and connecting it via an inverter to the provided 48V

lithium-ion battery.

Despite the challenges of self-building the chassis

and performing the electrical integration, the partici-

pant was able to complete the construction of the ve-

hicle and get it operational. While exact performance

metrics such as range and energy consumption were

0 2 4

6

8

0

5

10

15

Time t [s]

Torque τ [Nm]

τ

0

50

100

150

Motor Speed n [rpm]

n

Figure 6: Start-up scenario optimized with Hall sensors.

0

500

1,000

1,500

2,000

0

5

10

15

Motor Speed n [rpm]

Torque τ [Nm]

Hall Sensor

Sensorless

Figure 7: Performance maps of both repurposed alternators

under test with and without optimization.

not measured due to the lack of suitable test equip-

ment, the participant was able to drive the vehicle un-

der real-world conditions, demonstrating the feasibil-

ity of the system’s design and integration in the target

domain.

6.2 Controlled Performance Evaluation

in Germany

Due to the limited measurement capabilities in The

Gambia, the propulsion system was also evaluated un-

der controlled conditions in Germany. This involved a

comprehensive assessment using dedicated measure-

ment equipment to quantify key performance param-

eters of the prototype vehicle (Fig. 8(c)).

The converted tricycle used for testing had a dry

mass of 490 kg, with a payload capacity of 145 kg.

During testing, the vehicle was driven over paved and

unpaved roads with a payload of up to 180 kg to sim-

ulate intensified real-world conditions.

The propulsion system showed an average power

consumption of 576 W during regular driving at 17

km/h, with peak power consumption reaching 1600

Repurposing Alternators as Motors: Promoting Sustainability and Circular Economy in Low-Cost Mobility Systems

83

(a) (b) (c)

Figure 8: Prototype vehicles for field tests in (a) Africa and (c) Germany, and a sample of the chassis construction process (b)

in Africa.

W under higher loads on steep inclines. The integra-

tion of the solar panel allowed a 36% range extension

during operation, reducing the dependence on exter-

nal charging infrastructure. The battery charging time

for 50% of the 93 Ah capacity, under typical German

solar conditions in July with daylight charging, was

recorded at 10.7 hours. Under regular driving con-

ditions on level, paved roads and without additional

payload, a full charge provided a calculated range of

approximately 132 km using battery power solely.

In terms of performance, the vehicle reached a top

speed of 24 km/h, limited by a gear ratio of 5.17. This

ratio, which can be adjusted for higher speeds, lim-

its top speed but increases torque at low speeds. Is-

sues were observed during the start-up scenarios with-

out rotor position sensor optimization, where smooth

acceleration required very fine throttle control. Im-

plementing Hall sensor optimization significantly im-

proved responsiveness and torque during the initial

acceleration phase as shown in Figures 5, 6.

No major mechanical or electrical failures were

observed during the test phase, demonstrating the ro-

bustness of the propulsion system in terms of dura-

bility in day-to-day operation. Minor adjustments to

the motor controller settings were required to opti-

mize the balance between power output and energy

consumption.

7 EVALUATION

Existing mobility solutions in Africa often lack cost-

effectiveness, local adaptability, and environmental

integration. While some focus on sustainability

through electric or solar power, they typically de-

pend on imported components and centralized pro-

duction, which limits local assembly and maintenance

opportunities. Moreover, these concepts frequently

overlook the specific needs of African users, reduc-

ing their potential to promote community-driven eco-

nomic growth. This highlights the necessity for an

alternative approach that prioritizes affordability, re-

source availability, and local adaptability. The fol-

lowing evaluation demonstrates that the proposed ap-

proach fulfills all requirements R1-7, based on find-

ings from rig testing, a field study in The Gambia,

and controlled testing in Germany.

The mobility system has been designed to be eco-

nomically viable for widespread use. Repurposing a

truck alternator into an electric motor can reduce the

cost of the motor component by close to $150, or up

to $280 using scrap alternators in The Gambia, com-

pared to the significantly higher cost of purpose-built

electric motors. The low-cost optimization, which in-

tegrates three Hall sensors for rotor position sensing

add an additional cost of only $3.17, ensuring both af-

fordability and enhanced functionality. By lowering

the financial barriers to adopting sustainable propul-

sion technologies, this approach enhances accessibil-

ity to mobility solutions, particularly for underserved

populations. The reduced cost allows broader partic-

ipation in mobility, thereby addressing inequalities in

access to transportation (SDG 10: Reduced Inequal-

ities). Results from the Gambia field study demon-

strated that, even with limited resources, the partici-

pant could affordably implement the propulsion sys-

tem in a self-built chassis using a repurposed alterna-

tor, a solar panel, and locally sourced materials, val-

idating the system’s suitability within financial con-

straints (R1).

The production process emphasizes the use of

reused and repurposed components to lower costs and

reduce environmental impact. The alternator, a stan-

dard automotive part, is commonly available from

scrap vehicles, promoting a circular economy and

waste reduction (SDG 12: Responsible Consumption

and Production). The use of scrap metal and salvaged

materials for chassis construction, as observed in the

Gambian field study, further reinforces sustainable

production. Controlled testing in Germany confirmed

that repurposed components deliver adequate perfor-

mance, demonstrating that reliance on recycled mate-

rials does not compromise functionality, thus meeting

R2.

SMARTGREENS 2025 - 14th International Conference on Smart Cities and Green ICT Systems

84

The mobility system emphasizes renewable en-

ergy, particularly solar power, as a primary source of

energy without reliance on fossil fuels. During testing

in Germany, a solar panel extended the vehicle’s range

by 36%, demonstrating that solar charging can suffi-

ciently supplement battery power to improve energy

sustainability (SDG 7: Affordable and Clean Energy).

The field study in The Gambia confirmed the feasibil-

ity of integrating locally sourced solar panels, align-

ing the system with renewable energy goals. These

results demonstrate the sustainable operation of the

system, fulfilling R3.

The use of electric energy, combined with so-

lar power, ensures broad accessibility, low operating

costs, and independence from local power grids. Data

from German tests indicated that solar charging could

reduce the reliance on external charging infrastruc-

ture, which was confirmed in the African field study.

This system design effectively meets R4 by providing

an accessible, cost-effective energy solution (SDG 9:

Industry, Innovation, and Infrastructure).

The mobility system is designed to be compatible

with existing automotive and energy supply chains.

By using a standardized vehicle alternator, it lever-

ages the existing automotive parts supply without

requiring specialized production. The field study

demonstrated that local mechanics could successfully

repurpose components and integrate them into a self-

built chassis, satisfying R5 and supporting rapid,

resource-efficient deployment (SDG 17: Partnerships

for the Goals).

To ensure safety in the absence of explicit regula-

tions, the system voltage was limited to 48 V, a thresh-

old generally considered safe. Both the Gambian field

study and controlled tests in Germany confirmed us-

ability at this voltage, indicating compliance with lo-

cal regulatory expectations in areas with limited for-

mal vehicle regulations, satisfying R6.

The system design promotes local entrepreneur-

ship by enabling end-users to build, maintain, and

customize vehicles using locally available resources.

The Gambian participant constructed a customized

vehicle chassis from scrap materials, showcasing the

system’s adaptability and promoting relevant skills

within the local economy. This potential for local

assembly fosters small businesses focusing on parts

sales, maintenance, and modification, supporting eco-

nomic growth and aligning with R7 (SDG 8: Decent

Work and Economic Growth).

In conclusion, the proposed mobility system ad-

dresses the defined requirements R1-7 through a fo-

cus on cost-effectiveness, sustainability, accessibil-

ity, and adaptability. Evaluation results from rig and

field testing confirm the system’s compliance with fi-

nancial, environmental, and regulatory requirements

specific to the African market while supporting key

SDGs such as Affordable and Clean Energy (SDG 7),

Decent Work and Economic Growth (SDG 8), Re-

duced Inequalities (SDG 10), and Responsible Con-

sumption and Production (SDG 12).

8 CONCLUSION AND FUTURE

WORK

The proposed method of repurposing vehicle alter-

nators as electric motors demonstrates a feasible ap-

proach to advancing sustainability and circular econ-

omy principles in low-cost propulsion systems suit-

able for the African market. By reusing available

components such as alternators and utilizing locally

sourced materials for chassis construction, this sys-

tem not only minimizes waste but also reduces pro-

duction costs. Its compatibility with solar power max-

imizes the benefits of Africa’s sunlight, creating an

affordable and renewable energy solution that reduces

dependence on fossil fuels.

The system’s modular design supports local busi-

nesses by allowing for local assembly, maintenance,

and customization, fostering economic growth and

community-driven innovation. This adaptability po-

sitions the proposed system as a valuable tool for

increasing mobility access in resource-poor regions,

providing a scalable solution that can meet diverse

transportation needs, contributing to the achievement

of SDGs focused on inclusive transportation.

The proposed method is subject to several limita-

tions. The speed controller of the motor is restricted

by the inability to adjust its control parameters, which

affects the measurement results since no parameter

fine-tuning is possible. In the measurement process,

torque inaccuracies and slight noise from the test rig

limit the accuracy of the measurement results, which

were mitigated by filtering. In addition, the tests con-

ducted in Germany used a new truck alternator rather

than a reused one to ensure comparable results. This

may affect generalizability compared to repurposed

components in field applications.

Future research will include a larger field study

that will deploy multiple vehicles equipped with the

proposed propulsion system across Africa to operate

under different local conditions. This might enable

further refinements to improve adaptability, durabil-

ity, and overall user satisfaction in target markets. In

addition, motor performance optimizations are aimed

at improving the handling and speed capabilities of

the drive system, thus optimizing it for a variety of

real-world applications. The motor controller, while

Repurposing Alternators as Motors: Promoting Sustainability and Circular Economy in Low-Cost Mobility Systems

85

significantly impacting the propulsion system’s per-

formance, was not included in this research project.

Future studies should conduct a comparative anal-

ysis of different controllers, focusing on both cost-

effectiveness and performance. Additionally, the en-

vironmental and economic impact of using end of

life components for the presented mobility solution

should be elaborated quantitatively.

REFERENCES

Ayetor, G., Mbonigaba, I., Sackey, M., and Andoh, P.

(2021). Vehicle regulations in africa: Impact on used

vehicle import and new vehicle sales. Transportation

Research Interdisciplinary Perspectives, 10:100384.

Bako Motors (2024). Website Bako Motors. https://bako

motors.com. Accessed: October 2, 2024.

Cavoli, C. (2021). Accelerating sustainable mobility and

land-use transitions in rapidly growing cities: Identi-

fying common patterns and enabling factors. Journal

of Transport Geography, 94:103093.

Dayang Naki (2024). DY-H6 Hot Selling Africa Cargo

Tricycle Models with Powerful Engine of 250cc.

https://www.dayangnaki.com. Accessed: October 1,

2024.

De Magalh

˜

aes, L. and Santaeul

`

alia-Llopis, R. (2018). The

consumption, income, and wealth of the poorest: An

empirical analysis of economic inequality in rural and

urban sub-saharan africa for macroeconomists. Jour-

nal of Development Economics, 134:350–371.

DW (2018). Durch Autoexporte dicke Luft in Afrika.

https://www.dw.com/de/a-44805459. Accessed: Oc-

tober 11, 2024.

European Union (2022). Could a giant solar array in the

sahara resolve our energy needs? https://cordis.europ

a.eu/article/id/442711. Accessed: October 8, 2024.

ITQ (2024). Bamboo solar car – smart green island projects.

https://stetter-itq.com. Accessed: October 8, 2024.

Izogo, E. E. (2015). Customers’ service quality perception

in automotive repair. African Journal of Economic

and Management Studies, 6(3):272–288.

Kofa (2024). The TAILG Jidi - Powered by Kofa. https:

//www.kofa.co. Accessed: October 7, 2024.

Koroma, B., Oviedo, D., Yusuf, Y., Macarthy, J., Cavoli,

C., Jones, P., Levy, C., and Sellu, S. (2021). City pro-

file: Freetown, base conditions of mobility, accessibil-

ity and land use. T-SUM. UCL.

Luxman Light (2019). The influence of average annual sun-

shine and total solar radiation intensity in africa for so-

lar street light. https://luxmanlight.com/the-influence-

of-average-annual-sunshine. Accessed: October 8,

2024.

Minnerup, K., Kalt, S., Lin, X., Koberstaedt, S., and

Lienkamp, M. (2018). A 48 v drive train for a utility

vehicle designed for rural africa - review and analysis.

In 2018 21st International Conference on Electrical

Machines and Systems (ICEMS), pages 2477–2482.

Moos, M. and Sambo, W. (2018). An exploratory study

of challenges faced by small automotive businesses in

townships : the case of garankuwa, south africa. Jour-

nal of Contemporary Management, 15(1):467–494.

Oviedo, D., Cavoli, C., Yusuf, Y., Koroma, B., and Chong,

A. Z. W. (2024). Everyday accessibility practices

and experiences in a context of transitions to sustain-

able mobility: Qualitative evidence from sub-saharan

africa. International Journal of Sustainable Trans-

portation, 18(4):328–343.

Pojani, D. and Stead, D. (2017). The Urban Transport Cri-

sis in Emerging Economies: An Introduction, pages

1–10. Springer International Publishing, Cham.

Porter, G. (2002). Living in a walking world: Rural mobility

and social equity issues in sub-saharan africa. World

Development, 30(2):285–300.

Porter, G. (2016). Mobilities in rural africa: New connec-

tions, new challenges. Annals of the American Asso-

ciation of Geographers, 106(2):434–441.

QS Motors (2024). QS120 QSD120A-7. https://www.cnqs

motor.com. Accessed: October 12, 2024.

Reichelt Elektronik (2024). Tle4905l. https://www.reichelt

.de. Accessed: August 16, 2024.

Statista (2024a). Afrika: Erzeugung erneuerbarer En-

ergien in Afrika nach Quelle von 2000 bis 2023.

https://de.statista.com. Accessed: October 5, 2024.

Statista (2024b). Afrika: Rangliste der 20 umwelt-

freundlichsten L

¨

ander nach dem Environmen-

tal Performance Index (EPI) im Jahr 2024.

https://de.statista.com. Accessed: September 25,

2024.

Statista (2024c). Average retail prices for gaso-

line in Africa as of February 2024, by country.

https://www.statista.com. Accessed: October 6, 2024.

Statista (2024d). Entwicklung des durchschnittlichen Brut-

toinlandsprodukt (BIP) pro Kopf in Afrika von 2010

bis 2028. https://de.statista.com. Accessed: Septem-

ber 25, 2024.

Statista (2024e). Rangliste der 20 umweltfreundlichsten

L

¨

ander nach dem Environmental Performance Index

(EPI) im Jahr 2024. https://de.statista.com. Accessed:

October 18, 2024.

Teoh, R., Anciaes, P., and Jones, P. (2020). Urban mobility

transitions through gdp growth: Policy choices facing

cities in developing countries. Journal of Transport

Geography, 88:102832.

World Health Organization (2016). Ambient air pollution:

A global assessment of exposure and burden of dis-

ease. Technical report, WHO. Accessed: October 1,

2024.

Zhyt (2024). 1500 W Electric Tricycle Motor 48 V. https:

//www.amazon.de/dp/B0CXXJ5TSD. Accessed:

October 11, 2024.

ˇ

Solt

´

es, M., Koberstaedt, S., Lienkamp, M., Rauchbart, S.,

and Frenkler, F. (2018). Acar - a electric vehicle con-

cept for sub-saharan africa. In 2018 IEEE PES/IAS

PowerAfrica, pages 301–306.

SMARTGREENS 2025 - 14th International Conference on Smart Cities and Green ICT Systems

86