Inventory Management System Through the Integration of RPA and

IoT to Enhance Processes in SMEs Within Peru’s Automotive Sector

Tadashi Buitron

a

, Enzo Peña

b

and Pedro Castañeda

c

Facultad de Ingeniería de Sistemas de Información, Universidad Peruana de Ciencias Aplicadas (UPC), Lima, Peru

Keywords: IoT, RPA, Inventory Management, SMEs, Automation, Real-Time Monitoring, Operational Efficiency,

Automotive Sector, Supply Chain Optimisation.

Abstract: This paper presents the design and implementation of an inventory management system that integrates

Robotic Process Automation (RPA) and Internet of Things (IoT) technologies to enhance operational

efficiency in small and medium-sized enterprises (SMEs) within Peru's automotive sector. The system

addresses common challenges faced by SMEs, such as inaccurate inventories and inefficient stock

management, through automated processes and real-time monitoring. By streamlining repetitive tasks and

enabling continuous inventory updates, the solution reduces operating costs and improves record-keeping

accuracy. Initial results show a 30% reduction in management time and a 25% decrease in operational costs,

highlighting the transformative potential of RPA and IoT technologies in inventory management. The project

offers a practical model that can be scaled and replicated across other sectors, contributing to the long-term

competitiveness of SMEs.

1 INTRODUCTION

The rapid development and integration of

Information and Communication Technologies (ICT)

in business processes has led to increased efficiency

and effectiveness in various industries. However, this

technological advancement has also introduced new

challenges, particularly in the management and

security of the large amounts of data generated by

these systems. These challenges are exacerbated in

sectors such as retail, where data management is

crucial for inventory control, customer relationship

management and supply chain optimisation (Lo et al.,

2024).

As businesses increasingly rely on data-driven

decision making, the importance of robust and secure

data management systems cannot be underestimated.

Poor data management can lead to inefficiencies,

security breaches and financial losses, underlining the

need for effective solutions that address these issues.

The implementation of advanced technologies, such

as IoT and RPA, offers promising opportunities to

improve data management processes, but also

a

https://orcid.org/0009-0001-5925-7949

b

https://orcid.org/0009-0005-9929-6626

c

https://orcid.org/0000-0003-1865-1293

requires careful consideration of security and privacy

issues (Farinha et al., 2023).

Several approaches have been proposed to

improve data management in the retail sector. These

include the use of IoT-based systems for real-time

inventory tracking (Mohammadi et al., 2024), RPA-

driven tools for automating repetitive tasks (Farinha

et al., 2023), and blockchain technology for secure

data transactions (Mahariya et al., 2023). Each of

these solutions offers unique advantages, but they

also present their own challenges, such as high

implementation costs and the need for specialised

technical expertise (Chen et al., 2022).

Despite the potential benefits, existing solutions

often fail to address the specific needs of small and

medium-sized enterprises (SMEs). Many SMEs lack

the resources and technical knowledge to implement

and maintain complex data management systems.

Moreover, integrating new technologies into existing

systems can be disruptive and requires careful

planning and execution to avoid operational

inefficiencies (Mahariya et al., 2023).

This paper proposes a novel framework that

leverages IoT and RPA technologies to optimise data

Buitron, T., Peña, E. and Castañeda, P.

Inventory Management System Through the Integration of RPA and IoT to Enhance Processes in SMEs Within Peru’s Automotive Sector.

DOI: 10.5220/0013233900003944

In Proceedings of the 10th International Conference on Internet of Things, Big Data and Security (IoTBDS 2025), pages 231-236

ISBN: 978-989-758-750-4; ISSN: 2184-4976

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

231

management processes in SMEs. By focusing on

scalability, affordability and ease of integration, the

proposed solution aims to bridge the gap between

advanced technological capabilities and the practical

needs of SMEs. The framework includes a modular

design that allows companies to adopt and expand the

system gradually, minimising disruption and ensuring

a smooth transition (Farinha et al., 2023).

In the following, a detailed overview of the

proposed framework is provided, including its design,

implementation and potential impact on data

management practices in SMEs. The results of a case

study conducted to evaluate its effectiveness are also

presented. Finally, concluding remarks and

suggestions for future research directions are offered

(Lo et al., 2024).

2 STATE OF ART

After analysing the proposals in the market, these

projects offer a comprehensive perspective on the

implementation of IoT and RPA in inventory and

supply chain management, aligned with the specific

needs of automotive SMEs in Peru. IoT integration

can improve inventory accuracy by 95% and reduce

operating times by 50%, as observed in the research

by Jarašūnienė et al. (2023). Furthermore, the

combination of RFID and IoT, highlighted by Khan

et al. (2024), demonstrates how precise asset location

can optimise operational efficiency, transferring this

utility to the automotive sector to track spare parts in

warehouses. In parallel, Khan et al. (2023) reveal that

IoT integration in supply chains not only increases

operational efficiency by 25%, but also reduces

operational costs by 20-30%, showing its relevance

for optimising operations in this industry.

On the other hand, automation through RPA plays

a key role in process efficiency. Flechsig et al. (2022)

show how RPA in procurement management can save

50% in operational tasks, while Farinha et al. (2023)

present a methodological framework that can

automate up to 83% of critical processes. This

technology is complemented by IoT-based digital

platforms, such as the one proposed by Gao et al.

(2023), which increases processing capacity by

320%, allowing SMEs to adopt more agile solutions.

Finally, secure data management is addressed by Shin

et al. (2024) through OTA protocols, ensuring

integrity in data transmissions and avoiding errors in

inventory systems, which strengthens the

technological infrastructure of automotive

companies. The combination of these solutions offers

automotive SMEs a competitive advantage by

enabling accurate, efficient and sustainable inventory

management through IoT and RPA.

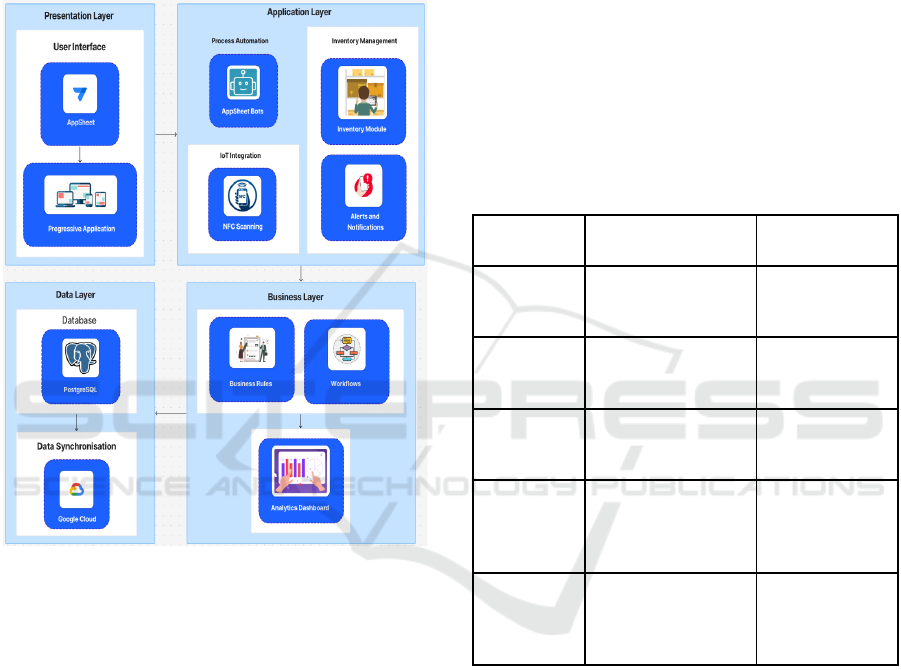

3 SYSTEM DESIGN

3.1 Architecture

The logical architecture of the developed application

integrates emerging technologies such as RPA and

IoT, with the objective of optimising inventory

management in SMEs in the automotive sector. The

solution, structured in multiple layers (Presentation,

Application, Business and Data), allows automating

processes, improving accuracy in inventory control

and providing a platform accessible through mobile

devices. Through an intuitive AppSheet interface and

the implementation of automated processes with

AppSheet Bots, the application is synchronised with

a PostgreSQL database stored in the Google Cloud,

ensuring efficient, real-time inventory management.

This architecture has been designed to offer

flexibility, scalability and rapid adaptation to the

changing needs of the sector.

3.1.1 Presentation Layer

The presentation layer is designed to provide an

intuitive and accessible user interface through

AppSheet. This interface is adaptive, functioning as a

Progressive Application (PWA), ensuring a

consistent experience on both mobile devices and

web browsers. This approach allows SMEs to manage

their inventories efficiently on any platform.

3.1.2 Application Layer

The application layer integrates technologies such as

process automation using AppSheet Bots, which is

responsible for executing repetitive tasks, such as

updating inventories. In addition, the implementation

of IoT with NFC scanning facilitates real-time data

capture, automatically updating the inventory

database. This module also manages alerts and

notifications, providing a robust system for efficient

inventory management.

3.1.3 Business Layer

In the business layer, rules and workflows are

implemented to manage operational processes, from

goods receipt to distribution. Business rules are

oriented to optimise inventory control, while an

analytics dashboard allows visualising and

monitoring performance, which facilitates data-

driven decision making.

IoTBDS 2025 - 10th International Conference on Internet of Things, Big Data and Security

232

3.1.4 Data Layer

The data layer is supported by a PostgreSQL

relational database, where all structured records of

inventories, transactions and users are stored. Data

synchronisation with Google Cloud ensures that the

information is available in real time, providing

consistency and security in the critical operations of

the application.

Figure 1: System architecture.

3.2 Methodology

3.2.1 Data Set

The dataset used in this project comes from L & M

DELSA SAC, an automotive parts company located

in Moquegua, Peru. The data has been generated

internally by the company for the management of its

automotive product inventory, including detailed

information on product ID, code, brand, vehicle

compatibility, engine, quantity in stock and price. The

dataset is non-public and has been collected through

the use of NFC tags that record in real time the inputs

and outputs of the products, which ensures

continuous updating of the database and enables

efficient inventory management.

3.2.2 Model

The proposed model for this system is composed of

four main layers: Presentation, Application, Business

and Data. Through the integration of RPA and IoT,

much of the workflow is automated, enabling real-

time inventory management without manual

intervention. This approach improves accuracy and

reduces processing times, optimising the operational

processes of automotive SMEs.

3.2.3 Indicators

The indicators selected to measure the impact of the

implementation of the inventory management system

are as follows:

Table 1: Indicators for IoT and RPA Implementation at

L&M DELSA SAC.

Indicator Description

Formula /

Calculation Method

Product search

time

Measures the efficiency

in locating products

using NFC tags.

Average time before

and after

implementation.

Inventory

accuracy

Evaluates the accuracy

of inventory records.

(Products correctly

recorded / Total

products) × 100

Operational

cost reduction

Determines the

economic savings

obtained by automation.

((Initial costs - Final

costs) / Initial costs)

× 100

Savings in

man-hours

Measures the impact of

automation on the

elimination of manual

tasks.

Manual hours

before - Manual

hours after

Automatically

generated alerts

Monitors the efficiency

of alert and notification

management.

Count of alerts

issued in a timely

manner / Expected

total

These indicators reflect the improvement in

operational efficiency and cost reduction through the

integration of IoT and RPA. The impact of the system

will be assessed through comparative analysis

between the initial and final values of each metric.

3.2.4 Interfaces

To optimise the user experience and facilitate

inventory management from mobile devices and web

browsers. The solution uses AppSheet, enabling a

consistent and responsive experience that adapts to

smartphones, tablets and computers.

The system stands out for the following features:

• Intuitive interface: Minimises the learning

curve for operational staff, making it easy to

Inventory Management System Through the Integration of RPA and IoT to Enhance Processes in SMEs Within Peru’s Automotive Sector

233

locate and manage products in real time via

NFC scanning.

• Control Dashboard: Provides a clear view of

inventory levels, critical products and recent

movements, allowing managers to make

informed decisions based on up-to-date data.

• Automatic alerts: The platform issues real-

time notifications on low stock levels or

critical dates, improving planning and

avoiding stock-outs.

• Automatic inventory updates: Each NFC tag

scan instantly synchronises data with the

Google Cloud database, ensuring accurate

and available information in real time.

The interface is designed to optimise operational

efficiency, reducing reliance on manual processes and

improving inventory management visibility.

4 RESULTS

The results obtained with the implementation of IoT

and RPA technologies in inventory management are

presented below. These are detailed in tables

reflecting the improvements achieved in efficiency,

accuracy and resource savings.

Table 2: IoT Implementation Results.

Indicator Initial

Metric

Final

Metric

Improvement

(%)

Description

Average

search

time

10

minutes

3 minutes 70% Reduction of

time to find

products.

Inventory

accuracy

80% 95% 25% Increased

accuracy of

inventory

records.

Data

synchroni-

sation

Manual

(24 hours)

Automatic 80% Reduction of

manual

update time.

Savings in

man-hours

20 hours/

month

5 hours/

month

75% Elimination

of repetitive

manual

tasks.

The results in Table 2 reflect a significant

improvement through the integration of IoT

technologies. The reduction in product search time is

attributed to the use of NFC tags, which speed up the

location of items in the warehouse. Increased

inventory accuracy is due to the automatic updating

of records, eliminating manual errors. In addition,

real-time data synchronisation via the Google Cloud

streamlines administrative tasks, allowing employees

to focus on more value-added activities.

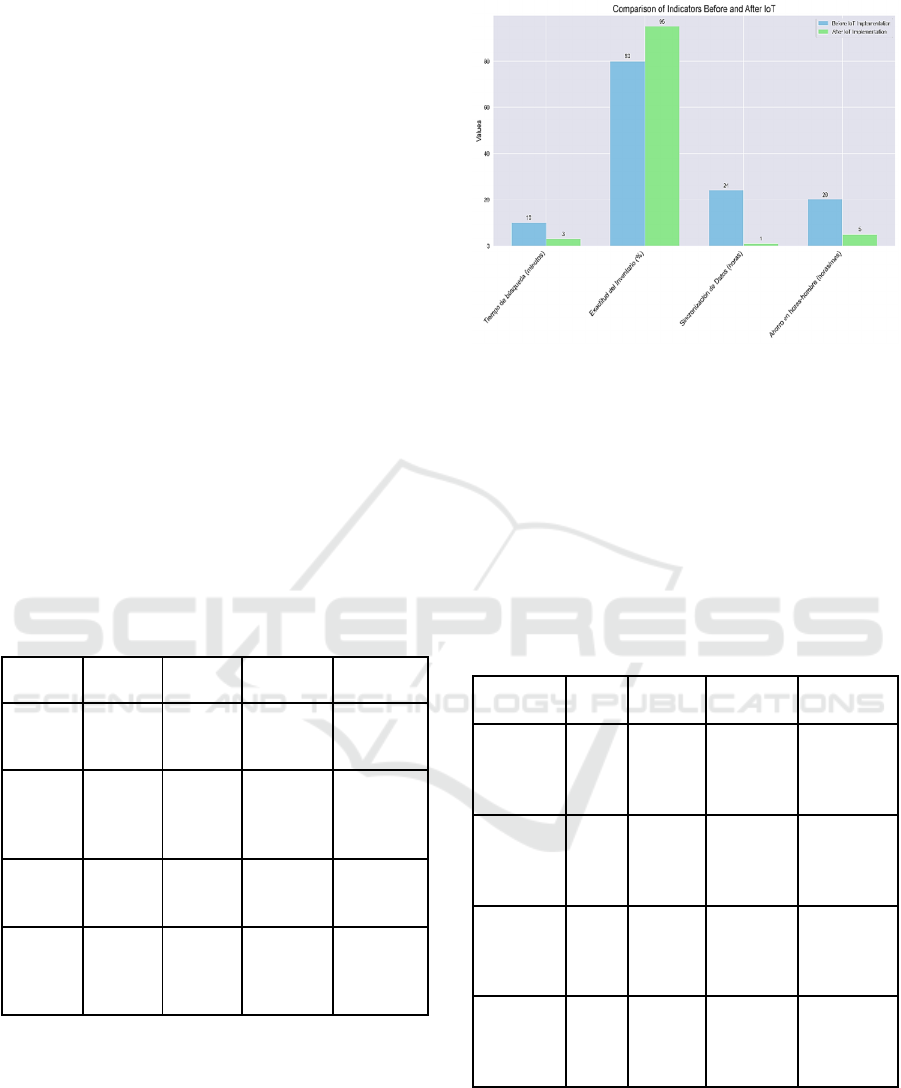

Figure 2: Comparison of Indicators Before and After IoT

Implementation.

Figure 2 shows the comparison of key indicators

before and after the implementation of IoT in

inventory management. There is a significant

reduction in search times from 10 minutes to 3

minutes. Also, inventory accuracy increased from

80% to 96%, minimising manual errors. Automatic

data synchronisation has reduced the update time

from 24 hours to 1 hour, enabling more efficient, real-

time control.

Table 3: Results of RPA Implementation.

Indicator Initial

Metric

Final

Metric

Improvement

(%)

Description

Operational

management

time

20

hours/

month

14

hours/

month

30% Reduction of

time in

administrative

tasks.

Alerts and

notifications

Manual Automatic 100% Reduced

stock-outs

and quick

response.

Operational

costs

S/5,000/

month

S/4,200/

month

16% Savings in

operating

costs through

automation

Savings in

man-hours

30

hours/

month

10 hours/

month

66.67% Time

optimisation

through

automation

In Table 3, the results obtained with the

implementation of RPA are mainly due to the

automation of repetitive processes through AppSheet

Bots. The reduction in operational time reflects the

elimination of administrative tasks that previously

required manual intervention. Operational cost

savings are attributed to reduced man hours and

IoTBDS 2025 - 10th International Conference on Internet of Things, Big Data and Security

234

increased efficiency, allowing the company to operate

more profitably. In addition, automated alerts

improved planning and prevented stock-outs,

ensuring a continuous flow in the warehouse

operation.

Figure 3: Comparison of Numerical Indicators for RPA

Implementation.

Figure 3 highlights the impact of RPA

implementation on administrative processes.

Operational management time was reduced from 20

to 14 hours per month, while man-hours saved

increased from 5 to 20 hours per month. Operating

costs were also reduced by 16% from S/5,000 to

S/4,200, reflecting the direct economic benefit of

automating repetitive tasks.

5 DISCUSSION

The results obtained with the implementation of IoT

and RPA at L&M DELSA SAC demonstrate a

significant improvement in inventory management,

particularly in the reduction of search times and

process optimisation. This solution improves the

investigated issue by providing a more efficient

management model, replacing manual processes with

automation and real-time synchronisation. The use of

automatic alerts has prevented stock-outs and enabled

better operational decision making, ensuring business

continuity. These findings are in line with previous

studies highlighting the importance of automation to

increase operational efficiency in inventory

management.

Compared to other approaches in the literature,

the combination of IoT and RPA shows clear

advantages over traditional methods based on

spreadsheets or RFID inventories without real-time

connectivity. However, some studies report that

integration with Artificial Intelligence allows for

greater personalisation and demand prediction, which

was not implemented in this work. The main

difference is that the presented solution is more

accessible for SMEs and can be scaled up gradually

without compromising operability, while more

advanced technologies may require higher initial

investments.

This project provides a replicable model that can

be applied not only in the automotive sector, but also

in other environments such as logistics and retail,

where efficient inventory management is crucial. At

an operational level, this solution contributes to

existing knowledge by demonstrating how affordable

technologies, such as IoT and RPA, can be used

effectively to improve accuracy and efficiency

without the need for expensive systems.

6 CONCLUSION

In summary, the integration of IoT and RPA into

inventory management significantly improved

operational efficiency, reducing both the time and

costs associated with inventory management.

Automated alerts and real-time monitoring prevented

stock-outs and optimised decision making. These

results highlight the relevance of automation in

sectors with high product turnover and operational

complexity.

This work demonstrates that the adoption of

advanced technologies can make a significant

difference in the competitiveness of SMEs. However,

it also reveals the importance of addressing

implementation challenges through a gradual

approach and adequate training of staff. Going

forward, it is recommended to explore the scalability

of the system in other industries and to evaluate the

integration of new technological tools to strengthen

the functionality and security of the system, thus

ensuring its long-term sustainability.

ACKNOWLEDGEMENTS

The authors are grateful to the Dirección de

Investigación de la Universidad Peruana de Ciencias

Aplicadas for the support provided for this research

work through the economic incentive. The authors

also extend their gratitude to L&M DELSA SAC for

their collaboration and for facilitating access to

essential data for the implementation of the system.

Finally, sincere thanks to all the people who, directly

or indirectly, contributed to the development of this

work.

Inventory Management System Through the Integration of RPA and IoT to Enhance Processes in SMEs Within Peru’s Automotive Sector

235

REFERENCES

Asatiani, A., Copeland, O., & Penttinen, E. (2023).

Deciding on the robotic process automation operating

model: A checklist for RPA managers. Business

Horizons, 66(1), 109–121. https://doi.org/10.1016/j.bus

hor.2022.03.004

Chen, M.-C., Cheng, Y.-T., & Siang, C.-Y. (2022).

Development of inventory management system based

on radio frequency identification technology. Sensors

and Materials, 34(3), 1163. https://doi.org/10.18494/

sam3497

Farinha, D., Pereira, R., & Almeida, R. (2023). A

framework to support Robotic process automation. JIT.

Journal Of Information Technology/Journal Of

Information Technology, 39(1), 149-166.

https://doi.org/10.1177/02683962231165066

Flechsig, C., Anslinger, F., & Lasch, R. (2022). Robotic

Process Automation in purchasing and supply

management: A multiple case study on potentials,

barriers, and implementation. Journal Of Purchasing

And Supply Management, 28(1), 100718.

https://doi.org/10.1016/j.pursup.2021.100718

Gao, Q., Wang, Q., & Wu, C. (2023). Construction of

enterprise digital service and operation platform based

on internet of things technology. Journal Of Innovation

& Knowledge/Journal Of Innovation And Knowledge,

8(4), 100433.

https://doi.org/10.1016/j.jik.2023.100433

Hu, X., Liu, W., Lu, L., & Zhou, Q. (2024). An IoT-based

low-cost architecture for smart libraries using SDN.

Scientific Reports, 14(1).

https://doi.org/10.1038/s41598-024-57484-2

Jarašūnienė, A., Čižiūnienė, K., & Čereška, A. (2023).

Research on Impact of IoT on Warehouse Management.

Sensors, 23(4), 2213.

https://doi.org/10.3390/s23042213

Khan, S. I., Ray, B. R., & Karmakar, N. C. (2024). RFID

localization in construction with IoT and security

integration. Automation In Construction, 159, 105249.

https://doi.org/10.1016/j.autcon.2023.105249

Khan, Y., Su’ud, M. B. M., Alam, M. M., Ahmad, S. F.,

Ahmad, A. y. A. B., & Khan, N. (2022). Application of

Internet of Things (IoT) in Sustainable Supply Chain

Management. Sustainability, 15(1), 694.

https://doi.org/10.3390/su15010694

Lo, W., Yang, C.-M., Zhang, Q., & Li, M. (2024). Increased

Productivity and Reduced Waste with Robotic Process

Automation and Generative AI-powered IoE Services.

Journal of Web Engineering, 23(01), 53–88.

https://doi.org/10.13052/jwe1540-9589.2313

Mahariya, N. S. K., Kumar, N. A., Singh, N. R., Gehlot, N.

A., Akram, N. S. V., Twala, N. B., Iqbal, N. M. I., &

Priyadarshi, N. N. (2023). Smart Campus 4.0:

Digitalization of University Campus with Assimilation

of Industry 4.0 for Innovation and Sustainability.

Journal Of Advanced Research In Applied Sciences

And Engineering Technology, 32(1), 120-138.

https://doi.org/10.37934/araset.32.1.120138

Mangler, J., Grüger, J., Malburg, L., Ehrendorfer, M.,

Bertrand, Y., Benzin, J. V., Rinderle-Ma, S., Serral

Asensio, E., & Bergmann, R. (2023). DataStream XES

Extension: Embedding IoT Sensor Data into Extensible

Event Stream Logs. Future Internet, 15(3).

https://doi.org/10.3390/fi15030109

Mohamed, S. A., Mahmoud, M. A., Mahdi, M. N., &

Mostafa, S. A. (2022). Improving Efficiency and

Effectiveness of Robotic Process Automation in

Human Resource Management. Sustainability, 14(7),

3920. https://doi.org/10.3390/su14073920

Mohammadi, T., Sajadi, S. M., Najafi, S. E., & Taghizadeh‐

Yazdi, M. (2024). Multi Objective and Multi-Product

Perishable Supply Chain with Vendor-Managed

Inventory and IoT-Related Technologies. Mathematics,

12(5), 679. https://doi.org/10.3390/math12050679

Navaei, A., Taleizadeh, A. A., & Goodarzian, F. (2023).

Designing a new sustainable Test Kit supply chain

network utilizing Internet of Things. Engineering

Applications of Artificial Intelligence, 124.

https://doi.org/10.1016/j.engappai.2023.106585

Patrício, L., Costa, L., Varela, L., & Ávila, P. (2023).

Sustainable implementation of Robotic Process

Automation based on a multi-objective mathematical

model. Sustainability, 15(20), 15045.

https://doi.org/10.3390/su152015045

Shin, Y., & Jeon, S. H. (2024). MQTree: Secure OTA

Protocol Using MQTT and MerkleTree. Sensors, 24(5),

1447. https://doi.org/10.3390/s24051447

IoTBDS 2025 - 10th International Conference on Internet of Things, Big Data and Security

236