Minimizing Energy Cost in a Job-Shop Scheduling Problem Under ToU

Pricing: A New Method Based on a Period-Indexed MILP

Marouane Felloussi

a

, Xavier Delorme

b

and Paolo Gianessi

c

Mines Saint-Etienne, Univ. Clermont Auvergne, INP Clermont Auvergne, CNRS, UMR 6158 LIMOS, F-42023

Saint-Etienne, France

Keywords:

Energy-Efficient Production Systems, ToU Pricing, Job-Shop Scheduling, Exact Method, Mixed-Integer

Linear Programming, Valid Inequalities.

Abstract:

This work addresses the job-shop scheduling problem under energy considerations, specifically focusing on

minimizing total energy costs within a Time-of-Use pricing framework, denoted as J

m

||T EC. We propose a

period-indexed Mixed-Integer Linear Programming formulation, which proves advantageous due to its smaller

model size compared to traditional time-indexed approaches. Initial studies highlight that while our model can

rapidly find feasible solutions, it struggles with weak linear relaxations. Different families of valid inequalities

are thus considered to improve the obtained lower bounds. In order to evaluate and compare the impact of the

proposed valid inequalities, computational experiments are presented and numerical results are discussed and

analyzed.

1 INTRODUCTION

The rising demand for energy, volatile prices, and

global warming concerns have heightened the focus

on energy efficiency. The industrial sector, responsi-

ble for over half of global end-use energy consump-

tion, is projected to see electricity use grow from 22%

in 2021 to 46% by 2050 due to process electrification

(International Energy Agency, 2023). Manufacturing

systems, as key contributors to industrial energy use,

must meet the rising demand for goods while address-

ing their energy-intensive nature. Enhancing energy

efficiency in this sector is crucial for sustainability.

Energy cost minimization provides a strategic means

of improving efficiency by leveraging Time-of-Use

(ToU) pricing, where varying per-unit energy prices

incentivize production during off-peak periods. Such

scheduling not only reduces costs and grid strain, but

also lowers greenhouse gas emissions.

As a relevant problem in manufacturing systems,

the Job-Shop Scheduling Problem (JSSP) stands out

as one of the most complex and studied problems

in operations research. The N P -hard (Garey et al.,

1976) problem consists of operations that must be

a

https://orcid.org/0009-0005-1351-5403

b

https://orcid.org/0000-0002-9465-1255

c

https://orcid.org/0000-0001-5457-3689

contiguously processed on dedicated machines and in

a predefined order. Each operation has a specific ma-

chine that it needs to be processed on and only one

operation in a job can be processed at a given time.

The problem then consists in sequencing the opera-

tions on machines in order to minimize the makespan,

i.e. the last completion time.

Incorporating energy considerations into the JSSP

adds complexity, even with simplified assumptions

like constant machine power usage. For instance,

when energy prices follow a ToU pricing scheme,

minimizing energy costs without worsening produc-

tion objectives results in a scheduling problem that

must optimize both production and energy efficiency.

A key combinatorial challenge in energy-efficient

scheduling is that incorporating non-regular crite-

ria like time-dependent energy pricing requires ex-

plicit timing decisions (Dauz

`

ere-P

´

er

`

es et al., 2024).

To model time-dependent energy costs, time-indexed

(TI) formulations are often preferred to disjunctive

(D) ones (see, e.g. Masmoudi et al. 2019). While TI

formulations provide strong dual bounds, they often

lead to large Mixed-Integer Linear Programs (MILP).

In the most common case where ToU profiles are

piecewise constant, period-indexed formulations can

be an alternative modeling approach. These involve

associating a variable with whether the processing of

an operation occurs during one of the ToU periods.

320

Felloussi, M., Delorme, X. and Gianessi, P.

Minimizing Energy Cost in a Job-Shop Scheduling Problem Under ToU Pricing: A New Method Based on a Period-Indexed MILP.

DOI: 10.5220/0013181200003893

In Proceedings of the 14th International Conference on Operations Research and Enterprise Systems (ICORES 2025), pages 320-327

ISBN: 978-989-758-732-0; ISSN: 2184-4372

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

In this paper, we address the job-shop scheduling

problem with minimization of the total energy costs

subject to a ToU pricing scheme. To do so, we pro-

pose a novel period-indexed MILP, where timing de-

cisions are indexed on ToU periods. Valid inequal-

ities and variable-fixing relations are introduced and

discussed to strengthen the linear relaxations.

The remainder of this paper is structured as fol-

lows: Section 2 reviews the relevant literature. Sec-

tion 3 introduces key notations, presents the proposed

mathematical formulation and discusses the valid in-

equalities used to enhance it. Computational experi-

ments are detailed and analyzed in Section 4. We con-

clude the paper with remarks and potential research

directions in Section 5.

2 SHORT LITERATURE REVIEW

Energy cost minimization under ToU pricing has been

explored in various scheduling settings. For parallel

machines, Gaggero et al. (2023) present a MILP with

symmetry-breaking properties and a heuristic for a

multi-objective problem addressing both energy cost

and makespan. Further, Tian and Zheng (2024) tackle

a single machine batch scheduling problem, develop-

ing a set partitioning formulation and novel branching

rules for their branch-and-price. In the shop schedul-

ing context, Park and Ham (2022) develop a Con-

straint Programming (CP) model for a flexible job-

shop problem considering machine states, while Jiang

and Wang (2020) introduce a time-indexed MILP for

the permutation flow-shop. Some research focuses

on minimizing total energy cost subject to opera-

tional constraints. Masmoudi et al. (2019) develop

disjunctive and time-indexed formulations, as well

as a matheuristic for the job-shop scheduling under

makespan and power limits. Bley and Linß (2022)

approach the job-shop with machine states and re-

lease/due dates with a branch-and-bound algorithm

based on a time-indexed formulation, enhanced by

preprocessing and propagation techniques.

To conclude this brief literature review, we high-

light some of the works using a period-based ap-

proach. In the machine scheduling environment,

Cheng et al. (2016) examine a single machine batch

scheduling problem minimizing total energy cost,

comparing time-indexed and period-indexed formu-

lations. As for unrelated parallel machines, Che et al.

(2017) propose a model to minimize total energy

cost, enhanced with valid inequalities and a two-stage

heuristic. For the same problem, Ding et al. (2016)

present a period-indexed formulation and a heuris-

tic based on a Dantzig-Wolf Reformulation (DWR).

On the other hand, there is limited research on shop

scheduling with period-indexed formulations. To the

best of our knowledge, Ho et al. (2022) is the only

work to date featuring this modeling choice, featuring

a Logic-Based Benders Decomposition (LBBD) for

the two-machines permutation flow-shop problem.

Table 1 formally classifies the different discussed

problem settings, using the 3-field notation proposed

in Graham et al. (1977) to characterize the general

setting of these problems. Additionally, φ

max

will de-

note the contracted power limit, on/off the machines

regulation via the “on/off” mechanism, and T EC the

total energy cost of a schedule. We also adopt the

naming conventions of Pinedo (2016) for schedul-

ing problems. For MILP approaches, we specify the

nature of the formulation using the previously intro-

duced acronyms D, TI, and PI.

3 PROBLEM DESCRIPTION AND

FORMULATION

3.1 Formal Problem Definition

We consider a shop floor with a set M of machines

and a set J of jobs to be performed over a time hori-

zon C . Each job j ∈ J must be executed on a pre-

defined ordered subset of machines M

j

⊆ M , giving

rise to as many operations subject to precedence con-

straints. Without loss of generality, we consider in

this study that every job executes over all machines:

an operation can hence be denoted as ( j,m) ∈ O

with O

:

= J × M denoting the set of operations, and

|M

j

| = |M |,∀ j ∈ J . For each j ∈ J , we denote

( j,m) ≺ ( j,m

′

) if operation ( j,m) must be processed

before operation ( j,m

′

), i.e. if in the ordered subset

M

j

, m precedes m

′

.

The processing time p

j,m

of an operation is known

and is deterministic. Each machine m has a constant

nominal power ϕ

m

, therefore each operation ( j,m)

has energy consumption of ϕ

m

p

j,m

. Energy usage is

subject to a ToU pricing, hence the time horizon C is

divided into a set K of periods, each period k ∈ K

featuring a duration l

k

and a price per energy unit c

k

.

Let t

k

denote the start date of period k, then t

1

= 0,

t

k+1

−t

k

= l

k

,∀k ∈ J1,|K |K, t

|K +1|

= C.

In addition to being precedence-compliant, the

processing of operations must be non-preemptive (i.e.

uninterrupted) and avoid overlapping on the same ma-

chine. The goal is to find a feasible schedule of all op-

erations within the time horizon C, such that the cost

of the energy used to process them, determined by the

ToU fees, is minimized. Using the three-field notation

Minimizing Energy Cost in a Job-Shop Scheduling Problem Under ToU Pricing: A New Method Based on a Period-Indexed MILP

321

Table 1: A summary of the cited works.

Problem class Article Problem

Solution

Approach

job-shop

scheduling

(Bley and Linß, 2022) Jm|on/off, r

j

,d

j

|T EC MILP (TI), B&B

(Masmoudi et al., 2019) Jm|φ

max

|T EC MILP (D,TI), MH

flexible job-shop

scheduling

(Park and Ham, 2022) FJm|on/off|C

max

,T EC MILP (TI), CP

(Jiang and Wang, 2020) FJm||C

max

,T EC MILP (TI), H

flow-shop scheduling (Ho et al., 2022) F2|prmu,on/off |TEC MILP (PI), LBBD

parallel machine

scheduling

(Gaggero et al., 2023) Pm||T EC,C

max

MILP (TI), H

(Che et al., 2017) Rm||T EC MILP (PI), H

(Ding et al., 2016) Rm||T EC MILP (PI), DWR

single machine

scheduling

(Tian and Zheng, 2024) 1|batch|TEC CG-H

(Cheng et al., 2016) 1|batch|TEC MILP (PI)

CG-H : column generation based heuristic TI : time-indexed formulation

MH : matheuristic D : disjunctive formulation

H : problem specific heuristic PI : period-indexed formulation

previously recalled, the problem can be referred to as

Jm||T EC.

3.2 Mathematical Formulation

In this section, a novel MILP for the studied problem

is presented. Its main feature is to be indexed on ToU

periods, since the variables that allow to compute the

cost of the energy consumption associated with an op-

eration are indexed on the ToU periods. In the follow-

ing, symbols j, j

′

∈ J , m,m

′

∈ M and k, k

′

∈ K will

respectively denote jobs, machines and ToU periods.

The decision variables are: 1) binary processing sta-

tus variables x

k

j,m

, modeling whether operation ( j,m)

is processed during period k or not, 2) non-negative

processing duration variables d

k

j,m

, equal to the du-

ration of the processing of operation ( j,m) in period

k, 3) non-negative variables s

j,m

∈ [0,C − p

j,m

] and

c

j,m

∈ [p

j,m

,C], denoting the starting and completion

dates of operation ( j,m) − also known in the litera-

ture as natural date variables, 4) binary machine dis-

junction variables u

j, j

′

,m

for j < j

′

, equal to 1 if job j

is processed earlier than j

′

on machine m, and to 0 if

it is processed later than j

′

on machine m. Further, we

define for each operation ( j,m) the values

s

j,m

=

∑

m

′

∈O

j

( j,m

′

)≺( j,m)

p

j,m

′

, s

j,m

= C − p

j,m

−

∑

m

′

∈O

j

( j,m)≺( j,m

′

)

p

j,m

′

(1)

as the earliest and latest starting dates respectively.

c

j,m

and c

j,m

are defined similarly.

Objective Function: The objective function mini-

mizing the total operational cost of a schedule is

min

∑

k∈K

c

k

∑

m∈M

ϕ

m

∑

j∈J

d

k

j,m

, (2)

which is the sum of energy consumption scaled by the

price over the corresponding periods. The constraints

in the proposed MILP are as follows:

Processing Times Partition: To ensure that the

operations are entirely executed within the given

makespan C, we partition the processing times for

each operation (j,m) across the different periods:

∑

k

d

k

j,m

= p

j,m

, ∀( j,m) ∈ O. (3)

Non-Preemption: To guarantee that operations are

not preempted, it suffices to link the processing time

variables to the natural date ones, which we also need

for precedence. First, variables x and d are linked

through the constraint

d

k

j,m

⩽ min(l

k

, p

j,m

)x

k

j,m

, ∀( j,m) ∈ O,∀k ∈ K , (4)

and to the natural date variables through the following

constraints:

d

k

j,m

⩽ t

k+1

− s

j,m

+ s

j,m

(1 − x

k

j,m

),

∀( j,m)∈O,∀k ∈ K ,

d

k

j,m

⩽ c

j,m

−t

k

x

k

j,m

.

(5)

Constraints (4) act jointly with constraints (5) :

• If x

k

j,m

= 1, i.e. operation ( j,m) executes on pe-

riod k, then ( j,m) has began executing in that pe-

riod or prior to it. The first period is the small-

est k

′

for which x

k

′

j,m

= 1. It has the smallest gap

t

k

′

+1

− s

j,m

, thus d

k

j,m

⩽ t

k

′

+1

− s

j,m

.

• The second constraint is similar but involves the

end dates: the operation completes in the current

period k or after it. The last period is the largest k

′

for which x

k

′

j,m

= 1. It has the smallest gap c

j,m

−

t

k

, thus d

k

j,m

⩽ c

j,m

−t

k

′

.

ICORES 2025 - 14th International Conference on Operations Research and Enterprise Systems

322

• In case operation ( j,m) starts and ends in the same

period k, both relations (5) are dominated by the

equation d

k

j,m

⩽ p

j,m

, imposed by (4).

• if ( j,m) spans over n ⩾ 2 consecutive periods

Jk, k + n − 1K, the constraints (4) associated with

k and k +n −1 are dominated, respectively, by the

associated constraints in (5), while the opposite

occurs for intermediate periods Jk + 1,k + n − 2K.

• The first constraint of (5) is not binding if x

k

j,m

=

0, whereas the second constraint is not binding if

x

k

j,m

= 0 due to (4).

Further, the following constraint links the natural date

variables of an operation:

c

j,m

= s

j,m

+ p

j,m

, ∀( j,m) ∈ O, (6)

ensuring that an operation ( j,m) is processed with-

out preemption, whereas relations (3), (4) and (5)

guarantee that the value of its processing time p

j,m

is correctly partitioned into consecutive ToU periods.

Precedence: Precedence constraints write as

c

j,m

⩽ s

j,m

′

, ∀ j ∈ J ,∀m,m

′

∈ M

j

: ( j,m) ≺ ( j,m

′

),

(7)

i.e. ( j,m) completes before the start of ( j,m

′

). Note

that c

j,m

could be replaced by s

j,m

+ p

j,m

in the differ-

ent equations. We maintain this notation for clarity.

Machine Disjunction: To ensure that any two given

operations scheduled on the same machine do not

overlap, we define the precedence variables through

the following big-M constraints:

(

c

j,m

− s

j

′

,m

⩽ ∆

j, j

′

,m

(1 − u

j,j

′

,m

), ∀ j, j

′

∈ J : j < j

′

c

j

′

,m

− s

j,m

⩽ ∆

j

′

, j,m

u

j,j

′

,m

, ∀m ∈ M ,

(8)

where ∆

j, j

′

,m

:

= c

j,m

− s

j

′

,m

. If j precedes j

′

on ma-

chine m, i.e. c

j,m

⩽ s

j

′

,m

, then u

j, j

′

,m

= 1.

3.3 Valid Inequalities

The introduced model PI is compact, involving

a polynomial number of variables and constraints.

However, due to the big-M constraints that linearize

its disjunctive structure, it can result in weak linear

relaxations despite using tight bounds on these con-

straints (Conforti et al., 2014). In the following sec-

tion, we introduce different families of valid inequal-

ities aimed at improving the introduced model.

Transitive Precedence: If operation ( j,m) is sched-

uled on machine m before ( j

′

,m), and ( j

′

,m) is sched-

uled before ( j

′′

,m), then u

j, j

′′

,m

must take value 1:

∀ j, j

′

, j

′′

∈ J : j < j

′

< j

′′

u

j, j

′

,m

+ u

j

′

, j

′′

,m

− 1 ⩽ u

j, j

′′

,m

,

∀m ∈ M .

(9)

Consecutive Period Processing Inequalities:

Given a machine m and a period k, at most one opera-

tion ( j,m) can be processed over k and the following

period k + 1, yielding in that case x

k

j,m

+ x

k+1

j,m

= 2.

Based on this consideration, we can write:

∀ j, j

′

∈ J : j < j

′

,

x

k

j,m

+ x

k+1

j,m

+ x

k

j

′

,m

+ x

k+1

j

′

,m

⩽ 3,

∀m ∈ M ,∀k ⩽ |K | − 1.

(10)

Via similar reasoning, all operations ( j, m) of dura-

tion lesser or equal than the shortest ToU period can

execute over at most two periods:

∑

k∈K

x

k

j,m

⩽ 2, ∀( j,m) ∈ O : p

j,m

⩽ min

k

l

k

. (11)

Non-Preemption Inequalities: If operation ( j,m)

completes at a period k, i.e. x

k

j,m

= 1 and x

k+1

j,m

= 0,

then processing cannot occur at periods k

′

⩾ k + 1:

∀( j,m) ∈ O,

|K |

∑

k

′

=k+1

x

k

′

j,m

⩽ (|K | − k)(1 − x

k

j,m

+ x

k+1

j,m

),

∀k ⩽ |K | − 1.

(12)

Similarly, we can derive inequalities for the opposite

case, in which the processing of ( j,m) starts at k:

∀( j,m) ∈ O,

k−2

∑

k

′

=1

x

k

′

j,m

⩽ (k − 2)(1 − x

k

j,m

+ x

k−1

j,m

),

∀k ⩾ 3.

(13)

Further, if the processing of ( j,m) extends over two

non-consecutive periods, then it must process over the

intermediate one:

∀( j,m) ∈ O,

x

k

j,m

⩾ x

k−1

j,m

+ x

k+1

j,m

− 1,

∀k ∈ J2,|K | − 1K.

(14)

Precedence Inequalities: Consider two operations

of the same job ( j,m) and ( j,m

′

) s.t. ( j,m) ≺ ( j,m

′

).

If ( j,m

′

) executes over period k, ( j,m) cannot execute

over all subsequent periods. As such, we have:

∀m,m

′

∈ O

j

:

K

∑

k

′

=k+1

x

k

′

j,m

⩽ (|K | − k)(1 − x

k

j,m

′

), ( j,m) ≺ ( j,m

′

),

∀k ⩽ |K| − 1.

(15)

The explanation of (15) is similar to that of relations

(12) and (13). They are non-binding if x

k

j,m

′

= 0, and

force all variables x

k

′

j,m

,(k

′

> k) to be 0 otherwise. By

the same logic, this applies to the preceding periods:

∀m,m

′

∈ O

j

:

k−1

∑

k

′

=1

x

k

′

j,m

′

⩽ (k − 1)(1 − x

k

j,m

), ( j,m) ≺ ( j,m

′

),

∀k ⩾ 2.

(16)

Processing Duration Inequalities: We can de-

rive upper bounds on period processing duration, i.e.

d

k

j,m

⩽ d

k

j,m

, where for each operation ( j,m) and period

Minimizing Energy Cost in a Job-Shop Scheduling Problem Under ToU Pricing: A New Method Based on a Period-Indexed MILP

323

k, we have:

d

k

j,m

=

0 if t

k+1

⩽ s

j,m

∨ c

j,m

⩽ t

k

,

t

k+1

− s

j,m

if t

k

⩽ s

j,m

⩽ t

k+1

,

c

j,m

−t

k

if t

k

⩽ c

j,m

⩽ t

k+1

,

l

k

otherwise.

This allows us to replace (4) by a stronger inequality:

d

k

j,m

⩽ min(l

k

, p

j,m

,d

k

j,m

)x

k

j,m

, ∀( j,m) ∈ O,∀k ∈ K .

(17)

Non-Overlap Inequalities: Given a period k and a

machine m, the sum of the processing durations of all

of the associated operations must not exceed the pe-

riod length due to the non-overlapping requirement.

This also applies to operations of jobs given the prece-

dence relations. It follows that:

∑

j∈J

d

k

j,m

⩽ l

k

, ∀m ∈ M ,∀k ∈ K . (18)

∑

m∈M

d

k

j,m

⩽ l

k

, ∀ j ∈ J ,∀k ∈ K . (19)

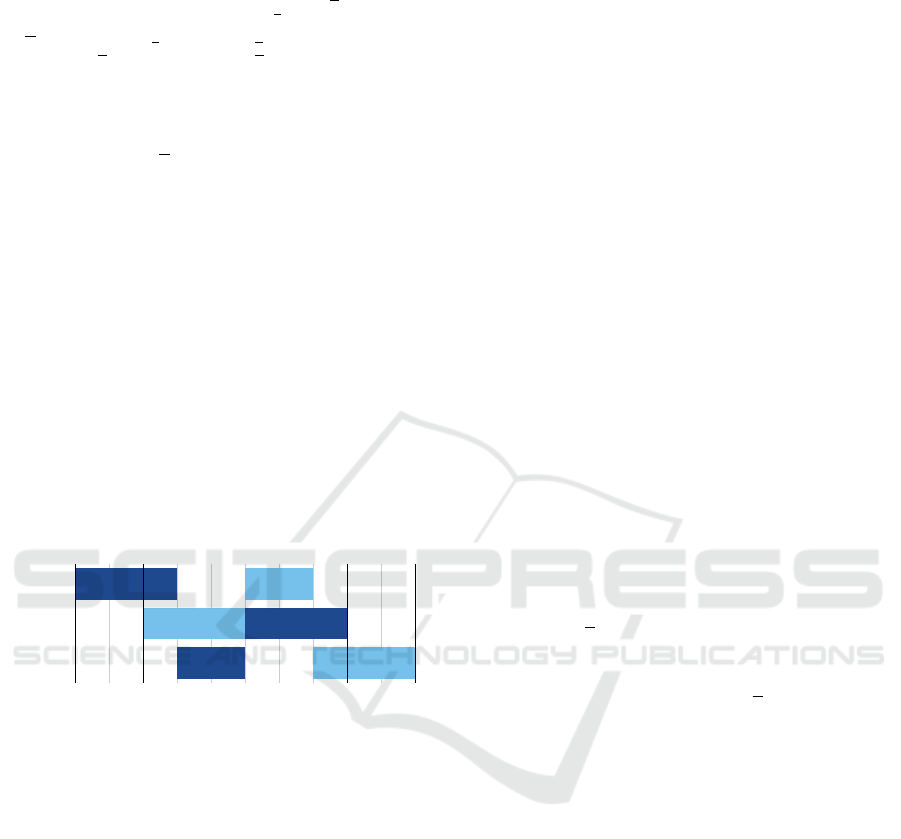

Consider the feasible schedule provided in Figure 1

with jobs J

1

and J

2

and machines M

1

, M

2

and M

3

. In

the second period starting at t

1

and ending at t

2

, we

have d

2

1,2

+ d

2

2,2

⩽ l

2

and d

2

2,2

+ d

2

2,1

+ d

2

2,3

⩽ l

2

.

M

1

(1,1) (2,1)

M

2

(2,2) (1,2)

M

3

(1,3) (2,3)

t

0

t

1

t

2

t

3

Figure 1: A two job, three machine example.

Note: Inequalities similar to (12), (13) and (18)

were used as model-defining constraints in Che et al.

(2017) for a parallel machine scheduling problem.

4 COMPUTATIONAL

EXPERIMENTS

In this section, we analyze the performance of the

time-indexed model against the proposed period-

indexed one. Further, we seek to assess the impact of

the derived valid inequalities on improving the model

linear relaxation and the Branch&Bound tree search.

The MILPs have been implemented on Julia 1.10 and

solved using Gurobi 11.0. Experiments are run with a

time limit of one hour, on a single thread of a 28-core

Intel Xeon Gold 6132, 2.60 GHz machine.

Set of Instances: We tested our formulation on the

benchmark instances provided by Masmoudi et al.

(2019). In that work, the Jm|φ

max

|T EC is tackled,

which generalizes the problem presented here by

considering a limit on the power usage along the

schedule, and two families of instances are derived

from the JSSP instances ft06 (Fisher and Thomp-

son, 1963) with 6 jobs and 6 machines, and la04

(Lawrence, 1984) with 5 jobs and 10 machines. The

authors enhance the instances with: a) 5 different sets

ϕ

i

of machine power values drawn randomly from

U[5, 10], b) 3 different planning horizon values λ ·C

⋆

with λ ∈

1.0,1.1,1.2

, C

⋆

denoting the minimal

makespan under a maximum power constraint, c) 3

different power peak thresholds equal to α ·

∑

m

ϕ

m

with α ∈

0.7,0.9,1.0

. Of the 90 resulting in-

stances, we consider the 30 having α = 1.0, as this

makes the peak power constraint non-binding and

gives rise to the Jm||T EC problem studied here.

As for the ToU tariffs, we considered the ones

used in the original instances based on the electricity

price profiles in France with on- and off-peak periods.

Base Model: In Table 2, we compare the results of

the reference time-indexed model of Masmoudi et al.

(2019) referred to as IP2, and the period-indexed for-

mulation (3)-(8), which we refer to as PI

0

. The com-

parison is performed on the basis of the 30 considered

instances under a 3600s time limit, averaged over the

machine power values, since they are drawn from the

same uniform distribution. For each model, the col-

umn T/(%)/[#x] reports the CPU time T for solving

the instance to optimality, or the final gap (%) if op-

timality is not proven within the time limit alongside

the number of feasible solutions [#x]. We also report

the gap %

r

between the root relaxation and the best

known solution, as well as the number of nodes #n

explored in the B&B tree before optimality is proven

or the time limit is exceeded. The best known solu-

tion is always optimal, as for all instances, at least one

of the two algorithms finds an optimum within time

limit. Further, we provide a comparison of the size of

the two models using the ratio of the number of vari-

ables (#cols) and that of the constraints (#rows), both

measured prior to Gurobi presolve.

The results seem to suggest that the parameter λ

has an impact on the effectiveness of IP2 and PI

0

.

In fact, for λ = 1.0, the PI

0

-based algorithm consis-

tently outperforms its IP2 counterpart despite larger

root gaps: optimal solutions are found significantly

faster for the 5 ft06 instances, while for the la04 ones,

for which IP2 cannot find cannot prove optimality (2

cases) or even find feasible solutions (3 cases), PI

0

converges to optimal solutions in 20s on average.

In general, the PI

0

-based algorithm is capable

of finding feasible solutions more quickly while IP2

ICORES 2025 - 14th International Conference on Operations Research and Enterprise Systems

324

Table 2: Comparison of the proposed model in its base form PI

0

and the time-indexed model IP2 of Masmoudi et al. (2019).

IP2 PI

0

relative

PI

0

IP2

inst./λ T/(%)/[#x] %

r

#n T/(%)/[#x] %

r

#n #cols #rows

ft06/1.0 0.25 0.27% 1 0.02 12.37% 1 0.20 0.33

ft06/1.1 0.368 0.05% 1 2.21 10.68% 2222 0.19 0.30

ft06/1.2 2.842 0.17% 16.4 64.40 10.28% 51K 0.20 0.32

la04/1.0 (0.63%)/[2] 0.47% 60 20.626 12.60% 3910 0.023 0.04

la04/1.1 1432.06 0.00% 8.6 (2.82%)/[5] 11.85% 612K 0.024 0.04

la04/1.2 2564.31 0.00% 27.6 (5.25%)/[5] 11.85% 506K 0.022 0.04

yields a tighter linear relaxation, which is in line with

the conclusions from Masmoudi et al. (2019). For

λ = 1.0, PI

0

is able to reach optimality within the

time limit as a result of a reduced search space, due

to the scheduling horizon being the smallest possible.

In contrast, the IP2-based algorithm encounters diffi-

culties in finding initial feasible solutions, particularly

for the la04 instances. The issue with IP2 appears to

be the computational time required for linear relax-

ations at each node of the B&B tree. Specifically, for

the la04 set at λ = 1.0, at most 60 nodes are visited on

average. Meanwhile, for PI

0

, the linear relaxation of

a node is computed much more rapidly, allowing it to

explore more nodes.

As λ increases beyond 1.0, the longer time hori-

zons expand the search space and expose the sym-

metry of PI

0

, leading to a shift in performance be-

tween the two models. Despite the increased time re-

quired to prove optimality, the IP2-based algorithm

finds feasible solutions more easily than PI

0

on the

la04 set and, with its tighter dual bound, proves op-

timality more quickly after exploring a comparable

number of nodes. Particularly, it can find the optimal

solution relying mostly on the root linear relaxation,

and in four cases, the optimal solution is reached at

the root node. Conversely, while the PI

0

-based algo-

rithm continues to find feasible solutions quickly, it

struggles to close the optimality gap due to the pres-

ence of numerous equivalent solutions as well as less

effective pruning due to looser relaxations, causing a

significant increase in the number of explored nodes.

Table 3: Runtime % to improve UB and LB for PI

0

.

inst./λ finding optimum proving optimality

ft06/1.0 0.1% 99.9%

ft06/1.1 6.0% 94.0%

ft06/1.2 7.8% 92.2%

la04/1.0 62.2% 38.8%

la04/1.1 0.2% -

la04/1.2 0.3% -

To this end, Table 3 aims to highlight the percent-

age of time for PI

0

that is spent on 1) finding a fea-

sible solution with optimal objective value, and once

it is found, 2) proving its optimality. From the re-

sults above, it appears that the majority of runtime is

spent on proving optimality. Note that for λ > 1.0,

even though incumbents with optimal objective val-

ues are identified early in the execution, the model

fails to close the gap.

Valid Inequalities: In Table 4, we show the impact

of different families of cuts on the efficiency of PI

0

.

Symbols T/(%), %

r

and #n have the same meaning as

in Table 2. The following PI

0

variants are tested,

• PI

1

, statically adding inequalities (9)-(16),

• PI

2

, incorporating inequalities (17)-(19),

• PI

all

, including all the described valid inequalities.

The studied valid inequalities were categorized based

on the involvement of processing duration variables,

particularly through upper-bound constraints rather

than if-then implications. Since processing durations

are partitioned across periods with varying costs, min-

imizing a total weighted sum tightens these upper-

bound constraints, especially in low-cost ToU peri-

ods. Further, non-overlap is modeled using big-M

constraints (8) on variables linked to processing du-

ration variables via inequalities (5), potentially con-

tributing to the weak relaxation in the base model.

The results of Table 4 demonstrate that the second set

of inequalities in PI

2

have a stronger impact. Opti-

mality is proven within at most four seconds on all

instances, which is a significant reduction in comput-

ing time, especially for larger λ values. For the la04

instances, as the time horizon grows, the impact of

these inequalities becomes greater as opposed to the

trend that PI

0

shows. Conversely, for the ft06 set, both

computing time and the number of explored nodes

grow as λ increases for all formulations. Further, the

second set of inequalities alone reduce the root gap

to the same order of magnitude as the much tighter

time-indexed model IP2. This is especially evident in

the la04 instances: for λ = 1.1 and λ = 1.2, the root

Minimizing Energy Cost in a Job-Shop Scheduling Problem Under ToU Pricing: A New Method Based on a Period-Indexed MILP

325

Table 4: Comparison of the different proposed PI

0

variants on the ft06 and la04 instances.

PI

0

PI

1

PI

2

PI

all

inst./λ T/(%) %

r

#n T/(%) %

r

#n T/(%) %

r

#n T/(%) %

r

#n

ft06/1.0 0.02 12.4% 1 0.02 12.4% 2 0.01 0.9% 1 0.01 0.9% 1

ft06/1.1 2.21 10.7% 2232 3.07 10.7% 2473 0.40 0.6% 470 0.62 0.6% 386

ft06/1.2 64.40 10.3% 50K 56.92 10.3% 38K 1.96 0.9% 1606 2.45 0.9% 1165

la04/1.0 20.62 12.6% 3910 23.14 12.6% 3700 4.00 0.5% 2237 6.44 0.5% 1900

la04/1.1 (2.8%) 11.8% 612K (3.3%) 11.8% 276K 0.18 0.0% 75 0.53 0.0% 86

la04/1.2 (5.3%) 11.8% 506K (5.4%) 11.8% 205K 0.05 0.0% 1 0.14 0.0% 1

gap reduces to 0%, whereas the average number of ex-

plored nodes decreases to just 75 and 1, respectively.

On the other hand, while the number of explored

nodes is reduced on four of the six sets for PI

1

, the

computing time remains almost unchanged with re-

spect to PI

0

. The performance of the root gap sug-

gests that the inequalities (9)-(16) overburden the lin-

ear relaxations at each node without improving the

gap, whereas the reduction in the number of nodes

could be attributed to bound propagation and locally

valid cuts within individual parts of the tree. Further,

when combining both families of inequalities in PI

all

,

we notice a slight loss of time performances with re-

spect to PI

2

throughout the whole benchmark set, de-

spite exploring equal or fewer nodes overall. We can

conclude that on the tested instances, the PI

2

-based

B&B is the most-performing algorithm.

Table 5: Root relaxation time and model size comparison.

inst. IP2 PI

0

PI

2

#rows

PI

2

IP2

ft06 < 0.1ms < 0.1ms < 0.1ms 0.35

la04 214.12s < 0.1ms 10ms 0.05

Table 5 compares the CPU time required to solve

the root node relaxation for IP2, PI

0

, and PI

2

, along

with the ratio of the number of rows between IP2

and PI

2

, aggregated by instance. While IP2 provides

strong relaxations, its computational cost significantly

rises for larger instances. In contrast, the valid in-

equalities introduced for PI

2

enhance the quality of

the root relaxation as shown in Table 4, with negligi-

ble impact on the model size and computation time.

These results highlight the strength of formulation

PI

2

on the tested instances. After adding inequal-

ities (17)-(19), the proposed period-based MILP (a)

remains compact, (b) retains its ability to quickly find

high-quality feasible solutions, (c) achieves a strong

root relaxation, (d) whilst also being able to solve

each linear relaxation relatively fast.

5 CONCLUSION AND FUTURE

WORK

In this work, we address the job-shop scheduling

problem under energy considerations, specifically

focusing on minimizing total energy costs within

a Time-of-Use (ToU) pricing scheme, denoted as

Jm||T EC. To achieve this, we propose a novel period-

indexed MILP, in which the variables used to com-

pute the cost of the energy usage of operations are

indexed based on the periods of the ToU profile. This

approach was preferred to a time-indexed alternative

to obtain a more compact MILP, as time-indexed for-

mulations can be very effective, but struggle when the

considered time span gives rise to large mathematical

programs, as it is the case with the reference TI model

in the literature.

Our results indicate that the proposed period-

indexed model is well-suited for achieving signif-

icantly smaller model sizes, and the Branch-and-

Bound (B&B) tree node linear relaxations can be

computed up to six orders of magnitude faster for

some of the tested instances with a larger time span.

With instances featuring a time horizon equal to the

optimal makespan of the original JSSP instance, the

B&B algorithm based on the period-indexed model

in its basic setting outperforms the time-indexed one.

This is due to the fact that the proposed period-

indexed formulation, in spite of weak linear relax-

ations, allows to find feasible solutions more easily

than the time-indexed counterpart, largely due to the

model size. However, as the time span is enlarged,

the latter benefits of larger scheduling horizons, find-

ing more feasible solutions and then converging more

quickly due to the tighter linear relaxation, whereas

the former struggles to close the optimality gap.

To address this issue, we explored the addition

of different sets of valid inequalities to the proposed

period-indexed model in order to tighten its linear re-

laxation. Three different variants of the base model

ICORES 2025 - 14th International Conference on Operations Research and Enterprise Systems

326

were tested in which the proposed valid inequalities

were alternatively or jointly considered. The results

show that inequalities aimed at strengthening non-

overlap constraints and tightening the bounds of the

period-indexed variables are the most effective. This

is because they allow the linear relaxation to be com-

parable to that of the time-indexed model, despite a

smaller number of variables and constraints, hence

preserving these advantages while ensuring a much

quicker convergence.

Future research directions include strengthening

the less-effective valid inequalities and/or adding

them dynamically in the B&B tree through tailored

separation routines. From a combinatorial perspec-

tive, it would certainly be interesting to generalize

the piecewise-constant ToU profile and consider more

complex cost structures. Another interesting direction

would be to consider variable power profiles instead

of constant ones. Finally, the flexibility of the period-

indexed formulation opens the possibility for its ap-

plication to other scheduling problems, as well as the

incorporation of other constraints, such as release and

due dates, as well as setup times, making it a versatile

tool for broader industrial applications dealing with

energy cost minimization.

REFERENCES

Bley, A. and Linß, A. (2022). Propagation and branch-

ing strategies for job shop scheduling minimizing

the weighted energy consumption. In International

Conference on Operations Research, pages 573–580.

Springer.

Che, A., Zhang, S., and Wu, X. (2017). Energy-conscious

unrelated parallel machine scheduling under time-of-

use electricity tariffs. Journal of Cleaner Production,

156:688–697.

Cheng, J., Chu, F., Chu, C., and Xia, W. (2016). Bi-

objective optimization of single-machine batch

scheduling under time-of-use electricity prices.

RAIRO - Operations Research, 50:715–732.

Conforti, M., Cornu

´

ejols, G., Zambelli, G., Conforti, M.,

Cornu

´

ejols, G., and Zambelli, G. (2014). Integer pro-

gramming models. Springer.

Dauz

`

ere-P

´

er

`

es, S., Ding, J., Shen, L., and Tamssaouet, K.

(2024). The flexible job shop scheduling problem: A

review. European Journal of Operational Research,

314(2):409–432.

Ding, J. Y., Song, S., Zhang, R., Chiong, R., and Wu, C.

(2016). Parallel machine scheduling under time-of-

use electricity prices: New models and optimization

approaches. IEEE Transactions on Automation Sci-

ence and Engineering, 13:1138–1154.

Fisher, H. and Thompson, G. (1963). Probabilistic learn-

ing combinations of local job-shop scheduling rules.

Prentice Hall, Englewood Cliffs, New Jersey, pages

225–251.

Gaggero, M., Paolucci, M., and Ronco, R. (2023). Exact

and heuristic solution approaches for energy-efficient

identical parallel machine scheduling with time-of-

use costs. European Journal of Operational Research,

311:845–866.

Garey, M. R., Johnson, D. S., and Sethi, R. (1976).

The complexity of flowshop and jobshop scheduling.

Mathematics of operations research, 1(2):117–129.

Graham, R., Lawler, E., Lenstra, J., and Kan, A. (1977).

Optimization and approximation in deterministic se-

quencing and scheduling: A survey. Annals of Dis-

crete Mathematics, 5:287–326.

Ho, M. H., Hnaien, F., and Dugardin, F. (2022). Exact

method to optimize the total electricity cost in two-

machine permutation flow shop scheduling problem

under time-of-use tariff. Computers and Operations

Research, 144.

International Energy Agency (2023). World en-

ergy outlook 2023. https://www.iea.org/reports/

world-energy-outlook-2023. Accessed: 2024-10-01.

Jiang, E. and Wang, L. (2020). Multi-objective optimization

based on decomposition for flexible job shop schedul-

ing under time-of-use electricity prices. Knowledge-

Based Systems, 204.

Lawrence, S. (1984). Resouce constrained project schedul-

ing: An experimental investigation of heuristic

scheduling techniques (supplement). Graduate School

of Industrial Administration, Carnegie-Mellon Uni-

versity.

Masmoudi, O., Delorme, X., and Gianessi, P. (2019).

Job-shop scheduling problem with energy considera-

tion. International Journal of Production Economics,

216:12–22.

Park, M. J. and Ham, A. (2022). Energy-aware flexible job

shop scheduling under time-of-use pricing. Interna-

tional Journal of Production Economics, 248.

Pinedo, M. (2016). Scheduling: Theory, Algorithms, and

Systems. Springer, 5th edition.

Tian, Z. and Zheng, L. (2024). Single machine parallel-

batch scheduling under time-of-use electricity prices:

New formulations and optimisation approaches. Euro-

pean Journal of Operational Research, 312:512–524.

Minimizing Energy Cost in a Job-Shop Scheduling Problem Under ToU Pricing: A New Method Based on a Period-Indexed MILP

327