The 3D Printing Center for Health: Advancing Personalized

Healthcare Solutions Through Additive Manufacturing

Claudia Quaresma

1,2 a

, Ana Oliveira

2,3 b

, Carla Quintão

1,2 c

and Bruno Soares

2,3,4 d

1

LIBPhys, Laboratory for Instrumentation, Biomedical Engineering and Radiation Physics, Faculdade de Ciências e

Tecnologia, Universidade Nova de Lisboa, Caparica, Portugal

2

3D Printing Center for Health, Lisboa, Portugal

3

UNIDEMI, Department of Mechanical and Industrial Engineering, NOVA School of Science and Technology,

NOVA University of Lisbon, 2829-516, Caparica, Portugal

4

Laboratório Associado de Sistemas Inteligentes, 4800-058, Guimarães, Portugal

Keywords: 3D Printing, Customised, Healthcare, Technology, Co-Creation.

Abstract: The 3D Printing Center for Health is a non-profit association dedicated to advancing personalized healthcare

through the innovative application of 3D printing technology. By using a patient-centered, co-creation

methodology, the Center collaborates with patients, healthcare professionals, and engineers throughout the

design and development process. This approach enables the production of cost-effective, highly customized

medical devices, including prosthetics, orthotics, assistive devices, and anatomical models tailored to meet

the unique anatomical and functional needs of each patient. While partnering with hospitals and rehabilitation

centers, the Center addresses accessibility and affordability gaps often encountered in traditional healthcare,

making advanced solutions more widely available. Clinical studies have shown substantial improvements in

patient mobility and satisfaction, as well as a significant reduction in production costs due to the efficiency of

additive manufacturing. This paper provides an overview of the Center’s mission, methods, and main

achievements, highlighting its contributions to healthcare innovation and improvements in patient-specific

care through advanced 3D printing technologies. The Center’s commitment to social responsibility,

innovation, and patient-specific design is setting new standards in rehabilitative care and establishing a

foundation for future advancements in accessible, high-quality healthcare solutions.

1 INTRODUCTION

Additive Manufacturing, also known as Three-

dimensional (3D) printing technology, has been

emerging as a transformative tool in healthcare, as it

enables the production of highly customized, patient-

specific medical devices that traditional

manufacturing methods often cannot achieve (Pereira

et al., 2022; Pathak et al., 2023; Nizam et al., 2024).

3D printing applications in healthcare range from

creating prosthetic limbs and orthotic devices to

producing detailed anatomical models for surgical

planning and education. By building objects layer by

layer from digital models, 3D printing allows for

a

https://orcid.org/0000-0001-9978-261X

b

https://orcid.org/0009-0005-3145-6830

c

https://orcid.org/0000-0003-1015-4655

d

https://orcid.org/0000-0003-2737-1154

unparalleled precision and customization,

significantly enhancing the quality and accessibility

of medical solutions (Tian et al., 2021).

Despite these advancements, significant gaps

remain in the healthcare sector, especially concerning

common prosthetic and orthotic solutions. Usually,

these devices are costly and often lack

personalization, leading to discomfort and limited

functionality for patients, which results in high

rejection rates (Kumar Banga et a. 2021).

Furthermore, access to affordable, high-quality

rehabilitation tools is limited, particularly for

pediatric patients who require frequent adjustments

due to children’s development (Pathak et al., 2023).

Quaresma, C., Oliveira, A., Quintão, C. and Soares, B.

The 3D Printing Center for Health: Advancing Personalized Healthcare Solutions Through Additive Manufacturing.

DOI: 10.5220/0013262000003911

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 18th International Joint Conference on Biomedical Engineering Systems and Technologies (BIOSTEC 2025) - Volume 1, pages 197-204

ISBN: 978-989-758-731-3; ISSN: 2184-4305

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

197

To address these challenges, the 3D Printing Center

for Health association was established with the

mission of developing accessible, cost-effective, and

highly customized healthcare solutions using

advanced 3D printing techniques. This non-profit

association brings together a multidisciplinary team

of engineers, healthcare professionals, and

researchers who collaborate on the design and

implementation of tailored medical devices. By

working closely with hospitals and rehabilitation

facilities, the 3D Printing Center for Health ensures

that these innovations are implemented in real-world

sceneries, thereby directly addressing the needs of

patients who, otherwise, would have limited access to

specialized care.

This paper aims to present an overview of the 3D

Printing Center for Health, highlighting its primary

projects and the methodologies that guide its research

and applications. It presents an overview of the

Center’s mission, methodologies, and key

achievements, underscoring its role in advancing

healthcare innovation and patient-specific care

through 3D printing. Through a series of case studies,

the paper illustrates the Center’s impact on patient

care, demonstrating how 3D printing can be

leveraged to create affordable and tailored healthcare

solutions that bridge critical gaps in traditional

healthcare delivery.

2 MATERIALS AND METHODS

The 3D Printing Center for Health employs a

structured, dynamic co-creation methodology that

keeps the patient at the heart of every stage of the

development process (Clanchy et al., 2024). This

patient-centered, adaptable approach is designed to

evolve with the patient's needs over time, ensuring

continuous alignment with both individual and

clinical requirements. Multidisciplinary collaboration

among engineers, healthcare professionals,

researchers, and patients enable the development of

devices that are uniquely tailored to the needs of each

patient (Silva et al., 2024). The Center’s mission is to

establish itself as a leader in promoting health and

functional independence through innovative 3D

printing technologies. By focusing on developing

customized, accessible solutions, the Center seeks to

empower individuals with motor disabilities and

other health needs, underscoring its commitment with

the advance of patient-centered healthcare.

The Center’s work is composed of three main

projects: 3D Anatomical Printing, e-NABLE 3D

Printing Center for Health and Motion Seeker.

a) 3D Anatomical Printing

This project focuses on the construction of anatomical

models based on medical imaging data, with a

particular reliance on Computed Tomography (CT)

scans and Magnetic resonance imaging (MRI). CT

imaging provides cross-sectional data that enables the

creation of precise, three-dimensional representations

of complex anatomical structures. These structures

can then be 3D printed, whether by Fused Deposition

Modeling (FDM), using mainly Polylactic Acid

(PLA) or through Vat Photopolymerization (SLA)

using Resins. These 3D-printed models are essential

for surgical planning, allowing clinicians to visualize

and assess patient-specific anatomy in a tangible way.

In addition to surgical planning, these models are

invaluable for educational purposes, providing

trainees and medical students with realistic, patient-

specific models for hands-on learning. Moreover,

these models can be used to explain to the patients

their health problems and how the medical team is

going to approach them, therefore comforting the

patients. Overall, the detailed visualization enabled

by CT-based 3D printed models enhances the

clinicians’ ability to anticipate challenges and devise

tailored surgical approaches, ultimately improving

patient outcomes and procedural success rates.

b) e-NABLE 3D Printing Center for Health

This project is dedicated to the development of

custom prosthetic devices, which can be precisely

adapted to address the specific motor dysfunctions

and needs of each patient. Through open-source

designs from the e-NABLE organization

(https://enablingthefuture.org), the Center’s team

leverages a foundation of shared knowledge to deliver

highly individualized solutions. These prosthetics are

printed with rigid and flexible materials, usually PLA

and Thermoplastic Polyurethane (TPU), respectively.

These materials are chosen for their unique

properties. PLA, a biodegradable thermoplastic

derived from renewable resources like corn starch,

offers rigidity and stability, making it ideal for

structural components of prosthetics that require

durability and shape retention. TPU, a flexible and

elastic thermoplastic, is used where adaptability and

comfort are paramount, such as in joint areas or grip-

enhancing sections of the prosthesis.

The design process involves exploring a range of

mechanical functionalities that maximize ease of use

and patient comfort.

Through this approach, the project not only

addresses the immediate functional needs of patients

but also paves the way for next-generation prosthetic

BIODEVICES 2025 - 18th International Conference on Biomedical Electronics and Devices

198

devices that are adaptable, comfortable, and

responsive to each individual’s unique requirements.

c) Motion Seeker

The Motion Seeker project is focused on designing

and developing customized assistive devices to

enhance functional independence for patients with

physical disabilities. Each assistive device is

meticulously tailored to support specific activities,

with the goal of empowering users to completely

engage in their daily tasks and social interactions. The

design process is conducted entirely by the Motion

Seeker team, consisting of engineers, healthcare

professionals, and designers who collaborate closely

with end-users and their families to ensure that each

device meets their unique functional needs. These

solutions are tailored to assist specific activities,

ensuring practical applicability and user comfort. As

with the developed prostheses within the scope of e-

NABLE 3D Printing Center for Health, the Motion

Seeker devices are predominantly printed with PLA

and TPU. However, more complex solutions may be

printed with higher performance materials, like

Acrylonitrile Styrene Acrylate (ASA), Acrylonitrile

Butadiene Styrene (ABS) or Nylon.

Systematic Co-Creation Process

The following steps are uniformly applied across all

projects to ensure consistency in device development:

1. Identification the Requirements: This initial

phase is crucial for establishing a clear understanding

of the specific needs and functional goals of each

assistive or prosthetic device. The requirements are

identified through a structured co-creation

methodology, which, as previously described,

actively involves patients, clinicians, and caregivers

in the decision-making process. By engaging all

stakeholders from the outset, this approach ensures

that the device aligns with the user’s unique

anatomical, functional, and lifestyle needs. During

this stage, detailed discussions and assessments are

conducted to gather insights into the patient’s daily

challenges, preferred usage scenarios, and any

existing limitations with traditional devices. The co-

creation process involves gathering both qualitative

and quantitative data. Qualitative insights are

collected through interviews and questionnaires with

patients and healthcare providers, while quantitative

measurements, such as anatomical measurements,

range of motion and strength assessments, are

performed to ensure that the functional requirements

of the device are fully understood. This collaborative

step is essential for ensuring that the project is

precisely tailored to each patient and provides a

foundation for the following design and development

phases. By defining these requirements

comprehensively, the team establishes a roadmap for

the next steps. This systematic approach ensures that

each device development is highly customized,

patient-centered, and responsive to the real-world

needs of users, setting the stage for a successful

design outcome.

2. Image Processing/3D Scanning: This phase

involves capturing patient-specific anatomical data

through advanced 3D scanning techniques to ensure

the precision required for a customized fit and

functionality of the device. Using technologies such

as CT, MRI, or high-resolution optical scanning,

detailed digital representations of the patient’s

anatomy are obtained. These imaging techniques

allow for precise measurements of bone structure,

soft tissue contours, or any unique anatomical

variations that may impact device design. Once

acquired, the scanned data undergoes initial image

processing to refine and optimize the anatomical

model. This includes segmentation, where specific

areas of interest (such as bones, muscles, or joints) are

isolated and refined, ensuring that only the most

relevant anatomical details are used in the design

process. This processing step is critical for removing

noise and highlighting key structural features, which

allows for greater accuracy in subsequent modelling

stages. In some cases, multiple imaging modalities

are combined to create a comprehensive 3D model

that captures both the internal and external anatomy.

For instance, CT scans may provide detailed skeletal

structure, while MRI data can add soft tissue

information, producing a more holistic anatomical

model. This level of detail is particularly valuable for

complex cases, enabling the design of devices that

closely conform to the patient's anatomy and offer

improved comfort and functionality. The resulting 3D

model is then imported into Computer-Aided Design

(CAD) software.

• 3. Computer-Aided Design (CAD) Modelling: In

this phase, the anatomical data captured through 3D

scanning is transformed into an accurate digital model

using Computer-Aided Design (CAD) software. The

3D Printing Center for Health typically relies on

Autodesk Fusion 360 (https://www.autodesk.com) for

creating patient-specific medical devices. Fusion 360s

advanced capabilities allow the design team to

replicate anatomical contours precisely, ensuring that

the digital model reflects the unique dimensions and

The 3D Printing Center for Health: Advancing Personalized Healthcare Solutions Through Additive Manufacturing

199

structural nuances of each patient’s body. The CAD

model functions as a flexible template for

customization, enabling the design team to adjust the

device’s shape, size, and functional elements to meet

the specific needs identified during the requirements-

gathering phase. This customization includes

designing features to support movement, applying

ergonomic principles to enhance comfort, and adding

adjustable components as necessary. Fusion 360

collaborative tools further allow for real-time design

adjustments based on continuous feedback from both

patients and clinicians, ensuring that the model remains

closely aligned with clinical requirements and user

preferences. Through an iterative design process, the

digital model is refined through multiple cycles.

Feedback from clinicians addresses functional aspects,

such as stability and support, while patient input

focuses on comfort, fitting, and aesthetic preferences.

This iterative cycle enables the team to make precise

adjustments that optimize the device’s usability and

effectiveness for real-world application. Once the

CAD model is finished, it undergoes through final

validation within the software to ensure structural

integrity and compatibility with 3D printing

specifications. The validated model is then prepared

for the next phase, material selection and 3D Printing.

This CAD modelling phase is essential to achieve a

highly customized, user-centered device, as it provides

the digital framework that guides fabrication.

4. Material Selection and 3D Printing: Suitable

materials are chosen based on the device's intended

function and patient needs. The majority of materials

used in device fabrication include PLA and/or TPU,

selected for their specific properties suited to patient

needs and the intended function of each device. PLA

provides rigidity and stability, ideal for structural

components, while TPU offers flexibility, making it

suitable for areas requiring greater adaptability and

comfort. Devices are fabricated using FDM, the most

common 3D printing technology, which enables rapid

prototyping and allows for iterative adjustments

throughout the design process. This ensures each

device meets high standards of functionality and

patient comfort.

5. Prototype Testing with Healthcare

Professionals and Patients: This phase is dynamic

and iterative, centered on testing the initial prototype

with both healthcare professionals and patients to

ensure it meets all functional, clinical, and

occupational needs. The first prototype is rigorously

evaluated for fitting, comfort, and usability in real-life

applications, with extensive feedback gathered from

all participants, both from interviews and from the use

of the System Usability Scale (SUS). (Bangor,

Kortum, and Miller 2008) This feedback is

invaluable, as it allows the team to make necessary

design adjustments that better align with the unique

requirements of each patient and the clinical

expectations. If modifications are needed, the design

is refined, reprinted, and subjected to further rounds

of testing. This cycle of adjustment, reprinting, and

retesting continues as needed, enabling the team to

optimize the device until it achieves the desired

outcomes. Throughout this process, the interests of

the patient, including both clinical and occupational

aspects, remain at the core of decision-making,

ensuring that the final device not only fulfills

technical specifications but also enhances the

patient's quality of life and independence. This

collaborative testing phase is essential for balancing

clinical functionality with patient comfort, as the

active involvement of patients and clinicians ensures

that the final device is as practical and effective as

possible. The comprehensive methodology enables

the Center to produce cost-effective, high-quality

devices tailored to address specific clinical needs

while maintaining rapid adaptability to feedback and

continuous improvement. The Center’s projects

leverage a structured, dynamic co-creation

methodology, ensuring each device meets patient-

specific anatomical and functional requirements.

Through a collaborative process involving patients,

clinicians, and engineers, device requirements are

iteratively refined, with adjustments made based on

ongoing feedback and clinical testing.

By applying this methodology consistently across all

projects, the 3D Printing Center for Health ensures

the production of cost-effective, high-quality devices

that meet specific clinical and patient needs. This

systematic approach enhances the Center’s ability to

adapt designs in response to feedback, enabling

continuous improvement and alignment with real-

world requirements.

3 RESULTS

The 3D Printing Center for Health has achieved

significant impact through its three main projects,

with measurable improvements in patient care and

functionality.

a) 3D Anatomical Printing

Anatomical models created through this project have

been used in various hospitals, providing clinicians

BIODEVICES 2025 - 18th International Conference on Biomedical Electronics and Devices

200

with detailed, patient-specific visual aids for surgical

planning and training. Different anatomical

structures, including a thoracic cage model printed in

PLA (Figure 1), have been produced to support

hands-on training exercises. Feedback from medical

professionals indicates that these models enhance

precision in complex surgical procedures by

improving anatomical visualization and enabling the

medical team to practice techniques in a realistic and

controlled environment.

Figure 1: Thoracic cage model printed in PLA.

b) e-NABLE 3D Printing Center for Health

The e-NABLE 3D Printing Center for Health has

successfully developed and delivered custom

prosthetic devices specifically designed for pediatric

upper-limb applications, providing vital support for

numerous patients with motor impairments. Using

open-source models from the e-NABLE organization

as a foundation, the Center customizes each

prosthesis to address the unique anatomical and

functional needs of each child. This approach allows

for the production of prostheses that enhance comfort,

functionality, and adaptability, promoting greater

independence and confidence in daily activities.

To meet the specific requirements of different

types of amputations, the Center has developed

various prosthetic models, including transcarpal

(Figure 2), transradial (Figure 3), and transhumeral

prostheses (Figure 4).

Each type is tailored according to the level of

amputation, ensuring an optimal fit and alignment

with the patient’s remaining limb structure. This

customization process enables children to perform

tasks more effectively and comfortably, with designs

that accommodate their growth and evolving needs.

Figure 2: Prosthesis designed for a child with a transcarpal

amputation.

Figure 3: Prosthesis designed for a child with a transradial

amputation.

Figure 4: Prosthesis designed for a child with a transumeral

amputation.

The 3D Printing Center for Health: Advancing Personalized Healthcare Solutions Through Additive Manufacturing

201

By integrating a patient-centered approach and

advanced 3D printing technology, the Center is able

to offer accessible, cost-effective prosthetic solutions

that significantly improve the quality of life for

pediatric patients with upper-limb deficiencies. The

SUS results were 95, 85 and 98 respectively which

show that this approach works. Furthermore, long

term monitoring showed that all patients still use the

prosthesis, contrary to the normal rejection rates after

6 months (Resnik L., Borgia M., Biester S., Clark

M.A., 2021), even when compared with the E-Nable

standard models.

With these prostheses, children are now able to

perform tasks and gestures they had previously been

unable to accomplish.

Currently, the Center is actively engaged in

research focused on the development of myoelectric

prosthetics, aiming to create devices that offer

enhanced control and responsiveness. Ongoing

research on myoelectric prosthetics suggests

promising future applications, with potential for more

intuitive, user-friendly designs that could further

improve patient autonomy.

c) Motion Seeker

One of the key projects under the 3D Printing Center

for Health, the Motion Seeker, exemplifies the

transformative potential of 3D-printed assistive

devices. This project focuses on developing devices

that enable patients to regain independence in

performing daily tasks. Devices developed within this

framework have notably improved the ability of

patients with motor handicaps to engage in previously

challenging activities, such as playing musical

instruments or using everyday objects (Figure 5).

Figure 5: Assistive device for daily tasks.

These devices are specifically designed from the

ground up to ensure maximum functionality and

comfort, from the initial conceptualization and design

phase up to the final 3D printing process.

The Center’s approach to designing devices based

on individual anatomical specifications ensures

optimal performance across a range of tasks, thus

improving the patient's overall independence.

Feedback from both patients and caregivers has

been overwhelmingly supportive, with reports

indicating a marked improvement in the ease of use

and comfort of these devices. Since January 2022

through October 2024, the Center has developed a

total of 82 devices, representing 43 unique designs,

which have helped 78 patients across 9 services from

various hospitals. Patients and caregivers have

expressed particular, appreciation for the adaptability

of these devices, noting how seamlessly they can be

used for different tasks, further emphasizing their

effectiveness in daily life. The combination of

tailored designs and advanced manufacturing

processes has led to assistive devices that not only

meet functional requirements but also provide long-

term comfort, contributing to enhanced patient

satisfaction and overall well-being, with an overall

SUS value of 91.

The 3D Printing Center for Health has made

significant advancements in medical device

development, demonstrating measurable clinical and

economic benefits through its innovative applications

of 3D printing technology in healthcare.

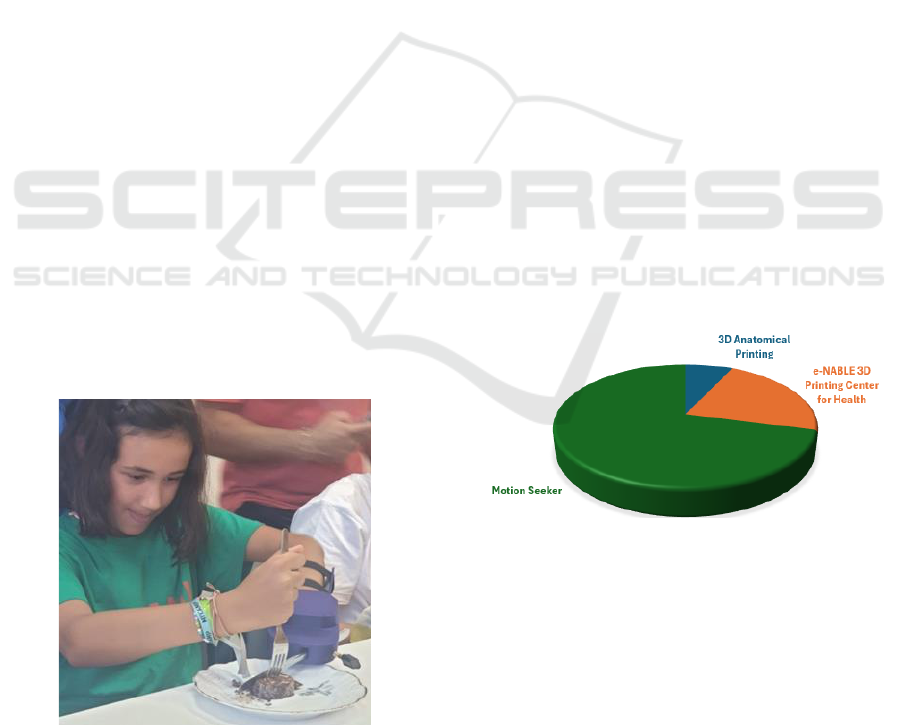

Figure 6 illustrates the distribution of project

activity within the 3D Printing Center for Health

across its three main initiatives.

Figure 6: Distribution of activity across each project.

The data indicate that most of the Center's efforts,

71%, are concentrated on the Motion Seeker project,

which focuses on developing customized assistive

devices aimed at improving functional independence

for patients with physical disabilities. The e-NABLE

3D Printing Center for Health project, dedicated to

creating personalized prosthetics primarily for

pediatric patients, represents 22% of the Center’s

work. Finally, 3D Anatomical Printing, which

involves creating detailed anatomical models for

surgical planning and educational purposes, accounts

BIODEVICES 2025 - 18th International Conference on Biomedical Electronics and Devices

202

for 7% of the Center’s activities. This distribution

reflects the Center’s strategic emphasis on assistive

devices for enhancing patient autonomy, followed by

efforts in prosthetics and anatomical modelling.

Among the Center’s most notable achievements,

clinical studies indicate a remarkable 90%

improvement in patient mobility among users of 3D-

printed rehabilitation devices. This improvement has

been attributed to the highly customized designs,

which align closely with individual anatomical and

functional needs compared to standard devices

available on the market. Additionally, the Center's

use of Additive Manufacturing has led to a 30%

reduction in production costs, an achievement that

greatly enhances the affordability and accessibility of

essential rehabilitation solutions.

The impact on patients has been equally profound,

with user testimonials reflecting a 95% satisfaction

rate. Patients consistently report enhanced comfort

and functionality, emphasizing how these devices are

helpful in their daily activities. For many users, these

assistive devices and prostheses have enabled them to

perform tasks and gestures that were previously

unachievable, underscoring the Center’s success in

addressing both physical and psychological needs.

The patient-centered approach, focusing on the

customization and refinement of 3D-printed devices,

has proven to be highly effective, reinforcing the 3D

Printing Center for Health’s role as a leader in

advancing patient care through innovative,

accessible, and responsive healthcare technologies.

4 CONCLUSIONS

The 3D Printing Center for Health has effectively

demonstrated the transformative potential of additive

manufacturing in healthcare through the creation of

customized, functional, and accessible assistive

devices. By employing a patient-centered design

approach and leveraging advanced 3D printing

technologies, the Center has elevated both the quality

and adaptability of medical devices, aligning them

closely with the specific clinical and occupational

needs of diverse users. Furthermore, the Center

addresses critical gaps in traditional healthcare,

particularly for underserved communities, by creating

high-quality, customized, and affordable devices that

enhance users' quality of life and promote social

inclusion. Future initiatives include expanding

research into myoelectric devices with

electromyographic control for real-time

responsiveness and exploring biocompatible smart

materials to enhance adaptability and durability.

Through this commitment to innovation and patient-

centered design, the 3D Printing Center for Health is

setting a new standard in rehabilitative care,

advancing healthcare technology, and promoting

equity across patient populations. Future initiatives

include developing myoelectric devices and

exploring biocompatible materials to enhance

adaptability and durability. Through this commitment

to innovation and accessibility, the Center sets a new

standard in rehabilitative care.

Additionally, the 3D Printing Center for Health

ensures the performance and safety of all devices by

adhering to local and international regulatory

requirements for medical devices. Each device

undergoes rigorous testing for structural integrity,

functionality, and safety before being approved for

clinical use. The Center collaborates with healthcare

institutions to guarantee compliance with applicable

legal frameworks. Additionally, a thorough risk

management process is implemented to identify and

address potential hazards throughout the

development cycle. This approach ensures that all

devices meet high standards of safety, reliability, and

efficacy, reinforcing the Center’s commitment to

advancing patient-centered healthcare solutions.

ACKNOWLEDGEMENTS

The authors acknowledge funding from Fundacão

para a Ciência e Tecnologia (FCT-MCTES) for its

financial support through the UNIDEMI projects

UIDB/00667/2020 and UIDP/00667/2020. dditional

support was provided by national funds from I.P.

through the DOI: 10.54499/UIDB/04559/2020

(LIBPhys-UNL).

REFERENCES

Bangor, Aaron Kortum, Philip T. Miller, James T., (2008)

An empirical evaluation of the system usability scale,

International Journal of Human-Computer Interaction,

6, 574-594

Clanchy K, Mitchell J, Mulholland K, Jurd E, Kendall E,

Lloyd DG, Palipana D, Pizzolato C and Shirota C

(2024) Towards co-design of rehabilitation

technologies: a collaborative approach to prioritize

usability issues. Front. Rehabil. Sci. 5:1302179. doi:

10.3389/fresc.2024.1302179

Kumar Banga, H., Kalra, P., M. Belokar, R., & Kumar, R.

(2021). Design and Fabrication of Prosthetic and

Orthotic Product by 3D Printing. IntechOpen. doi:

10.5772/intechopen.94846

The 3D Printing Center for Health: Advancing Personalized Healthcare Solutions Through Additive Manufacturing

203

Nizam, M., Purohit, R., & Taufik, M. (2024). 3D printing

in healthcare: A review on drug printing, challenges,

and future perspectives. Additive Manufacturing, 40,

110199.

Pathak K, Saikia R, Das A, Das D, Islam MA, Pramanik P,

Parasar A, Borthakur P, Sarmh P, Saikia M, Borthakur

B. (2023). 3D printing in biomedicine: advancing

personalized care through additive manufacturing.

Explor Med, 4:1135–67.

Pereira HR, Barzegar M, Hamadelseed O, Esteve AV,

Munuera J. (2022). 3D surgical planning of pediatric

tumors: a review. Int J Comput Assist Radiol Surg.

2022;17(4):805–16.

Resnik L., Borgia M., Biester S., Clark M. A., A

Longitudinal study of prosthesis use in veterans with

upper limb amputation (2021) Prosthetics and Orthotics

International, 45 (1), pp. 26 - 35

Silva J, Silva M, Soares B, Quintão C, Londral AR,

Quaresma C. Multi-activity 3D printed assistive

technology in children: a case study. Assist Technol.

2024;00(00):1–6.

Tian, Y., Chen, C. X., Xu, X., Wang, J., Hou, X., Li, K.,

Lu, X., Shi, H., Lee, E. S., & Jiang, H. B. (2021). A

review of 3D printing in dentistry: technologies,

affecting factors, and applications. Scanning, 2021,

Article ID 9950131.

BIODEVICES 2025 - 18th International Conference on Biomedical Electronics and Devices

204