A Two-Stage Approach for Wire Harness Cable Description Using 3D

Point Clouds for Robotic Manufacturing

Takumi Okuyama

1

, Pei-Chun Chien

2

, Hiroki Tsukida

2

,Yoichi Kato

3

and Jun Ohya

1

1

Department of Modern Mechanical Engineering, Waseda University, Tokyo, Japan

2

AI Digital Division, Yazaki Corporation, Tokyo, Japan

3

Global Center for Science and Engineering, Waseda University, Tokyo, Japan

Keywords:

Colored Point Cloud Registration, B-Spline, B

´

ezier Curve.

Abstract:

This paper proposes a two-stage methodology for accurately describing three-dimensional cable position aim-

ing to examine robot-based automated cable placement systems to work correctly in wire harness manufactur-

ing. The first stage is to extract 3D points on cables from point cloud acquired using a 3D stereo camera. For

extracting only the points on cables, we compare two sets of point clouds which are taken before laying cables

on an assembly board which holds the cables temporarily for taping and additional works, and after laying

cables. We propose a new method to eliminate unnecessary points such as points on the assembly board and

noises to get points only on cables from the two point cloud sets. In the second stage, cable positions are ap-

proximated as a mathematical function, B-Spline or B

´

ezier curve, by interpolating the extracted 3D points. We

use Smoothness, Curve Length, and Chamfer Distance as the evaluation criteria to assess the fitting quality to

the original cable geometry. Experiment results indicate that B-Spline provides smooth approximation, while

B

´

ezier curve can represent curve with rapid transition such as sharp bents. Measured Chamfer Distance is a

few times as large as the radius of the cables or shorter, demonstrating high fitting accuracy. This approach

offers a practical solution for cable recognition in automation contexts, with potential applications in automo-

tive and manufacturing industries.

1 INTRODUCTION

With the increasing use of electronic devices in au-

tomobiles, wire harnesses, which interconnect the

devices within an automobile, have become essen-

tial components. Traditionally, wire harnesses man-

ufacturing has been a highly labor-intensive process.

However, shortages of skilled workers, the demand

for high efficiency, and cost-saving pressures require

a new automated system for wire harness manufactur-

ing using robotics.

The manufacturing flow of wire harnesses consists

of designing the layout of wire harnesses, then rout-

ing the wire harnesses according to the layout, and

finally judging whether there are any abnormalities in

the wire harnesses.

Karlsson et al. presented an efficient solution to

automate the complex and time-consuming wire har-

ness design process within a customizable 3D envi-

ronment (Karlsson et al., 2024). Karlsson et al. en-

abled the automated generation of optimized wire har-

ness layouts, but did not deal with automatic routing

of wire harnesses.

Nguyen et al. proposed a novel vision-based rout-

ing method for 3D profile extraction of wire har-

nesses in a robotized assembly process, addressing

the complexities associated with deformable objects

like wire harnesses by integrating deep learning and

machine vision techniques (Nguyen and Yoon, 2021).

In Nguyen et al.’s study, the robot directly grasps and

manipulates the wire harnesses using a gripper and se-

cures them into clamps during the assembly process.

However, their system does not incorporate a process

to leverage the inherent flexibility of cables to repre-

sent their shape smoothly.

Nguyen et al. proposed a deep learning-based au-

tomated optical inspection (AOI) system for wiring

harness manufacturing, utilizing PointNet++ and syn-

thetic point cloud data generated from CAD models to

improve segmentation accuracy, address the domain

gap, and reduce dependence on extensive real-world

data collection (Nguyen et al., 2022). Nguyen et al.’s

study improved deep learning accuracy by leveraging

synthetic data for training. However, their system seg-

Okuyama, T., Chien, P.-C., Tsukida, H., Kato, Y. and Ohya, J.

A Two-Stage Approach for Wire Harness Cable Description Using 3D Point Clouds for Robotic Manufacturing.

DOI: 10.5220/0013246100003905

In Proceedings of the 14th International Conference on Pattern Recognition Applications and Methods (ICPRAM 2025), pages 689-695

ISBN: 978-989-758-730-6; ISSN: 2184-4313

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

689

ments multiple cables as a single bundle, but did not

classify individual cables.

Nguyen et al. proposed a 3D vision-based method

for detecting multiple wire branches in robotized

wire harness assembly, utilizing Fixed Radius Near-

est Neighbor (FRNN) for wire color classification and

YOLO-v7 for terminal identification, enabling pre-

cise segmentation and automated handling of com-

plex wire structures (Nguyen et al., 2024). Nguyen

et al. utilized RGB-D camera color information to

classify multiple cables, but did not discuss handling

occlusions.

Chien et al. presented a study on classifying cable

tendency using semantic segmentation by leveraging

real and simulated RGB data to identify normal and

abnormal (tensioned, loose, twisted) cable configura-

tions, which is crucial for automating cable assembly

processes (Chien et al., 2024). However, Chien et al.

did not deal with 3D descriptions of routed cables.

These conventional studies enabled the design of

wire harnesses, automated robotic arrangement, or

anomaly detection. Therefore, we recognized that a

critical challenge in achieving full automation lies in

the ability to enable robots to identify the exact de-

scription of each cable in a 3D space.

Our approach to identify cable positions is as fol-

lows. First, using an inexpensive 3D stereo camera,

we capture the shape of a wire harness consisting of

multiple cables and connectors as point cloud. Then,

the exact place of each cable is described as a math-

ematical function by interpolating the points on a ca-

ble which are extracted from the captured point cloud.

Here, the challenges are to extract a set of 3D points

only on a cable from a captured point cloud which

includes points on other cables, connectors, assembly

board, background and a lot of noises, and to calculate

a set of parameters of the mathematical function out

of the dispersedly placed points. Note that there may

be unseen parts of a cable which are hidden behind

other cables.

For the first problem, we capture two sets of point

clouds; one is taken before laying cable on the as-

sembly board and the other is taken after that. By

evaluating the difference of the two, points only on

cables can be extracted. For the second problem, we

use B-spline and B

´

ezier curve functions and evaluate

the result. The accuracy of the approximation is eval-

uated using criteria of smoothness, curve length and

Chamfer Distances.

Experimental result shows that our approach

worked well and measured approximation accuracy

was a few times as large as the radius of the cables or

shorter.

2 RELATED WORK

2.1 Research on Cable Recognition

In the field of cable recognition, some studies focused

on depth information.

Nguyen et al. proposed a deep learning-based

data processing pipeline for automated optical inspec-

tion of wiring harnesses in automotive manufactur-

ing, addressing challenges such as high customization

and manual labor intensity by utilizing real and syn-

thetic point cloud data (Nguyen et al., 2022). The

developed pipeline employs PointNet++ for segmen-

tation, integrating synthetic data generated through

CAD and simulations to reduce reliance on real data.

The results demonstrate that combining real and syn-

thetic data enhances model accuracy, with the best-

performing configuration achieving a mean IoU of

94.62% and enabling precise quality assessment of

wiring harness assembly states. This approach marks

a significant step toward scalable, efficient automation

in wiring harness manufacturing.

Nguyen et al. presented a novel 3D vision-based

method for detecting and extracting the profiles of

multiple wire branches in wire harnesses to address

the challenges of robotized assembly of flexible and

deformable objects (Nguyen et al., 2024). By utiliz-

ing point cloud data from high-quality RGB-Depth

cameras and combining techniques like YOLO-v7

for terminal identification, RANSAC for background

elimination, and FRNN for color-based classification,

the method efficiently detects wire terminals and re-

constructs 3D wire profiles. Validated in a robotic

system, this approach enabled robots to perform pre-

cise wire harness assembly tasks, including manipu-

lation and sequential placement of wire branches in

clamps, significantly reducing manual labor and en-

hancing assembly efficiency. This research marks a

substantial advancement in automating complex as-

sembly processes for deformable components.

Although these studies utilized 3D data to rec-

ognize cables, they did not take into account funda-

mental cable characteristics, such as a constant radius

and smoothness, nor did they consider handling oc-

clusions.

2.2 Point Cloud Registration

Point cloud registration is a technique used to align a

reference point cloud with a target point cloud. It-

erative Closest Point (ICP) is a fundamental algo-

rithm in this field of study (Besl and McKay, 1992).

ICP works by calculating the distances between the

nearest neighbor points in the reference and target

ICPRAM 2025 - 14th International Conference on Pattern Recognition Applications and Methods

690

point clouds, then identifying the transformation ma-

trix that minimizes these distances. However, because

ICP relies solely on positional information, its accu-

racy can decline in cases where the geometries does

not include enough unevenness or contain multiple

similar regions.

To address this limitation, Colored Point Cloud

Registration was introduced, incorporating both po-

sitional and color information (Park et al., 2017). By

combining the two data sources, this approach finds

a transformation matrix that minimizes the objective

function, providing more accurate registration than

that conventional ICP does.

3 3D STEREO IMAGE

CAPTURING

A typical wire harness assembly process in the au-

tomobile industry is as follows. Cables are cut to

the designed length and both ends are contained in

connectors. Then a worker places each connector to

a designated receptor on a board called “assembly

board”. After checking that the route of the cable

is as designed and there is no kink or too much ten-

sion, the cables are taped thoroughly to complete the

work. Our target for automation is the process of ca-

ble and connector placement on an assembly board.

This study focuses on the cable placement examina-

tion process.

Among 3D shape measuring devices, we chose 3D

stereo camera because it captures color and is rela-

tively inexpensive and easy to handle. In this study, a

RealSense D405 stereo camera, as shown in Figure 1,

was used.

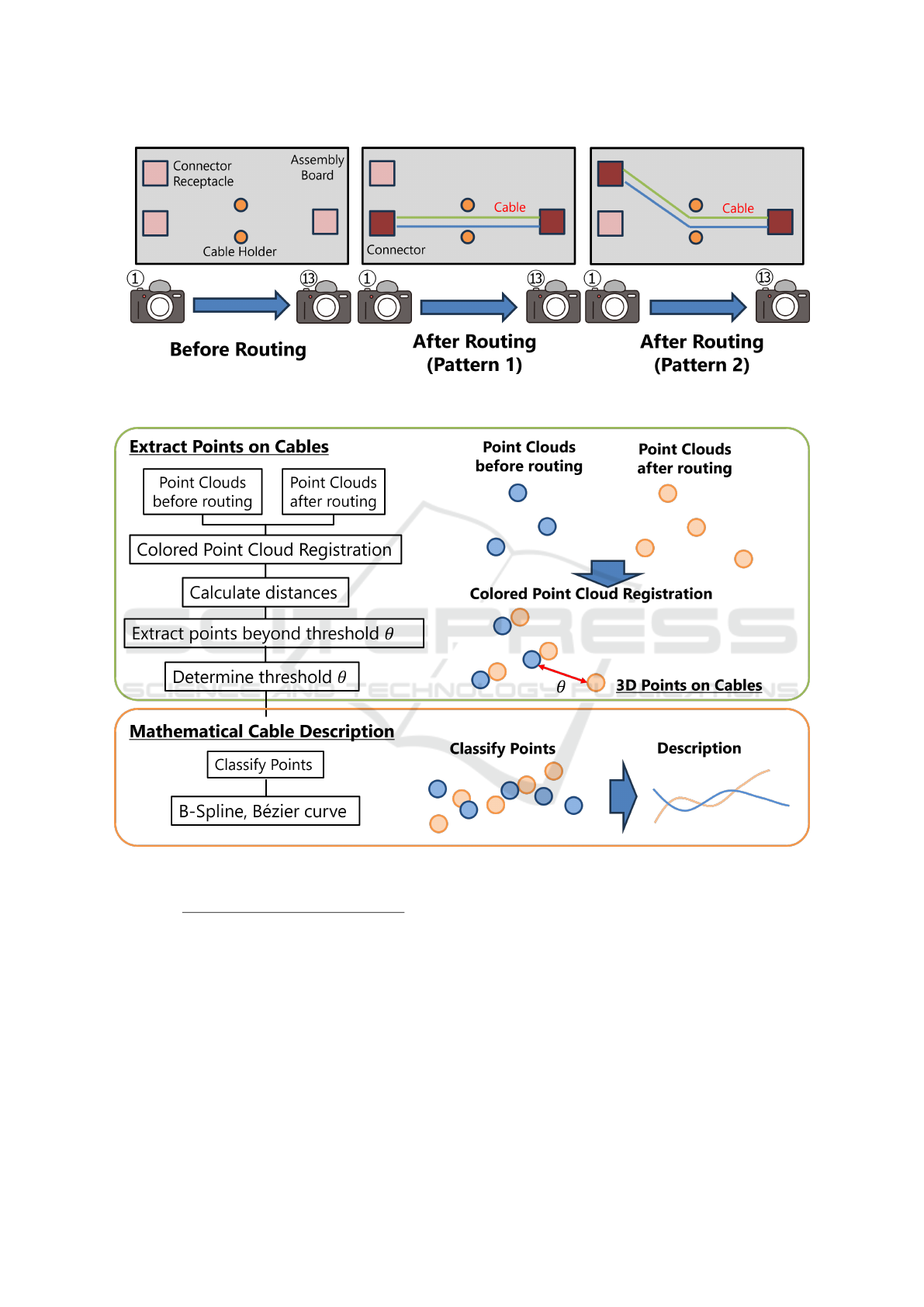

We captured 3D stereo images from 13 different

points which are equally distributed between the left

end and right end of an assembly board. From each

camera position, we captured images both before and

after the cable arrangement, as illustrated in Figure 2.

The assembly board includes connector receptors and

cable holders, through which the blue cable (1.30 mm

radius) and green cable (1.15 mm radius) are routed

to the receptor at right hand side. As shown in Figure

2, two patterns of cable routing were used. We used

the camera’s default application program to calculate

point clouds from the original stereo images.

4 DATA PROCESSING

This study proposes a two-stage methodology for

mathematically describing the place of each cable in

Figure 1: RealSense D405 camera mounted on UR5e robot.

wire harness as illustrated in Figure 3.

The first phase, which extracts point cloud on ca-

bles, begins with applying Colored Point Cloud Reg-

istration (CPCR) to align point clouds captured before

and after cable routing, CPCR produce a transforma-

tion matrix T. This matrix is applied to point cloud

P

after

to be aligned with point cloud P

before

. Here,

P

before

and P

after

are point cloud captured before the

routing and after the routing, respectively. Applying

T to P

after

produces the transformed point cloud, P

′

after

which is defined as:

P

′

after

= T q

j

| q

j

∈ P

after

(1)

where each q

j

represents a point in P

after

. Next, we

calculate the distance between each point p

i

in P

before

and the closest point in P

′

after

using a nearest neigh-

bor search. If the distance d(p

i

, P

′

after

) between p

i

and

the nearest point in P

′

after

exceeds a threshold θ, then

the point q

i

is considered to be a part of a cable and

included in new point cloud P

cables

.

d(p

i

, P

′

after

) = min

q

′

∈P

′

after

|p

i

− q

′

| > θ (2)

The extracted cable point cloud P

cables

is then defined

as:

P

cables

= q

i

∈ P

′

after

| d(p

i

, P

′

after

) > θ (3)

The threshold θ will be determined by evaluating how

well P

cables

represents the actual cables by experi-

ments.

The first step of the second phase is to classify

points in P

cables

to points on individual cable based on

color similarity. We use Euclidean distance between

the color of each point and the target color for clas-

sification. Let c

i

= (R

i

, G

i

, B

i

) be the color of point

i, and t = (R

t

, G

t

, B

t

) the target color. The Euclidean

A Two-Stage Approach for Wire Harness Cable Description Using 3D Point Clouds for Robotic Manufacturing

691

Figure 2: Overview of the assembly board.

Figure 3: Illustration of our methodology.

distance d

i

is given by

d

i

=

q

(R

i

− R

t

)

2

+ (G

i

− G

t

)

2

+ (B

i

− B

t

)

2

(4)

If d

i

is less than a specified tolerance, the point is

selected for further processing. While selecting the

color of the cable, statistical outlier removal is ap-

plied to eliminate noises. Here the points having the

same color together are considered to represent the

3D shape of a cable. However, there may be portions

where there is no point produced on the cable, for ex-

ample portions hidden by other cables. To interpolate

the obtained points and get a smooth and continuous

representation of a cable, we apply a 3D spline curve

using cubic B-spline interpolation. Given a sequence

of points {(x

i

, y

i

, z

i

)}, the spline curve S(t) is repre-

sented as

S(t) = (x(t),y(t),z(t)) =

n

∑

k=0

N

k,3

(t) · P

k

(5)

where:

• P

k

= (x

k

, y

k

, z

k

) are the points on a cable,

• N

k,3

(t) is the B-spline basis function of degree 3,

• t is the curve parameter within the range [0, 1].

The spline curve minimizes overall curvature, provid-

ing a smooth and continuous representation of the ca-

ble. As an alternative smooth curve-fitting method,

ICPRAM 2025 - 14th International Conference on Pattern Recognition Applications and Methods

692

Figure 4: Results of extracting points on cables.

Figure 5: Results of mathematical cable description.

we use a B

´

ezier curve, generated from a set of points.

For a set of n + 1 control points, the B

´

ezier curve B(t)

is defined by the Bernstein polynomials as follows:

B(t) =

n

∑

i=0

n

i

(1 −t)

n−i

t

i

P

i

(6)

where:

• P

i

= (x

i

, y

i

, z

i

) are points on a cable,

• t is the parameter of the curve, ranging from 0 to

1,

•

n

i

represents the binomial coefficient.

The resulting B

´

ezier curve provides a smooth path be-

tween points, with each point influencing the curve

shape based on its position and the binomial weight.

A Two-Stage Approach for Wire Harness Cable Description Using 3D Point Clouds for Robotic Manufacturing

693

Table 1: Evaluation metrics for B-Spline and B

´

ezier curve fitting on blue and green cables.

Pattern Method Color Smoothness [1/mm] Curve Length [mm] Chamfer Distance [mm]

1 B-Spline Blue 3.29 × 10

−7

3.10 × 10

2

3.012

Green 1.16 × 10

−6

3.74 × 10

2

3.498

B

´

ezier curve Blue 1.44 × 10

−6

3.15 × 10

2

1.530

Green 2.35 × 10

−6

3.80 × 10

2

2.146

2 B-Spline Blue 2.21 × 10

−7

2.89 × 10

2

2.245

Green 8.29 × 10

−7

3.50 × 10

2

3.389

B

´

ezier curve Blue 9.08 × 10

−7

2.92 × 10

2

0.989

Green 1.90 × 10

−6

3.51 × 10

2

2.156

5 EXPERIMENTS

5.1 Extracting Points on Cables from

Acquired Point Cloud

Figure 4 shows experimental results of the point cloud

extraction phase, highlighting the differences in point

clouds completeness at varying thresholds. As shown

in the Figure, the threshold θ controls the trade-off

between the noise level and the coverage of points on

cables. Ideally, the point clouds of connectors and

cables should be extracted in this phase. Based on

the observations, we chose 20 as the value of θ for

optimal cable extraction.

5.2 Mathematical Cable Description

Figure 5 shows experimental results of the Mathemat-

ical Cable Description phase, illustrating how both B-

Spline and B

´

ezier curve describe the cable shapes cor-

rectly. As shown in the Figure 5, curves effectively

interpolate missing sections to describe the cables. In

a close observation, B-Spline provides a smoothed

curve that does not strictly adhere to each selected

point, while the B

´

ezier curve aligns exactly with the

selected points, creating a more precise but poten-

tially complex curve.

To evaluate the accuracy of cable approximations,

we employ three metrics: Smoothness, Curve Length,

and Chamfer Distance. These metrics provide a quan-

titative assessments of curve quality and alignment

accuracy to the original cable geometry. Each met-

ric is calculated as an average of the values at the 13

locations for each wire routing pattern.

Smoothness quantifies the continuity and fluidity

of a curve, calculated as the sum of the second deriva-

tive (curvature) along its length. Lower smoothness

values indicate a smoother transition. We calculate

the second derivative in each axis (x, y, and z), then

sum up the curvature across all points and axes.

Curve length is calculated by summing up the Eu-

clidean distances between consecutive points along

the curve. This metric is valuable for assessing how

well the B-Spline or B

´

ezier curve fits the original ca-

ble length, providing an indication of how accurately

a curve represents the real cable’s path.

Chamfer Distance evaluates the fitting accuracy

between the original and approximated point clouds,

calculating the average squared distance from each

point in the original point cloud to its nearest neighbor

point on the approximated curve. A lower Chamfer

Distance indicates a closer match between the origi-

nal and approximated point clouds, reflecting a higher

quality of approximation.

These metrics provide a comprehensive evaluation

of the approximation accuracy and quality of the fitted

curves. By averaging these metrics at the 13 locations

for each wire routing pattern, we obtained a robust

assessment of the fitting performance of the proposed

method.

Table 1 summarizes the calculated values of met-

rics to compare the performance of B-Spline and

B

´

ezier curve fittings. B-Spline consistently demon-

strates smaller values for both smoothness and curve

length, indicating that a smoother and simpler curves

were obtained. In contrast, the B

´

ezier curve, which

exactly traces the given control points, may be better

suited for representing more complex or highly de-

tailed curves. The obtained Chamfer Distance values,

ranging from 0.989 mm to 3.498 mm across all pat-

terns, reflect a close match between the original and

the approximated point clouds. These values were

about a few times as large as the cables radius (1.30

mm for blue and 1.15 mm for green ones) or shorter,

indicating a high level of fitting accuracy. Also these

values are much smaller than the width of the robot

hand (92mm), indicating that it has no practical prob-

lem when in use. In addition, the case of four-color

cables was also experimented, and the prospect of

good results was obtained.

ICPRAM 2025 - 14th International Conference on Pattern Recognition Applications and Methods

694

6 CONCLUSIONS

This paper has proposed a novel two-stage method-

ology for accurately describing cable geometry us-

ing a 3D stereo camera. Through extracting point

cloud which only contains points on the target ca-

bles from the two sets of point clouds captured be-

fore and after cable arrangement and employing ad-

vanced curve fitting techniques to the obtained cable-

only point cloud, the methodology produces a contin-

uous and accurate representation of cable geometry.

Using the proposed methodology, the observed ap-

proximation accuracy was about a few times as large

as the radius of the cables or shorter. Future research

could focus on adapting the approach to handle var-

ious cable types and exploring alternative algorithms

to improve fitting accuracy further and computational

efficiency. Overall, this study contributes a founda-

tional approach to accurately modeling cable geome-

try in 3D, which may significantly aid in the develop-

ment of automated solutions for complex wire harness

routing in the automotive and manufacturing indus-

tries.

ACKNOWLEDGEMENTS

We would like to express our heartfelt gratitude to

Chen Yuchuan, who received BS degree from Waseda

University in March 2024, for his bachelor thesis re-

search that forms a foundation of this paper’s work.

REFERENCES

Besl, P. and McKay, N. D. (1992). A method for registration

of 3-d shapes. IEEE Transactions on Pattern Analysis

and Machine Intelligence, 14(2):239–256.

Chien, P.-C., Liao, P., Fukuzawa, E., and Ohya, J. (2024).

Classifying cable tendency with semantic segmenta-

tion by utilizing real and simulated rgb data. In Pro-

ceedings of the IEEE/CVF Winter Conference on Ap-

plications of Computer Vision, pages 8430–8438.

Karlsson, T.,

˚

Ablad, E., Hermansson, T., Carlson, J., and

Tenf

¨

alt, G. (2024). Automatic cable harness layout

routing in a customizable 3d environment. Computer-

Aided Design, 169:103671.

Nguyen, H. G., Habiboglu, R., and Franke, J. (2022). En-

abling deep learning using synthetic data: A case

study for the automotive wiring harness manufactur-

ing. Procedia CIRP, 107:1263–1268. Leading man-

ufacturing systems transformation – Proceedings of

the 55th CIRP Conference on Manufacturing Systems

2022.

Nguyen, T. P., Kim, D., Lim, H.-K., and Yoon, J. (2024).

Revolutionizing robotized assembly for wire harness:

A 3d vision-based method for multiple wire-branch

detection. Journal of Manufacturing Systems, 72:360–

372.

Nguyen, T. P. and Yoon, J. (2021). A novel vision-based

method for 3d profile extraction of wire harness in

robotized assembly process. Journal of Manufactur-

ing Systems, 61:365–374.

Park, J., Zhou, Q.-Y., and Koltun, V. (2017). Colored

point cloud registration revisited. In Proceedings of

the IEEE international conference on computer vi-

sion, pages 143–152.

A Two-Stage Approach for Wire Harness Cable Description Using 3D Point Clouds for Robotic Manufacturing

695