Handling Drift in Industrial Defect Detection Through MMD-Based

Domain Adaptation

Xuban Barberena

a

, F

´

atima A. Saiz

b

and I

˜

nigo Barandiaran

c

Vicomtech Foundation, Basque Research and Technology Alliance (BRTA), 20009 Donostia, Spain

Keywords:

Quality Control, Deep Learning, Artificial Vision, Domain Adaptation, Model Drift, Defect Detection.

Abstract:

This study enhances industrial quality control by automating defect detection using artificial vision and deep

learning techniques. It addresses the challenge of model drift, where variations in input data distribution

affect performance. To tackle this, the paper proposes a simpler, practical approach to unsupervised Domain

Adaptation (UDA) for object detection, focusing on industrial applicability. A technique based on the Faster

R-CNN architecture and a Maximum Mean Discrepancy (MMD) regularization method for feature alignment

is proposed. The study aims to detect data drift using state-of-the-art methods and evaluate the proposed UDA

technique’s effectiveness in improving surface defect detection. Results show that statistical tests effectively

identify variations, enabling timely adaptations. The proposed UDA method achieved mean Average Precision

(mAP50) improvements of 3.1% and 6.1% under vibration and noise scenarios, respectively, and a significant

17.8% improvement for conditions with particles, advancing existing methods in the literature.

1 INTRODUCTION

Industrial quality control is crucial for ensuring prod-

ucts meet market standards, particularly in manu-

facturing where high production quality is essential

for competitiveness. Recently, artificial intelligence

(AI) and computer vision technologies have been

adopted to automate defect detection, with deep learn-

ing (DL) proving effective for identifying surface de-

fects (Lei

˜

nena et al., 2024).

However, significant challenges arise in dynamic

industrial environments that can affect the accuracy

and robustness of AI models. DL models rely on

inference data being drawn from the same distribu-

tion as the training data. In these settings, variations

in lighting, sensor noise, movement of components,

and other factors can substantially alter image qual-

ity. This phenomenon, known as model drift or data

drift, occurs when the distribution of inference data

deviates from that of the training data, leading to per-

formance degradation in DL models.

Traditional methods to address drift typically in-

volve retraining models with new, often unannotated

data, which is costly and time-consuming. To com-

bat model drift, Unsupervised Domain Adaptation

(UDA) techniques have emerged, enabling models to

a

https://orcid.org/0009-0004-9037-4192

b

https://orcid.org/0000-0001-6065-7029

c

https://orcid.org/0000-0002-8080-5807

adapt to new data distributions without the need for

extensive manual data annotation. This adaptabil-

ity is crucial in industrial settings, where maintaining

model performance over time ensures consistent qual-

ity control and reduces operational costs. This paper

specifically addresses object detection methods, cru-

cial for identifying and localizing defects in images,

with a focus on surface defects in metallic compo-

nents. By combining drift detection techniques with

UDA, we aim to not only identify when performance

degrades, but also enable the model to adapt and con-

tinue performing accurately under changing condi-

tions.

While UDA has been widely studied in other

fields, its application to object detection has been lim-

ited due to the complexity of this task. Object de-

tection not only requires classifying objects but also

accurately localizing them within the image, adding

an extra layer of difficulty compared to tasks like

image classification. Ensuring robust performance

across domains for both classification and localization

makes UDA for object detection particularly chal-

lenging. Current methods often become overly com-

plex, assuming that sophistication translates to better

performance.

However, recent studies suggest that simpler ap-

proaches can achieve performance comparable to

more complex, state-of-the-art techniques. One

promising method involves using regularizers to find

data representations that remain invariant across do-

420

Barberena, X., Saiz, F. A. and Barandiaran, I.

Handling Drift in Industrial Defect Detection Through MMD-Based Domain Adaptation.

DOI: 10.5220/0013170900003912

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 20th International Joint Conference on Computer Vision, Imaging and Computer Graphics Theory and Applications (VISIGRAPP 2025) - Volume 2: VISAPP, pages

420-429

ISBN: 978-989-758-728-3; ISSN: 2184-4321

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

mains (Tzeng et al., 2014). Specifically, the Max-

imum Mean Discrepancy (MMD) (Gretton et al.,

2012) loss has been explored to minimize feature dis-

tribution distances during training, enhancing align-

ment and robustness against drift. Despite its appli-

cation in various contexts, MMD loss has not been

extensively utilized in UDA for object detection, par-

ticularly within the Faster R-CNN (Ren et al., 2015)

architecture.

This paper proposes implementing this method

as a simpler alternative to complex techniques, em-

phasizing practical applicability in industrial environ-

ments. This study aims to achieve two main objec-

tives: detecting data drift using state-of-the-art meth-

ods and evaluating the effectiveness of the proposed

UDA technique to enhance surface defect detection

in industrial environments. The simplicity and practi-

cality of this approach make it particularly suitable for

real-world industrial applications, where maintaining

performance without complex system redesigns is a

priority.

To conclude, the main contributions of this work

are:

• A comprehensive review of the state of the art in

image drift detection has been conducted, with

several approaches from different works imple-

mented. This enabled a comparative analysis of

these methods, specifically focused on a real in-

dustrial use case.

• We propose a simpler yet effective approach to en-

hance UDA methods for object detection in indus-

trial environments by minimizing the feature dis-

tribution discrepancy between source and target

domains. This method improves the model’s gen-

eralization without requiring complex redesigns.

A regularizer based on Maximum Mean Discrep-

ancy (MMD) is implemented to align feature dis-

tributions.

• Proposed method has been compared with, and

shown to outperform, one of the leading state-of-

the-art approaches.

• Given the difficulty in obtaining a database con-

taining industrial images with drift, a simulated

dataset was created to reflect various scenarios

that could arise in an industrial environment.

2 RELATED WORK

2.1 Object Detection

Object detection is a computer vision field focused

on identifying and localizing specific objects within

images or videos. This involves two primary ob-

jectives: classifying the presence of objects and ac-

curately determining their locations, typically repre-

sented by bounding boxes. Early methods relied on

handcrafted features like Histograms of Oriented Gra-

dients (HOG) (Dalal and Triggs, 2005) and Haar-

like features (Lienhart and Maydt, 2002), often com-

bined with classifiers such as Support Vector Ma-

chines (SVM) (Malisiewicz et al., 2011) or techniques

like Sliding Windows (Sudowe and Leibe, 2011).

However, these methods struggled with com-

plex patterns and variability in real-world images.

The introduction of Convolutional Neural Networks

(CNNs) revolutionized object detection by automati-

cally learning hierarchical features from raw images,

eliminating the need for handcrafted features and sig-

nificantly improving detection accuracy and robust-

ness. While CNNs excelled in classification tasks,

the R-CNN (Region-based Convolutional Neural Net-

works) (Girshick et al., 2014) architecture marked a

significant advancement by introducing a two-stage

detection method: generating region proposals (ROIs)

in the first stage and classifying them with a CNN in

the second. This approach evolved into more sophisti-

cated networks like Faster R-CNN (Ren et al., 2015),

which integrates region proposal networks (RPNs)

for end-to-end detection, achieving state-of-the-art re-

sults.

In contrast, single-stage detection methods

streamline the process by integrating detection and

localization into one step, improving processing

efficiency. Networks such as SSD (Single Shot

MultiBox Detector) (Liu et al., 2016) and YOLO

(You Only Look Once) (Redmon et al., 2016) divide

the input image into a grid of cells, predicting multi-

ple bounding boxes and their associated classification

probabilities simultaneously.

2.2 Model Drift

Traditional approaches relied on statistical tests, such

as the Kolmogorov-Smirnov test (Massey Jr, 1951)

and the Chi-square test (Pearson, 1900), which com-

pare distributions between training and new data.

While these statistical tests are still popular for de-

tecting data drift, they struggle with high-dimensional

data due to the curse of dimensionality, which makes

it harder to detect subtle shifts in distributions (Hastie

et al., 2009). As AI models, particularly in com-

puter vision, often work with high-dimensional fea-

tures, newer methods are required to effectively iden-

tify drift in such data.

Recent advances like Maximum Mean Discrep-

ancy (MMD) (Gretton et al., 2012) provide powerful

Handling Drift in Industrial Defect Detection Through MMD-Based Domain Adaptation

421

tools for comparing distributions without requiring la-

belled data, making them ideal for unsupervised drift

detection in industrial applications. Similarly, adver-

sarial approaches (Rabanser et al., 2019), where a do-

main classifier discriminates between source and tar-

get data, offer a flexible method for identifying and

addressing drift in high-dimensional feature spaces.

Additionally, recent methods such as (Greco et al.,

2024) contribute to improving drift detection, while

the survey by (Hinder et al., 2023) provides a com-

prehensive review of the state-of-the-art approaches

in this field.

2.3 Unsupervised Domain Adaptation

for Object Detection

UDA relies on fully labeled instances in the source

domain while having no labels for the target domain.

This approach is particularly relevant in real-world

scenarios where new data often lacks annotations.

UDA has been widely researched for tasks like clas-

sification (Saito et al., 2018) and semantic segmenta-

tion (Toldo et al., 2020). Unlike image classification,

which only requires assigning a label to an entire im-

age, object detection involves both classification and

localization, making the task more complex. Domain

adaptation for object detection must ensure that both

the feature extraction and the bounding box predic-

tion generalize well across domains, adding another

layer of difficulty compared to tasks like image clas-

sification or segmentation.

The survey (Oza et al., 2023) categorizes exist-

ing UDA for object detection methods into different

types. Adversarial feature learning aligns learned fea-

tures across domains by training two competing mod-

els: a generator (feature extractor) and a discrimina-

tor (domain classifier). The generator minimizes the

task loss (e.g., object detection) while trying to con-

fuse the discriminator, which is trained to differentiate

domains. By doing so, the generator learns domain-

invariant features. DA-Faster (Chen et al., 2018) was

one of the first to apply this adversarial approach

proposed in (Ganin and Lempitsky, 2015) within the

Faster R-CNN framework, pioneering UDA for ob-

ject detection and influencing many subsequent works

(Chen et al., 2021).

On the other hand, mean-teacher methods (Cai

et al., 2019) use a teacher-student model to leverage

labeled source data and unlabeled target data, with the

teacher providing pseudo-labels and the student im-

proving performance by aligning with the teacher’s

predictions. Image-to-Image Translation methods

have also been explored aiming to translate images

from one domain to another and create intermediate

images between domains to reduce the gap. For ex-

ample, (Arruda et al., 2019) employs a strategy based

on this to adapt the model from detecting daytime

scenes to nighttime scenes. Pseudo-label based self-

training methods are also popular as they generate

pseudo-labels for unlabeled target data using model

predictions and then retrain the model with both la-

beled source data and these pseudo-labels to boost

performance (Kim et al., 2019).

3 MATERIALS AND METHODS

In this section, the materials and methods used in this

study are detailed. First, the dataset employed for the

experimentation is presented. Next, the process fol-

lowed for drift detection is described. Finally, the pro-

posed domain adaptation architecture is explained in

detail.

3.1 Datasets

In the manufacturing industry, obtaining high-quality

data is a persistent challenge due to strict privacy

and confidentiality around production processes. This

limitation restricts access to diverse datasets and com-

plicates the capture of variations or drift, which are

essential for developing robust models.

Collecting drift data in highly optimized manufac-

turing environments is particularly difficult, as pro-

duction plants aim to minimize variations and main-

tain strict control over operational variables. Conse-

quently, while some types of drift may occur, they are

infrequent and inadequately documented for creating

comprehensive datasets.

Variations in manufacturing can arise from several

factors. Changes in lighting due to fluctuations in nat-

ural or artificial sources can alter product appearance.

Sensor failures or machine vibrations may introduce

noise into images, while the movement of parts or

cameras can lead to blurriness. Dust and dirt particles

in the environment can obstruct visibility and distort

image characteristics.

Given the challenges in obtaining real data that

captures these variations, synthetic drift conditions

have been simulated using the original data. To sim-

ulate drift conditions, we employed traditional data

augmentation techniques, introducing variations such

as changes in brightness, particles, noise, and vibra-

tion. These augmentations were carefully chosen to

reflect real-world industrial scenarios. Ensuring that

the synthetic data mimics true industrial drift con-

ditions is essential for the robustness of the domain

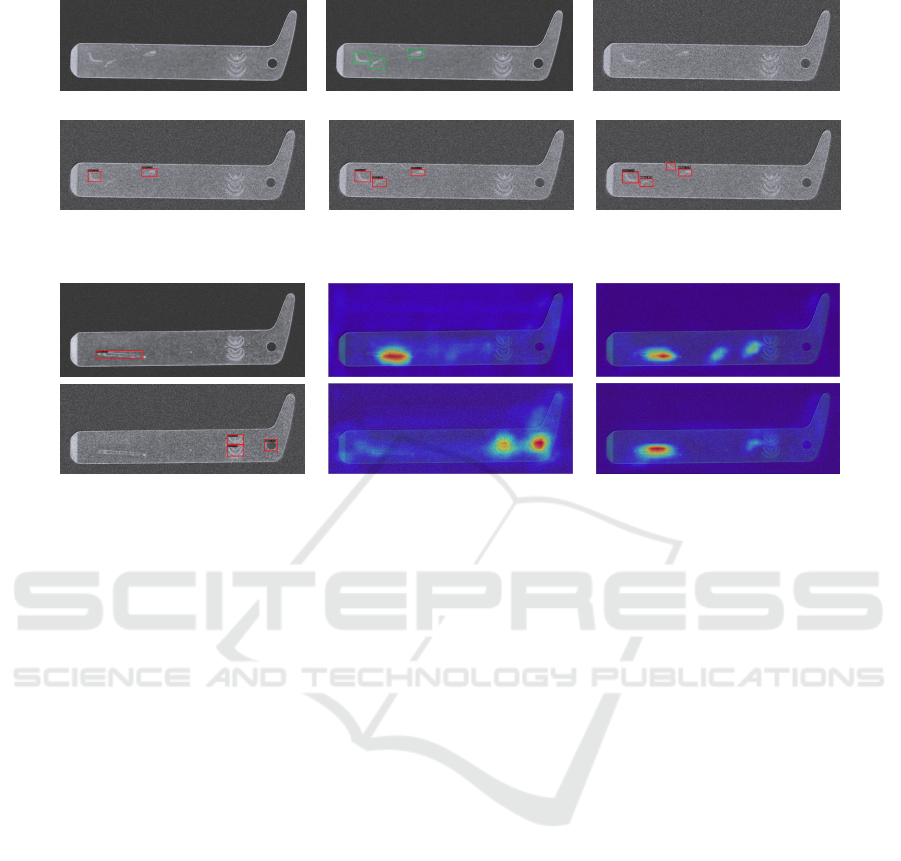

adaptation method. Figure 1 shows a sample of the

VISAPP 2025 - 20th International Conference on Computer Vision Theory and Applications

422

different sets that were simulated from the original

images.

(a) Original

(b) Brightness (c) Vibration

(d) Noise (e) Particles

Figure 1: Sample of synthetic data for different scenarios

based on an original image.

The original dataset comprises 625 images anno-

tated by domain experts, supplemented by an addi-

tional 625 unannotated images to form specific sets

for each drift scenario. As this study focuses on an

unsupervised problem, labels for evaluating domain

adaptation methods are not available. To facilitate a

fair assessment, the original test images were used to

create the drift test sets, ensuring consistent annota-

tions across all sets. This approach prevents potential

bias from unbalanced test datasets. The final dataset

is composed of 200 images, half of which contain

surface defects. This balance between defective and

non-defective images ensures that the model can ef-

fectively learn to differentiate between the two classes

under varying drift conditions, reducing the risk of

class imbalance affecting performance. Table 1 shows

the described distribution.

Table 1: Datasets distribution. All drift sets contain the

same number of samples.

Set Original

Images

Original

Labels

Drift

Images

Drift

Labels

Train 625 625 625 0

Test 200 200 200 200

3.2 Drift Detectors

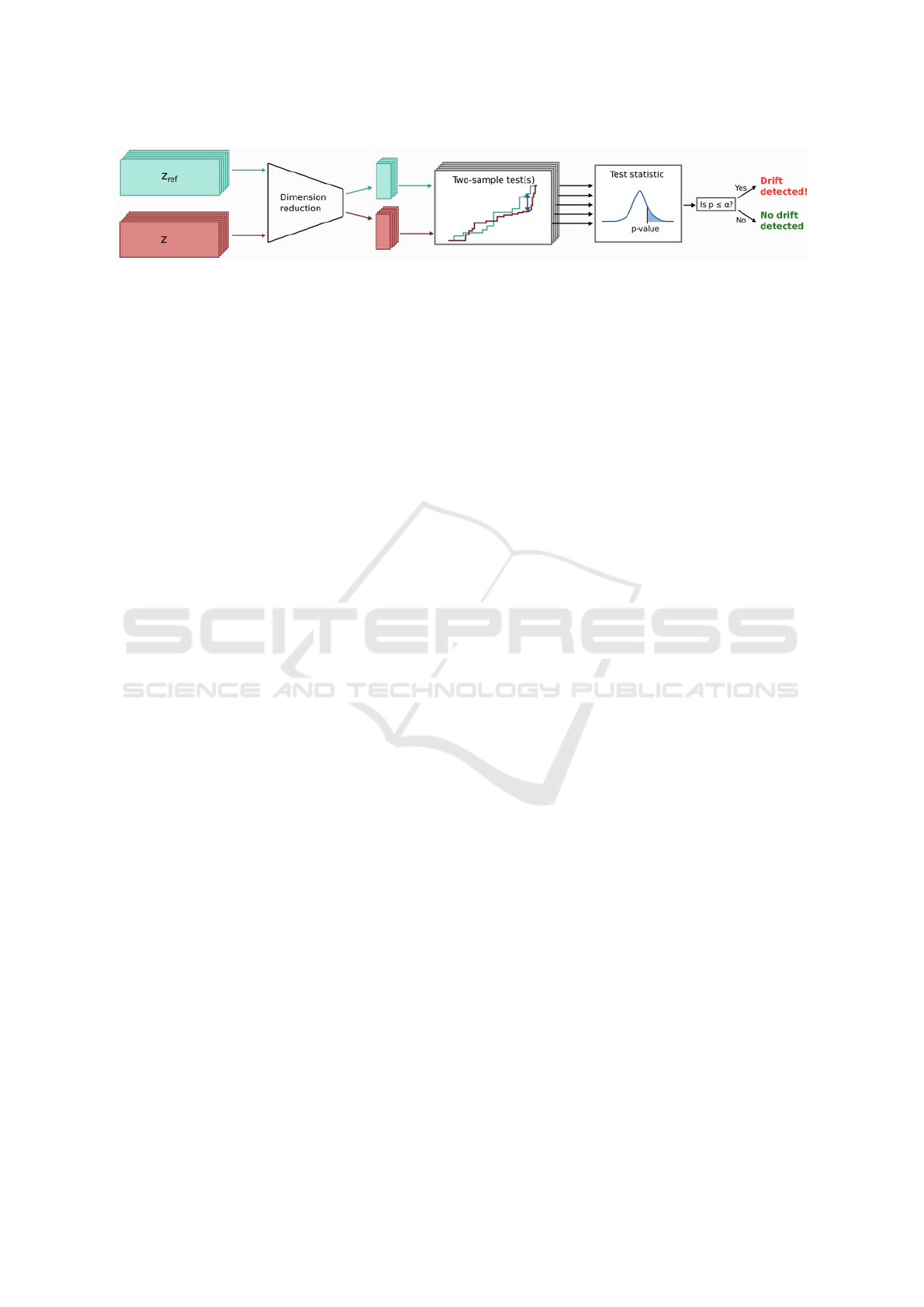

Figure 2 illustrates a common pipeline for detecting

drift in high-dimensional data, proposed in (Rabanser

et al., 2019). In this process, both the original ref-

erence data Z

re f

and the test data Z are subjected to

the same dimensionality reduction. Afterward, a two-

sample statistical test is applied to determine whether

drift is present.

3.2.1 Dimension Reduction

Given an input dataset X ∈ R

N×d

, where N is the num-

ber of observations and d is the number of dimen-

sions, the goal is to reduce the dimensionality from

d to K, where K ≪ d. This involves transforming the

original dataset X into a new dataset

ˆ

X with a reduced

dimension, preserving the essential structure and fea-

tures while simplifying analysis. There exist several

approaches to dimensionality reduction. One com-

mon type is linear projections such a PCA (Principal

Component Analysis), which involve applying a pro-

jection or transformation matrix R to the dataset X ,

such that

ˆ

X = XR. This linear transformation reposi-

tions data points into a lower-dimensional space using

linear combinations of the original variables, aiming

to preserve the structure and relationships of the origi-

nal data. Another approach is to use nonlinear projec-

tions such as t-SNE (t-Distributed Stochastic Neigh-

bor Embedding).

However, in recent years, autoencoders have been

used for image dimensionality reduction (Wang et al.,

2016). An autoencoder consists of an encoding func-

tion φ : X 7→ H that maps the input data to a lower-

dimensional latent space H , and a decoding function

ψ : H 7→ X that attempts to reconstruct the original

data from this latent representation. Training involves

learning φ and ψ to minimize reconstruction error.

However, (Rabanser et al., 2019) suggests that even

randomly initialized (untrained) autoencoders can be

used for dimensionality reduction with the goal of

detecting drift. Autoencoders, even when not fully

trained, have shown promise for dimensionality re-

duction in high-dimensional datasets like images. The

advantage of using an untrained autoencoder is that it

avoids overfitting to specific features in the data, pro-

viding a more general reduction technique that can ef-

fectively support drift detection across different con-

ditions. In this work, the approach of using an un-

trained autoencoder is employed to reduce the dimen-

sionality of the data as part of the preprocessing for

drift detection techniques.

3.2.2 Two-Sample Tests

Following the dimensionality reduction process using

untrained autoencoders, a two-sample test is applied,

which is a type of statistical test that compares two

independent datasets to determine whether they come

from the same distribution or if there are significant

differences between them. The null hypothesis H

0

states that the observed and expected (or reference)

data come from the same distribution, while the al-

ternative hypothesis H

1

asserts that they do not. If

the p-value associated with the statistical test is suffi-

Handling Drift in Industrial Defect Detection Through MMD-Based Domain Adaptation

423

Figure 2: Pipeline for the drift detection process on images.

ciently small (typically less than a predefined signifi-

cance level, such as 0.05), the null hypothesis can be

rejected. This suggests that there is enough evidence

to conclude that the observed and expected data do

not come from the same distribution, indicating a drift

in the data.

There are various tests available, but one of the

most commonly used in the literature is the non-

parametric univariate Kolmogorov-Smirnov (KS) test

(Massey Jr, 1951). This test compares the empiri-

cal cumulative distribution functions (ECDFs) of both

samples and calculates the maximum distance be-

tween them. The KS statistic is defined as:

KS = max

x

|F

s

(x) − F

t

(x)| (1)

where F

s

and F

t

are the ECDFs of the source and tar-

get data, respectively.

Another widely recognized test is Maximum

Mean Discrepancy (MMD) (Gretton et al., 2012),

a statistical measure used to assess the difference

between two probability distributions by compar-

ing their mean embeddings in a reproducing kernel

Hilbert space (RKHS). Specifically, the MMD is de-

fined as:

MMD

2

(P, Q) = E

P

[k(x, x)] − 2E

P,Q

[k(x, y)] + E

Q

[k(y, y)]

(2)

where P and Q are the two distributions being com-

pared, x and y are random samples drawn from dis-

tributions P and Q, respectively, and k (x, y) is a ker-

nel function that measures the similarity between the

transformed features of the samples. The expecta-

tion operator E computes the average values of the

kernel functions. A smaller MMD value indicates

greater similarity between the two distributions, while

a larger value suggests a significant difference.

3.2.3 Learned Drift Detectors

The option of reducing dimensionality and applying

statistical tests can be suitable in many cases, but in

more complex situations, this approach may be in-

sufficient. A more advanced alternative is the use

of learned drift detectors. Unlike traditional methods

that rely on statistical tests or direct comparison of

features between two datasets, learned drift detectors

use machine learning techniques to identify patterns

and relationships in the data, detecting significant de-

viations in these patterns.

The article (Lopez-Paz and Oquab, 2016) pro-

poses a classifier for two-sample tests that estimates

the accuracy of a binary classifier using the refer-

ence and test datasets. If the accuracy is significantly

higher than a predefined p-value, the null hypothesis

H

0

is not rejected.

Another relevant method is the Learned Kernel

(Liu et al., 2020), which detects drift adaptively in

data streams. This approach learns a weighted kernel

that captures differences between two data distribu-

tions by measuring the discrepancy between samples.

It is an extension of the Maximum Mean Discrepancy

(MMD), where the kernel is learned. The function of

the learnable kernel is defined as follows:

k(z, z

re f

) = (1 − ε)k

a

(Φ(z), Φ(z

re f

)) + εk

b

(z, z

re f

),

(3)

where Φ is a learnable projection, k

a

and k

b

are

kernel characteristics, and ε > 0 is a small constant.

3.3 Faster R-CNN

Faster R-CNN is a state-of-the-art object detection

framework that improves upon its predecessors by in-

tegrating a Region Proposal Network (RPN) to gen-

erate high-quality region proposals. The architecture

consists of two main components: the RPN, which is

responsible for proposing candidate object bounding

boxes, and a Fast R-CNN detector that classifies these

proposals and refines their coordinates. By sharing

convolutional features between the RPN and the de-

tection network, Faster R-CNN achieves significant

improvements in both speed and accuracy, making it

well-suited for real-time applications.

The loss function used in Faster R-CNN com-

prises two main components: the classification loss

and the bounding box regression loss, both calculated

in the RPN and detection network components. The

total loss L is defined as follows:

L

Faster R-CNN

= L

RPN

cls

+ L

RPN

reg

+ L

Det

cls

+ L

Det

reg

, (4)

where L

cls

is the classification loss, typically com-

puted using softmax cross-entropy for the predicted

VISAPP 2025 - 20th International Conference on Computer Vision Theory and Applications

424

class labels, and L

reg

is the bounding box regression

loss, which measures the accuracy of the predicted

bounding box coordinates. The bounding box regres-

sion loss is often formulated as a smooth L1 loss.

Faster R-CNN serves as the backbone architec-

ture in the majority of works that incorporate domain

adaptation modules for object detection, due to its

flexible and modular design, which facilitates the in-

tegration of adaptation techniques aimed at improving

performance across different domains.

3.4 MMD-Based Domain Adaptation

for Improved Object Detection

Under Drift in Industrial

Applications

The MMD regularizer is used to align the learned fea-

tures so that they are as similar as possible between

the source and target domains. The idea is that if the

model performs well on the original data, ensuring

that the feature distributions of the last convolutional

layer are aligned will allow the model to transfer its

knowledge to the new domain, making it domain-

invariant. This strategy operates on the premise that

minimizing the discrepancy between feature distri-

butions across domains enhances the model’s ability

to generalize in diverse conditions without requiring

complex redesigns, thereby facilitating a simpler im-

plementation in industrial environments.

The MMD regularizer adds a penalty to the loss

function objective to reduce model complexity and

improve its generalization ability. This is achieved by

imposing additional constraints during training, en-

couraging the model to learn more robust and general-

izable representations, while minimizing the discrep-

ancy between the feature distributions of the source

and target domains.

The loss computed in the regularizer module is

then added to the total loss of Faster R-CNN, which

is calculated based on the original images:

L

tot

= L

Faster R-CNN

(X

s

, y) + λM MD

2

(X

s

, X

t

), (5)

where L

Faster R-CNN

(X

s

, y) represents the total loss

of the Faster R-CNN architecture on the source la-

beled data (X

s

) and the ground truth labels (y).

MMD

2

(X

s

, X

t

) denotes the distance between the

source data (X

s

) and the target data (X

t

). Finally, λ

is a new hyperparameter that controls the intensity of

the domain confusion.

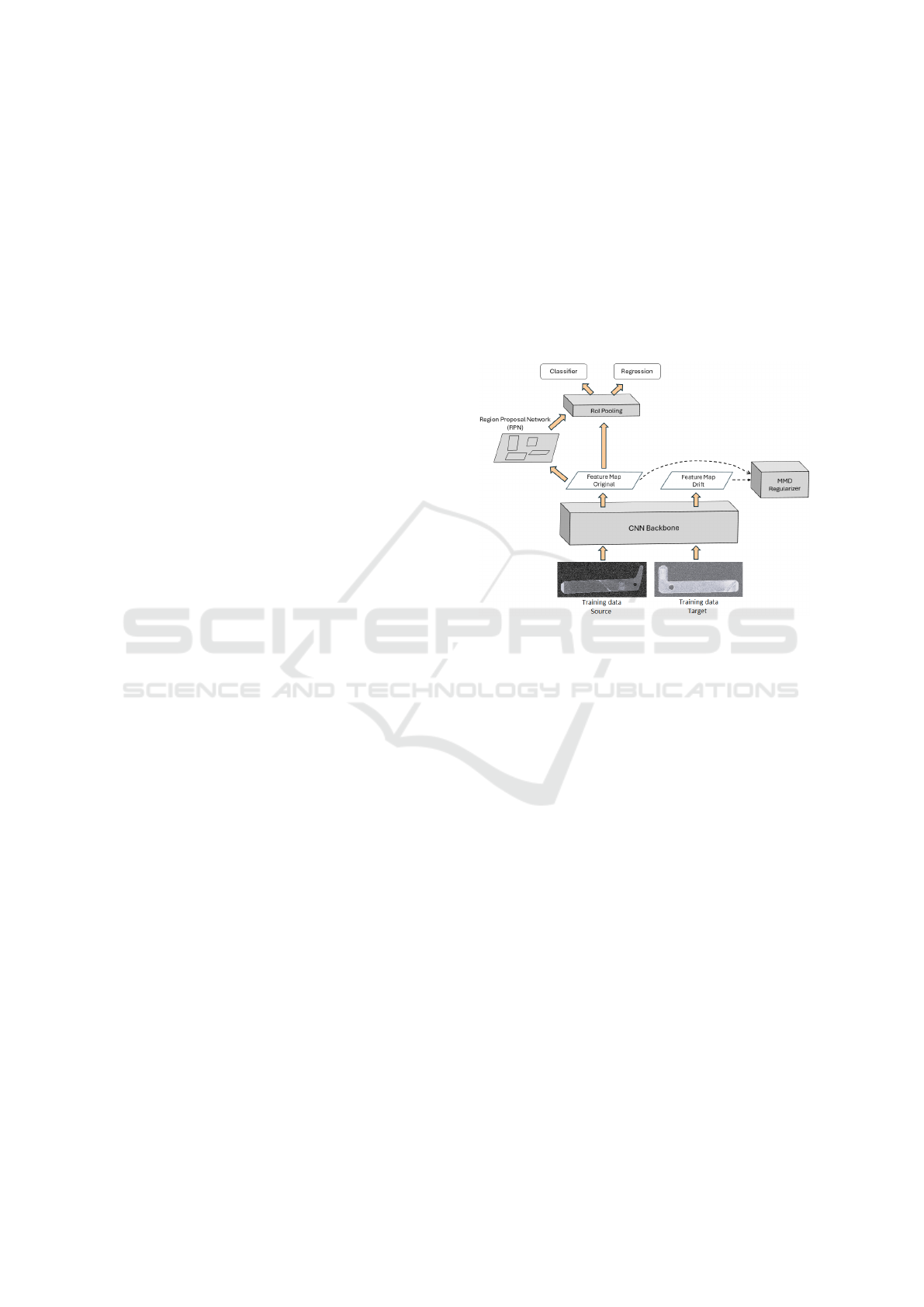

This process is illustrated in Figure 3. The dia-

gram represents the proposed method and highlights

the implementation of the regularizer in the last con-

volutional layer of the backbone, as these features are

the most abstract and representative of the content.

During training, for each mini-batch,

MMD

2

(Xs, Xt) loss is computed between the

feature maps of the last convolutional layer for X

s

and X

t

, while the L

Faster R-CNN

(X

s

, y) loss is computed

only on the labeled source data X

s

Both losses are

then combined using the hyperparameter λ, which

balances the supervised learning and domain align-

ment. The network weights are then updated based

on the total loss using the SGD optimizer.

Figure 3: Proposed Faster R-CNN architecture with MMD

regulizer.

4 RESULTS

This section details the experiments conducted to

evaluate state-of-the-art models for drift detection in

images and to compare the performance of the pro-

posed methods against the DA-Faster architecture,

which is a leading approach in object detection. The

experiments aim to assess how well these methods

can detect drift and enhance model performance in

various scenarios. Furthermore, visualization tech-

niques will be introduced to provide deeper insights

into the results and to illustrate the impact of the pro-

posed methods on the overall detection process.

4.1 Drift Detection

In this study, we compared four drift detection

methods: the Kolmogorov-Smirnov test, MMD, a

classifier-based detector, and the Learned Kernel

method. Each method has different strengths: statisti-

cal tests like KS are simple and efficient, while meth-

ods like the Learned Kernel offer more advanced de-

tection capabilities in high-dimensional and evolving

data streams, making them more suitable for complex

Handling Drift in Industrial Defect Detection Through MMD-Based Domain Adaptation

425

industrial applications.

The input image dimension is 128×320, and the

dimensionality reduction is performed using an un-

trained autoencoder or feature extractor consisting of

three convolutional layers with 64, 128, and 512 fil-

ters, respectively, each using a kernel size of 4×4, a

stride of 2, and ReLU activation. The output of the

convolutional layers is flattened and passed through a

dense layer that reduces the representation to a single

feature. This compact representation is specifically

designed to enable the application of two-sample test

methods for drift detection.

Table 2 presents the results for each drift detection

method across the generated datasets. It also high-

lights the lowest execution times for each dataset, in-

dicating the fastest method.

Table 2: Results for each detector of drift in the different

sets.

Original Brightness Vibration Noise Particles

KS

p-value 0.45 0.03 0.03 0.04 0.03

Drift? No Yes Yes Yes Yes

Time 1.791 1.808 1.804 1.874 1.817

MMD

p-value 0.57 0.01 0.04 0.03 0.04

Drift? No Yes Yes Yes Yes

Time 2.189 2.204 2.133 2.135 2.153

Classifier

p-value 0.81 0.00 0.01 0.01 0.01

Drift? No Yes Yes Yes Yes

Time 15.891 15.667 15.642 15.576 15.856

Learned Kernel

p-value 0.89 0.00 0.01 0.00 0.01

Drift? No Yes Yes Yes Yes

Time 1.712 1.604 1.571 1.507 1.740

A lower p-value indicates stronger evidence

against the null hypothesis that the datasets come

from the same distribution. Therefore, in terms

of drift detection effectiveness, the Learned Ker-

nel method consistently outperformed all other tech-

niques across the datasets, achieving the lowest p-

values. This demonstrates its capacity to adapt to drift

conditions effectively, making it the most reliable op-

tion for pseudo real-time industrial applications. Ad-

ditionally, the runtime of each method was evaluated,

confirming that all are generally suitable for produc-

tion requirements, except for the classifier, which re-

quires more time to process the data.

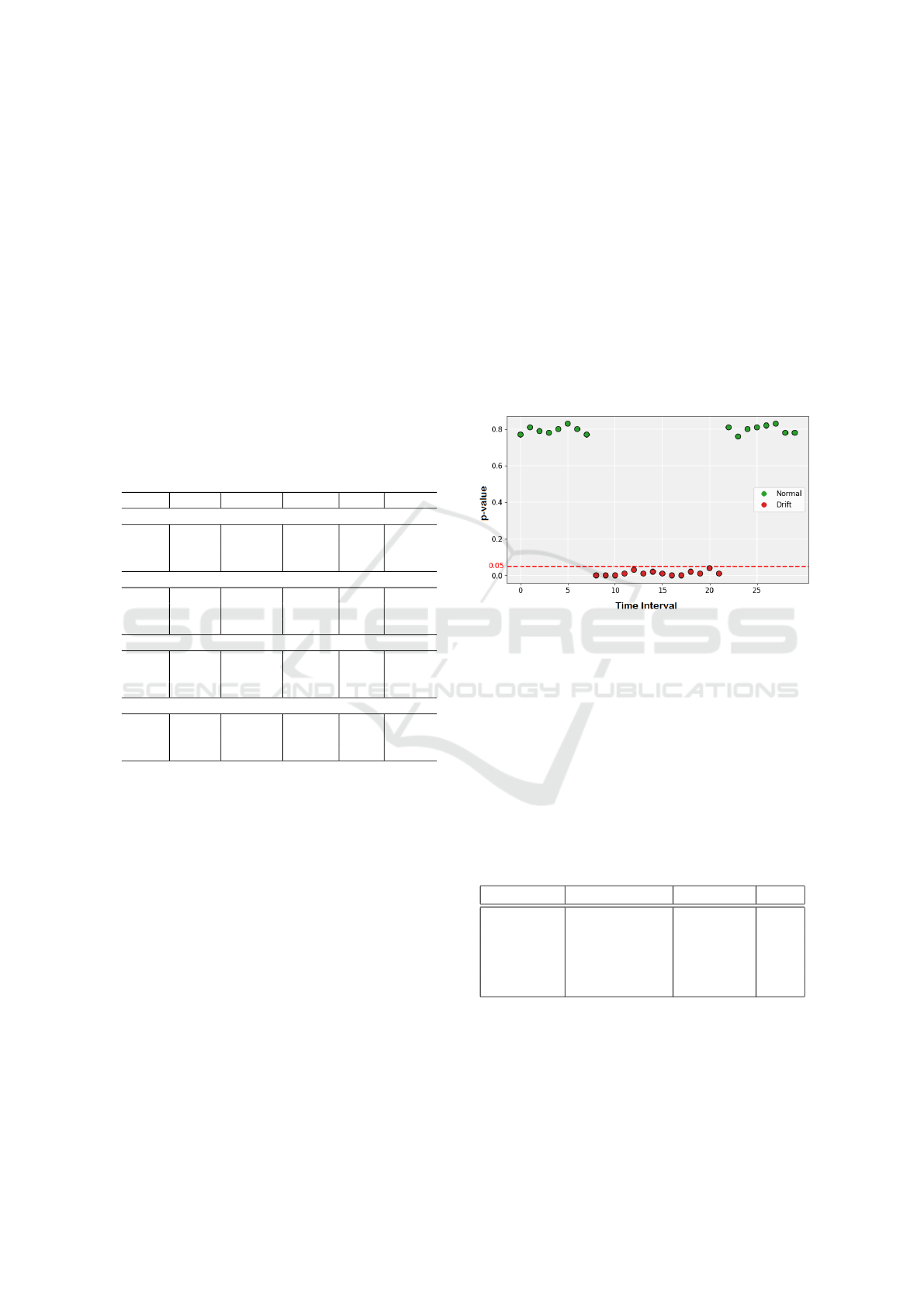

Additionally, the robustness of detections was

evaluated in pseudo-real-time by processing images

as small data streams, typical in dynamic industrial

scenarios. The evaluation of drift detection in pseudo-

real time, illustrated in Figure 4, is particularly cru-

cial in industrial settings where timely identification

of changes can prevent defects and maintain product

quality.

In the figure, each point represents a sample from

the data stream, with green points indicating origi-

nal samples that are consistent with the training data

and red points representing samples that exhibit drift.

The horizontal red line marks the p-value threshold

for detecting drift. In this case, the model used is the

Learned Kernel, which effectively identifies changes

by ensuring that the green points remain above the

line, indicating that there is no drift. Conversely, the

red points fall below the threshold, demonstrating the

model’s ability to successfully detect deviations in

pseudo-real-time.

Figure 4: Drift detection in pseudo-real time using the

Learned Kernel method in data streams. The green points

represent original samples and red points indicates samples

with drift.

4.2 Domain Adaptation

A specific model was trained for each drift scenario

using the same configuration and hyperparameters.

Table 3 presents the mAP50 metric for our model

and the state-of-the-art DA-Faster model across each

dataset, along with initial results from the original

Faster R-CNN model for reference.

Table 3: mAP50 of each model in the different test sets.

Test Set Faster R-CNN DA-Faster Ours

Original 84.2 - -

Brightness 81.2 79.8 81.7

Vibration 76.6 76.0 79.7

Noise 74.1 79.0 80.2

Particles 45.6 42.1 63.4

The initial model shows strong performance on

the original dataset, achieving 84.2% in the mAP50

metric. However, in the various drift scenarios, its

performance is significantly affected. When adapting

with DA-Faster, an improvement is only observed in

the noisy scenario, with a +4.9% increase compared

VISAPP 2025 - 20th International Conference on Computer Vision Theory and Applications

426

to the initial model.

In contrast, our proposed method consistently im-

proved the mAP50 metric across all drift scenarios.

Notably, it achieved enhancements of +6.1% in noisy

conditions and +17.8% in the presence of particles,

showcasing its ability to adapt effectively where DA-

Faster struggled, particularly in challenging environ-

ments.

Figure 6 shows examples of the detection results

before and after applying the proposed adaptation

method.

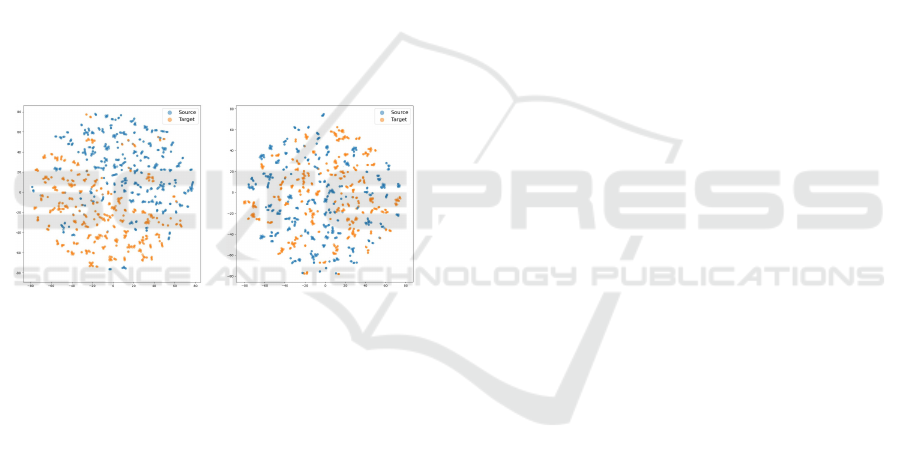

To further understand the effects of our domain

adaptation approach, we employed visualization tech-

niques such as t-SNE and Grad-CAM. The t-SNE vi-

sualizations (Figure 5) indicate that successful adap-

tation leads to more aligned features, reflecting the

model’s ability to generalize across domains. Addi-

tionally, Grad-CAM visualizations (Figure 7) illus-

trate how the model’s focus shifts correctly to relevant

areas after adaptation, enhancing its detection capa-

bilities in the presence of noise.

Initial Model Our Adapted Model

Figure 5: t-SNE on the features of the last convolutional

layer.

On the other hand, Grad-CAM (Gradient-

weighted Class Activation Mapping) was used to gen-

erate heatmaps that highlight the most important re-

gions in an image for the model’s predictions. Unlike

t-SNE, which offers a global feature distribution view,

Grad-CAM provides a localized interpretation of how

specific regions influence the network’s decision.

Figure 7 illustrates a component example where

the original model correctly focuses on defects. How-

ever, with added noise, the focus shifts incorrectly.

After adaptation, the model successfully refocuses on

the relevant areas for the new domain.

5 CONCLUSIONS

This study aimed to detect data drift using state-of-

the-art methods and evaluate the viability of UDA

for object detection techniques, including a proposed

MMD-based regularization method for the Faster R-

CNN architecture, for industrial deployment. The

proposed approach focuses on improving the model’s

generalization ability across varying conditions with-

out requiring complex redesigns or deep expertise in

advanced methods.

The results show that statistical tests were effec-

tive in detecting drift in images simulating industrial

conditions, making them suitable for production envi-

ronments by enabling timely adaptation. In terms of

DA, the proposed method outperformed DA-Faster in

scenarios with noise, vibration and particles, achiev-

ing a mAP50 improvement of 3.1%, 6.1% and 17.8%,

respectively. In contrast, DA-Faster only showed

marginal improvements and struggled to match per-

formance in other scenarios.

Controlling drift is crucial in industrial settings.

While effective detection methods exist, UDA for ob-

ject detection remains complex. Current UDA meth-

ods, though promising, are not always sufficient for

ensuring optimal performance across all industrial

scenarios. While the methods used here have shown

positive results, challenges may arise in real-world

applications, especially when dealing with more sub-

tle forms of drift, such as gradual changes in sensor

calibration or material properties. In such cases, the

methods employed may not perform as effectively,

and further adaptation or refinement could be neces-

sary to meet production-level requirements.

Moving forward, it would be beneficial to test the

proposed approach on public datasets. However, there

are limited publicly available datasets featuring in-

dustrial images with drift for UDA methods. Ad-

ditionally, future work could explore more complex

and diverse variations in datasets to better evaluate

generalization, investigate the application of the pro-

posed regularizer to other detection networks to as-

sess its generalization capacity, and conduct compar-

ative studies of domain adaptation techniques applied

to the same problem to provide broader insights.

ACKNOWLEDGEMENTS

This research has been supported by the Elkartek Pro-

gramme, Basque Government (Spain) (SMART-EYE,

KK-2023/00021 and BEREZIA, (KK-2023/00012).

Handling Drift in Industrial Defect Detection Through MMD-Based Domain Adaptation

427

Original Image Label Image with noise

Original Model Prediction Our Adapted Model Prediction DA-Faster Prediction

Figure 6: Example of the predictions made by different models on a component with noise.

Original Model Prediction Grad-CAM Original Model Grad-CAM Our Adapted Model

Figure 7: Example of Grad-CAM applied to an image affected by noise. The first row shows the original image, while the

second row displays the same image with added noise.

REFERENCES

Arruda, V. F., Paixao, T. M., Berriel, R. F., De Souza,

A. F., Badue, C., Sebe, N., and Oliveira-Santos, T.

(2019). Cross-domain car detection using unsuper-

vised image-to-image translation: From day to night.

In 2019 International Joint Conference on Neural Net-

works (IJCNN), pages 1–8. IEEE.

Cai, Q., Pan, Y., Ngo, C.-W., Tian, X., Duan, L., and Yao,

T. (2019). Exploring object relation in mean teacher

for cross-domain detection. In Proceedings of the

IEEE/CVF Conference on Computer Vision and Pat-

tern Recognition, pages 11457–11466.

Chen, Y., Li, W., Sakaridis, C., Dai, D., and Van Gool, L.

(2018). Domain adaptive faster r-cnn for object de-

tection in the wild. In Proceedings of the IEEE con-

ference on computer vision and pattern recognition,

pages 3339–3348.

Chen, Y., Wang, H., Li, W., Sakaridis, C., Dai, D., and

Van Gool, L. (2021). Scale-aware domain adaptive

faster r-cnn. International Journal of Computer Vi-

sion, 129(7):2223–2243.

Dalal, N. and Triggs, B. (2005). Histograms of oriented

gradients for human detection. In 2005 IEEE com-

puter society conference on computer vision and pat-

tern recognition (CVPR’05), volume 1, pages 886–

893. Ieee.

Ganin, Y. and Lempitsky, V. (2015). Unsupervised do-

main adaptation by backpropagation. In International

conference on machine learning, pages 1180–1189.

PMLR.

Girshick, R., Donahue, J., Darrell, T., and Malik, J. (2014).

Rich feature hierarchies for accurate object detec-

tion and semantic segmentation. In Proceedings of

the IEEE conference on computer vision and pattern

recognition, pages 580–587.

Greco, S., Vacchetti, B., Apiletti, D., and Cerquitelli, T.

(2024). Unsupervised concept drift detection from

deep learning representations in real-time. arXiv

preprint arXiv:2406.17813.

Gretton, A., Borgwardt, K. M., Rasch, M. J., Sch

¨

olkopf, B.,

and Smola, A. (2012). A kernel two-sample test. The

Journal of Machine Learning Research, 13(1):723–

773.

Hastie, T., Tibshirani, R., Friedman, J. H., and Friedman,

J. H. (2009). The elements of statistical learning: data

mining, inference, and prediction, volume 2. Springer.

Hinder, F., Vaquet, V., and Hammer, B. (2023). One or

two things we know about concept drift–a survey on

monitoring evolving environments. arXiv preprint

arXiv:2310.15826.

Kim, S., Choi, J., Kim, T., and Kim, C. (2019). Self-training

and adversarial background regularization for unsu-

pervised domain adaptive one-stage object detection.

In Proceedings of the IEEE/CVF International Con-

ference on Computer Vision, pages 6092–6101.

Lei

˜

nena, J., Saiz, F. A., and Barandiaran, I. (2024). Latent

diffusion models to enhance the performance of visual

defect segmentation networks in steel surface inspec-

tion. Sensors, 24(18):6016.

Lienhart, R. and Maydt, J. (2002). An extended set of haar-

like features for rapid object detection. In Proceed-

VISAPP 2025 - 20th International Conference on Computer Vision Theory and Applications

428

ings. international conference on image processing,

volume 1, pages I–I. IEEE.

Liu, F., Xu, W., Lu, J., Zhang, G., Gretton, A., and Suther-

land, D. J. (2020). Learning deep kernels for non-

parametric two-sample tests. In International confer-

ence on machine learning, pages 6316–6326. PMLR.

Liu, W., Anguelov, D., Erhan, D., Szegedy, C., Reed, S.,

Fu, C.-Y., and Berg, A. C. (2016). Ssd: Single shot

multibox detector. In Computer Vision–ECCV 2016:

14th European Conference, Amsterdam, The Nether-

lands, October 11–14, 2016, Proceedings, Part I 14,

pages 21–37. Springer.

Lopez-Paz, D. and Oquab, M. (2016). Revisiting classifier

two-sample tests. arXiv preprint arXiv:1610.06545.

Malisiewicz, T., Gupta, A., and Efros, A. A. (2011). Ensem-

ble of exemplar-svms for object detection and beyond.

In 2011 International conference on computer vision,

pages 89–96. IEEE.

Massey Jr, F. J. (1951). The kolmogorov-smirnov test for

goodness of fit. Journal of the American statistical

Association, 46(253):68–78.

Oza, P., Sindagi, V. A., Sharmini, V. V., and Patel, V. M.

(2023). Unsupervised domain adaptation of object

detectors: A survey. IEEE Transactions on Pattern

Analysis and Machine Intelligence.

Pearson, K. (1900). X. on the criterion that a given sys-

tem of deviations from the probable in the case of a

correlated system of variables is such that it can be

reasonably supposed to have arisen from random sam-

pling. The London, Edinburgh, and Dublin Philosoph-

ical Magazine and Journal of Science, 50(302):157–

175.

Rabanser, S., G

¨

unnemann, S., and Lipton, Z. (2019). Fail-

ing loudly: An empirical study of methods for detect-

ing dataset shift. Advances in Neural Information Pro-

cessing Systems, 32.

Redmon, J., Divvala, S., Girshick, R., and Farhadi, A.

(2016). You only look once: Unified, real-time object

detection. In Proceedings of the IEEE conference on

computer vision and pattern recognition, pages 779–

788.

Ren, S., He, K., Girshick, R., and Sun, J. (2015). Faster

r-cnn: Towards real-time object detection with region

proposal networks. Advances in neural information

processing systems, 28.

Saito, K., Watanabe, K., Ushiku, Y., and Harada, T. (2018).

Maximum classifier discrepancy for unsupervised do-

main adaptation. In Proceedings of the IEEE con-

ference on computer vision and pattern recognition,

pages 3723–3732.

Sudowe, P. and Leibe, B. (2011). Efficient use of geomet-

ric constraints for sliding-window object detection in

video. In International Conference on Computer Vi-

sion Systems, pages 11–20. Springer.

Toldo, M., Maracani, A., Michieli, U., and Zanuttigh, P.

(2020). Unsupervised domain adaptation in semantic

segmentation: a review. Technologies, 8(2):35.

Tzeng, E., Hoffman, J., Zhang, N., Saenko, K., and Darrell,

T. (2014). Deep domain confusion: Maximizing for

domain invariance. arXiv preprint arXiv:1412.3474.

Wang, Y., Yao, H., and Zhao, S. (2016). Auto-encoder

based dimensionality reduction. Neurocomputing,

184:232–242.

Handling Drift in Industrial Defect Detection Through MMD-Based Domain Adaptation

429