MIRSim-RL: A Simulated Mobile Industry Robot Platform and

Benchmarks for Reinforcement Learning

Qingkai Li

1,∗

, Zijian Ma

2,∗

, Chenxing Li

3,6,∗

, Yinlong Liu

4

, Tobias Recker

5

, Daniel Brauchle

6

,

Jan Seyler

6

, Mingguo Zhao

1

and Shahram Eivazi

3,6

1

Department of Automation, Tsinghua University, Beijing, China

2

Department of Mechanical Engineering, Technical University of Munich, Munich, Germany

3

Department of Computer Science, University of T

¨

ubingen, T

¨

ubingen, Germany

4

Department of Computer Science, University of Macau, Macau, China

5

Institute of Assembly Technology and Robotics, Leibniz University Hanover, Germany

6

Advanced Develop. Analytics and Control, Festo SE & Co. KG, Esslingen, Germany

Keywords:

Simulated Mobile Robot Platform, Reinforcement Learning, Whole-Body Control.

Abstract:

The field of mobile robotics has undergone a transformation in recent years due to advances in manipulation

arms. One notable development is the integration of a 7-degree robotic arm into mobile platforms, which has

greatly enhanced their ability to autonomously navigate while simultaneously executing complex manipulation

tasks. As such, the key success of these systems heavily relies on continuous path planning and precise con-

trol of arm movements. In this paper, we evaluate a whole-body control framework that tackles the dynamic

instabilities associated with the floating base of mobile platforms in a simulation closely modeling real-world

configurations and parameters. Moreover, we employ reinforcement learning to enhance the controller’s per-

formance. We provide results from a detailed ablation study that shows the overall performance of various

RL algorithms when optimized for task-specific behaviors over time. Our experimental results demonstrate

the feasibility of achieving real-time control of the mobile robotic platform through this hybrid control frame-

work.

1 INTRODUCTION

In recent decades, we have seen the widespread adop-

tion of integrating a robotic arm into mobile plat-

forms (Ramalepa and Jr., 2021; Guo et al., 2016).

For instance, Uehara et al. (Uehara et al., 2010) pro-

posed a mobile robot with an arm to assist individu-

als with severe disabilities. Similarly, Grabowski et

al. (Grabowski et al., 2021) demonstrated the practi-

cal application of such platforms in industrial settings,

where they assist workers in performing various tasks.

In mobile platforms equipped with a robotic arm,

a critical challenge lies in solving the problem of kine-

matic trajectory planning for both the arm and the

mobile base. A common approach has been to con-

trol the arm and the mobile platform independently

(Tin

´

os et al., 2006). However, this independent con-

trol paradigm is insufficient for platforms with inte-

grated arms, where the interaction between the two

∗

The authors with * contribute equally

systems introduces significant complexity when the

platform system is not heavy enough, for instance,

when the robot arm moves significantly, the center of

gravity of the entire robot platform shifts. This dis-

tinction forms the basis of the work presented in this

paper. Unlike traditional fixed-base robotic arms, mo-

bile platforms experience dynamic changes in their

floating base, which can adversely affect the stabil-

ity of the overall system. Therefore, a comprehensive

controller that simultaneously manages both the arm

and the mobile platform is essential to address these

stability issues effectively.

A prominent approach to addressing this chal-

lenge is the Whole-Body Control (WBC) technique

(Dietrich et al., 2012), which unifies the control of

both the robotic arm and the mobile platform into

a single solution. WBC enables direct control of

all joints through joint state commands, allowing for

coordinated motion across the entire robotic system.

Additionally, alternative methods such as neural net-

56

Li, Q., Ma, Z., Li, C., Liu, Y., Recker, T., Brauchle, D., Seyler, J., Zhao, M. and Eivazi, S.

MIRSim-RL: A Simulated Mobile Industry Robot Platform and Benchmarks for Reinforcement Learning.

DOI: 10.5220/0013159400003890

In Proceedings of the 17th International Conference on Agents and Artificial Intelligence (ICAART 2025) - Volume 1, pages 56-67

ISBN: 978-989-758-737-5; ISSN: 2184-433X

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

works (Guo et al., 2021) and reinforcement learning

(RL) (Xin et al., 2017) have emerged as powerful

tools to simplify the complexity of control strategies.

These machine-learning techniques excel at learning

and generalizing behaviors in an end-to-end manner,

further enhancing the capabilities of robotic control

systems.

Figure 1: Mobile Industrial Robot and its simulation on Py-

Bullet Engine. The left shows the real mobile robot plat-

form while the right is the simulation platform we built

upon Pybullet. (This platform is developed by Institute

of Assembly Technology and Robotics, Leibniz University

Hanover, Germany).

In this study, we present a novel framework that

integrates a mobile robot with an arm (Mobile In-

dustrial Robot

1

) into the PyBullet simulation environ-

ment (Coumans and Bai, 2021). We develop a whole-

body controller to manage path planning and platform

movement, which is designed based on real-world

parameters to facilitate efficient sim-to-real transfer.

Additionally, we utilize a series of RL algorithms (on-

line, offline, single-agent, and multi-agents) to en-

hance the controller’s performance by learning task-

specific behaviors, leading to a more balanced control

mechanism. The primary contributions of our work

are as follows:

• We develop a simulated mobile robot equipped

with a robotic arm, employing a WBC mecha-

nism within the Pybullet environment, integrated

through the Gym API (Brockman et al., 2016).

This framework enables the testing and validation

of algorithms in a safe and controlled environ-

ment before hardware implementation. It facili-

tates rapid iteration, reduces the risk of hardware

damage, and provides a cost-effective approach

for exploring complex control strategies.

• We propose various RL-based methods aimed at

improving controller performance, enabling the

system to adapt to task-specific behaviors and op-

timize control strategies over time.

1

Mobile Industrial Robot project page

• A comprehensive ablation study of different RL

algorithms is conducted on the simulated mobile

robot manipulation task to assess the effectiveness

of our methods. This analysis explores the influ-

ence of different approaches and parameters on

task performance, providing valuable insights for

future research.

2 RELATED WORK

A Mobile Manipulator (MM) is a highly coupled sys-

tem consisting of a manipulator arm attached to a mo-

bile robot. This configuration contrasts with static

manipulators, where the task space is constrained to a

predefined configuration in a known space (Stilman,

2010). Controlling a dynamic platform such as an

MM presents challenges, including motion planning

and the management of redundancy across the entire

system.

One extensively studied approach for control-

ling MMs is model-based control. For example,

Model Predictive Control (MPC) has been applied

to MMs (Minniti et al., 2021) to facilitate motion

planning in unknown environments. To address the

problem of additional degrees of freedom and dy-

namic obstacles, Wei et al. (Li and Xiong, 2019) pro-

posed an optimization-based method for real-time ob-

stacle avoidance. Their approach involved calculating

the global robotic Jacobian matrix of the MM, fol-

lowed by using MPC to plan control actions that re-

sulted in calculated joint velocities for both the arm

and the mobile base. Another promising technique

is the combination of data-driven models with MPC

to enhance MM performance. For instance, Carron

et al. (Carron et al., 2019) used data gathered dur-

ing platform movements to refine the model of the

robotic arm and improve trajectory tracking perfor-

mance. Their approach involved integrating inverse

dynamics feedback linearization with a data-driven

error model into the MPC framework.

Of particular relevance to our work is the Whole-

Body Control (WBC) technique. For instance, Di-

etrich et al. (Dietrich et al., 2012) applied WBC us-

ing null space projection based on a dynamic model

for redundancy resolution. Their algorithm enabled

torque control of the robotic arm, which effectively

scaled the apparent motor inertia, while simultane-

ously applying velocity commands in Cartesian co-

ordinates. This method solved challenges like center-

of-mass control, obstacle avoidance, and posture sta-

bilization. Similarly, Tao et al. (Teng et al., 2021)

employed WBC to enable efficient and complex

grapevine pruning tasks using a non-holonomic MM.

MIRSim-RL: A Simulated Mobile Industry Robot Platform and Benchmarks for Reinforcement Learning

57

To enhance task prioritization within the WBC

framework, Kim et al. (Kim et al., 2019) in-

troduced the Hierarchical Quadratic Programming

(HQP) method. This approach facilitated the execu-

tion of complex tasks without causing discontinuities

in the control input of the MM. Their controller was

able to compute continuous control inputs while dy-

namically adjusting task priorities, utilizing a continu-

ous task transition strategy. To improve generalization

in uncertain environments and tackle complex tasks,

recent research has increasingly focused on machine

learning methods for MM operation (Lober et al.,

2016; Welschehold et al., 2017; Wang et al., 2020b;

Wang et al., 2020a; Jauhri et al., 2022). A prominent

line of investigation has centered on using reinforce-

ment learning (RL) to train MMs to perform complex

behaviors by leveraging exploration and reward struc-

tures, without requiring explicit environment models.

Research in this domain can be broadly divided into

two categories.

The first category involves end-to-end RL ap-

proaches for solving WBC (Kindle et al., 2020; Wang

et al., 2020b; Jauhri et al., 2022). One of the pri-

mary limitations of such methods is the requirement

for vast amounts of data to learn an effective control

policy. To address this limitation, the second category

of research focuses on hybrid RL approaches that

combine RL with traditional control methods (Jauhri

et al., 2022; Iriondo et al., 2019; Iriondo et al., 2019).

We explored this area of research as well. For ex-

ample, Chalvatzaki et al. (Jauhri et al., 2022) devel-

oped a hybrid RL algorithm that integrates both dis-

crete and continuous actions to facilitate the learning

of a robust control policy. Their approach leveraged

prior action probabilities from classical control meth-

ods derived from the operational robot workspace to

enhance learning efficiency.

In addition to single-agent reinforcement learn-

ing (RL) settings, multi-agent RL has gained signif-

icant attention in recent years (Zhang et al., 2021).

Researchers have focused on extending off-policy

single-agent RL techniques to multi-agent environ-

ments, such as the Multi-Agent Deep Deterministic

Policy Gradient (MADDPG) (Lowe et al., 2020). Un-

like in single-agent RL, each agent in a multi-agent

system has limited access to the observations of other

agents, which presents additional coordination and

communication challenges. Furthermore, the high

data requirements in RL often result in prolonged

training periods. To address this, Offline RL (also

known as Batch RL) has been proposed to leverage

static datasets (Fujimoto et al., 2019) aiming to imi-

tate the optimal behavior, thereby reducing the need

for frequent interactions with the environment during

training.

In this work, we aim to integrate RL techniques

with the previously mentioned WBC mechanism, ap-

plied to a simulated mobile robot. Additionally,

we present a comprehensive benchmark and ablation

study of various RL algorithms to further validate and

assess the effectiveness of our platform. Through this

evaluation, we explore the strengths and limitations

of different RL methods in mastering robotic behav-

ior, providing valuable insights into their applicability

for advanced robotic tasks.

3 PRELIMINARIES

Offline Reinforcement Learning vs Online Rein-

forcement Learning. Online Reinforcement Learn-

ing (RL) involves continuous interaction between the

agent and the environment, with the training dataset

being dynamically updated as new experiences are

gathered. In contrast, Offline RL relies on a static

dataset D, composed of transitions (O

t

, A

t

, R

t

, O

t+1

),

where O

t

represents the observations, A

t

the actions,

R

t

the rewards, and O

t+1

the subsequent observations.

Since there is no interaction with the environment

during the offline training process, a key challenge

emerges: the distributional shift between the static

dataset and the agent’s evolving policy. This shift

must be carefully managed to prevent degraded learn-

ing performance and ensure the effectiveness of the

offline RL approach.

Offline Multi-Agent Reinforcement Learning. In

multi-agent reinforcement learning (MARL), the ob-

jective is to learn an optimal joint policy that accounts

for the interactions between all agents, rather than fo-

cusing solely on individual policies. Each agent, how-

ever, has access to only partial observations (O

i

t

) of

the environment. Under the Centralized Training with

Decentralized Execution (CTDE) framework (Lowe

et al., 2020), training is conducted using full-state

information (S

t

), while execution is based on each

agent’s local observations. Offline MARL (OMARL)

extends the principles of MARL by leveraging static,

pre-collected datasets (π

β

generated) to learn optimal

policies. In this setting, no further online interactions

π

α

are required.

4 METHODOLOGY

4.1 The Simulated Mobile Robot

Platform

We develop a simulated mobile robot platform,

named MirandaSim, equipped with a robotic arm us-

ICAART 2025 - 17th International Conference on Agents and Artificial Intelligence

58

Planner

+

Whole-Body Controller

Actions

Observations

Reward

Motion Target &

Controller

Parameter

Joint & Base

States

Joint Torque &

Wheel Velocities

Robot & Mobile

States

1 HZ

240 HZ

MirandaSim

Agents

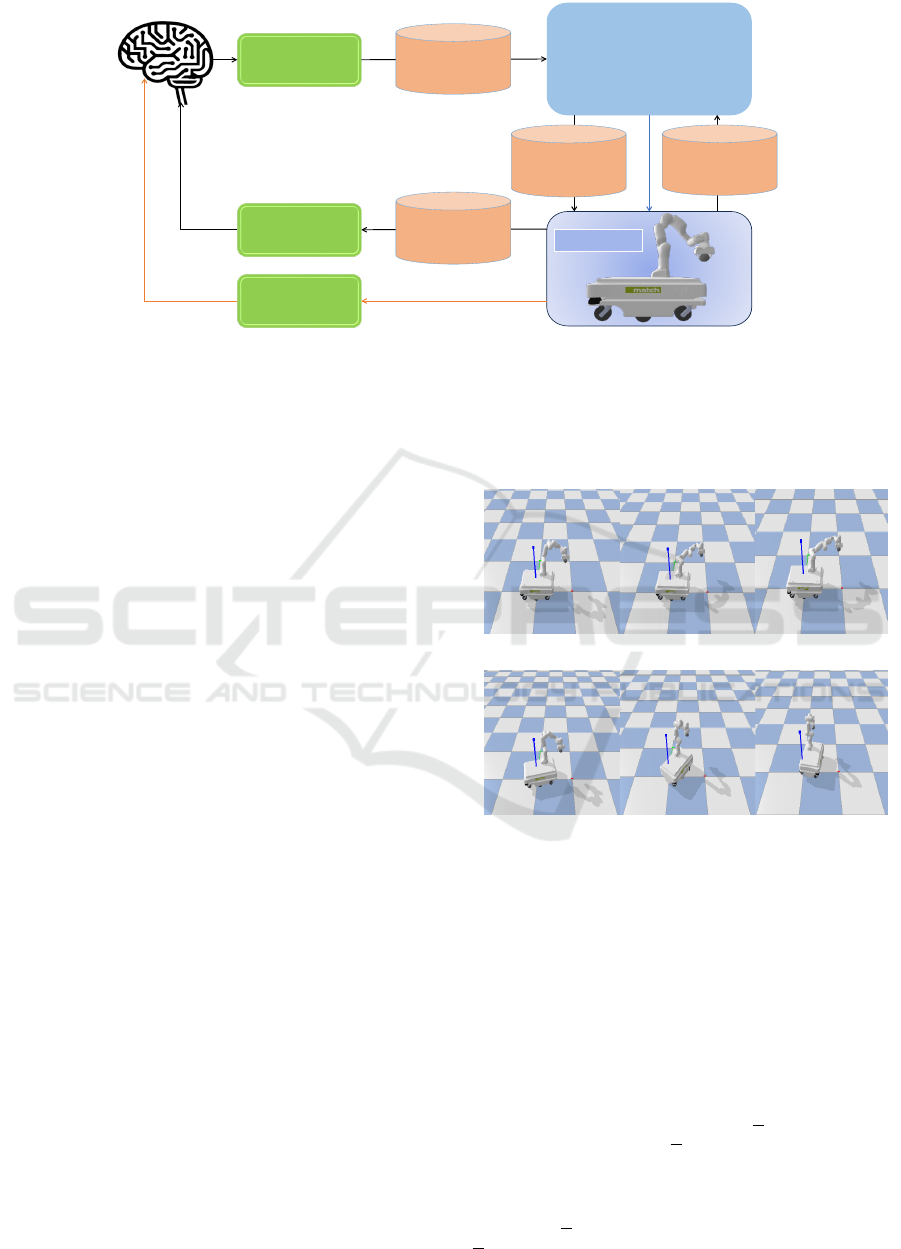

Figure 2: Mobile Industrial Robot mechanism. The platform called MirandaSim, is developed using the Gym API and

Pybullet Engine. The system operates at a frequency of 240 Hz for communication between the Whole-Body Control (WBC)

planner and the simulated platform. Additionally, a 1 Hz frequency is employed to transmit observations to the proposed

RL algorithms. In response, the RL module generates an action, which serves as the target for the WBC, and corresponding

joint torque values are transmitted back to the platform, alongside feedback on the system’s states. This structure enables the

development of an efficient control block.

ing Pybullet and OpenAI Gym, as shown in Figure 2,

which could be seen as an idealized model. This plat-

form operates under WBC, which generates reliable

movement trajectories by calculating joint torques

and wheel velocities based on the arm’s joint states

and the mobile platform’s base states. The communi-

cation between components occurs at a frequency of

240 Hz. Additionally, various RL techniques can be

applied within this framework.

MirandaSim provides comprehensive state infor-

mation, including the end-effector position of the

robotic arm and the base position of the mobile plat-

form. In this setup, RL determines the actions and

supplies target points for the WBC. The reward func-

tion currently used is a dense reward, calculated as the

negative distance between the achieved and desired

goals.

The robot arm and the mobile platform can oper-

ate independently, following a random action policy.

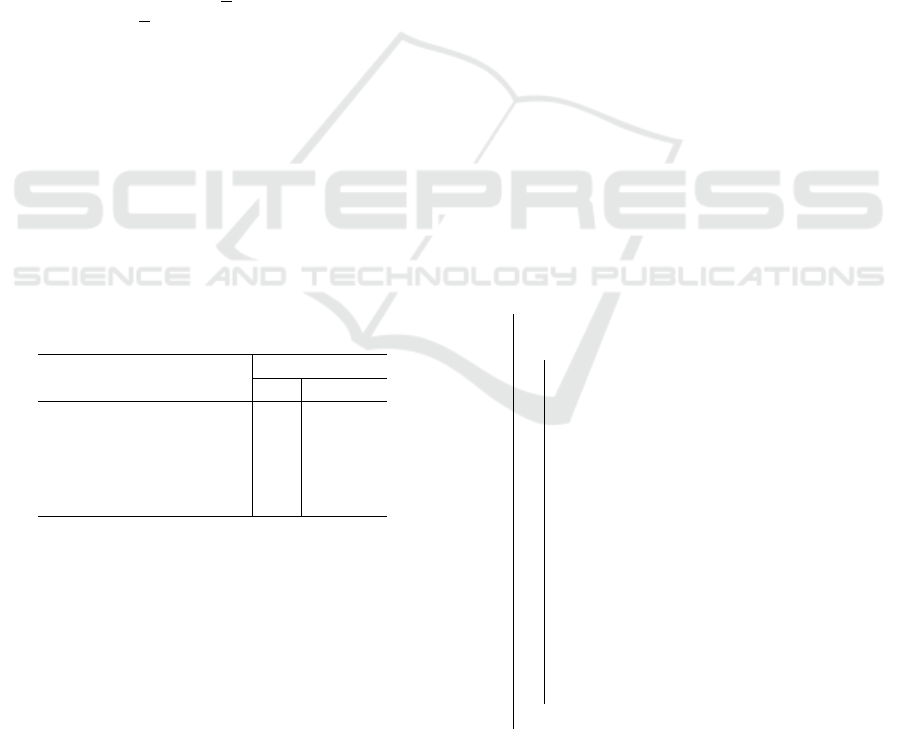

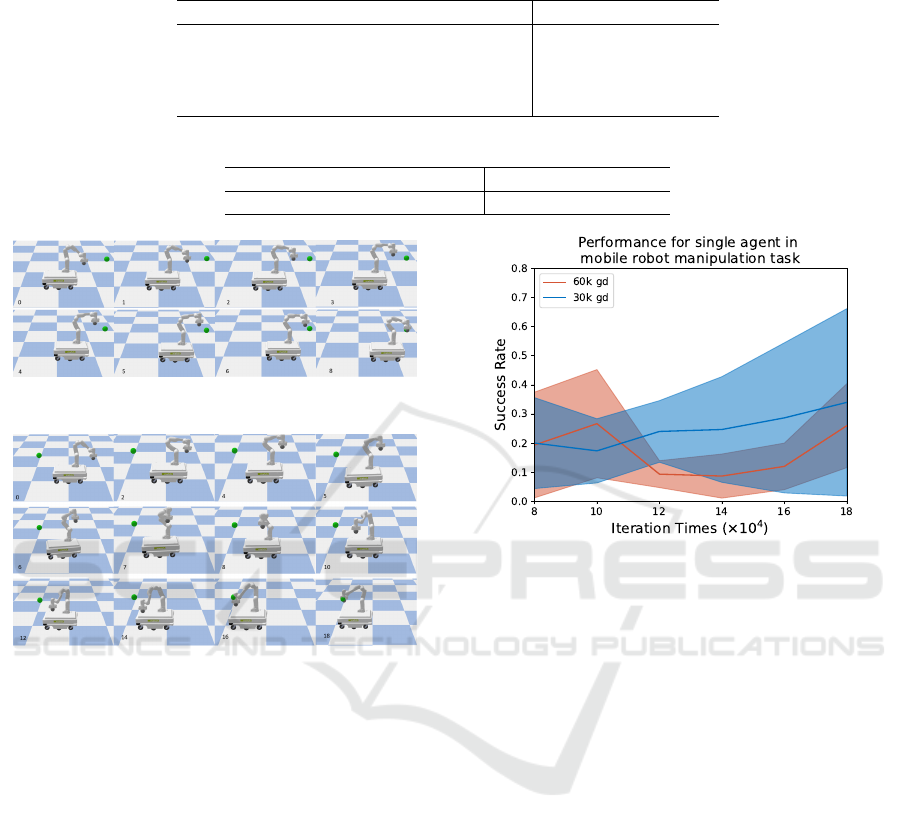

In Figure 3, we observe that the platform is capable

of both movement and rotation. However, the pre-

vious motion planner and control system lacks suffi-

cient coordination between the robot arm and the mo-

bile platform. Both components move towards their

individual goals separately, without synchronization.

This highlights the need for a WBC technique (Teng

et al., 2021), which could significantly enhance task

performance in future research.

4.2 Whole-Body Controller

As outlined in (Kim et al., 2019), the kinematic and

dynamic model of a nonholonomic mobile manipula-

(a) The robot arm can move to a position in random test.

(b) The mobile platform is able to rotate to a specific

angle in random test.

Figure 3: Random test of robot arm and mobile platform.

The top graph shows the robot arm reaching a specific point

without the platform moving, while the bottom graph il-

lustrates the platform rotating to a specific angle while the

robot arm remains stationary.

tor (MM) can be established, enabling the computa-

tion of control commands for task execution by solv-

ing a Quadratic Programming (QP) problem:

argmin

u

∥Au − b∥

2

s.t. d ≤ Cu ≤ d

(1)

where u is the control input vector, e.g. the joint

torques τ; A is the equivalent Jacobian matrix of the

task; b is the reference value for task control and

d ≤ Cu ≤ d are equality and inequality constraints,

MIRSim-RL: A Simulated Mobile Industry Robot Platform and Benchmarks for Reinforcement Learning

59

e.g. floating base dynamics, torque limits and moving

platform related constraints.

To efficiently solve for redundancy and han-

dle task conflicts, we use the Recursive Hierarchi-

cal Projection-Hierarchical Quadratic Programming

(RHP-HQP) algorithm (Han et al., 2021), offering

higher computational speed than the method de-

scribed in (Kim et al., 2019). In an HQP with n levels,

the task hierarchy at level k is solved in the projected

space of higher-priority tasks:

u

∗

k

= u

∗

k−1

+ P

k−1

x

∗

k

(2)

where u

∗

k

is the optimal control input at hierarchy k;

P

k−1

is the projection matrix constructed from a pa-

rameter matrix Ψ defining the task priorities and x

∗

k

is

the optimal result of the k-th QP

argmin

x

k

∥A

k

(P

k−1

x

k

+ u

∗

k−1

) − b

k

∥

2

s.t. d ≤ Cu ≤ d

(3)

We define two sets of task priorities for MM,

tailored to either optimize stability or reach perfor-

mance, as shown in Table 1. The final priority matrix

is determined using a parameter α ∈ [0, 1], allowing

for control of the trade-off between move stability of

the whole system and reaching performance:

Ψ(α) = αΨ

1

+ (1 −α)Ψ

2

(4)

By exploiting the parameter α, we can learn the trade-

off between move stability and reaching performance.

Table 1: Two sets of predefined task priorities, Ψ

1

for better

move stability and Ψ

2

for better manipulator’s reaching. A

lower number refers to a higher priority.

Task Description

Priority Level

Ψ

1

Ψ

2

Base velocity 1 3

Base orientation 1 3

Manipulator position 2 1

Manipulator orientation 3 2

Arm posture 4 4

4.3 DDPG Algorithm Based on

Whole-Body Controller

The Deep Deterministic Policy Gradient (DDPG) al-

gorithm, an Actor-Critic method, is widely recog-

nized for its stability and efficiency in robot control

tasks (Mnih et al., 2015). It utilizes an action-value

function (critic) to guide the learning process and de-

termines a deterministic policy π(s) = a where the ac-

tion a is generated by the actor-network. In our case,

the DDPG algorithm is adapted to work in conjunc-

tion with the WBC.

The WBC has different task requirements, such as

movement stability and manipulator accuracy. While

achieving optimal performance in both is theoretically

ideal, it is not feasible in real-time control scenarios.

The DDPG algorithm helps balance these competing

objectives in tasks like manipulator reaching.

The action space for the DDPG agent is repre-

sented by a 4 × 1 array, where the first three values

correspond to the end-effector’s position relative to

the world frame, and the fourth value helps the agent

learn balance through reward-based training.

To improve the efficiency of training, we in-

corporated Hindsight Experience Replay (HER)

(Andrychowicz et al., 2017; Li et al., 2022). HER

allows the agent to replay episodes with different

goals by constructing hindsight goals from intermedi-

ate states, enabling faster learning from the achieved

outcomes. Additionally, our platform supports of-

fline data loading, inspired by methods in (Kalash-

nikov et al., 2018; Li et al., 2023b; Li et al., 2023a),

where successful experiences are prioritized to accel-

erate learning. The complete DDPG-based algorithm

for WBC as our online RL algorithm is presented in

Algorithm 1.

Inputs: Initialize main (critic, actor) and

target (critic, actor) neural network weights

and replay buffer

Outputs: Trained agent

Initialize target network and main network

weights and replay buffer;

while i = 1, 2, ...T do

Initialize the state;

while i = 1, 2, ...T do

Load offline data (Optional);

Generate Action;

Obtain State

next

, Reward from the

planner based on WBC;

Store the obtained information in

replay buffer D;

Compute the target value from a

small batch in replay buffer (HER

techniques optional);

Update the main network critic by

minimizing the error between the

target value and critic Q;

Update the main network actor using

the sampled gradient;

Update the target network;

end

end

Algorithm 1: DDPG (Online RL algorithm) on Whole-

Body Controller.

ICAART 2025 - 17th International Conference on Agents and Artificial Intelligence

60

4.4 Offline RL Algorithm Based on

Whole-Body Controller

The Twin Delayed Deep Deterministic Policy Gradi-

ent with Behavior Cloning (TD3+BC) algorithm (Fu-

jimoto and Gu, 2021) serves as an effective rein-

forcement learning method applicable in batch rein-

forcement learning settings, demonstrating stable per-

formance. When compared to other state-of-the-art

offline reinforcement learning algorithms, TD3+BC

significantly reduces overall running time costs. The

algorithm consists of two main components. The first

component is the traditional TD3 algorithm, which

enhances the original DDPG approach by introducing

an actor updating delay and employing a double Q-

learning structure to mitigate the risk of overestimat-

ing Q-values during updates. Additionally, a Behav-

ior Cloning (BC) term is incorporated, as illustrated

by the following equation:

L

BC

=

1

N

N

∑

i=1

∥a

i

− π(s

i

)∥

2

(5)

Subsequently, the actor loss is augmented by the

BC term, facilitating an update of the actor-network.

The action space and other settings are the same as

the previous DDPG algorithm.

As previously described, in our platform, the ac-

tion space is defined by the first three values, which

represent the end-effector position, along with the fi-

nal control mode value. Given this, a multi-agent

approach can effectively address this task. The first

agent is tasked with determining the next state for the

system, while the second agent focuses on maintain-

ing the overall balance and stability of the platform.

Building on the TD3+BC framework, we propose

a Multi-Agent Behavior Cloning (MABC) approach.

Unlike standard TD3+BC, MABC simplifies the al-

gorithm by considering only the difference between

the actual action and the policy action, without incor-

porating a critic mechanism. This design allows for

efficient offline RL learning while maintaining per-

formance in control tasks. The complete offline RL

algorithm—including single-agent TD3+BC, Multi-

Agent TD3+BC (MATD3+BC), and MABC is out-

lined in Algorithm 2.

5 EXPERIMENT

The applications are implemented in a modular fash-

ion utilizing Pybullet and OpenAI Gym, as illustrated

in Fig. 1. OpenAI Gym serves as a robust toolkit for

researching Deep Reinforcement Learning (DRL) al-

gorithms. Additionally, the Pybullet engine offers ex-

cellent compatibility with the Gym, facilitating rapid

simulation results. The RL baseline algorithm is

sourced from Keras (Chollet et al., 2015) and other

researchers’ work (Pan et al., 2022), allowing for

efficient integration into our simulation framework.

Within this architecture, the RL agent determines the

action strategy, while the WBC employs this strategy

to execute motion planning and control.

In this section, we design one basic experiment

that collectively forms a comprehensive task utiliz-

ing our simulated mobile robot platform. The robot

is capable of grasping an object, subsequently, the

platform, equipped with the robotic arm, maneuvers

to a designated position while carrying the grasped

mass. The DDPG algorithm is employed as an

online RL solution with its own parameters. To

achieve the task, we further investigate how offline

RL and Offline Multi-Agent Reinforcement Learning

(OMARL) contribute to enhancing performance.

5.1 Simulation Setup

The manipulator-reaching task follows the learning of

the grasping object. In this phase, the action consists

of adjusting the end-effector position and the param-

eter α, as previously mentioned. The observation en-

compasses the robot manipulator’s position, the mo-

bile platform’s position, and the control mode value,

which is designed to enhance performance by balanc-

ing accuracy and stability. The reward is formulated

based on the error between the achieved state and the

desired goal.

The desired goals are sampled based on specific

intervals in the xyz space. The x sampling inter-

val is defined as (−0.8, −0.5) and (1, 1.5), accom-

modating both forward and backward movements.

The y sampling interval is set to (−0.2, 0.2), while

the z sampling interval is specified as (0.55, 0.8).

The initial state is fixed with the joint values

[0, −0.215, 0, −2.57, 0, 2.356, 2.356, 0.08, 0.08]. The

dimensions of the actions and states for the neural net-

works are 4 and 10, respectively.

For multi-agent tasks, the setup involves two dis-

tinct agents with different roles and observations. The

first agent is responsible for controlling the changes

in the end-effector position, and its observation space

consists of the state information necessary for guid-

ing the robot’s movement. The second agent, on the

other hand, handles the parameter α. The observation

for this agent is based on control mode data, allowing

it to fine-tune the system’s performance based on the

dynamic requirements of the task.

MIRSim-RL: A Simulated Mobile Industry Robot Platform and Benchmarks for Reinforcement Learning

61

Inputs: Initialize main (critic, actor) and target (critic, actor) neural network weights and replay buffer

Outputs: Trained agent

Initialize target network and main network weights and replay buffer;

while i ≤ T do

Initialize the state;

if Single-agent Setup then

Load offline data from WBC; ▷ TD3+BC

Compute the target value from a small batch in the replay buffer;

Update the main network critic by choosing Q

min

= min(Q

1

, Q

2

);

Update the main network actor with the BC loss term;

Update the target network;

else

if Use Critic Updating then

Load offline data from WBC; ▷ MATD3+BC

for Each Agent i do

Compute the target value from a small batch in the replay buffer;

Update the main network critic for agent i by choosing Q

i

min

= min(Q

i

1

, Q

i

2

);

Update the main network actor for agent i using the sampled gradient;

Update the target network;

end

else

Load offline data from WBC; ▷ MABC

for Each Agent i do

Compute the target value from a small batch in the replay buffer;

Update the main network actor for agent i only with the BC loss term;

Update the target network;

end

end

end

end

Algorithm 2: Offline RL algorithm (single-agent and multi-agent) on Whole-Body Controller.

5.2 Network Structure

In this task, the DDPG algorithm, based on WBC, is

implemented to learn how to reach the desired goal

for the robot’s end-effector. The details of the network

hyperparameters are presented in Table 2.

Table 2: Network structure in manipulator reaching task.

Critic learning rate 0.001

Actor learning rate 0.001

Total epochs 100

Total episodes 20

Total steps per epoch 25

Standard deviation 0.1

Buffer capacity 5000

Buffer warm-up 5000

Batch size 256

τ 0.005

γ 0.95

For offline and multi-agent settings, the TD3+BC

training information is as Table 3 shows.

Table 3: Offline RL and multi-agent RL Network structure

in manipulator reaching task.

Critic learning rate 0.0005

Actor learning rate 0.0005

Total steps per epoch 25

Total train (parameter update) times 100000

Standard deviation 0.1

Buffer capacity 30000

Batch size 256

τ 0.005

γ 0.95

5.3 Reward Mechanism

In this scenario, the reward mechanism consists of

three components. The first component penalizes the

agent if the end-effector does not reach the goal po-

sition. If the goal position is successfully reached, a

positive reward is provided to encourage successful

ICAART 2025 - 17th International Conference on Agents and Artificial Intelligence

62

behavior, as shown in Eq. 6.

r

1

(s, a) =

−d , if not reaching

+10 , else

(6)

Here, d represents the distance between the current

robot manipulator and the desired goal.

Additionally, we observe that in some cases, both

the mobile platform and manipulator may not reach

the target position in a few small steps. Therefore,

we compute the difference between the target and

achieved positions for both the manipulator and the

mobile platform. Let d

diffmm

denote the difference be-

tween the target and reached manipulator positions,

and d

diffmp

denote the difference between the target

and reached mobile platform base positions. The cor-

responding reward components are defined as shown

in Eq. 7 and Eq. 8.

r

2

(s, a) = −5 × d

di f f mm

(7)

r

3

(s, a) = −5 × d

di f f mp

(8)

Finally, the reward that we used to learn is the sum of

the above three rewards as Eq.9.

r(s, a) = r

1

(s, a) + r

2

(s, a) + r

3

(s, a) (9)

5.4 Results

In this section, learning curves of tasks and perfor-

mance are demonstrated. The learning curves are

sampled multiple times (three random seeds). We

present the mean value and standard deviation area

of these learning curves. Based on that, the task per-

formance is analyzed with the trained agent.

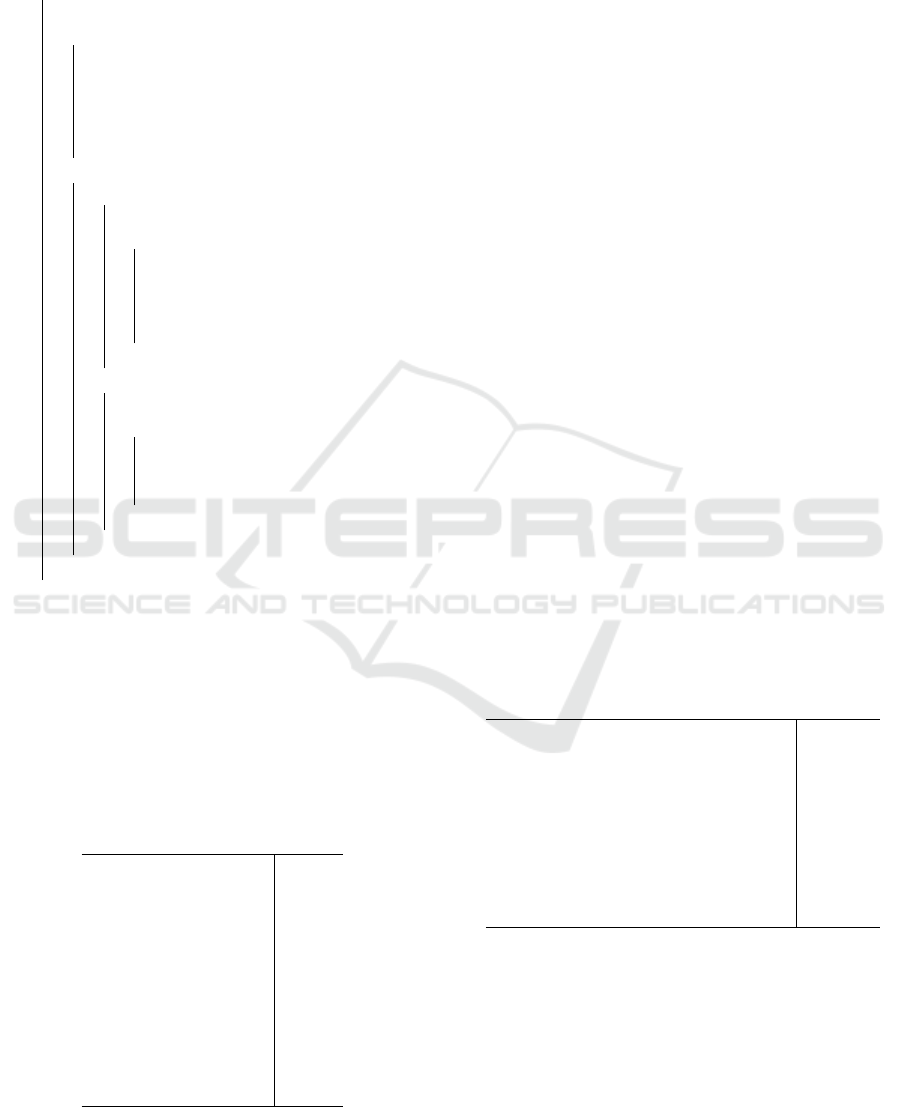

5.4.1 Online Train

The first experiment is the manipulator reaching task

using online RL techniques. In this experiment, both

the vanilla DDPG algorithm and the DDPG enhanced

with the Hindsight Experience Replay (HER) tech-

nique are employed to learn the task behavior. The

results are presented in Fig. 4 and Fig. 5.

This task proves to be more challenging than the

initial grasping task, as the agent must learn not only

the action policy but also the parameter α to balance

accuracy and stability. The HER technique signifi-

cantly enhances both training efficiency and success

rate. In Fig. 4, the green curves represent the per-

formance with HER, while the red curves show the

results without HER. The comparison is notable, with

the HER-enhanced agent achieving a success rate of

70% by approximately the 90th episode, whereas the

vanilla DDPG reaches under 40%.

We then evaluate the reference performance of the

trained agent. As shown in Fig. 6, the mobile plat-

form successfully reaches both positions in front of

Figure 4: Reward comparison in the manipulator reaching

task. The shaded area is the standard deviation.

Figure 5: Successful rate comparison in Manipulator reach-

ing task. The shaded area is the standard deviation.

and behind its initial location during the end-effector

reaching task. Notably, forward movements require

fewer steps than backward movements in our simu-

lated platform. In multi-agent settings, online train-

ing is often time-consuming and yields fewer success-

ful examples. Therefore, this paper does not present

multi-agent online training. Instead, successful multi-

agent data is derived from the single-agent successful

dataset, as discussed in a subsequent section.

5.4.2 Offline Train

As previously discussed, offline reinforcement learn-

ing (RL) techniques depend on a static dataset to ac-

complish specific tasks. Similar to supervised learn-

ing, the agent can leverage prior knowledge from the

pre-collected dataset. Consequently, the quality of the

offline dataset is critical for effective offline reinforce-

ment learning. Therefore, we not only implement

the proposed algorithms but also conduct an ablation

study examining various datasets and hyperparame-

ters in the neural network structure.

MIRSim-RL: A Simulated Mobile Industry Robot Platform and Benchmarks for Reinforcement Learning

63

Table 4: Performance comparison of Offline RL with different datasets in the manipulator reaching task, the Successful Rate

is collected at the iteration times of 18 × 10

4

.

Dataset Successful Rate (%)

60k good data 26.00(±14.42)

30k good data 34.00(±32.19)

5k random + 5k medium + 20k good data 12.67(±15.53)

10k random + 20k good data 16.00(±17.09)

Table 5: Performance comparison of Offline MARL with different datasets in the manipulator reaching task.

Dataset Successful Rate (%)

60k good data (Only MABC) 78(±7.21)

(a) Forward performance in the end-effector reaching

task

(b) Backward performance in the end-effector reaching

task

Figure 6: Reference performance in the manipulator reach-

ing task. Subfigure (a) illustrates the forward movements,

while subfigure (b) shows the backward movements. In

each sub-figure, the current step in an episode is displayed

in the bottom left corner. The maximum number of steps

per episode in our setup is 25.

Single-Agent. In our study, we initially collect two

datasets comprising 30,000 and 60,000 steps, respec-

tively. These datasets are derived from the rollout

of a pre-trained agent that successfully executed the

manipulator-reaching task. For the sake of clarity,

we refer to this as good data (gd). We then exam-

ine whether an increase in data quantity could en-

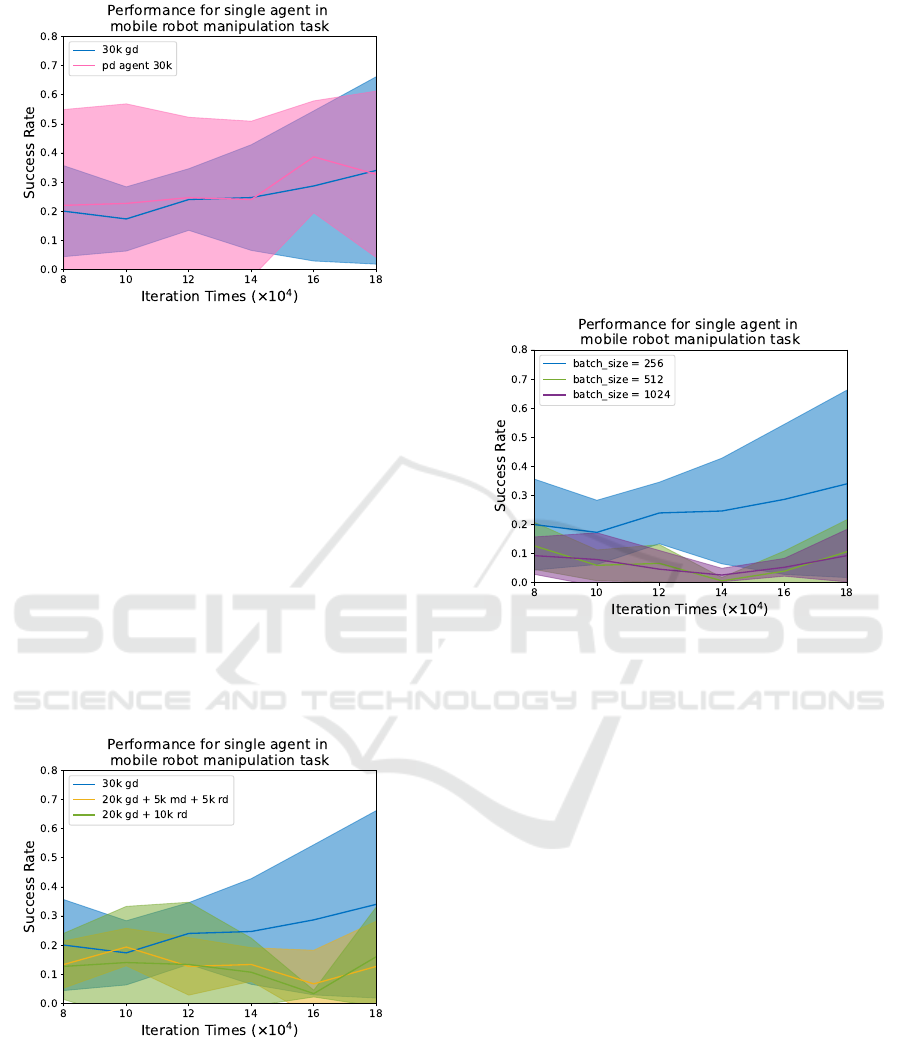

hance robot manipulation performance. As illustrated

in Figure 7 and summarized in Table 4, we find that

a larger dataset does not necessarily correlate with

improved learning performance. However, it does

contribute to greater stability in performance, as evi-

denced by the deviation rates of 14.42% for the larger

dataset compared to 32.19% for the smaller one.

To our knowledge, the term ”pre-trained agent”

Figure 7: Successful rate comparison in Manipulator reach-

ing task for different amounts of good data. Here, 60k gd

and 30k gd mean 60 and 30 thousand good data records, re-

spectively. The solid area represents the standard deviation.

refers to substantial prior work. Specifically, achiev-

ing optimal agent-generated rollouts necessitates

comprehensive online training. In this context, we

propose employing the Proportional-Derivative (PD)

method to collect successful trajectories based on

the WBC framework. These trajectories will subse-

quently be stored as offline data. However, we en-

counter challenges with the PD method in executing

backward movements within the 25-step constraint of

our platform’s WBC. To address this, we extend the

episode length to 50 steps and tested the agent’s per-

formance under this modified configuration, while the

pre-trained agent continued to operate within the orig-

inal 25-step framework. As illustrated in Figure 8, we

observe that the PD method yields results comparable

to the complete set of good data when used as offline

data.

Further, using only successful data can limit the

agent’s learning, as it will never encounter or learn

how to recover from failure scenarios. To address this,

we collect a second dataset consisting of 20,000 suc-

cessful states from the pre-trained agent and an addi-

tional 10,000 states generated randomly(rd). More-

over, the third dataset is created with 20,000 success-

ICAART 2025 - 17th International Conference on Agents and Artificial Intelligence

64

Figure 8: Successful rate comparison in Manipulator reach-

ing task for data generated by different agents. Here pd

means that the data is collected by a PD(proportional-

derivative) agent, gd means good data record. The shaded

area is generated by computing the standard deviation from

the training results.

ful data (gd), 5,000 random data (rd), and medium

data (md ) which created by first 10 random steps and

15 steps at most generated by pre-trained agent in the

whole 25 steps of one episode. In theory, this di-

verse dataset provides a broader distribution of states,

allowing the agent to learn how to handle both suc-

cess and failure scenarios. From Figure 9, the results

show that all gd generated offline data perform the

best whether on successful rate or the standard de-

viation. The TD3+BC algorithm is used to train the

agents on both datasets for 180,000 steps. The full

results are shown in Table 4.

Figure 9: Successful rate comparison in Manipulator reach-

ing task for different data composition, where gd means

good data records, md and rd for medium and random data

records, respectively. The solid curve is the mean success-

ful value of the training process. The filled region with the

responding color is the standard deviation area.

From Table 4, we notice that a more diverse

dataset, including a mixture of successful and random

trajectories, results in a lower success rate compared

to using only successful data. In our view, the un-

derlying reason is the limited size of the dataset com-

bined with a high proportion of random data. The

importance of data distribution in offline RL is still

valuable.

For hyperparameter tuning, we conduct experi-

ments by training offline RL agents with varying

batch sizes. As shown in Figure 10, the larger batch

sizes result in a lower success rate for the reaching

task (1024 batch size with 9.33% at 180,000 steps).

For batch size 512, the successful rate is 10.67%. This

suggests that simply increasing hyperparameter val-

ues does not always lead to better performance.

Figure 10: Successful rate comparison in Manipulator

reaching task for different batch size settings. The solid

curves represent the mean values over three random seeds.

The shaded region is the standard deviation.

Multi-Agent. Furthermore, the performance of

multi-agent settings is evaluated using the 30k suc-

cessful data previously collected in single-agent con-

figurations. The results are summarized in Ta-

ble 5. Interestingly, the simple MABC algorithm ex-

ceeded our expectations, achieving a mean success

rate of 78% with a relatively low standard devia-

tion. However, despite this promising result, the over-

all success rate remains below the desired level, and

MATD3+BC, in particular, failed to yield satisfactory

outcomes during training. This highlights the need for

further optimizations, such as expanding the dataset

and incorporating more diverse data distributions, to

enhance performance and stability.

6 CONCLUSION

In this paper, we present the development of a simu-

lated mobile robot with an arm platform, built with

Pybullet and Gym, which supports a reinforcement

learning framework. Instead of relying on traditional

controllers and planners, we employ a Whole-Body

MIRSim-RL: A Simulated Mobile Industry Robot Platform and Benchmarks for Reinforcement Learning

65

Controller to provide low-level control. On top of

this, reinforcement learning is integrated to enhance

the controller’s overall performance. To evaluate the

effectiveness of the platform and the proposed meth-

ods, we conducted one typical simulated experiment.

The results demonstrate the feasibility of the platform

and its associated methodologies. Furthermore, the

system exhibits potential for handling more complex

tasks in the future.

In our future work, we aim to extend this research

to real-world experiments based on the simulated re-

sults. Additionally, further investigation is needed

into multi-agent training with critic updates.

REFERENCES

Andrychowicz, M., Wolski, F., Ray, A., Schneider, J., Fong,

R., Welinder, P., McGrew, B., Tobin, J., Abbeel, P.,

and Zaremba, W. (2017). Hindsight experience replay.

arXiv preprint arXiv:1707.01495.

Brockman, G., Cheung, V., Pettersson, L., Schneider, J.,

Schulman, J., Tang, J., and Zaremba, W. (2016). Ope-

nai gym.

Carron, A., Arcari, E., Wermelinger, M., Hewing, L., Hut-

ter, M., and Zeilinger, M. N. (2019). Data-driven

model predictive control for trajectory tracking with a

robotic arm. IEEE Robotics and Automation Letters,

4:3758–3765.

Chollet, F. et al. (2015). Keras.

Coumans, E. and Bai, Y. (2016–2021). Pybullet, a python

module for physics simulation for games, robotics and

machine learning. http://pybullet.org.

Dietrich, A., Wimb

¨

ock, T., Albu-Sch

¨

affer, A. O., and

Hirzinger, G. (2012). Reactive whole-body control:

Dynamic mobile manipulation using a large number

of actuated degrees of freedom. IEEE Robotics & Au-

tomation Magazine, 19:20–33.

Fujimoto, S. and Gu, S. S. (2021). A minimalist ap-

proach to offline reinforcement learning. In Ran-

zato, M., Beygelzimer, A., Dauphin, Y., Liang, P.,

and Vaughan, J. W., editors, Advances in Neural Infor-

mation Processing Systems, volume 34, pages 20132–

20145. Curran Associates, Inc.

Fujimoto, S., Meger, D., and Precup, D. (2019). Off-policy

deep reinforcement learning without exploration.

Grabowski, A., Jankowski, J., and Wodzy

´

nski, M. (2021).

Teleoperated mobile robot with two arms: the in-

fluence of a human-machine interface, vr training

and operator age. International Journal of Human-

Computer Studies, 156:102707.

Guo, H., Su, K.-L., Hsia, K.-H., and Wang, J.-T. (2016).

Development of the mobile robot with a robot arm.

In 2016 IEEE International Conference on Industrial

Technology (ICIT), pages 1648–1653.

Guo, N., Li, C., Wang, D., Song, Y., Liu, G., and Gao, T.

(2021). Local path planning of mobile robot based on

long short-term memory neural network. Automatic

Control and Computer Sciences, 55:53–65.

Han, G., Wang, J., Ju, X., and Zhao, M. (2021). Recursive

hierarchical projection for whole-body control with

task priority transition. 2022 IEEE/RSJ International

Conference on Intelligent Robots and Systems (IROS),

pages 11312–11319.

Iriondo, A., Lazkano, E., Susperregi, L., Urain, J., Fernan-

dez, A., and Molina, J. (2019). Pick and place op-

erations in logistics using a mobile manipulator con-

trolled with deep reinforcement learning. 9(2):348.

Jauhri, S., Peters, J., and Chalvatzaki, G. (2022). Robot

learning of mobile manipulation with reachability be-

havior priors. IEEE Robotics and Automation Letters,

7:8399–8406.

Kalashnikov, D., Irpan, A., Pastor, P., Ibarz, J., Herzog, A.,

Jang, E., Quillen, D., Holly, E., Kalakrishnan, M.,

Vanhoucke, V., et al. (2018). Qt-opt: Scalable deep

reinforcement learning for vision-based robotic ma-

nipulation. arXiv preprint arXiv:1806.10293.

Kim, S., Jang, K., Park, S., Lee, Y., Lee, S. Y., and Park, J.

(2019). Whole-body control of non-holonomic mobile

manipulator based on hierarchical quadratic program-

ming and continuous task transition. 2019 IEEE 4th

International Conference on Advanced Robotics and

Mechatronics (ICARM), pages 414–419.

Kindle, J., Furrer, F., Novkovic, T., Chung, J. J., Sieg-

wart, R., and Nieto, J. (2020). Whole-body control of

a mobile manipulator using end-to-end reinforcement

learning. arXiv preprint arXiv:2003.02637.

Li, C., Liu, Y., Bing, Z., Schreier, F., Seyler, J., and

Eivazi, S. (2023a). Accelerate training of reinforce-

ment learning agent by utilization of current and pre-

vious experience. In ICAART (3), pages 698–705.

Li, C., Liu, Y., Bing, Z., Seyler, J., and Eivazi, S. (2022).

Correction to: A novel reinforcement learning sam-

pling method without additional environment feed-

back in hindsight experience replay. In Kim, J., En-

glot, B., Park, H.-W., Choi, H.-L., Myung, H., Kim, J.,

and Kim, J.-H., editors, Robot Intelligence Technology

and Applications 6, pages C1–C1, Cham. Springer In-

ternational Publishing.

Li, C., Liu, Y., Hu, Y., Schreier, F., Seyler, J., and Eivazi,

S. (2023b). Novel methods inspired by reinforcement

learning actor-critic mechanism for eye-in-hand cali-

bration in robotics. In 2023 IEEE International Con-

ference on Development and Learning (ICDL), pages

87–92.

Li, W. and Xiong, R. (2019). Dynamical obstacle avoidance

of task- constrained mobile manipulation using model

predictive control. IEEE Access, 7:88301–88311.

Lober, R., Padois, V., and Sigaud, O. (2016). Efficient re-

inforcement learning for humanoid whole-body con-

trol. In 2016 IEEE-RAS 16th International Confer-

ence on Humanoid Robots (Humanoids), pages 684–

689. IEEE.

Lowe, R., Wu, Y., Tamar, A., Harb, J., Abbeel, P., and Mor-

datch, I. (2020). Multi-agent actor-critic for mixed

cooperative-competitive environments.

ICAART 2025 - 17th International Conference on Agents and Artificial Intelligence

66

Minniti, M. V., Grandia, R., F

¨

ah, K., Farshidian, F.,

and Hutter, M. (2021). Model predictive robot-

environment interaction control for mobile manipula-

tion tasks. 2021 IEEE International Conference on

Robotics and Automation (ICRA), pages 1651–1657.

Mnih, V., Kavukcuoglu, K., Silver, D., Rusu, A. A., Ve-

ness, J., Bellemare, M. G., Graves, A., Riedmiller,

M., Fidjeland, A. K., Ostrovski, G., Petersen, S.,

Beattie, C., Sadik, A., Antonoglou, I., King, H., Ku-

maran, D., Wierstra, D., Legg, S., and Hassabis, D.

(2015). Human-level control through deep reinforce-

ment learning. Nature, 518(7540):529–533.

Pan, L., Huang, L., Ma, T., and Xu, H. (2022). Plan better

amid conservatism: Offline multi-agent reinforcement

learning with actor rectification. In International Con-

ference on Machine Learning.

Ramalepa, L. P. and Jr., R. S. J. (2021). A review on co-

operative robotic arms with mobile or drones bases.

Machine Intelligence Research, 18(4):536–555.

Stilman, M. (2010). Global manipulation planning in robot

joint space with task constraints. IEEE Transactions

on Robotics, 26(3):576–584.

Teng, T., Fernandes, M., Gatti, M., Poni, S., Semini, C.,

Caldwell, D. G., and Chen, F. (2021). Whole-body

control on non-holonomic mobile manipulation for

grapevine winter pruning automation *. 2021 6th

IEEE International Conference on Advanced Robotics

and Mechatronics (ICARM), pages 37–42.

Tin

´

os, R., Terra, M. H., and Ishihara, J. Y. (2006). Mo-

tion and force control of cooperative robotic manipu-

lators with passive joints. IEEE Transactions on Con-

trol Systems Technology, 14(4):725–734.

Uehara, H., Higa, H., and Soken, T. (2010). A mobile

robotic arm for people with severe disabilities. In

2010 3rd IEEE RAS & EMBS International Confer-

ence on Biomedical Robotics and Biomechatronics,

pages 126–129.

Wang, C., Zhang, Q., Tian, Q., Li, S., Wang, X., Lane, D.,

P

´

etillot, Y. R., Hong, Z., and Wang, S. (2020a). Multi-

task reinforcement learning based mobile manipula-

tion control for dynamic object tracking and grasping.

2022 7th Asia-Pacific Conference on Intelligent Robot

Systems (ACIRS), pages 34–40.

Wang, C., Zhang, Q., Tian, Q., Li, S., Wang, X., Lane, D.,

P

´

etillot, Y. R., and Wang, S. (2020b). Learning mo-

bile manipulation through deep reinforcement learn-

ing. Sensors (Basel, Switzerland), 20.

Welschehold, T., Dornhege, C., and Burgard, W. (2017).

Learning mobile manipulation actions from human

demonstrations. 2017 IEEE/RSJ International Con-

ference on Intelligent Robots and Systems (IROS),

pages 3196–3201.

Xin, J., Zhao, H., Liu, D., and Li, M. (2017). Applica-

tion of deep reinforcement learning in mobile robot

path planning. In 2017 Chinese Automation Congress

(CAC), pages 7112–7116. IEEE.

Zhang, K., Yang, Z., and Bas¸ar, T. (2021). Multi-agent rein-

forcement learning: A selective overview of theories

and algorithms.

MIRSim-RL: A Simulated Mobile Industry Robot Platform and Benchmarks for Reinforcement Learning

67