ScaleVis: Interactive Exploration of Measurement Instrument

Verification Data

Haris Memi

´

c

1

, Sanjin Radoš

2 a

, Almira Softi

´

c

3 b

and Krešimir Matkovi

´

c

4 c

1

Institute of Metrology of Bosnia and Herzegovina, Sarajevo, Bosnia and Herzegovina

2

Austrian Federal Computing Center, Vienna, Austria

3

University of Sarajevo, Faculty of Mechanical Engineering, Sarajevo, Bosnia and Herzegovina

4

VRVis Research Center, Vienna, Austria

Keywords:

Interactive Visual Exploration, CMV, Non-Automatic Weighing Instrument Verification Data.

Abstract:

Legal metrology ensures consumer protection from inaccurate measurements by regulating numerous instru-

ments, some under EU harmonized legislation and others governed by national decisions based on the In-

ternational Organization for Legal Metrology (OIML) recommendations. Verification laboratories produce

measurement reports, often in unstructured PDF formats. Exploring and analyzing these reports remains in-

herently tedious and error-prone due to their format as numerous unstructured PDF files. To address these

challenges, we introduce ScaleVis, a system combining standard and specialized visualizations to facilitate

the exploration and analysis of measurement data including spatial information relevant to eccentricity mea-

surements. The system incorporates data cleaning to resolve inconsistencies from manual entry and provides

insights into measurement trends and deviations. Focusing on non-automatic weighing instruments, we ana-

lyze verification results to identify significant deviations in linearity and eccentricity. This study focuses on the

analysis of non-automatic weighing instruments from various manufacturers and application domains. Using

verification results from competent laboratories, we examine the metrological behavior of these instruments,

identifying the ranges of linearity and eccentricities with the largest deviations from prescribed errors. A use

case with domain experts underscores ScaleVis’s potential to streamline data analysis in legal metrology, with

initial feedback indicating strong utility and effectiveness.

1 INTRODUCTION

Metrology systems have different arrangements in re-

lation to whether they are centralized or decentralized

(distributed). This paper describes a distributed le-

gal metrology system, i.e., metrological controls are

performed by laboratories that are authorized to per-

form verifications of measuring instruments on behalf

of the state in accordance with national regulations.

These laboratories are required to inform the com-

petent state institution about the verifications carried

out by sending test reports confirming the compliance

of the inspected measuring instruments in accordance

with the prescribed requirements. Laboratories sub-

mit reports in the prescribed format to fulfill require-

ments set by normative documents. Based on these

a

https://orcid.org/0000-0002-5620-9407

b

https://orcid.org/0000-0003-2636-7348

c

https://orcid.org/0000-0001-9406-8943

reports, a document database with the measurement

results of all measuring instruments used has been es-

tablished. However, the database represents only an

history archive of data without any detailed overall

analysis. Therefore, aware of the significant momen-

tum in the digitalization of all processes and services

offered on the market, digitalization in the field of le-

gal metrology is also necessary (Oppermann et al.,

2022). Existing databases can gain an additional pur-

pose for various analyses that ultimately contribute to

protecting the end consumer and speeding up moni-

toring processes. Efficient means of exploration and

analysis are urgently needed.

In this work, we focus on non-automatic weigh-

ing instruments (NAWIs), verified in accordance with

the requirements outlined in OIML Recommendation

R76. Measurement data from three different types of

NAWIs (precision scales, accuracy class II) produced

by different manufacturers are analyzed to reveal load

points that are most susceptible to significant errors,

1000

Memi

´

c, H., Radoš, S., Softi

´

c, A. and Matkovi

´

c, K.

ScaleVis: Interactive Exploration of Measurement Instrument Verification Data.

DOI: 10.5220/0013380700003912

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 20th International Joint Conference on Computer Vision, Imaging and Computer Graphics Theory and Applications (VISIGRAPP 2025) - Volume 1: GRAPP, HUCAPP

and IVAPP, pages 1000-1007

ISBN: 978-989-758-728-3; ISSN: 2184-4321

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

identify trends where certain load points may consis-

tently exhibit larger errors, and enable comparisons

between NAWIs from different manufacturers.

Interactive visual analysis is a well-established ap-

proach for understanding complex data. To facilitate

insights into measurement reports, we employ a coor-

dinated multiple views system. Our focus is on errors

reported in three standard procedures: measurement

errors under increasing load, errors under decreasing

load, and eccentricity error measurements. Ideally,

a scale should display consistent weight readings re-

gardless of the load’s position. Since eccentricity er-

ror measurement involves a spatial component, we ac-

count for this aspect when designing the correspond-

ing visualization. In addition to the eccentricity error

view, the system incorporates histograms, parallel co-

ordinates, and box plots. All views are integrated into

the coordinated multiple views system, enabling com-

posite brushing to seamlessly link and explore data

across multiple perspectives. We also briefly describe

the preprocessing steps, which include extracting and

cleaning data from the PDF files.

The system’s design is the outcome of close col-

laboration between visualization and metrology ex-

perts. Through numerous discussion sessions, we

identified key tasks and requirements, which are en-

capsulated in task abstractions and requirements spec-

ification. These insights guided the development of

our visualization mappings and interaction design.

In this paper, our primary focus is not on introduc-

ing novel visualization techniques, but rather on lever-

aging the capabilities of coordinated multiple views

(CMV) to explore complex metrology data. Given the

vast amount of unstructured data available in various

institutes that handle legal metrology, new exploration

methods are urgently needed. The main contributions

of this paper can be summarized as follows:

• ScaleVis, an interactive analysis tool for metrol-

ogy data.

• Task abstractions and requirements analysis for

measurement reports used in legal metrology.

• A use case that illustrates the usefulness of the

proposed approach.

2 RELATED WORK

Interactive Visual Analysis (IVA) is an iterative ap-

proach to derive insights from large, multifaceted

datasets, with linking and brushing as its core con-

cept (Kehrer and Hauser, 2013), (Weber and Hauser,

2014). Introduced by Becker and Cleveland (Becker

and Cleveland, 1987), brushing was expanded by

Martin and Ward in XmdvTool, enabling logical oper-

ations like AND, OR, XOR, and NOT for composite

brushes (Ward, 1994), (Martin and Ward, 1995). Co-

ordinated and Multiple Views (CMV) extends this by

synchronizing multiple data views, where actions like

zooming, highlighting, or filtering in one view auto-

matically update others (Roberts, 2007).

Aigner et al. (Aigner et al., 2011) provide an

overview of tools and techniques for visualizing time-

oriented data, including curve views and timelines.

Although our data is load-dependent rather than time-

dependent, we employ curve views, commonly used

for temporal data.

Parallel coordinates plots (Inselberg, 1985) effec-

tively display multidimensional data and are increas-

ingly recognized beyond the visualization commu-

nity. Our domain experts quickly adopted them due to

their intuitive nature and minimal need for data trans-

formation (Siirtola and Räihä, 2006).

While interactive visualization has been applied

across various domains (Reina et al., 2020), its use in

measurement-instrument verification is limited. This

paper bridges that gap by introducing coordinated

multiple views for metrology. Though visual ana-

lytics tools are widely used (Heer and Shneiderman,

2012), their application in metrology has mainly fo-

cused on consolidating data. We offer a novel contri-

bution by advancing data analysis for legal metrology

in a close collaboration with metrology experts.

The National Institute of Standards and Technol-

ogy (NIST) emphasizes digitalization as a key driver

for advancing measurement systems and compliance

in legal metrology. As a significant challenge shap-

ing the future of metrology, digitalization enables in-

novations like AI integration and data-sharing net-

works for managing and visualizing measurement

data, highlighted at the 2023 International Confer-

ence on Weighing. National metrology institutes are

developing strategies focused on digital, machine-

readable certificates for verification and testing labo-

ratories (Eichstädt et al., 2021), alongside algorithms

to enhance data quality.

Studies have analyzed measurement results to

assess non-conformity risks in NAWIs and evalu-

ate risks for manufacturers and customers (Medina,

2018). These analyses include measurement results

obtained in processes of type approval, verifications,

and inspections. Also, there are related analysis, con-

sidering influences on measuring results like environ-

mental conditions and measurement uncertainty ob-

tained in processes of verification and calibration in

laboratory controlled conditions and working on-side

conditions (Memi

´

c et al., 2023).

ScaleVis: Interactive Exploration of Measurement Instrument Verification Data

1001

3 BACKGROUND

Measurements are integral to daily life, whether

tracking time, shopping, refueling, or monitoring

health metrics. Metrology, the science of measure-

ment, encompasses scientific, legal, and industrial

branches. Legal metrology ensures accuracy and reli-

ability, protecting consumers from fraud by maintain-

ing measurements within prescribed maximum per-

missible errors (mpe). Countries determine priori-

ties and instruments under state metrological supervi-

sion. WELMEC, the European Regional Metrology

Organization, provides details on measuring instru-

ments subject to legal metrology, including their reg-

ular verification intervals to ensure compliance with

mpe. EU directives MID (2014/32/EU) and NAWID

(2014/31/EU) govern harmonized instruments.

The OIML suggests expanding legal metrology to

include additional instruments. This paper analyzes

verification results of non-automatic weighing instru-

ments (NAWIs) over an extended period. NAWIs,

widely used in medical, retail, pharmaceutical, and in-

dustrial settings, are governed by the EU directive and

verified per EN 45501 or OIML R76 standards. Ac-

credited laboratories, meeting ISO/IEC 17020, pro-

vided data for this study. Verification confirms com-

pliance through tests like repeatability, linearity, and

eccentricity, ensuring adherence to prescribed errors.

Table 1 provides an example of measurement re-

sults following the OIML R76-2 recommendation,

with error E calculated using these results. The mea-

surement error for linearity and eccentricity is deter-

mined by:

E = I + 1/2e − ∆L − L (1)

To calculate the corrected error, the error E

0

(mea-

sured with an unloaded or near-zero load receptor)

must be subtracted:

E

c

= E − E

0

(2)

During verification, NAWIs must satisfy the condi-

tion:

|E

c

| ≤ |mpe| (3)

4 ANALYSIS TASKS AND

REQUIREMENTS

In this paper, we focus on exploration and analy-

sis of linearity and eccentricity. The linearity test is

carried out throughout the entire measurement range

of NAWI, i.e., the load points are evenly distributed

throughout the entire measurement range and the

maximum permissible error (mpe). The minimum

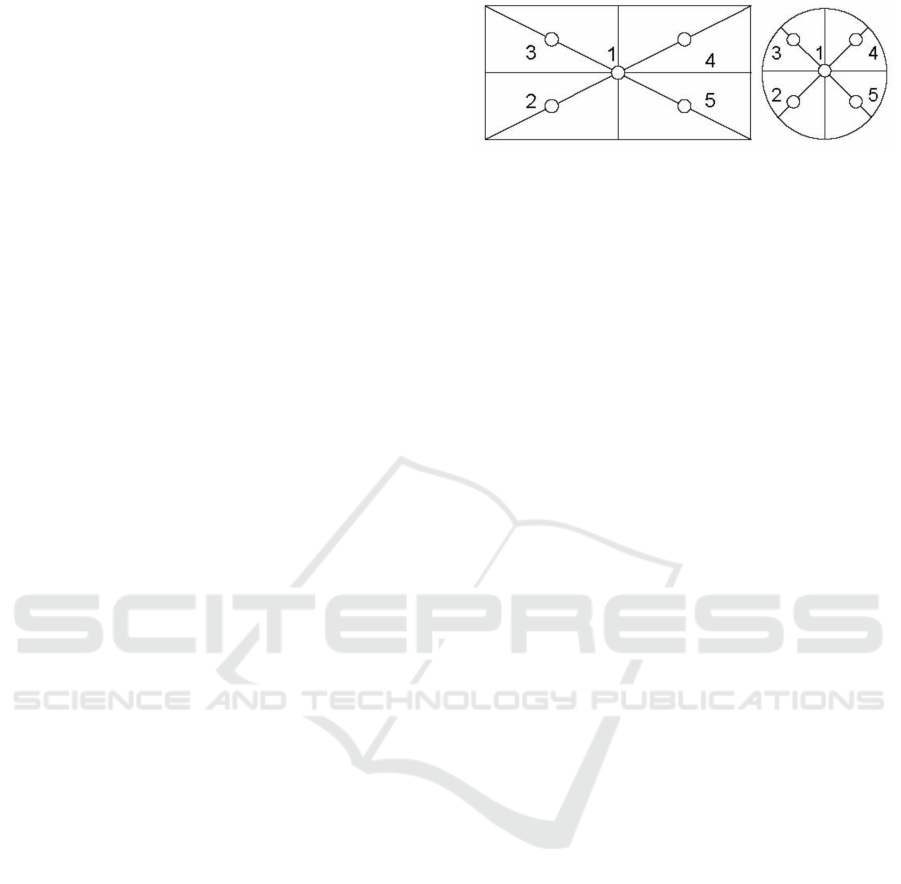

Figure 1: Predefined load placement positions for the ec-

centricity test on rectangular and round scales. The scale

should show the same value regardless of load placement.

number of load points taken into account when deter-

mining linearity errors is five, considering the small-

est and largest weighing capacity. Eccentricity testing

takes place in five load points, as shown in Figure 1,

with a load corresponding to one-third of the maxi-

mum capacity of the subject NAWI.

At the highest level, experts are primarily con-

cerned with determining whether a measuring de-

vice meets the required normative document (OIML

R 76). This initial assessment is straightforward—

checking if all errors fall below the prescribed thresh-

olds. While this analysis is essential, the extensive

raw measurement data offers a wealth of additional

insights. For a more exploratory approach, it is not

enough to merely classify a device as compliant or

non-compliant. Examining the distribution of the fi-

nal corrected errors (Ec), even in cases where the

thresholds are not exceeded, provides deeper insights

and fosters a better understanding of the measurement

data. The complete analysis refers to the requirements

of final corrected errors (in further text referred to “er-

ror”) in comparison to maximum permissible errors.

This is precisely the goal of our work: to enable such

in-depth exploration and provide tools that facilitate a

comprehensive understanding of metrological data.

To inform our design, we engaged in a collabo-

ration between visualization and metrology experts.

Through numerous meetings and discussions, we

identified key analysis tasks. Following the approach

outlined by Brehmer and Munzner (Brehmer and

Munzner, 2013), we systematically analyzed these

tasks to derive essential requirements for our visual-

ization design.

T1. Understand linearity errors, explore their devel-

opment based on load, and analyze distributions

categorized by manufacturer and time.

T2. Understand eccentricity errors and analyze their

distributions based on spatial positions.

T3. Compare distributions of eccentricity and linear-

ity errors.

T4. Gain an overview of the available data, includ-

ing the number of manufacturers, years of mea-

surement, temperature, and other supplementary

IVAPP 2025 - 16th International Conference on Information Visualization Theory and Applications

1002

Table 1: An example of measurement results provided by approved laboratories, following the OIML R76-2 recommendation.

The down arrow (↓) denotes measuring results obtained by progressively increasing loads, while the up arrow (↑) indicates

measuring results obtained by progressively decreasing loads.

Load Indication Addition load Error corrected Error mpe

L in g I in g ∆L in g E in g E

c

in g in g

↓ ↑ ↓ ↑ ↓ ↑ ↓ ↑

0 0.0 0.0 0 0 0 0 0 0 0.025

5 5.0 5.0 0 0 0 0 0 0 0.05

50 50.0 50.0 0 0 0 0 0 0 0.05

200 200.0 200.0 0 0 0 0 0 0 0.05

300 300.0 300.0 0 0 0 0 0 0 0.05

400 400.01 400.01 0 0 0.01 0.01 0.01 0.01 0.05

600 600.01 600.01 0 0 0.01 0.01 0.01 0.01 0.1

610 610.02 610.02 0 0 0.01 0.02 0.02 0.02 0.1

data recorded in the measurement files.

Based on the tasks described above, the following de-

sign requirements are specified:

R1. Depict all linearity errors aligned to each other

to be able to identify patterns.

R2. Visualize distributions of eccentricity errors tak-

ing spatial arrangement onto account.

R3. Provide means to see eccentricity errors correla-

tions.

R4. Visualize distribution of errors and compare

them.

R4a. Support comparison of error development

over time.

R4b. Support comparison of error differences

based on manufacturer.

R5. Visualize supplementary data to easy understand

their distribution.

5 VISUALIZATION DESIGN

To address all the identified requirements, we em-

ploy a coordinated multiple views system. The data

is structured in a table where each row corresponds to

a measurement. For each measurement, we include

supplemental data (e.g., year of measurement, serial

number, age of the scale), maximum linearity error

for an increasing load, maximum error for a decreas-

ing load, eccentricity loads and their corresponding

errors, and, as a special element, the linearity mea-

surement data itself, represented as a measurement

data curve. A similar data model has been described

by Konyha et al. (Konyha et al., 2006).

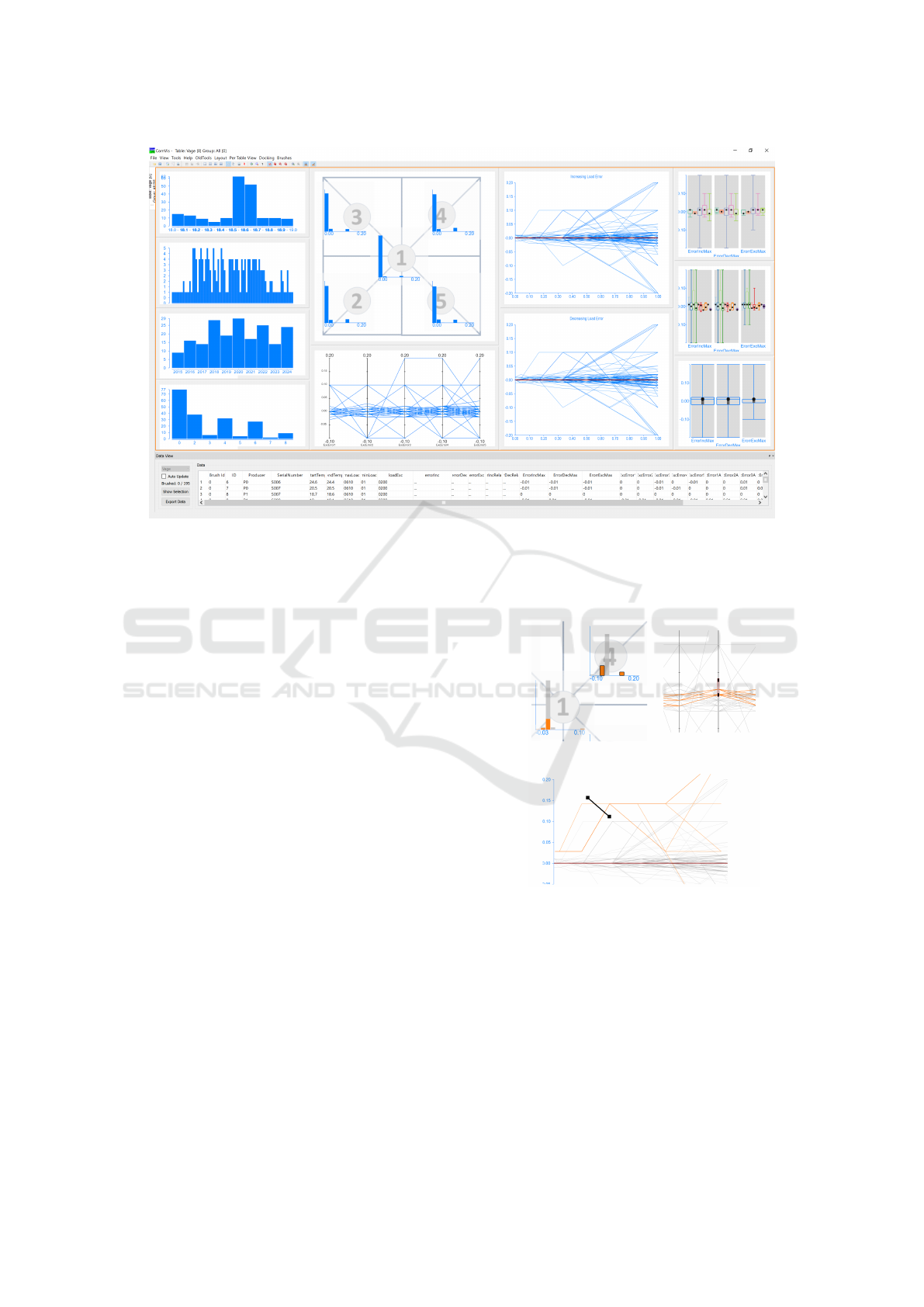

Figure 2 provides a screenshot of the proposed

views configuration. The histograms on the left dis-

play supplemental data and fulfill requirement R5, al-

lowing experts to easily interpret the information.

The views in the second column of Figure 2 fo-

cus on eccentricity errors. The top view, referred to

as the eccentricity error view, visualizes error distri-

butions at each measurement point (R2). Initially, we

attempted to represent these using five histograms in a

row, but aligning each histogram with its correspond-

ing position required additional effort. By overlaying

the histograms on a map of the measurement points,

the correspondence became immediately clear.

While the eccentricity error view effectively

shows the distributions of individual errors, it does not

clearly convey how the errors from a single measure-

ment are related (R3). To address this, we propose us-

ing a parallel coordinates plot. This standard plot type

supports highlighting when hovering with the mouse,

making it easier to explore individual measurements.

Such interaction is particularly useful because the er-

rors have discrete values due to the digital nature and

limited precision of the scales being examined. No-

tably, we maintained the axis order from one to five,

as reordering (e.g., placing the axis one in the middle)

proved confusing for domain experts. This confusion

likely arose because left and right axes could not be

placed unambiguously in that arrangement.

The curve views display linearity errors for all

measurements (R4). Since measurements can involve

different load values depending on a scale’s range, we

provide an option to normalize all data, mapping the

horizontal axis to a standardized range from 0 to 1.

Displaying all curves simultaneously allows users to

examine errors within the context of the entire dataset.

To address scalability issues, the view supports den-

sity mapping: when many curves are present, they are

rendered with reduced opacity. This approach high-

lights the main trends effectively while retaining visi-

bility of the overall dataset. Finally, we also show the

ScaleVis: Interactive Exploration of Measurement Instrument Verification Data

1003

Figure 2: A screenshot of the view configuration used in one of the exploration sessions. The histograms on the left display

various supplemental data. The central left column shows eccentricity errors, while the central right column presents linearity

measurement errors for both increasing and decreasing loads. The box plots on the right show the distribution of errors in

relation to the manufacturer (top), scale age (middle), and error distributions for all measurements (bottom). The table at the

bottom shows the values of all dimensions.

zero line in red, so that users can easily see positive

and negative errors.

On the right side of Figure 2, box plots illustrate

the distributions of maximum linearity errors for in-

creasing and decreasing load measurements, as well

as for eccentricity tests. For eccentricity, the bottom

view features a box plot for each error type and five

separate box plots corresponding to the five eccen-

tricity measurement positions. The two upper plots

present error distributions for all three error types,

split by manufacturer (top) and scale age (middle),

addressing requirements R4a and R4b.

The data view at the bottom provides a tabular

overview of all measurement data. When drill-down

exploration is performed using composite brushing,

the view display only the selected subset of data.

5.1 Interaction

All views in the system support linking and brushing,

the fundamental principle of coordinated multiple

views. Users can interactively select a subset of data

in any view, and the corresponding items in all other

views are automatically highlighted. Brushes can be

combined using Boolean operations, enabling flexible

and complex data exploration. The histograms allow

for bin-based selections. In the parallel coordinates

plot, brushing is performed by marking an interval

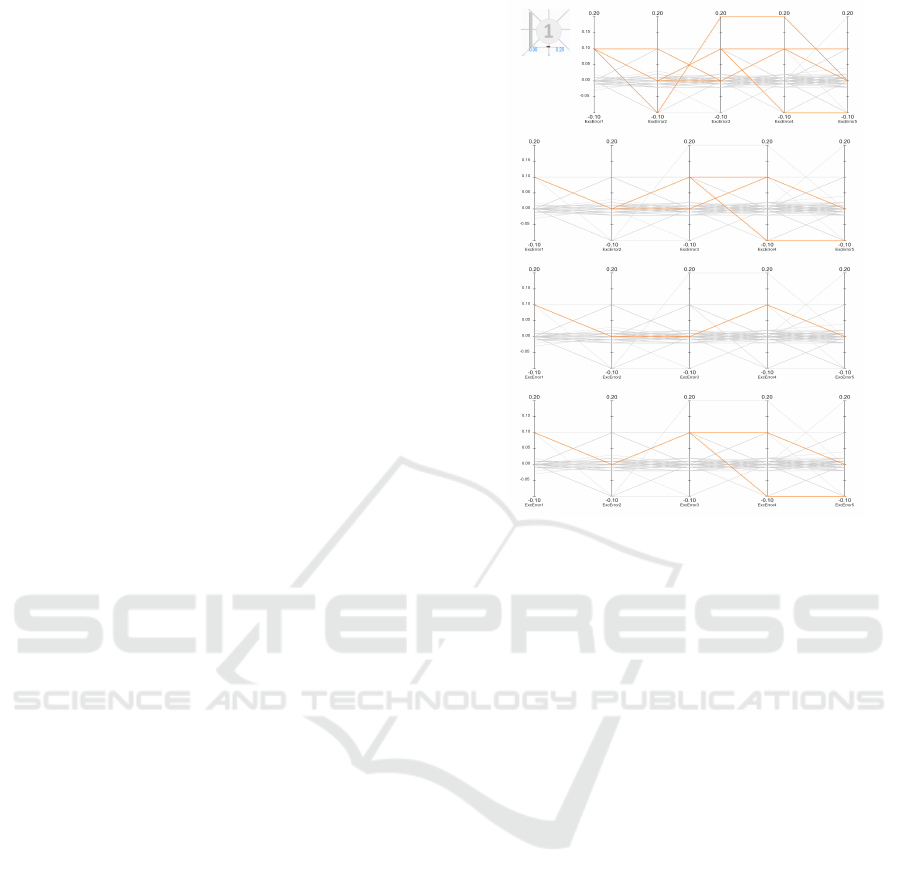

Figure 3: Users can brush histogram bins by clicking, select

curves with a line brush, and define ranges in the parallel

coordinates plot. Brushes are graphically represented, mov-

able, and resizable, as shown by the black-bordered bins,

parallel coordinates brush, and line brush in the curve view.

Multiple brushes can be combined with Boolean operations.

along any axis. The curve views feature a specialized

line brush, where the user draws a line, and all curves

that intersect it are brushed. Figure 3 demonstrates

these brushing techniques.

IVAPP 2025 - 16th International Conference on Information Visualization Theory and Applications

1004

6 USE CASE

We describe a use case conducted by two visualiza-

tion researchers and two metrology researchers, all

of whom coauthor this paper. For this use case, we

collected measurement reports from several approved

laboratories in PDF format. These reports do not fol-

low a standardized template; each laboratory uses its

own format, but the format remains consistent for all

tests conducted by a given laboratory. The reports

are manually filled in by human operators, and as a

result, they sometimes contain typographical errors,

empty rows, or missing data. These inconsistencies

highlight typical challenges encountered when deal-

ing with data of unknown quality. The first step in our

use case is data pre-processing.

6.1 Data Pre-Processing

Measurement reports from the NAWI Verification

Data are stored in PDFs with inconsistent formats,

varying in content, table structure, and result order.

To address this, we developed Python scripts to ex-

tract data efficiently, ensuring consistency and repro-

ducibility. These scripts currently support four widely

used report templates based on the country of ori-

gin and can be extended for additional templates.

Scanned documents are not included but could be sup-

ported in the future.

We processed 195 reports, creating an

anonymized dataset by replacing manufacturers

and serial numbers with randomized values to ensure

privacy. While all measurements meet legal require-

ments, further analysis offers valuable insights for

domain experts.

6.2 Interactive Visual Analysis

Once the data is processed, it can be loaded and anal-

ysis begins. The histograms of the supplemental data

show, for example, how many scales are represented

only once in the data set (each scale has to be tested

on a biannual basis), how many are tested twice, etc.

The highest number of tests is five, in our data set.

6.2.1 Exploring the Eccentricity Error

The eccentricity error view indicates different error

distributions depending on the position. We show dis-

tribution of absolute errors (see Figure 2). Ideally,

all data would fall into the leftmost bin, representing

minimal errors. The central part of the scales, position

1 are most precise (which was somehow expected).

Positions 4 and 5 exhibit slightly worse behavior com-

pared to positions 2 and 3.

Figure 4: Exploring eccentricity errors across positions: We

begin by brushing the high errors at position 1 by selecting

the corresponding bin in the histogram, then refine the focus

to cases with near-zero errors at position 2, identifying five

distinct patterns before examining individual cases.

We brush high eccentricity errors at position one

and examine the parallel coordinates to identify the

other eccentricity errors associated with these cases.

There are five measurements with the high error at

the position 1. Figure 4 shows the brushed bin and

the corresponding parallel coordinates in the top row.

The parallel coordinates plot shows the original

error values, not the absolute ones. Notably, the five

selected measurements display distinct patterns. To

explore further, we drill down and refine the brush.

Figure 4 also shows the results of these refinements.

First, we analyze cases with medium errors at position

2. Three such cases are identified, and they again ex-

hibit different error patterns. Further refinement iso-

lates individual cases, allowing us to observe how er-

rors vary across positions. One case in the final visu-

alization shows a positive error at position 3, followed

by negative errors at positions 4 and 5, for example.

These inconsistencies may stem from factors like

measurement changes, operator errors, or other influ-

ences. Identifying such cases without visualization

would be extremely challenging. Once detected, these

cases can be thoroughly examined. If inconsistencies

frequently occur for a particular scale type or are con-

sistently reported by the same laboratory, further in-

vestigation may be required.

ScaleVis: Interactive Exploration of Measurement Instrument Verification Data

1005

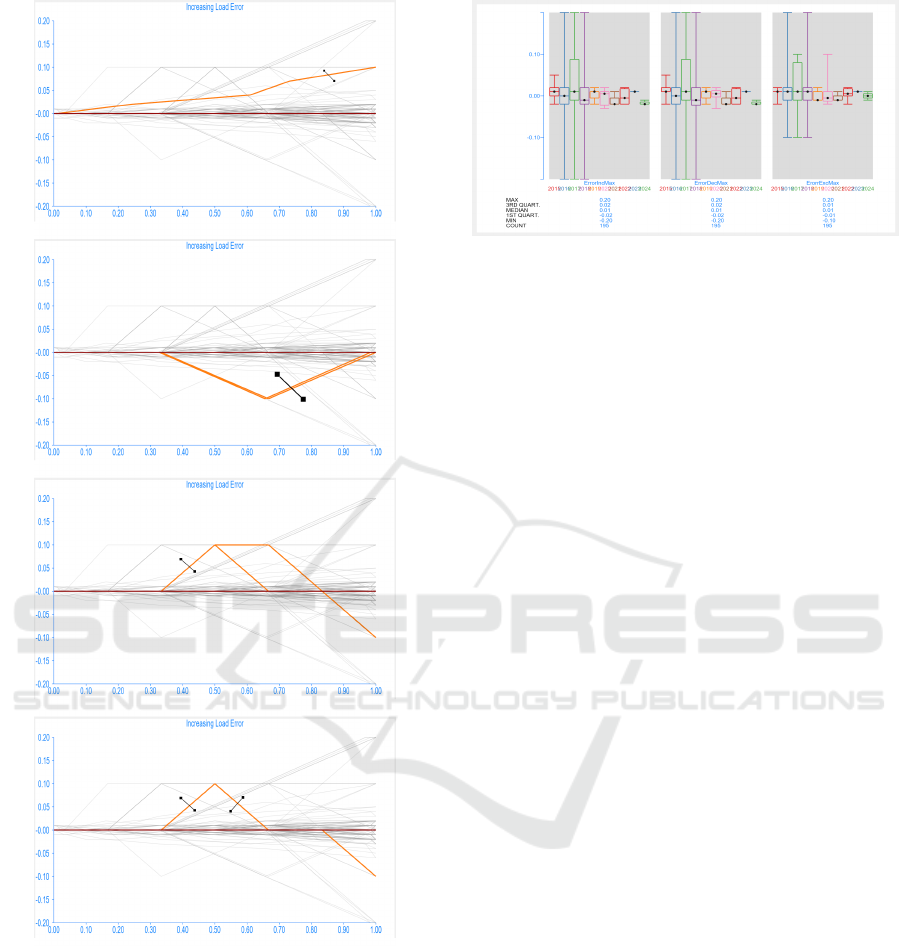

Figure 5: Exploring increasing load errors: While the er-

ror typically rises with load (top), some cases show unusual

patterns, such as mid-measurement increases followed by

decreases (second view) or early rises that fall to zero or

negative values (third and fourth views). The line brush aids

in selecting and analyzing these cases efficiently.

6.2.2 Exploring the Increasing Load Error

The curve view shows data for a series of measure-

ments with increasing and decreasing load. As the

load approaches the scale limits, we expect the ab-

solute value of the error to rise. In the curve view

(see Figure 2), we observe that most measurements

Figure 6: Box plots illustrate descriptive statistics, showing

aggregated maximums of three measurements. Increasing

and decreasing load measurements display similar behav-

ior, while eccentricity exhibits consistent medians early on

before oscillating in later years.

exhibit consistently low errors. However, there are

a few cases with unusual behavior. Let us examine

these cases now.

We use the line brush to select and analyze the

curves. Figure 5 illustrates some interesting findings.

The top view in Figure 5 shows a curve with a rela-

tively high error for the largest load, where the error

rises as the load increases. Although the error is high

at the end, this behavior is expected.

The second view in Figure 5 highlights cases with

a large negative error occurring mid-measurement, an

unusual behavior with unclear causes. The next view

in Figure 5 shows cases with a high positive error mid-

measurement. Refinement reveals two behaviors: the

error either drops to zero and turns negative or stays

high briefly before becoming negative Such oscilla-

tions in error warrant further investigation.

6.2.3 Errors Across the Years

Finally, the box plots reveal several interesting in-

sights. Figure 6 displays the distributions of the ag-

gregated maximum values for increasing load, de-

creasing load, and eccentricity measurements over the

years. The years correspond to when the measure-

ments were performed. This view also provides quan-

titative data, if needed.

We observe different patterns in the data distri-

butions for the loads. The increasing and decreasing

load measurements exhibit oscillating median values.

Larger minimum and maximum values were reported

in the earlier years.

For the eccentricity load, the median remains very

consistent during the first four years (2015–2018) be-

fore starting to oscillate. The largest minimum and

maximum values also appear in the early years, but

not consistently across all of them.

IVAPP 2025 - 16th International Conference on Information Visualization Theory and Applications

1006

7 CONCLUSION

ScaleVis provides many benefits for the end user as

well as in supervision of laboratories by metrology

institutes in process of verification. Analysis of mea-

surement data is a demanding task, but digitaliza-

tion and visualization of metrology reports provides

a faster insight into instruments deviations from the

expected behavior, such as changes in the curve when

testing linearity and eccentricity at different loads.

While these deviations are minor compared to per-

missible errors, visualization highlights instruments

requiring further monitoring, crucial in sensitive ap-

plications like healthcare. Factors like hysteresis or

improper handling often cause data deviations, im-

proving the efficiency of metrological supervision.

Visualization quickly detects anomalies in metrologi-

cal characteristics for further investigation.

We used interactive visualization to explore the

metrology data. The feedback from domain experts

has been very positive, and we see the work presented

in this paper as the beginning of a collaboration with

the metrology experts who coauthored this paper.

Due to time constraints and data sensitivity, we

started with a relatively small set of reports. Now that

the usefulness of the approach has been demonstrated,

we expect to gain access to a much larger corpus of

data. The system has been designed to scale effec-

tively with additional data, and all views have been

proven to function with significantly larger datasets.

Given the scales’ precision and digital data limi-

tations, errors are numerically represented but from a

limited set (e.g., 0.1, 0.2. . . with no intermediate val-

ues). To address overlapping data, we plan to explore

scattering techniques in future research.

ACKNOWLEDGMENTS

The VRVis GmbH is funded by BMK, BMAW, Tyrol,

Vorarlberg and Vienna Business Agency in the scope

of COMET - Competence Centers for Excellent Tech-

nologies (911654) which is managed by FFG.

REFERENCES

Aigner, W., Miksch, S., Schumann, H., and Tominski, C.

(2011). Visualization of time-oriented data, volume 4.

Springer.

Becker, R. A. and Cleveland, W. S. (1987). Brushing scat-

terplots. Technometrics, 29(2):127–142.

Brehmer, M. and Munzner, T. (2013). A multi-level ty-

pology of abstract visualization tasks. IEEE Trans-

actions on Visualization and Computer Graphics,

19(12):2376–2385.

Eichstädt, S., Keidel, A., and Tesch, J. (2021). Metrology

for the digital age. Measurement: Sensors, 18:100232.

Heer, J. and Shneiderman, B. (2012). Interactive dynamics

for visual analysis. Commun. ACM, 55(4):45–54.

Inselberg, A. (1985). The plane with parallel coordinates.

The Visual Computer, 1(2):69–91.

Kehrer, J. and Hauser, H. (2013). Visualization and visual

analysis of multifaceted scientific data: A survey. Vi-

sualization and Computer Graphics, IEEE Transac-

tions on, 19(3):495–513.

Konyha, Z., Matkovic, K., Gracanin, D., Jelovic, M., and

Hauser, H. (2006). Interactive visual analysis of fami-

lies of function graphs. IEEE Transactions on Visual-

ization and Computer Graphics, 12(6):1373–1385.

Martin, A. R. and Ward, M. O. (1995). High dimen-

sional brushing for interactive exploration of multi-

variate data. In Visualization, 1995. Visualization ’95.

Proceedings., IEEE Conference on, pages 271–.

Medina, N. (2018). Legal requirements for nawis: are they

good enough for customers’ protection? Journal of

Physics: Conference Series, 1065(8).

Memi

´

c, H., Bošnjakovi

´

c, A., Džemi

´

c, Z., and Softi

´

c, A.

(2023). Ocjena uskla

¯

denosti u oblasti zakonskog

mjeriteljstva na osnovu rezultata kalibracije Confor-

mity Assessment in the Field of Legal Metrology

Based on Calibration Results. In Jašarevi

´

c, S. and Br-

darevi

´

c, S., editors, Quality 2023, pages 151–158.

Oppermann, A., Eickelberg, S., Exner, J., Bock, T.,

Bernien, M., Niepraschk, R., Heeren, W., Baer, O.,

and Brown, C. (2022). Digital transformation in

metrology: Building a metrological service ecosys-

tem. Procedia Computer Science, 200:308–317.

Reina, G., Childs, H., Matkovi

´

c, K., Bühler, K., Waldner,

M., Pugmire, D., Kozlíková, B., Ropinski, T., Ljung,

P., Itoh, T., Gröller, E., and Krone, M. (2020). The

moving target of visualization software for an increas-

ingly complex world. Computers & Graphics, 87:12–

29.

Roberts, J. C. (2007). State of the art: Coordinated & multi-

ple views in exploratory visualization. In Andrienko,

G., Roberts, J. C., and Weaver, C., editors, Proc. of

the 5th International Conference on Coordinated &

Multiple Views in Exploratory Visualization. IEEE CS

Press.

Siirtola, H. and Räihä, K.-J. (2006). Interacting with paral-

lel coordinates. In Interacting with Computers.

Ward, M. O. (1994). Xmdvtool: integrating multiple meth-

ods for visualizing multivariate data. In VIS ’94: Pro-

ceedings of the conference on Visualization ’94, pages

326–333, Los Alamitos, CA, USA. IEEE Computer

Society Press.

Weber, G. and Hauser, H. (2014). Interactive visual ex-

ploration and analysis. In Hansen, C. D., Chen, M.,

Johnson, C. R., Kaufman, A. E., and Hagen, H., edi-

tors, Scientific Visualization, Mathematics and Visual-

ization, pages 161–173. Springer.

ScaleVis: Interactive Exploration of Measurement Instrument Verification Data

1007