Joint Calibration of Cameras and Projectors

for Multiview Phase Measuring Profilometry

Hyeongjun Cho

a

and Min H. Kim

b

School of Computing, KAIST, Daejeon, South Korea

{hjcho, minhkim}@vclab.kaist.ac.kr

Keywords:

3D Imaging, Multiview Camera Calibration, Phase-Measuring Profilometry.

Abstract:

Existing camera-projector calibration for phase-measuring profilometry (PMP) is valid for only a single view.

To extend a single-view PMP to a multiview system, an additional calibration, such as Zhang’s method, is nec-

essary. In addition to calibrating phase-to-height relationships for each view, calibrating parameters of multiple

cameras, lenses, and projectors by rotating a target is indeed cumbersome and often fails with the local optima

of calibration solutions. In this work, to make multiview PMP calibration more convenient and reliable, we

propose a joint calibration method by combining these two calibration modalities of phase-measuring pro-

filometry and multiview geometry with high accuracy. To this end, we devise (1) a novel compact, static

calibration target with planar surfaces of different orientations with fiducial markers and (2) a joint multiview

optimization scheme of the projectors and the cameras, handling nonlinear lens distortion. First, we auto-

matically detect the markers to estimate plane equation parameters of different surface orientations. We then

solve homography matrices of multiple planes through target-aware bundle adjustment. Given unwrapped

phase measurement, we calibrate intrinsic/extrinsic/lens-distortion parameters of every camera and projector

without requiring any manual interaction with the calibration target. Only one static scene is required for

calibration. Results validate that our calibration method enables us to combine multiview PMP measurements

with high accuracy.

1 INTRODUCTION

Phase-measuring profilometry (PMP) system aims to

reconstruct the 3D shape of a static object by cap-

turing a series of phase-shift images with structured

lights from a projector. In each iteration, a projector

projects a unique sinusoidal structured light image to

an object, and a camera captures an image of the ob-

ject. Each pixel value of the structured light images

represents an encoded output of phases, which indi-

rectly represent the pixel indices in the screen space of

the projector. Since a position of a pixel index in the

projector is encoded into the structured light images,

height information can be obtained from the phase

map in sub-pixel resolution by decoding and unwrap-

ping the series of images (Juarez-Salazar et al., 2019).

Thanks to high accuracy in measuring 3D geometry,

this method has been broadly used for a wide range of

industries.

The methods that map a phase to 3D data can

be divided into the phase-height model and multi-

a

https://orcid.org/0000-0001-9399-4232

b

https://orcid.org/0000-0002-5078-4005

view geometry model (Feng et al., 2021). A phase-

height model obtains a height of a point from the ref-

erence plane. It requires a pairwise calibration of the

camera and the projector, which is based on a frac-

tional form that requires strict geometric constraints

that the camera and the projector should be located

at the same height from the reference plane (Takeda

and Mutoh, 1983), i.e., the z-axis of the camera and

the projector should be parallel to each other and per-

pendicular to the reference plane. This factional for-

mulation has been improved to linear inverse (Zhang

et al., 2007; Sansoni et al., 2000; Xiao et al., 2012;

Li et al., 1997) or polynomial (Li et al., 2006; Li

et al., 2001; Guo et al., 2019; Ma et al., 2018; Chen

et al., 2020; Cai et al., 2017). However, as the phys-

ical constraints are the basic assumption to solve the

phase-height function, this phase-height model is very

susceptible to hardware distortion, and it is often in-

valid if these constraints are not consistent. Note that

this model does not describe explicit parameters in-

cluding lens distortion, camera matrix, rotation, and

translation so it is not directly applicable to a multi-

view system. An additional calibration step, such as

78

Cho, H. and Kim, M. H.

Joint Calibration of Cameras and Projectors for Multiview Phase Measuring Profilometry.

DOI: 10.5220/0013145400003912

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 20th International Joint Conference on Computer Vision, Imaging and Computer Graphics Theory and Applications (VISIGRAPP 2025) - Volume 3: VISAPP, pages

78-89

ISBN: 978-989-758-728-3; ISSN: 2184-4321

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

Zhang’s method (Zhang, 2000), is required to extend

the model with another camera-projector pair.

In contrast, the multiview geometry model treats

a projector in the system as an inverse pinhole cam-

era. The phase represents the geometric relationship

between the object point and the principal point of

the projector. The multiview geometry model solves

the 3D reconstruction problem by epipolar geome-

try, such as triangulation (Juarez-Salazar and Diaz-

Ramirez, 2019; Jiang et al., 2018; Juarez-Salazar

et al., 2019), or ray-plane intersection (Li et al., 2020;

Feng et al., 2019). Moreover, the main benefit of the

multiview geometry model is the explicit calibration

of every parameter in each device. And thus, the mul-

tiview geometry models have scalability by means of

explicitly calibrated parameters.

To this end, the traditional calibration meth-

ods for the pinhole camera model require multiple

scenes with a moving checkerboard calibration tar-

get (Zhang, 2000). First, by estimating the homogra-

phy matrices of each view of a checkerboard, we can

compute the focal length, principal point, lens distor-

tion, rotation, and translation parameters of each cam-

era. Once obtaining the camera calibration model,

we can project multiple checkerboard patterns on a

whiteboard and solve the projector’s calibration pa-

rameters, assuming it is a pinhole camera model (Lan-

man and Taubin, 2009; Moreno and Taubin, 2012).

A self-calibration method could be used for optimiz-

ing device parameters if a system uses RGB-D cam-

era (Ibrahim et al., 2023). However, calibrating a pair

of a general RGB camera and a projector is cumber-

some because the method requires several checker-

board images for not only the camera but also the

projector, respectively. This calibration process re-

quires capturing many checkerboard images by phys-

ically rotating the target every time. It is inconvenient

and not easily implementable within a small or tiny

room inside a 3D scanning instrument head.

In this paper, we propose a joint calibration of

phase-measurement profilometry and multiview ge-

ometry, tackling the challenges of multiview PMP

calibration. We design a static calibration target con-

sisting of multiple planar surfaces with unique Aruco

markers (Munoz-Salinas, 2012), as shown in Fig-

ure 1(b). Each surface in our calibration target has

various positions and orientations, and thus we es-

timate the calibration of the intrinsic/extrinsic/lens-

distortion parameters by extracting many homogra-

phies. These fiducial markers are used to precisely

estimate the shape of the calibration target on an ab-

solute scale.

Our static target can simplify the cumbersome cal-

ibration, removing manual interaction with a checker-

board in the traditional approach. On the other hand,

it introduces a new challenge in optimizing camera

and projector parameters due to the nonlinearity of

the lens distortion model. Since the homography is

decomposed into the camera matrix and the extrin-

sic matrix, it is important for a homography to take

up a large scale of valid area in screen space. Other-

wise, a homography with a small area in the screen

space is overfitted to a specific range of radius param-

eter. Therefore, a homography valid in a large area

acts like a constraint for intrinsics not to fall into lo-

cal optima. Since optimization of intrinsic and extrin-

sic is a chicken-and-egg problem, it can also act as

a constraint for extrinsics. Therefore, the traditional

calibration method is valid because the target occu-

pies a large area in the images. On the other hand,

each surface of our target has a small area in the im-

age as we intend to put as many surfaces in the image

as possible. Our solution requires another constraint

to the intrinsics or extrinsics. Adapting the traditional

bundle adjustment (Triggs et al., 1999) to the multi-

view PMP problem, we devise a multiview constraint

to the positions and orientations of every surface in

our target.

Note that our calibration target design is flexi-

ble as long as it consists of a sufficient number of

planar surfaces with detectable fiducial markers. In

other words, we can freely customize the shape of

the calibration target considering a camera-projector

system configuration, such as the arrangement of de-

vices, depth of field, or field of view of devices, etc.

In addition, our bundle-adjusting calibration provides

robust and accurate parameters that can reconstruct

microscopic details. Since we also solve the shape

of the calibration target, it is beneficial to modify the

objective function in the bundle adjustment step with

a dense pixel of inputs rather than specific feature

points.

In summary, our key contributions are:

• A novel customizable static calibration target that

can remove the need to move a calibration target

during explicit calibration, making the PMP cali-

bration efficient.

• A multiview PMP calibration that can avoid local

optima in non-linear parameter optimization using

a static calibration target, achieving high-accuracy

registration of multiview geometry.

2 RELATED WORK

Recently, deep neural networks are widely applied to

general problems of 3D reconstruction, such as sin-

gle shot reconstruction (Li et al., 2022), noise filter-

Joint Calibration of Cameras and Projectors for Multiview Phase Measuring Profilometry

79

ing (Lin et al., 2020), or reducing artifacts caused

by shadow (Wang and Pang, 2022) and shiny ob-

jects (Ueda et al., 2022). However, learning-based

calibration has been rarely discussed in the previ-

ous literature. In this section, we therefore focus

on traditional approaches and foundations of relevant

phase-height models and multiview geometry models

briefly.

2.1 Phase-Height Models

Linear Models. The traditional calibration models

describe the inverse of a height h as a linear inverse

function of ∆ψ, where ∆ψ = ψ−ψ

ref

and ψ

ref

is a pre-

calculated phase with the reference plane (Takeda and

Mutoh, 1983; Zhang et al., 2007; Sansoni et al., 2000;

Xiao et al., 2012; Li et al., 1997). However, a geomet-

rical constraint that restricts the position of system de-

vices is required. To relax the geometrical constraints,

the phase-height function becomes more complex. To

take the tilted camera or projector into account for the

phase-height mapping, the main difference between

the traditional model and the inverse linear model is

that the coefficients used in the phase-height function

are no more globally consistent. In other words, the

coefficients differ pixel-by-pixel in the camera. Fur-

thermore, the calibration of the linear inverse model

mostly depends on the initial value of the parameters,

so the calibration process will not converge if the ini-

tial parameters are too far from the optimal param-

eters. The main limitation is that the inverse linear

model cannot well define nonlinear problems such as

lens distortion into the phase-height function.

Polynomial Models. To deal with the nonlinearity,

some approaches to modify the phase-height func-

tion from inverse linear to inverse polynomial are pro-

posed (Li et al., 2006; Li et al., 2001). However, there

still exists a convergence problem with wrong initial

parameters. Due to the improvement of computa-

tional resources, many inverse polynomial models are

recently introduced (Guo et al., 2019; Ma et al., 2018;

Chen et al., 2020; Cai et al., 2017). To reduce the risk

of non-convergence, an approach that attempts to ap-

proximate the inverse polynomial functions to a poly-

nomial form has emerged (Zhang et al., 2011). How-

ever, the choice of the maximum order in the polyno-

mial function should be sensitive due to Runge’s phe-

nomenon (Guo et al., 2005). The main limitation of

these polynomial and inverse polynomial models are

ineffectiveness and inconsistency. The models require

pixel-wise coefficients for their phase-height function

to relax the geometrical constraints.

Governing Equation Models. The main differ-

ence between governing equation model and the other

phase-height models is that the governing equation

model is a function of u,v,ψ, instead of ∆ψ, where

u and v are pixel indices of the camera. The basic

governing equation is expressed in fractional form,

where the highest order of u,v, ψ are 1 in both numer-

ator and denominator (Du and Wang, 2007). Wang et

al. focus on refining the relationship between the nor-

malized coordinates and pixel index in a governing

equation with higher orders (Wang et al., 2010). Lee

et al. expand the model from phase-height function

to phase-3D-point by calibrating three different gov-

erning equations of x, y, and h, respectively (Lee and

Kim, 2017). By introducing the pixel indices as vari-

ables in the phase-height function, governing equa-

tion models consist of the global parameters rather

than pixel-wise parameters (L

´

eandry et al., 2012; Fu

et al., 2013). Another advantage of a governing equa-

tion is distortion robustness. Since the denomina-

tor and numerator of the governing equation are both

polynomials of u, v, ψ, the lens distortion of both cam-

era and projector can apply to the parameters of the

governing equation (Huang et al., 2010).

2.2 Multiview Geometry Models

Multiview geometry models are based on epipolar

geometry. In practice, Zhang’s approach (Zhang,

2000) has been commonly used by capturing multi-

ple checkerboard images by moving a calibration tar-

get. This calibration assumes that the camera’s and

the projector’s geometry follow the pinhole camera

model. By estimating the homography matrices of

each view of a checkerboard, we can compute the fo-

cal length, principal point, lens distortion, rotation,

and translation parameters of each camera and projec-

tor. The reconstruction method can be ray-ray match-

ing (Juarez-Salazar and Diaz-Ramirez, 2019; Jiang

et al., 2018; Juarez-Salazar et al., 2019) or ray-plane

matching (Li et al., 2020; Feng et al., 2019) by map-

ping phases to normalized coordinates of the pro-

jector. The main benefit of the multiview geometry

model is the explicit calibration of every parameter

in each device. However, since phase-height models

focus on the physical and geometrical relationship of

the camera, projector, and reference plane, the param-

eters of the phase-height models focus only on one

camera-projector pair, which is inefficient for multi-

ple camera-projector systems. Also, this process re-

quires capturing many checkerboard images by phys-

ically rotating the target every time. It is inconvenient

and not easily implementable within a small or tiny

room inside a 3D scanning instrument head.

VISAPP 2025 - 20th International Conference on Computer Vision Theory and Applications

80

It is worth noting that these phase-height models

cannot describe the implicit/explicit parameters and

the lens distortion parameter of cameras and projec-

tors. Thus, it is not directly applicable to a multi-

view system, requiring an additional calibration pro-

cess, such as Zhang’s method (Zhang, 2000). Even

though a calibration method consisting of multiple

cameras and projectors without any fiducial markers

is proposed (Tehrani et al., 2019), the traditional scale

ambiguity of structure-from-motion remains in recon-

structed 3D geometry. Thus, we aim to combine these

two modalities of the phase-to-height model and the

multiview geometry model with improving multiview

PMP calibration. To do so, we develop a novel design

of a static calibration target and multiview calibration

method. The following section provides technical de-

tails of our approach.

Bundle Adjustment. Bundle adjustment (Triggs

et al., 1999) is an approach to calibrating optimal

camera parameters. The bundle adjustment approach

is also applicable to the camera-projector system. Fu-

rukawa et al. adopt bundle adjustment as the last

step in the calibration procedure to refine the focal

length parameter in the camera-projector system (Fu-

ruakwa et al., 2009). Garrido-Jurado et al. modify

the bundle-adjustment step to calibrate the parame-

ters of the camera-projector system (Garrido-Jurado

et al., 2016). Li et al. introduce a weighted sum to

the optimization objective in the calibration procedure

(Li et al., 2019). Since they use bundle adjustment

for self-calibration, the calibration procedure is ini-

tialized with the unknown shape of a target. There-

fore, the accuracy of the system parameters and re-

construction often suffer from the lack of robustness

depending on the complexity of the target shape be-

cause the calibration is processed with specific feature

points and correspondences. In contrast, we leverage

the fiducial markers that allow us to calibrate the sys-

tem parameters robustly and also provide them with

an absolute scale.

3 STATIC CALIBRATION

TARGET DESIGN

Target Design. We design a novel calibration tar-

get especially designed for multiview PMP calibra-

tion. The 3D structure of our target consists of a set

of planes. Since we compute extrinsic/intrinsic/lens-

distortion parameters from estimated homographies

from a single static target, we aim to have many

different face orientations. Also, we want to detect

face orientations using automatically detectable fidu-

(a)

(b)

Figure 1: Our novel PMP calibration target design. (a) Un-

folded surfaces with unique fiducial markers, which are at-

tached to the 3D model. (b) A fabricated calibration target.

cial markers, such as Aruco markers (Munoz-Salinas,

2012). Each plane is designed to have detectable

markers with predefined local coordinates, and we set

the plane’s coordinate system at the bottom as refer-

ence world coordinates. In this case, optimizing a ro-

tation and translation from the local coordinate sys-

tem to the world coordinate system is required. Con-

sidering the printing resolution of the markers on each

surface, we result in 18 polygons. They are attached

on each face on a 3D structure (Figure 1b). Also, as

we illuminate sinusoidal phase patterns on the target

to get phase maps, we print patterns with middle gray

colors. Its dimensions are 60 × 60 × 12.3 mm. Note

that the shape of the calibration target is not restricted

to a specific form, and the target described in Figure 1

is a possible example that is applicable to our calibra-

tion method described in Section 4.

Target Geometry Model. Our calibration target

consists of independent planar surfaces which have

their own local coordinates. For convenience, let sur-

face index 0 be the reference surface at the bottom.

i.e., the local coordinate system of surface 0 is the

same as the world coordinate system. Each surface

of our target has enough numbers (3 at least and 12 at

most) of Aruco markers. Each marker has a unique ID

to recognize which surface the corners of the marker

lay on.

Given a point X

si

=

x

si

y

si

0

⊺

∈ R

3

be an lo-

cal coordinate of the i-th corner point in surface s, the

corresponding world coordinates are

ˆ

X

w

=

R

s

t

s

0 1

ˆ

X

si

, (1)

where the hat symbol denotes that a point is expressed

in a homogeneous coordinate notation, and R

s

, t

s

are

the rotation/translation from local coordinates of sur-

face s to world coordinates. Then given rotation and

Joint Calibration of Cameras and Projectors for Multiview Phase Measuring Profilometry

81

translation of surface s, we can derive a plane equa-

tion in terms of n

s

, the normal of the surface and c

s

,

the constant of the surface as: n

s

·X

w

+c

s

= 0 , where

n

s

= R

s

0 0 1

⊺

and c

s

= −n

s

· t

s

.

4 NONLINEAR OPTIMIZATION

OF PMP CALIBRATION

Overview. Our nonlinear optimization of calibration

consists of four main steps: First, we detect fidu-

cial markers to obtain plane equations of each sur-

face on the target. The corner points observed by

multiview cameras let us initially calibrate each cam-

era’s parameters as initial. We then illuminate phase-

shift images of different frequencies to compute an

unwrapped phase map for each camera-and-projector

pair. Given the phase maps of all pairs, we compute

the depth values of every pixel in phase maps. Lastly,

by minimizing the sum of distances between the es-

timated depths and the target planes, we optimize the

camera/project parameters iteratively.

4.1 Initial Camera Calibration Using

Target

Camera/Projector Models. We first formulate the

geometry of the camera and the projector by using

the standard pinhole camera model. We also include

a sixth-order radial distortion model for the perspec-

tive camera. The telecentric camera is formulated by

removing the z projection component from the camera

model. The projector is based on the inverse pinhole

camera model. Refer to the supplemental document

for more details.

To calibrate the parameters of a camera in a sin-

gle shot, it is required to capture multiple surfaces

with markers in a single image. Theoretically, at least

three surfaces with different poses should be captured

to build homographies (Zhang, 2000). The optimiza-

tion process consists of two steps. First, a i-th corner

on a surface s is projected to undistorted image coor-

dinate p

csi

(refer to Section 1 in the supplemental doc-

ument). Second, the undistorted pixel index p

undist

csi

is

achieved by the distortion removal process with the

pixel index or detected corner in the image. Then the

loss can be defined as the square of the Euclidean dis-

tance of pixels in the image space between p

csi

and

p

undist

csi

:

L

csi

(p

′

csi

,X

si

) (2)

= ∥p

undist

csi

(p

′

csi

;K

c

,d

c

) − p

csi

(X

si

;R

c

,t

c

,K

c

,R

s

,t

s

)∥

2

2

.

(a) Phase-shifting patterns ( )

1

φ

4

φ

16

φ

64

φ

(b) Reconstructed phase map ( )

(c) Phase maps of four different frequencies (d) Final unwrapped phase map

4

φ

4

φ

Figure 2: (a) Phase-shifting pattern examples with a fre-

quency ( f = 4). (b) The reconstructed phase map. (c) Phase

maps of four different frequencies. (d) Final unwrapped

phase map from camera 1.

Let S

cam

, S

surface

denote a set of cameras and sur-

faces, Θ

cam

, Θ

surface

denote a set of parameter θ

c

=

{K

c

,R

c

,t

c

,d

c

} and θ

s

= {R

s

,t

s

} for every camera

c ∈ S

cam

and surface s ∈ S

surface

, the optimization min-

imizes the sum of losses for every c and corner simul-

taneously.

minimize

Θ

surface

,Θ

cam

∑

c∈S

cam

∑

s∈S

surface

∑

i

L

csi

(p

′

csi

,X

si

). (3)

In the optimization process, the world coordinates of

every Aruco marker’s corner are shared globally. It

prevents a specific camera’s parameters from falling

into local minima because the loss of other cameras

increases when it happens. With the multiview con-

straint, the parameters of every camera and the pose

of every surface converge globally.

4.2 Phase Extraction

A sequence of N sinusoidal structured light images

with a frequency f encodes a phase, which is lin-

early related to the pixel index of a projector in ver-

tical or horizontal direction (Feng et al., 2021). For

k ∈ [0,N − 1], when the n-th structured light image

with frequency f is projected onto an object, the re-

flected light is captured by a camera with the intensity

of I

f k

(u,v) for each pixel u,v. The pixel intensity is

formulated as follows:

I

f k

(u,v) = I

a

(u,v) +I

b

(u,v)cos(φ

f

(u,v) +2πk/N),

(4)

where φ

f

(u,v) ∈ [− f π, f π]. We then easily recon-

struct the phase φ by

φ

f

(u,v) = tan

−1

∑

N−1

k=0

I

f k

(u,v)sin(2πk/N)

∑

N−1

k=0

I

f k

(u,v)cos(2πk/N)

. (5)

We capture images with structured lights of four fre-

quencies: 1, 4, 16, and 64. A sequence of wrapped

VISAPP 2025 - 20th International Conference on Computer Vision Theory and Applications

82

camera

projector

Calibration

target surface

n

x

s

Figure 3: Visualization of our bundle-adjusting calibration.

Once we obtain an unwrapped phase map, we can measure

depth by computing an intersection point X

intersect

with a

plane formed by x

n,p

(green plane) and a camera vector

x

n

(blue arrow). Given X

intersect

, our nonlinear optimiza-

tion updates the camera and the projector’s parameters it-

eratively by minimizing the distance between X

intersect

and

X

projected

intersect

(red line) along the surface normal n

s

of the target

surface s (red arrow).

phase φ

f

(u,v) is unwrapped to obtain ψ(u, v). Note

that we print the fiducial markers with the middle gray

color in order to decode phase shift patterns without

artifacts. See Figure 2 for an example. Refer to the

supplemental document for more details.

Phase Outlier Removal. Since a phase map pro-

duced by a series of images is weak to the noise of

the images, a minor noise occurring to a pixel of a sin-

gle image can bring about serious errors in 3D points.

Therefore, we must filter out the noisy phases from

the phase map to reconstruct the correct shape. Refer

to the supplemental document.

4.3 Nonlinear Optimization

Depth by Intersection. Given a pair of camera pixel

(u

c

,v

c

) and phase (ψ

u

(u

c

,v

c

),ψ

v

(u

c

,v

c

)) achieved

by horizontally and horizontally structured light, we

can obtain the intersection point X

intersect

by com-

puting an intersection point between a phase plane

from the projector and a ray vector from the cam-

era. In Figure 3, x

n,p

(or y

n,p

) can be obtained with

(ψ

u

(u

c

,v

c

),ψ

v

(u

c

,v

c

)) and projector intrinsics. Then,

given the line x = x

n,p

(or y = y

n,p

) on the normalized

projector plane and the projector’s center of projec-

tion (COP) O

p

, we can calculate the normal of phase

plane n

p

(green arrow). Then the phase plane (green

plane) can be expressed as {X : n

p

· (X − O

p

) = 0},

where X is a point in the world coordinates.

And we can express a unit vector of pixel ray from

the camera (blue arrow) as v

c

= x

n

− O

c

, where x

n

is

the point on normalized camera plane gained by pixel

coordinates (u

c

,v

c

), and O

c

is the COP of the camera.

Then, point X can be expressed as {X : X = O

c

+

λv

c

}. Then we can figure out X

intersect

by solving λ,

z

c

= λ =

n

p

· (O

p

− O

c

)

n

p

· v

c

. (6)

Similarly, we can represent point X captured by a

telecentric lens camera as {X : X = x

n

+ λv

c

}, where

v

c

= R

−1

c

0 0 1

⊺

. Then we can solve λ as

z

c

= λ − 1, λ =

n

p

· (O

p

− x

n

)

n

p

· v

c

. (7)

Then the intersection point is X

intersect

= O

c

+ λv

c

with the pinhole camera, and X

intersect

= x

n

+λv

c

with

the telecentric lens camera.

Bundle-Adjusting Optimization. Let S

proj

and

Θ

proj

denote a set of projectors and a set of parame-

ter θ

p

= {K

p

,R

p

,t

p

,d

p

} for every projector p ∈ S

proj

.

For each surface s of our target, we can obtain the

pixel area A(c,s) of the same orientation, where the

marker exists in the camera image c, because each

fiducial marker has a unique ID. Since the pose of a

surface of the target is optimized in Section 4.1, we

can define a loss of bundle adjustment as a distance

between X

intersect

and a surface (red line) along the

surface normal (red arrow):

L

bundle

(c, p,s)

=

∑

(u

c

,v

c

)∈A(c,s)

{n

s

X

intersect

(u

c

,v

c

,ψ

u,p

(u

c

,v

c

),

ψ

v,p

(u

c

,v

c

);θ

c

,θ

p

) + c

s

}

2

. (8)

Since cameras and projectors affect each other, the

overall bundle adjustment process should be per-

formed simultaneously:

minimize

Θ

cam

,Θ

proj

∑

p∈S

proj

∑

c∈S

cam

∑

s∈S

surface

L

bundle

(c, p,s). (9)

Unlike other existing camera-projector calibration

methods using bundle-adjustment approach (Furu-

akwa et al., 2009; Garrido-Jurado et al., 2016; Li

et al., 2019), we introduce an additional condition that

the calibration target consists of planar surfaces and

assume their orientations are known via Equation (3).

Therefore, the objective function has a form of the

sum of point-plane distance errors rather than repro-

jection errors. We have achieved sufficiently accurate

parameters, through our calibration target and bundle-

adjustment approach, to reconstruct microscopic de-

tails of the object without requiring additional uni-

form color illumination as needed in (Li et al., 2019).

Joint Calibration of Cameras and Projectors for Multiview Phase Measuring Profilometry

83

4.4 Reconstruction

Prior to reconstructing 3D point clouds, we measure

a confidence map corresponding to a depth map. A

confidence map is used for two purposes. First, we

can filter out the points with low confidence. Second,

confidence values can be used to refine the 3D shape.

For each D

c

, a depth map achieved from a camera c

is required to calculate the confidence of each pixel.

Given X

c

(u,v), a 3D point obtained from D

c

(u,v) can

be transformed into the camera coordinate of another

camera c

′

:

ˆ

X

c

′

=

x

c

′

y

c

′

z

c

′

1

=

R

c

′

t

c

′

0 1

R

c

t

c

0 1

−1

ˆ

X

c

. (10)

Then the point

ˆ

X

c

′

can be projected to a pixel p

c

′

=

u

′

v

′

⊺

. Finally, in terms of the difference between

the z

c

′

and D

c

′

(u

′

,v

′

), the confidence of the pixel (u, v)

with the camera c is computed as follows

C

c,c

′

(u,v) =

(

1, if V

c

′

(X

c

(u,v)) = 0,

exp{−(z

c

′

− D

′

c

(u

′

,v

′

))

2

}, otherwise,

(11)

where V

c

′

is a visibility term which is 1 if X

c

(u,v)

is visible to c

′

and 0 otherwise. The final confidence

C

c

(u,v) is obtained by

C

c

(u,v) =

∏

c

′

∈S

cam

,c

′

̸=c

C

c,c

′

(u,v). (12)

Then we can get rid of the pixels that C

c

(u,v) < τ

conf

.

After all, a set of total point clouds and corre-

sponding confidences are obtained by spreading out

D

c

and C

c

to the world space for every camera c ∈

S

cam

. Now let S

total,c

(u,v) be a set whose element is

a paired depth d of visible point X

c

in the total point

cloud from a pixel (u,v) of camera c and correspond-

ing confidence weight ω. Then the refined depth map

D

refined

c

is obtained as a weighted sum of depth whose

weight is the confidence as follows:

D

refined

c

(u,v) =

∑

(d,ω)∈S

total,c

(u,v)

ω · d

∑

(d,ω)∈S

total,c

(u,v)

ω

. (13)

5 EXPERIMENTAL RESULTS

Experiment Setup. We build a multiview PMP

setup with five cameras and four projectors. We place

a telecentric-lens camera on top and four ordinary

cameras in four cardinal directions on a metallic sup-

port. On top of each side camera, we install four

projectors illuminating four different frequencies with

Camera 0

Camera 1

Camera 2

Camera 3

Camera 4

Projector 0

Projector 1

Projector 2

Projector 3

Figure 4: Schematic diagram of the cross-section view of

our multiview PMP imaging setup.

four tap phase shifts with π/2 intervals. See Figure 4.

Since we design our target convex for each side of the

target to get as much light from a projector as pos-

sible, we pair a projector with every camera except

for the camera in the opposite direction in the cali-

bration procedure. On the other hand, we pair a pro-

jector only with the top-view camera and the camera

on the same side in the reconstruction procedure to

reduce the risk of noise produced from the shadowed

area of a non-convex object. We have implemented

our optimization with the Adam optimizer in Pytorch,

and rigid body transformations are optimized via Li-

etorch (Teed and Deng, 2021).

5.1 Multiview Reconstruction Results

Now we demonstrate multiview 3D reconstruction re-

sults.

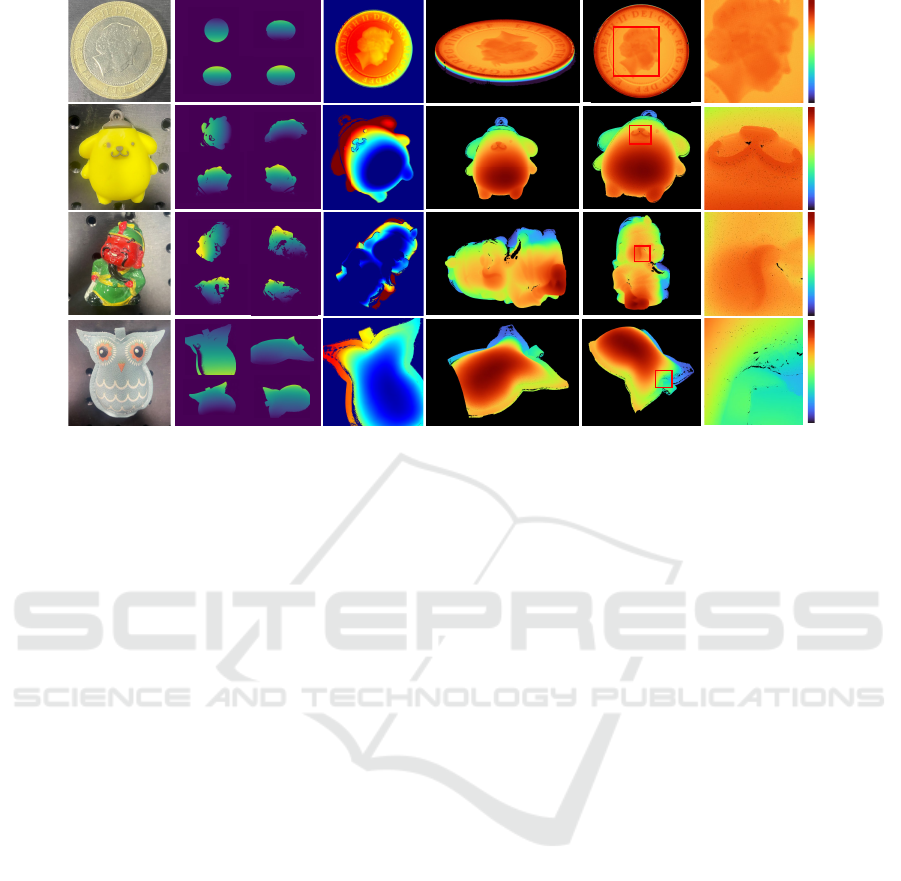

Real-World Object Results. Figure 5 demonstrates

our multiview 3D reconstruction results. From the

leftmost end, we show (a) photographs of objects, (b)

multiview phases from different views, (c) the com-

bined depth, and (d) the final 3D reconstruction re-

sults rendered in different angles. As shown in the

coin object, the microscale geometry of the object is

captured with high accuracy, i.e., the height of the

Queen’s relief is less than 500 µm. The side geom-

etry of the coin is also clearly acquired by the side-

view observation registered by our method with high

accuracy. Moreover, the detailed geometries, such as

letters inscribed in the statue, are well reconstructed

in our method. Other objects’ front and side surfaces,

like dolls, can be scanned with high accuracy. Also,

note that the front surfaces of the object are recon-

structed with multiview phase maps. No artifact at

the front reflects highly accurate registration results

by our calibration method.

Multiview Reconstruction Accuracy. In order to

evaluate the registration accuracy of multiview depth

maps to the final geometry, we compare our multi-

view 3D reconstruction results with 3D geometry ac-

quired by a commercial laser scanner, NextEngine.

To achieve the most detailed and accurate geometry

VISAPP 2025 - 20th International Conference on Computer Vision Theory and Applications

84

(a) Photograph (b) Multiview phase (c) Combined depth (d) 3D reconstruction rendered in different angles

height (mm)0 4.66height (mm)0 24.28

height (mm)0

25.13

height (mm)0

20.62

Closeup

Figure 5: 3D reconstruction results of real-world objects. (a) Photographs of objects. (b) Multiview phase maps. (c) Combined

depth maps. (d) 3D reconstruction rendered in different views.

from the scanner, we use one-pass scanning results

by the scanner. For a fair comparison, we compare

the one-pass scan results with our multiview recon-

struction results, evaluating Hausdorff’s distance be-

tween the laser-scanned 3D data and the point cloud

reconstructed by our method. Note that the distances

in overlapping areas are significantly low, while high

errors occur only when there is no geometry in the

NextEngine scan results. As shown in Figure 6, our

reconstructed geometry from multiview phase mea-

surements presents a good agreement with geometry

measurement by the commercial scanner. This means

that the system parameters estimated by our nonlinear

optimization using our static target are highly accu-

rate.

Confidence Filtering. Before reconstructing 3D ge-

ometry, it is essential to estimate a confidence map

given a depth map. Since we measure the confidence

of a depth map pixel-by-pixel by comparing depth

maps in the multi-view system, we can mitigate the

risk of reconstructing invalid depths from the wrong

phase input. Given the geometrical relationships be-

tween multiple views, we can measure reliability and

filter them out by evaluating if a point is not supposed

to exist in the depth maps of the other views. As

shown in Figure 7(b), the leg of the knight on the left-

most side of the image produces invalid phase input to

a camera view because its points are not reconstructed

in a consistent place by the camera. It validates that

our confidence-based filter algorithm performs well

in removing unreliable points. Then, other reliable

depth values are combined into the final 3D geometry

as shown in Figure 7(d).

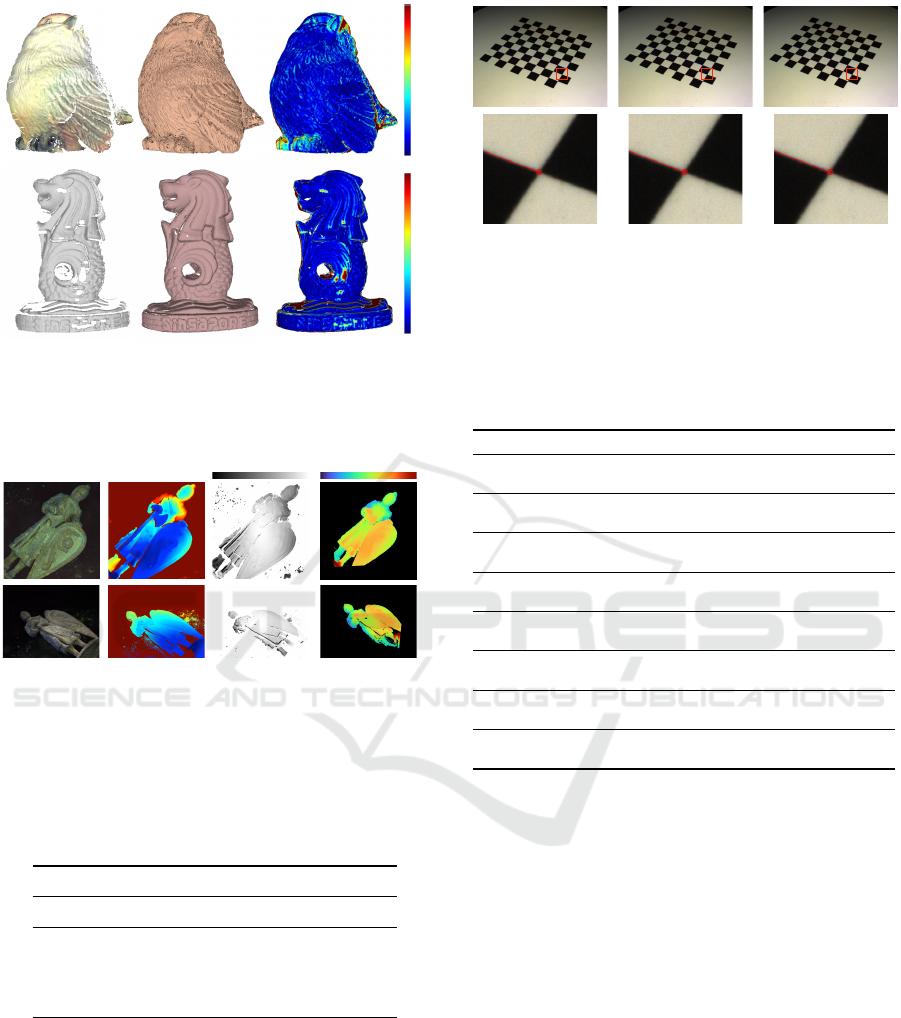

5.2 Camera Intrinsic Compared with

Zhang’s Method

To validate parameters calibrated by our method, we

compare the reprojection errors of our method for

9 × 8 checkerboard corners with standard Zhang’s

method (Zhang, 2000). To do this, we prepare a cali-

bration image set consisting of 15 images of different

checkerboard poses to calibrate Zhang’s method. The

reprojection errors are measured with the same val-

idation image set for both Zhang’s and our method.

Tab. 1 shows the reprojection error results, and Fig. 8

shows the checkerboard images marked with repro-

jected corners of Zhang’s and ours. Since we use a

static target where each surface orientation is fixed

and surface orientation observation locally isolated,

the errors of our method tend to be higher than

Zhang’s. However, we demonstrate that our method

shows errors of less than 1 pixel. The error difference

between the standard method and ours is very simi-

lar even only our method does not require changing

the surface orientation and our method just uses the

single static scene of our target.

5.3 View-Pairwise Consistency Results

In this section, we demonstrate that each depth map

built from a view before the final reconstruction fits

Joint Calibration of Cameras and Projectors for Multiview Phase Measuring Profilometry

85

(c) Geometry differences

0.707

0

(a) NextEngine scanner (b) Our method

0 0.866

Hausdorff distance (mm) Hausdorff distance (mm)

Figure 6: Accuracy evaluation of our registration using the

optimized calibration parameters. (a) 3D geometry captured

by a commercial scanner. (b) Our multiview reconstruction

result. (c) Hausdorff’s distance map. Blue means zero error.

(a) Photograph !

(b) Depth map!

(c) Confidence map!

Confidence!0! 1!

(d) Reconstruction result!

height (mm)!0! 4.66!

Figure 7: Our confidence filtering results. (a) Object pho-

tographs from different views. (b) Estimated depth maps

from each view. (c) Confidence maps that we computed

through reprojection. (d) Final 3D reconstruction result ren-

dered from each view.

Table 1: Reprojection errors of the validation sets of images

with standard pinhole camera calibration method and our

method.

Zhang Ours

RMSE MAE RMSE MAE

Cam 0 0.4938 0.1892 0.8543 0.3513

Cam 1 0.4028 0.1590 0.5612 0.2116

Cam 2 0.3416 0.1348 0.4058 0.1570

Cam 3 0.4349 0.1664 0.7204 0.2794

well. The overall process and corresponding middle

results are shown in Fig. 9. It is evidence of accurate

calibration that a point cloud generated from a view

has a consistent shape with respect to the point cloud

from another view without any post-processing, such

as rigid-body registration. The results described in

this section are measured with point clouds before the

final reconstruction sampled with voxels whose diam-

eter is 0.025mm.

(a) Detected! (b) Reprojected (Zhang)! (b) Reprojected (ours)!

Figure 8: The images (top) and their close-ups (bottom).

(a) 9 × 8 checkerboard image marked with detected corners.

(b) Corners reprojected by Zhang’s method. (c) Corners

reprojected by our method.

Table 2: Statistics including mean and standard deviation

(SD) of Hausdorff’s distance between point clouds gener-

ated by four side-views and top view for various real-world

objects.

View 0 View 1 View 2 View 3

Owl

Mean 0.0817 0.1149 0.126 0.1197

SD 0.1077 0.1536 0.1626 0.1489

Pouch

Mean 0.0393 0.0427 0.0493 0.0367

SD 0.0534 0.0689 0.0772 0.0527

Cat

Mean 0.1168 0.0851 0.1024 0.0945

SD 0.1504 0.1129 0.1334 0.1304

Tire

Mean 0.1027 0.0795 0.0961 0.0953

SD 0.1496 0.1228 0.1432 0.1429

Girl statue

Mean 0.0605 0.0565 0.0488 0.0687

SD 0.0826 0.0853 0.0663 0.1028

Canon holder

Mean 0.1091 0.0691 0.1382 0.1043

SD 0.1566 0.1205 0.1643 0.1423

Singapore lion statue

Mean 0.0945 0.0947 0.0906 0.0838

SD 0.1479 0.1416 0.1404 0.1400

Yellow doll

Mean 0.1188 0.1058 0.1825 0.0986

SD 0.1669 0.1515 0.2125 0.1242

Hausdorff Distance. First, we measure Hausdorff’s

distance between point clouds generated from a dif-

ferent view. Since the top-view camera mainly ob-

serves an object, we compare each point cloud gen-

erated from a side-view camera with the point cloud

generated from the top-view camera. Since there must

be a region that is not overlapped, we measure the

mean and variance of Hausdorff’s distances less than

0.5mm to accurately measure the distance between

overlapped regions. Tab. 2 shows the statistical re-

sults for Hausdorff’s distances of the objects in the

paper and supplemental. We can figure out that ev-

ery depth map fits each other with the distance in the

range between 30µm to 200µm. Fig. 10 shows the

point clouds colored by Hausdorff’s distances, we can

figure out that Hausdorff’s distance of a point in the

overlapped region is extremely low.

Iterative Closest Point. Secondly, we measure

the errors between point clouds by registration of a

point cloud from side-view to the point cloud from top

VISAPP 2025 - 20th International Conference on Computer Vision Theory and Applications

86

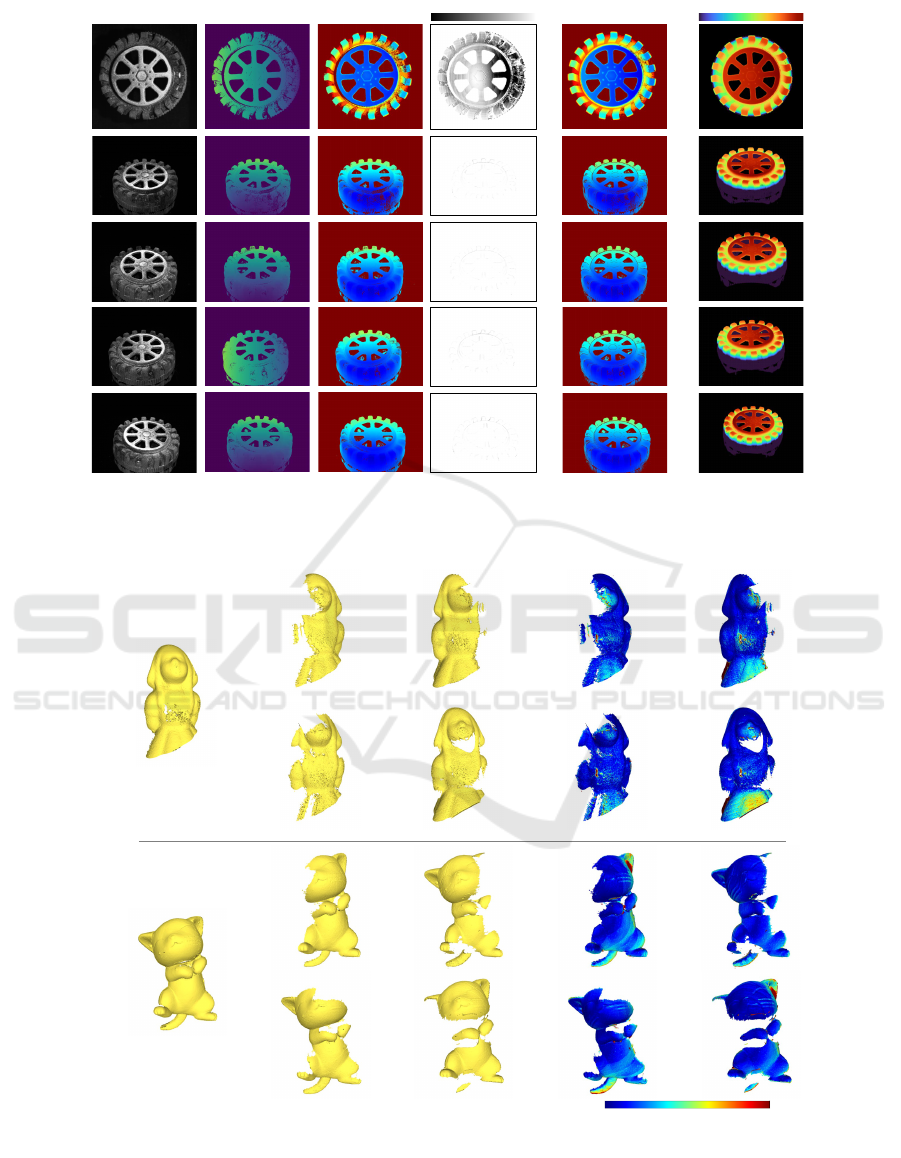

(a) Photograph (c) Depth map

(d) Confidence map

Confidence 0.9 1

(f) Reconstruction result

height (mm) 16.39 23.20

(e) Combined depth map

(b) Phase map

Figure 9: 3D reconstruction results of real-world objects with a top-view (the first row) and 4 side-views (the second to the

fifth row). (a) Photographs of objects. (b) Multiview phase maps. (c) Multiview depth maps. (d) Multiview confidence maps.

(e) Multiview combined depth maps. (f) 3D reconstruction rendered in different views.

(c) Geometry differences(a) Point clouds (top view) (b) Point clouds (side view)

0 0.5 Hausdorff distance (mm)

Figure 10: Point clouds are generated by depth maps of top and side views and their geometry differences. (a) Point clouds

generated by top view. (b) Point clouds generated by side view. (c) Geometry differences measured as Hausdorff’s distance.

Joint Calibration of Cameras and Projectors for Multiview Phase Measuring Profilometry

87

Table 3: Errors of transformations of R and t with various real-world objects.

View 1 View 2 View 3 View 4

E(R) E(t) E(R) E(t) E(R) E(t) E(R) E(t)

Owl 0.0105 0.2491 0.0096 0.1145 0.0077 0.2770 0.0102 0.1077

Pouch 0.0033 0.0870 0.0027 0.1099 0.0012 0.0588 0.0022 0.0465

Cat 0.0143 0.2934 0.0036 0.1316 0.0084 0.1095 0.0124 0.3287

Tire 0.0053 0.1910 0.0019 0.0552 0.0038 0.0918 0.0034 0.1425

Girl statue 0.0054 0.0365 0.0046 0.0695 0.0016 0.1008 0.0094 0.1661

Canon holder 0.0017 0.2710 0.0026 0.2155 0.0014 0.3009 0.0031 0.2427

Singapore lion statue 0.0066 0.2092 0.0033 0.0946 0.0062 0.1669 0.0054 0.0828

Yellow doll 0.0139 0.1937 0.0182 0.3800 0.0157 0.4056 0.0141 0.1515

Mean 0.0008 0.1914 0.0058 0.1463 0.0006 0.1889 0.0075 0.1586

view (Wang and Solomon, 2019). To do this,

given R and t which represent the transform calcu-

lated from Iterative Closest Point algorithm (Chen

and Medioni, 1992), it is obvious that R = I

3

and t = 0

3

where I

3

and 0

3

3 × 3 denote identity

matrix and 3 × 1 zero vector. We define errors of

rotation and translation as E(R) =

∥

R − I

3

∥

F

and

E(t) =

∥

t

∥

2

. Tab. 3 shows the measured error of ICP

transformation from each side-view 1, 2, 3, and 4

to the top-view with objects in the main paper and

supplement. The reason that the value of E(t) is

higher than Hausdorff’s distance described in Tab. 2

is supposed to be due to the small misalignment of

the rotations.

6 CONCLUSION

We have presented a phase-measuring profilometry

calibration method specially designed for multiview

PMP systems. We propose a novel compact, static

calibration target design, which is applicable to exist-

ing PMP instrument heads even with a small room for

calibration. We tackle the overfitting problem of cali-

bration parameters that often occurs in the static cali-

bration of multiview geometry. We resolve this chal-

lenge by devising a multiview-based bundle-adjusting

approach. Our nonlinear optimization method can

acquire explicit calibration parameters not only for

projectors but also for perspective/telecentric cameras

with high accuracy. No physical interaction is re-

quired during the calibration process. We anticipate

that our method makes the multiview PMP calibra-

tion process simpler, and it is beneficial for the 3D

imaging industry as it can achieve high-accuracy reg-

istration of multiview input.

ACKNOWLEDGEMENTS

Min H. Kim acknowledges the Samsung Research

Funding & Incubation Center (SRFC-IT2402-02),

the Korea NRF grant (RS-2024-00357548), the

MSIT/IITP of Korea (RS-2022-00155620, RS-2024-

00398830, 2022-0-00058, and 2017-0-00072), Mi-

crosoft Research Asia, LIG, and Samsung Electron-

ics.

REFERENCES

Cai, Z., Liu, X., Li, A., Tang, Q., Peng, X., and Gao, B. Z.

(2017). Phase-3d mapping method developed from

back-projection stereovision model for fringe projec-

tion profilometry. Optics express, 25(2):1262–1277.

Chen, L., Huayang, L., Xu, Z., and Huan, Z. (2020). Coding

line structured light based on a line-scan camera and

its calibration. Optics Express, 28(17):24799–24812.

Chen, Y. and Medioni, G. (1992). Object modelling by reg-

istration of multiple range images. Image and vision

computing, 10(3):145–155.

Du, H. and Wang, Z. (2007). Three-dimensional shape mea-

surement with an arbitrarily arranged fringe projec-

tion profilometry system. Optics letters, 32(16):2438–

2440.

Feng, S., Zuo, C., Zhang, L., Tao, T., Hu, Y., Yin, W., Qian,

J., and Chen, Q. (2021). Calibration of fringe projec-

tion profilometry: A comparative review. Optics and

Lasers in Engineering, 143:106622.

Feng, Z., Man, D., and Song, Z. (2019). A pattern and

calibration method for single-pattern structured light

system. IEEE Transactions on Instrumentation and

Measurement, 69(6):3037–3048.

Fu, Y., Wang, Y., Wang, W., and Wu, J. (2013). Least-

squares calibration method for fringe projection pro-

filometry with some practical considerations. Optik,

124(19):4041–4045.

Furuakwa, R., Inose, K., and Kawasaki, H. (2009). Multi-

view reconstruction for projector camera systems

based on bundle adjustment. In Proc. IEEE CVPR

Workshops, pages 69–76. IEEE.

Garrido-Jurado, S., Munoz-Salinas, R., Madrid-Cuevas,

F. J., and Marin-Jim

´

enez, M. J. (2016). Simultaneous

reconstruction and calibration for multi-view struc-

tured light scanning. J. Visual Communication and

Image Representation, 39:120–131.

Guo, H., He, H., Yu, Y., and Chen, M. (2005). Least-squares

calibration method for fringe projection profilometry.

Optical Engineering, 44(3):033603.

Guo, W., Wu, Z., Xu, R., Zhang, Q., and Fujigaki, M.

(2019). A fast reconstruction method for three-

VISAPP 2025 - 20th International Conference on Computer Vision Theory and Applications

88

dimensional shape measurement using dual-frequency

grating projection and phase-to-height lookup table.

Optics & Laser Technology, 112:269–277.

Huang, L., Chua, P. S., and Asundi, A. (2010). Least-

squares calibration method for fringe projection pro-

filometry considering camera lens distortion. Applied

optics, 49(9):1539–1548.

Ibrahim, M. T., Gopi, M., and Majumder, A. (2023). Self-

calibrating dynamic projection mapping system for

dynamic, deformable surfaces with jitter correction

and occlusion handling. In IEEE Int. Symp. on Mixed

and Augmented Reality, pages 293–302.

Jiang, C., Lim, B., and Zhang, S. (2018). Three-

dimensional shape measurement using a structured

light system with dual projectors. Applied optics,

57(14):3983–3990.

Juarez-Salazar, R. and Diaz-Ramirez, V. H. (2019). Flexible

camera-projector calibration using superposed color

checkerboards. Optics and Lasers in Engineering,

120:59–65.

Juarez-Salazar, R., Giron, A., Zheng, J., and Diaz-Ramirez,

V. H. (2019). Key concepts for phase-to-coordinate

conversion in fringe projection systems. Applied op-

tics, 58(18):4828–4834.

Lanman, D. and Taubin, G. (2009). Build your own 3d scan-

ner: 3d photography for beginners. In ACM siggraph

2009 courses, pages 1–94.

L

´

eandry, I., Br

`

eque, C., and Valle, V. (2012). Calibration

of a structured-light projection system: development

to large dimension objects. Optics and Lasers in En-

gineering, 50(3):373–379.

Lee, Y. B. and Kim, M. H. (2017). Integrated calibration of

multiview phase-measuring profilometry. Optics and

Lasers in Engineering, 98:118–122.

Li, C., Monno, Y., Hidaka, H., and Okutomi, M. (2019).

Pro-cam ssfm: Projector-camera system for structure

and spectral reflectance from motion. In Proc. IEEE

ICCV, pages 2414–2423.

Li, J.-L., Su, H.-J., and Su, X.-Y. (1997). Two-frequency

grating used in phase-measuring profilometry. Ap-

plied Optics, 36(1):277–280.

Li, W., Li, H., and Zhang, H. (2020). Light plane calibration

and accuracy analysis for multi-line structured light

vision measurement system. Optik, 207:163882.

Li, W., Su, X., and Liu, Z. (2001). Large-scale three-

dimensional object measurement: a practical coordi-

nate mapping and image data-patching method. Ap-

plied Optics, 40(20):3326–3333.

Li, Y., Qian, J., Feng, S., Chen, Q., and Zuo, C. (2022).

Composite fringe projection deep learning profilom-

etry for single-shot absolute 3d shape measurement.

Optics express, 30(3):3424–3442.

Li, Y., Su, X., and Wu, Q. (2006). Accurate phase–height

mapping algorithm for pmp. Journal of Modern Op-

tics, 53(14):1955–1964.

Lin, B., Fu, S., Zhang, C., Wang, F., and Li, Y. (2020).

Optical fringe patterns filtering based on multi-stage

convolution neural network. Optics and Lasers in En-

gineering, 126:105853.

Ma, Q., Cao, Y., Chen, C., Wan, Y., Fu, G., and Wang, Y.

(2018). Intrinsic feature revelation of phase-to-height

mapping in phase measuring profilometry. Optics &

Laser Technology, 108:46–52.

Moreno, D. and Taubin, G. (2012). Simple, accurate, and

robust projector-camera calibration. In 2012 Second

International Conference on 3D Imaging, Modeling,

Processing, Visualization & Transmission, pages 464–

471. IEEE.

Munoz-Salinas, R. (2012). Aruco: a minimal library for

augmented reality applications based on opencv. Uni-

versidad de C

´

ordoba.

Sansoni, G., Carocci, M., and Rodella, R. (2000). Cal-

ibration and performance evaluation of a 3-d imag-

ing sensor based on the projection of structured light.

IEEE Transactions on instrumentation and measure-

ment, 49(3):628–636.

Takeda, M. and Mutoh, K. (1983). Fourier transform pro-

filometry for the automatic measurement of 3-d object

shapes. Applied optics, 22(24):3977–3982.

Teed, Z. and Deng, J. (2021). Tangent space backpropa-

gation for 3d transformation groups. In Proceedings

of the IEEE/CVF Conference on Computer Vision and

Pattern Recognition, pages 10338–10347.

Tehrani, M. A., Gopi, M., and Majumder, A. (2019). Auto-

mated geometric registration for multi-projector dis-

plays on arbitrary 3d shapes using uncalibrated de-

vices. IEEE transactions on visualization and com-

puter graphics, 27(4):2265–2279.

Triggs, B., McLauchlan, P. F., Hartley, R. I., and Fitzgibbon,

A. W. (1999). Bundle adjustment—a modern synthe-

sis. In International workshop on vision algorithms,

pages 298–372. Springer.

Ueda, K., Ikeda, K., Koyama, O., and Yamada, M. (2022).

Absolute phase retrieval of shiny objects using fringe

projection and deep learning with computer-graphics-

based images. Applied Optics, 61(10):2750–2756.

Wang, C. and Pang, Q. (2022). The elimination of errors

caused by shadow in fringe projection profilometry

based on deep learning. Optics and Lasers in Engi-

neering, 159:107203.

Wang, Y. and Solomon, J. M. (2019). Prnet: Self-supervised

learning for partial-to-partial registration. Advances in

neural information processing systems, 32.

Wang, Z., Nguyen, D. A., and Barnes, J. C. (2010). Some

practical considerations in fringe projection profilom-

etry. Optics and Lasers in Engineering, 48(2):218–

225.

Xiao, Y., Cao, Y., and Wu, Y. (2012). Improved algorithm

for phase-to-height mapping in phase measuring pro-

filometry. Applied optics, 51(8):1149–1155.

Zhang, Z. (2000). A flexible new technique for camera cal-

ibration. IEEE Transactions on Pattern Analysis and

Machine Intelligence, 22(11):1330–1334.

Zhang, Z., Ma, H., Zhang, S., Guo, T., Towers, C. E., and

Towers, D. P. (2011). Simple calibration of a phase-

based 3d imaging system based on uneven fringe pro-

jection. Optics letters, 36(5):627–629.

Zhang, Z., Towers, C. E., and Towers, D. P. (2007).

Uneven fringe projection for efficient calibration in

high-resolution 3d shape metrology. Applied Optics,

46(24):6113–6119.

Joint Calibration of Cameras and Projectors for Multiview Phase Measuring Profilometry

89