A Green Transportation Problem for e-Commerce Deliveries

Th

´

eo Le Brun

1,2

, Marie-Jos

´

e Huguet

2

, Sandra Ulrich Ngueveu

2

and Romulus Grigoras

1

1

OneStock, Toulouse, France

2

LAAS-CNRS, Universit

´

e de Toulouse, CNRS, INP, INSA, Toulouse, France

Keywords:

Order Orchestration, Transportation Problem, e-Commerce, Sustainability.

Abstract:

To get involved in the fight against climate change, e-commerce actors should reduce the environmental impact

of their activities. For retailers, a key challenge to is identify the stock sources for fulfilling online orders. In

this paper, our goal is to orchestrate orders while minimizing the associated environmental impact. We propose

a model of Green Transportation Problem for E-commerce Deliveries (GTP-ED) which can be seen as a general

case of Fixed Charge Transportation Problem. We detail how we obtain the environmental objective function

and how we generate instances based on real world and realistic data and that good quality solutions can be

obtained quickly. Then, we show the relevance of our environmental objective function by comparing the

results with an orchestration based on minimizing the distance traveled by the parcels, which leads to a 30%

increase of environmental cost. Finally, we compare the GTP-ED with an economic approach and outline a

significant tension between our environmental and economic objectives in that context.

1 INTRODUCTION

The development of e-commerce has raised new tech-

nical and operational challenges for retailers. Every-

day, retailers have to prepare, to pack and to ship

orders to satisfy their customers, leading to billions

of deliveries all around the world. The dedicated lo-

gistics generate environmental impacts that should be

mitigated to take part in the fight against the environ-

mental crisis. In 2022, the logistics to ship the billion

of parcels delivered in France was responsible for ap-

proximately 1 MteqCO

2

(CPV Associ

´

es et al., 2023).

In few years, the e-commerce sector has become om-

nichannel, meaning that orders come from various

sales channels (websites, marketplaces, call centers...)

and can be fulfilled using any stock, including stores’

stocks. Thus, the retailers take into account a unified

stock, but this additional flexibility, very efficient to

increase sales and reduce unsold stock, raises opera-

tional issues. Among them are the stock management

and the determination of the stock location to be used

to fulfill orders. To handle these challenges, most

retailers use an Order Management System (OMS).

Based on unified stocks, the OMS informs whether

products are available to be sold online or not. Once

orders are placed through a retailer’s channel, the

OMS orchestrates and monitors the orders. Order

orchestration aims at deciding which stock location

will be chosen to ship each item for each order. Usu-

ally, retailers use dispatching rules to optimise a given

monetary cost based criteria. This paper presents an

optimization model designed to minimise the envi-

ronmental impact of order orchestration. The studied

problem is related to the Transportation Problem, in

which the goal is to minimise the distribution cost of

products from a set of sources to a set of destinations.

The remainder of this paper is organised as fol-

lows: Section 2 proposes a literature review on or-

der orchestration, transportation problems and envi-

ronmental costs over Operational Research field. Sec-

tion 3 introduces the proposed environmental objec-

tive function and formalises the problem.. In Sec-

tion 4, we expose how we obtained realistic datasets

to test our model and detail some results. We analyse

the computational performances and the relevance of

our environmental objective function. Finally, con-

clusion and future works are drawn in Section 5.

2 LITERATURE REVIEW

Order Orchestration for e-Commerce Retailers:

on order orchestration mainly focused on monetary

objective functions. The first optimisation model

for e-commerce retailers was proposed in (Xu et al.,

2009), whose aim is to orchestrate orders over a time

278

Le Brun, T., Huguet, M.-J., Ngueveu, S. U. and Grigoras, R.

A Green Transportation Problem for e-Commerce Deliveries.

DOI: 10.5220/0013162900003893

In Proceedings of the 14th International Conference on Operations Research and Enterprise Systems (ICORES 2025), pages 278-285

ISBN: 978-989-758-732-0; ISSN: 2184-4372

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

horizon while minimizing split orders, i.e. multi-

items orders shipped from multiple stock locations.

They propose to periodically re-evaluate the orches-

tration of orders which have not been fulfilled yet.

A MILP formulation is provided, identified as a net-

work design problem where minimizing the number

of splits is equivalent to minimizing the number of

activated arcs in the network. They perform a de-

composition and a heuristic approach to solve large

scale instances. In (Acimovic and Graves, 2015) or in

(Jasin and Sinha, 2015), the goal is to determine the

optimal order fulfillment policy which minimises the

shipping costs of e-commerce retailers including an

estimate of shipping cost for future orders. They use a

MILP formulation to elaborate demand forecasts and

then propose heuristic methods to determine the op-

timal order fulfillment policy. In (Lei et al., 2018),

the authors address a problem in which retailers must

take about items pricing and orders fulfillment. The

objective is to maximize the total profits equal to

the sales profits minus the expected shipping costs.

The resulting problem is NP-hard. They propose two

heuristics which separate item pricing decisions and

order fulfillment decisions. (Cheref et al., 2018) study

an orchestration problem including fixed and variable

costs, respectively related to shipping costs and prod-

ucts costs. They use a matheuristic and provide some

performance guarantees.

Transportation Problem: The order orchestration

we consider in this paper can be related to a variant

of Transportation Problem with multiple items. We

perform below a short literature review on this prob-

lem, for a more detailed survey, we refer to (Kacher

and Singh, 2021) or (Malack

´

y and Madle

ˇ

n

´

ak, 2023).

In the Transportation Problem (TP), the goal was to

match the supplies of factories in a given product with

the demand of several cities while minimizing the

transportation cost and it was assumed that the total

supply and the total demand were equal (Hitchcock,

1941). The TP could be modeled with the following

linear program: min

∑

i, j

c

i j

x

i j

, s.t.

∑

i

x

i j

= d

j

,

∑

j

x

i j

= q

i

where x

i j

≥ 0 represent the decision

variables (amount of products from factory i to city

j), d

j

the demands, q

i

the stocks and c

i j

the costs.

As shown in (Matsui and Scheifele, 2016), lots of

efficient algorithms exist to solve the TP.

Since then, many variants appeared. (Haley, 1962)

introduces a three-dimensional TP, called Solid

Transportation Problem. For this problem, a third in-

dex is used to model several types of products which

have to be delivered and three capacity constraints

are considered. The Fixed Charge Transportation

Problem (FCTP) has also received a lot of attention.

(Balinski, 1961) introduced the FCTP as a variant

where fixed costs are added to classical variable costs.

Binary decision variables are introduced to take into

account those fixed costs. The FCTP was shown to be

NP-hard (Klose, 2008). To solve large instances in

a reasonable amount of time, (Roberti et al., 2015)

and later (Mingozzi and Roberti, 2018) proposed a

column generation scheme, which allowed them to

significantly improve the size of solved instances.

The Transportation Problem with Packing Con-

straints, is a variant of FCTP, introduced by (Flamand

et al., 2023). It takes into account variable costs

proportional to the amount of products bought at a

given supplier and fixed costs depending on the usage

of the vehicles for each path. In addition to that, they

add packing constraints, ensuring that vehicles used

between a supplier and a customer have a sufficient

capacity to carry all the goods shipped on this way.

Environmental Cost: Over the path of a parcel,

several sources of environmental impacts can be

found: transportation, handling, storage and packag-

ing (CPV Associ

´

es et al., 2023). Transportation is

the most often considered impact and may include

transportation from factories to warehouses, between

warehouses or from warehouses to customers.

In (Colissimo, 2023), the French carrier Colissimo,

describes how to compute the environmental cost of

a parcel traveling through its network. In their work,

the environmental cost corresponds to the amount of

CO

2

emitted. It includes transportation and building

impacts and depends on origin and destination zip

codes, parcel volume and parcel mass. The path of

a parcel is decomposed into several legs, and for each

one a formula is given for evaluating the environmen-

tal impact. Data are based on average data from the

previous year and include vehicle types, motorisation,

load factor etc... Regarding the building impacts, a

unit environmental cost is affected to each parcel de-

pending on previous year data.

In the literature, TP with environmental objective

function are often multi-objective with a second ob-

jective being economic. In (Shojaie and Raoofpanah,

2018), the authors add a fixed environmental cost for

each vehicle having to deliver a certain customer from

a certain supply. This cost corresponds to the vehi-

cle pollution and depends on the type of vehicle and

the pair origin-destination. In their variant of Green

Transportation Problem with Multi Objective, (Midya

et al., 2021) also consider the vehicle emissions as the

environmental cost but adopted a different measuring

strategy as they consider the cost proportional to the

amount of goods to be shipped on the given path.

A Green Transportation Problem for e-Commerce Deliveries

279

3 PROBLEM FORMULATION

In this paper, our goal is to solve the order orches-

tration faced by retailers, with a special care about

environmental impacts. Thus, we aim at providing

every item of every order, while respecting the stocks

and minimising a given environmental cost function.

More precisely, we have two specific locations, the

stock locations associated to sources and, for each or-

der, the customer delivery locations associated to des-

tinations. Our goal is to determine which stock lo-

cations can be associated with each delivery location

as in classical TP. We underline that in the problem

we consider, the routing decisions are not part of the

retailers’ scope. Indeed, in our problem, the trans-

portation from a source to a destination is ensured

by an external carrier and, is associated to a unique

link. Moreover, the orders we consider are placed

by individuals, meaning that the amounts demanded

are quite low and enforce the use of integer decision

variables. Before presenting the Mixed Integer Lin-

ear model of our problem, we focus on the considered

environmental cost function.

The Environmental Cost Function: Along the

shipping of an item, types of environmental impacts

are numerous. The environmental impacts considered

in this paper are evaluated by the amount of green-

house gases emissions, measured in g CO

2

equivalent,

whereas deliveries are also causes of pollution, waste

or resource depletion. Items leaving the Stock Loca-

tion are packed into parcels and may be gathered with

other items having the same origin and destination.

Thus, costs upstream the Stock Location are item re-

lated, while costs downstream the Stock Location, in-

cluding packaging, are parcel related. The environ-

mental impact of a shipped item can be seen as the

sum of the following elements:

• Manufacturing costs (MC

k

) caused by the manu-

facturing of item k.

• Supply costs (SuC

ks

) including all the environ-

mental impacts to store, handle and carry the item

k to the stock location s.

• Storage costs (StC

ks

) due to the functioning of

buildings used for the storage. They are related

to the item k and the stock location s.

• Packaging costs (PC

b

) due to the packaging used

to ship the item. They are proportional to the

amount of packaging required and depends on the

material used. PC

b

are related to the characteris-

tics of the chosen box b.

• Transportation costs (TC

bso

) caused by the trans-

portation of the parcel b from the stock location s

to the customer destination o through one or sev-

eral hubs. We consider K

bso

the set of items sent

from the stock location s to the customer location

for order o in a box b, m

k

the mass of an item k and

M

b

and V

b

the mass and volume of a box b. Then,

we use the formula provided by Colissimo (Col-

issimo, 2023) to compute the transportation costs.

TC

bso

= EV

so

× V

b

+ EM

so

× (M

b

+

∑

k∈K

bso

m

k

),

where EV

so

and EM

so

are two emission factors

proportional to the volume and to the mass respec-

tively. EV

so

and EM

so

are specific to each path

(from stock location to customer) and depend on

the distance covered, the vehicle type and the fuel

used by the carrier.

• Handling costs (HC

bso

) due to sorting and han-

dling along the transportation leg. They are re-

lated to the origin s and destination o and to the

parcels b to be handled.

• Consumer Travel costs (CTC

o

) due to the travel

of customers to pick up their parcel (equals 0 in

case of Home Delivery). They are fixed costs de-

pending on the customer’s distance and mean of

transportation.

Order orchestration is only about assigning items to

stock location. Thus, for the remaining of the pa-

per, Manufacturing and Consumer Travel costs are

not taken into account in the objective function. In-

deed, they can be considered as non-decisionary fixed

costs as the same amount has to be added no matter

the decisions taken. Moreover, the measure of the en-

vironmental cost requires information about parcels

to be shipped. In particular, the Transportation costs

formula to compute TC

bso

requires the volume and

the mass of the parcel. We chose this formula as it

is used by a major carrier. Among the drawbacks we

identified, the requirement for the parcel volume was

the most detrimental. Indeed, it implies to determine

the volume of the parcel depending on the items to

be shipped. This problem is close to the well-know

NP-hard 3D-Bin Packing Problem (Martello et al.,

2000). We chose to simplify the computation of the

parcels volume by simply requiring the total volume

of parcels shipped to be higher than the total volume

of items to be shipped. This method can be used for

a retailer sending clothes for example. However, to

avoid products jamming, a small margin on the vol-

ume of the parcel is considered.

Resulting MILP - Green Transportation Problem

for e-Commerce Deliveries (GTP-ED): Our Green

Transportation Problem for E-commerce Deliveries,

denoted by GTP-ED, can be seen as a variant of a

Fixed-Charge Transportation Problem (FCTP) that

ICORES 2025 - 14th International Conference on Operations Research and Enterprise Systems

280

includes an environmental cost function. The stock

locations of items correspond to sources of the TP.

Also, a unique delivery location is associated to each

customer order. Thus the orders correspond to their

respective delivery point, that are the destinations of

the TP. Let us consider O the set of orders, K the

set of items, S the set of stock locations and B the

set of boxes. We denote by d

ko

the demand in item

k for order o and by q

ks

the stock for item k in stock

location s. Let v

k

be the volume of an item k and

V

b

the volume of a box b. The model of the GTP-ED is:

(GTP-ED) min F

G

=

∑

s∈S

∑

o∈O

(

∑

k∈K

I

kso

x

kso

+

∑

b∈B

P

bso

y

bso

) (1)

∑

s∈S

x

kso

= d

ko

∀k ∈ K , ∀o ∈ O (2)

∑

o∈O

x

kso

≤ q

ks

∀k ∈ K , ∀s ∈ S (3)

∑

b∈B

y

bso

V

b

− α

∑

k∈K

x

kso

v

k

≥ 0 ∀s ∈ S , ∀o ∈ O (4)

x

kso

∈ N ∀k ∈ K , ∀s ∈ S, ∀o ∈ O (5)

y

bso

∈ N ∀b ∈ B, ∀s ∈ S, ∀o ∈ O (6)

where x

kso

is an integer variable (Constraints (5)) ac-

counting for the number of items k used from the

stock location s to fulfill the order o and y

bso

is an inte-

ger variable (Constraints (6)) representing the number

of boxes b sent from the stock location s to the des-

tination of order o. Let us notice that decision vari-

ables are chosen as integers and unbounded but sim-

ple upper bounds can be found. Indeed, the number

of items k to be sent from a stock location s can nei-

ther be higher than the stocks q

ks

of item k in location

s nor than the demand d

ko

of order o for item k, i.e.,

∀k ∈ K , s ∈ S, o ∈ O, x

kso

≤ min(d

ko

, q

ks

). Then, for

each order o, the maximum number of boxes of type

b is lower than the number of boxes b required to get

more space than the total volume required for the or-

der o, i.e., ∀b ∈ B, s ∈ S, o ∈ O, y

bso

≤ ⌈

α

∑

k∈K

d

ko

v

k

V

b

⌉.

Constraints (2) ensure that demands are fulfilled,

Constraints (3) ensure that stocks are not exceeded

and Constraints (4) ensure that the total volume of

parcels shipped from a stock location s to the desti-

nation of order o is higher than the total volume of

items to be shipped on this path with a margin coeffi-

cient α ≥ 1.

The Objective (1) of the GTP-ED is to minimise the

environmental cost, denoted F

G

and expressed in

geqCO

2

, which can be decomposed into item related

costs and parcel related costs. Item related costs I

kso

correspond to the cost of sending one item k from the

stock location s to the destination of order o and are

equal to I

kso

= SuC

ks

+ StC

ks

+ EM

so

m

k

with SuC

ks

the cost caused by the supply of an item k to the

stock location s, StC

ks

the cost of storing one item

k in the stock location s, EM

so

the mass transporta-

tion cost over the path (so) and m

k

the mass of an

item k. Parcel related costs P

bso

correspond to the

cost of sending one box of size b from the stock lo-

cation s to the destination of order o and are equal to

P

bso

= PC

b

+HC

bso

+EV

so

V

b

+EM

so

M

b

with PC

b

the

cost due to packaging of a box of size b, HC

bso

the

cost for handling a box of size b over the path (so),

EV

so

the volumetric transportation cost over the path

(so), EM

so

the mass transportation cost over the path

(so) and M

b

the mass of a box b.

This resulting model can be proven to be NP-hard. In-

deed, under the hypothesis H

1

: |B| = 1, H

2

: |K | = 1

and H

3

:

V

b

αv

k

≥ max

o∈O

d

ko

, the GTP-ED becomes an

integer version of the FCTP, known as NP-hard.

To scale-up when solving the GTP-ED, the initial set

of orders can be decomposed into subsets of orders

which can be solved independently. Let us consider

a multi-graph G = (V , E). The set of nodes corre-

sponds to the set of orders i.e. V = O. For each

pair of node (o, o

′

), an edge is drawn between o

and o

′

for each item k demanded in both orders, i.e.

d

ko

≥ 1 and d

ko

′

≥ 1. Each connected component of

graph G corresponds to a subset of independent or-

ders on which GTP-ED can be solved independently

without loss of optimality. Such decomposition was

also considered in (Xu et al., 2009) through a graph

based on items instead of graph based on orders.

4 EXPERIMENTS

In this section, we start by describing the datasets

used and the experimental setup. Then we detail the

results obtained and provide an analysis to identify

trends and future work.

4.1 Datasets

Based on the literature review, we did not find pub-

lic datasets related to our problem. So, we create our

own datasets to evaluate our contribution. The first

dataset is based on a real retailer anonymised oper-

ating in France, while the second dataset

1

was ran-

domly generated using realistic hypothesis.

1

data2 is publicly available on https://gitlab.laas.

fr/chaire-retail-responsable/gtped

A Green Transportation Problem for e-Commerce Deliveries

281

Dataset Based on Real Data. This dataset (data1)

is based on average characteristics of a fashion omni-

chanel retailer operating in France. We consider

100 orders that were randomly selected from past

anonymised orders (we fixed |O| = 100 based on

preliminary experiments on the limit of the MILP

solver). With the selected orders, we then have a

number of associated items (|K | = 244) and a num-

ber of stock locations (|S| = 135) where these items

are available. The demand in items for each order and

the stock level for each item in every stock location is

based on average real data.

Dataset Based on Realistic Randomized Genera-

tion. This generated dataset (data2) is similar to

data1 based on real data. First, we consider the same

value for the set of orders, items and stock locations:

|O| = 100, |K | = 244 and |S| = 135. The geographi-

cal coordinates of stock locations and destinations of

orders are randomly generated following a uniform

law U(−4, 8) for the longitude and a U(42, 51) for

the latitude. To generate demands and stocks, we re-

spected the orders of magnitude observed in the real

data. For each order o, we first generate a number

n

o

of items such that n

o

= max(1, ⌊N (2, 4)⌋) (where

N stands for the normal law). Then, we perform n

o

draws with replacement to determine the items which

have been ordered. For each item and stock loca-

tion, the stock level is generated using a uniform law:

∀k, s q

ks

∼ U({0, 1, 2, 3, 4, 5}). Whereas it is theoreti-

cally possible to get an unfeasible problem due to lack

of stocks, it never occurred in our experiments.

Additional Data. For each dataset, we have to gen-

erate some additional data for parcels and for cost

parameters. Based on French carrier data (available

on public web site), we fixed the number of boxes

(B = 6) and obtained their characteristics (size, mass

and volume). All the cost values were obtained from

different sources. Items volume and mass were ran-

domly generated but in a way to obtain realistic values

for the fashion industry. Storage Costs, Supply Costs

and Handling Costs, relies on a report about environ-

mental impacts of e-commerce (CPV Associ

´

es et al.,

2023). The values are randomly generated so as to re-

spect the orders of magnitude provided in the report.

All details about the generation of these parameters

are publicly available (see footnote 1).

4.2 Experimental Setup

For each dataset, made of 100 orders, we build several

subsets from 10 to 100 orders with their respective

numbers of items and stock locations. To do that, we

successively consider the orders of the initial dataset

(the 10-order instance corresponds to the first 10 or-

ders in the initial dataset, and so on). For each sub-

set of data (from 10 to 100 orders), we first generate

values for stocks, demands and boxes. Then, we ran-

domly generate 10 instances by changing the values

for items masses, items volumes and costs. We used

Julia 1.10 and CPLEX 20.1 (in single thread mode)

for the implementation of the mathematical model of

all MILP models. The experiments ran on a server

with a Intel E5-2695 v4 2.1G processor. Finally,

16GB of RAM and 1h of solving time were allocated

to each instance.

4.3 Computational Results and Analysis

We present the results of the experiments which have

been performed to test and analyse the GTP-ED. We

first detail the computational performances of the

model and then analyse the relevance of the envi-

ronmental objective comparatively to other objective

functions. In this paper, we only present the results

for data1, however more complete results are publicly

available (see footnote 1).

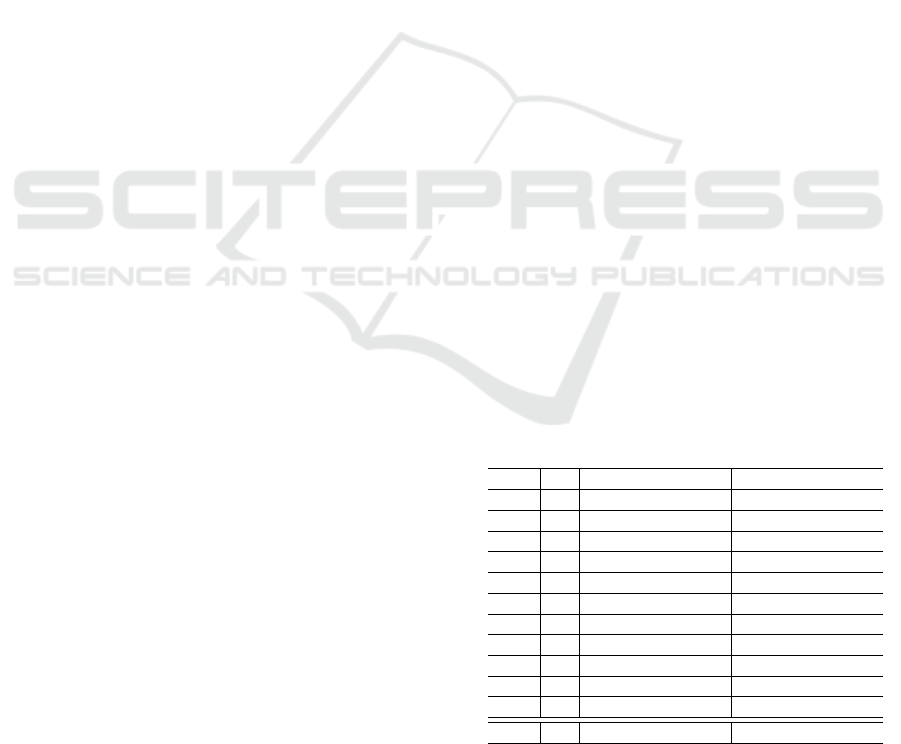

Performances Analysis. Firstly, we looked at the

performances of our MILP model for the GTP-ED. Ta-

ble 1 presents the computation time (CPU), the gap at

root node (RG), the final gap (FG) and the number of

instances optimally solved for data1. For each size of

instance, we provide the mean, denoted as µ, and the

standard deviation, denoted as σ, observed over the

10 instances of the set for CPU, RG and FG.

Table 1: Performance computational results - data1.

data1

CPU(s) RG(%) FG(%) #Opt

/ 10

|O| µ σ µ σ µ σ

10 2.5 0.8 4.9 1.5 0.0 0.0 10

20 6.3 1.2 4.8 1.8 0.0 0.0 10

30 10.3 1.4 3.0 1.7 0.0 0.0 10

40 25.0 6.9 3.1 2.3 0.0 0.0 10

50 406.6 1069.6 2.8 0.6 0.1 0.1 9

60 413.2 1068.2 2.3 0.5 0.0 0.1 9

70 2784.5 1383.3 2.6 0.5 0.1 0.2 4

80 2695.1 1467.7 2.7 0.4 0.3 0.3 3

90 2116.7 1579.5 2.4 0.3 0.3 0.3 5

100 3395.8 738.9 2.5 0.4 0.3 0.2 1

In terms of computing time, solving small size

instances is quite fast as the mean solving time is

less than 30 seconds for instances up to 40 orders for

data1 and up to 20 for data2. Larger instances require

much more computing time and lots of them reach the

ICORES 2025 - 14th International Conference on Operations Research and Enterprise Systems

282

one hour time limit. Indeed, for both datasets, solv-

ing to optimality large instances is difficult. Less than

half instances above 70 orders are optimally solved

for data1 and no instance above 50 orders are opti-

mally solved for data2. Those results tend to confirm

that the GTP-ED is hard to solve. However, we still

notice that good quality solutions are obtained as the

mean FG is always lower than 2% with low standard

deviation. The RG confirms the ability to quickly get

good quality solutions as for large instances the mean

is most often lower than 5% with a low standard devi-

ation. We notice two exceptions for instances of size

30 and 70 for data2, where one instance is observed to

have a huge RG. Besides, we observe significant dif-

ferences in terms of performance between data1 and

data2. The generation of stocks data may be part of

the explanation. Indeed, we chose a uniform law to

generate stocks for data2, while in data1, averaged

on real data, empty stocks seem to appear more often.

From an operational point of view, retailers could

prefer good quality solutions quickly obtained to or-

chestrate orders during working days to prevent from

stock changes due to physical store sales. Neverthe-

less, retailers may appreciate optimal solutions to or-

chestrate orders placed during nights and week-ends

when time is less constraining.

To improve the scalability of our problem, we used

the decomposition presented at the end of the section

3. It actually helps to improve the resolution as about

10% more instances are solved to optimality after one

hour. Besides, for instances solved to optimality, the

savings in terms of CPU are significant, about two

times faster in average for both datasets.

Objectives Analysis. In the GTP-ED, we consider a

new objective function which requires lots of param-

eters and data. Such complexity was justified to mea-

sure an overall environmental cost. However, we still

need to justify the relevance of this objective function

in the optimisation process. To do so, we compare the

results obtained on GTP-ED with two other optimisa-

tion problems.

The first problem is the Distance Transportation Prob-

lem for E-commerce Deliveries (DTP-ED). In this

problem, we want to minimise the total distance trav-

eled by the parcels subject to the same constraints as

for the GTP-ED. This problem can be seen as a simple

way to reduce the overall environmental cost by re-

ducing the number of kilometers traveled. The model

is given hereafter with D

so

representing the Haversine

distance (in km) between the stock location s and the

destination of the order o :

(DTP-ED) min F

D

=

∑

s∈S

∑

o∈O

D

so

∑

b∈B

y

bso

(7)

s.t. (2) − (6)

To compare the solutions of GTP-ED and DTP-ED, we

solve both problems and collect the results for the in-

stances solved to optimality after one hour, respec-

tively F

∗

G

, (x

∗

G

, y

∗

G

) and F

∗

D

, (x

∗

D

, y

∗

D

). After solving

DTP-ED we perform a post processing on y

∗

D

variables.

Indeed, the solver tends to select the largest boxes

even if smaller ones are sufficient. Thus, for each

pair (so) we keep the number of boxes assigned by

the solvers but perform an optimisation to select the

best ones.

Then, we compute:

• ∆G(DTP-ED) = F

G

(x

∗

D

, y

∗

D

) − F

∗

G

, the surplus of

environmental cost obtained with the optimal so-

lutions of DTP-ED

• ∆D(GTP-ED) = F

D

(x

∗

G

, y

∗

G

) − F

∗

D

, the additional

distance obtained with the optimal solutions of

GTP-ED

Table 2 compares the results obtained on the prob-

lems GTP-ED and DTP-ED for optimally solved in-

stances of data1. The first column (|O|) indicates the

size of the instance and the second column (#) the

number of instances optimally solved for both prob-

lems. The third column F

∗

G

shows the optimal envi-

ronmental cost when solving GTP-ED. The fourth col-

umn ∆G(DTP-ED) shows the surplus of environmental

cost for solutions of DTP-ED. Similarly, the fifth col-

umn, F

∗

D

, shows the optimal distance obtained while

solving DTP-ED and the sixth column, ∆D(GTP-ED),

indicates the surplus of distance induced by GTP-ED.

Table 2: Objective comparison between GTP-ED and

DTP-ED - data1.

F

G

(kg eqCO2) F

D

(1000km)

|O| # F

∗

G

∆G(DTP-ED) F

∗

D

∆D(GTP-ED)

10 10 27.3 +8.9 8.7 +9.7

20 10 46.9 +14.9 18.0 +25.1

30 10 67.9 +21.4 27.6 +36.0

40 10 99.5 +31.9 41.4 +39.1

50 9 110.2 +36.0 47.6 +50.1

60 10 136.6 +44.4 67.0 +69.6

70 8 122.9 +41.0 63.0 +61.6

80 6 101.6 +33.1 50.5 +49.4

90 6 108.1 +35.6 58.2 +53.7

100 4 80.9 +25.4 42.9 +42.7

Total 83 902.0 +292.6 436.9 +424.8

From this table, we can observe that using DTP-ED

to solve the 83 instances of data1 increases the en-

vironmental cost by 32% compared to using the

A Green Transportation Problem for e-Commerce Deliveries

283

GTP-ED. In the same way, this rise is about 28% for

data2. Consequently, the savings offered by GTP-ED

compared to a more basic model are significant and

highlight its relevance from an environmental point

of view. However, the environmental gains of the

GTP-ED are accompanied by a significant increase in

terms of logistics flows and kilometers traveled. In-

deed, the solutions of GTP-ED almost double the total

distance compared to the solutions of DTP-ED. This

can be explained by the measurement of the environ-

mental cost that does not only rely on transportation

costs, which themselves do not only depend on dis-

tance traveled but are driven by the volume of parcels

carried. Thus, our objective function proposed in the

GTP-ED seems to be relevant from an environmental

point of view.

Furthermore, the objective functions used opera-

tionally are most of the time monetary related. Thus,

our objective function should be evaluated from an

economic point of view. For this purpose, we intro-

duce a third optimisation problem called Economic

Transportation Problem for E-commerce Deliveries

(ETP-ED) whose aim is to minimise the economic

costs. As many carriers charge a fixed price per parcel

collected, the economic cost we consider is propor-

tional to the number of parcels shipped. In our case,

we assume that the collection price of each parcel is

set at 1C. The model of the ETP-ED is given here-

after, with M

so

= 0 if o is a Click and Collect order

whose pick-up location is s (no parcel collected from

the carrier), M

so

= 1 C otherwise:

(ETP-ED) min F

E

=

∑

s∈S

∑

o∈O

M

so

∑

b∈B

y

bso

(8)

s.t. (2) − (6)

As done previously, we solve GTP-ED and ETP-ED

to collect F

∗

G

, (x

∗

G

, y

∗

G

) and F

∗

E

, (x

∗

E

, y

∗

E

) Then, we per-

form the same post-processing on y

∗

E

as the one ex-

posed for y

∗

D

and then compute :

• ∆G(ETP-ED) = F

G

(x

∗

E

, y

∗

E

) − F

∗

G

, the surplus of

environmental cost obtained with the optimal so-

lutions of ETP-ED

• ∆E(GTP-ED) = F

E

(x

∗

G

, y

∗

G

) − F

∗

E

, the surplus of

economic cost obtained with the optimal solutions

of DTP-ED

The objective comparison between GTP-ED and

ETP-ED are given in Table 3 for data1. The first, sec-

ond and third columns are same as the ones of Ta-

ble 2. The fourth column shows, ∆G(ETP-ED), the

surplus of environmental cost obtained while solv-

ing the ETP-ED. The fifth column shows F

∗

E

the opti-

mal economic cost and the sixth column, ∆E(GTP-ED)

indicates the surplus of economic cost induced by

GTP-ED.

Table 3: Objective comparison between GTP-ED and

ETP-ED - data1.

F

G

(kgeqCO2) F

E

(C)

|O| # F

∗

G

∆G(ETP-ED) F

∗

E

∆E(GTP-ED)

10 10 27.3 +18.7 90.0 +126.0

20 10 46.9 +32.9 182.0 +213.0

30 10 67.9 +47.1 270.0 +315.0

40 10 99.5 +64.6 343.0 +428.0

50 9 110.2 +75.3 391.0 +487.0

60 10 136.6 +91.4 491.0 +619.0

70 8 122.9 +79.0 468.0 +544.0

80 6 101.6 +64.5 383.0 +444.0

90 6 108.1 +68.5 429.0 +438.0

100 4 80.9 +48.2 313.0 +353.0

Total 83 902.0 +590.3 3360.0 +3967.0

From the table, we can see that ETP-ED induces

a 65% surplus of environmental cost over the 83 in-

stances of data1. This surplus rises to 70% over the

43 instances of data2. Once again, the GTP-ED proves

its relevance from an environmental point of view. In

parallel, GTP-ED causes a significant economic cost

rise. We observe a 118% increase for data1 and a

68% increase for data2. As it could have been ex-

pected, our environmental and economic objectives

seem to be in opposition. If retailers want to operate

an eco-friendly order orchestration with the GTP-ED,

they would have to pay additional fees. Besides, by

favouring economic costs in a context where the pric-

ing depends only on the number of parcels shipped,

they renounce to reduce their environmental footprint.

However, the considered economic function F

E

is

only based on the number of collected parcels. By

integrating other parameters, such as fuel expenses or

volume to be carried, it may lead to different trade-

offs.

5 CONCLUSION

In this paper, we introduce the Green Transportation

Problem for E-commerce Deliveries which aims at

minimizing the environmental footprint of order or-

chestration. The resulting model is a general case of

the well-known Fixed Charge Transportation Problem

with an environmental objective function. We per-

form a few experiments to test the performances of

the GTP-ED and the relevance of its objective function.

We see that the solver struggles to solve to optimal-

ity instances above 60 orders in a reasonable amount

of time, whereas good quality solutions are provided

quickly. We highlight that the performances are im-

proved by decomposing the model into subsets of in-

dependent orders. Then, we show that our GTP-ED

is relevant from an environmental point of view com-

ICORES 2025 - 14th International Conference on Operations Research and Enterprise Systems

284

pared to a simpler orchestration strategy based on dis-

tance minimisation. However, in a context where

the pricing depends only on the number of parcels

shipped, the GTP-ED causes an increase of economic

costs that enforces retailers to favour either environ-

mental matters or economic ones.

Future works include additional experiments to

deeper analyse parameters influence. First, we expect

the stocks level and the number and types of boxes

to impact the performances and results. Secondly, the

GTP-ED uses a complex objective function with dif-

ferent terms and we will explore their interactions.

Lastly, it would be interesting to compare the results

of the GTP-ED with real world orchestration rules used

by retailers. It can highlight the environmental rel-

evance of our model but also reveal its deficiencies

from an operational point of view.

Finally, our model can be improved to gain in rel-

evance and scalability. To solve larger instances to

optimality, we aim to develop decomposition meth-

ods such as column generation. Moreover, as re-

tailers would probably prefer quick good solutions

rather than slow but optimal ones, using heuristics or

Lagrangian decomposition may be relevant. Lastly,

rather than opposing environment and economy, a

multi-objective optimisation should be performed to

provide a tool to retailers to make the best trade-off

between environmental and economic issues.

ACKNOWLEDGEMENTS

This work has been supported by OneStock and the

Responsible Retail Chair (Chaire, 2024).

REFERENCES

Acimovic, J. and Graves, S. C. (2015). Making better ful-

fillment decisions on the fly in an online retail envi-

ronment. Manufacturing & Service Operations Man-

agement, 17(1):34–51.

Balinski, M. L. (1961). Fixed-cost transportation problems.

Naval Research Logistics Quarterly, 8(1):41–54.

Chaire (2024). Chaire de formation et de recherche

retail responsable. https://sites.laas.fr/projects/

ChaireRetailResp/ [Accessed : 16-12-2024].

Cheref, A., Artigues, C., H

´

ebrard, E., Lopez, P., Charvillat,

V., R

´

egent, Y., and Ngueveu, S. U. (2018). Algorithme

d’approximation pour un probl

`

eme d’affectation

d’une commande multiproduit multifournisseur. In

12

`

eme Conf

´

erence Internationale de MOd

´

elisation,

Optimisation et SIMulation (MOSIM 2018), page 7p.

Colissimo (2023). Colissimo box – CO2 calculator.

CPV Associ

´

es, GSV Communication, and RDC Environ-

ment (2023). Commerce en ligne - impacts envi-

ronnmentaux de la logistique, des transports et des

d

´

eplacements :

´

etat des lieux, outil d’

´

evaluation et

pistes de progr

`

es. Report.

Flamand, T., Iori, M., and Haouari, M. (2023). The trans-

portation problem with packing constraints. Comput-

ers & Operations Research, 157:106278.

Haley, K. (1962). New methods in mathematical program-

ming—the solid transportation problem. Operations

research, 10(4):448–463.

Hitchcock, F. L. (1941). The distribution of a product from

several sources to numerous localities. Journal of

mathematics and physics, 20(1-4):224–230.

Jasin, S. and Sinha, A. (2015). An lp-based correlated

rounding scheme for multi-item ecommerce order ful-

fillment. Operations Research, 63(6):1336–1351.

Kacher, Y. and Singh, P. (2021). A comprehensive litera-

ture review on transportation problems. International

Journal of Applied and Computational Mathematics,

7:1–49.

Klose, A. (2008). Algorithms for solving the single-sink

fixed-charge transportation problem. Computers &

Operations Research, 35(6):2079–2092.

Lei, Y., Jasin, S., and Sinha, A. (2018). Joint dynamic

pricing and order fulfillment for e-commerce retail-

ers. Manufacturing & Service Operations Manage-

ment, 20(2):269–284.

Malack

´

y, P. and Madle

ˇ

n

´

ak, R. (2023). Transporta-

tion problems and their solutions: literature re-

view. Transportation Research Procedia, 74:323–

329. TRANSCOM 2023: 15th International Scientific

Conf. on Sustainable, Modern and Safe Transport.

Martello, S., Pisinger, D., and Vigo, D. (2000). The three-

dimensional bin packing problem. Operations re-

search, 48(2):256–267.

Matsui, T. and Scheifele, R. (2016). A linear time algorithm

for the unbalanced hitchcock transportation problem.

Networks, 67(2):170–182.

Midya, S., Roy, S. K., and Yu, V. F. (2021). Intuitionistic

fuzzy multi-stage multi-objective fixed-charge solid

transportation problem in a green supply chain. In-

ternational Journal of Machine Learning and Cyber-

netics, 12:699–717.

Mingozzi, A. and Roberti, R. (2018). An exact algorithm

for the fixed charge transportation problem based on

matching source and sink patterns. Transportation

Science, 52(2):229–238.

Roberti, R., Bartolini, E., and Mingozzi, A. (2015). The

fixed charge transportation problem: An exact algo-

rithm based on a new integer programming formula-

tion. Management Science, 61(6):1275–1291.

Shojaie, A. A. and Raoofpanah, H. (2018). Solving a two-

objective green transportation problem by using meta-

heuristic methods under uncertain fuzzy approach.

Journal of Intelligent & Fuzzy Systems, 34(1):1–10.

Xu, P. J., Allgor, R., and Graves, S. C. (2009). Benefits

of reevaluating real-time order fulfillment decisions.

Manufacturing & Service Operations Management,

11(2):340–355.

A Green Transportation Problem for e-Commerce Deliveries

285