Bottleneck Identification in Resource-Constrained Project Scheduling via

Constraint Relaxation

Luk

´

a

ˇ

s Nedb

´

alek

1,2

and Anton

´

ın Nov

´

ak

2

1

Faculty of Mathematics and Physics, Charles University, Prague, Czech Republic

2

Czech Institute of Informatics, Robotics and Cybernetics, Czech Technical University in Prague, Czech Republic

Keywords:

Scheduling, RCPSP, Bottlenecks, Constraint Relaxation.

Abstract:

In realistic production scenarios, Advanced Planning and Scheduling (APS) tools often require manual in-

tervention by production planners, as the system works with incomplete information, resulting in suboptimal

schedules. Often, the preferable solution is not found just because of the too-restrictive constraints specifying

the optimization problem, representing bottlenecks in the schedule. To provide computer-assisted support for

decision-making, we aim to automatically identify bottlenecks in the given schedule while linking them to

the particular constraints to be relaxed. In this work, we address the problem of reducing the tardiness of a

particular project in an obtained schedule in the resource-constrained project scheduling problem by relaxing

constraints related to identified bottlenecks. We develop two methods for this purpose. The first method adapts

existing approaches from the job shop literature and utilizes them for so-called untargeted relaxations. The

second method identifies potential improvements in relaxed versions of the problem and proposes targeted

relaxations. Surprisingly, the untargeted relaxations result in improvements comparable to the targeted relax-

ations.

1 INTRODUCTION

In the modern manufacturing industry, Advanced

Planning and Scheduling (APS) tools are used to

schedule production automatically. However, not all

parameters and information are available to the APS

systems in practice. Thus, the solutions obtained

with the scheduling tools may not be preferable to the

users. This leads to repeated interactions of the pro-

duction planners with the APS system, adjusting the

problem parameters to obtain an acceptable schedule.

We address a common problem in production—

reducing the delay of a selected project in an existing

production schedule. We achieve this by identifying

manufacturing bottlenecks in the schedule and related

constraints. Bottlenecks represent resources or con-

straints with the most significant impact on produc-

tion performance. The algorithm identifies these bot-

tlenecks and suggests appropriate relaxations in the

form of a modified schedule. The modified schedule

is then offered to the decision maker to compare the

improvements, and the changes can then be accepted,

rejected, or augmented to suit the current needs.

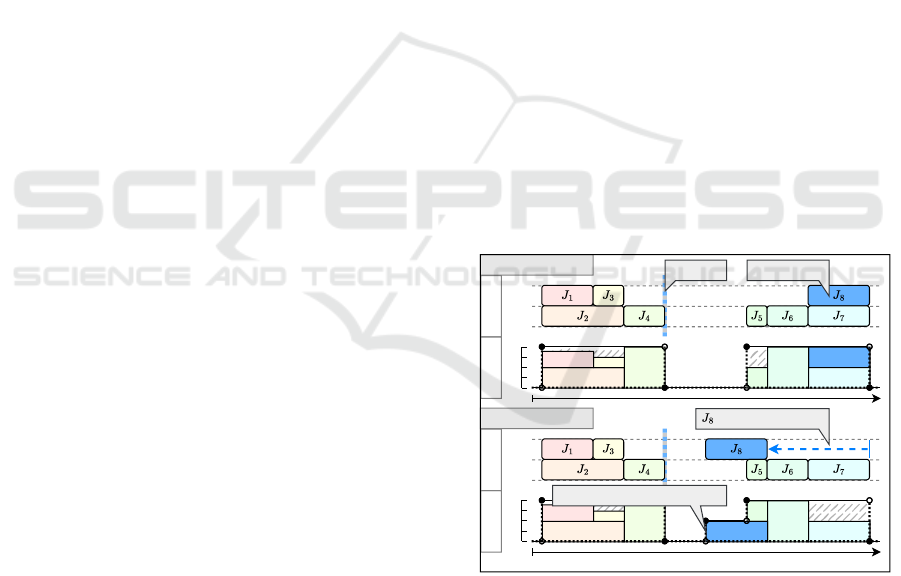

See an example in Figure 1. In the original sched-

ule, the target project J

8

should preferably have been

Capacity

Capacity

JobsResource 1

Resource 1

Jobs

Time

Time

Relaxed schedule

Original schedule

Due date Target project

Capacity constraint relaxation

Tardiness improvement

Figure 1: Example of an original and relaxed schedule with

8 jobs and a single resource. The Jobs segments show the

(overlapping) scheduling of jobs in time. The Resource 1

segments show the cumulative consumption of the single

resource by the scheduled jobs. In the Relaxed schedule

the Capacity constraint relaxation refers to the temporary

increase of the resource capacity.

completed earlier, but the resource capacity is insuf-

ficient. The target project could be completed earlier

by relaxing the capacity constraint, as shown in the

relaxed schedule. This relaxation can then be inter-

340

Nedbálek, L. and Novák, A.

Bottleneck Identification in Resource-Constrained Project Scheduling via Constraint Relaxation.

DOI: 10.5220/0013253700003893

In Proceedings of the 14th International Conference on Operations Research and Enterprise Systems (ICORES 2025), pages 340-347

ISBN: 978-989-758-732-0; ISSN: 2184-4372

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

preted as, e.g., adjusting the start of a shift for a single

employee.

The above example is a particularly simple case of

the problem; in reality, activities of different projects

have complex interactions across multiple resources,

making the identification of the constraints to be re-

laxed a difficult problem. In some sense, this ap-

proach is similar to the concept of duality known in

continuous optimization (e.g., shadow prices in Lin-

ear Programming), which does not apply to discrete

optimization problems.

We develop two different methods to address the

problem. The first method adapts existing approaches

from the literature, which address the problem in

simpler scheduling models. The second method uti-

lizes relaxations that focus specifically on the target

project. To compare the methods, we present a set of

problem instances designed to model the addressed

scheduling problem, and we evaluate the two meth-

ods using the presented problem instances.

2 RELATED WORK

Following the work of Wang et al. (2016), we focus

on Execution bottleneck machines, which are bottle-

necks in a constructed schedule for a given problem

instance, i.e., not for the model of the production but

for the specific data. The identified execution bottle-

necks may vary between problem instances and their

constructed schedules. Focusing on execution bottle-

necks aims to improve performance for the specific

problem instance, i.e., case-based relaxation.

2.1 Bottlenecks in the RCPSP

To the best of our knowledge, no relevant research

focuses mainly on identifying bottlenecks in the

RCPSP. The closest research on bottlenecks can be

found for the Job-Shop problem—scheduling on unit-

capacity resources.

Luo et al. (2023) studied how identifying bottle-

neck machines can guide the scheduling process of a

genetic algorithm. In their case study, Arkhipov et al.

(2017) proposed a heuristic approach for estimating

project makespan and resource load profiles. Those

estimations are, in turn, used to identify bottleneck re-

sources. However, the identified bottleneck resources

were not addressed further.

2.2 Relaxing the Identified Bottlenecks

Lawrence et al. (1994) studied how identified bottle-

necks shift between machines in response to introduc-

ing relaxations to the original problem. They relaxed

“short-run” bottlenecks by increasing the capacity of

the identified bottleneck resources and then observed

whether the bottlenecks shifted to a different machine.

The authors observed that while such relaxations are

effective at relaxing local bottlenecks, they also in-

crease the “bottleneck shiftiness”.

In their study, R. Zhang et al. (2012) addressed

the Job-Shop problem by first relaxing its capacity

constraints, solving the modified relaxed problem and

identifying bottlenecks in its solution. The obtained

information was used to guide a proposed simulated

annealing algorithm to find a solution to the original

problem. Thus, the relaxation served only as an inter-

mediate step toward obtaining a solution, rather than

being the desired result.

2.3 Contribution

The specific contributions of this paper are:

• We extend two standard Job-Shop bottleneck

identification indicators for application to the

RCPSP. We then develop a method utilizing the

extended indicators for proposing untargeted re-

source constraint relaxations.

• We develop an approach for proposing targeted

relaxations specifically for the RCPSP extended

with time-variant resource capacities.

3 PROBLEM STATEMENT

3.1 Scheduling Model

We assume the PSm | intree |

∑

j

w

j

T

j

variant of the

RCPSP with several extensions to model the ad-

dressed problem.

We define a problem instance I as a 4-tuple

(J ,P , R ,T ), where J = {1,...,n} is the set of jobs,

P is the set of all precedences constraints, R =

{1,...,m} is the set of resources, T ∈ N is the time

horizon of the problem instance.

Each job j ∈ J has a processing duration p

j

and a

due date d

j

. A tardiness weight w

j

defines the penalty

for each time period the job is tardy, i.e., not com-

pleted before its due date. Preemption of jobs is not

allowed. The order of jobs is constrained with prece-

dence constraints i→ j or (i, j) ∈ P . We define the

precedence graph G = (J ,P ), which is assumed to be

an inforest, consisting of a set of connected in-trees.

Jobs are assigned to resources R with time-variant

renewable capacities. The capacity of a resource

k ∈ R during a time period t ∈ {1,. . .,T } is denoted

Bottleneck Identification in Resource-Constrained Project Scheduling via Constraint Relaxation

341

as R

(t)

k

. We assume the capacities of resources to

represent the availability of workers operating the re-

source. Such capacities can (to some extent) be al-

tered in correspondence to changing the number of

operating workers. For a job j, the per-period con-

sumption of a resource k is denoted as r

jk

. We as-

sume that jobs can simultaneously consume multiple

resources. The resource capacity functions R

(t)

k

are

assumed to be periodic with a period of 24. With

this, we model working shifts for the operating work-

ers (e.g., one, two, or three-shift operations).

The set of projects P = { j ∈ J | ∄i : j→i} is the

set of roots of the precedence in-trees. A job j ∈ P is

called a project. For a job j, due date d

j

∈ N

0

is given

if j ∈ P; +∞ otherwise, and tardiness weight w

j

≥ 0

is specified if j ∈ P; 0 otherwise, i.e., the tardiness

penalty and its weight is applied to the last job of each

connected component representing a single project.

3.2 Constraint Programming

Formulation

The above scheduling problem can be stated as the

following constraint programming model:

min

∑

j∈J

w

j

T

j

(1)

s.t. C

i

≤ S

j

∀i→ j ∈ P (2)

∑

j∈J

c

(t)

jk

≤ R

(t)

k

∀t ∈ {1,...,T } ∀k ∈ R (3)

where S = (S

1

,. . . ,S

n

) ∈ N

n

0

C = (S

1

+ p

1

,. . . ,S

n

+ p

n

)

T

j

= max(0,C

j

− d

j

)

c

(t)

jk

= r

jk

if S

j

≤ t < C

j

; 0 otherwise

The expression (1) is the optimization minimiza-

tion objective — the weighted tardiness of jobs.

Equation (2) formulates the precedence constraints.

and Equation (3) describes the resource capacity con-

straints — in every time period, the combined con-

sumption of jobs scheduled during the period cannot

exceed any of the resource’s capacities.

We assume we have access to a solver capable

of solving (1)–(3) in a reasonable time (i.e., to pro-

vide computer-assisted decision-making to produc-

tion planners) through the use of constraint program-

ming solvers, such as CP-SAT or IBM CP Optimizer.

3.3 Constraints Relaxation

Some constraints, such as job precedences, job du-

rations, or resource consumption, are inherent to the

problem (i.e., defining technological processes, phys-

ical constraints, etc.) and cannot be relaxed. The

available capacities of the resources can be modified

when they reflect, e.g., the number of the available

workforce at the specific stage of the production pro-

cess.

We consider resource capacity additions and

capacity migrations as the possible relaxations of

scheduling constraints (3). Capacity addition is

a 4-tuple (k,s,e, c), where over the time periods

{s,. . . ,e − 1} the capacity of the resource k is in-

creased by c. Analogously, capacity migration is a

5-tuple (k

from

,k

to

,s, e,c), where over the time peri-

ods {s,. ..,e − 1} the capacity of the resource k

from

is lowered by c and the capacity of the resource k

to

is

increased by the same amount c. For a modified in-

stance I

∗

, the sets of all migrations and additions are

denoted as M

I

∗

and A

I

∗

, respectively.

In a real-world production system, migrating ca-

pacities can be more cost-effective than adding new

capacities. For example, reassigning workers from an

underutilized machine to a bottleneck machine is typ-

ically less expensive than extending workers’ shifts

into overtime or planning an entirely new and irreg-

ular shift. Therefore, capacity migrations are usu-

ally preferred. However, if the required capacity ad-

justments cannot be achieved through capacity migra-

tions, capacity additions can be utilized.

3.4 General Procedure

The general procedure for solving the presented prob-

lem, identifying bottlenecks, relaxing corresponding

constraints, and solving the modified problem in-

stance works as follows:

1. Obtain a solution S to the problem instance I .

2. Select a target project p ∈ P for tardiness improve-

ment. We consider an improvement to be any non-

zero decrease in the project’s tardiness.

3. Identify bottlenecks in the solution S to I .

4. Relax constraints corresponding to the identified

bottlenecks. To do so, we utilize capacity migra-

tions and capacity additions, as described in Sec-

tion 3.3. Such relaxations are captured in a modi-

fied problem instance I

∗

.

5. Find solution S

∗

to I

∗

.

6. Evaluate the obtained solution S

∗

. Specifically,

how the introduced relaxations improve the tar-

diness of the target project.

ICORES 2025 - 14th International Conference on Operations Research and Enterprise Systems

342

4 SOLUTION PROCEDURE

We present two algorithms designed for identifying

and relaxing bottlenecks in the RCPSP. Both algo-

rithms aim to improve the tardiness of a selected

project by introducing relaxations to the capacity con-

straints. We divide the approaches into two groups

— untargeted and targeted relaxations depending on

whether they consider the target project when identi-

fying bottlenecks. Thus, untargeted relaxations affect

the selected project only indirectly.

4.1 Untargeted Relaxations

In this section, we propose adaptations of existing

bottleneck identification indicators from the Job-Shop

literature. Utilizing the adapted indicators, we pro-

pose the Identification Indicator-based Relaxing Al-

gorithm (IIRA) for untargeted relaxations of capacity

constraints in an obtained schedule.

4.1.1 Adapted Identification Indicators

We adapt two existing bottleneck identification indi-

cators. The Machine Utilization Rate (MUR), first

utilized as a bottleneck identification indicator by

Lawrence et al. (1994), considers the ratio of ex-

ecuted work on a resource to the total time the re-

source was used. The Average Uninterrupted Active

Duration (AUAD), initially proposed by Roser et al.

(2001), computes the average length of uninterrupted

execution periods, where an uninterrupted execution

period is a sequence of scheduled immediately con-

secutive jobs.

Both identification indicators consider the rela-

tionship between the total duration of job executions

on a resource and the duration for which the resource

is idle. In a Job-Shop scheduling problem, this rep-

resents all the available information. In the RCPSP,

however, we can utilize different resource capacities

and variable resource loads for computing more com-

plex identification indicators.

We propose Machine Resource Utilization Rate

(MRUR) as the adaptation of MUR and Average Un-

interrupted Active Utilization (AUAU) as the adapta-

tion of AUAD. For resource k, the MRUR is defined

as:

MRUR

k

def

=

∑

j∈J

(p

j

· r

jk

)

∑

C

max

t=1

R

(t)

k

,

where C

max

def

= max

j∈J

C

j

. For resource k, the AUAU

is defined as:

AUAU

k

def

=

∑

A

k

i=1

PRU

(i)

k

A

k

,

where the Period Resource Utilization (PRU) PRU

(i)

k

of resource k during the uninterrupted active period i

is defined as

PRU

(i)

k

def

=

∑

j∈J

UAP(i)

k

p

j

· r

jk

∑

a

E

k,i

t=a

S

k,i

R

(t)

k

.

For resource k ∈ R , (a

S

k,1

,a

E

k,1

),. . . ,(a

S

k,A

k

,a

E

k,A

k

) is

the sequence of uninterrupted active periods, where

a

S

k,i

∈ {1,. . . ,T − 1} denotes the start of the period i

and a

E

k,i

∈ {a

S

ki

+ 1, . . .,T } denotes the end of the pe-

riod i. An uninterrupted active period is a (maximal)

set of jobs scheduled consecutively or in parallel with

no idle time on the considered resource during the pe-

riod. In the formula for PRU

(i)

k

,

J

UAP(i)

k

def

= { j ∈ J

k

: a

S

k,i

≤ S

j

≤ a

E

k,i

}

is the set of jobs executed on resource k during the

uninterrupted active period i, where

J

k

= { j ∈ J : r

jk

> 0}.

4.1.2 Identification Indicator-Based Relaxing

Algorithm

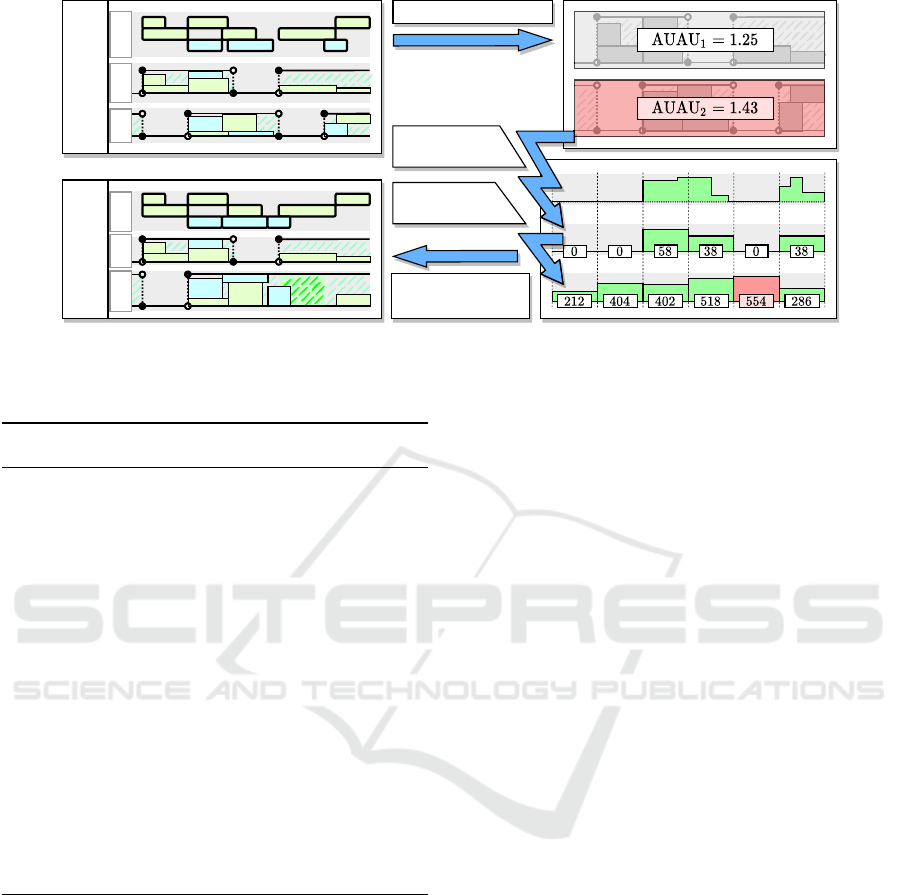

The function of Identification Indicator-based Relax-

ing Algorithm (IIRA) is illustrated in Figure 2 and is

formally described in Algorithm 1.

First, the bottleneck resource is identified us-

ing a specified bottleneck identification indicator I ∈

{AUAU, MRUR} (lines 2 and 3). The granular load

of the bottleneck resource (line 4) indicates the re-

source’s utilization over granular periods — granu-

lar periods each represent G time periods for efficient

computation. Convolution with a chosen kernel func-

tion is used to obtain the improvement potential of

granular periods (line 5) and periods with the most

improvement potential are then selected for capacity

increase, relaxing the represented capacity constraints

(lines 6 and 7). The convolution “distributes” the lo-

cal information about the machine load to adjacent

periods to estimate which periods to focus on. Fi-

nally, a new solution to the modified problem instance

is found (line 8), capacity functions are reduced to

only contain additional capacities consumed by jobs,

and migrations and additions are identified.

4.2 Targeted Relaxations

As an alternative to untargeted relaxations, in this sec-

tion, we present a method for detecting bottlenecks

and relaxing related constraints in the RCPSP which

focuses on a specified target project and its tardiness.

Bottleneck Identification in Resource-Constrained Project Scheduling via Constraint Relaxation

343

Modified Schedule

Original Schedule

Identify bottleneck resource

Convolve with

improvement kernel

function

Relax capacity

over identified

improvement period

Compute

resource load and

granular resource load

Jobs

R1

Capacity

R2

Capacity

R2

Capacity

R1

Capacity

Jobs

Figure 2: Illustration of the IIRA. Starting with the original schedule, the bottleneck resource is identified using the identifi-

cation indicator, granular resource load is computed for the resource, utilizing convolution, a specific improvement period is

chosen for capacity relaxation, and a modified schedule is obtained.

Algorithm 1: Identification Indicator-based Relaxing Algo-

rithm (IIRA).

Parameters: Identification indicator I, convolution

kernel C, granularity G, improvement periods

limit P

max

, iterations limit I

max

, capacity improve-

ment ∆.

Input: Solution S to problem instance I .

1: repeat:

2: Evaluate S

∗

using I, obtaining: I

k

∀k ∈ R

3: Identify bottleneck resource: k

′

← argmax

k

I

k

4: Compute granular resource load L

k

′

(G)

5: Period improvement potential: Ψ ← L

k

′

(G)∗ C

6: Select periods with highest Ψ(i): p

1

,. . . , p

P

max

7: Increase capacity R

′

k

′

over the periods by ∆

8: Find solution S

∗

to the modified instance I

∗

9: Reduce capacity changes in R

′

1

,. . . ,R

′

m

10: Find migrations M

I

∗

and additions A

I

∗

11: for I

max

iterations

Output: Modified instance I

∗

and its solution S

∗

,

additions A

I

∗

, migrations M

I

∗

.

The proposed Schedule Suffix Interval Relaxing Al-

gorithm is based on finding improvement intervals in

partially relaxed versions of the given problem. A

small subset of the improvement intervals is then se-

lected, and capacity constraints corresponding to the

selected improvement intervals are relaxed. The tar-

geted relaxation aims to identify relaxations specifi-

cally for the target project requiring small changes to

improve the tardiness of the project.

4.2.1 Preliminaries

To formulate Schedule Suffix Interval Relaxing Al-

gorithm (SSIRA), we state the necessary definitions

and the key ideas. First, we define the suffix-relaxed

schedule, which is a modification of an obtained

schedule where the algorithm finds improvement in-

tervals.

Definition 1 (Suffix-relaxed schedule). Let S =

(S

1

,. . . ,S

n

) be a schedule to a problem instance I .

Given a time period t ∈ {1,. . . , T }, the suffix-relaxed

schedule for the time period t is given by σ

(t)

=

(σ

(t)

1

,. . . ,σ

(t)

n

), where

σ

(t)

j

def

=

(

S

j

if S

j

≤ t;

max

n

σ

(t)

i

+ p

i

: i→ j ∈ P

o

otherwise.

The precedence graph is acyclic; thus, all values

of σ

(t)

i

are well-defined. The suffix-relaxed schedule

essentially relaxes resource capacity constraints for

all jobs that start after the time period t in the original

schedule. The main idea is to incrementally observe

how jobs that are constrained by insufficient capac-

ities and precedence constraints could be scheduled

earlier.

We define the left-shift closure as a tool for guid-

ing the search for improvement intervals towards im-

proving the tardiness of the target project. The left-

shift closure of a job j defines the set of all jobs that

need to be scheduled earlier for the job j to decrease

its completion time.

Definition 2 (Left-shift closure). Let S = (S

1

,. . . ,S

n

)

be a schedule to problem instance I . The left-shift

closure of a job j ∈ J is the set L( j) ⊆ J , where:

i) j ∈ L( j).

ii) All precedence predecessors immediately preced-

ing in the schedule are included.

iii) All jobs sharing a common resource immediately

preceding in the schedule are included.

ICORES 2025 - 14th International Conference on Operations Research and Enterprise Systems

344

iv) If j is scheduled exactly at any start of a re-

source’s availability interval, all jobs scheduled

at the end of the previous availability interval are

included. For a given resource, an availability in-

terval is a sequence of consequtive time periods

where the resource’s capacity is non-zero.

Condition i) is a trivial base case. Condition ii)

states that a immediate precedence predecessor i of

the job j (i.e., i→ j ∈ P ) is included in L( j) if the

jobs are scheduled consecutively, i.e. C

i

= S

j

. Condi-

tion iii) involves all jobs scheduled consecutively be-

fore the job j, which share at least one required re-

source. In this case, the consumption of the shared re-

source by the preceding job can be sufficiently large to

prevent the job j from being scheduled earlier. Condi-

tion iv) involves jobs at the end of the previous work-

ing shift. Assuming sufficient slack in precedence

constraints, the job j starts exactly at the start of a

working shift because it could not have been sched-

uled at the end of the previous working shift due to the

lack of remaining capacities on its required resources.

4.2.2 Schedule Suffix Interval Relaxing

Algorithm

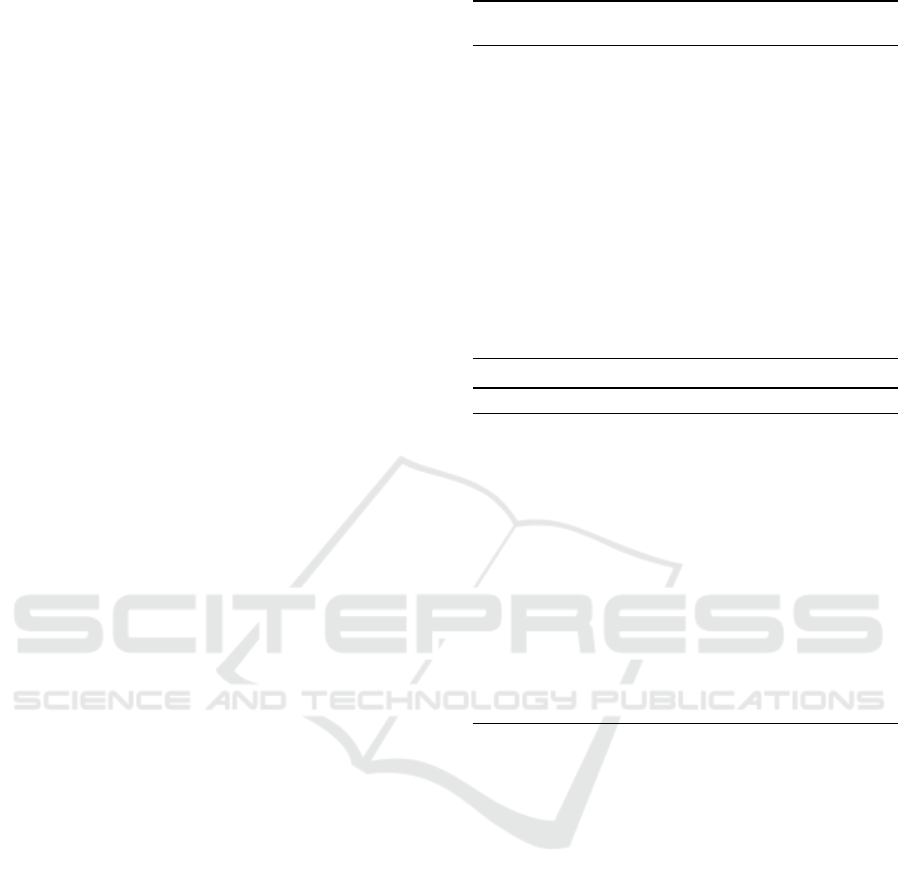

The schematic highlight of SSIRA is displayed in Fig-

ure 3 and is formally given in Algorithm 2. First,

improvement intervals are identified using the FIND-

INTERVALSTORELAX function (line 3). Resource

capacities are then relaxed based on these intervals

(line 4). Finally, as in the IIRA, a solution to the modi-

fied instance is found, capacity functions are reduced,

and migrations and additions are identified.

The FINDINTERVALSTORELAX function, de-

scribed in Algorithm 3, finds improvement intervals

in suffix-relaxed schedules and selects the best inter-

vals based on a given ordering. Suffix-relaxed sched-

ules are computed for each time period (line 1), repre-

senting all possible job-interval relaxations. The left-

shift closure of the target project is computed (line 2).

This closure represents the set of jobs considered for

improvement. For jobs within the closure, poten-

tial improvement intervals are identified (lines 3–6),

where the starting time of each interval is the earliest

relaxed starting time across all suffix-relaxed sched-

ules (line 5). Finally, a given number of intervals is

selected based on a specified sort key (line 7).

5 EXPERIMENTS

We evaluate the performance of an untargeted bottle-

neck detection method called Identification Indicator-

based Relaxing Algorithm (IIRA) and a targeted

method called Schedule Suffix Interval Relaxing Al-

Algorithm 2: Schedule Suffix Interval Relaxing Algorithm

(SSIRA).

Parameters: Iterations limit I

max

, improvement in-

tervals limit IT

max

, interval sort key K .

Input: Solution S to instance I , target project p.

1: I

∗

← I , S

∗

← S ▷ Modified instance and solution

2: repeat:

3: χ

1

,. . . ,χ

IT

max

← FINDINTERVALSTORELAX

4: Increase capacities R

∗

1

,. . . ,R

∗

m

in the intervals

5: Find solution S

∗

to the modified instance I

∗

6: Reduce capacity changes in R

∗

1

,. . . ,R

∗

m

7: Find migrations M

I

∗

and additions A

I

∗

8: for I

max

iterations

Output: Modified instance I

∗

and its solution S

∗

,

additions A

I

∗

, migrations M

I

∗

.

Algorithm 3: FindIntervalsToRelax.

Input: Problem instance I , its solution S, improve-

ment intervals limit IT

max

, interval sort key K ,

target project p.

1: Compute suffix-relaxed schedules σ

(1)

,. . . ,σ

(T )

2: Compute left-shift closure L(p)

3: X ←

/

0

4: for j ∈ L(p) :

5: s ← min

t

n

σ

(t)

j

: σ

(t)

j

< S

j

o

6: X ← X ∪

( j, s, s + p

j

)

7: Find first χ

1

,. . . ,χ

IT

max

from X ordered by K

Output: Improvement intervals χ

1

,. . . ,χ

IT

max

,

a set of 3-tuples ( j, s, e) ∈ J × {1,...,T }

2

.

gorithm (SSIRA). We first design benchmark in-

stances that model the addressed problem and choose

ranges of parameters for each algorithm, creating

evaluation parameter sets. Then, we conduct the ex-

periments, make several observations about the out-

comes, and discuss the achieved results.

5.1 Setup

We use and modify specific instances from the

PSPLIB single-mode instance set. The modifica-

tions include splitting the precedence graph to create

individual project components, introducing job due

dates, introducing time-variable resource capacities,

and scaling down job durations and resource con-

sumptions for otherwise infeasible instances. We pro-

pose eight problem instance groups, each consisting

of five individual instances of similar properties (e.g.,

precedence graph structure or project due dates).

We use the IBM CP Optimizer for finding optimal

solutions. The solver time limit for finding a single

solution was set to 10 seconds. Subsequent solving of

Bottleneck Identification in Resource-Constrained Project Scheduling via Constraint Relaxation

345

Modified Schedule

Original Schedule

Find improvement intervals in

suffix-relaxed schedules

Find improvement intervals

and select best intervals

by selected sorting order

Relax capacities during

selected improvement intervals

Selected by

time period sorting

Jobs

R1

Capacity

R2

Capacity

R2

Capacity

R1

Capacity

Jobs

Figure 3: Illustration of the SSIRA. Starting with the original schedule, improvement intervals are found in suffix-relaxed

schedules, the best improvement intervals are selected, corresponding capacities are relaxed, and a new schedule is obtained.

Table 1: Improving solutions found for the proposed prob-

lem instances. The Improved value states the number of in-

stances the algorithm found an improving solution for, the

Unique value states how many were uniquely found w.r.t.

the other algorithm, and the Best value states how many

were the best-improving solutions.

Algorithm Criteria Solutions % (of 40)

Improving 29 72.5%

72.5%

72.5%

IIRA Unique 0 0%

Best 22 55%

Improving 35 87.5%

87.5%

87.5%

SSIRA Unique 6 15%

Best 25 62.5%

modified instances utilizes solver warm-starting. The

experiments and the created instances can be found

on GitHub

1

.

For both algorithms IIRA and SSIRA, all com-

binations of parameter values are considered, form-

ing a total of 288 combinations for the IIRA and 36

combinations for the SSIRA. Algorithms are evalu-

ated with each combination of values on every prob-

lem instance.

The following metrics are computed:

• Tardiness improvement ∆T

p

def

= T

p

−T

∗

p

. This met-

ric is also meaningful for the IIRA (i.e., un-

targeted), where we measure ∆T

p

for the target

project p.

• Solution difference ∆S

def

=

∑

j∈J

C

j

−C

∗

j

.

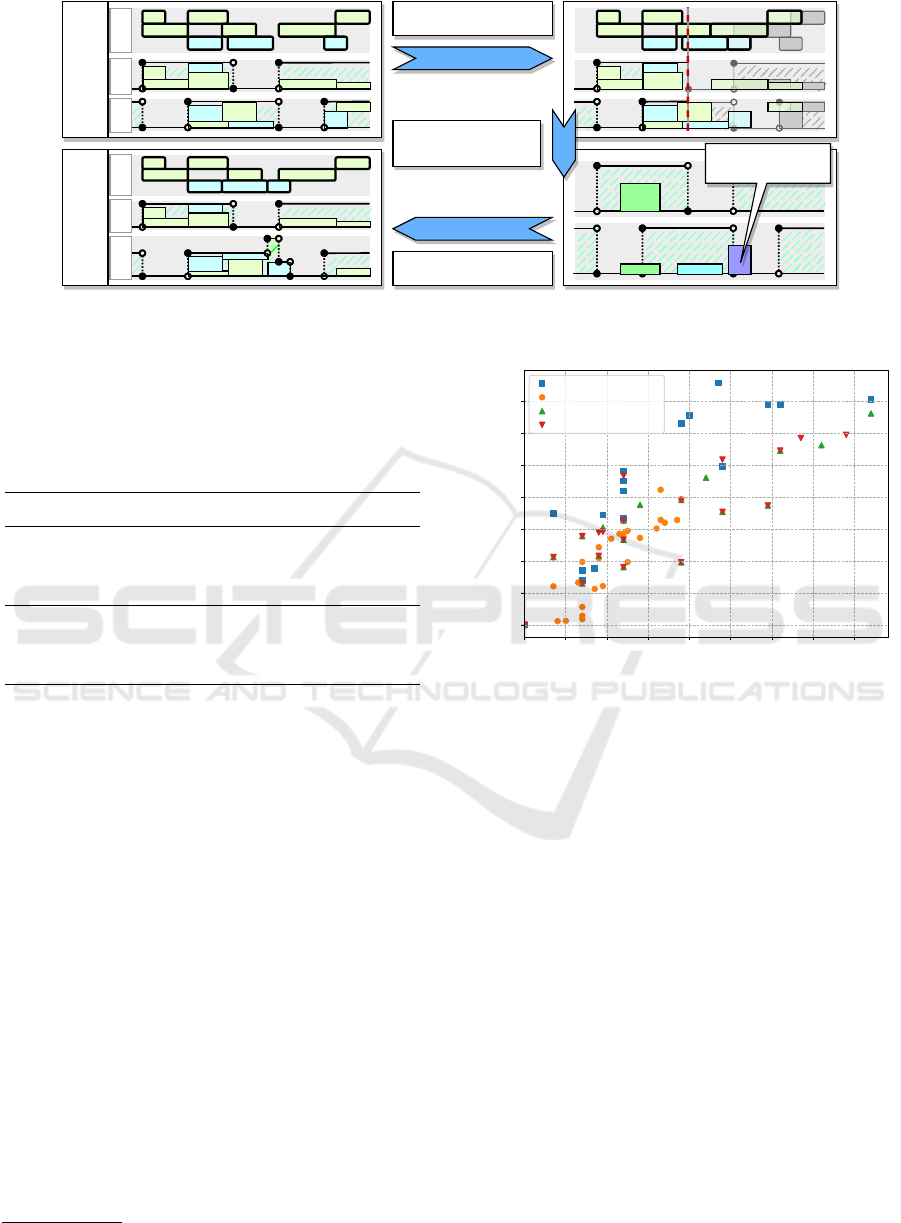

5.2 Comparative Results

Table 1 summarizes achieved improvements. The

SSIRA found improvements for more instances than

1

https://github.com/Krtiiik/RCPSPSandbox

0 10 20 30 40 50 60 70 80

Improvement ∆T

p

0

400

800

1200

1600

2000

2400

2800

Schedule difference ∆S

SSIRA (improvement sort)

SSIRA (time sort)

IIRA (AUAU)

IIRA (MRUR)

Figure 4: An example evaluation displays schedule differ-

ences versus achieved improvement. Surprisingly, the IIRA

often finds better solutions than SSIRA.

the IIRA, moreover, IIRA did not improve any in-

stance which the SSIRA would not improve.

As expected, greater tardiness improvements gen-

erally induce larger schedule differences. The SSIRA

utilizing the K

∆S

sort key tends to propose the least

favorable solutions in terms of the induced schedule

difference and is the most inconsistent in finding im-

proving solutions. The SSIRA with the K

t

sort key

finds improving solutions consistently across many

instances. However, for some instances, the IIRA

is able to find better solutions than the SSIRA. In

Figure 4, we present an example of results concern-

ing tardiness improvement related to induced sched-

ule difference showcasing the aforementioned trends.

5.3 Discussion

The SSIRA finds an improvement more often than the

IIRA. We believe this is because the SSIRA, unlike

the IIRA, utilizes targeted relaxations focusing on the

target project. However, the IIRA was still able to

ICORES 2025 - 14th International Conference on Operations Research and Enterprise Systems

346

find many improving solutions, sometimes even sur-

passing the performance of the targeted relaxations

proposed by the SSIRA. This is an unexpected result,

as the initial assumption was that targeted relaxations

would achieve better improvements than general re-

laxations. It seems to us that targeted relaxations of

the SSIRA might be too specific, not providing suffi-

cient slack in the modified constraints and thus mak-

ing the model too sensitive to minor variations when

finding solutions for the relaxed problem. In addition,

focusing only on the jobs from the left-shift closure

of the target project might be a good heuristic, but it

might be too restrictive. Another possibility is that

the SSIRA often proposes multiple relaxations simul-

taneously, incorrectly assuming their independence.

6 CONCLUSION

We addressed the problem of bottleneck identification

in production schedules as a computer-aided tool for

production planners. First, we formulated an exten-

sion of the standard RCPSP as a simplified model

of production. Then, we focused on execution-level

machine bottlenecks in obtained schedules. Follow-

ing the identification of such bottlenecks, we pro-

posed constraint relaxations for related resource ca-

pacity constraints to find a solution of better quality.

We extended two well-known Job-Shop bottle-

neck identification indicators for the RCPSP. We pro-

posed the IIRA, utilizing the extended indicators and

untargeted relaxations. We also proposed the SSIRA,

designed to utilize targeted relaxations.

We observed that the SSIRA is more consistent in

finding improving solutions than the IIRA. However,

for many instances, the IIRA is able to find great im-

provements with lower induced schedule differences

than those proposed by the SSIRA. Thus, untargeted

methods utilizing bottleneck identification indicators

appear to be promising in the RCPSP, even for a spe-

cific (targeted) project.

Future work might involve modeling the relax-

ations as an optimization problem to better capture the

complex dependencies of the considered constraints,

or further exploring the use of bottleneck identifica-

tion indicators in the RCPSP and its applications in re-

lated problems such as 3-dimensional spatial RCPSP

(J. Zhang et al., 2024).

ACKNOWLEDGEMENTS

This work was supported by the Grant Agency

of the Czech Republic under the Project GACR

22-31670S, and was co-funded by the European

Union under the project ROBOPROX (reg. no.

CZ.02.01.01/00/22 008/0004590).

REFERENCES

Arkhipov, D. I., Batta

¨

ıa, O., and Lazarev, A. A. (2017).

Long-term production planning problem: scheduling,

makespan estimation and bottleneck analysis. IFAC-

PapersOnLine, 50(1):7970–7974. 20th IFAC World

Congress.

Lawrence, S. R. and Buss, A. H. (1994). Shifting produc-

tion bottlenecks: causes, cures, and conundrums. Pro-

duction and Operations Management, 3(1):21–37.

Luo, J., Vanhoucke, M., and Coelho, J. (2023). Auto-

mated design of priority rules for resource-constrained

project scheduling problem using surrogate-assisted

genetic programming. Swarm and Evolutionary Com-

putation, 81:101339.

Roser, C., Nakano, M., and Tanaka, M. (2001). A

practical bottleneck detection method. In Proceed-

ing of the 2001 Winter Simulation Conference (Cat.

No.01CH37304), WSC-01. IEEE.

Wang, J.-Q., Chen, J., Zhang, Y., and Huang, G. Q. (2016).

Schedule-based execution bottleneck identification in

a job shop. Computers & Industrial Engineering,

98:308–322.

Zhang, J., Li, L., Demeulemeester, E., and Zhang,

H. (2024). A three-dimensional spatial resource-

constrained project scheduling problem: Model and

heuristic. European Journal of Operational Research,

319(3):943–966.

Zhang, R. and Wu, C. (2012). Bottleneck machine identifi-

cation method based on constraint transformation for

job shop scheduling with genetic algorithm. Informa-

tion Sciences, 188:236–252.

Bottleneck Identification in Resource-Constrained Project Scheduling via Constraint Relaxation

347