Class-Specific Dataset Splitting for YOLOv8: Improving Real-Time

Performance in NVIDIA Jetson Nano for Faster Autonomous Forklifts

Chaouki Tadjine

1,2 a

, Abdelkrim Ouafi

2 b

, Abdelmalik Taleb-Ahmed

1 c

and Yassin El Hillali

1 d

1

Univ. Polytechnique Hauts-de-France, CNRS, Univ. Lille, UMR 8520 - IEMN - Institut d’Electronique de

Microelectronique et de Nanotechnologie, Valenciennes, F-59313, Hauts-de-France, France

2

Univ. Mohamed Khider Biskra, Department of Electrical Engineering, Faculty of Sciences and Technology, LVSC - Lab.

Vision et Syst

`

emes de Communication, 07000, Biskra, Algeria

fi

Keywords:

YOLOv8, LOCO Dataset, Object Detection, Autonomous Forklifts, Real-Time Inference, NVIDIA Jetson

Nano.

Abstract:

This research examines a class-specific YOLOv8 model setup for real-time object detection using the Logistics

Objects in Context dataset, specifically looking at how it can be used in high-speed autonomous forklifts to

enhance obstacle detection. The dataset contains five common object classes in logistics warehouses. It is

divided into transporting tools (forklift and pallet truck) and goods-carrying tools (pallet, small load carrier,

and stillage) to meet specific task needs. Two YOLOv8 models were individually trained and implemented

on the NVIDIA Jetson Nano, with each one specifically optimized for a tool category. Using this approach

tailored to specific classes resulted in a 30.6 percent decrease in inference time compared to training a single

YOLOv8 model on all classes. Task-specific detection saw a 74.4 percent improvement in inference time

for transporting tools and 56.2 percent improvement for goods-carrying tools. Furthermore, the technique

decreased the hypothetical distance traveled during inference from 45.14 cm to 31.32 cm and even as low as

11.55 cm for transporting tools detecting while still preserving detection accuracy with a minor drop of 1.25%

in mean average precision. The integration of these models onto the NVIDIA Jetson Nano made this approach

compatible for future autonomous forklifts and showcases the potential of the technique to improve industrial

automation. This study demonstrates a useful and effective method for real-time object detection in intricate

warehouse settings by matching detection tasks with practical needs.

1 INTRODUCTION

The technology of object detection is crucial for au-

tomating logistics warehouses, allowing self-driving

forklifts to move through intricate surroundings, mon-

itor products, and dodge obstacles instantly (Zaccaria

et al., 2020). Quick and precise object detection

is crucial for keeping operations efficient, avoiding

accidents, and ensuring smooth processes, particu-

larly when forklifts are moving at increased veloci-

ties. The Logistic Objects in Context (LOCO) dataset,

created for logistics object detection tasks, consists of

five equipments in warehouse settings: forklift, pal-

let truck, pallet, small load carrier (SLC), and stillage

(Mayershofer et al., 2020). The dataset has unbal-

a

https://orcid.org/0009-0000-6110-9956

b

https://orcid.org/0000-0002-6083-1688

c

https://orcid.org/0000-0001-7218-3799

d

https://orcid.org/0000-0002-3980-9902

anced annotations, whereas the premilinary annota-

tions are demonstrated in Figure 1.

Figure 1: LOCO dataset annotations.

788

Tadjine, C., Ouafi, A., Taleb-Ahmed, A. and El Hillali, Y.

Class-Specific Dataset Splitting for YOLOv8: Improving Real-Time Performance in NVIDIA Jetson Nano for Faster Autonomous Forklifts.

DOI: 10.5220/0013308700003905

In Proceedings of the 14th International Conference on Pattern Recognition Applications and Methods (ICPRAM 2025), pages 788-793

ISBN: 978-989-758-730-6; ISSN: 2184-4313

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

In the state-of-the-art works related to the LOCO

dataset (Savas and Hinckeldeyn, 2022; Khalfallah

et al., 2024; Clavero et al., 2024), they train an ob-

ject detection model to detect all five object classes at

once, which is not the optimal and efficient choice to

use in for every specific warehouse task. For instance,

it is crucial to identify equipment such as pallets,

small load carriers, and stillages used for transporting

goods in picking operations that prioritize identify-

ing items for shipping. Identifying moving equipment

like forklifts and pallet trucks is essential for safely

navigating and avoiding obstacles in warehouse ac-

tivities.

In order to meet these specific requirements, we

suggest categorizing the objects based on their us-

age: either for transporting (forklift and pallet truck)

or carrying goods (pallet, small load carrier, and stil-

lage). This categorization helps in focusing on object

detection by aligning it with task requirements, which

may reduce computational burden.

Our approach utilizes this categorization by cre-

ating individual YOLOv8 models for each category,

enabling detection specific to the task. The effective-

ness of this approach was assessed in improving in-

ference efficiency and preserving detection accuracy.

By utilizing the trained models on the NVIDIA Jetson

Nano, we assessed how well they can achieve quicker

inference times while maintaining the necessary prac-

ticality for autonomous forklift operations within dy-

namic warehouse settings.

Lightweight models like YOLOv8n are ideal for

edge devices like the NVIDIA Jetson Nano to attain

real-time performance due to their blend of speed and

accuracy (Asdikian et al., 2024). In this research, we

taught YOLOv8n models using the class-specific par-

tition of the LOCO dataset and assessed their results

in relation to real-time object tracking and obstacle

evasion. The focus on the Jetson Nano was on achiev-

ing fast inference time and high accuracy, essential

for high-speed forklifts. Quicker inference times are

important because they enable vehicles to react faster

to obstacles, enhancing safety and efficiency in logis-

tic operations. By looking into the prototyping works

for forklift automation (Mohamed et al., 2018; Behrje

et al., 2018; Cidal et al., 2019; Zaccaria et al., 2021),

the only forklift that has publicly available top speed

is Jungheinrich EVT 216, whereas this forklift has

maximum speeds of 11 km/h, which is around 3.055

m/s. Therefore, we considered it as reference speed

in our evaluations.

2 METHODOLOGY

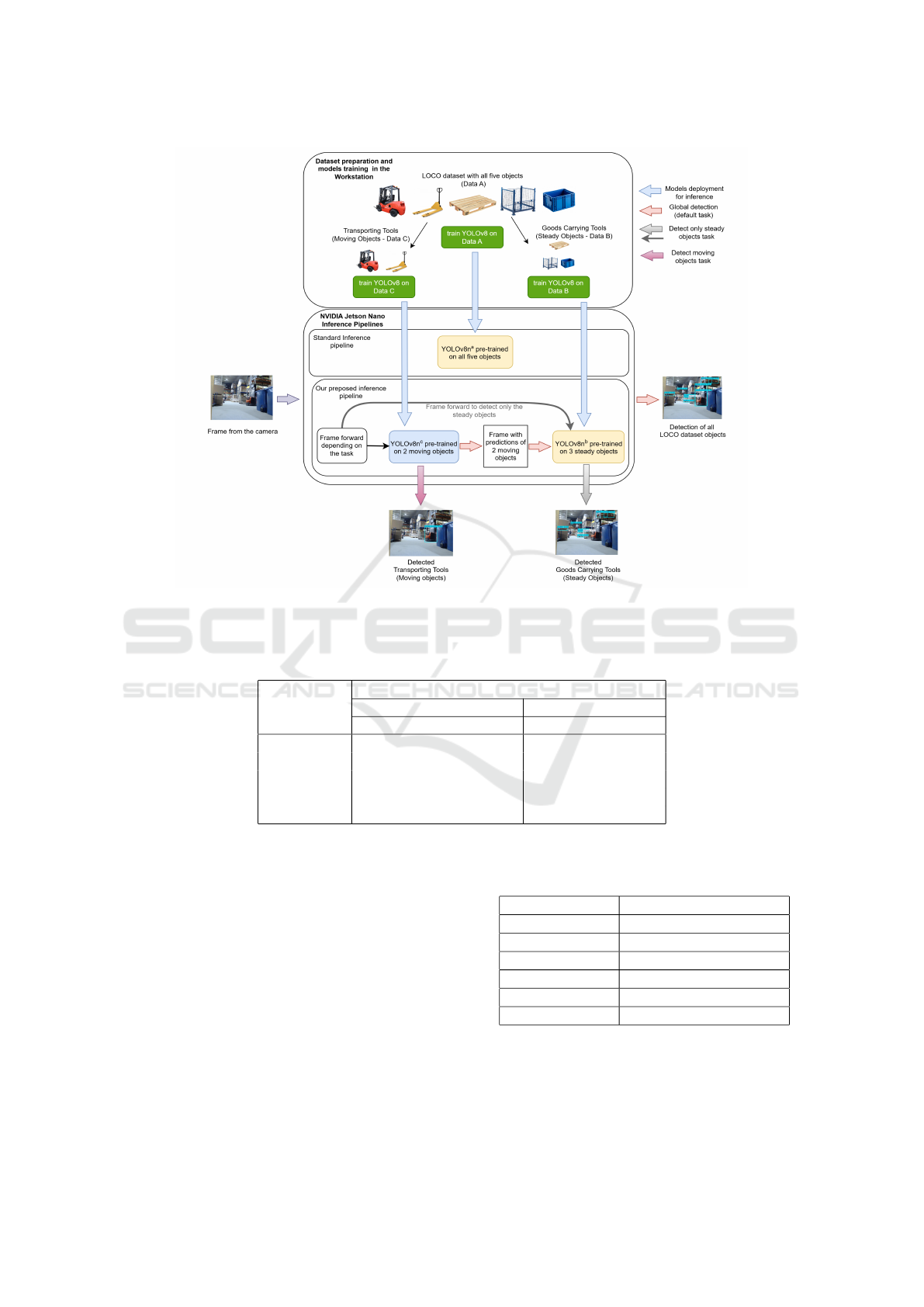

The proposed method in our approach is to sepa-

rate the dataset objects leading to train two fine-tuned

YOLOv8 models, whereas they can be used depend-

ing on the requested task, however they can be com-

bined to work same as single model trained for all the

dataset at once. The figure 2 summarizes the func-

tionality of the proposed method.

2.1 Dataset Preparation

The LOCO dataset has five classes with unbalanced

annotations, it was split into 60% for training, 25% for

validation, and 15% for testing. Due the unbalanced

nature of the dataset, the splitting was an annotation-

based split, ensuring that each class was proportion-

ally represented in the training, validation, and testing

sets. This approach preserves the class distribution

across all phases of model development.

From this annotated split, we divided the dataset

by isolating the annotations of forklifs and pallet

trucks (transporting tools) to train it in one model.

The remaining three classes (goods carrier tools) were

used to train a second model. This approach en-

sured that we maintained the same annotations for

each class across all models, which was crucial for

conducting a fair comparison between the combined

and split model approaches. Table 1 represents the

data fed into the models.

2.2 Model Settings

We chose YOLOv8n for our tests because of its com-

pact design, which makes it ideal for running on the

limited resources of the Jetson Nano. YOLOv8n nor-

mally uses a 640x640 input image resolution, find-

ing a middle ground between detection precision and

computational speed.

Initially, we trained YOLOv8n on the complete

dataset with a standard resolution of 640x640 for all

five classes in our evaluation. We fine-tuned the class-

specific split models by adjusting the resolution ac-

cording to the class distribution. The model trained on

the two-class subset (tools for transporting) utilized

a smaller image size of 256x256, while the model

trained on the three-class subset (tools for carrying

goods) used a larger resolution of 384x384. This

method guaranteed that the total resolution of both di-

vided models was 640x640, ensuring a fair compari-

son in total resolution.

Class-Specific Dataset Splitting for YOLOv8: Improving Real-Time Performance in NVIDIA Jetson Nano for Faster Autonomous Forklifts

789

Figure 2: Proposed class-specific dataset splitting method on YOLOv8 for LOCO dataset.

Table 1: The used data for training, validation, and testing for YOLOv8n evaluation. YOLOv8n

a

is trained on data A.

YOLOv8n

b

is trained on data B, and YOLOv8n

c

is trained on data C. Data A is a combination of DATA B and C that contains

all classes.

Class

Data A

Data B Data C

Train Val Test Train Val Test

SLC 13303 5532 3316 – – –

Forklift – – – 353 153 92

Pallet 72306 30097 18042 – – –

Stillage 3247 1351 809 – – –

Pallet Truck – – – 1695 708 474

(–): No annotations for this class in the subset.

2.3 Experimental Setup

For model training, we utilized a workstation

equipped with a powerful GPU to ensure efficient

processing and faster training times for the YOLOv8

models. The specifications of the workstation are in

Table 2.

After the models training, we moved them to the

Jetson Nano for validation. We utilized the desig-

nated ultralytics docker container for the Jetson Nano

(Jocher et al., 2023). This method is required since

the Jetson Nano officially operates on Ubuntu 18.04,

which includes an incompatible Python version for

the YOLOv8 setup. The Docker container has Python

Table 2: Workstation Specifications for Model Training.

Component Specification

CPU Intel Core i7-12700K

Memory 64GB DDR5 6000 MHz

GPU NVIDIA RTX 3090

Python version 3.8.19

PyTorch version 2.0.1

CUDA version 11.7

3.8.0 and CUDA 10.2, as well as PyTorch 1.11.0, to

guarantee compatibility and efficient execution of the

YOLOv8 models. Table 3 displays the Jetson Nano

specifications.

ICPRAM 2025 - 14th International Conference on Pattern Recognition Applications and Methods

790

Table 3: NVIDIA Jetson Nano 4GB Specifications.

Component Specification

GPU Tegra X1 (128-core Maxwell)

CPU Quad-core ARM Cortex-A57

Memory 4GB LPDDR4

Storage 32GB

Python Version 3.8 via docker

PyTorch Version 1.11.0

CUDA version 10.2

During validation, we set the batch size to one to

emulate the performance of frame-by-frame real-time

video processing. This configuration allows us to as-

sess how effectively the models can detect in a contin-

uous video stream, simulating real-world conditions

that autonomous forklifts would encounter in logistics

environments. Furthermore, we evaluated the model’s

efficiency for rapid forklift operations by calculating

the distance covered in each frame prediction.

In model assessment, we used Precision (P), Re-

call (R), and Mean Average Precision (mAP) as the

main metric, which are commonly used for com-

paring object detection models. These metrics of-

fer a thorough evaluation of precision among various

classes and aid in evaluating the efficiency of models

in identifying different objects in the logistics setting.

3 RESULTS AND DISCUSSION

We trained YOLOv8n in three settings and named our

pretrained models as YOLOv8n

a

, YOLOv8n

b

, and

YOLOv8n

c

. YOLOv8n

a

is the model that was trained

for all the objects in dataset. YOLOv8n

b

is trained on

goods-carrying objects. YOLOv8n

c

is model trained

on transporting tools. Table 4 showcases the accu-

racies and inference times obtained in the NVIDIA

Jetson Nano.

3.1 Detection Accuracy Comparison

The YOLOv8n

b

and YOLOv8n

c

Outperformed

YOLOv8n

a

when evaluated with precision, which

means the detections has less confusion over

YOLOv8n

a

. YOLOv8n

c

reached higher accuracy for

forklift detection in all evaluation matrices and out-

performed the YOLOv8n

a

on this class. However,

the other objects showed slightly lower mAP@50 and

recall results when using YOLOv8n

c

or YOLOv8n

b

compared to YOLOv8n

a

. Specifically, the accuracy

loss across classes ranged between approximately 1%

to 5% per class in mAP. Despite the modest accu-

racy losses in detecting other objects, our method

demonstrated enhanced detection performance for

high-resolution (1080p) for forklift detection us-

ing YOLOv8n

c

compared to YOLOv8n

a

as demon-

strated in figure 3. Nevertheless, the YOLOv8n

b

and

YOLOv8n

c

models showed lower performance when

480p resolution footage was employed, resulting in

more objects being missed compared to YOLOv8n

a

.

The reduced accuracy in YOLOv8n

b

and YOLOv8n

c

models is due to the smaller image sizes (256 and

384), leading to decreased detection reliability for ob-

jects at lower resolutions and far distances. Figure

4 displays the findings from detecting images with a

480p resolution.

3.2 Inference Time Comparison

YOLOv8n

b

demonstrated a noteworthy enhancement

with an inference time of 64.7 ms, which is a sig-

nificant improvement of approximately 56.2% com-

pared to YOLOv8n

a

with 147.7 ms. Specifically, the

time it takes to detect specialized forklifts and pallet

trucks using the YOLOv8n

c

model has been reduced

by 74.4%, now taking only 37.8 ms, showing a sig-

nificant increase in efficiency with customized mod-

els that have smaller image sizes. The data in table 5

displayed the overall time taken for inference by two

models compared to a model trained on 5 classes.

3.3 Inference Impact over High-Speed

Forklift

The combined inference time for YOLOv8n

b

and

YOLOv8n

c

models, trained on 3 and 2 classes respec-

tively, was significantly faster than the inference time

of YOLOv8n

a

, which was trained on all 5 classes.

Together, YOLOv8n

b

and YOLOv8n

c

have an infer-

ence time of 102.5 ms (64.7 ms for YOLOv8n

b

and

37.8 ms for YOLOv8n

c

), compared to 147.7 ms for

YOLOv8n

a

. This leads to a 30.6% improvement in

inference time, demonstrating that dividing the detec-

tion task among specialized models with lower reso-

lution can efficiently decrease processing time. This

increase in efficiency is particularly advantageous for

real-time tasks, as quicker detection can enhance the

responsiveness of autonomous systems, like forklifts

in warehouses with varying speeds.

The inference time of each YOLOv8 model used

in a forklift moving at 11 km/h (around 305.56 cm/s)

directly affects how frequently the system can iden-

tify and respond to obstacles. As an illustration,

YOLOv8n

b

takes 64.7 ms for inference, allowing

the forklift to move 19.77 cm in each inference cy-

cle. This enhances the forklift’s ability to detect ob-

jects effectively while moving. YOLOv8n

c

allows

the forklift to move 11.55 cm in one inference, de-

Class-Specific Dataset Splitting for YOLOv8: Improving Real-Time Performance in NVIDIA Jetson Nano for Faster Autonomous Forklifts

791

Table 4: Performance results for YOLOv8n

a

, YOLOv8n

b

, and YOLOv8n

c

across evaluation metrics (Precision, Recall, and

mAP50) with their inference times on NVIDIA Jetson Nano.

Class

YOLOv8n

a

YOLOv8n

b

YOLOv8n

c

Precision Recall mAP50 Precision Recall mAP50 Precision Recall mAP50

SLC 0.749 0.424 0.579 0.771 0.307 0.541 – – –

Forklift 0.854 0.497 0.685 – – – 0.887 0.562 0.725

Pallet 0.872 0.449 0.663 0.887 0.332 0.613 – – –

Stillage 0.881 0.508 0.711 0.900 0.442 0.685 – – –

Pallet Truck 0.820 0.503 0.666 – – – 0.837 0.442 0.643

Inference (ms) 147.7 64.7 37.8

Image size 640 384 256

(-): Model not trained for this class.

(a) YOLOv8n

a

(b) YOLOv8n

b

(c) YOLOv8n

c

Figure 3: Comparative detection results for 1080p image. YOLOv8n

c

gave best performance to detect pallet trucks.

(a) Detection result for YOLOv8n

a

(b) Detection result for YOLOv8n

b

(c) Detection result for YOLOv8n

c

Figure 4: Comparative detection results for 480p image. YOLOv8n

a

detected a pallet truck as a forklift.

Table 5: Combined models performance over single model.

Model Precision Recall mAP50 mAP50-95 Inference (ms)

YOLOv8n

a

0.8350 0.476 0.661 0.397 147.7

YOLOv8n

b+c

(ours) 0.8575 0.431 0.6485 0.392 102.5

creasing inference time to 37.8 ms giving faster up-

dates. This particular frequency is very beneficial

for quickly detecting nearby objects, minimizing the

chances of missing obstacles.

When YOLOv8n

b

and YOLOv8n

c

are combined,

their cumulative inference time of 102.5 ms leads to a

distance of 31.32 cm per inference cycle. Although

this is slower than YOLOv8n

c

alone, it remains a

substantial improvement over the YOLOv8n

a

model,

trained on all five classes, which has an inference time

of 147.7 ms and results in a distance of 45.14 cm per

inference. The increased time interval between frame

updates in YOLOv8n

a

may reduce the accuracy of ob-

stacle detection, as the forklift may travel a consider-

able distance before the next frame is analyzed by the

model. In fast-paced environments, this delay could

heighten the chance of quickly appearing obstacles.

Table 6 illustrates the distance covered during each

inference with a forklift moving at a speed of 11km/h.

ICPRAM 2025 - 14th International Conference on Pattern Recognition Applications and Methods

792

Table 6: Theoretical distance per inference for Forklift with

speed of 11km/h.

Model mAP50 Inference (ms) Distance (cm)

YOLOv8n

a

0.661 147.7 45.14

YOLOv8n

b+c

(ours) 0.6485 102.5 31.32

YOLOv8n

b

(ours) 0.613 64.7 19.77

YOLOv8n

c

(ours) 0.684 37.8 11.55

4 CONCLUSIONS

This research findings confirmed that training the

YOLOv8 model with a class-specific dataset split

from the LOCO dataset greatly improved inference

efficiency, resulting in a 30.6% decrease in overall in-

ference time. Significantly, there were even more im-

provements in targeted detection tasks, with inference

times decreasing by 74.4% for transporting tools and

56.2% for carrying tools. When applied to a forklift

moving at a top speed of 11 km/h, this method re-

duced the distance covered per inference round from

45.14 cm to 31.32 cm, resulting in a minimum travel

distance of 11.55 cm when identifying transporting

equipment. Hence, these improvements were made

with only a 1.25% decrease in mAP, ensuring ade-

quate accuracy for real-world use.

In addition, the research discovered that decreas-

ing the image size setting in YOLOv8 resulted in a

notable decrease in inference times, which enhanced

its efficiency in real-time object detection. Yet, the

decrease in resolution led to failures in detection, es-

pecially for smaller objects. The results show that de-

creasing image size is most advantageous for datasets

with bigger object annotations, while the accuracy of

detection remains mostly unchanged. Hence, it is ad-

vised to utilize this technique in situations with high-

resolution photos and bigger objects to strike a perfect

equilibrium between speed of inference and perfor-

mance of detection.

ACKNOWLEDGEMENTS

We acknowledge the use of ChatGPT4o to enhance

the readability of our paper.

REFERENCES

Asdikian, J. P. H., Li, M., and Maier, G. (2024). Per-

formance evaluation of YOLOv8 and YOLOv9 on

custom dataset with color space augmentation for

Real-time Wildlife detection at the Edge. In 2024

IEEE 10th International Conference on Network Soft-

warization (NetSoft), pages 55–60. ISSN: 2693-9789.

Behrje, U., Himstedt, M., and Maehle, E. (2018). An Au-

tonomous Forklift with 3D Time-of-Flight Camera-

Based Localization and Navigation. In 2018 15th

International Conference on Control, Automation,

Robotics and Vision (ICARCV), pages 1739–1746.

Cidal, G. M., Cimbek, Y. A., Karahan, G., B

¨

oler, O. E.,

¨

Ozkardesler, O., and

¨

Uvet, H. (2019). A Study

on the Development of Semi Automated Warehouse

Stock Counting System. In 2019 6th International

Conference on Electrical and Electronics Engineering

(ICEEE), pages 323–326.

Clavero, C., Patricio, M. A., Garc

´

ıa, J., and Molina, J. M.

(2024). DMZoomNet: Improving Object Detection

Using Distance Information in Intralogistics Environ-

ments. IEEE Transactions on Industrial Informatics,

20(7):9163–9171. Conference Name: IEEE Transac-

tions on Industrial Informatics.

Jocher, G., Qiu, J., and Chaurasia, A. (2023). Yolov8 by

ultralytics. original-date: 2022-09-11T16:39:45Z.

Khalfallah, S., Bouallegue, M., and Bouallegue, K. (2024).

Object detection for autonomous logistics: A yolov4

tiny approach with ros integration and loco dataset

evaluation. Engineering Proceedings, 67(1).

Mayershofer, C., Holm, D.-M., Molter, B., and Fottner,

J. (2020). LOCO: Logistics Objects in Context. In

2020 19th IEEE International Conference on Machine

Learning and Applications (ICMLA), pages 612–617.

Mohamed, I. S., Capitanelli, A., Mastrogiovanni, F.,

Rovetta, S., and Zaccaria, R. (2018). Detection, local-

isation and tracking of pallets using machine learning

techniques and 2D range data.

Savas, R. and Hinckeldeyn, J. (2022). Critical Eval-

uation of LOCO dataset with Machine Learning.

arXiv:2209.13499 [cs].

Zaccaria, M., Giorgini, M., Monica, R., and Aleotti, J.

(2021). Multi-Robot Multiple Camera People Detec-

tion and Tracking in Automated Warehouses. In 2021

IEEE 19th International Conference on Industrial In-

formatics (INDIN), pages 1–6.

Zaccaria, M., Monica, R., and Aleotti, J. (2020). A Com-

parison of Deep Learning Models for Pallet Detection

in Industrial Warehouses. In 2020 IEEE 16th Interna-

tional Conference on Intelligent Computer Communi-

cation and Processing (ICCP), pages 417–422.

Class-Specific Dataset Splitting for YOLOv8: Improving Real-Time Performance in NVIDIA Jetson Nano for Faster Autonomous Forklifts

793