Self-Supervised Iterative Refinement for Anomaly Detection in Industrial

Quality Control

Muhammad Aqeel

a

, Shakiba Sharifi

b

, Marco Cristani

c

and Francesco Setti

d

Dept. of Engineering for Innovation Medicine, University of Verona, Strada le Grazie 15, Verona, Italy

Keywords:

Robust Anomaly Detection, Self-Supervised Learning, Iterative Refinement Process, Industrial Quality

Control.

Abstract:

This study introduces the Self-Supervised Iterative Refinement Process (IRP), a robust anomaly detection

methodology tailored for high-stakes industrial quality control. The IRP leverages self-supervised learning

to improve defect detection accuracy by employing a cyclic data refinement strategy that iteratively removes

misleading data points, thereby improving model performance and robustness. We validate the effectiveness

of the IRP using two benchmark datasets, Kolektor SDD2 (KSDD2) and MVTec-AD, covering a wide range

of industrial products and defect types. Our experimental results demonstrate that the IRP consistently outper-

forms traditional anomaly detection models, particularly in environments with high noise levels. This study

highlights the potential of IRP to significantly enhance anomaly detection processes in industrial settings, ef-

fectively managing the challenges of sparse and noisy data.

1 INTRODUCTION

Anomaly detection (AD) plays an indispensable role

in quality control in a wide range of manufacturing

industries, ensuring the integrity of materials such as

marble (Vrochidou et al., 2022), steel (Bo

ˇ

zi

ˇ

c et al.,

2021b), and leather (Jawahar et al., 2023). Accurately

detecting items that are non-compliant with product

specifications is crucial for maintaining product stan-

dards and consumer satisfaction. However, this task

is fraught with challenges, primarily due to the di-

verse and complex textures of the materials, the rarity

of defects, and the significant scarcity of accurately

labeled data necessary for effective supervised learn-

ing. Anomalies typically occupy only a tiny portion

of an image, making their detection difficult for hu-

man inspectors and automated systems. This chal-

lenge is compounded by the labor intensive and error-

prone nature of manually labeled training data, a pro-

cess that becomes increasingly unsustainable in high-

throughput manufacturing settings.

The evolution of anomaly detection in recent years

has increasingly leaned towards unsupervised and

a

https://orcid.org/0009-0000-5095-605X

b

https://orcid.org/0009-0008-6309-635X

c

https://orcid.org/0000-0002-0523-6042

d

https://orcid.org/0000-0002-0015-5534

self-supervised learning paradigms, prized for their

ability to operate without extensively labeled datasets.

These approaches, while innovative, presuppose the

existence of pristine training data, free from anoma-

lies (Ono et al., 2020; Beggel et al., 2020). This ideal

is seldom met in practical scenarios, where the inclu-

sion of even a few anomalous samples can severely

skew the learning process, leading to either too re-

strictive or overly permissive models. Models trained

under these conditions are prone to overfitting, result-

ing in many false positives during operational deploy-

ment. In contrast, including anomalies in the train-

ing set can escalate the incidence of false negatives,

severely undermining the system’s reliability.

To illustrate the severity of this issue, Fig. 1

demonstrates a decrease in AUCROC scores as noise

increases in the training data. Traditional detection

methods show a marked deterioration in performance

as data imperfections increase, highlighting their vul-

nerability. In contrast, our proposed Self-Supervised

Iterative Refinement Process (IRP) maintains a higher

level of performance, showcasing its robustness and

adaptability across a broad range of challenging con-

ditions. We deliberately limit our evaluation to sce-

narios where the noise does not render the data overly

corrupt, ensuring meaningful learning and generaliza-

tion. This decision reflects our commitment to devel-

oping a method that optimally balances performance

Aqeel, M., Sharifi, S., Cristani, M. and Setti, F.

Self-Supervised Iterative Refinement for Anomaly Detection in Industrial Quality Control.

DOI: 10.5220/0013178100003912

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 20th International Joint Conference on Computer Vision, Imaging and Computer Graphics Theory and Applications (VISIGRAPP 2025) - Volume 2: VISAPP, pages

173-183

ISBN: 978-989-758-728-3; ISSN: 2184-4321

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

173

Figure 1: Typical impact of noisy data in training an anomaly detection model.

with practical applicability in realistically noisy envi-

ronments.

Addressing these complexities requires a robust

detection system capable of navigating the intrica-

cies of noisy and incomplete data sets. Current ad-

vances in deep learning, such as autoencoders (Za-

vrtanik et al., 2022), generative adversarial networks

(GAN) (Luo et al., 2022), and discrete feature space

representations (Hu et al., 2022), offer promising

ways to improve anomaly detection. However, these

technologies still struggle with determining the opti-

mal anomaly score function, ensuring sufficient ro-

bustness against noise and outliers, and generalizing

effectively to novel, unseen data sets.

In response to these ongoing challenges, this pa-

per introduces a methodology named Self-Supervised

Iterative Refinement Process (IRP) specifically de-

signed for robust anomaly detection. This process

combines advanced machine learning techniques with

a cyclic data refinement strategy to iteratively enhance

the training data set quality, thereby significantly im-

proving the model’s performance and robustness. IRP

systematically identifies and removes the most mis-

leading data points based on a dynamically adjusted

scoring mechanism, thereby refining the model’s abil-

ity to generalize from normal operational data while

minimizing the influence of outliers.

The main contributions of this paper are as fol-

lows.

• We propose the Self-Supervised Iterative Refine-

ment Process (IRP), a robust training method-

ology that employs a cyclic refinement strategy

to enhance data quality and model accuracy in

anomaly detection systematically;

• The dynamic threshold adjustment mechanism

adapts the exclusion threshold based on a robust

statistical measure, ensuring precise and adaptive

outlier removal. This feature improves the sys-

tem’s ability to accurately identify and exclude

data points that do not conform to the expected

pattern, improving overall detection performance.

• We present an experimental validation of our

proposed methodology in two challenging public

datasets, namely KSDD2 and MVTec-AD, which

demonstrate significant improvements over tradi-

tional approaches and establish a new standard for

robustness in the field.

2 RELATED WORK

Detecting and identifying defects is crucial in man-

ufacturing to ensure processes function correctly.

VISAPP 2025 - 20th International Conference on Computer Vision Theory and Applications

174

Anomaly detection involves identifying issues such as

scratches, blemishes, blockages, discoloration, holes,

and, in general, any surface or structural irregularity

on a manufactured item (De Vitis et al., 2020). Recent

surveys review AD’s state of the art from both techno-

logical and methodological perspectives (Chen et al.,

2021; Bhatt et al., 2021). Traditionally, AD can be

formulated as a supervised or unsupervised learning

problem. Supervised methods use both anomaly and

normal samples during training, while unsupervised

methods only use normal samples at training time.

While supervised methods achieve better results, the

high cost of annotated datasets and advances in gener-

ative AI have shifted focus towards unsupervised ap-

proaches. Many unsupervised methods rely on im-

age reconstruction using encoder-decoder networks

to spot anomalies by comparing original and recon-

structed images (Akcay et al., 2019; Defard et al.,

2021; Roth et al., 2022). These networks struggle

to reconstruct anomalous regions accurately, having

never encountered them during training, which can re-

sult in high false positive rates with variable training

data. To address this, (Zavrtanik et al., 2021) employs

a reconstruction network to restore normal appear-

ances in anomalous images, while another approach

introduces textual prompts describing defects as in

(Capogrosso et al., 2024; Girella et al., 2024). Com-

paring features instead of whole images also helps to

reduce false positives (Zavrtanik et al., 2022; Rudolph

et al., 2021).

Robust anomaly detection (RAD) addresses the

problem of mitigating the effect of bad annotations in

the training set. It has been widely studied in sev-

eral fields, using methods ranging from robust sta-

tistical techniques (Rousseeuw and Hubert, 2018) to

deep learning approaches like autoencoders (Beggel

et al., 2020; Zhou and Paffenroth, 2017) and recur-

rent neural networks (Su et al., 2019). These methods

all aim to reduce sensitivity to noise in the labeling

process. Alternatively, (Zhao et al., 2019) focused on

removing noisy labels while using high-performing

anomaly detectors. Here, a two-layer online learning

framework filters suspicious data and detects anoma-

lies from the remaining data. We argue that training

two different models (one for predicting data qual-

ity and one for anomaly detection) adds unnecessary

complexity. More recently, researchers have explored

self-supervised learning (SSL) as a promising avenue

for anomaly detection. SSL methods often rely on

adaptations of deep CNN for enhancing learning ca-

pabilities from unlabelled data (Bo

ˇ

zi

ˇ

c et al., 2021a;

Zhang et al., 2022; Tian and Jia, 2022), or using

domain-adaptation techniques (Zhang et al., 2021). In

our previous work (Aqeel et al., 2024), we demon-

strated that SSL could be effective in filtering badly

labeled data in the training set. This paper extends

our previous work by using an iterative refinement ap-

proach, which is based on statistical observations of

anomaly score estimation on the training set, to fur-

ther improve robustness and accuracy in anomaly de-

tection.

3 ITERATIVE REFINEMENT

PROCESS

The Iterative Refinement Process (IRP) introduces a

novel approach to significantly enhance the robust-

ness and accuracy of anomaly detection in an indus-

trial environment by applying advanced probabilis-

tic models to iteratively refine the training dataset.

Despite being agnostic with respect to the anomaly

detection model, for our preliminary evaluation of

the impact of our approach, we used the DifferNet

model (Rudolph et al., 2021), which provided foun-

dational insights into the potential refinements neces-

sary for handling complex anomaly detection in in-

dustrial settings. The DifferNet model employs a nor-

malizing flow-based architecture to provide precise

density estimations of image features extracted via a

convolutional neural network. DifferNet establishes

a bijective relationship between the feature space and

the latent space, enabling each vector to be uniquely

mapped to a likelihood score. This scoring is de-

rived from the model’s ability to discern common pat-

terns from uncommon ones, making it especially ef-

fective for detecting subtle anomalies often found in

defect detection scenarios. Initially, each data point

x

i

, which refers to a transformed image, is evaluated

using a probabilistic model tailored to anomaly detec-

tion. The model calculates an anomaly likelihood as

follows:

A(x

i

) = −log p(x

i

;θ) (1)

where p(x

i

;θ) is the probability density function of

the transformed image x

i

, with θ representing the pa-

rameters of the model. The framework engages in a

dynamic data refinement cycle, where each point is

assessed against an adaptive threshold calculated as

λ times the median of the anomaly scores, A(x

i

). If

any data point’s anomaly score exceeds this thresh-

old, it is removed to refine the dataset. The refined

dataset, denoted D

new

, excludes the most anomalous

data point, x

max

, where x

max

is the point with the max-

imum anomaly score exceeding the threshold. This

process of refinement and retraining on D

new

contin-

ues until the dataset achieves optimal stability and

performance. The steps involved in this refinement

process are elaborated in Algorithm 1, and the entire

Self-Supervised Iterative Refinement for Anomaly Detection in Industrial Quality Control

175

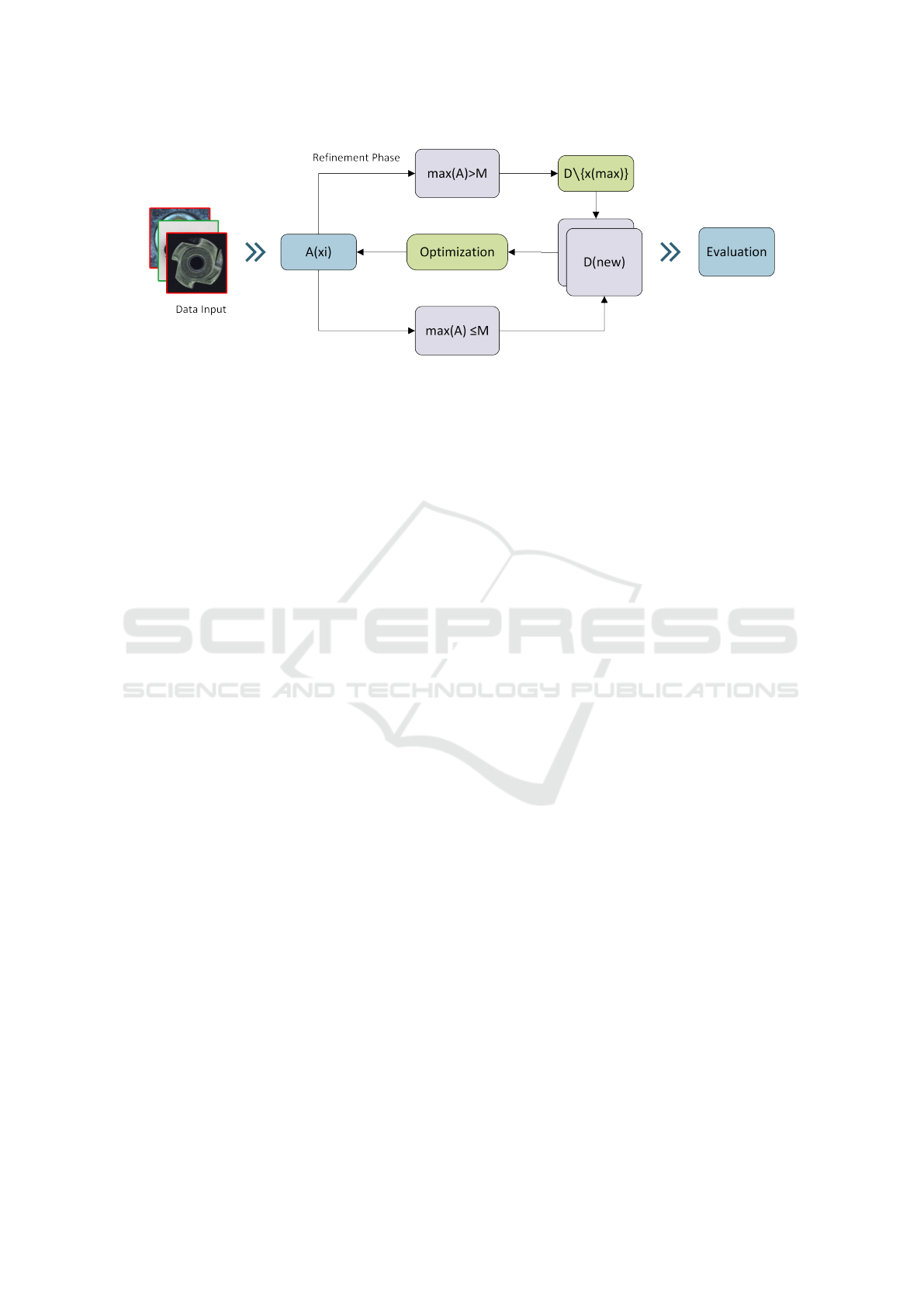

Figure 2: Illustrative schematic of the Iterative Refinement Process, demonstrating the independent cycle of training, valida-

tion, retraining, and testing.

sequence from data input through anomaly detection,

refinement, and final evaluation is illustrated in Fig. 2.

3.1 Probabilistic Anomaly Scoring

Mechanism and Dynamic

Refinement

Integral to DifferNet’s approach is a robust probabilis-

tic scoring system that enhances the accuracy and ro-

bustness of defect detection through dynamic refine-

ment processes. This anomaly detection framework

utilizes a convolutional neural network (CNN) as a

pretrained feature extractor, denoted as f

ex

, which is

not optimized further post-training. This extractor

transforms input data x ∈ X into a feature space Y ,

specifically:

y = f

ex

(x) ∈ Y (2)

These extracted features y are further processed by

a state-of-the-art normalizing flow model f

NF

, which

maps them into a well-defined latent space Z with a

known distribution p

Z

(z). This transformation is cru-

cial as it enables the precise estimation of the data’s

likelihood based on the latent representation:

z = f

NF

(y) where z ∼ N (0, I) (3)

The anomaly scores are derived directly from the

latent space by evaluating the likelihood of the trans-

formed features. A lower likelihood indicates a higher

probability of an anomaly, as it reflects the devia-

tion of the features from the model of ’normal’ data.

These scores are computed by averaging the negative

log-likelihoods of multiple transformed versions of an

image x, which are generated using a set of prede-

fined transformations T . The transformations T rep-

resent a collection of operations that perturb or mod-

ify the original data in controlled ways to simulate

variations that may highlight anomalies more clearly.

These transformations may include geometric modi-

fications, such as rotations, translations, and scalings,

or they may involve noise injections or other pertur-

bations that simulate real-world variations in the data.

The purpose of applying these transformations is

twofold. First, it helps with data augmentation by

generating multiple alternative versions of the input

data, thereby making the anomaly detection process

more robust to specific features of the original data.

Second, it stabilizes the anomaly scoring by reducing

the impact of random noise introduced by any single

transformation. By averaging the scores over several

transformed instances of the data, the final anomaly

score becomes more reliable, reflecting the underly-

ing anomaly rather than spurious noise.

For each transformation T

i

∈ T , the anomaly score

is calculated by applying T

i

to the input data x, pass-

ing it through the feature extractor f

ex

, and then map-

ping the resulting features to the latent space using the

normalizing flow model f

NF

. The final score is the ex-

pected value of the negative log-likelihoods of these

transformed instances, as shown in Equation 4. This

approach ensures that the anomaly score reflects the

data’s likelihood in the transformed space, improving

the robustness of the anomaly detection process by

incorporating multiple views of the data.

τ(x) = E

T

i

∈T

[−log p

Z

( f

NF

( f

ex

(T

i

(x))))] (4)

Our significant contribution is manifest in the

dynamic adjustment of the assessment threshold θ,

which is iteratively recalibrated in response to evolv-

ing data characteristics and directly influenced by the

statistical nature of the anomaly scores. We chose the

median as a central measure for thresholding due to

its robustness against outliers and skewed data distri-

butions. The median offers a more stable and rep-

resentative central tendency, particularly in datasets

where the majority of values are concentrated around

a certain range with a few extreme outliers. This char-

acteristic makes the median especially suitable for de-

termining thresholds in anomaly detection, where the

presence of anomalies can distort the distribution of

VISAPP 2025 - 20th International Conference on Computer Vision Theory and Applications

176

Algorithm 1: Iterative Refinement and Retrain-

ing.

Dataset of images D = {x

1

, x

2

, . . . , x

n

}

Pre-train model on D for N epochs

Compute anomaly scores A = {a

1

, a

2

, . . . , a

n

}

where a

i

= −log p(x

i

;θ)

Compute median of scores M = median(A)

if max(A) > λ ×M then

x

max

← x

i

where a

i

= max(A)

Delete x

max

from D

D

new

← D \{x

max

}

else

D

new

← D

Retrain model on D

new

repeat

Repeat steps 3 to 9

until Convergence

scores. The threshold defined as:

Threshold = λ ×M (5)

where λ is the scaling factor and M is the median of

the anomaly scores. This ensures that data points with

anomaly scores exceeding the threshold are consid-

ered outliers and are removed from the dataset.

D

new

= D

old

\ {x | τ(x) > Threshold} (6)

This iterative refinement process not only en-

hances the quality and performance of the model but

also stabilizes it at an optimal level. Moreover, this

method is designed not only to detect but also local-

ize anomalies within images, leveraging the gradient

of the loss function to clearly demarcate regions con-

tributing to anomalies, thus providing a robust mech-

anism for practical deployment in industrial quality

control systems.

4 EXPERIMENTAL RESULTS

This section presents the experimental results ob-

tained from applying the Iterative Refinement Process

(IRP) to anomaly detection. The experiments were

designed to evaluate the effectiveness of the IRP in

improving detection accuracy and robustness under

various conditions.

4.1 Datasets

We assess the performance of our approach using

two publicly available datasets, which are extensively

used to assess the robustness and effectiveness of de-

fect detection models:

Kolektor SDD2 (KSDD2): The KSDD2 dataset

(Bo

ˇ

zi

ˇ

c et al., 2021b) consists of RGB images

showcasing defective production items, meticulously

sourced and annotated by Kolektor Group d.o.o. The

defects vary widely in size, shape, and color, ranging

from minor scratches and spots to significant surface

faults. For uniform evaluation, all images are center-

cropped and resized to dimensions of 448×448 pix-

els. The training set comprises 2085 normal and 246

positive samples, while the testing set includes 894

negative and 110 positive samples.

MVTec-AD Dataset: The MVTec-AD dataset

(Bergmann et al., 2019) is utilized to demonstrate the

effectiveness of our proposed method across a vari-

ety of real-world industrial products. The MVTec-AD

dataset contains 15 different types of industrial prod-

ucts, encompassing over 70 different types of defects,

each labelled with both defect types and segmenta-

tion masks. To address the original lack of defective

images in the training set, we resampled half of the

defect images to include in our training data. The re-

vised training set contains 889 normal and 1345 de-

fective images, while the testing set comprises 1210

normal and 724 defective images.

4.2 Implementation Details

Experiments were conducted using PyTorch frame-

work. We resized images to 448 ×448 pixels and ap-

plied standardized preprocessing techniques, includ-

ing optional rotations and normalization. The net-

work architecture features three scales of input res-

olution, 8 coupling blocks within the normalizing

flow model, and fully connected layers in the scale-

translation networks each containing 2048 neurons,

with no dropout our proposed method’s effectiveness

across variousapplied. Training parameters are set

with a learning rate of 2 × 10

−4

, and the model un-

dergoes 400 epochs with batch size 96.

We compared our proposed methodology with ex-

isting models including DifferNet (Rudolph et al.,

2021) and One Shot Removal (OSR) (Aqeel et al.,

2024). DifferNet leverages a multi-scale feature ex-

traction process to assign meaningful likelihoods to

images, thereby facilitating defect localization. Dif-

ferNet represents also the model for feature extrac-

tion used in our self supervised procedure. OSR

enhances the robustness of surface defect detection

models through a novel training pipeline, which in-

volves initial training, anomalous sample removal,

and model fine-tuning.

The performance of our model was tested under

varying noise levels, from 0% to 50%. These noise

levels simulate the inclusion of bad samples typically

Self-Supervised Iterative Refinement for Anomaly Detection in Industrial Quality Control

177

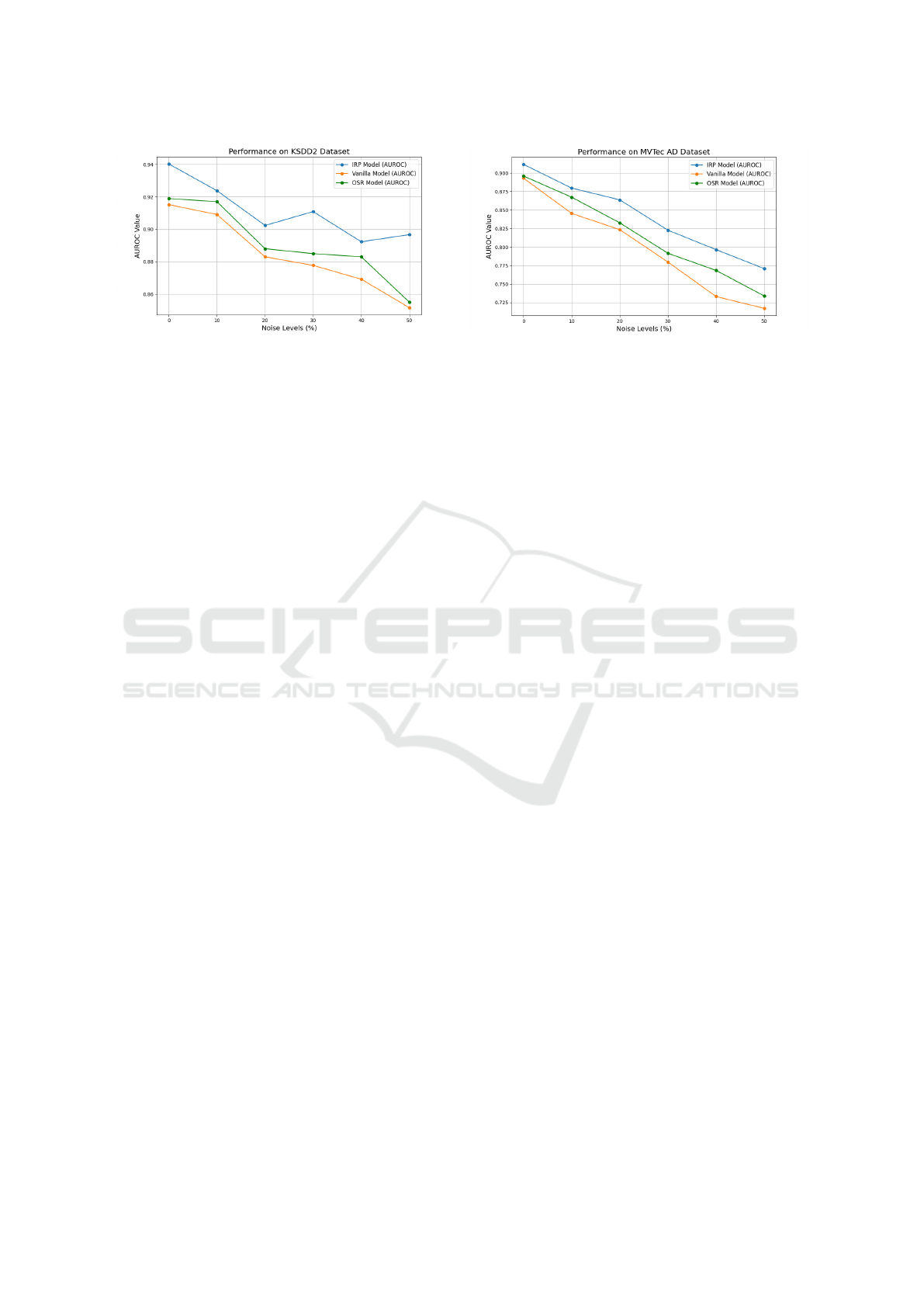

(a) KSDD2 (b) MVTec-AD

Figure 3: Figure (a) displays the performance trends of various models on the KSDD2 dataset, while figure (b) shows results

for the MVTec-AD dataset, across different noise levels. The graphs illustrate the models’ performance before and after

applying the IPR model: the blue line represents the IPR model, the green line denotes the OSR model, and the yellow line

illustrates the performance of the vanilla model.

encountered in unsupervised learning scenarios. We

measured the model’s performance using the AUROC

score across these noise levels, providing a reliable

indicator of its ability to distinguish between normal

and anomalous data. Each experiment was repeated

three times to ensure consistency and to assess the im-

pact of noise on detection accuracy.

4.3 Performance on KSDD2 Across

Varying Noise Levels

This section presents the evaluation results of the IRP

on the KSDD2 dataset. The analysis explores the

performance of the IRP model under different noise

levels, highlighting its defect detection capabilities in

challenging environments. As shown in Fig. 3, the

IRP model is compared against two conventional ap-

proaches—the traditional vanilla model (DifferNet)

and the One Shot Removal (OSR) model proposed

in (Aqeel et al., 2024). Across all tested noise levels,

the IRP model consistently outperforms the competi-

tors, demonstrating remarkable resilience by main-

taining superior AUROC values, as systematically

documented in Table 1.

The IRP model excels particularly at higher noise

levels. For example, at 50% noise, the IRP model

achieves a significantly higher AUROC of 0.8967 on

the KSDD2 dataset, while the vanilla and OSR mod-

els show notable declines. This robustness stems from

the IRP’s advanced noise-cancellation algorithms,

adaptive thresholding, and self-supervised feature ex-

traction, which enable effective handling of heavily

corrupted data.

Moreover, the statistical analysis accompanying

our findings reinforces the IRP model’s superiority.

The standard deviation values reported in Table 1 in-

dicate lower variability in performance across differ-

ent experimental runs, underscoring the model’s re-

liability and predictability. Such attributes are indis-

pensable in industrial applications, where the cost of

false negatives can be prohibitive, and the ability to

detect anomalies reliably is paramount. The com-

prehensive data presented in the table not only show-

cases the IRP model’s adaptability and robust perfor-

mance across diverse and challenging scenarios but

also highlights its viability as a potent tool for main-

taining stringent quality control standards in manu-

facturing processes. These findings suggest that the

IRP, through its self-supervised learning approach,

can be effectively deployed in industrial settings to

enhance defect detection where traditional models

might falter due to high variability in defect rates and

challenging noise conditions.

4.4 Performance on MVTec Across

Varying Noise Levels

The robustness and adaptability of IRP have been

rigorously evaluated across various product classes

within the MVTec-AD dataset, including Bottle, Ca-

ble, Capsule, Carpet, Leather, MetalNut, Pill, Screw,

Tile, and Zipper. Each class, with its distinct de-

fect types and unique challenges, served as an ideal

testbed for the IRP. We systematically varied the noise

levels in the dataset from 0% to 50% to meticulously

assess the IRP’s capabilities under progressively chal-

lenging conditions, using the Area Under the Curve

of the Receiver Operating Characteristic (AUROC)

to quantify defect detection accuracy across different

thresholds.

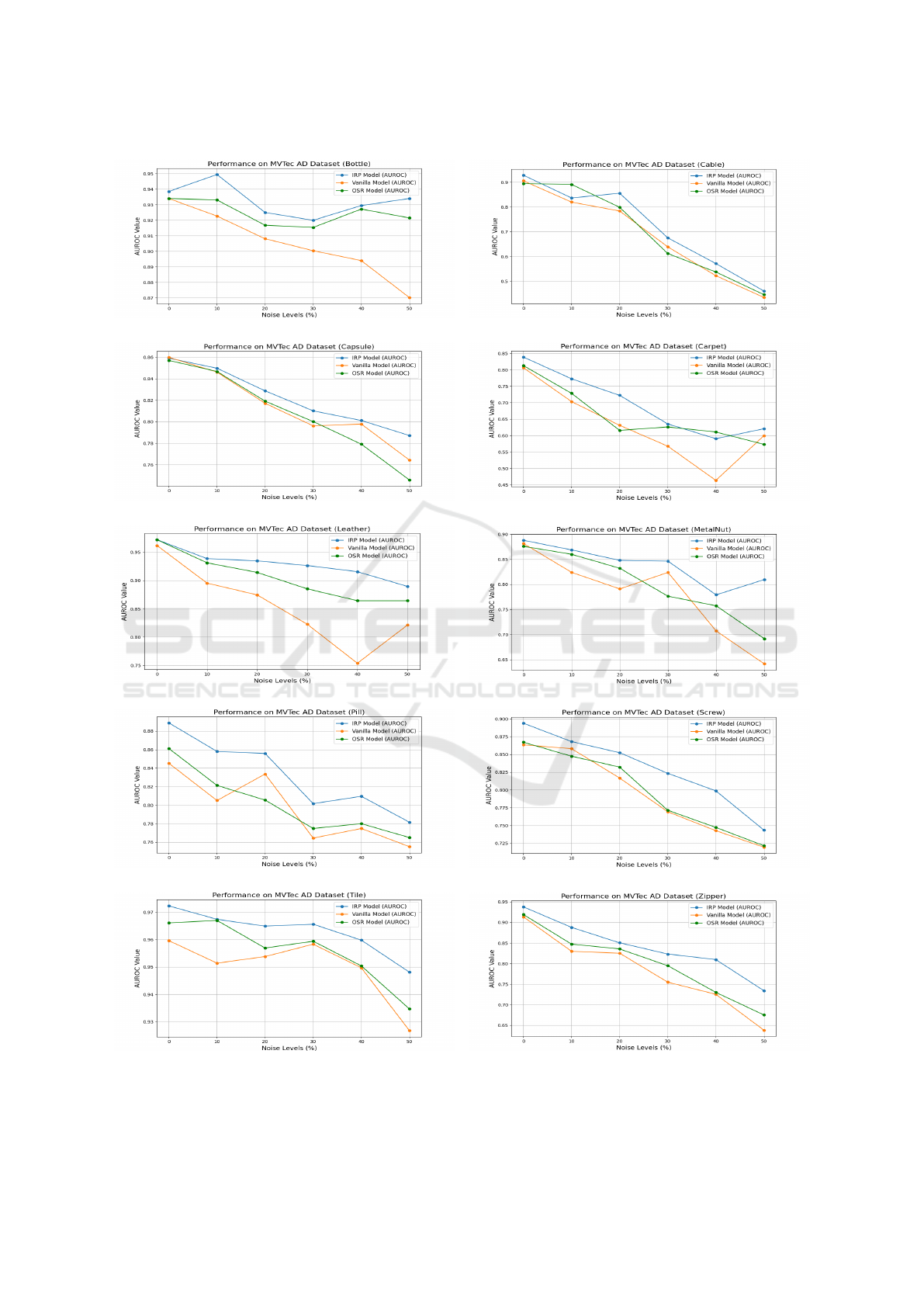

As illustrated in Fig. 4, the IRP model consis-

tently achieves high AUROC values across all classes,

demonstrating its robust ability to manage noise ef-

fectively. Notably, in classes with complex and vari-

able defect characteristics such as Screw and Cable,

the IRP exhibits exceptional resilience, showcasing

VISAPP 2025 - 20th International Conference on Computer Vision Theory and Applications

178

Table 1: AUROC scores of the IRP model at different noise levels for MVTec-AD and KSDD2 datasets.

Category Entity

Noise Level

0% 10% 20% 30% 40% 50%

Classes

Bottle 0.9386 0.9495 0.9250 0.9200 0.9295 0.9340

Capsule 0.8592 0.8498 0.8288 0.8102 0.8012 0.7872

Cable 0.9288 0.8368 0.8560 0.6756 0.5716 0.4604

Carpet 0.8386 0.7727 0.7222 0.6354 0.5905 0.6206

Leather 0.9722 0.9388 0.9348 0.9266 0.9157 0.8897

MetalNut 0.8880 0.8688 0.8480 0.8464 0.7792 0.8096

Pill 0.8888 0.8580 0.8558 0.8016 0.8096 0.7816

Screw 0.8938 0.8680 0.8524 0.8234 0.7988 0.7436

Tile 0.9723 0.9674 0.9649 0.9656 0.9598 0.9481

Zipper 0.9378 0.8880 0.8504 0.8232 0.8096 0.7340

Models

Vanilla 0.8931 0.8455 0.8235 0.7797 0.7331 0.7171

OSR 0.8960 0.8674 0.8327 0.7916 0.7684 0.7338

IRP on MVTec-AD 0.9118 0.8797 0.8638 0.8228 0.7965 0.7708

IRP on KSDD2 0.9403 0.9238 0.9024 0.9109 0.8923 0.8967

Standard Deviation ±0.0246 ±0.0149 ±0.0086 ±0.0518 ±0.0777 ±0.1099

its advanced anomaly detection capabilities. Con-

versely, in classes like Capsule and Pill, where defects

are more subtle, the IRP effectively distinguished be-

tween normal variations and actual defects, underlin-

ing its sophisticated feature extraction capabilities.

This uniform and robust performance across var-

ied classes and noise levels highlights the IRP model’s

adaptability and effectiveness in industrial applica-

tions, especially in environments with diverse and un-

predictable defect rates. The IRP’s ability to main-

tain high accuracy at elevated noise levels underscores

its potential as a dependable tool for quality control

in manufacturing environments. Furthermore, Fig. 3

provides an overarching view of the IRP’s perfor-

mance across the MVTec-AD dataset. This visual

representation emphasizes the IRP’s superior perfor-

mance relative to the vanilla and OSR models, mainly

as it consistently improves defect handling under in-

creasingly challenging conditions. This enhancement

affirms the IRP’s role as a robust and reliable quality

control instrument in complex manufacturing land-

scapes, where defect rates fluctuate significantly. Ta-

ble 1 complements these insights by detailing the AU-

ROC scores at various noise levels for the MVTec-

AD and KSDD2 datasets, including measures of er-

ror magnitude. This detailed presentation not only

confirms the performance stability of the IRP across

different settings but also highlights the model’s reli-

ability, evidenced by the low standard deviation in its

performance metrics.

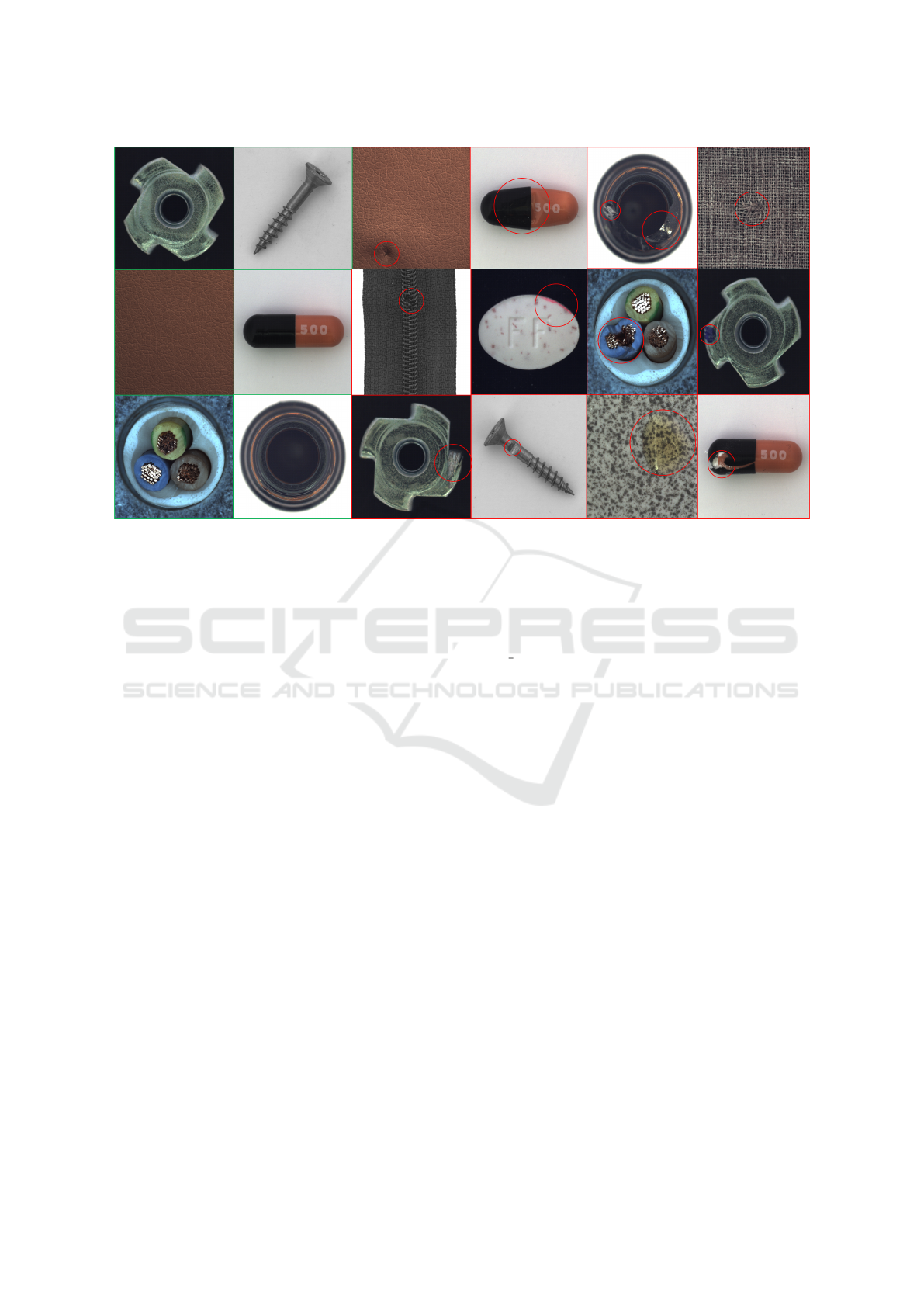

4.5 Quantitative Analysis of Removed

Samples

This section presents a detailed quantitative analy-

sis of the samples removed during the defect de-

tection process for both the KSDD2 and MVTec-

AD datasets. This analysis is segmented by product

categories and noise levels, providing insights into

the effectiveness of the Iterative Refinement Process

(IRP) in improving defect detection accuracy. Ta-

ble 2 shows the number of good and bad samples

removed at various noise levels (0% to 50%) across

different product categories within the KSDD2 and

MVTec-AD datasets. The categories include Cable,

Capsule, Metalnut, Pill, Screw, and Zipper. Each

entry in the table specifies the count of good (non-

defective) and bad (defective) samples removed dur-

ing the training and validation phases. The accom-

panying image Fig. 5 illustrates the samples that were

removed during iterative refinement, showcasing both

defective samples, which exhibit noticeable defects

and noise patterns, and some good samples that were

also deleted as part of the refinement process.

The table indicates that at 0% noise, only good

samples are removed. This might seem counterin-

tuitive, but it can be explained by the fact that these

good samples are likely close to the decision bound-

ary, making them appear anomalous during the ini-

tial iterations of the IRP. Removing these borderline

good samples helps refine the model by reducing po-

tential noise and improving its generalization capabil-

ity. This phenomenon demonstrates the IRP’s ability

Self-Supervised Iterative Refinement for Anomaly Detection in Industrial Quality Control

179

(a) Bottle (b) Cable

(c) Capsule (d) Carpet

(e) Leather (f) MetalNut

(g) Pill (h) Screw

(i) Tile (j) Zipper

Figure 4: AUROC performance of the IRP across various classes of the MVTec-AD dataset. Each sub-figure demonstrates

the defect detection efficacy for a different class, illustrating the robustness and adaptability of the IRP in handling diverse

defect characteristics.

VISAPP 2025 - 20th International Conference on Computer Vision Theory and Applications

180

Table 2: Images deleted at various noise levels for KSDD2 and MVTec-AD datasets, segmented by product categories.

Noise Level (%)

KSDD2 MvTec

Cable Capsule Metalnut Pill Screw Zipper

Good Bad Good Bad Good Bad Good Bad Good Bad Good Bad Good Bad

0% 11 0 6 0 16 0 14 0 17 0 15 0 19 0

10% 3 5 5 7 11 6 6 8 9 8 12 5 10 5

20% 3 7 5 9 5 12 5 11 5 11 6 9 8 9

30% 2 8 4 11 4 14 3 11 4 13 7 11 5 11

40% 4 12 3 12 2 13 2 9 5 12 6 10 6 14

50% 4 13 4 12 5 13 1 9 3 11 2 12 5 13

to fine-tune the model even when no bad samples are

present. As noise levels increase, the number of bad

samples removed rises, which is expected. However,

the table also shows that good samples remain re-

moved across all noise levels. This ongoing removal

of good samples close to the boundary helps main-

tain the model’s robustness by continuously refining

its decision boundaries.

The quantitative analysis of removed samples un-

derscores the IRP model’s capacity to enhance defect

detection accuracy through systematic refinement. By

removing samples close to the decision boundary, the

IRP improves the overall performance, even in the

absence of bad samples. As noise levels increase,

the model adeptly identifies and eliminates defective

samples while maintaining a balance by removing

borderline good samples. This approach fine-tunes

the model and ensures its robustness and reliability

in real-world industrial applications.

5 DISCUSSION

The robust performance of the Self-Supervised Iter-

ative Refinement Process (IRP) across varying noise

levels underscores its potential utility in industrial set-

tings, where defect patterns may be unpredictable.

The model’s ability to maintain high AUROC values

under increasing noise conditions illustrates its ca-

pacity to effectively distinguish subtle defect features

from normal variability, which is an essential attribute

for critical quality control environments.

While the model demonstrates strong perfor-

mance, there is scope to enhance its operational effi-

ciency. The current training setup, designed for mod-

erate scale and tailored to specific experimental con-

ditions, serves well under controlled scenarios. How-

ever, as we aim to deploy the model in more dy-

namic industrial settings, optimizing its capacity to

handle larger datasets and faster processing cycles

will be crucial. These enhancements are intended to

reduce the time required to reach model convergence

and increase image processing throughput, ensuring

the model can meet the demands of real-time defect

detection. Future developments could include refin-

ing the training algorithms to accelerate convergence

without compromising accuracy, and expanding the

system’s architecture to support more simultaneous

operations. These improvements will be critical for

deploying the model in environments where rapid

decision-making is essential. Furthermore, the de-

tailed analysis of different classes within the MVTec-

AD dataset highlights the IRP’s adaptability to di-

verse manufacturing scenarios. The pronounced re-

silience in classes with intricate defect patterns, such

as Screws and Cables, underscores the model’s so-

phisticated feature recognition capabilities, which are

likely bolstered by advanced data preprocessing and

anomaly scoring mechanisms. Further research could

focus on optimizing the model to enhance detection

accuracy in scenarios with extremely subtle defect

signals, such as those found in high-grade pharma-

ceutical manufacturing.

Future research efforts might also refine the prob-

abilistic models used within the IRP, enhancing their

sensitivity to minor anomalies and incorporating real-

time learning capabilities to adapt to new types of de-

fects as they emerge dynamically. Addressing the cur-

rent limitations by increasing the processing capac-

ity of the model and reducing dependency on lengthy

epoch training will be critical. Additionally, explor-

ing the integration of the IRP with other industrial

monitoring systems could broaden its applicability,

ensuring it remains a versatile and effective tool in

the rapidly evolving landscape of manufacturing tech-

nologies.

6 CONCLUSION

The experimental validation of the Self-Supervised

Iterative Refinement Process (IRP) presented in this

study underscores its substantial efficacy in enhanc-

ing anomaly detection across diverse industrial set-

Self-Supervised Iterative Refinement for Anomaly Detection in Industrial Quality Control

181

Figure 5: A visual representation of good (outlined in green) and defective (outlined in red) samples under different noise

levels. Defects are marked with red circles, illustrating the distribution of flaws within the samples.

tings. Employing robust statistical measures and so-

phisticated anomaly scoring mechanisms, the IRP

has consistently demonstrated superior performance

over traditional methods such as the vanilla model

and One Shot Removal (OSR) model, particularly

in environments characterized by high noise lev-

els. Through rigorous testing on the KSDD2 and

MVTec-AD datasets, the IRP not only achieved high

AUROC scores but also exhibited remarkable re-

silience against variable noise intensities, effectively

maintaining its defect detection capabilities even un-

der challenging conditions. The system’s ability to

accurately distinguish between defective and non-

defective items, even with subtle defect features,

highlights its potential as a critical tool for maintain-

ing high standards in industrial quality control. These

results validate the effectiveness of the IRP, showcas-

ing its adaptability to different defect types and its

robust performance across a spectrum of industrial

products. The study’s outcomes suggest that the IRP

can greatly enhance the precision and reliability of de-

fect detection systems, ensuring significant improve-

ments in quality assurance processes within manufac-

turing environments.

ACKNOWLEDGEMENTS

This study was carried out within the PNRR research

activities of the consortium iNEST (Interconnected

North-Est Innovation Ecosystem) funded by the Eu-

ropean Union Next-GenerationEU (Piano Nazionale

di Ripresa e Resilienza (PNRR) – Missione 4 Com-

ponente 2, Investimento 1.5 – D.D. 1058 23/06/2022,

ECS 00000043).

REFERENCES

Akcay, S., Atapour-Abarghouei, A., and Breckon, T. P.

(2019). GANomaly: Semi-supervised anomaly detec-

tion via adversarial training. In Asian Conference on

Computer Vision (ACCV).

Aqeel, M., Sharifi, S., Cristani, M., and Setti, F. (2024).

Self-supervised learning for robust surface defect de-

tection. In International Conference on Deep Learn-

ing Theory and Applications (DELTA).

Beggel, L., Pfeiffer, M., and Bischl, B. (2020). Robust

anomaly detection in images using adversarial autoen-

coders. In European Conference on Machine Learn-

ing and Knowledge Discovery in Databases (ECML-

PKDD).

Bergmann, P., Fauser, M., Sattlegger, D., and Steger, C.

(2019). Mvtec ad–a comprehensive real-world dataset

for unsupervised anomaly detection. In Proceedings

of the IEEE/CVF conference on computer vision and

pattern recognition, pages 9592–9600.

Bhatt, P. M., Malhan, R. K., Rajendran, P., Shah, B. C.,

Thakar, S., Yoon, Y. J., and Gupta, S. K. (2021).

Image-based surface defect detection using deep

learning: A review. Journal of Computing and In-

formation Science in Engineering, 21(4):040801.

VISAPP 2025 - 20th International Conference on Computer Vision Theory and Applications

182

Bo

ˇ

zi

ˇ

c, J., Tabernik, D., and Sko

ˇ

caj, D. (2021a). End-to-end

training of a two-stage neural network for defect de-

tection. In International conference on pattern recog-

nition (ICPR). IEEE.

Bo

ˇ

zi

ˇ

c, J., Tabernik, D., and Sko

ˇ

caj, D. (2021b). Mixed su-

pervision for surface-defect detection: from weakly to

fully supervised learning. Computers in Industry.

Capogrosso, L., Girella, F., Taioli, F., Chiara, M., Aqeel,

M., Fummi, F., Setti, F., Cristani, M., et al. (2024).

Diffusion-based image generation for in-distribution

data augmentation in surface defect detection. In

International Joint Conference on Computer Vision,

Imaging and Computer Graphics Theory and Appli-

cations, volume 2, pages 409–416. SciTePress.

Chen, Y., Ding, Y., Zhao, F., Zhang, E., Wu, Z., and

Shao, L. (2021). Surface defect detection methods

for industrial products: A review. Applied Sciences,

11(16):7657.

De Vitis, G. A., Foglia, P., and Prete, C. A. (2020). Row-

level algorithm to improve real-time performance of

glass tube defect detection in the production phase.

IET Image Processing, 14(12):2911–2921.

Defard, T., Setkov, A., Loesch, A., and Audigier, R. (2021).

Padim: a patch distribution modeling framework for

anomaly detection and localization. In International

Conference on Pattern Recognition (ICPR).

Girella, F., Liu, Z., Fummi, F., Setti, F., Cristani, M., and

Capogrosso, L. (2024). Leveraging latent diffusion

models for training-free in-distribution data augmen-

tation for surface defect detection. In International

Conference on Content-based Multimedia Indexing

(CBMI).

Hu, M., Wang, Y., Feng, X., Zhou, S., Wu, Z., and Qin,

Y. (2022). Robust anomaly detection for time-series

data.

Jawahar, M., Anbarasi, L. J., and Geetha, S. (2023). Vision

based leather defect detection: a survey. Multimedia

Tools and Applications, 82(1):989–1015.

Luo, Z., He, K., and Yu, Z. (2022). A robust unsupervised

anomaly detection framework. Applied Intelligence,

52(6):6022–6036.

Ono, Y., Tsuji, A., Abe, J., Noguchi, H., and Abe, J. (2020).

Robust detection of surface anomaly using lidar point

cloud with intensity. The International Archives of the

Photogrammetry, Remote Sensing and Spatial Infor-

mation Sciences, 43:1129–1136.

Roth, K., Pemula, L., Zepeda, J., Sch

¨

olkopf, B., Brox, T.,

and Gehler, P. (2022). Towards total recall in indus-

trial anomaly detection. In IEEE/CVF Conference on

Computer Vision and Pattern Recognition (CVPR).

Rousseeuw, P. J. and Hubert, M. (2018). Anomaly detection

by robust statistics. Wiley Interdisciplinary Reviews:

Data Mining and Knowledge Discovery, 8(2):e1236.

Rudolph, M., Wandt, B., and Rosenhahn, B. (2021). Same

same but differnet: Semi-supervised defect detection

with normalizing flows. In IEEE/CVF Winter Confer-

ence on Applications of Computer Vision.

Su, Y., Zhao, Y., Niu, C., Liu, R., Sun, W., and Pei, D.

(2019). Robust anomaly detection for multivariate

time series through stochastic recurrent neural net-

work. In ACM SIGKDD International Conference on

Knowledge Discovery and Data Mining.

Tian, R. and Jia, M. (2022). Dcc-centernet: A rapid detec-

tion method for steel surface defects. Measurement,

187:110211.

Vrochidou, E., Sidiropoulos, G. K., Ouzounis, A. G., Lam-

poglou, A., Tsimperidis, I., Papakostas, G. A., Sarafis,

I. T., Kalpakis, V., and Stamkos, A. (2022). Towards

robotic marble resin application: Crack detection on

marble using deep learning. Electronics, 11(20).

Zavrtanik, V., Kristan, M., and Sko

ˇ

caj, D. (2021). Draem-

a discriminatively trained reconstruction embedding

for surface anomaly detection. In IEEE/CVF Inter-

national Conference on Computer Vision (ICCV).

Zavrtanik, V., Kristan, M., and Sko

ˇ

caj, D. (2022). DSR–

a dual subspace re-projection network for surface

anomaly detection. In European Conference on Com-

puter Vision (ECCV).

Zhang, C., Wang, Z., Liu, B., Xiaolei, W., et al. (2022).

Steel plate defect recognition of deep neural network

recognition based on space-time constraints. Ad-

vances in Multimedia, 2022.

Zhang, S., Zhang, Q., Gu, J., Su, L., Li, K., and Pecht,

M. (2021). Visual inspection of steel surface defects

based on domain adaptation and adaptive convolu-

tional neural network. Mechanical Systems and Signal

Processing, 153:107541.

Zhao, Z., Birke, R., Han, R., Robu, B., Bouchenak, S.,

Mokhtar, S. B., and Chen, L. Y. (2019). Rad: On-line

anomaly detection for highly unreliable data. arXiv

preprint arXiv:1911.04383.

Zhou, C. and Paffenroth, R. C. (2017). Anomaly detection

with robust deep autoencoders. In ACM SIGKDD In-

ternational Conference on Knowledge Discovery and

Data Mining.

Self-Supervised Iterative Refinement for Anomaly Detection in Industrial Quality Control

183