Automated Generation of Standardised Digital Twins Based on MBSE

Models

Philippe Barbie

a

, Andreas Pollom

b

, Rene-Pascal Fischer

c

and Martin Becker

d

Fraunhofer IESE, Fraunhofer-Platz 1, 67663 Kaiserslautern, Germany

fi

Keywords:

MBSE (Model-Based System Engineering), Digital Twins, AAS (Asset Administration Shell), Model

Transformation, Standardisation, Automated Generation.

Abstract:

Digital Twins have emerged as a key technology to enable a mirrored digital representation of physical sys-

tems. The Asset Administration Shell (AAS) is a standardised concept for implementing these Digital Twins.

However, the implementation of Digital Twins for existing systems poses an enormous challenge, as many

physical systems were not originally developed for the integration of Digital Twins. Our aim is to generate

ready to use standardised Digital Twins by automatically evaluating MBSE models of system components that

are already in productive use. To achieve this, a tool was created that analyzes existing MBSE models and

then generates AAS using the established open-source middleware Eclipse BaSyx.

Model-Based Systems Engineering (MBSE) is an approach that has been used successfully for many years and

uses systematic modeling to plan and support the logical and physical structure of systems over their entire

life cycle. Building on this established methodology, we aim to extend its application to create and manage an

accessible Digital Twin, ensuring its functionality and alignment with the represented system throughout its

entire lifecycle. As part of this paper, we will demonstrate how a simplified space satellite system, documented

as an MBSE model, can be automatically transferred into a fully functional AAS within our application pro-

totype. The integration of MBSE principles not only increases the accuracy of the generated Digital Twins,

but also improves their scalability and maintainability. This is why our solution has the potential to convince

those who currently have reservations about adopting the novel Digital Twin technology for systems within

their company.

1 INTRODUCTION

Digital Twins have emerged as a key technology

to enable a mirrored digital representation of phys-

ical systems. This development is of immense im-

portance, particularly for improving operational effi-

ciency, for predictive maintenance and for improving

general system understanding. The immediate impor-

tance of Digital Twins lies in their ability to bridge the

gap between the physical and digital worlds, to repre-

sent system states in real time and to enable a new

era of connected and intelligent systems. The concept

is enhanced by the introduction of shared vendor in-

dependent standardised data spaces that promote the

collaborative use of systems by unifying information

a

https://orcid.org/0009-0002-7359-7410

b

https://orcid.org/0000-0001-5160-0442

c

https://orcid.org/0000-0001-8261-2761

d

https://orcid.org/0009-0000-1814-5062

sharing through standardised structures.

In fact, the idea of integrating MBSE mod-

els into the design process of Digital Twins is

not new (Heithoff et al., 2023),(Bordeleau et al.,

2020),(Spaney et al., 2023),(Bibow et al., 2020),(Nast

et al., 2023),(Dhouib et al., 2023). Conceptual system

models are mainly used in the initial planning and

creation phase of a new Digital Twin in the form of

a Digital Twin Prototype (DTP) (Albuquerque et al.,

2023). However, the composition and implementa-

tion of operational Digital Twins with standardised

data access, which are used during operation after the

initial planning phase of a system, is a much more

challenging task. These operational Digital Twins

are known in the literature as Digital Twin Instance

(DTI) and Digital Twin Environment (DTE) (Albu-

querque et al., 2023). Furthermore, the implementa-

tion of Digital Twins based on existing legacy systems

is a major challenge. Many physical systems were

Barbie, P., Pollom, A., Fischer, R.-P. and Becker, M.

Automated Generation of Standardised Digital Twins Based on MBSE Models.

DOI: 10.5220/0013190300003896

In Proceedings of the 13th International Conference on Model-Based Software and Systems Engineer ing (MODELSWARD 2025), pages 75-84

ISBN: 978-989-758-729-0; ISSN: 2184-4348

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

75

not originally developed with Digital Twins in mind,

so it can be difficult to adapt these older systems to

the new technology. On the other hand, systems that

were designed using MBSE methods are inherently

well suited for the integration of Digital Twin tech-

nology, as their specifications, relations and configu-

rations are already recorded in a structured manner,

which represents a high potential for further develop-

ment towards a functional Digital Twin.

With this contribution, we want to illustrate the

potential for automatically generating a standardised

Digital Twin Instance (DTI) for a given system, by

utilizing existing specifications encoded in a Model-

Based System Engineering (MBSE) model. This not

only speeds up the initial Digital Twin creation pro-

cess but also ensures a high level of accuracy and fi-

delity in the Digital Twins later life-cycle stages. An

additional benefit is the seamless integration of al-

ready standardised Submodels into the automated cre-

ation of an Asset Administration Shell (AAS) for a

given system. This vendor-independent standardised

implementation of Digital Twins enables seamless

integration across different systems and platforms.

It also allows for the straightforward incorporation

and realization of required standards, such as Digital

Nameplate or CO2 Footprint at the stage of system

modeling. The concept of an AAS as Digital Twin

implementation is shown in Figure 1.

The paper is structured as follows: Section 2 in-

troduces the reader to the fields of Model-Based Sys-

tem Engineering and Digital Twins, and reviews re-

lated work addressing these topics. Additionally, it

discusses the state of the art in the creation of Dig-

ital Twins using MBSE methods, as well as a com-

parison to approaches similar to the one presented

in this paper. Section 3 describes the various com-

ponents of the AAS Metamodel, including the As-

set Administration Shell (AAS), Submodels, and Sub-

model Elements like Enities and Properties. Section

4 explains our approach to automatically generate a

functional operating Digital Twin in form of a BaSyx

AAS, by evaluating a given MBSE Model. Section

5 shows an example use case of a UML model of a

generic space satellite, which shall be automatically

transformed into a Digital Twin by using our approach

and the prototypical implementation of our Enterprise

Architect (EA) Add-In. It was decided to use UML

instead of SysML to indicate that the presented ap-

proach is applicable to all UML-based modeling lan-

guages. Section 6 provides the technical background

of our prototypical implementation and explains how

we were able to realise the approach described in Sec-

tion 4. Section 7 outlines the key benefits of the ap-

proach, including automation of Digital Twin gener-

ation, high accuracy, scalability, seamless integration

with industry standards, legacy system adaptation, ef-

ficient life-cycle management, and the reuse of exist-

ing MBSE models. Section 8 concludes the main re-

sults of our work and provides an outlook on future

activities.

Figure 1: Concept of the Asset Administration Shell (AAS)

to implement a standardised Digital Twin.

2 RELATED WORK

For a better comprehension of our proposed approach,

the concepts of MBSE and Digital Twin are de-

scribed below and relevant work in both areas is ad-

dressed. Furthermore, we examine the current ad-

vancements in creating and managing Digital Twins

through MBSE methodologies and provide a analy-

sis of approaches that are comparable to the approach

presented in this paper.

2.1 Model-Based System Engineering

Model-Based System Engineering (MBSE), as de-

fined by the International Council on Systems En-

gineering (INCOSE), aims to streamline traditional

document-centric systems engineering practices by

formalizing models to represent requirements, design,

analysis, and validation throughout the entire devel-

opment lifecycle (International Council on Systems

Engineering, 2007)(International Council on Systems

Engineering, 2014). While MBSE promises to en-

hance development by facilitating information reuse

and consolidating data into a single system model,

practical implementation necessitates various views

to address system complexity effectively. Creating a

comprehensive system model involves three core ele-

ments: method, language, and tool (Gr

¨

aßler and Ol-

eff, 2022). The method dictates the necessary steps

MODELSWARD 2025 - 13th International Conference on Model-Based Software and Systems Engineering

76

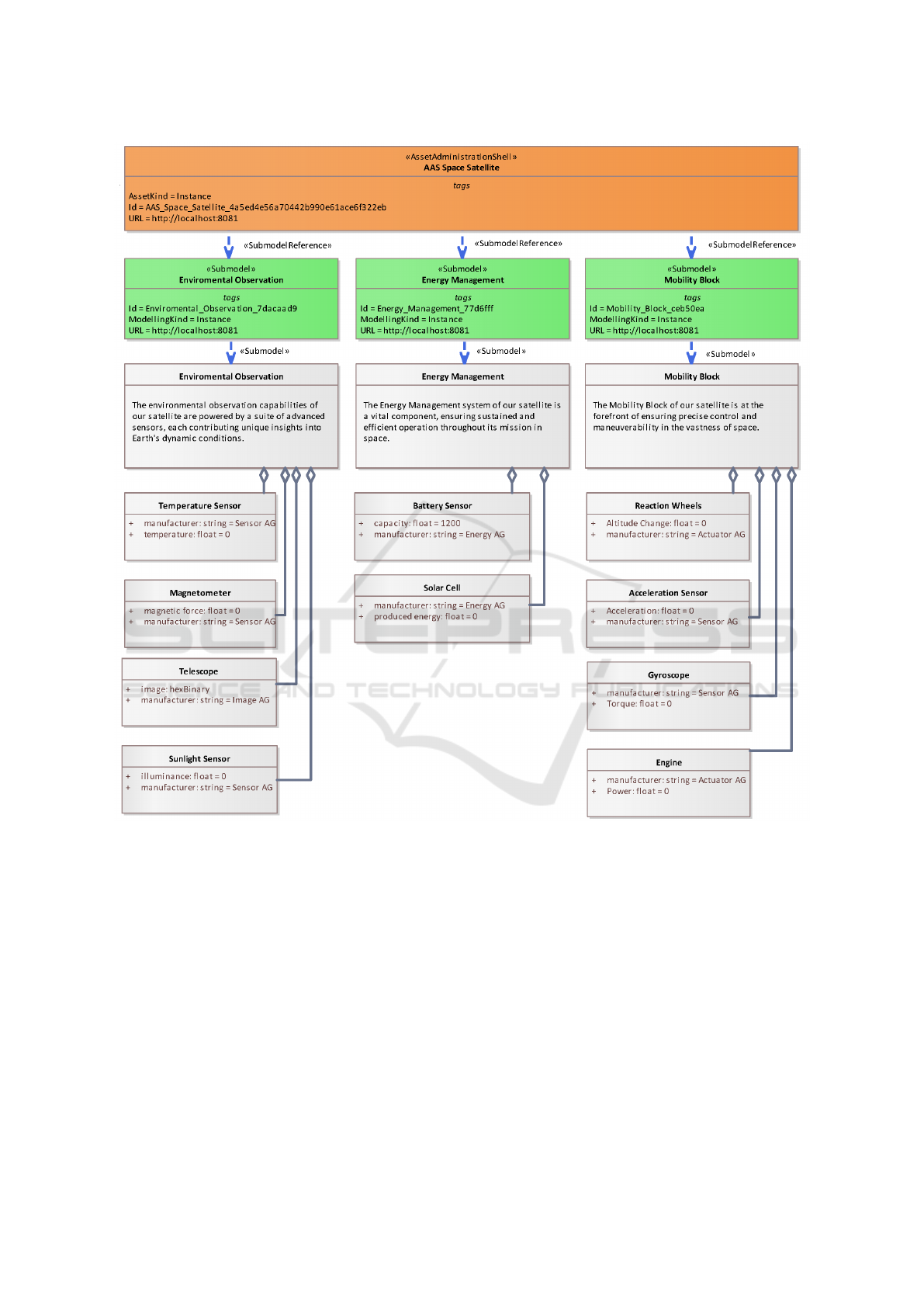

Figure 2: Cut-out from a UML satellite model as an example for the automatic generation of a Digital Twin based on a MBSE

model (Fraunhofer IESE, 2024).

and rules, determining the appropriate level of ab-

straction. The language defines the model’s syntax

and semantics, while the tool provides a graphical

user interface aligned with the chosen language for

model realization.

Overall, while MBSE holds promise for improved

system development, practical implementation re-

quires understanding the relationships between life-

cycle phases and model-driven development steps,

as well as the appropriate tool usage at each stage.

This highlights the ongoing need for further automa-

tion and integration to achieve seamless MBSE adop-

tion (International Council on Systems Engineering,

2014)(International Council on Systems Engineering,

2022). In software development, the conventional

approach often involves translating requirements di-

rectly into code, resulting in challenges with complex

systems, such as quality issues and increased devel-

opment time and costs. To mitigate these challenges,

a step-wise refinement from requirements to architec-

ture, design, and then code is recommended. How-

ever, a more advanced approach, known as Model-

Driven Engineering (MDE), emphasizes modeling

over programming. MDE involves creating artifacts

similar to traditional software engineering but priori-

tizes semi-automated model transformations for sub-

Automated Generation of Standardised Digital Twins Based on MBSE Models

77

sequent steps. This approach demands formally de-

fined syntax and unambiguous semantics to ensure

consistent and development-oriented models.

2.2 Digital Twin

The concept of the Digital Twin was first introduced

by Grieves in 2002 as part of a presentation about

Product Lifecycle Management (Grieves, 2002). Both

Digital Twins and Digital Shadows are digital rep-

resentations of all relevant attributes and properties

of an existing physical or conceptual asset. Bergs

et al. state in their paper ”The Concept of Digital

Twin and Digital Shadow in Manufacturing” (Bergs

et al., 2021) that a Digital Shadow is characterized by

a one-way data flow from an existing physical object

to a digital model. This model reflects the state of the

physical object, and any changes in the physical ob-

ject’s state are mirrored in the digital representation.

However, the flow of data does not occur in reverse.

In contrast, for a Digital Twin, data flows seamlessly

between the physical and digital objects in both direc-

tions, creating a fully integrated relationship between

the two entities. In today’s digital world, it is manda-

tory to have bidirectional communication between the

asset and its representation for it to be a functional

Digital Twin (Grieves and Vickers, 2017). As a re-

sult, a Digital Twin is a Cyber-Physical System, com-

bining the virtual and physical worlds, but with a new

focus on data and simulation (Tao et al., 2019). By

definition, Digital Twins and Cyber-Physical Systems

try to create ways of interaction and interoperability

between companies, their partners, and whole indus-

tries (Bader and Maleshkova, 2019).

Industry 4.0 (I4.0) introduces the foundational

concept of Asset Administration Shell (AAS) to rep-

resent and manage Digital Twins, by offering a struc-

tured, hierarchical, and machine-readable represen-

tation of the diverse aspects of assets and has been

published as European standard IEC 63278-1 (Inter-

national Electrotechnical Commission, 2023). It was

defined by the Plattform Industrie 4.0 as a specifica-

tion for an industry-ready Digital Twin, while the Ref-

erence Architecture Model Industrie 4.0 (RAMI 4.0)

describes it as a digital representation of I4.0 com-

ponents (Bader, 2020). (Tantik and Anderl, 2017)

used the requirements of the AAS to roughly define

its structure by creating a frame of several segments,

which try to solve the problems facing a Digital Twin.

On both sides of the AAS, there are interfaces, one for

external and one for internal communication between

I4.0 systems and the asset itself. For our implemen-

tation we use the MIT licensed Open Source Middle-

ware Eclipse BaSyx (The Eclipse Foundation, 2024b)

(The Eclipse Foundation, 2024a), which is a reference

implementation of the concepts for I4.0 and uses the

AAS to represent a Digital Twin based on the latest

AAS specification (AAS Version 3) provided by the

(Industrial Digital Twin Association (IDTA)), 2023).

2.3 State of the Art

In the following, the current state of the art is dis-

cussed, which deals with the integration of MBSE

methods in the creation process of Digital Twins.

(Heithoff et al., 2023) and (Bordeleau et al., 2020)

examine the challenges in the initial generation of

Digital Twins and how these can be overcome us-

ing MBSE methods. Both (Spaney et al., 2023) and

(Bibow et al., 2020) present architectural models as

concepts for building and using model-based Digi-

tal Twins. In addition to our method, (Bibow et al.,

2020), (Nast et al., 2023) and (Dhouib et al., 2023)

also pursue an approach for the automated genera-

tion of Digital Twins from MBSE models. These

approaches share the same core idea as our contribu-

tion, but differ in their implementation. In (Nast et al.,

2023), a model created in the ADOxx modeling tool

is analyzed to create a web-based Digital Twin using

JSON, but it is specific to this solution and does not

take advantage of the standardised AAS concept. The

same applies to (Bibow et al., 2020), whose approach

evaluates a model created in the MontiArc model-

ing tool and tags its content with a domain-specific,

text-based language to define events inside the Digi-

tal Twin. We consider this approach to be ambitious,

but tend to separate the definition of the data struc-

ture of the Digital Twin from its event planning and

autonomous services. The approach presented in this

paper is most similar to that of (Dhouib et al., 2023),

as it also generates an AAS based on an MBSE model.

As a modeling tool (Dhouib et al., 2023) uses the

tool Papyrus. The main difference to (Dhouib et al.,

2023) is that in our approach, any existing UML-

based model (e.g. SysML) can be directly used to

generate an AAS, whereas (Dhouib et al., 2023) de-

fines its own metamodel specific for the purpose of

AAS creation. This means that the AAS in (Dhouib

et al., 2023) must first be modeled manually from

scratch, or based on an existing MBSE model, before

the Digital Twin can be generated automatically.

3 AAS METAMODEL

The vendor independent standardised Digital Twin

specification Asset Administration Shell (AAS), de-

veloped as part of the Plattform Industrie 4.0 initia-

MODELSWARD 2025 - 13th International Conference on Model-Based Software and Systems Engineering

78

Figure 3: Cut-out from the BaSyxWeb-UI, showing the resulting generated Digital Twin Instance of the example Satellite

System Digital Twin.

tive, and maintained by the (Industrial Digital Twin

Association (IDTA)), 2023), serves as a real time dig-

ital representation of physical assets. The AAS is

built around two primary concepts: the information

related to the asset itself and the Submodels that en-

capsulate its functionalities and manage its data. In

this context, the AAS can represent both types and in-

stances of assets, as prescribed by the Reference Ar-

chitecture Model Industrie 4.0 (RAMI 4.0) (Grangel-

Gonz

´

alez et al., 2016). Each AAS, its Submodels, and

related elements such as concept descriptions are as-

signed unique global identifiers, while properties and

similar elements only require local identifiers within

their respective Submodels. The concept and decom-

position of a AAS is shown in Figure 1. A part of

the AAS metamodel is shown in Figure 4, with fo-

cus specifically on the elements that are relevant to

our approach. The complete AAS metamodel can

be accessed in (Industrial Digital Twin Association

(IDTA)), 2023).

3.1 Asset Administration Shell

The Asset Administration Shell element represents a

single real world physical or non-physical asset. The

assetKind attribute is used to designate whether an

AAS represents a type (template) or an instance of

that asset. An AAS usually links to multiple Submod-

els describing the contents of an asset regarding a spe-

cific use case. The AAS does not own those Submod-

els, so that a Submodel itself can be existent without

a AAS referencing it. Also, one Submodel can theo-

retically be referenced by multiple AAS.

3.2 Submodel

Submodels are critical to the structure an AAS, as they

organize its digital representation and technical func-

tionality. Each Submodel focuses on a specific do-

main or aspect of the asset, enabling the modularity

and flexibility needed to manage complex systems.

Submodels can be standardised to ensure uniformity

across industries, or they can be customized to fit

unique requirements. Submodels own multiple Sub-

model Elements, that can be data elements of various

types like Entities or Properties. Those Submodel El-

ements are owned by the Submodel and cannot exist

without it.

3.3 Submodel Element

Submodel Elements come in several forms, such as

collections, Entities or Properties. Submodel Ele-

ments describe specific characteristics or functional-

ities of the asset. This versatility allows Submodels

to capture the complex relationships and behaviors of

physical assets within digital environments. The Sub-

model Element description itself is abstract, as shown

in Figure 4.

3.4 Property

Properties are Submodel Elements that store a single

value, such as temperature, pressure, or status. These

values are typed according to the standard W3C XML

Schema (Biron and Malhotra, 2004), which provides

a wide range of predefined and derived data types. All

Automated Generation of Standardised Digital Twins Based on MBSE Models

79

available data types are listed in Figure 5. The precise

definition of property values allows for accurate data

exchange and interpretation across systems, ensuring

that Digital Twins can function effectively in diverse

environments across multiple vendors.

3.5 Entity

The Entity Submodel Element is able to describe the

hierarchical structure of an asset. The system de-

composition of the asset can be reflected by embed-

ding multiple Entities within one another. Entities

are classified as either co-managed or self-managed,

depending on whether they have their own AAS for

detailed representation. Co-managed entities are de-

scribed in more depth through their own AAS, while

self-managed entities rely on the parent AAS for rep-

resentation. Entities contain so called Statements,

which are composed of any type of Submodel Ele-

ments. Those can be Properties to describe values of

that Entity or other Entities to build up a more com-

plex system decomposition.

Figure 4: Highly simplified Metamodel of the AAS specifi-

cation (Industrial Digital Twin Association (IDTA)), 2023),

reduced to highlight the contents used by the approach pre-

sented in this paper.

4 APPROACH

The approach presented in this paper enables the au-

tomated generation of Digital Twins using an MBSE

model of the physical system to be represented. To

achieve this, the original model must be slightly ex-

tended with additional model elements. These ele-

ments serve as anchor points for the subsequent gen-

eration of Asset Administration Shells (AAS) and

Submodels. These additional elements contain meta

information, such as the URL where the AAS and

Submodel repositories are made available, as well as

other metadata describing the AAS and Submodels

according to the AAS specification (Industrial Digital

Twin Association (IDTA)), 2023). To further specify

the transformation from a MBSE model to a Digital

Twin, additional connectors with the special stereo-

type Submodel and SubmodelReference must be cre-

ated. Submodel connectors are used to define the en-

try points for the automated generation of AAS Sub-

models, while SubmodelReference connectors define

which Submodel can be accessed within a particular

AAS. This relation-based approach ensures a targeted

and controlled extraction of relevant parts from the

entirety of the model. When the AAS generation pro-

cess is started, an automated evaluation of the sys-

tem model is triggered. This evaluation includes an

analysis of the given model decomposition, the con-

tained model elements and the relevant element at-

tributes. Predefined attribute types and initial values

are also included in the generation of Submodels and

their Properties. Once all the necessary AAS and Sub-

model elements have been added to the model and

linked to the corresponding parts of the model, the

final step is the automated generation of a ready-to-

use and operational Digital Twin. The generated Dig-

ital Twin is now ready to be connected to real sen-

sors, actuators and hardware modules of the appro-

priate physical system. This MBSE-driven definition

and automated generation of Digital Twins, not only

speeds up the initial creation process, but also ensures

consistency between the resulting Digital Twin and its

real-world counterpart. In this way the system model

can be automatically transformed in a AAS Type (tem-

plate) for future refinement or a individual AAS In-

stance, which represents one unique system in the real

world. By applying the generation algorithm, a single

MBSE model can be used to realize multiple parallel

instances of Digital Twins (DTI). By re-running the

algorithm, a completely new Digital Twin Instance

(DTI) can be created, or an already created DTI can

be updated to the current model state. These appli-

cation possibilities also reflect in the UI of the En-

terprise Architect Add-In prototype, shown in Figure

7. In addition, behavioral specifications such as state

machines and activity and sequence diagrams can be

integrated into the MBSE model to capture the data

transfer to other systems. The documentation of the

Digital Twin using established MBSE methods offers

numerous additional advantages in the maintenance,

management and care of a Digital Twin throughout

its entire life cycle.

5 EXAMPLE USE CASE: SPACE

SATELLITE

As a demonstration of the functionality of this ap-

proach, we have created a UML model of a simpli-

fied generic space satellite, which is shown in Figure

2. Although it is a system model, it was decided to

MODELSWARD 2025 - 13th International Conference on Model-Based Software and Systems Engineering

80

Figure 5: TypeDefXsd Datatypes as specified in (Industrial

Digital Twin Association (IDTA)), 2023).

use UML instead of SysML to indicate that the pre-

sented approach is applicable to all UML-based mod-

eling languages. Nevertheless, the approach would

work in the same way if applied to a SysML model

instead, highlighting its versatility across UML-based

modeling languages. The satellite consists of various

components, which are divided into three functional

blocks: Environmental Monitoring, Energy Manage-

ment and Mobility. A temperature sensor, a sunlight

sensor, a magnetometer and a telescope are used for

environmental monitoring. The energy management

consists of a solar cell with a battery and a battery

sensor. The movement of the satellite is realized by

a group of reaction wheels, a gyroscope, a motor and

an acceleration sensor. In the model shown, all sen-

sors have at least one attribute that later represents the

current measured value in the Digital Twin, and all

actuators have an attribute that represents the current

control value. These attributes can be further refined

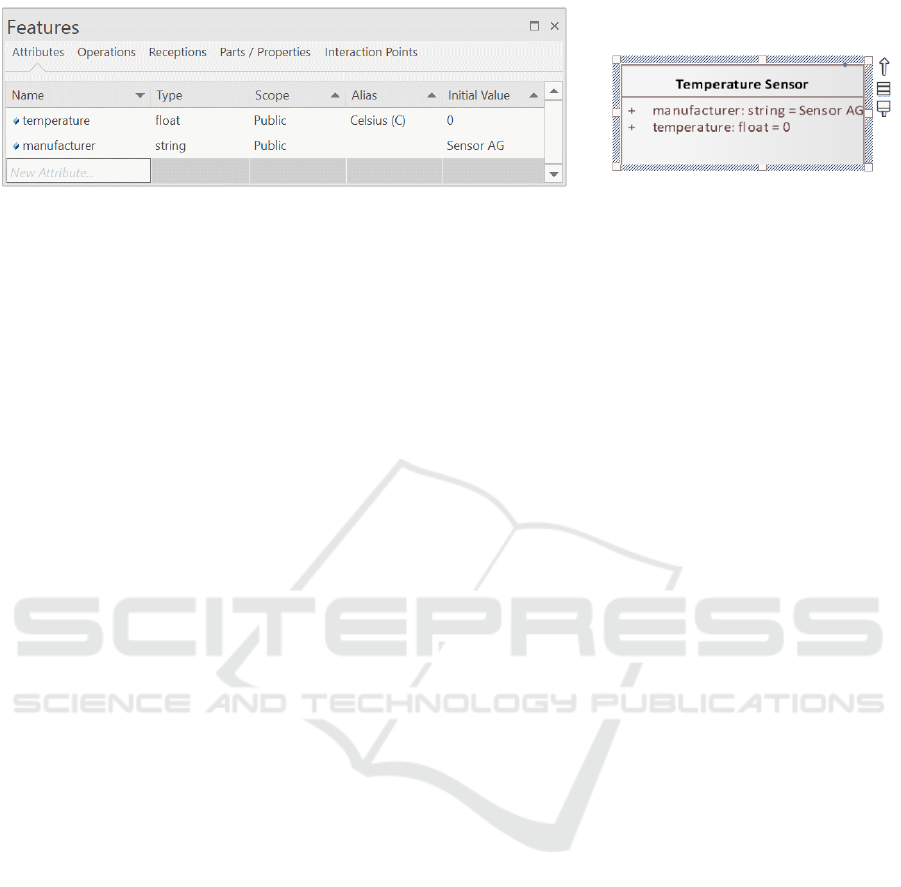

in the attribute view shown in Figure 6. The model

also specifies the unit of measurement of the values

and the data type used to store the values in digitized

form (Int, Float, String, etc.). This information will

also be transferred to the generated Digital Twin, with

the AAS standard ensuring data typing in compliance

with the W3C XML Schema (Biron and Malhotra,

2004), as shown in Figure 5.

Each of these attributes is also provided with an

initial value. This initial value serves as a temporary

placeholder in the AAS until the real physical system

has been connected to the Digital Twin and the first

real value is available. In addition, all elements have

a Manufacturer attribute, which contains the name of

the manufacturer of the sensor or actuator. The sys-

tem shown here is of course a very simplified example

model, which is far from representing a real satellite

and would in practice have many additional individ-

ual attributes for each individual sensor. Nevertheless,

this simplified model demonstrates the functionality

of our approach and helps with its comprehensibility.

The complete satellite model is also available online

for download (Fraunhofer IESE, 2024) and can be ac-

cessed as an Enterprise Architect file, Model-XML

file or as a PDF file. In order to be able to auto-

matically generate a Digital Twin from the example

model shown in Figure 2, we need to create an ad-

ditional element in the model with the stereotype As-

setAdministrationShell, which represents a new AAS

to access relevant Submodels of the satellite. In our

example from Figure 2, this is the element with the

name AAS Space Satellite. In addition, we need to

provide meta information for this element such as an

AssetKind and the URL for the correct addressing of

the AAS repository. At this point, it should be men-

tioned that the Id attribute, which is used to uniquely

address the AAS, does not need to be specified man-

ually, as this attribute is automatically generated from

the name of the AAS and a unique UUID when the

algorithm is executed. The Id is always generated au-

tomatically and saved in the model if it does not yet

exist at the time the Digital Twin is generated.

In the next step, we must define which parts of the

MBSE model are to be generated as Submodels by

linking these parts of the model with special model el-

ements of the Submodel stereotype. These Submodel

elements are also shown in Figure 2. To achieve this

assignment, we use connectors of the stereotype Sub-

model, which point to the corresponding elements in

the model. In addition, we create SubmodelRefer-

ence connectors, which assign a Submodel to an As-

set Administration Shell model element. In our ex-

ample, we create a separate Submodel for each func-

tion block (Environmental Monitoring, Energy Man-

agement and Mobility) of the satellite and link these

to a single AAS for the entire satellite system. Meta-

data such as URL and ModelingKind must also be de-

fined for these Submodel elements. The Id attribute

is (again) generated randomly if it does not already

exist.

As soon as the preparation of the model has been

completed by creating these few additional elements,

the generation process can be initiated. All elements

that are addressed by Submodel elements through

Submodel connectors are analyzed and their decom-

position is further evaluated. Each element in the

model that has an aggregation or composition con-

nector with one of these elements is constructed as

part of an Entity in the resulting AAS. As mentioned

in Section 3.5, each Entity can contain a list of En-

tities or Properties in its Statement attribute. In this

way, any number of decomposition levels can be real-

Automated Generation of Standardised Digital Twins Based on MBSE Models

81

Figure 6: Attribute view of the Temperature Sensor Interface element (Fraunhofer IESE, 2024).

ized in the resulting Digital Twin, based on the given

model decomposition. For a more detailed consider-

ation of the elements and attributes described above,

the complete Enterprise Architect model of the satel-

lite scenario described can be downloaded from the

following reference (Fraunhofer IESE, 2024).

In order to perform the automated generation of

the AAS, our application requires a running instance

of the BaSyx middleware (The Eclipse Foundation,

2024b) (The Eclipse Foundation, 2024a), which im-

plements the current IDTA specification (Industrial

Digital Twin Association (IDTA)), 2023) of Asset

Administration Shells. Once the generation process

has been executed, the resulting Digital Twin is cre-

ated in a few seconds, uploaded into the BaSyx envi-

ronment and displayed in the BaSyx WebUI as shown

in Figure 3. On the left side of Figure 3 we see the

resulting AAS and its Id, which is used to explic-

itly address this AAS using the BaSyx REST API.

The middle column of Figure 3 contains all Sub-

models that are referenced via the selected AAS in

the left-hand column. It can be seen that all three

functional blocks (Environmental Monitoring, En-

ergy Management and Mobility) of the system model

were created as Submodels in the resulting Digital

Twin. Each Submodel contains corresponding Enti-

ties for sensors and actuators. Properties are also in-

cluded, which contain the Asset Administration Shell

attributes Name, Description, ValueType and Value.

In Figure 3, the Temperature property is selected in

the currently selected Submodel, which is therefore

shown in detail in the right-hand column. In the de-

tails shown there, we can see that the Temperature

value is measured in Celsius (C), the ValueType has

been defined as xs:float and the current temperature

value is 0 (initial value). Additionally, at the bottom

of the right column, we can see when this value was

last synchronized by the BaSyx server. These prop-

erties are now ready to process real values from the

real-world system.

6 PROTOTYPICAL

IMPLEMENTATION

In order to make our approach applicable, we have

realised a prototype implementation that follows the

procedure from Section 5. We prepared our example

model inside the modelling tool Enterprise Architect

by Sparx Systems and developed an Add-In written in

the programming language C#, to evaluate a MBSE

model and automatically generate a Digital Twin in

the form of an AAS (Version 3.0) (Industrial Digital

Twin Association (IDTA)), 2023). The technical real-

isation of the Digital Twin was archived by using the

MIT-licensed open source middleware Eclipse BaSyx

(The Eclipse Foundation, 2024b) (The Eclipse Foun-

dation, 2024a). In addition, a C# .NET Framework

translation of the AAS class library AAS4J (Asset

Administration Shell for Java) (The Eclipse Founda-

tion, 2024) was used. By using this library translation

and the BaSyx REST API, we were able to directly

integrate the BaSyx client functionality inside the C#

Code of the EA Add-In. This way the model data is

directly read from the EA-API, analysed in our C# ap-

plication, and then written to the Digital Twin using

the BaSyx REST API. This implementation allows

a straightforward transmission of the MBSE model

from EA into a BaSyx based Digital Twin realisation.

By activating the generation algorithm through the

provided EA Add-In UI shown in Figure 7, the cre-

ation of the Digital Twin is started and after a few sec-

onds the ready to use AAS is generated and uploaded

to the prepared BaSyx server addressed in the URL

attribute, as mentioned in Section 4 and 5. The gen-

erated Digital Twin will either be uploaded as a AAS

Type (template) for future refinement or as an Digital

Twin Instance (DTI) representing a unique real-world

system. The various application options are also vis-

ible in the UI of the EA-Add-In, shown in Figure 7.

The most important part of the algorithm is of course

the method for analyzing the model content and au-

tomatically mapping this content to the standardised

AAS structure (Industrial Digital Twin Association

(IDTA)), 2023).

MODELSWARD 2025 - 13th International Conference on Model-Based Software and Systems Engineering

82

7 KEY BENEFITS

The key benefits of this approach center around au-

tomating the generation of Digital Twins from MBSE

models. By automating the creation of Digital Twins,

the approach significantly reduces manual effort and

accelerates the implementation process. This effi-

ciency is particularly advantageous when handling

complex systems, where traditional methods would

be time-consuming and labor-intensive.

Another notable advantage is the high accuracy

and fidelity of the generated Digital Twins. Because

they are derived from detailed MBSE models, the

Digital Twins retain a high level of precision, faith-

fully reflecting the system’s specifications. This leads

to more reliable and realistic representations of phys-

ical assets in their digital form.

The approach also promotes scalability and maintain-

ability. The use of MBSE principles ensures that the

Digital Twins are built on a structured foundation,

making it easier to scale them as the system grows

or evolves. This also facilitates updates and modi-

fications throughout the system’s lifecycle, ensuring

that the Digital Twin remains a dynamic, up-to-date

reflection of the asset.

Another key benefit is the seamless integration

with industry standards. The Digital Twins generated

from this approach adhere to the standardised struc-

ture of the Asset Administration Shell (AAS) (Indus-

trial Digital Twin Association (IDTA)), 2023), ensur-

ing compatibility with various systems and compli-

ance standards. This standardization simplifies inter-

operability, making it easier to integrate the Digital

Twins into broader industrial ecosystems.

Lastly, the reuse of existing MBSE model for gen-

erating Digital Twins consolidates information, re-

ducing redundancies and improving data consistency

across different lifecycle stages. This use of data not

only saves time but also ensures a higher level of con-

sistency in system representation, further enhancing

the reliability and efficiency of the resulting Digital

Twins.

8 CONCLUSION AND FUTURE

WORK

This publication contributes to the automation of the

generation of Digital Twins based on MBSE mod-

els. The aim is to facilitate both the initial creation,

the documentation and the maintenance of the result-

ing Digital Twin throughout its lifecycle. To make

our approach applicable, we have realized a prototype

implementation in the Enterprise Architect modeling

Figure 7: User Interface of the developed Enterprise Archi-

tect Add-in, to apply the approach presented in this paper to

a chosen MBSE model.

tool from Sparx Systems, which follows the approach

from Section 4.

In the future, we plan to expand the approach with

additional functions to make it even more attractive

for productive use. In particular, the analysis and au-

tomated mapping between the elements of the MBSE

model and the elements of the Asset Administration

Shell must be a focus of further research in this area.

The link between AAS Entities of the self-managed

Entity type as mentioned in Section 3, and their as-

sociated reference AAS should also be definable via

the MBSE model in future implementations of the ap-

proach. In addition, we are also considering support-

ing other modeling tools as Enterprise Architect in the

future by outsourcing the analysis algorithm. Addi-

tionally, it would be highly advantageous to support

the conceptualization of new Digital Twins as part of

research projects, allowing for the acquisition of fur-

ther practical experience with the approach.

Automated Generation of Standardised Digital Twins Based on MBSE Models

83

REFERENCES

Albuquerque, G., Fischer, P. M., Azeem, S. M., Bernstein,

A.-C., Utzig, S., and Gerndt, A. (2023). Digital Twins

as Foundation for Augmented Reality Applications in

Aerospace, pages 881–900. Springer International

Publishing, Cham.

Bader, S. (2020). Details of the Asset Administration Shell.

Part 1 - The exchange of information between partners

in the value chain of Industrie 4.0 (Version 3.0RC01).

Federal Ministry for Economic Affairs and Energy

(BMWi).

Bader, S. R. and Maleshkova, M. (2019). The seman-

tic asset administration shell. In Acosta, M., Cudr

´

e-

Mauroux, P., Maleshkova, M., Pellegrini, T., Sack,

H., and Sure-Vetter, Y., editors, Semantic Systems. The

Power of AI and Knowledge Graphs, pages 159–174.

Springer International Publishing.

Bergs, T., Gierlings, S., Auerbach, T., Klink, A.,

Schraknepper, D., and Augspurger, T. (2021). The

concept of digital twin and digital shadow in manu-

facturing. Procedia CIRP, 101:81–84. 9th CIRP Con-

ference on High Performance Cutting.

Bibow, P., Dalibor, M., Hopmann, C., Mainz, B., Rumpe,

B., Schmalzing, D., Schmitz, M., and Wortmann, A.

(2020). Model-driven development of a digital twin

for injection molding. In Dustdar, S., Yu, E., Sali-

nesi, C., Rieu, D., and Pant, V., editors, Advanced In-

formation Systems Engineering, pages 85–100, Cham.

Springer International Publishing.

Biron, P. V. and Malhotra, A. (2004). Xml schema part

2: Datatypes second edition. W3C Recommenda-

tion. https://www.w3.org/TR/2004/REC-xmlschema-

2-20041028/.

Bordeleau, F., Combemale, B., Eramo, R., van den Brand,

M., and Wimmer, M. (2020). Towards model-driven

digital twin engineering: Current opportunities and

future challenges. In Babur,

¨

O., Denil, J., and Vogel-

Heuser, B., editors, Systems Modelling and Manage-

ment, pages 43–54, Cham. Springer International Pub-

lishing.

Dhouib, S., Huang, Y., Smaoui, A., Bhanja, T., and Gezer,

V. (2023). Papyrus4manufacturing: A model-based

systems engineering approach to aas digital twins.

pages 1–8.

Fraunhofer IESE (2024). Example space satel-

lite - enterprise architect model download.

https://oc.iese.de/index.php/s/

BEXAJEwn5wBFSNJhnw909rM5PVqe9SuZ.

Grangel-Gonz

´

alez, I., Halilaj, L., Coskun, G., Auer, S., Col-

larana, D., and Hoffmeister, M. (2016). Towards a

semantic administrative shell for industry 4.0 compo-

nents. In 2016 IEEE Tenth International Conference

on Semantic Computing (ICSC), pages 230–237.

Grieves, M. (2002). Conceptual ideal for plm. Presentation

for the Product Lifecycle Management (PLM) center,

University of Michigan.

Grieves, M. and Vickers, J. (2017). Digital twin: Mitigat-

ing unpredictable, undesirable emergent behavior in

complex systems. In Transdisciplinary perspectives

on complex systems, pages 85–113. Springer.

Gr

¨

aßler, I. and Oleff, C. (2022). Systems engineering: ver-

stehen und industriell umsetzen. Springer Vieweg,

Berlin [Heidelberg].

Heithoff, M., Konersmann, M., Michael, J., Rumpe, B.,

and Steinfurth, F. (2023). Challenges of integrating

model-based digital twins for vehicle diagnosis.

Industrial Digital Twin Association (IDTA)) (2023).

Specification of the Asset Administration

Shell. Industrial Digital Twin Associa-

tion. https://industrialdigitaltwin.org/content-

hub/aasspecifications.

International Council on Systems Engineering (2007). Sys-

tems Engineering Vision 2020: Integrating frame-

work.

International Council on Systems Engineering (2014). Sys-

tems Engineering Vision 2025: A world in mo-

tion. Technical report. https://www.incose.org/about-

systems-engineering/se-vision-2025.

International Council on Systems Engineering (2022).

Systems Engineering Vision 2035: Engineer-

ing solutions for a better world. Technical

report. https://www.incose.org/about-systems-

engineering/se-vision-2035.

International Electrotechnical Commission

(2023). International standard iec 63278-1.

https://webstore.iec.ch/publication/65628.

Nast, B., Reiz, A., Ivanovic, N., and Sandkuhl, K. (2023). A

modeling approach supporting digital twin engineer-

ing: Optimizing the energy consumption of air condi-

tioning facilities.

Spaney, P., Becker, S., Str

¨

obel, R., Fleischer, J., Zenhari, S.,

M

¨

ohring, H.-C., Splettst

¨

oßer, A.-K., and Wortmann,

A. (2023). A model-driven digital twin for manu-

facturing process adaptation. In 2023 ACM/IEEE In-

ternational Conference on Model Driven Engineer-

ing Languages and Systems Companion (MODELS-

C), pages 465–469.

Tantik, E. and Anderl, R. (2017). Integrated data model and

structure for the asset administration shell in indus-

trie 4.0. Procedia CIRP, 60:86–91. Complex Sys-

tems Engineering and Development Proceedings of

the 27th CIRP Design Conference Cranfield Univer-

sity, UK 10th – 12th May 2017.

Tao, F., Zhang, H., Liu, A., and Nee, A. Y. C. (2019). Dig-

ital twin in industry: State-of-the-art. IEEE Transac-

tions on Industrial Informatics, 15(4):2405–2415.

The Eclipse Foundation (2024). Aas4j - opensource github

repository. https://github.com/eclipse-aas4j/aas4j.

The Eclipse Foundation (2024a). Eclipse basyx - open-

source github repository. https://github.com/eclipse-

basyx.

The Eclipse Foundation (2024b). Eclipse basyx - website.

https://eclipse.dev/basyx/about/.

MODELSWARD 2025 - 13th International Conference on Model-Based Software and Systems Engineering

84