Personalized Task Reassignment in Industry 5.0: A MILP-Based

Solution Approach

Claudia Diamantini

a

, Ornella Pisacane

b

, Domenico Potena

c

and Emanuele Storti

d

Dipartimento di Ingegneria dell’Informazione,

Università Politecnica delle Marche, 60121 Ancona, Italy

Keywords:

Process Optimization, Task Assignment, Business Continuity, Industry 5.0, Organizational Mining, Mixed

Integer Linear Programming.

Abstract:

Industry 5.0 involves a transformation towards human-centric and green-aware industrial ecosystems. Sus-

tainable, safe and efficient allocation of process activities to workers is crucial in this context, as excessive

workloads can bring detrimental effects on them, potentially causing long-term harm and reducing overall

productivity. This paper addresses the problem of reassigning activities to workers, balancing between ef-

ficiency and sustainability through a flexible and periodic negotiation process, in which workers can refuse

assigned activities if these exceed a sustainable stress level, which is monitored through wearable devices. We

model it through Mixed Integer Linear Programming (MILP) with a hierarchical objective function, aimed

at first maximizing the number of assignments and then minimizing the cost due to reassignments, levels of

stress and possible overtimes. As experiments show, the solution time of our MILP model makes dynamic

negotiation feasible in realistic settings.

1 INTRODUCTION

The advent of Industry 5.0, coupled with the Inter-

net of Everything (IoE), marks a new era of inter-

connection and smart automation in industrial pro-

cesses, towards human-centric and green-aware in-

dustrial ecosystems (Leng et al., 2022). One of the

critical challenges in this context is the sustainable

and safe allocation of tasks to workers, balancing pro-

ductivity with the physical and mental health of the

workforce. Excessive workloads and stress can lead

to detrimental effects on workers, potentially causing

long-term harm, while also impacting the enterprise

by degrading the quality of work and reducing overall

productivity.

This paper addresses the problem of assigning

tasks to workers, integrating sustainability, by propos-

ing a framework that dynamically adapts to chang-

ing conditions and worker capabilities. This helps

in finding a balance between efficiency and sustain-

ability, setting the stage for a more human-centric In-

dustry 5.0 ecosystem. The reassignment relies on a

a

https://orcid.org/0000-0001-8143-7615

b

https://orcid.org/0000-0003-1174-0162

c

https://orcid.org/0000-0002-7067-5463

d

https://orcid.org/0000-0001-5966-6921

flexible negotiation process, in which resources, i.e.

workers, can refuse assigned activities if these ex-

ceed a sustainable stress level, which is monitored

through wearable devices that operate on the edge,

preserving the privacy of individual workers. The

optimization problem is modeled through Mixed In-

teger Linear Programming (MILP) with a hierarchi-

cal objective function. Our primary goal is to max-

imize the number of assignments, followed by mini-

mizing the total cost due to reassignments, sustainable

stress level and possible overtimes, under a set of con-

straints. These depend on priority of activities, along

with available workload, performance and skills of

resources. Furthermore, social relations among re-

sources, modeled through organizational mining tech-

niques, are taken into account to prioritize reassign-

ment between resources with a high degree of affin-

ity. As such, this work is positioned in the domain of

Task Assignment optimization. Unlike previous stud-

ies, our focus is on the periodic reassignment of ac-

tivities to resources, facilitating dynamic adaption to

evolving requirements through a resource-driven ne-

gotiation process. Experiments demonstrate that, in

realistic settings, the solution time of our MILP model

makes periodic resolution feasible, enabling dynamic

negotiation.

Diamantini, C., Pisacane, O., Potena, D. and Storti, E.

Personalized Task Reassignment in Industry 5.0: A MILP-Based Solution Approach.

DOI: 10.5220/0013197400003929

In Proceedings of the 27th International Conference on Enterprise Information Systems (ICEIS 2025) - Volume 2, pages 813-820

ISBN: 978-989-758-749-8; ISSN: 2184-4992

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

813

The rest of this work is structured as follows: Sec-

tion 2 discusses related literature. The methodology

of the approach is introduced in Section 3, along with

the representation model for resources and activities,

and the MILP model. An experimental evaluation is

discussed in Section 4. Finally, Section 5 concludes

the paper and draws some future research directions

worth of investigation.

2 RELATED WORK

Allocating resources is often addressed as an opti-

mization problem. Indeed, several approaches have

been thoroughly reviewed in surveys on the subject

(De Bruecker et al., 2015; Pufahl et al., 2021), differ-

ing in terms of (a) the optimization criteria, (b) the

role of process models and data to drive the decision,

and (c) the adopted solution technique. Most research

focuses on process-oriented optimization, which aims

to find the resources that best fit the activity to replace.

This can involve a one-to-one (activity-to-resource)

approach or a more complex allocation. Optimization

can be performed from either a local or global per-

spective, considering different priorities of ongoing

process instances and their related activities. Other

possible measures to optimize include the process

cost, the cycle time of the process or the throughput.

Simpler approaches are based on manually de-

fined (logic) rules (e.g., Kumar et al., 2002), capa-

ble to find a feasible solution in less time than al-

ternative approaches, although with fewer guaran-

tees on its quality. Inductive approaches derive rules

for resource assignment, exploiting declarative min-

ing, reinforcement learning, decision trees, associa-

tion rules, support vector machines (Liu et al., 2008),

or by modeling social relations by Hidden Markov

Models. On the other hand, several literature con-

tributions make use of mathematical programming to

deal with the problem of assigning resources to ac-

tivities. For example, considering input/output of ac-

tivities and precedence, Hirsch and Ortiz-Peña (2017)

formulate a Mixed Integer Non-Linear Program and

design a set of heuristics, minimizing the comple-

tion time. In Arias et al. (2018), as we do, multi-

ple criteria are considered, such as information from

past executions of the process (e.g., frequency, perfor-

mance, quality), the required skills to perform each

activity and their resource workload. An Integer Lin-

ear Programming model is then formulated to allocate

a single resource to an activity and a heuristic is used

for batch resource recommendation, although not tak-

ing into account the priorities among the activities as

well as the similarity among the resources. In Xie

et al. (2016), the authors develop a dynamic task as-

signment approach for minimizing the cycle time of

processes at the run-time stage. Each resource has a

predefined list of assigned activities to perform, from

which the system schedules what to execute by rely-

ing on stochastic and queuing theory. Shared tasks

can be dynamically assigned to idle resources by role

type. Finally, heuristic approaches can balance solu-

tion quality and computational effort. As shown in

Pufahl et al. (2021), multiple approaches can be used,

e.g., semantic languages (Cabanillas et al., 2013), Par-

ticle Swarm Optimization to minimize the cycle-time

(Zhao et al., 2017), or math-heuristics for efficient re-

source replacement (Diamantini et al., 2024).

Unlike most work in the literature, focused on

minimizing the cycle time, our goal is to maximize

the number of assigned activities, while minimizing a

total cost depending on reassignments, levels of stress

and possible overtimes. This is achieved through a

hierarchical objective function, similar to the one al-

ready proposed in Diamantini et al. (2024). How-

ever, in that work, the problem of reassigning activ-

ities to resources did not take into account the lev-

els of stress, the possibility that a resource may also

refuse an activity and possible overtimes. Therefore,

the objective function represented only the number of

assignments (to maximize) and the total cost due to

reassignments (to minimize). The resulting decision

problem consisted of assigning activities of unavail-

able resources to those available resources with the

required skills. The activities already assigned to each

available resource were not subject to change and

were thus considered definitively assigned. In con-

trast, in the present work all the assignments are re-

considered on each period of observation, resulting in

a more complex problem. Indeed, this can be seen as a

Dynamic Task Assignment Problem (D-TAP) (Spivey

and Powell, 2004), where however we assume that

resources and tasks are known at each time period.

Therefore, to the best of our knowledge, our paper is

the first dealing with a dynamic and periodic reassign-

ment problem considering a resource-focused negoti-

ation based on sustainable stress levels.

3 METHODOLOGY

In this work, we refer to an Industry 5.0 scenario

in which an organization utilizes a Business Pro-

cess Management (BPM) system capable of monitor-

ing the execution of activities assigned to resources

within a set of business processes. Employees are

equipped with a smart object capable of tracking their

assigned activities and monitoring health parameters

ICEIS 2025 - 27th International Conference on Enterprise Information Systems

814

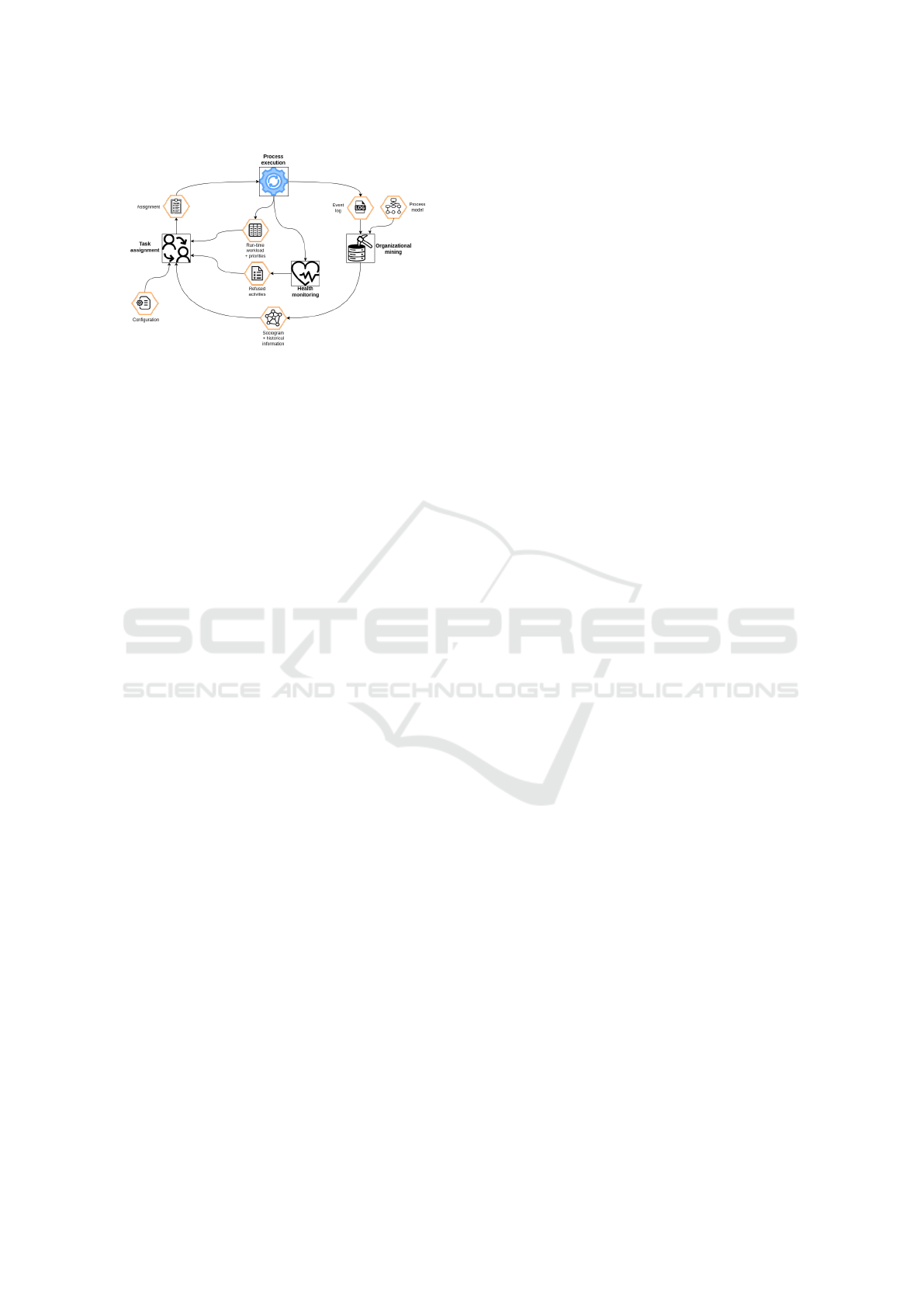

Figure 1: Overview of the context-aware task assignment

methodology.

to detect their stress levels. The device can automati-

cally refuse a subset of the assigned activities if the

employee’s monitored stress level exceeds the esti-

mated stress effort for those activities. The smart ob-

ject can either be an all-in-one device with computa-

tional capabilities or a combination of a fitness band

for health monitoring connected to a smartphone app

for task management.

The methodology builds on the steps that are

sketched in Figure 1. Initially, activities are assigned

to resources based on the available workload and his-

torical information, including skills, performance and

past collaborations. These are extracted from data on

executed activities, which are collected in an event

log. The log is analysed and processed using organi-

zational mining techniques (Song and van der Aalst,

2008) to derive a sociogram, i.e. a social graph of

collaboration relations. The scenario considered in

this work involves activities that are planned in ad-

vance and assigned to resources at design time. Re-

assignment of these activities requires re-planning all

remaining tasks. This means that we do not wait for

the execution of an activity to be completed before

deciding how to assign the next one. Unlike some

BPM systems that focus on roles, this approach tai-

lors assignments to the specific characteristics of in-

dividual employees. Additionally, information on the

run-time workload of resources and priorities of ac-

tivity are extracted from the system. In particular,

the priority of an activity indicates its level of ur-

gency. Higher priority activities must be executed

before lower priority ones, ensuring critical activities

are completed first. Employees’ devices may refuse

activities (among those they should still perform) at

any time during the process execution if their stress

level increases. The system collects these refused ac-

tivities and, with a given periodicity, re-executes task

assignment. Hence, the task assignment problem re-

distributes activities to maximize the number of as-

signments, and to minimize reassignment costs, ac-

counting for several conditions. C1) Availability: an

activity can be assigned to a resource with sufficient

residual workload. Overtime is possible within na-

tional labor law constraints but should be considered

an exception, used only when no other solutions are

available. C2) Sustainable stress compliance: an ac-

tivity can be assigned to a resource only if its esti-

mated stress level is below the threshold of refused

activities. New activities can be assigned to resources

that have not refused any activities. C3) Affinity: re-

sources more compatible with those to be replaced are

preferred. Affinity takes into account past work rela-

tions, resource capabilities, performance and experi-

ence. C4) Minimality: the original assignment plan

should be preserved as much as possible: as a conse-

quence, reassigning an activity to the same resource is

preferred if possible. C5) Priority: in order to assign

an activity with a given priority, all activities with a

higher priority must be assigned.

Overall, the iterative approach to reassignment

can be viewed as a dynamic negotiation process. It

operates in a privacy preserving manner, as refusals

are managed locally on the employees’ devices, and

the reasons are not communicated back to the system,

ensuring that sensitive information about employees’

stress levels remains confidential. By periodically re-

assessing and redistributing activities, the system can

adapt to changing conditions and continuously opti-

mize assignments in a fair and efficient manner.

3.1 Representation Model for Resources

and Activities

We denote by T a set of activities, i.e., tasks that are

aimed to achieve a goal, and by R the set of resources

within the organization. We denote by L the set of

activity types (or label), e.g., pallet moving, product

packaging, tool cleaning. The function Ω : T → L

maps an activity to its type.

3.1.1 Process-Related Information

Information on resources can be retrieved from ei-

ther process models (in a top-down approach), or

from logs of past process executions (according to

a bottom-up approach), although a mix of the two

approaches is frequently used. Following the Pro-

cess Mining terminology (Van Der Aalst et al., 2005),

hereby we refer to the term event to denote the execu-

tion of a specific activity by a resource. A trace is a

possible sequence of events, where C is the set of all

possible traces. An event log L is a subset of all bags

(multi-sets) over C, and is used to extract information

on activities, resources and relations among them.

Personalized Task Reassignment in Industry 5.0: A MILP-Based Solution Approach

815

An activity a

k

∈ T is characterized by an average

workload λ

k

∈ [0, 1] which is obtained by averaging

past execution times in the event log of activities be-

longing to same type. Hence, activities of the same

type will share the same average workload value, i.e.,

∀a

i

, a

j

∈ T, i ̸= j, Ω(a

i

) = Ω(a

j

) → λ

i

= λ

j

. We con-

sider a reference time period that can be defined ar-

bitrarily at the application level (e.g., a working day

or week). Details about the computation of the pa-

rameter are available in Diamantini et al. (2024). A

resource is characterized in terms of a set of skills,

namely the activity types that they performed at least

once in the past. Relations among resources are uti-

lized to model the affinity of a resource in being as-

signed an activity type previously assigned to another.

The notion of affinity stems from recognizing,

in the log, collaboration relations between two re-

sources. Among the several measures defined in the

literature on organizational mining (Van Der Aalst

et al., 2005), here we focus on possible causality, and

specifically on handover of work. Within a trace,

there is a handover of work from a resource r

1

to

a resource r

2

if there are two subsequent activities

a

1

and a

2

where a

1

is completed by r

1

and a

2

by

r

2

. In this work, we ignore self-transfers by con-

sidering indirect succession and causal relation, i.e.,

we take into consideration succession between activ-

ities, with any length, only if aligned to the process

model. To detect causal relations, we rely on the ap-

proach discussed in Diamantini et al. (2016), which

enables to make causal relations between events in a

trace explicit. The metric is computed for a pair of

resources r

1

, r

2

and with respect to a pair of activity

types Ω(a

1

), Ω(a

2

) by dividing the total number of

proper causal successions (with no self-transfer) by

the total number of causal successions of activities

with types Ω(a

1

), Ω(a

2

) between any two resources

r

i

, r

j

, with i ̸= j. In other terms, the metric evaluates

how peculiar the relation between two resources in

the execution of such two activity types is (infrequent

relations will be taken into account as well). The in-

formation can be represented in a sociogram, i.e., a

labeled directed multigraph of social relations where

nodes represent resources and a labeled edge linking

two nodes represents the activity type, the handover

of work and the number of causal successions. Fig-

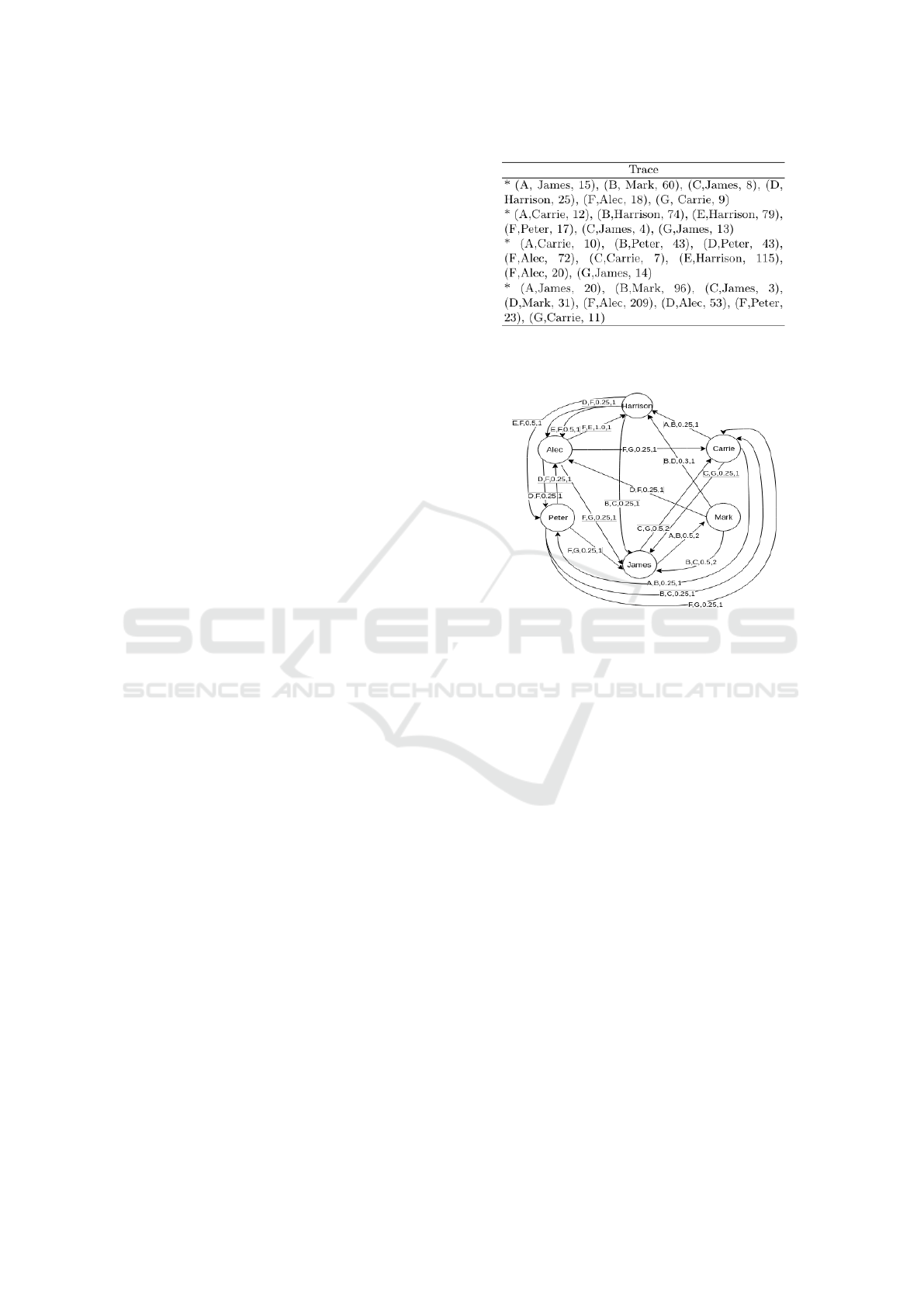

ure 2 and Figure 3 show an example of event log and

related sociogram, respectively.

The priority of an activity is a further process-

related information derived from the BPM system.

We model it as a process-dependent function that de-

fines a total order over the set of activities to assign.

Each activity’s priority depends on (a) the process in-

stance in which it is expected to be executed (accord-

Figure 2: An example of event log with 4 traces (each event

includes the activity type, the resource and the duration).

Figure 3: The sociogram corresponding to the example in

Figure 2.

ing to business rules) and (b) its position within the

process, considering that if two activities a

h

, a

k

are in

causal relation, then priority of a

h

is higher than pri-

ority of a

k

. The specific priority value, given to each

process instance, is domain-dependent and therefore

left to implementation. Given an activity a

k

, P

k

is the

set of activities with a priority higher than a

k

.

3.1.2 Contextual Information

Contextual information on a resource r

i

∈ R is ex-

tracted from the information system of the organiza-

tion, in terms of current workload γ

i

∈ [0, 1], while the

maximum workload µ

i

∈ [0, 1] is set by the organiza-

tion. Both are expressed w.r.t. to a reference period.

Finally, assigning an estimated stress level ξ

k

∈

[0, 1] to an activity a

k

is essential for understanding

and managing its impact on employees’ well-being.

Similarly to the workload, the estimated stress level

for activities belonging to the same type is identical,

i.e. ∀a

i

, a

j

∈ T, i ̸= j, Ω(a

i

) = Ω(a

j

) → ξ

i

= ξ

j

. This

estimation quantifies the stress level associated to a

particular activity, considering factors like physical

and mental effort. The value can be obtained in mul-

tiple ways, e.g. by an expert-defined stress model, by

employee self-reporting, or learning approaches, al-

ICEIS 2025 - 27th International Conference on Enterprise Information Systems

816

though in this work we leave its definition to the spe-

cific implementation.

3.2 MILP Model

Hereby, we describe the MILP model, formulated to

solve the problem of assigning activities to resources.

The reassignment problem needs to be solved by pe-

riodically collecting all the refusal notifications com-

ing from the employees’ smart objects. Notifications

serve as alerts that some resources are unable to per-

form some activities, previously assigned to them.

Therefore, the approach for task re-assignment is to

challenge the assignment of all the activities, even

those not refused, in order to perform as many activ-

ities as possible, preferring solutions that disrupt the

previous allocation plan as little as possible.

For the sake of simplicity, in the following formu-

lation, we refer each activity as well as each resource

only through its subscript. For each resource i ∈ R ,

A

i

is the set of activities assigned to him/her, and

R A

i

⊆ A

i

is the subset of possible activities he/she

refuses. In addition,

¯

R ⊆ R is the set of resources

with at least one refused activity.

The problem is mathematically formulated

through MILP, through the decision variable

x

ik

, ∀i ∈ R , k ∈ T , equal to 1 if the resource i is

assigned to the activity k, 0 otherwise. Moreover,

differently from Diamantini et al. (2024), the level of

stress of each activity assigned to a resource is also

considered. Therefore, the non-negative continuous

decision variable δ

s

i

∀i ∈ R is introduced, denoting

the additional percentage assigned to the level of

stress of the resource i, relative to the maximum

level of stress ν

s

i

that the resource can tolerate. The

parameter ν

s

i

is computed as: ∀i ∈ R \

¯

R (i.e., who

did not refuse any activity), ν

s

i

= max

k∈A

i

{ξ

k

}. In-

stead, ∀i ∈

¯

R (i.e., who refused at least one activity),

ν

s

i

= max

k∈A

i

\R A

i

{ξ

k

}.

In some cases, it may not be possible to reassign

all the activities. Therefore, the non-negative contin-

uous decision variable δ

w

i

, ∀i ∈ R is introduced, de-

noting the additional percentage assigned to the resid-

ual workload of i relative to the maximum workload.

The residual workload of a resource i is computed as:

µ

i

− γ

i

. Finally, as in Diamantini et al. (2024), the in-

put coefficient α

ik

, ∀i ∈ R , k ∈ T , equals 1 if resource

i can perform activity k, and 0 otherwise, based on the

skills required for k.

The proposed MILP model is in the following.

min

∑

j∈R

∑

k∈A

j

∑

i∈R :α

ik

=1

(c

i jk

− M

k

)x

ik

+

∑

i∈R

P ∗ δ

s

i

+

∑

i∈R

Q ∗ δ

w

i

(1)

∑

i∈R :α

ik

=1

x

ik

≤ 1, ∀k ∈ T (2)

∑

k∈T :α

ik

=1

λ

k

∗ x

ik

≤ (µ

i

− γ

i

) ∗ (1 + δ

w

i

), ∀i ∈ R (3)

∑

i∈R :α

ik

=1

x

ik

≤

∑

j∈R

∑

k∈P

k

:α

jk

=1

x

jk

|P

k

|

, ∀k ∈ T (4)

ξ

k

∗ x

jk

≤ (1 + δ

s

i

) ∗ ν

s

i

, ∀k ∈ T, i ∈ R (5)

0 ≤ δ

s

i

≤

¯

δ

s

i

∀i ∈ R (6)

0 ≤ δ

w

i

≤

¯

δ

w

i

∀i ∈ R (7)

x

ik

∈ {0, 1}∀i ∈ R , k ∈ T (8)

The objective function to minimize (1) consists of

three cost components. The first one is the total cost

of assigning activities to resources minus the penalty

(M

k

) to pay for each unassigned activity k. This way,

in order to incentive as many assignments as possi-

ble, the cost of each activity assigned is decreased by

the corresponding penalty. M

k

depends on the activ-

ity k in order to take into account the relative impor-

tance given to each activity. In the traditional task

assignment problem, the total cost is minimized by

assigning all tasks. On the contrary, in our problem,

in order to consider the stress levels (not higher than

a given threshold) and then, make the instance feasi-

ble, unassigned tasks are also allowed. Higher prior-

ity tasks are prioritized because failure to assign them

could make other tasks in the cascade unfeasible. This

is why constraints (4), on task priority, are formu-

lated. We refer to Diamantini et al. (2024) for the de-

tailed definition of the cost factors c

i jk

, proportional

to 1 − sim(r

i

, r

j

, a

k

), where sim is a similarity func-

tion that measures the affinity (C3 - Affinity) between

resources i and j in performing the activity k. In turn,

sim is calculated as the weighted average of the han-

dover of work (derived from the sociogram), the rel-

ative efficiency and the relative experience in execut-

ing the task k (both derived from the event log). The

weights of the three components depend on the appli-

cation scenario. For example, for tasks that require

a high degree of collaboration (e.g., management or

knowledge-driven processes), the weight of the han-

dover of work will be very high, whereas for semi-

automated tasks such as production processes, it will

be less important. Moreover, c

iik

, ∀i ∈ R , k ∈ A

i

is set

equal to 0, in order to preserve, as much as possible,

the original assignment plan (C4 -Minimality). This

way, it is guaranteed that, when possible, the plan

Personalized Task Reassignment in Industry 5.0: A MILP-Based Solution Approach

817

of the activities each resource has to perform is not

completely changed. The second cost component ac-

counts for the penalties (equal to P for all resources)

due to increased stress level for resources, while the

third component refers to the penalties (equal to Q for

all the resources) due to their possible overtimes.

Each activity k ∈ T is assigned to at most one re-

source (2). The maximum workload of a resource i is

never exceeded (C1 - Availability, (3)). Indeed, the

possibility to increase the residual workload of the

resource i (i.e., µ

i

− γ

i

) of a certain percentage δ

w

i

is

also considered. A lower priority activity is not as-

signed if all its higher priority activities are not as-

signed (C5 - Priority, (4)). It is worth noting that the

proposed model takes into account the well-being of

the employees also through the objective function (1).

In particular, while the well-being of employees is

not directly maximized, solutions that result in stress

levels significantly exceeding their tolerable thresh-

olds are avoided because the related penalty factor

P, in (1), is set to a very large value. For each pair

(i ∈ R , k ∈ T ), the level of the stress of k, if assigned

to i, does not exceed the maximum level of stress

possible, increased of a certain percentage (C2 - Sus-

tainability, (5)). The nature of each decision variable

δ

s

i

, ∀i ∈ R that is non-negative and not higher than a

threshold

¯

δ

s

i

is guaranteed through (6). This thresh-

old is computed differently according to the resource

type: ∀i ∈

¯

R , it is

ν

s

i

+

¯

ν

s

i

2

, where

¯

ν

s

i

= min

k∈R A

i

{ξ

k

}.

Instead, ∀i ∈ R \

¯

R , it is an input parameter indicated

by the decision maker. Finally, constraints (7 – 8) de-

fine the nature of the other decision variables, where

¯

δ

w

i

is set according to national labour laws. In order to

speed up the computational times required by solver

for the proposed model, we apply the following pre-

processing rules:

x

ik

= 0, ∀i ∈ R , k ∈ R A

i

(9)

x

ik

= 0, ∀i ∈ R , k ∈ T : α

ik

= 1, ξ

k

> (1 +

¯

δ

s

i

) ∗ ν

s

i

(10)

Assigning activity k to resource i, who has refused it

(i.e., k ∈ R A

i

), is not allowed (9). Finally, assigning

activity k to resource i who has the required skills but

cannot tolerate its stress level, is also prohibited (10).

4 EXPERIMENTS

In this section, tests aimed at evaluating the efficiency

and effectiveness of the approach in various scenarios

are presented. Specifically, we examined how several

parameters change with the number of resources, as-

signed tasks, level of stress and number of refused ac-

tivities. The average time taken to solve the model is

reported, along with the average percentage MIP GAP

achieved by the solver, the average number of activi-

ties not assigned in the solution, the average number

of resources asked to work overtime and their aver-

age overtime, the average number of resources with

additional level of stress and their average additional

stress level.

4.1 Settings

The model was solved on a set of instances that were

synthetically generated by setting the number of re-

sources to 100 and by varying the number of activ-

ity types (N

A

) in {10, 20, 40}, the probability that a

resource refuses at least one assigned activity (P

re f

)

in {0.1, 0.2, 0.4} and the minimum current workload

of a resource (MWL) in {0.2, 0.4, 0.6}. Each activity

type is defined by randomly assigning a workload ef-

fort λ

k

∈ [0.01, 0.3] and a stress level ξ

k

∈ [0.1, 1.0],

assuming uniform distributions. Each resource can

perform a randomly assigned number of activity types

between 2 and 4. The current workload of the re-

source is randomly chosen between MW L and 0.8,

and a number of activities are assigned, each with a

random priority value, up to the maximum workload

level of 1.0. A resource can be selected to refuse some

activities, with probability P

re f

. In this case, a stress

threshold t

s

is randomly picked from the stress levels

of the assigned activities. Consequently, all activities

with a stress level ≥ t

s

are flagged to be refused by

the resource. In total, two instances, for each com-

bination of the input parameters, were generated, re-

sulting in 54 instances.The penalties (M

k

, P, Q) were

set by giving higher priority to the fact that all the ac-

tivities can be performed in the workday, without ad-

ditional costs due to overtime. Thus, M

k

was chosen

greater than P so that we would prefer to perform all

the activities, taking the risk of assigning them also

with a higher stress level (δ

s

>0). This choice is also

motivated by the fact that the resources with δ

s

>0 may

more likely refuse some activities, and this could lead

to re-running the procedure with a reduced margin on

the allowable stress level. In details, M

k

is 100 for

each activity k and P is 20. The parameter Q is set

to 10

5

, higher than M

k

, because the overtime should

be considered if strictly necessary, as it implies ad-

ditional costs. The parameter

¯

δ

w

i

was set to 0.2, in

accordance with Italian law limiting the maximum

amount of overtime possible per resource.

Experiments were performed on a machine with 4

cores, 2.3GHz with 32GB RAM. We used the com-

mercial optimization solver Cplex (release 20.1.0.0),

by setting its MIP tolerance equal to 0 and its time

limit equal to 300 seconds.

ICEIS 2025 - 27th International Conference on Enterprise Information Systems

818

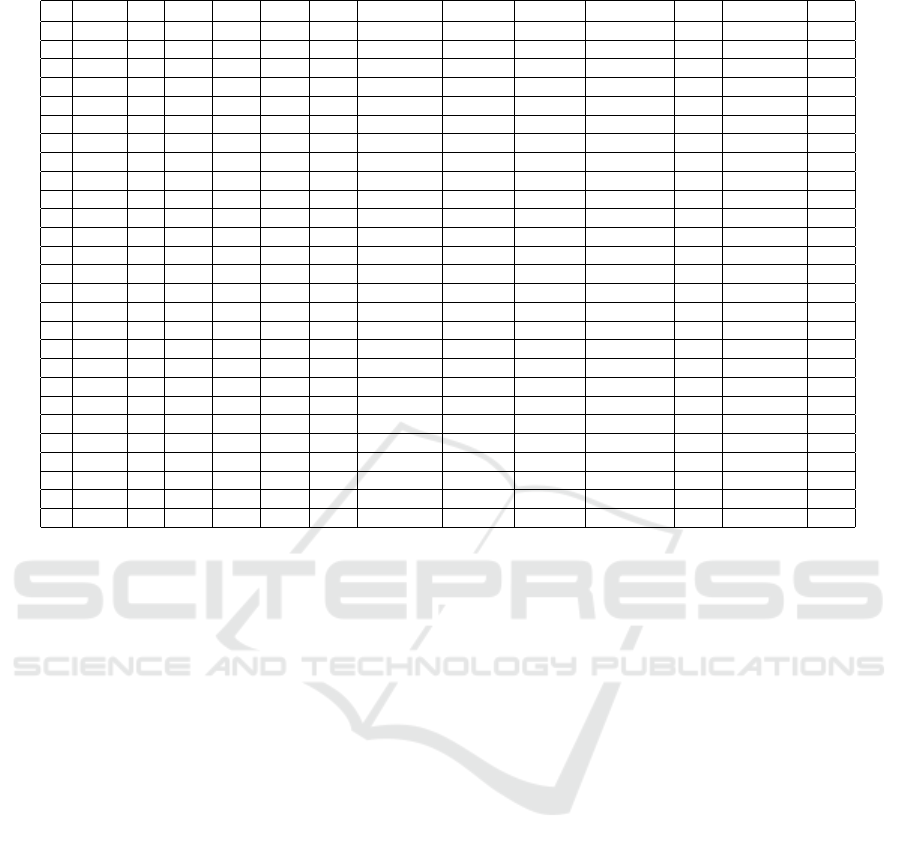

Table 1: Average results of the two instances generated for |R | = 100.

N

A

MWL P

ref

|T| ξ

k

Rej. λ

k

MIP GAP Not Ass. Time (s) Res. δ

w

i

>0 δ

w

i

Res. δ

s

i

>0 δ

s

i

10 0.2 0.1 906.5 0.605 485 0.058 3.4E-3 0 300.9 17 0.000 1 0.009

10 0.2 0.2 374.5 0.418 129 0.122 8.3E-5 0 178.0 0 0.000 0 0.000

10 0.2 0.4 382 0.530 127 0.119 5.5E-5 0 300.2 0 0.000 0 0.000

10 0.4 0.1 360 0.474 176 0.101 3.7E-5 0 300.3 0 0.000 0 0.000

10 0.4 0.2 361.5 0.432 109.5 0.107 5.6E-5 0 276.0 0 0.000 0 0.000

10 0.4 0.4 468 0.447 168 0.077 3.2E-4 0 300.3 0.5 0.000 0 0.000

10 0.6 0.1 205.5 0.535 81 0.123 0 0 76.1 0 0.000 0 0.000

10 0.6 0.2 225 0.461 90.5 0.115 0 0 30.1 0 0.000 0 0.000

10 0.6 0.4 266 0.405 57 0.106 1.8E-6 0 186.4 0 0.000 0 0.000

20 0.2 0.1 409.5 0.434 198.5 0.122 8.3E-5 0 300.2 0 0.000 0 0.000

20 0.2 0.2 551.5 0.616 285.5 0.086 2.1E-4 0 300.4 0 0.000 0.5 0.012

20 0.2 0.4 454.5 0.585 150 0.108 6.7E-5 0 300.3 0 0.000 0 0.000

20 0.4 0.1 346 0.522 180 0.106 1.7E-5 0 300.1 0 0.000 0 0.000

20 0.4 0.2 413.5 0.600 213 0.088 1.1E-4 0 300.2 0 0.000 0 0.000

20 0.4 0.4 464 0.471 105.5 0.083 2.7E-5 0 300.2 0 0.000 0 0.000

20 0.6 0.1 394 0.564 227 0.070 1.0E-4 0 300.2 0 0.000 0.5 0.011

20 0.6 0.2 321.5 0.599 165.5 0.085 7.5E-5 0 300.1 0 0.000 0 0.000

20 0.6 0.4 376 0.433 102.5 0.073 2.5E-5 0 250.4 0 0.000 0 0.000

40 0.2 0.1 547 0.478 277.5 0.087 1.4E-4 0 300.2 0.5 0.013 0 0.000

40 0.2 0.2 519 0.518 231.5 0.086 2.0E-4 0 300.2 0 0.000 0 0.000

40 0.2 0.4 476.5 0.511 141 0.096 9.2E-5 0 300.2 0 0.000 0.5 0.011

40 0.4 0.1 398 0.491 220.5 0.092 7.1E-5 176 150.2 0 0.000 0.5 0.047

40 0.4 0.2 282 0.480 119.5 0.127 6.4E-6 0 193.3 0 0.000 0 0.000

40 0.4 0.4 393 0.536 131 0.094 7.5E-5 0 276.6 0 0.000 1.5 0.039

40 0.6 0.1 203 0.558 77.5 0.124 0 0 46.7 0 0.000 0 0.000

40 0.6 0.2 273.5 0.475 101.5 0.098 7.6E-6 0 198.8 0 0.000 0 0.000

40 0.6 0.4 327 0.480 88.5 0.086 4.4E-5 0 173.4 0 0.000 0 0.000

4.2 Results

Table 1 shows the average results of the two instances

generated for each combination of parameters. In de-

tails, it reports the parameters representing the pair

of instances (N

A

,MW L,P

re f

), the average number of

planned activities at time t when the instance is gen-

erated (|T|), the estimated level of stress (ξ

k

) of activ-

ities, the number of refused activities at time t (Rej.),

the average workload of activities (λ

k

), the average

percentage MIP GAP achieved by Cplex (MIP GAP),

the average number of activities not assigned in the

solution (Not Ass.), the average time taken to solve

the model (time), the average number of resources

who have been asked to work overtime (Res. δ

w

>0)

and their average overtime (δ

w

), the average number

of resources with additional level of stress (Res. δ

s

>0)

and their average additional stress level (δ

s

).

The model was solved to the optimality only for 3

instances. In the remaining instances, the percentage

MIP GAP ranges between 1.76E-06 and 3.40E-03.

As expected, there is a strong correlation between the

status of the solution (i.e., optimal or feasible) and the

number of refused activities. To overcome this issue,

one could increase either the time limit (i.e., higher

than 300 seconds) or the number of cores available to

Cplex. However, it should be noted that such a num-

ber of refusals, in an organization with at most 100

employees, seems to us very high and unlikely.

The number of unassigned activities is a critical

factor in ensuring the proper execution of daily op-

erations. In all instances except one, the obtained

solution assigns all the activities. When not all activ-

ities are assigned, if the total cost of delaying some

activities to the next days exceeds the cost of having

worked overtime, the penalty Q can be reduced.

As for the level of stress, the average δ

s

, calculated

only for those resources for which it is greater than 0,

ranges between 0.92% and 4.68% (2.153% on aver-

age), involving maximum 3 resources. This implies

that the probability a plan is not accepted, due to the

fact that some assignments exceed the stress level of

some resources, is very low. In any case, there would

be time to invoke Cplex several times to solve the

MILP model without generating dead time. In fact,

the average time remaining before the end of the cur-

rent activities, i.e. before the next activity starts, ex-

ceeds the time needed to solve the model. For each

instance, we calculated the average activity execution

time (using the λ

k

assigned to each planned activity

and considering an 8-hour workday). We assume that,

at the time the instance is generated, a resource has

already performed half of their current activity. The

result is that the remaining time is on average 4.69

times the time limit (i.e., 300 seconds) and on aver-

age, 109.15 times the time needed to find a solution.

Moreover, in the solutions with all the activities as-

signed, the overtime is rarely used and, if necessary,

Personalized Task Reassignment in Industry 5.0: A MILP-Based Solution Approach

819

with very low costs: on average, 3.28 minutes per re-

source required to work overtime (with values ranging

between 0.05 and 12.86 minutes), for a total of 4.14

minutes on average per instance.

5 CONCLUSION

In this work, we proposed an approach for addressing

the problem of reassigning activities to workers, bal-

ancing between efficiency and sustainability through

a flexible and periodic negotiation process. In fact,

workers can refuse assigned activities if these ex-

ceed a sustainable stress level, which is monitored

through wearable devices. We formulated the prob-

lem through MILP, in order to select the available re-

sources for performing the refused activities, at the

minimum total cost, under completeness, availability,

priority and sustainability constraints. An experimen-

tal campaign was carried out on a set of synthetic in-

stances and the numerical results were discussed by

also performing a sensitivity analysis.

As a future work, we plan to extend the experi-

ments considering real processes. Furthermore, de-

signing metaheuristic and/or matheuristic approaches

is worth of investigation, particularly for efficiently

addressing large-sized instances of the problem.

ACKNOWLEDGEMENTS

This work has been partially supported by the

PRIN 2022 project “HOMEY: a Human-centric IoE-

based Framework for Supporting the Transition To-

wards Industry 5.0”, funded by the European Union

- Next Generation EU, Mission 4 Component 1

(code: 2022NX7WKE, CUP: F53D23004340006)

and by the PNRR project FAIR - Future AI Research

(PE00000013), Spoke 9 - AI, under the NRRP MUR

program funded by the Next Generation EU.

REFERENCES

Arias, M., Munoz-Gama, J., Sepúlveda, M., and Miranda,

J. C. (2018). Human resource allocation or rec-

ommendation based on multi-factor criteria in on-

demand and batch scenarios. European Journal of In-

dustrial Engineering, 12(3):364–404.

Cabanillas, C., García, J. M., Resinas, M., Ruiz, D.,

Mendling, J., and Ruiz-Cortés, A. (2013). Priority-

based human resource allocation in business pro-

cesses. In International Conference on Service-

Oriented Computing, pages 374–388. Springer.

De Bruecker, P., Van den Bergh, J., Beliën, J., and Demeule-

meester, E. (2015). Workforce planning incorporating

skills: State of the art. European Journal of Opera-

tional Research, 243(1):1 – 16.

Diamantini, C., Genga, L., Potena, D., and van der Aalst, W.

(2016). Building instance graphs for highly variable

processes. Expert Systems with Applications, 59:101–

118.

Diamantini, C., Pisacane, O., Potena, D., and Storti, E.

(2024). Combining an lns-based approach and organi-

zational mining for the resource replacement problem.

Computers & Operations Research, 161:106446.

Hirsch, M. J. and Ortiz-Peña, H. (2017). Information sup-

ply chain optimization with bandwidth limitations.

International Transactions in Operational Research,

24(5):993–1022.

Kumar, A., van der Aalst, W. M. P., and Verbeek, H. M. W.

(2002). Dynamic work distribution in workflow man-

agement systems: How to balance quality and perfor-

mance. Journal of Management Information Systems,

18(3):157–194.

Leng, J., Sha, W., Wang, B., Zheng, P., Zhuang, C., Liu, Q.,

Wuest, T., Mourtzis, D., and Wang, L. (2022). Indus-

try 5.0: Prospect and retrospect. Journal of Manufac-

turing Systems, 65:279–295.

Liu, Y., Wang, J., Yang, Y., and Sun, J. (2008). A semi-

automatic approach for workflow staff assignment.

Computers in Industry, 59(5):463–476.

Pufahl, L., Ihde, S., Stiehle, F., Weske, M., and Weber,

I. (2021). Automatic resource allocation in business

processes: A systematic literature survey. Computing

Research Repository, abs/2107.07264.

Song, M. and van der Aalst, W. M. (2008). Towards com-

prehensive support for organizational mining. Deci-

sion Support Systems, 46(1):300 – 317.

Spivey, M. Z. and Powell, W. B. (2004). The dy-

namic assignment problem. Transportation science,

38(4):399–419.

Van Der Aalst, W. M., Reijers, H. A., and Song, M.

(2005). Discovering social networks from event logs.

Computer Supported Cooperative Work (CSCW),

14(6):549–593.

Xie, Y., Chien, C.-F., and Tang, R.-Z. (2016). A dynamic

task assignment approach based on individual work-

lists for minimizing the cycle time of business pro-

cesses. Computers & Industrial Engineering, 99:401–

414.

Zhao, W., Zeng, Q., Zheng, G., and Yang, L. (2017). The

resource allocation model for multi-process instances

based on particle swarm optimization. Information

Systems Frontiers, 19(5):1057–1066.

ICEIS 2025 - 27th International Conference on Enterprise Information Systems

820