Design and Development of an Interactive and Intelligent Wood

Harvester Machine Operator Simulator

Barve Pranjali Ramesh

a

, Ian Backus and Raffaele de Amicis

b

Oregon State University, Corvallis, U.S.A.

{barvep, backusi, deamicisr}@oregonstate.edu

Keywords:

Virtual Reality Training, Harvester Simulator, Forestry Machine Operation, Interactive Learning.

Abstract:

This paper presents the design and development of a virtual reality (VR) forestry harvester simulator, opti-

mized for the untethered Meta Quest. The simulator offers an immersive training environment where users

can practice essential harvester operations such as navigation, tree processing, and control of the harvester head

and boom. A comprehensive functional evaluation was conducted using 20 black-box test cases to ensure the

simulator functions as intended, with testing performed in both standalone and PC-tethered configurations.

The results confirmed the simulator’s reliability, highlighting differences in responsiveness and graphical per-

formance across configurations. With the portability and accessibility of the Meta Quest, the system provides a

flexible, cost-effective solution suitable for both training and educational applications. Future work will focus

on evaluating the usability of the system and validating its effectiveness within formal educational settings by

integrating the simulator into forestry curricula.

1 INTRODUCTION

Worldwide, forestry contributes to economic develop-

ment, environmental sustainability, and social well-

being. As of 2023, the global forestry sector was val-

ued at over $1 trillion, providing millions of jobs and

essential resources, such as timber, paper, and bioen-

ergy (Lippe et al., ). A key component of this indus-

try is the use of harvesting machines, complex and

powerful tools designed to efficiently cut and process

trees. Over time, these machines have evolved from

basic mechanized tools into highly advanced systems

equipped with with semi-autonomous features.

As harvesting technology advances, so does the

complexity of operating these machines. Modern

harvesters, while capable of performing many au-

tonomous tasks, still require human oversight, placing

greater demands on operators. Operating these ma-

chines involves managing challenging terrain, adapt-

ing to weather conditions, and processing large

amounts of real-time data tasks comparable to those

performed by fighter jet pilots (Burman and L

¨

ofgren,

2016). This level of complexity highlights the need

for effective training, where operators must develop

precise control and adaptive decision-making skills.

a

https://orcid.org/0009-0008-1103-0252

b

https://orcid.org/0000-0002-6435-4364

Traditionally, heavy equipment operators have

been trained on-site, which is costly and resource-

intensive. In response, many industries are turning

to simulators for cost-effective and controlled training

environments. With the rise of Virtual Reality (VR)

technology, simulators have become even more effec-

tive, offering immersive environments for training op-

erators of complex machinery (De Crescenzio et al.,

2011). In the forestry industry, where operators face

high physical and cognitive demands, VR solutions

are particularly valuable.

VR-based simulators provide several key advan-

tages for forestry training. They enable training ses-

sions without disrupting actual harvesting operations,

improving both time and cost efficiency. Physical fa-

tigue, particularly in the neck, arms, and shoulders,

is a common issue for operators, and VR simulations

can help alleviate such strain. Mental fatigue from

managing complex control interfaces and navigating

off-road environments also increases the risk of acci-

dents (Wei-Sheng Wang and Huang, 2024). VR sim-

ulators address these challenges by providing a safe,

controlled environment to enhance operator skills and

proficiency.

276

Ramesh, B. P., Backus, I. and de Amicis, R.

Design and Development of an Interactive and Intelligent Wood Harvester Machine Operator Simulator.

DOI: 10.5220/0013188000003912

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 20th International Joint Conference on Computer Vision, Imaging and Computer Graphics Theory and Applications (VISIGRAPP 2025) - Volume 1: GRAPP, HUCAPP

and IVAPP, pages 276-283

ISBN: 978-989-758-728-3; ISSN: 2184-4321

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

2 BACKGROUND AND RELATED

WORK

Early studies established the feasibility of using VR

for training forestry operators. (Lapointe and Robert,

2000) designed a VR system that simulated the con-

trol of a harvester’s manipulator arm and processing

head through a workstation and two-axis joysticks.

This system replicated the physical environment op-

erators encounter, demonstrating that VR could sig-

nificantly increase harvesting productivity while re-

ducing maintenance costs. Similarly, (Lopes et al.,

2018) found that participants with no prior experience

in forestry operations could quickly develop the nec-

essary skills using a Harvester Virtual Reality Simu-

lator (HVRS).

Over the years, simulator technologies have ad-

vanced, integrating increasingly sophisticated hard-

ware and software components. (Zheng et al., 2018)

developed a training system featuring a steering

wheel, pedals, a shifter, and control handles, with vi-

sual feedback rendered through Unity3D. This sys-

tem demonstrated the importance of creating realis-

tic driving interfaces to enhance operator immersion

and skill acquisition. Similarly, (Luecke, 2012) devel-

oped the GREENSPACE VR simulator to train com-

bine operators in precision farming. By incorporating

authentic operator controls, GREENSPACE offered a

realistic driving experience and promoted the adop-

tion of precision farming methods.

Innovative input technologies have also been ex-

plored to enhance user interaction with virtual train-

ing environments. (Nainggolan et al., 2020) evalu-

ated the Leap Motion Controller as an input device for

controlling virtual joysticks and levers. Their research

highlighted the potential for novel, gesture-based in-

put systems to improve user satisfaction and control

precision, pointing to future directions for immersive

training systems.

Because of the heavy dependency on physical

hardware like steering wheels, pedals, and joysticks

the costs and complexity of setting up training envi-

ronments increases, making it less accessible for in-

stitutions with limited resources and funds. These se-

tups also restrict flexibility, as new or updated train-

ing modules would require modifications to physical

setups, rather than being adaptable entirely through

software updates.

US companies like JohnDeere (Deere, 2024) and

CM Lab Simulations (Labs, 2024), Finnish compa-

nies Ponsse (Ponsse, 2024) and Mevea (Mevea, 2024)

have developed a virtual training platform for log-

ging harvesters with high immersion, good stability

and real-time interaction. However, these simulators

are likely to come with significant development and

maintenance costs. This can make it challenging for

smaller educational institutions or training centers to

adopt such advanced simulators.

Addressing these shortcomings could signifi-

cantly enhance the efficacy of VR training systems for

harvester and logging machinery by improving their

immersion, accessibility, and ability to accommodate

a range of learner needs.

The collective body of research and industry ef-

forts underscores the growing importance of VR tech-

nologies in forestry training. As these technologies

continue to evolve, they are poised to play a central

role in equipping operators with the skills required to

manage increasingly complex machinery. VR-based

simulators offer a cost-effective and accessible solu-

tion for initial training.

3 VIRTUAL REALITY AND DICE

FRAMEWORK

Traditional training methods often struggle to keep

pace with the evolving needs of industries such as

forestry, where technological advancements demand

more specialized skills. With VR systems becoming

more affordable, portable, and accessible sometimes

costing less than a typical smartphone the question

arises: when is it time to shift from traditional meth-

ods to next-generation VR solutions?

The DICE framework, proposed by Bailenson

(Bailenson and Lesher, 2024), provides valuable cri-

teria to determine when VR is the appropriate training

medium. DICE stands for: Dangerous, Impossible,

Counterproductive, and Expensive situations where

VR offers significant advantages over conventional

practices. A VR-based training simulator for forestry

harvester operators aligns well with the DICE frame-

work by addressing each of these dimensions:

Dangerous: Operating forestry harvesters in-

volves maneuvering heavy equipment across uneven

terrain and navigating dense forest environments,

which can pose risks, especially for novice operators.

Training in a virtual environment mitigates the risk

of accidents and injuries, offering users a safe space

to develop their skills without exposure to real-world

hazards. VR allows trainees to practice critical ma-

neuvers repeatedly until they achieve proficiency, re-

ducing the likelihood of mishaps during live opera-

tions.

Impossible: Simulating rare or extreme scenar-

ios in real life, such as operating in severe weather

conditions, handling equipment failures, or respond-

ing to falling trees, can be impractical for safety rea-

Design and Development of an Interactive and Intelligent Wood Harvester Machine Operator Simulator

277

sons. VR enables operators to experience and prepare

for these uncommon situations, equipping them with

the decision-making skills necessary to respond effec-

tively when such challenges arise in the field.

Counterproductive: Traditional on-site training

often requires taking expensive equipment out of ser-

vice, slowing down productivity, and diverting skilled

operators from their regular duties to mentor trainees.

Moreover, forestry operations are seasonal, with busy

periods leaving little room for in-depth training. VR

eliminates these disruptions by allowing operators to

train at any time without impacting ongoing opera-

tions. This ensures that essential training does not

interfere with crucial harvesting windows, helping to

maintain productivity throughout the year.

Expensive: On-site training involves consider-

able costs, including machinery operation, mainte-

nance, fuel, and the risk of equipment damage dur-

ing practice. VR simulators offer a cost-effective al-

ternative by reducing reliance on physical machinery.

Operators can practice as many times as needed with-

out incurring additional costs, minimizing the finan-

cial burden associated with real-world training.

VR enhances training with consistency and scala-

bility, allowing standardized modules to be replicated

across locations and schedules, ensuring uniform skill

development. This promotes safety and efficiency in

forestry operations.

Aligned with the DICE framework, VR simulators

provide immersive, repeatable, and risk-free training

scenarios, essential for mastering complex machinery.

Integrating VR into forestry training reduces costs,

minimizes disruptions, and prepares operators for the

challenges of modern forestry.

4 SIMULATOR DESIGN

4.1 Software Stack

The software stack for this project is built around

Unity 2022.3.23f1, which serves as the primary game

engine. Unity is selected for its versatility and ro-

bust tools for creating immersive 3D experiences. The

project makes use of Unity’s built-in physics engine to

simulate real-world interactions with high accuracy. It

also helps to enable realistic physical behavior and in-

teractions within the virtual environment. The built-in

3D rendering capabilities are used to guarantee op-

timal performance and visual quality which allows

complex models and environments to be rendered

smoothly. The project is developed using C#, which

is the preferred programming language in Unity for

its ability to handle object-oriented programming and

efficient manipulation of game objects. Visual Studio

2022 is selected as the Integrated Development Envi-

ronment (IDE). Git and GitHub Desktop are utilized

for version control and code management throughout

the development process. To support extended real-

ity (XR) functionality, the project integrates the Ocu-

lus XR Plugin along with Unity’s XR Plugin Man-

agement. These packages are critical for managing

and deploying the application to various XR plat-

forms, ensuring compatibility with devices like the

Meta Quest series, and providing users with a smooth

and immersive VR experience. Together, this suite

of technologies forms a cohesive and efficient frame-

work for the development, testing, and deployment of

the VR project.

4.2 Meta Quest

Unity supports development and deployment on the

Meta Quest (Quest, 2024), making it ideal for the sim-

ulator.

The Meta Quest 2 and 3s are more affordable

than other VR devices. For training environments,

especially in educational or industrial contexts, bud-

get constraints often necessitate selecting a solution

that balances performance with cost. Its affordability

made it an ideal choice for prototyping and validating

the system’s functionality.

Therefore, the simulator has been developed and

optimized for the Meta Quest 2 and 3s standalone VR

headset. With Six Degrees of Freedom (6DOF) the

headset provides full immersive experience to the user

in a virtual space. The headset also features built in

3D positional audio.

The Meta Quest controllers are used as the pri-

mary user input. The controllers are programmed

through scripting, allowing users to manipulate scene

objects within the virtual environment. During the de-

velopment phase, we used the the quest link cable to

connect the headset to the computer. This allowed us

to test and debug the changes made in the VR envi-

ronment instantly, making it easier to iterate quickly

without having to repeatedly build and deploy the ap-

plication to the headset.

The controllers are also made visible to the user

in the virtual environment using a prefab model. The

prefab for the Meta Quest controllers are sourced

from Meta Horizon. The controller models are avail-

able in .fbx format which makes it easy to import and

use in Unity.

GRAPP 2025 - 20th International Conference on Computer Graphics Theory and Applications

278

4.3 Harvester Model

The simulation utilizes the John Deere - 959MH

Tracked Harvester model integrated into the VR en-

vironment which has been sourced from (CGTrader,

) and developed by Markos 3D. The virtual harvester

(Figure 1) closely resembles the real one capturing its

complexities in detail.

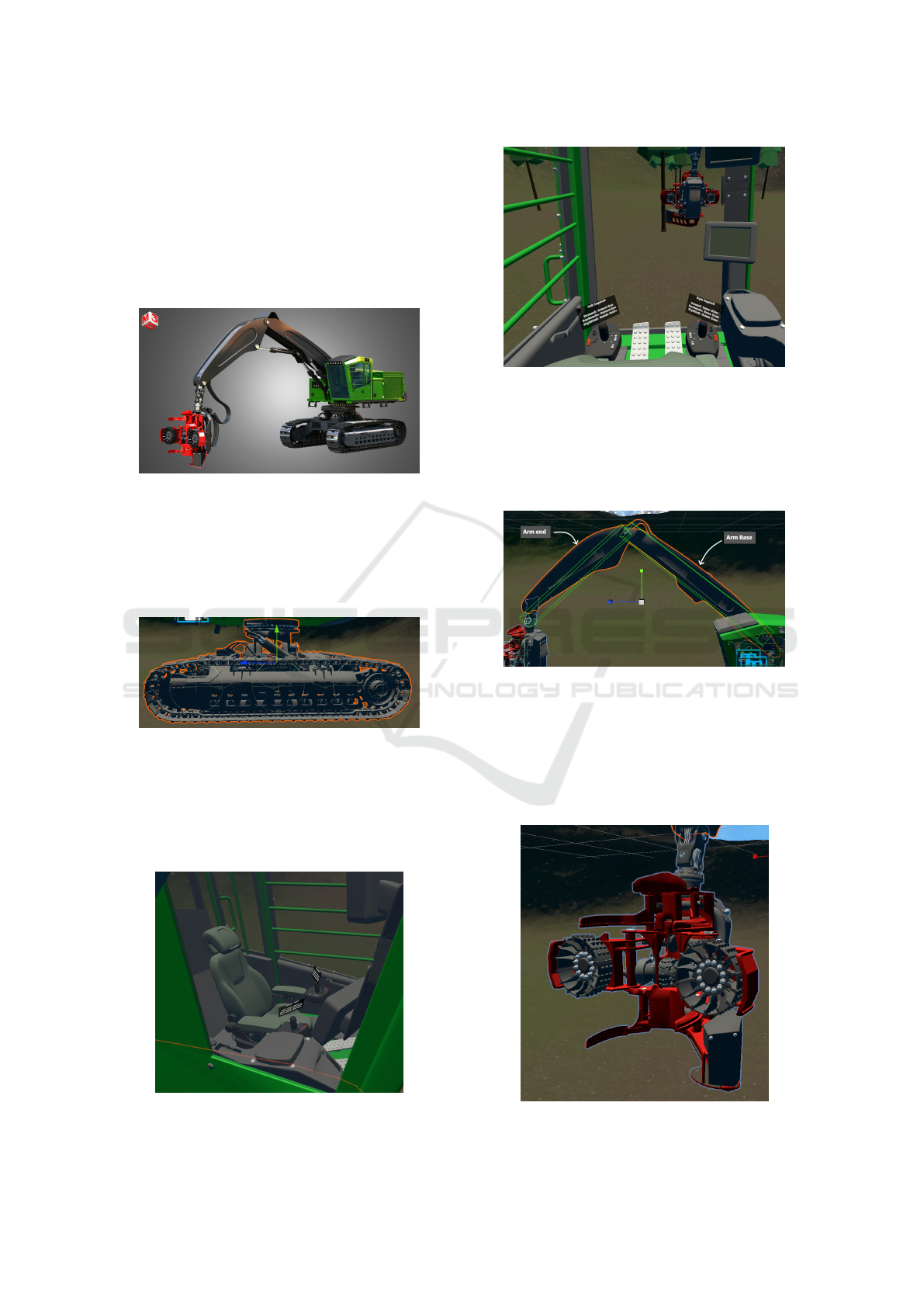

Figure 1: Virtual John Deere Harvester model.

The 4 main components of the harvester are -

tracks (Figure 2), cabin (Figure 4), harvester arm

(Figure 5) and harvester head (Figure 6). The tracks

consist of three wheels - front, middle and rear along

with a crawler on both the right and left side.

Figure 2: Harvester track.

The operator’s cabin features components like the

seat, control panel, buttons, joysticks, pedals, moni-

tors, and windows (Figure 3 and 4). We removed the

front glass pane from the original model to improve

visibility, as it obstructed the view.

Figure 3: Operator Seat.

Figure 4: Inside the cabin.

The harvester end and the harvester base make up

the harvester arm (Figure 5), sometimes referred to as

the harvester boom. Retraction, extension, lowering,

and raising of the arm are all made possible by the

Unity scripts.

Figure 5: Harvester arm.

The harvester head (Figure 6) consists of inner and

outer claws to grasp trees. It also consists of inner and

outer wheel components which process the grasped

tree. Apart from this it also features a blade to cut

trees and an arm that connects the harvester head to

the boom.

Figure 6: Harvester head.

Design and Development of an Interactive and Intelligent Wood Harvester Machine Operator Simulator

279

4.4 Scenario Creation

The virtual scenario, as shown in Figure 7 is designed

in Unity platform. Starting with the ground, it was

created using the game object terrain. Various heights

were applied at different locations to replicate the

contours of mountain terrain. To provide a more nat-

ural look, we also applied grass and dirt textures to its

surface.

Figure 7: Harvester model and the virtual forest in Unity.

We modeled the trees in Unity with ProBuilder.

The tree prefab consists of a trunk and branches as

its child game objects. This modular design approach

treats each part, such as the trunk and branches, as

separate units or components. This allows flexibility

in creating a variety of tree types and adapting the

simulator to different use scenarios.

4.5 Simulator Design

The VR simulator, developed in Unity with C#, runs

as an Android APK on the standalone Meta Quest

headset. The Quest controllers enable intuitive inter-

action and precise control of the harvester within the

simulation.

Upon entering the VR simulator, users find them-

selves positioned inside the harvester cabin, seated in

the operator’s chair. For a better experience, the user

may also choose to sit on a physical chair while using

the simulator. The headset dynamically adjusts the

view as users move their heads. Movement within the

simulator is restricted to the cabin area, as all opera-

tional procedures must be conducted from the seated

position. Each button of the controller has a certain

action associated with it, for example, cutting, tilting,

processing, etc. The cabin also features virtual joy-

sticks on the front panel that can be manipulated us-

ing the controllers to perform specific functions. The

Meta Quest controllers and virtual joysticks, shown in

Figure 8, are labeled for easy function identification.

Figure 8: Labelled controls.

The virtual joystick once grabbed using the con-

trollers, switches its color to blue to give a visual cue,

indicating that they have been grabbed. The harvester

operates within a training field where trees are strate-

gically placed, allowing users to practice various op-

erational techniques. Figure 9 provides a high level

overview of the system architecture.

Figure 9: System architecture.

The design of the system was guided by feedback

from subject matter experts in the forestry department

at Oregon State University, ensuring that it aligns with

industry requirements. The main goal of the system is

to create a tool that is portable, accessible, and cost-

effective, making advanced training solutions avail-

able to a wider range of users and settings.

4.6 Tasks

The training sessions are divided into different mod-

ules of increasing complexity ranging from simple

navigation of a harvester to cutting and processing

a tree. These modules are divided based on the

principle of task simplification and part-task training

(Wickens et al., 2021), wherein complex tasks are di-

vided into smaller parts and trained individually be-

fore being reintegrated. Each part is a simpler version

of a complex task. As the proficiency develops, the

difficulty of the task gradually increases.

GRAPP 2025 - 20th International Conference on Computer Graphics Theory and Applications

280

Module 1 - Driving the, Harvester (Naviga-

tion): The primary objective of this initial module is

to enable the user to navigate the harvester to a desig-

nated location. This is achieved by manipulating the

thumbsticks on the controllers. Specifically, pushing

the thumbstick on the left-hand controller forward or

backward moves the harvester in the corresponding

direction, while pushing the thumbstick on the right-

hand controller left or right allows for lateral move-

ment.

Module 2 - Harvester Head and Boom Move-

ments: In this module the user has to learn correctly

how to control the movements of the harvester’s head

and arm. This involves manipulating virtual joysticks

and using specific controller buttons to achieve pre-

cise actions. To tilt the harvester head, the user has

to press the trigger button on the left-hand controller.

Pressing the grab buttons on either the right or left

controller allows the user to grip the respective vir-

tual joystick. Once the virtual joysticks are grabbed,

the movement of the harvester boom and harvester

head can be controlled. For lowering and raising

the harvester boom, the left virtual joystick needs to

be pushed forward and pulled backward respectively.

Similarly, to retract and extend the harvester boom,

the user needs to operate the right virtual joystick.

Pulling the joystick backward retracts the harvester

arm, whereas pushing it forward extends the arm. The

user can also adjust the harvester head by rotating it,

to align it properly with the tree. For rotation, push-

ing the right virtual joystick to the right rotates the

harvester head clockwise, and pushing it to the left

rotates it counterclockwise.

Module 3 - Processing Tree: The objective of

this module is to instruct users on the various actions

required for effectively processing trees with the har-

vester. Users should be able to grab, release, process,

and cut a tree. Once the harvester head is appropri-

ately positioned in front of a tree for a secure grip,

the user can press the B button on the right-hand con-

troller to close the harvester claw and grasp the tree.

To release the tree, the user must press the A button

on the right-hand controller. Pressing the trigger but-

ton on the right-hand controller will cut the tree. Ad-

ditionally, users learn to position the tree for further

processing. To process the tree upward or forward,

the X button on the left-hand controller is utilized,

while processing the tree downward or backward is

achieved by pressing the Y button on the left-hand

controller. Demonstrations of these interactions are

recorded and can be accessed through YouTube video

(XX, 2024b).

5 BLACK BOX TESTING

To thoroughly evaluate the functional capabilities of

the harvester simulator within the virtual reality (VR)

environment, we designed and conducted a series of

black-box tests. Black-box testing, which focuses on

the system’s outputs in response to a variety of user

inputs without examining the internal code, was cho-

sen to assess how effectively the simulator handles

real-world usage scenarios. A comprehensive suite

of 20 test cases was developed, covering a wide range

of interactions to validate the key functionalities of

the application and ensure it could handle both typi-

cal and edge-case user behaviors (XX, 2024a).

The primary objective of these tests was to eval-

uate the simulator’s ability to perform as intended

across multiple scenarios, as well as to assess its re-

silience when exposed to unexpected or erroneous in-

puts. These cases were designed not only to confirm

that the simulator functions correctly under normal

conditions but also to identify any potential flaws or

vulnerabilities that could emerge during atypical us-

age.

To ensure the pertinence, comprehensiveness, and

ethical soundness of our testing methodology, the en-

tire process underwent a rigorous review by the Insti-

tutional Review Board (IRB) of our institution. The

IRB approval was a critical step, as it confirmed that

the study adhered to the highest ethical standards for

research involving human participants. This approval

also enabled us to engage with practitioners from the

AR/VR field, allowing us to gather meaningful feed-

back and insights from experts actively involved in the

development, application, and optimization of immer-

sive training systems.

By combining comprehensive functional testing

with ethical oversight, we ensured that the simulator

not only meets technical requirements but also aligns

with best practices for responsible research. This ap-

proach allowed us to validate the simulator’s readi-

ness for deployment while gathering valuable input

from practitioners, further informing the iterative de-

velopment and refinement of the system.

5.1 Participants and Methods

The testing group consisted of 8 Computer Science

students, evenly split between 4 males and 4 females

at both graduate and undergraduate levels. The partic-

ipants’ ages ranged from 20 to 26 years, with a mean

age of 22.0 years and a standard deviation (STD) of

2.24 years. All participants had prior experience us-

ing VR headsets but were unfamiliar with the internal

workings of the harvester simulator. This ensured that

Design and Development of an Interactive and Intelligent Wood Harvester Machine Operator Simulator

281

their interactions with the system were unbiased, fo-

cusing purely on functionality from an end-user per-

spective.

The decision to involve computer science students

as participants in this process supported the verifica-

tion of the system. These participants, with their fa-

miliarity with VR systems, were well-positioned to

identify technical issues, assess interaction mecha-

nisms, and provide actionable feedback on the sys-

tem’s functional aspects without requiring extensive

onboarding. This approach allowed us to efficiently

validate the system’s design and development during

the early stages.

The test setup was designed to simulate realistic

conditions under which the simulator might be used.

As shown in Figure 10, participants were seated in

a physical chair to mimic the posture they would as-

sume during an actual training scenario.

Figure 10: A participant trying out the harvester simulator

on standalone VR headset.

The participants were given verbal instructions to

perform specific tasks within the simulator. Since

most participants were familiar with the naming con-

ventions for buttons and triggers on the VR con-

trollers, commands such as “Cut the tree using the

trigger button on the right-hand controller” were eas-

ily understood. However, additional guidance was

sometimes needed to help students identify the less

commonly used buttons, such as the grab and trigger

controls. More familiar buttons, such as X, Y, A, B,

and the thumbsticks, were easily identified by partic-

ipants without further assistance.

Each testing session lasted approximately 10 to 15

minutes. We conducted black-box testing on both a

standalone version of the simulator and a PC-tethered

version. Four students (2 male, 2 female) tested the

standalone version, while another four students (2

male, 2 female) tested the PC-tethered version. This

dual approach allowed us to evaluate the simulator’s

performance under different configurations, assessing

how it functioned independently on the VR headset

and how it performed when connected to a PC. We

specifically looked for differences in responsiveness,

graphical quality, and overall user interaction between

the two setups.

In the standalone configuration, students were

solely responsible for confirming whether the sim-

ulator behaved as expected based on their interac-

tions. For the PC-tethered version, the instructor

monitored and verified the simulator’s real-time be-

havior through Unity’s game view. This observation

ensured the simulator met the desired functional re-

quirements on both platforms.

5.2 Result

The black-box testing revealed that the harvester sim-

ulator responded correctly to most user inputs. How-

ever, 2 out of the 8 participants encountered issues

while understanding the exact operation of pushing

the left virtual joystick forward or backward, indicat-

ing a potential intuitivity issue. They also reported

that the pushing of the virtual joystick required more

effort, indicating a potential input sensitivity issue.

Most participants reported that the interaction felt in-

tuitive, though feedback suggested the need for more

visual feedback for familiarizing with the controls.

Students quickly became familiar with the basic

harvester operations. The instructor’s verbal instruc-

tions helped the participants understand how the con-

trollers worked. By the end of the session, most stu-

dents were capable of performing the complex task of

processing a tree without any guidance.

The harvester simulator substantially satisfies user

expectations with its intuitive control responses, ac-

cording to the findings of the black-box testing. How-

ever, the identified sensitivity issues suggest a need

for calibration of the input mechanisms to ensure

smooth interactions. Addressing these issues will

likely enhance user satisfaction and make the simu-

lator more effective for training purposes.

6 DISCUSSION AND

CONCLUSION

In this paper, we present the design and development

of a virtual reality (VR) forestry harvester simula-

tor, specifically optimized to run on the untethered

Meta Quest. The simulator offers users an immersive

platform to practice essential harvester operations, in-

cluding navigation, tree processing, and precise con-

trol of the harvester head and boom. By leveraging

the portability and accessibility of the Meta Quest, the

simulator eliminates the need for external hardware,

GRAPP 2025 - 20th International Conference on Computer Graphics Theory and Applications

282

making it more flexible and accessible for training in

various settings.

As part of this study, we conducted a thorough

evaluation of the simulator’s functionality using 20

carefully crafted test cases. This rigorous black-box

testing ensured that the system performed as intended,

providing a reliable and accurate experience across

all core operations. To further validate the system,

we assessed its performance both as a standalone ap-

plication on the Meta Quest and when tethered to a

PC, comparing differences in responsiveness, graphi-

cal quality, and user interaction.

In future work, we will focus on evaluating the us-

ability of the system and validating the effectiveness

of the training simulator in formal educational set-

tings. This will involve collaboration with academic

institutions to integrate the simulator into forestry cur-

ricula, allowing us to measure its impact on students’

learning outcomes and practical skill development.

One current limitation lies in the restricted num-

ber of interactions, constrained by the limited buttons

on standard VR controllers. To address this, future

research will explore innovative interaction methods

that reduce reliance on physical controllers. Hand

gesture recognition, for example, could be used to

manipulate the virtual model’s control panel, offering

a more natural and intuitive way for users to interact

with the system

ACKNOWLEDGEMENT

This publication was prepared by Oregon State Uni-

versity using Federal funds under award #07-79-

07914 from the Economic Development Administra-

tion, U.S. Department of Commerce. The statements,

findings, conclusions, and recommendations are those

of the authors and do not necessarily reflect the views

of the Economic Development Administration or the

U.S. Department of Commerce.

SUPPLEMENTAL MATERIALS

Supplemental materials are available at https://bit.ly/

2025-GRAPP

REFERENCES

Bailenson, J. and Lesher, M. (2024). Virtual Reality and Its

Opportunities and Risks. OECD Publishing.

Burman, L. and L

¨

ofgren, B. (2016). Human-machine inter-

action improvements of forest machines. skogforsk–

the forestry research institute of sweden.

CGTrader. 959mh tracked harvester. https://www.

cgtrader.com/3d-models/vehicle/industrial-vehicle/

959mh-tracked-harvester.

De Crescenzio, F., Fantini, M., Persiani, F., Di Stefano, L.,

Azzari, P., and Salti, S. (2011). Augmented reality for

aircraft maintenance training and operations support.

IEEE Comput. Graph. Appl., 31(1):96–101.

Deere, J. (2024). Our company and purpose.

https://www.deere.com/en/.

Labs, C. (2024). Cm labs official website. https://www.cm-

labs.com/en/.

Lapointe, J.-F. and Robert, J.-M. (2000). Using vr for ef-

ficient training of forestry machine operators. Educa-

tion and Information Technologies, 5:237–250.

Lippe, R. S., Schweinle, J., Cui, S., Gurbuzer, Y., Kata-

jam

¨

aki, W., Villarreal-Fuentes, M., and Walter, S.

Contribution of the forest sector to total employment

in national economies: estimating the number of peo-

ple employed in the forest sector. Food and Agricul-

tural Organization of the United Nations.

Lopes, E. d. S., Pagnussat, M. B., and Cabral, O. d. J.

(2018). Effect of age and education level on operator’s

perfomance with harvester virtual reality simulator.

Luecke, G. R. (2012). Greenspace: Virtual reality interface

for combine operator training. Presence, 21(3):245–

253.

Mevea (2024). Mevea official website. https://mevea.com/.

Nainggolan, F., Siregar, B., and Fahmi, F. (2020). User

experience in excavator simulator using leap motion

controller in virtual reality environment. In Journal

of Physics: Conference Series, volume 1566, page

012093. IOP Publishing.

Ponsse (2024). Ponsse official website.

https://www.ponsse.com/#/.

Quest, M. (2024). Getting started with quest 2 and

quest 3. https://www.meta.com/help/quest/articles/

getting-started/.

Wei-Sheng Wang, Chia-Ju Lin, H.-Y. L. T.-T. W. and

Huang, Y.-M. (2024). Feedback mechanism in immer-

sive virtual reality influences physical hands-on task

performance and cognitive load. International Jour-

nal of Human–Computer Interaction, 40(15):4103–

4115.

Wickens, C. D., Helton, W. S., Hollands, J. G., and Ban-

bury, S. (2021). Engineering psychology and human

performance. Routledge.

XX, X. (2024a). Harvester functionlity tests.

https://bit.ly/functionlitytests.

XX, X. (2024b). Harvester interactions demo. https://bit.ly/

2025-GRAPP.

Zheng, Y., Cheng, B., Huang, Q., and Liu, J. (2018). Re-

search on virtual driving system of a forestry log-

ging harvester. Wireless Personal Communications,

102:667–682.

Design and Development of an Interactive and Intelligent Wood Harvester Machine Operator Simulator

283