A Brief Discussion on PDMS Surface Wettability Enhancement

Methods for Microfluidic Applications

Lucas B. Neves

1

, Inês Maia Gonçalves

1

, João Eduardo Ribeiro

2

, Rui A. Lima

1,3,4

and Ana Sofia Moita

5

1

MEtRICs, Mechanical Engineering Department, University of Minho, Campus de Azurém, 4800-058 Guimarães, Portugal

2

Centro de Investigação de Montanha (CIMO), Instituto Politécnico de Bragança, Campus de Santa Apolónia, 5300-253

Bragança, Portugal

3

CEFT—Transport Phenomena Research Center, Faculty of Engineering, University of Porto, Rua Dr. Roberto Frias,

4200-465 Porto, Portugal

4

Associate Laboratory in Chemical Engineering (ALiCE), Faculty of Engineering, University of Porto, 4200-465 Porto,

Portugal

5

IN+, Center for Innovation, Technology and Policy Research, Instituto Superior Técnico, Universidade de Lisboa. Av.

Rovisco Pais, 1049-001 Lisboa, Portugal

Keywords: PDMS Surface Modification, Microfluidic Applications and Wettability Enhancement.

Abstract: This position paper examines recent advancements in surface modification techniques for

polydimethylsiloxane (PDMS) to improve its inherent hydrophobicity and enhance its application in

microfluidic devices. While PDMS is valued for its transparency, biocompatibility, flexibility, stability, and

non-toxicity, its hydrophobic nature limits fluid handling capabilities, which is essential for efficient

microfluidic performance. Various methods, including oxygen plasma treatment, UV irradiation, and

chemical Layer-by-Layer (LBL) deposition, have been explored to improve PDMS wettability. Surfactant-

based modifications have shown promising results for achieving long-term hydrophilicity with

straightforward application. Studies demonstrate that methods such as Polyethylene Glycol (PEG) coating

and surfactant incorporation enable continuous capillary-driven flow without external pumps and improve

sample purity by minimizing issues like bubble formation and cell aggregation. These advancements hold

great potential of PDMS modifications to create more efficient and reliable microfluidic devices, and

consequently to expand its applications in the biomedical and microfluidic fields.

1 INTRODUCTION

The development of materials with customized

properties to meet the specific demands of

microdevices has been crucial for advancing the field

of microfluidics. Polydimethylsiloxane (PDMS)

ranks among the most utilized materials in this area

due to its characteristics, including biocompatibility,

flexibility, stability, and non-toxicity. However, the

naturally hydrophobic surface of PDMS poses

challenges for fluid handling applications,

compelling modifications to improve its wettability

and allow efficient liquid flow without compromising

the structure or functionality of the device. With

increasing research on surface treatments to enhance

these characteristics, various techniques have

emerged, including gas-phase processes, chemical

methods, and surfactant modifications. These

methods aim not only to optimize flow in

microfluidic devices but also to improve separation

efficiency and reduce issues such as bubble formation

and particle aggregation.

2 ENHANCING PDMS SURFACE

WETTABILITY FOR

MICROFLUIDIC

APPLICATIONS

Given the growing application of surface treatments

to modify PDMS wettability in microfluidic devices,

recent studies have investigated effective methods to

enhance this property. PDMS is widely used in

Neves, L. B., Gonçalves, I. M., Ribeiro, J. E., Lima, R. A. and Moita, A. S.

A Brief Discussion on PDMS Surface Wettability Enhancement Methods for Microfluidic Applications.

DOI: 10.5220/0013233200003911

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 18th International Joint Conference on Biomedical Engineering Systems and Technologies (BIOSTEC 2025) - Volume 1, pages 171-174

ISBN: 978-989-758-731-3; ISSN: 2184-4305

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

171

microfluidics due to its biocompatible, non-toxic,

stable, and flexible properties (Neves et al., 2024).

However, its hydrophobic nature poses limitations for

fluid handling, prompting the development of various

surface treatment methods. Among the most studied

methods are gas-phase treatments such as oxygen

plasma (Long et al., 2017; Peterson et al., 2005;

Vickers et al., 2006) and UV irradiation (Zhou et al.,

2010), as well as chemical methods, such as Layer-

by-Layer (LBL) deposition (Zhou et al., 2010).

Surfactant modification has shown promising results,

offering a straightforward and effective solution for

creating long-lasting hydrophilicity without requiring

complex procedures (Lin & Chung, 2021; Trantidou

et al., 2017).

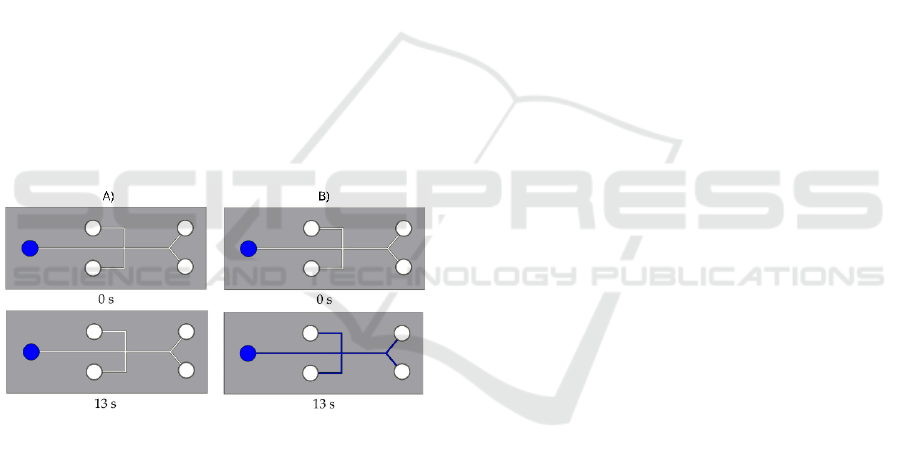

Long et al. (Long et al., 2017) applied oxygen

plasma followed by a Polyethylene Glycol PEG

coating to increase PDMS hydrophilicity. The

microfluidic device performance was evaluated using

rhodamine droplets, resulting in complete channel

filling within 13 seconds, whereas untreated PDMS

showed no flow within the first 60 seconds, as

depicted in Figure 1. This method proved effective for

achieving a sustained hydrophilic state, allowing

continuous flow without the need for external

pumping for up to 420 hours.

Figure 1: Schematic diagram of a capillary test on PDMS

after 420 h of treatment by O

2

-plasma-PEG based on the

work of Long et al. (Long et al., 2017). The images make it

clear that B) at 13 s the channels were completely filled and

A) with untreated PDMS, no flow was observed at least

during the first 60 s. Adapted from (Neves et al., 2024).

Peterson et al. (Peterson et al., 2005) examined the

performance of native and ox-PDMS coatings in

glass-silicon microfluidic devices. The ox-PDMS

coating maintained a consistent flow rate for over 14

minutes, while untreated PDMS showed a significant

reduction, with flow rates nearly 40% lower.

Holczer et al. (Holczer & Fürjes, 2017) applied

surfactants to modify PDMS surfaces and develop

autonomous microfluidic systems for bioanalytical

devices. Vilčáková and colleagues (Vilčáková et al.,

2012) also tested Carbon Nanotubes (CNT)-based

composites with various surfactants such as

Dodecylbenzene Sulfonic Acid (DBSA) and

Cetyltrimethylammonium Bromide (CTAB), using

mechanical mixing and sonication to ensure even

distribution in PDMS.

Wu and Hjor (Wu & Hjort, 2009)incorporated the

non-ionic surfactant Pluronic F127 into the PDMS

prepolymer before curing. After introducing water

into the microchannels, Pluronic F127 molecules

migrated to the PDMS-water interface, reducing

surface energy and decreasing the contact angle from

99° to 63° after 24 hours, compared to the 104°

contact angle of untreated PDMS.

A study, carried out between the research group at

IN+, Instituto Superior Técnico, MEtRICS

(University of Minho) and in collaboration with

colleagues from Tokyo Medical and Dental

University further explored the use of surfactants to

alter PDMS during the manufacture process, by

adding components, such as surfactants, combined

with PDMS in concentrations of 1 and 2 wt.%. Sessile

droplet method was used in an optical tensiometer

(THETA from Attention), on the day of the

fabrication and one week later. Given the relevance

of assuring the optical access to many of the

fabricated devices in biomedical applications, the

potential changes in the transparency of the samples

were also evaluated by measuring the respective

transmittance spectrum, considering that studying

PDMS transparency is crucial due to its wide

application in optical, microfluidic and biomedical

devices, where optical clarity enables observation and

effective functioning in systems that require

interaction with light. The transmittance spectrum

was in dried samples with thickness of 2-3mm, using

a Ultra-violet (UV) - Visible spectrophotometer UV-

2600 (Shimadzu, Japan) and corresponding software.

The transmittance spectrum was measured after the

samples dried from the contact angle measurements.

The Ultra-violet (UV) - Visible spectrophotometer

UV-2600 (Shimadzu, Japan) and associated software.

The measurements were performed with a wavelength

ranging from 200 to 800 nm.

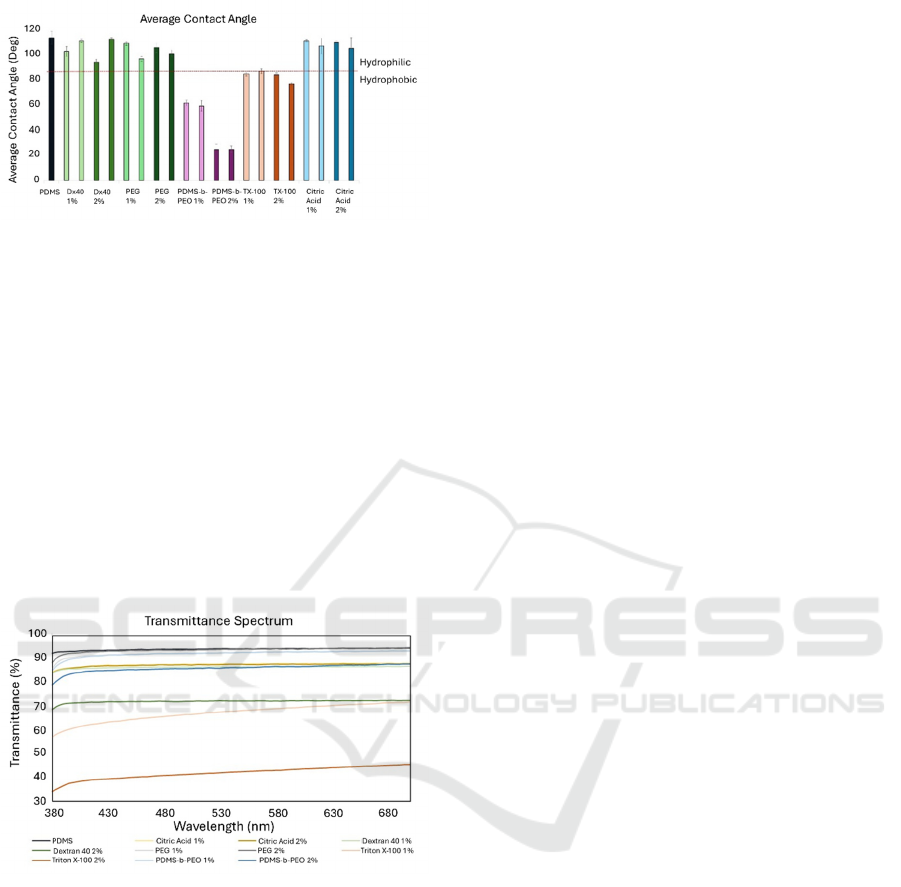

Furthermore, understanding and optimizing

transparency helps to tailor the material to specific

requirements, ensuring efficiency in emerging

technologies. Two tested surfactants were able to

improve the wettability of the PDMS surface to a

hydrophilic behavior remaining, for at least one week

after fabrication, as shown in Figure 2. First column

in each material represents the measures performed in

the first day of fabrication, while the second

represents the values of the contact angles measured

one week later.

BIODEVICES 2025 - 18th International Conference on Biomedical Electronics and Devices

172

Figure 2: Average contact angle between PDMS and

modified PDMS surfaces and distilled water measured at

the day of manufacture (d0) and one week after (w1).

The transparency of the PDMS shows to be

affected by one of those two surfactants, while the

other only led to a small decrease with the highest

concentration. Hence, while incorporating 1or 2 wt.%

of PEG in the bulk of PDMS was observed to have no

significant effect on the transparency of the PDMS,

the addition of citric acid reduced the transparency to

around 87%, when using each of the concentrations

(Figure 3). Other surfactants such as 1 wt.%

Polydimethylsiloxane-block-Poly(ethylene oxide)

(PDMS-b-PEO) maintained the transparency around

91%.

Figure 3: Transmittance spectrum of PDMS and modified

PDMS additivated with various surfactants.

Details on the measurements procedure can be

found in Gonçalves et al. (2024a).

More recently, Gonçalves et al. (Gonçalves et al.,

2024b) investigated PDMS surface modification

using surfactants Pluronic® F127, PEG, and PEO.

Notably, PEO at a concentration of 2.5% proved

highly effective in improving blood plasma

separation within microfluidic devices. This

modification promoted smoother fluid flow,

minimized cell clustering, and reduced air bubble

formation, leading to higher sample purity.

These studies highlight the promising results of

surface modification methods to improve PDMS

performance in microfluidic devices, especially in

applications that demand accurate fluid flow control

and effective biomolecule interaction.

3 CONCLUSIONS

Several PDMS surface modification approaches have

shown significant potential in addressing the

limitations associated with its hydrophobicity,

enabling the development of more efficient and

adaptable microfluidic devices. Recent studies

highlight the effectiveness of oxygen plasma

treatments, surfactant coatings, and polymer-based

methods in achieving long-term hydrophilicity. By

integrating straightforward and effective

modification techniques, such as surfactant

incorporation, it is possible to enhance fluid control

and sample purity, benefiting the use of PDMS in

biochemical and medical analysis microdevices.

These advances emphasize the importance of ongoing

research to optimize PDMS performance, expanding

its potential in microfluidic solutions for biomedical

applications.

ACKNOWLEDGEMENTS

Authors acknowledge the partial financial support of

the projects 2022.06207.PTDC and PTDC/EEI-

EEE/2846/2021 through national funds (OE), within

the scope of the Scientific Research and

Technological Development Projects (IC&DT)

program in all scientific domains (PTDC), through

the Foundation for Science and Technology, I.P.

(FCT, I.P). Authors also acknowledge to Fundação da

Ciência e da Tecnologia (FCT), for partially funding

this research through project PTDC/EME-TED/7801/

2020, and by LA/P/0083/2020 IN +,

UIDP/50009/2020-FCT and UIDB/50009/2020,

UIDB/04077/2020, UIDP/04077/2020,

UIDB/00532/2020, LA/P/0045/2020 (ALiCE),

CIMO (UIDB/00690/2020) and SusTEC

(LA/P/0007/2020), and 2022.03151.PTD. A.S. Moita

also acknowledges FCT for partially financing her

contract through

CEECINST/00043/2021/CP2797/CT0005, doi:

10.54499/CEECINST/00043/2021/CP2797/CT0005.

A Brief Discussion on PDMS Surface Wettability Enhancement Methods for Microfluidic Applications

173

REFERENCES

Gonçalves, M., Gonçalves, I. M., Borges, J., Faustino, V.,

Soares, D., Vaz, F., Minas, G., Lima, R., & Pinho, D.

(2024). Polydimethylsiloxane Surface Modification of

Microfluidic Devices for Blood Plasma Separation.

Polymers 2024, Vol. 16, Page 1416, 16(10), 1416.

https://doi.org/10.3390/POLYM16101416

Holczer, E., & Fürjes, P. (2017). Effects of embedded

surfactants on the surface properties of PDMS;

applicability for autonomous microfluidic systems.

Microfluidics and Nanofluidics, 21(5), 81.

https://doi.org/10.1007/s10404-017-1916-5

Lin, L., & Chung, C. K. (2021). PDMS Microfabrication

and Design for Microfluidics and Sustainable Energy

Application: Review. Micromachines 2021, Vol. 12,

Page 1350, 12(11), 1350. https://doi.org/10.3390/MI

12111350

Long, H. P., Lai, C. C., & Chung, C. K. (2017).

Polyethylene glycol coating for hydrophilicity

enhancement of polydimethylsiloxane self-driven

microfluidic chip. Surface and Coatings Technology,

320, 315–319. https://doi.org/10.1016/j.surfcoat.2016.

12.059

Neves, L. B., Afonso, I. S., Nobrega, G., Barbosa, L. G.,

Lima, R. A., & Ribeiro, J. E. (2024). A Review of

Methods to Modify the PDMS Surface Wettability and

Their Applications. Micromachines 2024, Vol. 15,

Page 670, 15(6), 670. https://doi.org/10.3390/MI1506

0670

Peterson, S. L., McDonald, A., Gourley, P. L., & Sasaki, D.

Y. (2005). Poly(dimethylsiloxane) thin films as

biocompatible coatings for microfluidic devices: Cell

culture and flow studies with glial cells. Journal of

Biomedical Materials Research Part A, 72A(1), 10–18.

https://doi.org/10.1002/JBM.A.30166

Trantidou, T., Elani, Y., Parsons, E., & Ces, O. (2017).

Hydrophilic surface modification of PDMS for droplet

microfluidics using a simple, quick, and robust method

via PVA deposition. Microsystems & Nanoengineering,

3(1), 1–9. https://doi.org/10.1038/micronano.2016.91

Vickers, J. A., Caulum, M. M., & Henry, C. S. (2006).

Generation of Hydrophilic Poly(dimethylsiloxane) for

High-Performance Microchip Electrophoresis.

Analytical Chemistry, 78(21), 7446–7452.

https://doi.org/10.1021/ac0609632

Vilčáková, J., Moučka, R., Svoboda, P., Ilčíková, M.,

Kazantseva, N., Hřibová, M., Mičušík, M., &

Omastová, M. (2012). Effect of Surfactants and

Manufacturing Methods on the Electrical and Thermal

Conductivity of Carbon Nanotube/Silicone

Composites. Molecules, 17(11), 13157–13174.

https://doi.org/10.3390/molecules171113157

Wu, Z., & Hjort, K. (2009). Surface modification of PDMS

by gradient-induced migration of embedded Pluronic.

Lab on a Chip, 9(11), 1500–1503. https://doi.org/10.10

39/B901651A

Zhou, J., Ellis, A. V., & Voelcker, N. H. (2010). Recent

developments in PDMS surface modification for

microfluidic devices.

ELECTROPHORESIS, 31(1), 2–

16. https://doi.org/10.1002/elps.200900475

BIODEVICES 2025 - 18th International Conference on Biomedical Electronics and Devices

174