Comparative Analysis of Simulated Annealing and Particle Swarm

Optimization for Multi-Robot Task Allocation in ROS

Dhruv Kumar Sharma

a

, Ujjwal Singh

b

, Snehal Nalawade

c

and Pratik Shah

d

Indian Institute of Information Technology Vadodara, Gujarat, India

Keywords:

Multi-Robot System, Garbage Cleaning, Task Scheduling Algorithms, ROS2, Gazebo, Simulated Annealing,

Particle Swarm Optimization.

Abstract:

A comparative analysis of two prominent optimization techniques—simulated annealing (SA) and particle

swarm optimization (PSO)—is conducted within the framework of multi-robot systems (MRS). The research

investigates how each algorithm effectively allocates tasks among multiple robots, focusing on performance

metrics, convergence speed, and robustness in dynamic environments. Through extensive simulations in ROS,

utilizing a dedicated testbed for real-world scenario emulation, distinct advantages and limitations of both

algorithms are revealed across various setups. The testbed integrates realistic garbage generation, dynamic

obstacles, and robot interactions, allowing for detailed empirical evaluations. The study highlights the practical

implications of using SA and PSO for multi-robot coordination, laying the groundwork for future research on

hybrid approaches and algorithmic enhancements in complex robotic applications.

1 INTRODUCTION

In recent years, the integration of multi-robot systems

has gained significant attention due to their potential

to execute complex tasks more efficiently than single-

robot counterparts. These systems leverage the col-

laborative capabilities of multiple robots to achieve

objectives that would be infeasible for a single entity,

thereby enhancing both robustness and scalability.

Latest studies have focused on multi-robot task

allocation strategies in uncertain environments for

cleaning. (Wang et al., 2023) developed a robust

optimization model using mixed-integer linear pro-

gramming, comparing techniques like simulated an-

nealing, genetic algorithms, particle swarm optimiza-

tion, and deep reinforcement learning (DRL) for task

distribution. (Jeon et al., 2015) studied the realloca-

tion strategies for tasks. Performance Maximization

was considered the most effective strategy to achieve

cleanliness and efficiency. (Orr and Dutta, 2023) sur-

veyed Applications of Multi-Agent DRL, which in-

clude GNNs, attention mechanisms and simulators

for path planning as well as task allocation. (Le et al.,

a

https://orcid.org/0009-0007-8928-6947

b

https://orcid.org/0009-0001-4828-3834

c

https://orcid.org/0009-0002-6325-7201

d

https://orcid.org/0000-0002-4558-6071

2020), and (Le et al., 2018) focused task assignment

and reallocation task with efficiency and obstacle han-

dling. The work of (Hong et al., 2021) introduced task

reassignment efficiency under constraints when using

replicator dynamics. (Elfakharany and Ismail, 2021)

proposed decentralized task allocation under end-to-

end DRL, optimizing coordination in the unstructured

environment. (Park et al., 2022) demonstrated real-

time cooperative task allocation using reinforcement

learning, improving adaptability and performance.

While most research on multi-robot systems has

focused on coverage path planning or task alloca-

tion, this paper presents an efficient algorithm for task

allocation and scheduling in a multi-robot cleaning

system. By leveraging the modular architecture of

the Robot Operating System (ROS), we enable syn-

chronized communication and coordination, enhanc-

ing overall system performance.

Our study highlights the potential of ROS-based

multi-robot systems utilizing either SA or PSO to im-

prove efficiency and reliability. Comprehensive simu-

lations compare the performance of these algorithms,

demonstrating their effectiveness and applicability to

real-world scenarios.

Sharma, D. K., Singh, U., Nalawade, S. and Shah, P.

Comparative Analysis of Simulated Annealing and Particle Swarm Optimization for Multi-Robot Task Allocation in ROS.

DOI: 10.5220/0013192000003890

In Proceedings of the 17th International Conference on Agents and Artificial Intelligence (ICAART 2025) - Volume 1, pages 481-488

ISBN: 978-989-758-737-5; ISSN: 2184-433X

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

481

2 PROBLEM STATEMENT

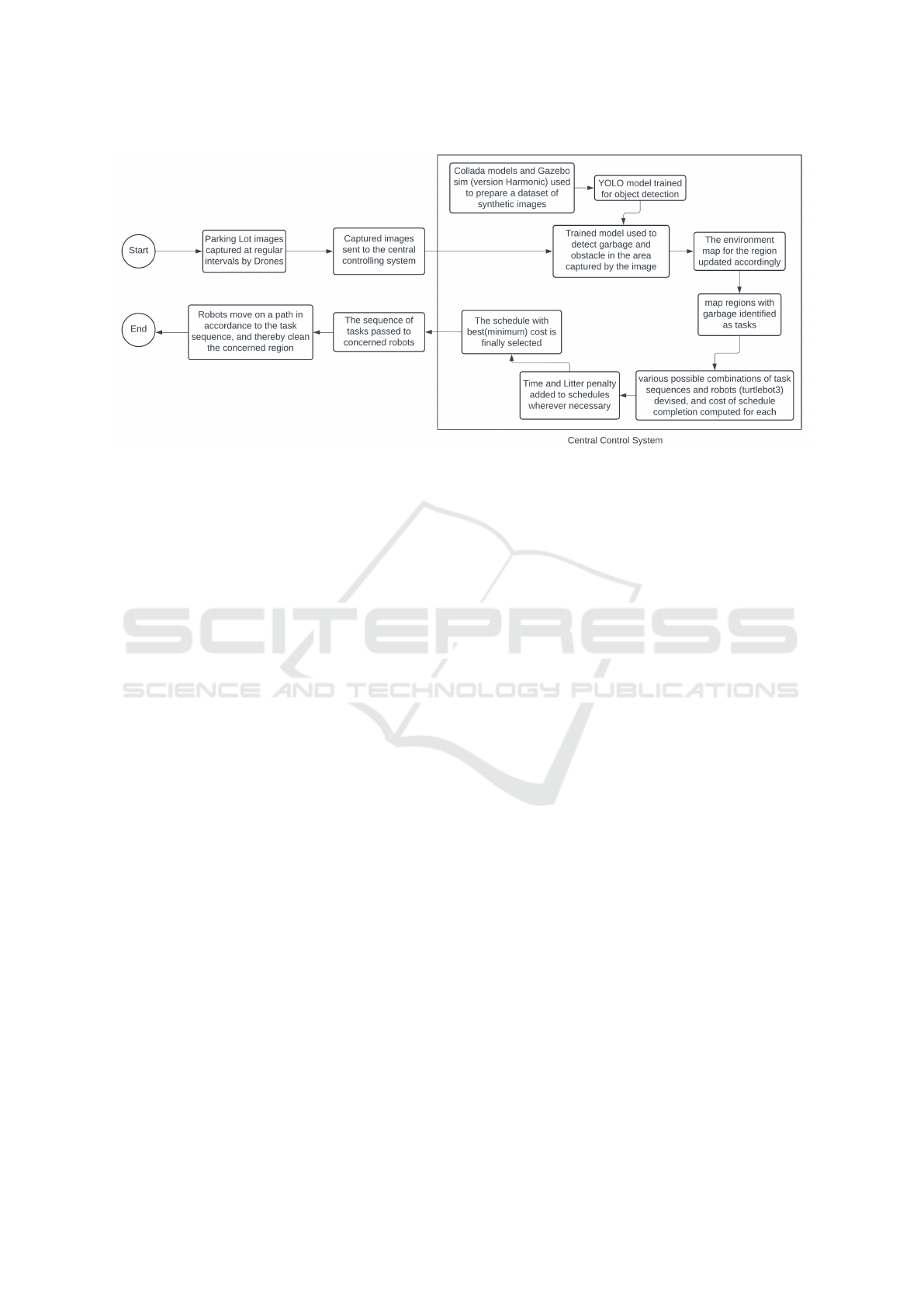

We designed a multi-robot cleaning system for large

areas, featuring drones for image capture, ground

cleaning robots, and a central control system coordi-

nating all operations. Drones, equipped with sensors,

send environmental data to the central system, which

updates a map and dynamically assigns cleaning tasks

based on real-time garbage and obstacle detection.

We developed a testbed to evaluate robot con-

figurations, task allocation, and scheduling strategies

in realistic scenarios. It includes a garbage genera-

tion routine and uses ROS2 for robot control. The

slam toolbox (Macenski, 2019), (Macenski and Jam-

brecic, 2021) package handles dynamic obstacle de-

tection, while nav2 (Macenski et al., 2020) ensures

efficient navigation. Simulations are conducted in

Gazebo for realistic and flexible testing.

2.1 Problem Formulation

In a large public area with randomly generated

garbage and obstacles such as vehicles and pedestri-

ans, the goal is to ensure continuous cleaning while

optimizing robot utilization. The area is represented

as an environment map—a numerical matrix encod-

ing objects and conditions—to facilitate algorithmic

processing.

The system employs N cleaning robots, M drones,

and a central management unit. Drones survey the

area at set altitudes, capturing ground images and

transmitting them to the central unit. A YOLOv8

model, trained on the area, processes these images

to identify garbage and obstacles, updating the envi-

ronment map accordingly. This map informs a task

scheduling algorithm that assigns cleaning tasks to

robots, optimizing their movement across regions and

dynamically adjusting to changes in garbage distribu-

tion. Task schedules are communicated to robots via

the central unit, which continuously monitors and up-

dates the map, reassigning tasks as needed.

Key variables:

• N → Total number of robots

• K → Total number of tasks

• n

r

→ Number of tasks allocated to robot r

• P → Precedence adjacency list; where P

r

repre-

sents a list of tasks assigned to robot r, and task

P

ri

precedes P

r j

∀ i < j

• D → Distance matrix. A K × K matrix containing

distances between tasks.

• litter[i] → Amount of litter present at task i

• l

r

→ Total litter collected by robot r after task al-

location

• t

r

→ Time taken by robot r to complete its as-

signed tasks

• L

r

→ Litter capacity of robot r

• T

r

→ Time capacity of robot r

• α → Litter penalty constant

• β → Time penalty constant

• C

r

→ Cost associated with robot r after task allo-

cation

System performance is evaluated by the ability to

maintain cleanliness, with robots efficiently covering

regions and removing garbage to ensure optimal area

cleanliness. The objective is to minimize the aver-

age waiting time, reducing the mean interval between

garbage accumulation and its removal.

2.2 Constraints

Several constraints are taken into consideration while

devising the task assignment & scheduling algorithm.

1. The robot’s battery level (time remaining) is

checked before assigning new tasks to ensure suf-

ficient charge.

2. The robot’s garbage load (current dump) is

monitored, and it is directed to the dumping

ground if the load approaches the tank’s capac-

ity (dump capacity) before resuming collection

tasks.

3. Both robots and the central system are informed

of the locations of charging stations and dumping

grounds.

All the constraints and objective functions in-

volved are as follows:

l

r

=

n

r

∑

i=1

litter[P

ri

] (1)

Equation (1) determines the total amount of litter col-

lected by robot r following the task allocation process.

The tasks assigned to the robot are retrieved from the

Precedence list P

r

, and the litter corresponding to each

task is accessed from litter[P

ri

]. This is then summed

across all tasks to yield the total litter collected by

robot r.

t

r

=

n

r

∑

i=1

D[P

r(i−1)

][P

ri

]

s

+ litter[P

ri

] ×t

(2)

Equation (2) calculates the time taken by robot r

to complete its assigned tasks. The time includes

ICAART 2025 - 17th International Conference on Agents and Artificial Intelligence

482

Figure 1: Multi-Robot garbage detection & task allocation system: The termination conditions for the algorithm includes

completion of all tasks, i.e. the algorithm terminates when all garbage and obstacle tasks in the mapped region are assigned

and completed by the robots as per the computed optimal schedule.

both the travel time from task P

r(i−1)

to task P

ri

and the time required to clean the litter at task P

ri

.

D[P

r(i−1)

][P

ri

] represents the distance between the two

tasks, and s is the speed of the robot. litter[P

ri

] rep-

resents the amount of litter present at task P

ri

, and t

represents the time required to clean unit litter.

C

r

= t

r

+ max(0,α × (l

r

− L

r

))

+max(0,β× (t

r

− T

r

))

(3)

Equation (3) calculates the total cost associated with

robot r after task allocation. The cost includes the

time taken to complete the tasks, the litter penalty (if

applicable), and the time penalty (if applicable). This

cost function is critical in evaluating the efficiency of

each robot.

C

max

≥ t

r

+ max(0,α × (l

r

− L

r

))

+max(0,β× (t

r

− T

r

))

(4)

Equation (4) determines the maximum cost C

max

among all robots. It represents the worst-case sce-

nario in terms of task allocation and is essential for

identifying bottlenecks in the system.

min

x∈X

C

max

(x) (5)

Finally, The goal of the optimization process is to

minimize the maximum cost C

max

among all robots.

By achieving this, the system ensures that tasks are

allocated in a manner that optimizes the overall per-

formance, leading to the best possible outcome.

3 ENVIRONMENT-AGENT

FORMULATION

The environment is represented by a matrix A with

values a

i j

∈ {0,1,2}, where 0 denotes a clean region,

1 denotes waste, and 2 indicates an obstruction.

The cost-function-driven task scheduler assigns

tasks according to the current map and robot state

in real time, ensuring efficiency. After that, robots

clean the designated regions, and constant updates

on robot conditions and environmental factors ensure

seamless operations. This well-coordinated strategy,

which combines robots to carry out tasks and drones

to gather data, guarantees an effective cleaning proce-

dure.

On a testbed, environment photos were manu-

ally labeled on the Roboflow platform and divided

into training, testing, and validation sets to create the

dataset used to train the YOLOv8 garbage detection

model. Because of its excellent garbage detection ac-

curacy, the trained YOLOv8 model is an essential part

of our system.

A cost optimization function is critical in task

scheduling and resource allocation, aiming to min-

imize operational costs by considering factors like

time, energy consumption, and resource utilization. It

evaluates various candidate solutions to balance per-

formance metrics with system constraints, ensuring

efficient resource allocation while reducing costs. In

research involving robotic systems or complex envi-

ronments, such functions enhance system efficiency

and scalability by guiding real-time decision-making

Comparative Analysis of Simulated Annealing and Particle Swarm Optimization for Multi-Robot Task Allocation in ROS

483

Data: Robots, Distance matrix, P matrix,

Dump capacity, Speed, Dump location,

Penalty coefficients α,β, Time limit T

0

Result: Total cost total cost

total cost ← 0

for each robot i do

Initialize travel time ← 0,

total litter ← 0, previous task ← depot

for each task j ∈ P

i

do

if total litter + litter[ j] >

dump capacity then

travel time +=

time to dump and back to next task

total litter ← litter[ j]

end

else

total litter += litter[ j]

end

travel time += time to next task

previous task ← j

end

total time ← travel time +total litter ×t

robot cost ← total time

Add penalties if applicable:

if total litter > dump capacity then

robot cost +=

(total litter − dump capacity) · α

end

if total time > T

0

then

robot cost += (total time − T

0

) · β

end

total cost ← max(total cost, robot cost)

end

return total cost

Algorithm 1: Calculate Cost.

based on dynamic factors like workload, task priority,

and resource availability. The cost function used is

given in Algorithm 1. In our study, we employ Sim-

ulated Annealing (SA) and Particle Swarm Optimiza-

tion (PSO) within the cost optimization framework to

explore and exploit the solution space, enabling the

reduction of costs while satisfying system constraints.

For more details on the SA and PSO algorithms,

refer to APPENDIX A and APPENDIX B.

4 TESTBED DEMONSTRATION

The testbed developed consists of three main com-

ponents: a 3D model representing the cleaning en-

vironment, models of the cleaning robots, and mod-

els of surveying drones. The communication between

the simulated environment and the central control sys-

tem, as well as the tasks of path planning and naviga-

tion, are managed using ROS (Robot Operating Sys-

tem) along with its associated packages, specifically

slam toolbox and nav2.

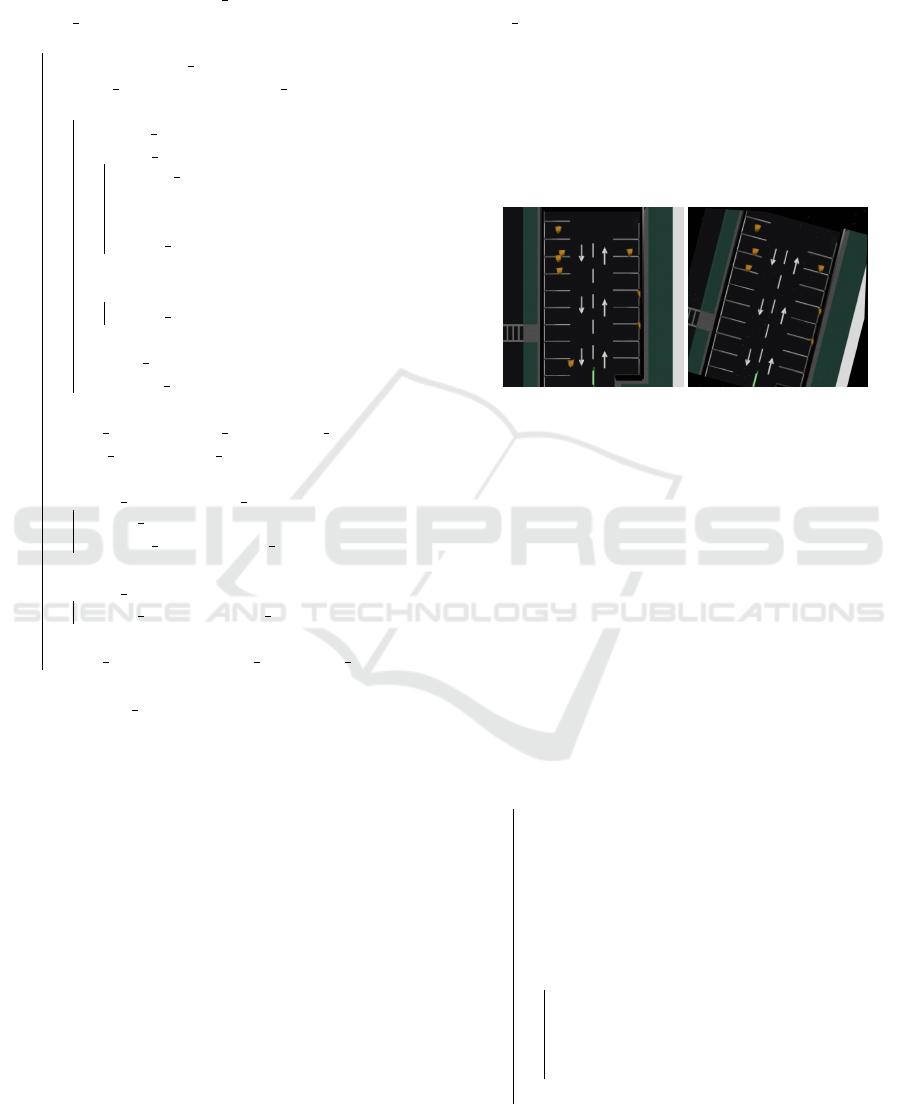

We consider a generic parking lot as the testbed

environment. The 3D model is sourced from Sketch-

fab. This environment model is used to generate a

dataset, which is essential for training the garbage de-

tection model. Sample augmented images from the

simulation are provided in Figure 2, illustrating the

environment used for model training.

(a) (b)

Figure 2: Augmented images from the simulation used for

training the garbage detection model.

To simulate the generation of garbage in a dy-

namic environment, a garbage spawning routine (Al-

gorithm 2) is used, relying on three probabilistic com-

ponents: time intervals (modeled by an exponential

distribution), the number of garbage bags (following

a Poisson distribution), and their spatial coordinates

(determined by a uniform distribution). These proba-

bilistic models enable varied and realistic scenarios.

Data: Initial spawn rate λ

Result: Garbage bags spawned at random

coordinates

initialize λ;

while true do

draw time interval T from exponential

distribution;

schedule the next garbage spawn event

after T seconds;

draw the number of garbage bags N from

the Poisson distribution, at scheduled

time;

for i = 1 to N do

draw x and y coordinates from the

uniform distribution;

spawn garbage bag i at the specified

coordinates (x,y);

end

end

Algorithm 2: Garbage Spawning Routine.

ICAART 2025 - 17th International Conference on Agents and Artificial Intelligence

484

The cleaning robots in the simulation are based on

the TurtleBot3, a ROS-enabled mobile robot platform.

For the surveying tasks, an X3 UAV model, obtained

from Gazebo Fuel, is used. Modifications were made

to the drone model, including the addition of a Li-

DAR sensor for altitude measurement and adjusting

the onboard camera to capture images of the ground

beneath the drone. These modifications enhance the

drone’s capability for environmental monitoring and

data collection.

The implementation of the described testbed is

available at this GitHub repository.

5 EXPERIMENT AND

SIMULATIONS

5.1 Performance Analysis with Varying

Robot Counts and Task Complexity

This study evaluates how performance metrics—cost,

time elapsed, and energy—vary with the number of

robots and garbage spawning rates. The number of

robots is varied from 1 to 10, and the Poisson distri-

bution parameter (λ), governing garbage generation

rates, is varied from 1 to 10. For each combination of

robot count and λ, metrics are calculated as the mean

of 10 independent observations to ensure reliability.

Results demonstrate that Particle Swarm Opti-

mization (PSO) outperforms Simulated Annealing

(SA) across all metrics. PSO consistently achieves

lower costs, faster task completion, and reduced en-

ergy consumption. For example, with λ = 2 and 8

robots, PSO incurs a cost of 134.2 compared to SA’s

168.6, while for λ = 9 and 9 robots, PSO’s cost is

403.2 compared to SA’s 556.2. Similarly, in terms

of time and energy, PSO completes tasks more effi-

ciently. For λ = 4 and 8 robots, PSO reduces time

to 211.4 units compared to SA’s 268.8, and for λ = 9

and 9 robots, PSO uses 317.0 energy units, signifi-

cantly lower than SA’s 3170.0. These findings high-

light PSO’s superior optimization capability in dy-

namic, resource-intensive environments.

The penalties (α and β) play a critical role in in-

fluencing the total cost of the system. Robots that ex-

ceed their litter capacity or battery limitations incur

these penalties, which substantially increase the over-

all costs. This effect is especially pronounced in sce-

narios with fewer robots, as each robot must cover a

larger area, leading to greater chances of surpassing

these thresholds. Generally, the total cost, time, and

energy required to complete cleaning tasks decrease

as the number of robots increases. This is because a

larger number of robots can share the workload, al-

lowing tasks to be completed more quickly and with

lower energy consumption. However, an excessive

number of robots may introduce coordination chal-

lenges, reflecting the ”law of diminishing returns,”

where the benefits of adding more robots are offset

by the overhead of managing them.

Performance metrics improve with an increasing

number of robots, as task distribution reduces indi-

vidual workload. However, excessive robots lead to

diminishing returns due to coordination challenges.

Higher λ values increase costs, time, and energy, par-

ticularly with fewer robots, as each must cover larger

areas. Efficient task allocation requires balancing

robot count with task complexity, ensuring minimized

costs and energy consumption. Tables 1 and 2 sum-

marize the optimal configurations for SA and PSO.

Table 1: Summary of optimal Number of Robots, Lambda

Poisson, Cost, Time, and Energy for Different Configura-

tions (SA).

Robots Lambda Poisson Cost Time Energy

3 1 68.5 68.5 169.0

8 2 168.6 168.6 546.4

4 3 252.4 252.4 730.8

9 4 268.8 268.8 1314.6

8 5 319.4 319.4 1486.2

6 6 395.3 395.3 1602.6

8 7 493.4 493.4 2344.0

8 8 565.1 565.1 2782.8

9 9 556.2 556.2 3170.0

Table 2: Summary of optimal Number of Robots, Lambda

Poisson, Cost, Time, and Energy for Different Configura-

tions (PSO).

Robots Lambda Poisson Cost Time Energy

3 1 35.4 36.2 35.4

8 2 134.2 134.6 457.2

8 3 289.8 294.8 871.2

10 4 246.4 271.6 942.4

9 5 351.8 385.4 548.8

5 6 282.6 345.2 423.6

10 7 341.8 475.2 341.8

9 8 402.4 550 402.4

10 9 403.2 563.8 317

5.2 Impact of Robot Battery Capacity

on Cleaning Cost Efficiency

This experiment focuses on a controlled setup where

several parameters are fixed, and the focus is placed

on the effect of time capacity. The parameters in-

volved are:

Poisson Distribution (fixed): λ is set to a constant

value of 4. This reflects a moderate rate of task arrival

Comparative Analysis of Simulated Annealing and Particle Swarm Optimization for Multi-Robot Task Allocation in ROS

485

(garbage generation) in the system.

Number of Robots (fixed): Set to 3 robots, provid-

ing a baseline capacity for task allocation.

Dump Capacity (fixed): Set to a high value of

100,000 units to avoid penalties associated with ex-

ceeding the dump capacity. This ensures that the ex-

periments focus on other factors without the influence

of dump-related penalties.

Time Capacity (variable): The time capacity is

varied in this setup. By modifying the time capacity,

the system is tested under different operational con-

straints, allowing an exploration of how time restric-

tions affect the overall performance.

The rationale behind this setup is to isolate the im-

pact of time capacity on the task allocation process,

while minimizing other variables (such as penalties

related to dump capacity). This controlled experiment

provides insights into the algorithms’ efficiency when

time becomes the primary limiting factor.

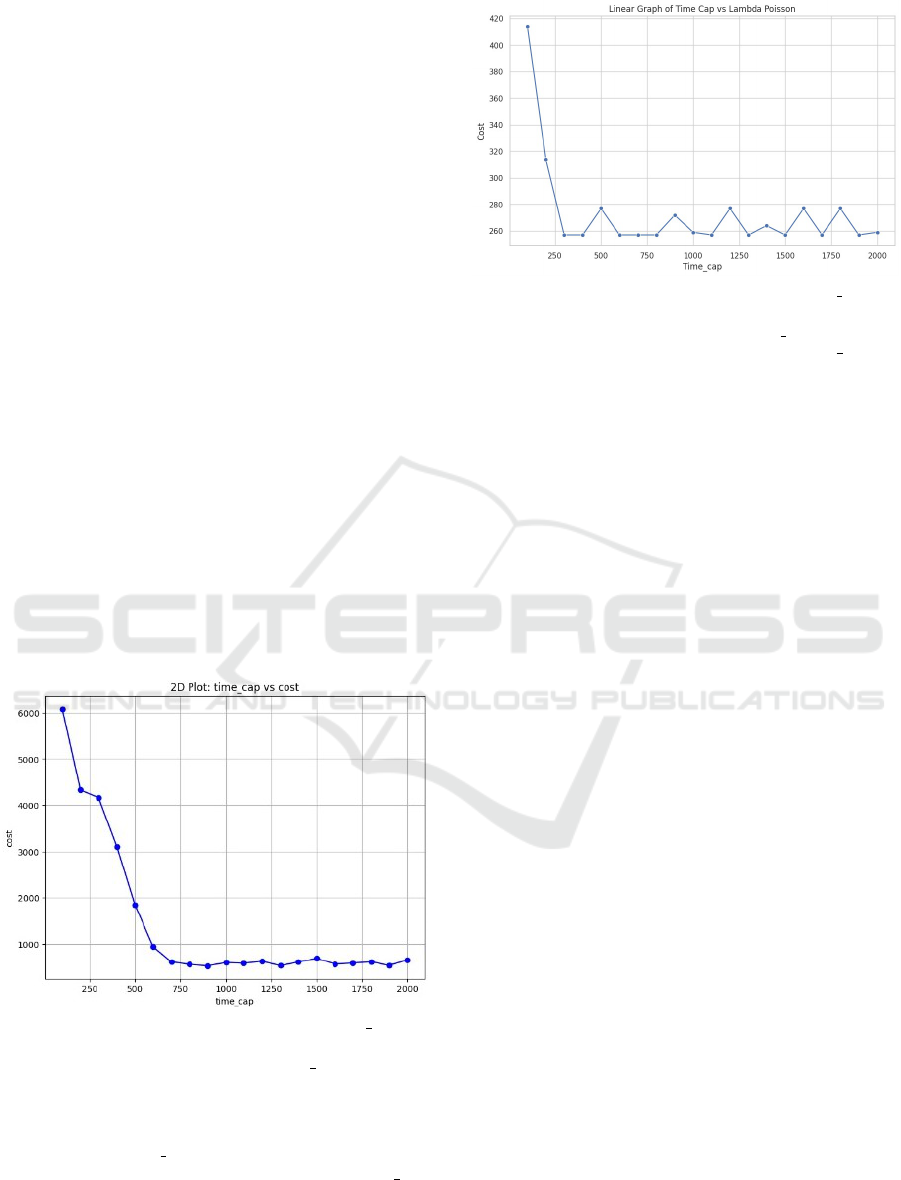

Figure 3 and Figure 4 indicate the relationship of

time-capacity for the set of batteries and cost incurred

by the multi-robot system. Cost decreases steeply

with the increase in battery capacities primarily be-

cause of decreased charging demands, or time and

energy spent going to the charging station and back

to cleaning zones, after which it reaches a cost range.

This indicates that optimizing battery capacity can

significantly reduce operational costs up to a certain

point, after which the cost stabilizes.

Figure 3: Effect of Robot Battery Capacity(time cap) on

System Cost [SA] (Time Capacity vs. Cost). The parame-

ters kept constant here are: λ = 4, and num robots = 3.

Figure 3 represents a system where costs are ini-

tially much higher and more significantly affected by

increasing the time cap. The model stabilizes after

some point, indicating that increasing the time cap

further offers diminishing returns.

Figure 4 represents a system where the cost is

much lower from the start, but there is less stability

Figure 4: Effect of Robot Battery Capacity(time cap) on

System Cost [PSO] (Time Capacity vs. Cost). The parame-

ters kept constant here are: λ = 4, and num robots = 3.

over time, with more fluctuations as the time cap in-

creases.

5.3 Limitations

The study assumes homogeneous abilities of ground

robots and uniform environments, which simplifies

simulations but may not accurately capture the com

plexities of real-world scenarios. Additionally, the

use of fixed robot speeds and constant garbage gener

ation rates does not account for dynamic factors, such

as varying terrain conditions or human activity, which

could significantly impact performance in practical

applications.

6 CONCLUSION

This research underscores the efficacy of multi-robot

systems when integrated with the ROS framework

and an optimized algorithm for task scheduling. The

implementation of algorithms like simulated anneal-

ing (SA) and particle swarm optimization (PSO)

within the ROS ecosystem has demonstrated signif-

icant improvements in task coordination, resource

utilization, and operational efficiency. By facilitat-

ing seamless communication and synchronization be-

tween multiple robots, our system effectively ad-

dresses the complexities associated with dynamic task

environments.

In conclusion, the findings from this study

contribute valuable insights into the design and

deployment of multi-robot systems, offering a viable

solution for complex tasks in diverse domains.

Future research may focus on further refining the

task scheduling algorithms, expanding the system’s

capabilities, and exploring its application in more

challenging and dynamic environments. The ad-

vancements achieved here lay the groundwork for

ICAART 2025 - 17th International Conference on Agents and Artificial Intelligence

486

more sophisticated multi-robot applications, paving

the way for broader adoption in both industrial and

research settings.

REFERENCES

Elfakharany, A. and Ismail, Z. H. (2021). End-to-end deep

reinforcement learning for decentralized task alloca-

tion and navigation for a multi-robot system. Applied

Sciences, 11(7).

Hong, L., Cui, W., and Chen, H. (2021). A novel multi-

robot task allocation model in marine plastics clean-

ing based on replicator dynamics. Journal of Marine

Science and Engineering, 9(8).

Hu, J., Lennox, B., and Arvin, F. (2021). Collaborative cov-

erage for a network of vacuum cleaner robots. In An-

nual Conference Towards Autonomous Robotic Sys-

tems, pages 112–115. Springer.

Jeon, S., Jang, M., Lee, D., Cho, Y.-J., and Lee, J. (2015).

Multiple robots task allocation for cleaning a large

public space. In 2015 SAI Intelligent Systems Con-

ference (IntelliSys), pages 315–319.

Le, C. P., Pham, A. Q., La, H. M., and Feil-Seifer, D.

(2020). A multi-robotic system for environmental dirt

cleaning. In 2020 IEEE/SICE International Sympo-

sium on System Integration (SII), pages 1294–1299.

Le, C. P., Pham, H. X., and La, H. M. (2018). A multi-

robotic system for environmental cleaning. ArXiv,

abs/1811.00690.

Macenski, S. (2019). On use of slam toolbox, a fresh(er)

look at mapping and localization for the dynamic

world. In Proceedings of ROSCon 2019.

Macenski, S. and Jambrecic, I. (2021). Slam toolbox: Slam

for the dynamic world. Journal of Open Source Soft-

ware, 6(61):2783.

Macenski, S., Mart

´

ın, F., White, R., and Gin

´

es Clavero, J.

(2020). The marathon 2: A navigation system. In

2020 IEEE/RSJ International Conference on Intelli-

gent Robots and Systems (IROS).

Ni, J., Gu, Y., Tang, G., Ke, C., and Gu, Y. (2024). Cooper-

ative coverage path planning for multi-mobile robots

based on improved k-means clustering and deep rein-

forcement learning. Electronics, 13(5).

Orr, J. and Dutta, A. (2023). Multi-agent deep reinforce-

ment learning for multi-robot applications: A survey.

Sensors, 23(7).

Park, B., Kang, C., and Choi, J. (2022). Cooperative multi-

robot task allocation with reinforcement learning. Ap-

plied Sciences, 12(1).

Wang, Y., Hernandez, A., Shen, L., and Zhang, H. (2024).

Path planning of water surface garbage cleaning robot

based on improved immune particle swarm algorithm.

AIP Advances, 14(2).

Wang, Y., Hong, X., Ma, Z., Ma, T., Qin, B., and Su, Z.

(2023). Towards practical multi-robot hybrid tasks

allocation for autonomous cleaning. arXiv preprint

arXiv:2303.06531.

APPENDIX A

Simulated Annealing

Simulated Annealing (SA) is an optimization algo-

rithm that navigates the solution space by allowing

both upward and downward adjustments, helping es-

cape local minima and move toward a global solution.

It gradually reduces a ”temperature” parameter to bal-

ance exploration and refinement, making it effective

for complex problems.

Cooling Rate: The cooling rate (α) is defined as

T

new

= α · T

old

, where it controls the rate of temper-

ature decrease. Its value varies between 0 and 1. A

higher α (closer to 1) promotes broader exploration,

reducing the risk of getting trapped in local minima,

while a lower α focuses on refining the current so-

lution but risks suboptimal outcomes. Proper tuning

ensures an optimal balance between exploration and

exploitation. The employed algorithm is given in Al-

gorithm 3.

Data: Initial temperature T

0

, Cooling rate r

Result: Best solution and Cost

Initialize T ← T

0

, random P matrix,

current cost ← cost of P matrix

best cost ← current cost,

best solution ← P matrix

while T > T

s

do

for i ← 1 to L

k

do

Apply a random operation: swap(),

invert(), or move(); Compute ∆ ←

cost change

if ∆ < 0 or random() < exp(−∆/T )

then

Update current solution,

current cost

if current cost < best cost then

Update best solution,

best cost

end

end

end

T ← T · r

end

return best solution,best cost

Algorithm 3: Simulated Annealing (SA).

APPENDIX B

Particle Swarm Optimization

Particle Swarm Optimization (PSO) is a collabora-

tive optimization algorithm where a swarm of parti-

Comparative Analysis of Simulated Annealing and Particle Swarm Optimization for Multi-Robot Task Allocation in ROS

487

cles explores the solution space, adjusting their posi-

tions based on their own experience and the best so-

lutions found by others. This information sharing en-

ables an efficient balance between exploration of new

areas and exploitation of promising regions, making

PSO effective for complex problems.

Inertia Factor (ω): The inertia factor (ω) governs

the influence of a particle’s current velocity on its next

velocity. A higher ω encourages broad exploration,

while a lower ω focuses on refining around the best-

known solutions. The velocity update formula is:

v

i

(t +1) = ω· v

i

(t)+c

1

·r

1

·(p

i

−x

i

)+c

2

·r

2

·(g −x

i

),

where v

i

(t) is the current velocity of particle i, p

i

is

its personal best position, and g is the global best po-

sition. A decaying ω is often used to start with global

exploration and gradually shift to local exploitation

for better convergence. The employed algorithm is

given in Algorithm 4.

Data: N: Number of particles, T : Max

iterations, w,c

1

,c

2

: PSO factors

Result: global best: Optimal solution,

global best cost: Optimal cost

Initialize global best cost ← ∞, particles with

random positions and velocities

for each particle do

if particle.personal best cost <

global best cost then

Update global best and

global best cost

end

end

for t = 1 to T do

for each particle do

Update velocity:

particle.velocity ← w · velocity + c

1

·

rand · (personal best − position)+

c

2

· rand · (global best − position)

Update position using velocity

new cost ← particle.calculate cost()

if new cost <

particle.personal best cost then

Update personal best

if new cost < global best cost

then

Update global best and

global best cost

end

end

end

end

return global best, global best cost

Algorithm 4: Particle Swarm Optimization (PSO).

ICAART 2025 - 17th International Conference on Agents and Artificial Intelligence

488