Development of a New Architecture for next Generation e-Bikes

Tiago Gândara

1a

and José Santos

2b

1

Departamento de Engenharia Mecânica, Campus Universitário de Santiago, 3810-193 Aveiro, Portugal

2

TEMA-Centro de Tecnologia Mecânica e Automação, Departamento de Engenharia Mecânica,

Universidade de Aveiro, Campus Universitário de Santiago, 3810-193 Aveiro, Portugal

Keywords: e-Bike, System Architecture, Battey Management System, Motor Controller.

Abstract: The growing e-bike market demands more efficient, connected, and user-friendly systems. However, existing

e-bike architectures are closed, limiting the integration of new technologies such as power management

algorithms and security features. This paper proposes a new system architecture utilizing a microcontroller-

based motor controller and CAN bus, allowing integration and data exchange with external devices.

Experimental testing was conducted to validate the system’s functionality, including testing energy efficiency

improvements and security features such as emergency stop protocols. Results demonstrate that the proposed

architecture can enhance energy efficiency and provides reliable security, offering a flexible and scalable

solution for future e-bike developments.

1 INTRODUCTION

With the increasing popularity of electric bicycles (e-

bikes) as a sustainable mode of transportation, the

demand for systems tailored to their specific needs

has risen. E-bikes offer numerous benefits, including

reduced reliance on fossil fuels, decreased urban

congestion, and improved accessibility to

transportation (Fishman and Cherry, 2016). These

advantages have contributed to the rapid growth of

the e-bike market. In Europe alone, the market is

projected to expand from $19.36 billion in 2024 to

$29.28 billion by 2029, with a compound annual

growth rate (CAGR) of 8.63% (Mordor Intelligence,

2024).

Besides individual ownership, bike-sharing

systems have further driven the adoption of e-bikes

by offering sustainable and convenient solutions for

short-term transportation. Beyond their role in

reducing pollution, their minimal space requirements

make them an ideal choice for improving quality of

life in urban environments (Boglietti et al., 2021).

Additionally, studies indicate that 18% to 32% of

bike-sharing users would prefer e-bikes if available

(Schnieder, 2023).

a

https://orcid.org/0009-0004-2040-7155

b

https://orcid.org/0000-0003-0417-8167

As e-bikes become integral to urban mobility,

their underlying technologies must evolve to address

growing user expectations. Recent advancements in

e-bike systems have focused on improving user

experience, safety, and efficiency. Smart

technologies now enable optimized routing to reduce

travel times, enhance security with collision sensors,

and improve energy efficiency to extend range.

Some authors have focused on developing

solutions for bicycle route optimization and data

collection. (Nunes et al., 2020) developed an IoT-

based module embedded in bicycles to collect real-

time sensor data, aiming to enhance cyclists' safety

and provide a web-based connectivity platform for

route optimization and policy support. (Grama et al.,

2018) proposed a modular solution designed to be

adapted based on cyclists' needs. The modules

focused on two primary functions: measuring bicycle

parameters and monitoring environmental conditions.

The goal was to develop a platform for collecting and

sharing data on air pollution in urban environments.

(Andres et al., 2019) used co-operative interaction

between the vehicle and the user to get green traffic

lights by adjusting the vehicle’s speed. (Cammin et

al., 2023) introduced a real-time IoT architecture

designed to address road traffic challenges by

34

Gândara, T. and Santos, J.

Development of a New Architecture for next Generation e-Bikes.

DOI: 10.5220/0013208800003941

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 11th International Conference on Vehicle Technology and Intelligent Transport Systems (VEHITS 2025), pages 34-44

ISBN: 978-989-758-745-0; ISSN: 2184-495X

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

reducing accidents and improving traffic flow

through 5G-enabled smart city integration.

Other authors have developed solutions related to

increasing the autonomy through optimization of

energy consumption. (Arango et al., 2021) developed

experimental models for the efficiency of mid-drive

motor e-bike components and integrated them into a

system-wide efficiency map, maximizing range

without compromising speed. (De La Iglesia et al.,

2017) developed an intelligent motor management

system designed to optimize assistance levels and

reduce battery power consumption. The system

utilized data from bicycle sensors, historical cyclist

data, and neural networks to make informed

decisions, resulting in a 10.32% reduction in

electricity consumption. (Vishnu et al., 2024)

developed a novel control algorithm for a Hybrid

Energy Storage System (HESS) that integrates a

battery and a supercapacitor and proved that the

HESS approach could improve range and

performance.

Some authors have also studied collision

detection in e-bikes, with advancements in sensor

technologies aimed at improving safety and

autonomy in complex environments. For instance,

(Xie et al., 2021) focused on tracking vehicles at

intersections using a narrow, low-density LiDAR

system. (Zhao et al., 2017) developed an autonomous

bicycle equipped with a high-density three-

dimensional LiDAR system, enabling the bicycle to

effectively detect and avoid obstacles, showcasing the

potential of advanced sensor technologies.

Despite these technological advancements,

implementing new systems in e-bikes is challenging

due to the prevalence of closed-system architectures.

Most e-bikes operate as isolated black boxes,

preventing data exchange and integration with

external devices. As a result, integrating advanced

features often requires additional sensors and

microcontrollers, leading to increased system

complexity and costs.

As of today, a system architecture that allows for

data-sharing, embedded algorithms implementation

and easy integration with other modules is yet to be

designed. The proposed architecture aims to bridge

this gap, providing a flexible foundation for the

development and integration of advanced features

that enhance performance, safety, and user

experience.

1.1 Typical e-Bike Architecture

A typical e-bike architecture consists of several key

components including the electric motor, battery,

controller, sensors, human interface, and a battery

management system (BMS). The motor, either hub or

mid-drive, converts electrical energy into mechanical

power, while the battery provides the necessary

energy. The controller manages power flow,

interpreting input from sensors like pedal-assist and

speed sensors to regulate motor output. The human

interface, often a display and control buttons, allows

riders to adjust power modes and monitor key metrics

like speed and battery status. A typical e-bike is

shown in Figure 1.

The battery is responsible for powering the whole

system. Usually, the battery is composed of lithium-

ion cells, which have a nominal voltage of 3.6 volts

(V) and are connected in series of 10, 13 or 14, which

translate into overall nominal battery voltages of 36V,

46.8V or 50.4V, respectively.

Figure 1: Typical e-bike (Lightmobie, 2025).

To improve the e-bikes range and reduce the

electrical current through each lithium cell, typical

batteries use parallel connections of cells. By

connecting multiple cells in parallel (often in

configurations like 3p or 4p), the overall capacity of

the battery is increased, allowing for longer ride times

and reducing strain on individual cells. The battery

management system (BMS) ensures battery safety by

preventing overcharging and overheating. The BMS

is also responsible for collecting voltage data from all

the battery’s cells through individual probes. Despite

the availability of this data, it is often underutilized,

as most motor controllers only acquire limited

information, such as overall voltage for state-of-

charge (SoC) estimation.

Brushless DC (BLDC) motors are widely used in

e-bikes due to their high efficiency, compact size, and

Development of a New Architecture for next Generation e-Bikes

35

low maintenance. Unlike traditional brushed motors,

BLDC motors have no physical brushes, which

reduces friction and wear, resulting in a longer

lifespan and better performance. The controller is

responsible for the motor rotation, which is achieved

by switching power to the motor windings in a precise

sequence based on rotor position feedback from Hall

sensors or sensor-less methods (Xia, C., 2012).

The display is powered by a power line from the

controller, usually of 5V. There is also a data line

which is used by the controller and the display. This

communication is used to exchange information

regarding the speed, SoC and level of assistance, and

the Universal Asynchronous Receiver Transmitter

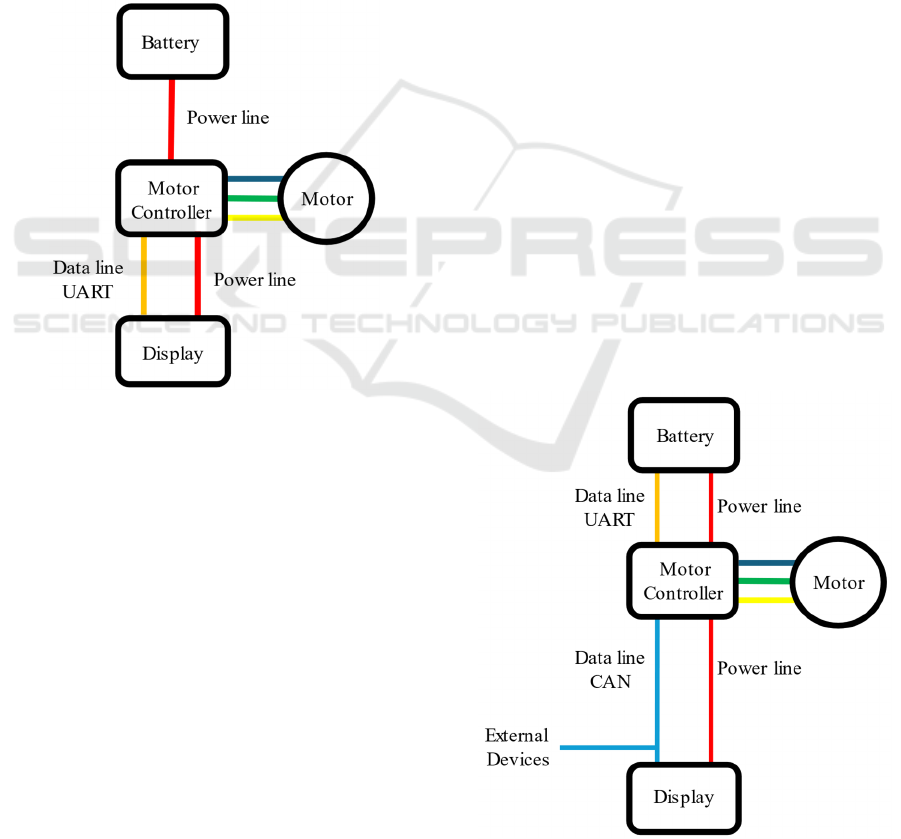

(UART) protocol is utilized. Figure 2 illustrates a

usual e-bike hardware architecture.

Figure 2: Usual e-bike hardware architecture.

In many current e-bike systems, software-defined

assistance levels and speed limits (e.g., 25 km/h per

the European Standard EN 15194:2017+A1:2023)

dictate performance. However, these systems leave

little room for innovation or adaptability to emerging

technologies. Therefore, in this paper, a new

architecture for any kind of e-bike is proposed.

2 PROPOSED ARCHITECHTURE

The proposed architecture is intended to integrate the

same type of batteries and motors, differing from the

typical architecture only in the controller and display.

To facilitate the integration of future devices and

technologies, all the information handled by the

controller and display must be available to access.

Communication systems for e-bikes can be based on

several protocols, each offering different features and

capabilities. While some options like FlexRay and

automotive Ethernet provide specific benefits for

intra-vehicles networks (Tuohy et al., 2015), CAN

stands out as the ideal choice for e-bike applications.

FlexRay, though fast and fault-tolerant, is too

expensive and complex for e-bikes. Automotive

Ethernet offers high bandwidth but comes with higher

hardware costs. CAN, however, provides a balanced

solution with robust performance, real-time

communication, scalability, and cost-effectiveness,

making it well-suited for integrating subsystems such

as motors, batteries, and controllers in e-bikes (Tuohy

et al., 2015).

Controller Area Network (CAN) is a robust,

message-based communication protocol used for

reliable data exchange between multiple devices in

real-time, commonly in automotive and industrial

systems. It operates on a two-wire bus, where each

device (node) can send and receive messages based

on priority, ensuring efficient communication. CAN

is designed with built-in error detection and fault

tolerance, making it highly reliable in noisy

environments (Navet and Simonot-Lion, 2008).

As of today, most e-bike battery management

systems are only capable of sharing their data through

a simple UART communication protocol. Therefore,

a secondary device may be needed to receive the data

and make it available for other devices in the CAN

network (in this case, the controller). For this reason,

the proposed architecture utilizes a CAN data bus

connecting only the controller and the display, as

displayed in Figure 3.

Figure 3: Proposed architecture.

VEHITS 2025 - 11th International Conference on Vehicle Technology and Intelligent Transport Systems

36

2.1 Controller Architecture

To comply with the requirements of the new

architecture, the new controller must be able to

establish a UART communication with the BMS,

allow for the implementation of energy management

algorithms, share and receive data through the CAN

network, and offer all the functionalities that regular

controllers do. For these reasons, an ESP32

microcontroller was chosen to be the core of the

system.

The ESP32 is a low-cost, low-power

microcontroller with integrated Wi-Fi and Bluetooth,

developed by Espressif Systems. It features a dual-

core processor, multiple GPIO pins, and various

interfaces (such as SPI, I2C, and UART) that support

versatile connectivity and control. It has been shown

that ESP32 is an excellent option for embedded

systems and smart devices due to the performance

properties and price (Maier A. et al., 2017).

2.1.1 Controller Hardware

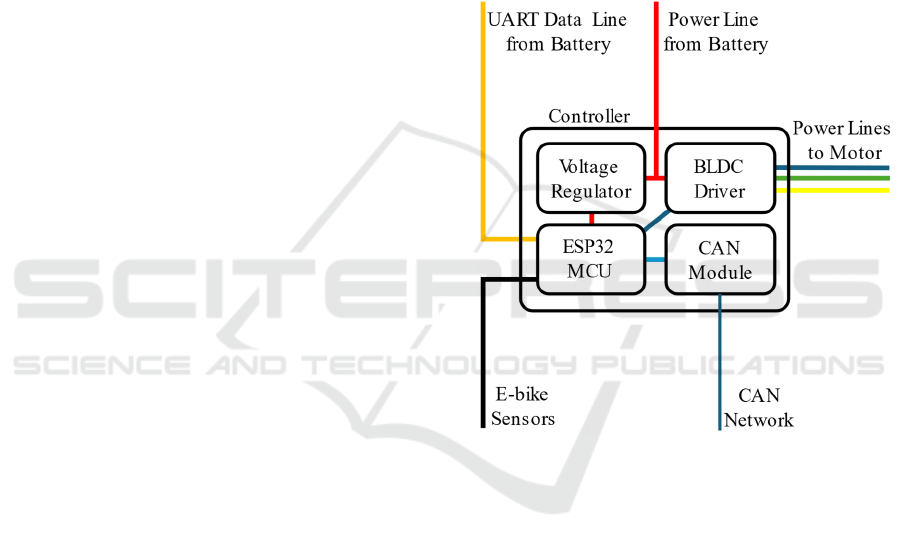

In this section, the hardware utilized on the controller

and its integration is described. As the battery

supplies a voltage of at least 36V, and the

microcontroller works on either 3.3 or 5V, a voltage

regulator is needed to ensure that the proper voltage

is supplied to the microcontroller. This voltage

regulator is also required to supply any other low-

voltage devices on the controller.

As mentioned before, BLDC motor rotation is

achieved by switching power to the motor windings

in a precise sequence. This switching is usually done

with 6 MOSFETs configured in a three-phase bridge

arrangement, where each phase of the motor has a

pair of MOSFETs (one high-side and one low-side)

controlling the current flow. The MOSFETs are

switched in synchronization with the rotor position,

typically determined by Hall effect sensors, to

maintain optimal magnetic alignment and produce

continuous rotational force. A microcontroller can

detect the motor position in switch power to motor

windings correctly, however this method is usually

avoided because the microcontroller might not be

able to detect the motor’s position fast enough when

its rotation is high.

An alternative solution is to use a dedicated

BLDC motor driver. This device utilizes an analogic

integrated circuit to detect the motor’s position and

switch power accordingly. The motors rotation speed

can be controlled by supplying a signal to the driver,

typically a Pulse Width Modulation (PWM) signal.

Drivers are designed to read the voltage that the PWM

signal generates, and its value must be between 0 and

5 volts. The ESP32’s maximum voltage is 3.3V and,

therefore, voltage level shifters or optocouplers are

required to convert the signals. However, this is not

the case if a 5V microcontroller is utilized.

Since the ESP32’s CAN controller hands only the

digital communication logic, and not the physical

transmission, a CAN transceiver is required to

convert the logic signals into the differential signals

required for the CAN communication. The rest of the

e-bike’s sensors such as pedal and brake sensors can

be connected directly to the microcontroller. Figure 4

is an illustration of all the components that integrate

the controller and how they are connected.

Figure 4: Controller architecture and components.

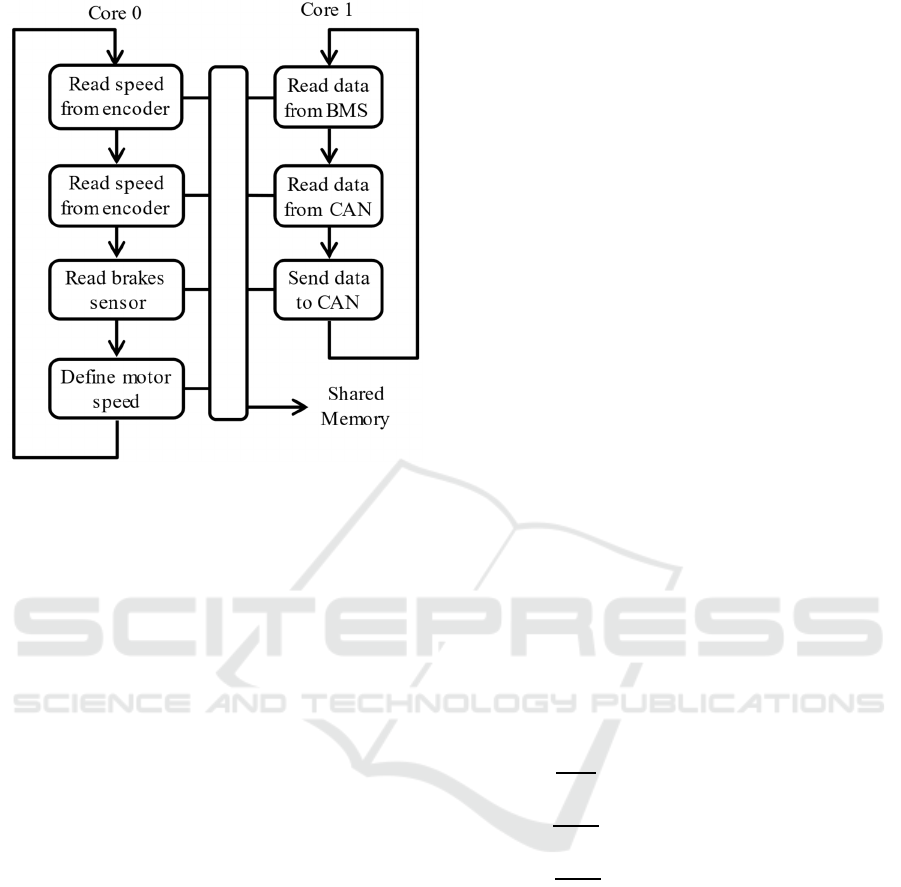

2.1.2 Controller Software

In order to take full advantage of the ESP32’s

functionalities, the computational workload was split

to run on both CPU cores. Tasks related to speed

reading and calculation, pedal and brake sensor

reading, and motor driver control run on core 0. Tasks

related to communications such as BMS data reading,

CAN data reading and CAN data sending run on core

1. This parallelism reduces latency and improves

general responsiveness of the system, while

simplifying the code structure by assigning specific

tasks to each core. Both cores share a common

memory, allowing each individual task to access data

that was registered by any other task. Figure 5

illustrates the individual tasks, their specific core, and

how they’re sequenced.

Development of a New Architecture for next Generation e-Bikes

37

Figure 5: Controller software architecture.

Despite the sequence presented in Figure 5, only

some tasks are performed each cycle. For example, if

the encoder does not send any pulse to calculate

speed, the program will automatically move to the

next task. The same concept applies to all tasks.

The encoder sends pulses to the microcontroller

every time a specific point of the motor is detected

during its rotation. The microcontroller then

calculates the time between these pulses to calculate

the speed. Every time a pulse is detected, the velocity

(v) in meters per second is calculated with the

following equation,

𝑣=

25.4 𝜋 𝐷

𝑡

𝑡

𝑛

⁄

(1)

where n

se

is the number of encoder position sensors,

D is the wheel diameter in inches and t

n

– t

n-1

is the

time between pulses in milliseconds. Using just this

equation to calculate speed would mean that the speed

is not updated in case the vehicle stops. To overcome

this, a timeout needs to be set, sacrificing the

possibility of reading speeds below a specific speed

value. A higher speed value indicates that the

controller will be faster to acknowledge the vehicle

stopped. Motor with more encoder position sensors

will be capable of reading lower speeds than single

encoder position sensor motors. Sacrificing the ability

to read speeds below 0.56 m/s (2.0 km/h) has proven

to be a good balance between speed reading

capability and stopping acknowledgement time

during experimental tests. Solving for t

n

– t

n-1

in

equation 1, the value of 3703 milliseconds is obtained

for a motor with 1 encoder position sensor (n

s

= 1).

The pedal sensor works in a similar way to the

motor encoder. The pedal has a set of magnets that,

when in movement, become close to a fixed Hall

effect sensor, which sends a signal to the

microcontroller. Since the magnets always follow a

circular trajectory, the signal becomes a pulse like the

encoder output signal. Despite the controller not

considering the specific pedaling speed for motor

control, the time between pulses is useful to detect

when the user starts and stops pedaling. The pedal

rotation speed (ω) in rad/s is calculated as

𝜔=

2000 𝜋

𝑡

𝑡

𝑛

⁄

(2

)

where t

m

– t

m-1

is the time between pulses in

milliseconds and n

sp

is the number of magnets in the

pedal sensor. Just like the speed calculation, a timeout

value needs to be set to know when the user stopped

pedaling. A lower value means the controller will take

less to acknowledge the pedals stopped, but the

minimum pedal speed will be higher. For a pedal

sensor with 12 magnets, experimental tests revealed

that a timeout of 750 milliseconds makes a good

balance between pedal stopping acknowledgement

and minimum pedal speed. Solving for ω in equation

2, an angular speed of 0.70 rad/s.

During discharge, the SoC (in percentage) is

calculated through simple segmented functions as

𝑆𝑜𝐶=

⎩

⎪

⎪

⎨

⎪

⎪

⎧

8.3𝑉

𝑛

23.3, 𝑉3.4𝑛

150𝑉

𝑛

505,3.4𝑛

𝑉3.7𝑛

100𝑉

𝑛

320, 𝑉3.7𝑛

(3

)

where V is the measured voltage on the battery

terminals and n

c

is the number of cells in series. This

simplified model was adopted for proof-of concept

only, but more complex methods to calculate the SoC

can be employed (Hassan et al., 2022).

The braking sensors are installed in both brake

levers, and act as normally open switches. Using

either the front brake or rear brake will make the

controller stop the motor assist immediately. For that

reason, the brakes share the same input on the

microcontroller, as illustrated on Figure 6.

VEHITS 2025 - 11th International Conference on Vehicle Technology and Intelligent Transport Systems

38

Figure 6: Braking sensors circuit.

The last task that runs on core 0 is the motor speed

setting task. Depending on the data collected by the

previous tasks, this task will determine the

appropriate motor rotation speed. There are 5

different assistance levels, which are chosen by the

user with a set of buttons connected to the display.

Each assistance level will help the user get to a

specific maximum speed, separated by increments of

5 km/h. The motor will only deliver the specific

assistance level power if the user is pedaling and not

braking. Once the user stops the pedal movement or

brakes, the power is interrupted.

There is also the possibility of no assistance at all,

usually called ‘Level 0’. In this case, the e-bike

becomes a regular bicycle, relying only on the user’s

pedaling to generate motion. In case the user is

walking while carrying his e-bike at his side, there is

a specific mode called ‘Walk mode’ (W). This mode

will set the motor to a speed of 6 km/h, without the

need of pedals to be moving, removing the effort to

carry the e-bike around while walking. Table 1

summarizes the different assistance levels and

specific max speeds.

Table 1: Assistance levels and velocities.

Assistance Level Ma

x

Velocit

y

(km/h)

W

6

0 -

1 5

2 10

3 15

4 20

5 25

The first task that runs on core 1 is the BMS data

retrieving task. The BMS is responsible for

monitoring and managing the battery pack to ensure

safe and efficient operation. It balances the charge

across individual cells, protects against overcharging,

over-discharging, and overheating, and provides data

related to all the cells. Depending on the manufacturer

and model of BMS, the specific details about the

communication protocol may be different, however,

the vast majority of BMS provide their data through

a standard UART communication protocol.

In this work, the BMS that was utilized for

experimental tests only sends data on request. There

are two types of requests: When a type 1 request is

sent to the BMS, it replies with the overall voltage of

the battery, current and temperature. When a type 2

request is sent, the BMS replies with information on

the voltages of each cell of the battery. For each type

of request, the BMS takes around 100ms to reply with

information. Only one request can be processed by

the BMS at a time, so the requests are made

alternately and the update time for each type of data

is 200ms.

The second task running on core 1 is responsible

for handling any information arriving from the CAN

network and writing it on the microcontroller’s

internal memory. The only incoming information is

the level of assistance that the user selects on the

display.

For this work, the CAN protocol J1939 was

selected. Developed by the Society of Automotive

Engineers (SAE), J1939 standardizes messages,

addressing, and diagnostics across vehicle systems,

enabling interoperability between components from

different manufacturers. It defines message

structures, known as Parameter Group Numbers

(PGNs), to organize data like engine speed, vehicle

speed, and fuel levels, and assigns Suspect Parameter

Numbers (SPNs) to specific data points within

messages. J1939 is widely used for real-time data

sharing, diagnostics, and control in multi-component

vehicular systems (Society of Automotive Engineers

[SAE], 2023).

Despite not having all the parameters required for

e-bikes, the J1939 protocol offers the possibility to

use custom PGNs and SPNs. That way, any extra

information that is not listed in the protocol can be

transmitted through the CAN network. After

associating the e-bike’s data with the available SPN

codes, the custom addresses were created.

The last task running on core 1 is responsible for

gathering information from the microcontroller’s

internal memory and sending it to the CAN network.

While some information such as vehicle speed and

level of assistance is useful for the display, the rest of

the data can be useful for external devices. Table 2

lists the SPN codes and their descriptions.

Development of a New Architecture for next Generation e-Bikes

39

Table 2: CAN SPN codes.

SP

N

Description

84 Wheel-Base

d

Vehicle Spee

d

114 Batter

y

Current

168 Batter

y

Voltage

521 Brake Statu

s

3607 Engine Emergenc

y

Shutdown

10001 Level o

f

assistance

10002 Controller Temperature

10003 Batter

y

Temperature

10010 Cell 1 Voltage

10011 Cell 2 Voltage

10012 Cell 3 Voltage

10013 Cell 4 Voltage

10014 Cell 5 Voltage

10015 Cell 6 Voltage

10016 Cell 7 Voltage

10017 Cell 8 Voltage

10018 Cell 9 Voltage

10019 Cell 10 Voltage

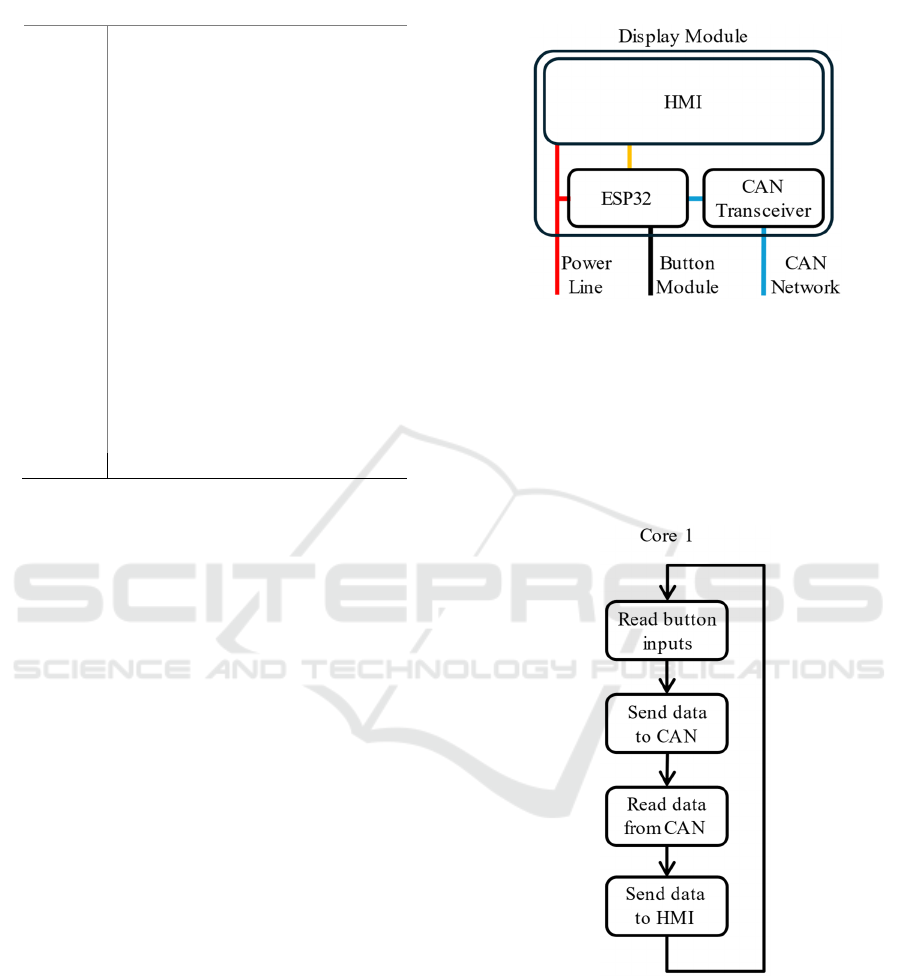

2.2 Display Module Architecture

Following the same design principle as the controller,

the display module architecture adopts an ESP32 as

its microcontroller. The display module will be

responsible for receiving commands from the user

through physical buttons, send and receive data

through the CAN network, and display to the user all

the important information.

2.2.1 Display Module Hardware

The display module is powered by a power line from

the voltage regulator on the controller. Since this

work’s objective is only proof of concept, an HMI

(Human-Machine Interface) is used to display the

relevant information for its ease of use, instead of a

regular display. An HMI allows users to interact with

the system, using display plus controls like buttons or

a touchscreen. A display, in contrast, simply shows

information without enabling user input. In this case,

the display module will not be taking advantage of the

input capabilities of the HMI, as user inputs are

received through physical buttons.

A button module with three buttons identical to

regular e-bike button module is used. There are two

buttons to change the assistance level (Up or Down)

and a general-purpose button that allows the user to

change settings on the display. In the same way as the

controller, a CAN transceiver is necessary to send and

receive messages from the CAN network. Figure 7

illustrates the display module architecture.

Figure 7: Display module architecture and components.

2.2.2 Display Software

Since the display module computational workload is

lighter when compared to the controller’s workload,

only core 1 of the microcontroller is used for the

display module. Figure 8 illustrates the individual

tasks and how they’re sequenced.

Figure 8: Display module tasks and sequencing.

The cycle begins by reading any inputs from the

user through the physical buttons. If the user changes

the assistance level, task 2 will take care of sending

that information through the CAN network. The third

task will check the CAN transceiver module for any

incoming data. In case there is new data, then the last

task will update the information on the HMI.

VEHITS 2025 - 11th International Conference on Vehicle Technology and Intelligent Transport Systems

40

The HMI needs to be set up through an application

provided by the manufacturers. A set of variables are

created and linked to a specific set of pixels on the

HMI’s display. These variables can then be updated

using simple UART communication by the ESP32.

Since the HMI’s touchscreen is not being used, this

communication is not bidirectional, and only the

microcontroller sends information to the HMI. The

structure of the message sent by the microcontroller

may vary depending on the HMI manufacturer.

Figure 9 illustrates the set of variables that will be

displayed on the screen.

Figure 9: HMI Variables Displayed.

Besides all the information provided by the

controller through the CAN network, the HMI

displays the instant power draw, total energy draw,

distance travelled, and average energy consumption

since the trip started. The instantaneous power draw

(P) in watts is calculated as

𝑃=𝑉𝐼

(4)

where V is the battery’s voltage, and I is the

instantaneous current. The total energy (E

t

) used in

watt-hour (Wh) is calculated with

𝐸

=𝐸

+ 𝑃𝛥𝑡 3600

⁄

(5)

where E

t-1

is the previous total energy, P is the current

power and Δt is the time between calculations. Every

time a new speed is recorded, the distance travelled

(x

t

) in meters per second is calculated with the

previous total travelled distance (x

t-1

), the vehicle’s

speed (v) in meters per second and the time between

calculations (Δt

v

), using equation 5.

𝑥

=𝑥

+𝑣𝛥𝑡

(6)

Finally, the average energy consumption (E

a

) in

watt-hour per kilometer is calculated as

𝐸

=𝐸

𝑥

⁄

(7)

with the total distance in kilometers, in this case.

3 EXPERIMANTAL TESTS

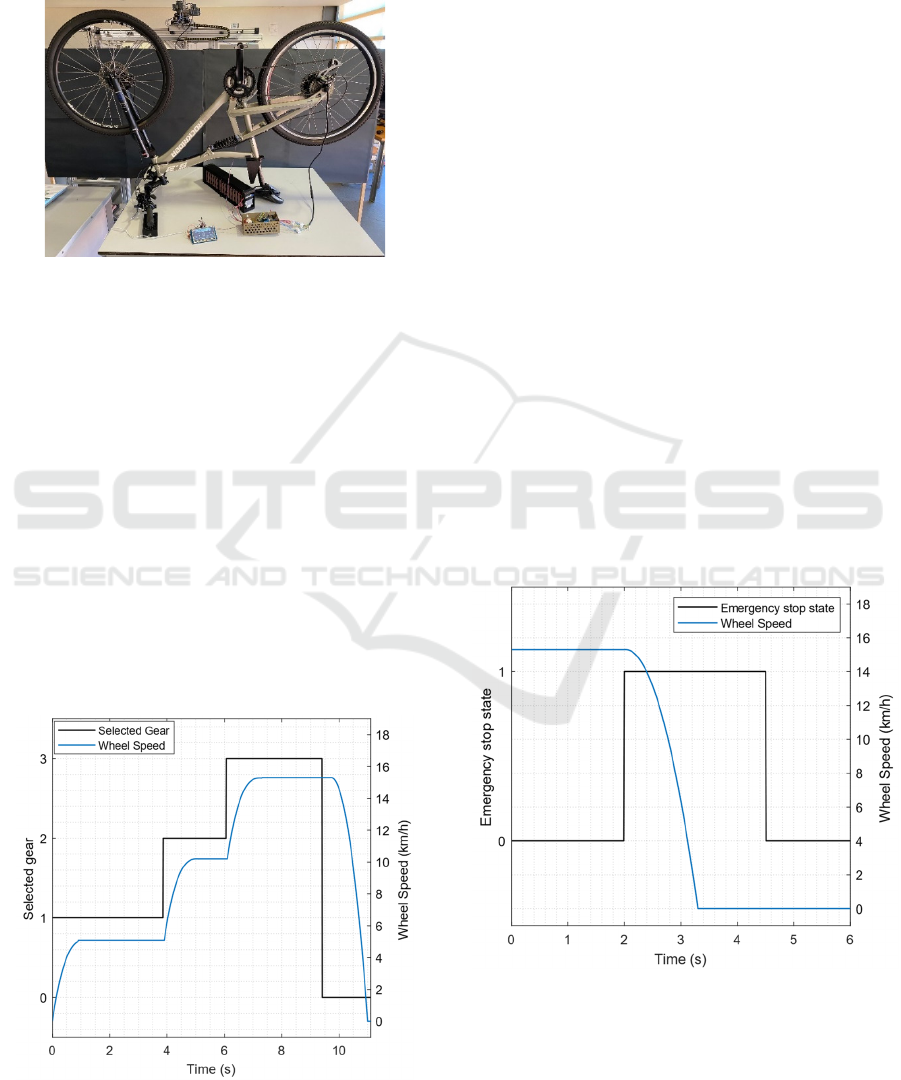

To test the presented concept, an experimental setup

was conceived and built. The conducted experiment’s

objective is to confirm that the proposed system can

replicate the functionality of a regular e-bike, while

allowing the implementation of algorithms and

communication with external devices that can read

the data from the system and send an emergency stop

command if necessary.

To conduct the experiment, an e-bike motor was

installed in a regular bicycle, and three prototypes

were constructed: a controller, a battery with BMS

and a display module. An ESP32 with a CAN

transceiver was used to simulate an external device.

Using 30 individual lithium-ion cells, a battery with

BMS was constructed. Figure 10 shows the 3D model

in CAD software.

Figure 10: Battery 3D model.

A controller housing was designed to

accommodate all the components, and the prototype

was 3D printed. The controller assembly was divided

into 2 levels. The bottom level of the controller

houses the ESP32, the optocouplers module and the

BLDC driver. Besides housing the CAN transceiver

and the power converter, the top level is also utilized

for cable management. In Figure 12 is an illustration

of the controller’s bottom level in CAD software.

Figure 12: Controller’s bottom level.

Development of a New Architecture for next Generation e-Bikes

41

The display module was assembled and connected

to the rest of the system. After assembling all the

devices, the experimental setup was complete and

experimental testing was possible. Figure 14 shows

the whole experimental setup.

Figure 14: Experimental setup.

After building the experimental test setup, several

tests were conducted to evaluate the regular

functionality of the e-bike and its enhanced features.

The first test aimed to verify the basic functionality of

the system under normal operating conditions.

Initially, assistance level 1 was selected, and the

pedals were moved manually. After a few seconds,

assistance level 2 was manually selected. Finally,

assistance level 3 was selected, and after a brief period,

the pedals were brought to a stop, automatically

switching the assistance level to 0. The readings were

performed by an external microcontroller connected to

the bicycle's CAN bus. Measurements of the assistance

level and wheel speed were recorded throughout the

entire duration of the test, which lasted approximately

11 seconds. The data collected during the first test is

presented in Figure 15.

Figure 15: Assistance level and vehicle wheel speed during

test 1.

In Figure 15, the plot clearly shows the transition

between assistance levels and the corresponding

variations in wheel speed, demonstrating the system's

ability to adapt to user input in real-time. Since the

tests were conducted in a laboratory for proof-of-

concept only, the acceleration time between

assistance level changes is relatively small. In a real

use case scenario, the acceleration time is expected to

be substantially larger. When the pedal movement

stops, there is a slight delay in the deceleration of the

motor. This was expected, since it is related to the

acknowledgment time of the pedal’s movement stop.

A second test was performed to evaluate the

system's response to an emergency stop command

issued by an external device, as well as to validate the

integrated safety features of the proposed

architecture. As a security feature, the controller was

programmed to keep the motor disabled even if an

emergency stop command is deactivated. This

ensures that motor operation cannot resume

unintentionally, requiring a full system reset to

unlock the motor.

Initially, the assistance level was set to 3, and the

pedals were manually rotated to simulate normal

operation. An external device then sends a continuous

emergency command via the CAN bus which lasts for

2.5 seconds. The values of the emergency stop

variable and wheel speed were continuously recorded

during the test. The data collected during the second

test is presented in Figure 16.

Figure 16: Emergency stop state and vehicle wheel speed

during test 2.

The results confirm the system's ability to

integrate with external safety mechanisms, since

when an emergency command was detected, the

VEHITS 2025 - 11th International Conference on Vehicle Technology and Intelligent Transport Systems

42

controller immediately halted motor assistance, not

resuming motor operation when the emergency state

was deactivated.

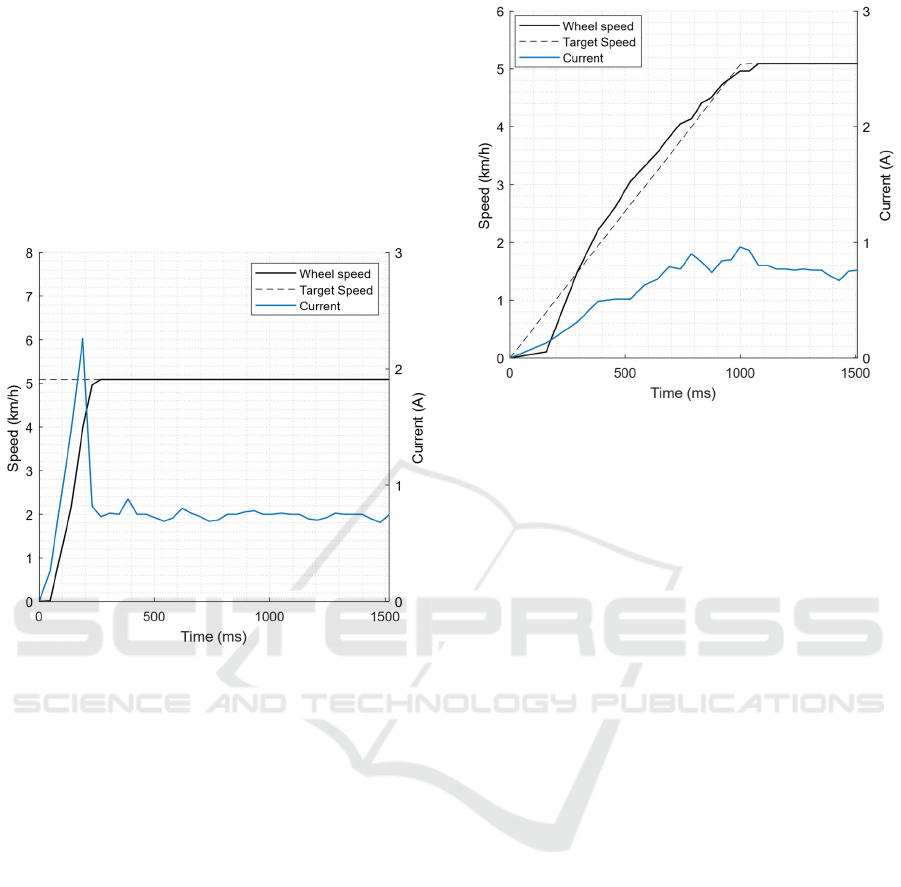

The final test aimed to demonstrate the potential for

improving energy efficiency through the implemen-

tation of algorithms. In this test, the electrical current

through the motor was first recorded during an

acceleration from rest to the speed corresponding to

gear 1. The current and wheel speed readings during

the acceleration can be seen in Figure 17.

Figure 17: Current and wheel speed reading during regular

acceleration.

In this case, when the assistance level is selected

and the pedals move, the microcontroller immediately

sends a command to the motor driver to achieve the

desired speed. The results show an evident current

spike which can waste a significant amount of energy.

To eliminate current spikes during accelerations,

a simple algorithm is proposed. Instead of sending a

fixed speed value to the motor, a simple algorithm can

increase the target speed linearly during a specific

time interval. For proof-of-concept only, a total time

interval of 1 sec was selected for incremental speed

increase. For the same final speed (gear 1) as the

previous current test, the results of an incremental

algorithm can be seen on Figure 18.

As the results from Figure 18 show, utilizing an

incremental speed control algorithm has a positive

impact on energy consumption, since no current

spikes are visible. This example demonstrates the

potential to enhance the e-bike's performance through

embedded algorithms that can monitor and control

not only speed but also other variables like current,

temperature and cooling solutions.

Figure 18: Current and wheel speed reading during

incremental acceleration.

4 CONCLUSIONS

In this work, a new architecture for e-bike systems

was proposed, centered on an open, microcontroller-

based design with a CAN communication bus. This

innovative approach addresses the limitations of

traditional black-box systems by enabling seamless

integration of algorithms, external modules, and

subsystems, thereby fostering adaptability and

enhanced functionality. Several prototypes were built

and used for experimental testing to validate the

system's performance and compliance with current e-

bike legislation. Testing demonstrated the

architecture's practicality, showcasing features such

as emergency stop functionality, real-time data

sharing, and possibility of implementation of power

management algorithms. These results highlight the

system's capability to support the evolving demands

of urban mobility by offering a flexible, efficient, and

connected platform for next-generation e-bike

development.

ACKNOWLEDGEMENTS

This work was developed in the scope of the project

AM2R – “Agenda Mobilizadora para a Inovação

Empresarial do Setor das Duas Rodas” [C644866475-

00000012 – Project n. 15], financed by PRR –

Recovery and Resilience Plan under the Next

Generation EU from the European Union, and by the

Development of a New Architecture for next Generation e-Bikes

43

projects UIDB/00481/2020 and UIDP/00481/2020 -

Fundação para a Ciência e a Tecnologia,

https://doi.org/10.54499/UIDB/00481/2020.

REFERENCES

Fishman, E., & Cherry, C. (2015). E-bikes in the

Mainstream: Reviewing a Decade of Research.

Transport Reviews, 36(1), 72–91. https://doi.org/10.10

80/01441647.2015.1069907.

Mordor Intelligence (2024), Europe e-bike market -

Growth, trends & forecasts up to 2029. Last accessed:

January 22, 2025, available at: https://www.mordorin

telligence.com/industry-reports/europe-e-bike-market.

Boglietti, S., Barabino, B., & Maternini, G. (2021). Survey

on e-Powered Micro Personal Mobility Vehicles:

Exploring Current Issues towards Future

Developments. Sustainability, 13(7), 3692.

https://doi.org/10.3390/su13073692.

Schnieder, M. (2023). Ebike Sharing vs. Bike Sharing:

Demand Prediction Using Deep Neural Networks and

Random Forests. Sustainability, 15(18), 13898.

https://doi.org/10.3390/su151813898.

Nunes, P., Nicolau, C., Santos, J. P., Completo, A. (2020).

From a Traditional Bicycle to a Mobile Sensor in the

Cities. In Proceedings of the 6th International

Conference on Vehicle Technology and Intelligent

Transport Systems - VEHITS pages 81-88.

https://doi.org/10.5220/0009349700810088.

Grama, A., Petreus, D., Baciu, C., Bia, B., Coca, O.,

Socaciu, V. (2018). Smart Bike Improvement Using

Embedded Systems. 2018 41st International Spring

Seminar on Electronics Technology (ISSE), 1–4.

https://doi.org/10.1109/ISSE.2018.8443769.

Andres, J., Kari, T., Kaenel, J.V., Mueller, F.F. (2019). Co-

riding With My eBike to Get Green Lights.

Proceedings of the 2019 ACM Designing Interactive

Systems Conference, pp. 1251 – 1263

https://doi.org/10.1145/3322276.3322307.

Cammin C., Mousavi M.R., Trautwein I., Freymann A.,

Beutelspacher C., Nehrke L., Ludwig S., Kirchheim A.

(2023). Concept for a Real-Time IoT-Architecture for

Collision Avoidance in Smart Cities based on the 5G

Mobile Technology. 2023 IEEE International

Conference on Omni-Layer Intelligent Systems.

https://doi.org/10.1109/COINS57856.2023.10189240.

Arango I., Lopez C., Ceren A. (2021). Improving the

autonomy of a mid-drive motor electric bicycle based

on system efficiency maps and its performance. World

Electric Vehicle Journal, 12 (2), art. no. 59.

https://doi.org/10.3390/wevj12020059.

De La Iglesia, D. H., Villarrubia, G., De Paz, J. F., & Bajo,

J. (2017). Multi-Sensor Information Fusion for

Optimizing Electric Bicycle Routes Using a Swarm

Intelligence Algorithm. Sensors, 17(11), 2501.

https://doi.org/10.3390/s17112501.

Vishnu S., Dash A., Praveena Krishna P.S., Arjun M.,

Jayalakshmi N.S. (2022). Hybrid Control Algorithm for

BLDC Drive Involving Battery and Supercapacitor in

E-bikes. 2022 International Virtual Conference on

Power Engineering Computing and Control:

Developments in Electric Vehicles and Energy Sector

for Sustainable Future. DOI: 10.1109/PECCON5501

7.2022.9851060.

Xie, Z., Jeon, W., Rajamani, R. (2021). Low-density lidar

based estimation system for bicycle protection. IEEE

Transactions on Intelligent Vehicles, 6(1), 67–77.

https://doi.org/10.1109/TIV.2020.3010728.

Zhao, M., Stasinopoulos, S., Yu, Y. (2017). Obstacle

detection and avoidance for autonomous bicycles. In

2017 13th IEEE Conference on Automation Science

and Engineering (CASE) (pp. 1310–1315).

https://doi.org/10.1109/COASE.2017.8256281.

Lightmobie, Lda (2025). Retrieved from:

https://lightmobie.pt/

Xia, C. (2012). Permanent Magnet Brushless DC Motor

Drives and Controls. Wiley-IEEE Press.

ISBN: 9781118188330

European Committee for Standardization. (2017). EN

15194: 2017 Cycles – Electrically power assisted cycles

– EPAC Bicycles. Brussels: CEN.

S. Tuohy, M. Glavin, C. Hughes, E. Jones, M. Trivedi, L.

Kilmartin, (2015) "Intra-Vehicle Networks: A

Review," in IEEE Transactions on Intelligent

Transportation Systems, vol. 16, no. 2, pp. 534-545, ,

https://doi.org/10.1109/TITS.2014.2320605.

Navet N., and Simonot-Lion F., (2008). Automotive

Embedded Systems Handbook. CRC Press.

ISBN: 9780849380266

Maier A., Sharp A., Vagapov Y. (2017). Comparative

analysis and practical implementation of the ESP32

microcontroller module for the internet of things. ITA

2017 - Proceedings of the 7th International

Conference, art. no. 8101926, pp. 143 – 148.

DOI: 10.1109/ITECHA.2017.8101926

Ul Hassan, M., Saha, S., Haque, Md. E., Islam, S.,

Mahmud, A., Mendis, N. (2022). A comprehensive

review of battery state of charge estimation techniques.

Sustainable Energy Technologies and Assessments, 54,

102801. https://doi.org/10.1016/j.seta.2022.102801.

Society of Automotive Engineers (SEA), (2023). Serial

Control and Communications Heavy-Duty Vehicle

Network. Society of Automotive Engineers.

VEHITS 2025 - 11th International Conference on Vehicle Technology and Intelligent Transport Systems

44