An Easy-to-Implement Multi-Channel Stepper Motor Control System

Based on MCU and FPGA

Zhen Dai

1 a

, Congcong Zhou

2 b

and Xuesong Ye

1

1

Biosensor National Special Laboratory, College of Biomedical Engineering and Instrument Science, Zhejiang University,

Hangzhou, Zhejiang, 310027, China

2

Sir Run Run Shaw Hospital, School of Medicine, Zhejiang University, National Engineering Research Center for

Innovation and Application of Minimally Invasive Devices, East Qingchun Road, Hangzhou, Zhejiang, 310016, China

Keywords:

MCU, FPGA, Trapezoidal Acceleration, Stepper, Velocity Profile, Multi-Channel.

Abstract:

This paper proposes a system architecture based on MCU and FPGA that supports the control of dozens of

stepper motors, characterized by low cost, high real-time performance, and ease of implementation. The

system leverages the integrated floating-point unit in the MCU, along with its rich peripherals and ease of

development, combined with the parallel processing capabilities and abundant I/O resources of the FPGA.

Additionally, to address various complex scenarios in medical devices, an asymmetric trapezoidal velocity

profile is implemented on the FPGA with minimal resource consumption of 528 LUTs and 353 Flip-Flops. Fi-

nally, the feasibility of the circuit is validated through logic waveform capture and oscilloscope measurements,

and position error tests on actual stepper motors demonstrate that the system is suitable for most applications.

1 INTRODUCTION

Stepper motors are used in various industrial appli-

cations where low power is required, and low speed,

torque, fast dynamics and precise positioning are im-

portant factors. For example, in medical applications

for accurate medication dosage with peristaltic pumps

or pipettes and as motion control actuators in dial-

ysis equipment (Silaban et al., 2020). The goal of

medical mechatronics is to create devices that can in-

teract with muscles, skeletal, and nervous system to

assist impaired human motor function, such as lower

limb exoskeletons. They are primarily needed by sol-

diers, individuals engaged in heavy manual labor, dis-

abled people, and the elderly. They assist in perform-

ing various movements or support gait-rehabilitation

patient. Considering factors such as size, weight,

and safety, stepper motors are a recommended choice

(Fang et al., 2023).These assistive devices require

multi-motor motion control. Pneumatic stepper mo-

tors are useful in actuating robotic systems that are

suitable for use in magnetic resonance imaging (MRI)

scanners for minimally invasive surgical interventions

such as breast biopsy, prostate biopsy, endovascular

interventions, and interventions in other organs. Driv-

ing a Pneumatic stepper requires the coordination of

a

https://orcid.org/0009-0008-6515-1308

b

https://orcid.org/0000-0001-8397-1491

multiple pneumatic pumps, valves, and cylinders to

function properly (Groenhuis et al., 2022). Mechani-

cal ventilators play a crucial role in assisting patients

with breathing while the underlying disease runs its

course. Cheaper alternatives for mechanical ventila-

tion, especially automated artificial manual-breathing

units (AMBU) bags, have received wide attention

from clinicians, researchers and policymakers, ow-

ing to fast production, economical deployment and

easy accessibility to a larger portion of the population

all across the world. The device can precisely con-

trol various ventilation parameters by driving multi-

ple stepper motors and pump valves (Kumar et al.,

2021). Protocols in the academic life science labora-

tory are heavily reliant on the manual manipulation of

tools, reagents and instruments by a host of research

staff and students. Automated laboratories offer ad-

vantages such as reducing human errors, improving

safety, and enhancing efficiency, but the biggest chal-

lenge they face is cost (Holland and Davies, 2020).

Automated laboratories often involve the transfer of

various reaction solutions, and stepper motors, as a

low-cost actuator, can meet the automation control

needs of the laboratory at a low cost.In conclusion,

electronic systems in the field of medical devices of-

ten need to drive multiple motors as actuators to per-

form various functions. In scenarios where cost is

a constraint, stepper motors are the preferred choice

Dai, Z., Zhou, C. and Ye, X.

An Easy-to-Implement Multi-Channel Stepper Motor Control System Based on MCU and FPGA.

DOI: 10.5220/0013150800003911

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 18th International Joint Conference on Biomedical Engineering Systems and Technologies (BIOSTEC 2025) - Volume 1, pages 149-156

ISBN: 978-989-758-731-3; ISSN: 2184-4305

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

149

due to their low cost, durability, and low noise.

Currently, the common electronic system for driv-

ing stepper motors consists of three modules: the con-

troller, the power driver, and the stepper motor, as

shown in the Figure 1. The controller generates the

pulse sequence to drive the stepper motor, the power

driver converts the pulse sequence into a high-power,

two-phase, four-wire drive signal, and the stepper mo-

tor rotates under the changing magnetic field pro-

duced by the driver.

Ardunio

MCU

FPGA

...

LV8728

DRV8845

...

Robot

Peristaltic Pump

...

Controller

Power

Driver

Stepper

A+

A-

B+

B-

Figure 1: Normal stepper control system.

The controller is often chosen to be an

MCU(Micro Controller Unit) (Zhang and Yu, 2022;

Zhang et al., 2017; Fonseca-Campos et al., 2023),

or an FPGA(Field Programmable Gate Array) (Zunin

and Romanova, 2021; Chen et al., 2024). However,

these papers mainly discuss how to drive stepper mo-

tors on these hardware platforms, with few discussing

the hardware resources consumed.

The advantage of the MCU is that it can utilize

the FPU(Floating Point Unit) unit to perform com-

plex floating-point mathematical operations and use

timer resources to generate PWM(Pulse Width Mod-

ulation) waves at specific frequencies. However, due

to the limited I/O ports and timer resources of an

MCU, the number of stepper motors it can drive is re-

stricted. When multiple steppers are spinning at high

speeds, the MCU must calculate the next pulse period

before it arrives. Therefore, in scenarios where mul-

tiple steppers need to be driven, using an MCU re-

quires careful management of computational tasks to

ensure that calculations are completed on time, allow-

ing each motor to operate as expected. Additionally,

the high-speed rotation of multiple steppers results in

more frequent timer interrupts, which increases the

CPU’s load. These issues complicate the development

of multi-stepper motor control using an MCU, of-

ten requiring multiple MCUs to form a complex star-

shaped network. On the other hand, the FPGA bene-

fits from its parallel processing capabilities and abun-

dant I/O resources, making it much easier to drive

multiple steppers simultaneously. It is highly flexi-

ble and can be programmed according to the needs

of the application and the devices being controlled

(Boulaala et al., 2020). However, most FPGA-driven

stepper solutions involve complex floating-point mul-

tiplication, division, and square root calculations,

which can only be handled by high-performance FP-

GAs with integrated DSP hard cores or by using

vendor-provided IP cores. These FPGAs are gener-

ally more expensive compared to standard FPGAs and

consume more hardware resources.

To address these issues, this paper proposes an

MCU+FPGA solution, which combines the MCU’s

advantage of handling complex calculations with the

FPGA’s abundant I/O resources and parallel process-

ing capability. This solution is simple and feasible,

and it can drive multiple stepper simultaneously.

2 MULTI-CHANNEL STEPPER

MOTOR CONTROL SYSTEM

2.1 Trapezoidal Velocity Theory for

Stepper Motor

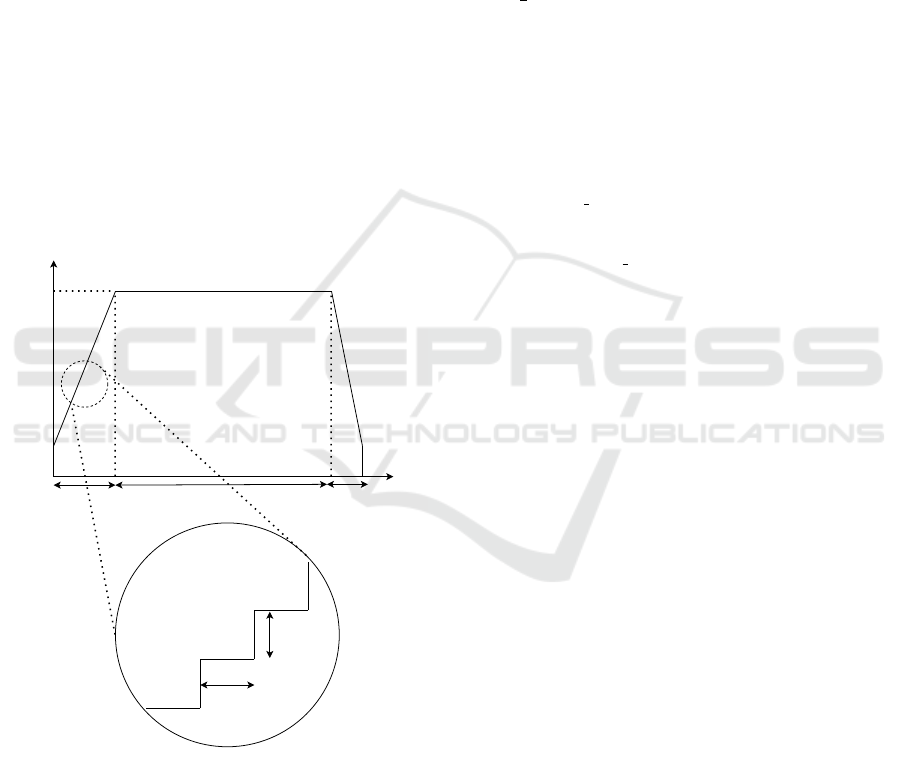

The torque frequency curve of the stepper motor is the

correlation curve between the output torque and input

pulse frequency of the stepper motor (bang Che et al.,

2023). As shown in the Figure 2, with the increase in

speed, the torque of the stepper decreases rapidly. The

parameter f s represents the stepper’s max starting fre-

quency, and starting the stepper at a speed greater than

this value will result in stalling and loss of synchro-

nization. Accordingly, the speed should be reduced

from the target speed to a suitable lower rate to avoid

extra and unnecessary stepping caused by shaft iner-

tia.

f(Hz)

M(N×m)

O

M

0

f

max

f

s

Figure 2: Torque frequency curve of the stepper.

To ensure that the stepper motor reaches the tar-

get speed without losing steps, various acceleration

curves have been proposed in past research, such as

trapezoidal curves, exponential curves, and S-curves.

Among them, the trapezoidal curve is widely used

in the industrial field due to its ease of implementa-

tion. To accelerate a stepper from a starting speed to

BIODEVICES 2025 - 18th International Conference on Biomedical Electronics and Devices

150

a desired target speed, the current speed just needs to

be changed at periodic intervals, which requires two

timers. The first timer is used to generate pulses with

the same frequency of stepping rate(steps per second

or SPS), which represents the ideal stepper speed.

The second one is an acceleration timer used to up-

date the first timer on a periodically. As shown in

the Figure 3, it is a graph of the trapezoidal acceler-

ation/deceleration profile and an enlarged view of the

profile’s discretization. The acceleration dv/dt can be

divided into two components: the SPS change inter-

val (when to change the speed) and the SPS variation

(how much to change the speed). Therefore, the same

acceleration can be represented by different combina-

tions of SPS change intervals and SPS variation. To

achieve the same acceleration, if the SPS variation is

set smaller, the corresponding SPS should be updated

more frequently. Conversely, when the SPS variation

is set larger, the update interval increases, but certain

SPS values may not be reached which sacrifices SPS

resolution (Quinones, 2012).

Time

f

s

f

0

PSP

Acceleration Uniform Deceleration

f

target

Change

Interval

Speed

Variation

Acceleration

t1 t2 t1

Figure 3: Trapzoidal velocity profile of the stepper.

When the stepper can rotate at the specified fre-

quency, the next challenge is how to generate a valid

trapezoidal acceleration/deceleration profile. Com-

pared to symmetric profile, an asymmetric profile al-

lows for different acceleration during the acceleration

and deceleration phases, providing more flexibility to

meet the needs of various application scenarios. For

example, in medical instruments, sampling systems

often integrate syringe pumps to achieve precise dis-

pensing of microfluid volumes. The syringe pump

moves the piston by rotating a lead screw driven by a

stepper, thereby controlling liquid aspiration and dis-

pensing. During the dispensing process, a strategy

of starting at low speed and stopping at high speed

is typically adopted (Ning et al., 2021). Take Fig-

ure 3 as an example, an asymmetric trapezoidal accel-

eration/deceleration profile can described by the fol-

lowing equations, in which v

uni

= v

0

+ A

acc

t

1

, x

acc

=

v

0

t +

1

2

A

acc

t

2

1

, x

uni

= v

uni

t

2

:

a(t) =

A

acc

0 ≤ t < t

1

0 t

1

≤ t < t

1

+t

2

−A

de

t

1

+t

2

≤ t < t

1

+t

2

+t

3

(1)

v(t) =

v

0

+ A

acc

t 0 ≤ t < t

1

v

uni

t

1

≤ t < t

1

+t

2

v

uni

− A

de

(t − t

1

− t

2

) t

1

+t

2

≤ t < t

1

+t

2

+t

3

(2)

x(t) =

v

0

t +

1

2

A

acc

t

2

0 ≤ t < t

1

x

acc

+ v

uni

(t − t

1

) t

1

≤ t < t

1

+t

2

x

acc

+ x

uni

+ v

uni

(t − t

1

− t

2

)−

1

2

A

de

(t − t

1

− t

2

)

2

t

1

+t

2

≤ t < t

1

+t

2

+t

3

(3)

Based on the equations and the figure, it can be

seen that the following variables determine the shape

of the trapezoidal velocity profile:

1. Start speed

2. Acceleration

3. Acceleration phase steps

4. Uniform speed steps

5. Deceleration

6. Deceleration phase steps

Using stepper motors is often aimed at leveraging

their ability to convert pulse signals into correspond-

ing displacement increments. Thus the total number

of movement steps is the most critical parameter, and

the acceleration and deceleration steps can be deter-

mined by the ratio of the total steps, while the constant

speed and stop speed are jointly determined by the

initial speed, acceleration/deceleration, and the num-

ber of steps in the acceleration/deceleration phases.

Additionally, the velocity profile is limited by the fol-

lowing factors due to the mechanical characteristics

of each motor:

1. Maximum start speed

2. Maximum uniform speed

3. Maximum acceleration/deceleration

When the pulse frequency received by the motor ex-

ceeds these limits, it can result in motor stalling,

missed steps, or in severe cases, burnout, so these fac-

tors must be carefully controlled.

An Easy-to-Implement Multi-Channel Stepper Motor Control System Based on MCU and FPGA

151

2.2 The Construction of the

Multi-Channel Stepper Motor

Control System

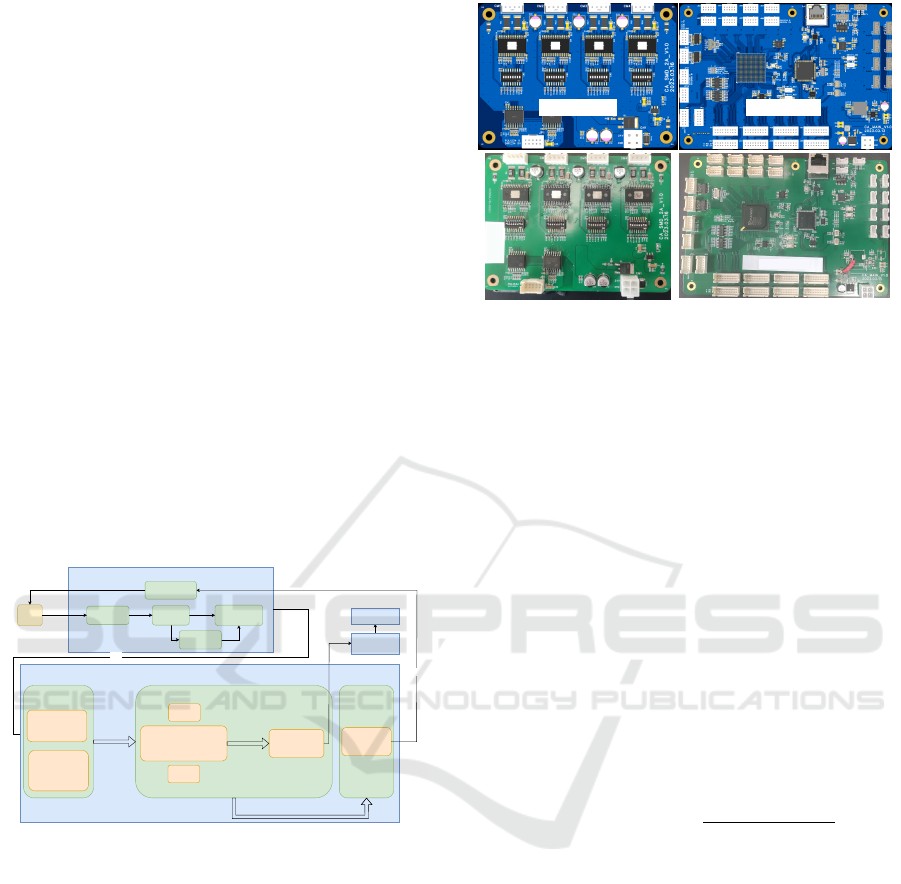

From the above analysis, it can be observed that once

a valid trapezoidal velocity profile is determined, gen-

erating the pulse sequence corresponding to the pro-

file online only requires updating the motor speed

using timers and adders according to the parameter.

The validation of the velocity profile, however, must

be computed before generating the profile via equa-

tions. Due to the programmable hardware character-

istics of FPGA, it is convenient to write a large num-

ber of timers and adders as needed. Therefore, the

generation of the velocity profile and pulse sequence

should be handled by the FPGA. The MCU, on the

other hand, is easier to program and modify, interacts

conveniently with users via peripherals, and its inte-

grated FPU makes it ideal for calculations. Hence,

user interaction and velocity profile validation should

be managed by the MCU. Based on the above analy-

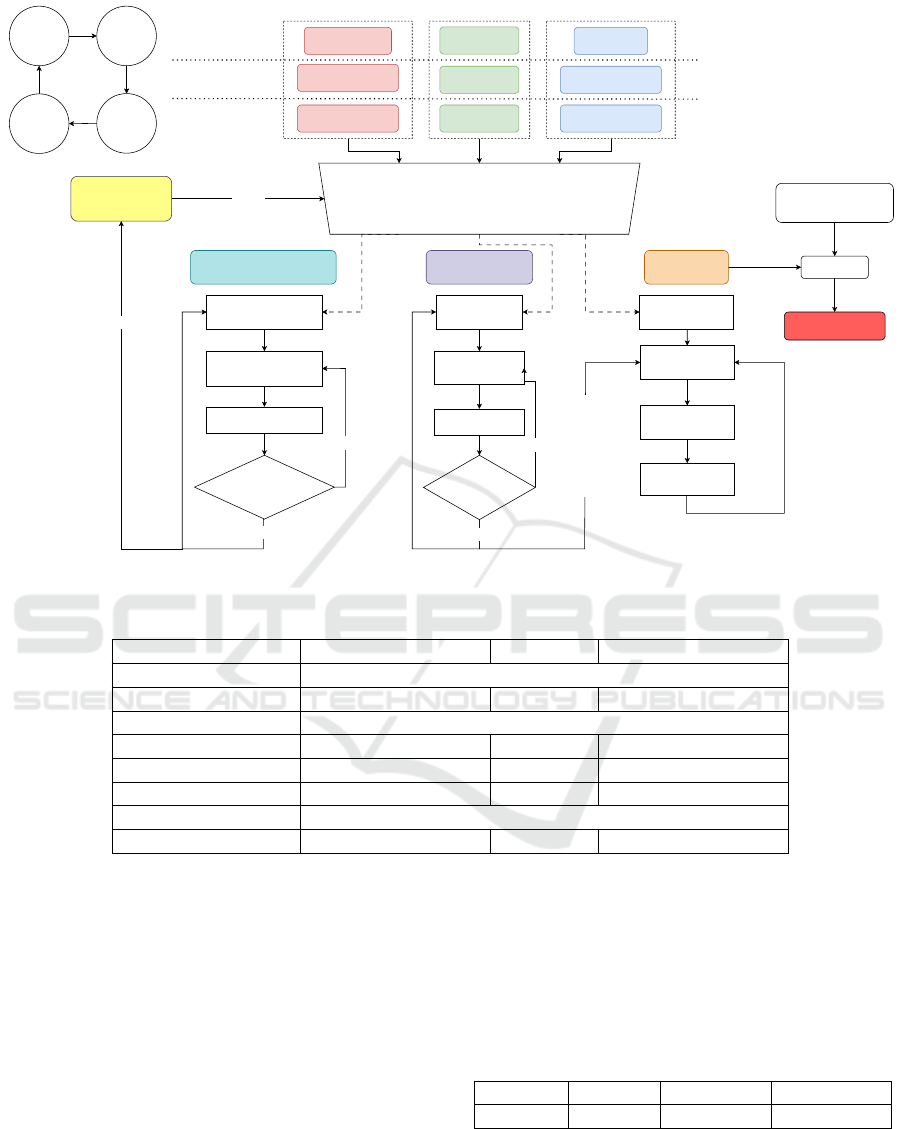

sis, the system is designed as shown in the Figure 4

and the hardware platform is shown in the Figure 5.

User

UART

MCU

Parameter

check

Parameter

calculation

Parameter

correction

SPI

Command

encapsulation

FPGA

Command

Decapsulation

Decapsulation of

normal function

comands

Decapsulation of

trapezoidal

velocity profile

parameters

Stepper Motion Control Stepper State

Report

Reset

module

Trapezoidal velocity profile

generation module

PWM generation

module

Command

and

Parameters

Pulse period

count value

Stepper Motor

Driver

Stepper Motor

Position, Reset state, Moving state...

State

encapsulation

SPI

State

decapsulation

UART

Stop

module

Figure 4: The scheme for the multi-channel stepper motor

control system based on FPGA and MCU.

The MCU interact with the user through the se-

rial port and receive commands such as stop, reset,

and run using trapezoidal velocity profile, it also re-

turns the stepper motor’s motion status to the user.

If the user inputs illegal velocity profile parameters,

the MCU ensures that the total number of steps re-

mains unchanged and then corrects the rest parame-

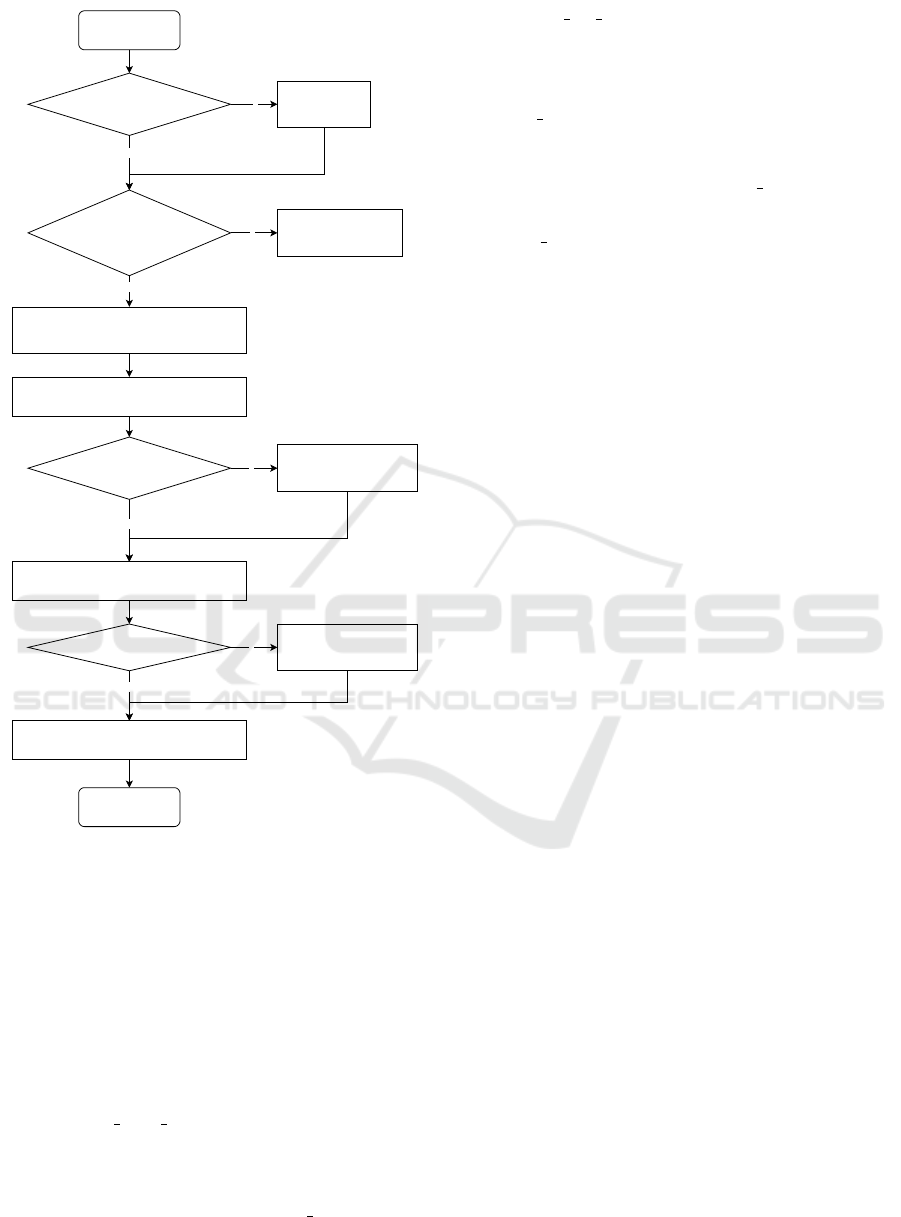

ters to valid values. The program flow is illustrated

in the Figure 6. Communication between the MCU

and FPGA is conducted using two sets of high-speed

serial communication (SPI), which doesn’t consume

too many I/O resources. One set is used for the MCU

to issue commands and velocity profile parameters,

while the other set is used for querying the motor’s

motion status and position. The FPGA receives and

parses the commands and velocity profile parameters,

Power Driver MCU+FPGA

Figure 5: The hardware platform for the multi-channel step-

per motor control system based on FPGA and MCU.

activates the specified logic function modules, and

the resulting pulse sequence drives the stepper motor

through the motor driver board.

2.3 Implementation of the Trapezoidal

Velocity Profile on FPGA

The pulse is typically generated by a timer that counts

the clock signal, maintaining the I/O output at a high

level for a certain duration and then at a low level for

the remaining time. The pulse period is determined

by the counter value. Thus for a pulse with a fre-

quency value of SPS, the corresponding clock count

value is determined by the following Equation 4. Due

to the fixed clock frequency, it is not possible to gen-

erate pulses of any arbitrary frequency, so the actual

generated pulse might differ slightly from the desired

one.

clock count value =

clock f requency

SPS

(4)

The pulse generation is handled by an independent

logic module. This module receives a system clock

count value and generates a pulse with the corre-

sponding period. After generating the pulse, it sends

a completion signal, indicating that the stepper has

completed one step. To enable real-time generation of

the trapezoidal velocity profile, a state machine-based

module is designed. This module receives the veloc-

ity profile parameters and pulse completion signals,

and it outputs the current pulse period count value to

the pulse generation module.The entire process con-

sists of four states:

1. IDLE: Listens for the start signal and stores the

velocity profile parameters.

2. ACCEL: Updates the stepper motor’s speed based

on the set acceleration.

BIODEVICES 2025 - 18th International Conference on Biomedical Electronics and Devices

152

Input trapezoidal

velocity profile

parameter

N

start speed > maximum start speed ?

N

acceleration/deceleration

>

maximum acceleration/deceleration

?

Y

correct start speed to

maximum start speed

correct

acceleration/deceleration to

maximum

acceleration/deceleration

Y

calculate the acceleration/deceleration time intervals

based on the acceleration/deceleration and the preset

speed variation

calculate the uniform speed based on start speed,

acceleration phase steps and acceleration

Y

N

uniform speed > maximum uniform speed ?

reduce acceleration phase steps

to ensure that uniform speed is

maximum uniform speed

calculate the end speed based on uniform speed,

deceleration phase steps and deceleration

N

Yend speed < 0 ?

calculate the new uniform phase steps

reduce deceleration phase steps

to ensure that end speed is

positive

output corrected

trapezoidal velocity

profile parameter

Figure 6: The program flow of trapezoidal velocity profile

correction.

3. UNIFORM: Maintains the stepper motor’s speed

during the constant-speed phase.

4. DECEL: Updates the stepper motor’s speed based

on the set deceleration. After generating all the

necessary steps, the system returns to the IDLE

state.

The module mainly consists of four registers and

a multiplexer:

1. remaining steps reg: It stores the remaining steps

in the acceleration, constant speed, and decelera-

tion phases. After each completed step, it decre-

ments by one. When the count reaches zero, it

triggers a signal that changes state reg to the next

state and reloads the step count for the next phase.

2. interval cnt reg: It stores the clock count for up-

dating the SPS interval. When the count decre-

ments to zero, it triggers the SPS update signal

and reloads the count value.

3. SPS reg: It stores the discrete value of the current

velocity profile at the current moment. Initially,

it is assigned the start speed, and when it receives

the SPS update signal, the SPS reg is updated to

achieve acceleration/deceleration.

4. state reg: It stores the current state of the state

machine and, in different states, selects the corre-

sponding movement parameters for calculation.

The detailed implementation is shown in the Fig-

ure 7.

3 RESULTS AND DISCUSSION

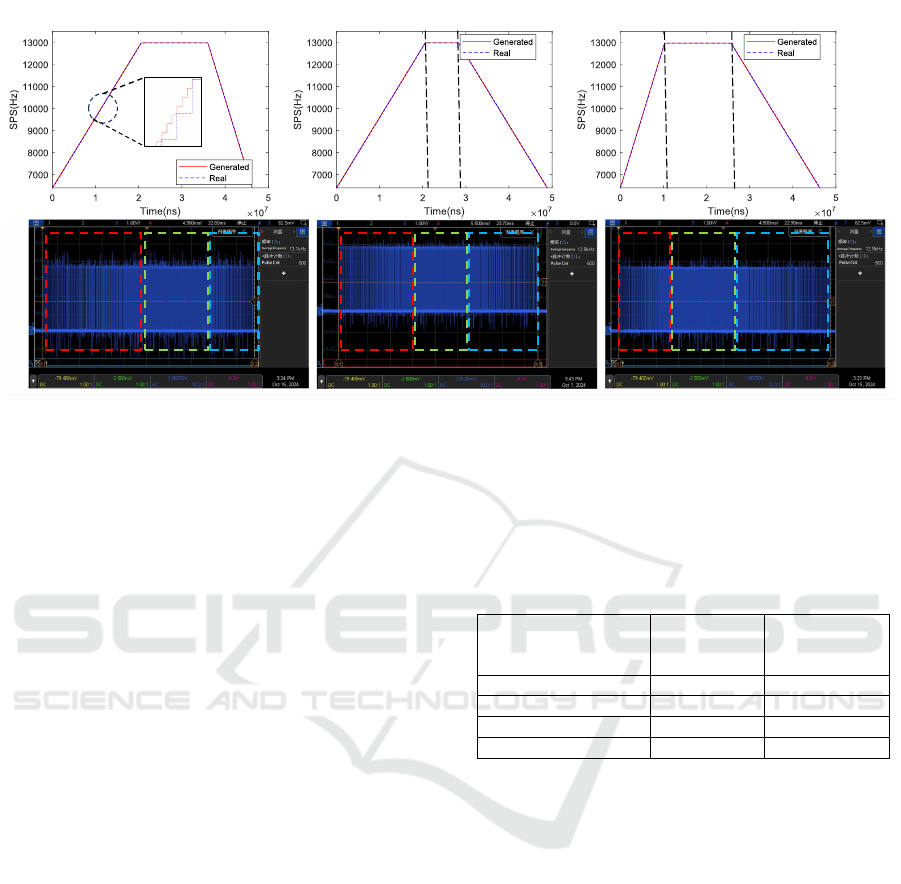

3.1 Simulation and Actual Waveform

To verify whether the generated velocity profiles meet

expectations, three scenarios were set up: double

acceleration, double deceleration, and equal accel-

eration/deceleration, with different motion parame-

ters detailed in the Table 1. An embedded online

logic analyzer in the FPGA captured the ideal ve-

locity profiles generated by the trapezoidal velocity

profile generation module, along with the PWM fre-

quency from the PWM generation module. Oscil-

loscope measurements of the pulse waveform were

taken, as shown in the Figure 8. Images from left to

right are three scenarios: double deceleration, equal

acceleration/deceleration, and double acceleration.

Overall, the generated PWM frequency closely

followed the velocity profiles. However, it is impor-

tant to note that upon zooming in on the waveforms,

discrepancies can be observed between the actual pro-

duced frequencies and the generated velocity profiles.

The primary reason is that the SPS will be updated

several times during a long pulse period. As a result,

the next pulse can only be generated at the newest

target frequency after the current pulse period fin-

ishes. Additionally, the actual pulse frequency pro-

duced may differ slightly from expectations due to

the resolution limits imposed by the system clock fre-

quency. The oscilloscope pulse waveform images il-

lustrate how the pulse density varies over time, fol-

lowing the trend of the generated trapezoidal veloc-

ity profile. Using the oscilloscope’s measurement

function, it was observed that a total of 500 pulses

were generated during the motion process, with the

pulse frequency in the steady-state being approxi-

mately 13kHz, which aligns with the expected result.

An Easy-to-Implement Multi-Channel Stepper Motor Control System Based on MCU and FPGA

153

Divider

Pulse cycle cnt

remainning_steps_reg

reload

remaining_steps

state_reg

SPS_incre_steps

accel_interval_cnt

accel_steps

none

none

uniform_steps

decel_steps

decel_interval_cnt

SPS_decre_steps

remaining_steps --

N

Y

Change

remaining_steps == 0?

wait for one pulse

completion signal

interval_cnt_reg

reload

interval_cnt

wait for system

clock

interval_cnt --

N

interval_cnt == 0?

SPS_reg

remainning_steps

interval_cnt

SPS_variation

load SPS_start

wait for update

signal

create update signal

Y

add SPS_variation

update SPS_reg

FPGA System Clock

Frequency

IDLE ACCEL

UNIFORMDECEL

remainning_steps

Select

Multiplexer

ACCEL DECELUNIFORM

interval_cnt SPS_variation

Figure 7: The implementation of trapezoidal velocity profile generation module.

Table 1: The motion parameters in three scenarios.

Parameter Double Deceleration Symmetry Double Acceleration

Start Frequency 6400Hz

Accel Interval 25us 25us 12.5us

SPS Incre Variation 8

Accel Steps 200 200 100

Uniform Steps 200 100 200

Decel Interval 12.5us 25us 25us

SPS Decre Variation 8

Decel Steps 100 200 200

3.2 Position Accuracy of Stepper

Movement

To verify the feasibility of the system and the effec-

tiveness of the trapezoidal velocity profile algorithm,

a 42-stepper motor was selected, controlled via the

LV8728 driver, which supports up to 128 micro-steps.

The motor’s rotational angle was measured using the

MT6701 magnetic encoder chip to assess angular er-

ror. After setting the micro-step count to 32, the mo-

tor was controlled to rotate 1, 10, and 100 rounds,

with each experiment repeated 10 times. The aver-

age error values are shown in the Table 2. From the

data, it can be observed that there is still some devi-

ation between the actual and ideal rotation angles. A

potential cause for this discrepancy is the discontin-

uous change in acceleration. As the number of revo-

lutions increases, the cumulative error grows as well,

but it remains within 1.8

◦

, the step angle of the motor.

Therefore, this level of control accuracy is sufficient

for most applications where high precision is not re-

quired.

Table 2: Angle displacement errors with different Rounds.

Rotation 1 Round 10 Rounds 100 Rounds

Error(

◦

) 0.088 0.175 1.165

3.3 FPGA Resource Utilization

As mentioned above, the trapezoidal accelera-

tion/deceleration implementation in FPGA primarily

BIODEVICES 2025 - 18th International Conference on Biomedical Electronics and Devices

154

ACCEL UNIFORM DECEL ACCEL UNIFORM DECEL ACCEL UNIFORM DECEL

ACCEL UNIFORM DECEL UNIFORM DECELACCEL

Figure 8: The generated real-time velocity profile, the actual produced velocity profile, and the produced pulse waveform

graphs in three scenarios.

involves registers for recording motion parameters,

counters for timing, and a divider. However, many

synthesis tools cannot generate an efficient division

operation, consuming too many resources. To ad-

dress this, a custom pipeline divider was implemented

based on the shift-and-subtract algorithm. The divi-

dend is a fixed-width constant value (system clock of

50MHz, corresponding to a 26-bit width), while the

divisor is the dynamically changing target PWM fre-

quency. The total computation time consists of the

switching time between the states and the width of

the dividend. Thus the total computation time is 27

system clock, which is 540ns at the 50MHz system

clock. It’s important to ensure that the speed update

interval does not fall below 27 clock cycles, other-

wise, the divider will not be able to keep up with the

velocity profile.

This paper compares the proposed solution with

other studies in terms of its ability to generate asym-

metric velocity profiles and the types of computations

implemented on FPGA implementations, as shown

in the Table 3. The FPGA resource consumption

after deploying this solution on the Pango Logos

PGL50G platform is also summarized in the Table

4. Since this approach avoids complex computations,

both the trapezoidal velocity profiles generation mod-

ule and the PWM generation module use relatively

few resources, making it well-suited for implement-

ing multi-channel stepper motor control systems. As

shown in the table, the trapezoidal acceleration and

deceleration control for a single motor occupies less

than 1.5% of the total FPGA resources. If the en-

tire FPGA is utilized for instantiating this functional

module, it can theoretically control at least 65 stepper

motors simultaneously. This design has already been

implemented in a compact fully automated chemilu-

minescence immunoassay analyzer, where it currently

controls 20 stepper motors concurrently.

Table 3: Resources usage of different entity.

Work

Asymmetric

Profile

Generation

Types of

Computations

(Chen and Su, 2008) Unable 3

(Chen et al., 2024) Unable 4

(Cho et al., 2009) Able 4

Proposed Able 2

4 CONCLUSIONS

This paper presents a low-cost, high real-time perfor-

mance, and easily implementable system for control-

ling multiple stepper motors. It utilizes a MCU for

user interaction, which validate and correct input pa-

rameters to a valid range before sending them to the

FPGA. The FPGA then generates a trapezoidal veloc-

ity profile in real-time based on the parameters, con-

trolling the motors to move as expected. Unlike pre-

vious implementations on FPGA, this solution does

not involve complex mathematical calculations or

floating-point operations, resulting in lower resource

consumption and easier implementation. To address

various complex application scenarios in medical de-

vices, this paper achieves an asymmetric trapezoidal

velocity profile, allowing for more flexible motor con-

trol by modifying parameters to meet different appli-

cation needs. Finally, tests on the motor’s angular er-

An Easy-to-Implement Multi-Channel Stepper Motor Control System Based on MCU and FPGA

155

Table 4: Resources usage of different entity.

Module LUT Used LUT Util% FF Used FF Util%

Trapezoidal

velocity profile

generation

272 0.635 160 0.249

Divider 124 0.289 133 0.207

PWM

generation

132 0.308 60 0.093

Total 528 1.234 353 0.550

ror demonstrated that the error was kept within one

step angle, indicating that the velocity profile imple-

mented on the FPGA can be used in scenarios where

precision requirements are not high. Additionally,

resource consumption statistics show a total of 528

LUTs and 353 Flip-Flops were used, making it possi-

ble to control a larger number of stepper motors with

limited resources.

ACKNOWLEDGEMENTS

This research was supported by the Key Research

and Development Plan of Zhejiang Province (Grant

Nos. 2023C03094) and Zhejiang Provincial Natu-

ral Science Foundation of China under Grant No.

LY22H180006.

REFERENCES

bang Che, X., Zeng, H., Zhou, K., Xiao, H., wen Wang, X.,

Wu, X., and bo Li, C. (2023). Modeling and simula-

tion of the stepping motor operation curve. Journal of

Physics: Conference Series, 2658(1):012062.

Boulaala, M., Elmessaoudi, D., Buj-Corral, I., El Mes-

bahi, J., Ezbakhe, O., Astito, A., El Mrabet, M.,

and El Mesbahi, A. (2020). Towards design of

mechanical part and electronic control of multi-

material/multicolor fused deposition modeling 3d

printing. The International Journal of Advanced Man-

ufacturing Technology, 110:45–55.

Chen, T.-C. and Su, Y.-C. (2008). High performance algo-

rithm realization on fpga for stepper motor controller.

In 2008 SICE Annual Conference, pages 1390–1395.

Chen, Z., Gao, X., Wang, A., Liang, Z., and Zhang, X.

(2024). An online open-loop s-curve velocity profile

control method for stepping motors on fpga. IEEE

Transactions on Industrial Electronics, pages 1–11.

Cho, J. U., Le, Q. N., and Jeon, J. W. (2009). An fpga-based

multiple-axis motion control chip. IEEE Transactions

on Industrial Electronics, 56(3):856–870.

Fang, Y., Hou, B., Wu, X., Wang, Y., Osawa, K., and

Tanaka, E. (2023). A stepper motor-powered lower

limb exoskeleton with multiple assistance functions

for daily use by the elderly. Journal of Robotics and

Mechatronics, 35(3):601–611.

Fonseca-Campos, J., Reyes-Ram

´

ırez, I., Mata-Machuca,

J. L., Fonseca-Ruiz, L., Cortez-Herrera, P. N., Flores-

Cotera, L. B., and Aguilar-L

´

opez, R. (2023). Im-

plementation in microcontrollers of an algorithm for

the simple generation of speed profiles in a stepper

motor and their associated kinematics. IEEE Access,

11:143782–143803.

Groenhuis, V., Siepel, F. J., and Stramigioli, S. (2022).

Magnetic resonance pneumatic stepper motor with

multiple concentric shafts output. IEEE/ASME Trans-

actions on Mechatronics, 27(4):2379–2389.

Holland, I. and Davies, J. A. (2020). Automation in the life

science research laboratory. Frontiers in bioengineer-

ing and biotechnology, 8:571777.

Kumar, M., Kumar, R., Kumar, V., Chander, A., Gupta,

V., and Sahani, A. K. (2021). A low-cost ambu-bag

based ventilator for covid-19 pandemic. In 2021 IEEE

Biomedical Circuits and Systems Conference (Bio-

CAS), pages 1–5.

Ning, S., Long, Y., Zhao, Y., Liu, J., Bo, X., Lu, S., and

Gao, J. (2021). Research on micro-liquid dispensing

driven by a syringe pump with the consideration of air

volume. Microsystem Technologies, pages 1–14.

Quinones, J. I. (2012). Applying acceleration and decelera-

tion profiles to bipolar stepper motors. Analog Appli-

cations.

Silaban, F., Budiyanto, S., and Raharja, W. (2020). Step-

per motor movement design based on fpga. Interna-

tional Journal of Electrical and Computer Engineer-

ing (IJECE), 10:151.

Zhang, L., Liu, L., Shen, J., Lai, J., Wu, K., Zhang, Z.,

and Liu, J. (2017). Research on stepper motor motion

control based on mcu. In 2017 Chinese Automation

Congress (CAC), pages 3122–3125.

Zhang, Z. and Yu, Y. (2022). S-type speed control curve

based on the number of pulses. Journal of Physics:

Conference Series, 2196:012038.

Zunin, V. V. and Romanova, I. I. (2021). Development

and implementation of synchronous control of stepper

motors with acceleration. In 2021 International Con-

ference on Industrial Engineering, Applications and

Manufacturing (ICIEAM), pages 509–514.

BIODEVICES 2025 - 18th International Conference on Biomedical Electronics and Devices

156